Flame-retardant antiskid woven bag manufacturing method

A manufacturing method and technology of woven bags, which are applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as small contact area without anti-skid performance, insufficient frictional adhesion of manipulators, and easy slippage, etc., to achieve Increase the anti-slip uniformity, increase the surface roughness and surface area, increase the effect of anti-slip performance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a method for manufacturing a flame-retardant non-slip woven bag, comprising the following steps:

[0031] S1: Blending and drying of raw materials: put polypropylene particles, calcium carbonate, and additives into a drying mixer and stir to dry;

[0032] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, is extruded into a film through the die, and passes through the water of 30-40 ℃ After cooling, the embryos are cut into filaments with a blade, and stretched through a drying plate to form flat filaments. After the flat filaments are heat-set, they are collected into rolls by a wire winding machine;

[0033] S3: Weaving process: weave the rolled flat yarn into a cylindrical woven bag through a circular loom, and after passing the inspection, wind up through a winder;

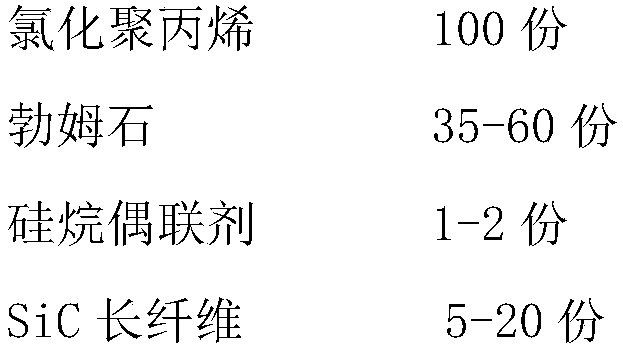

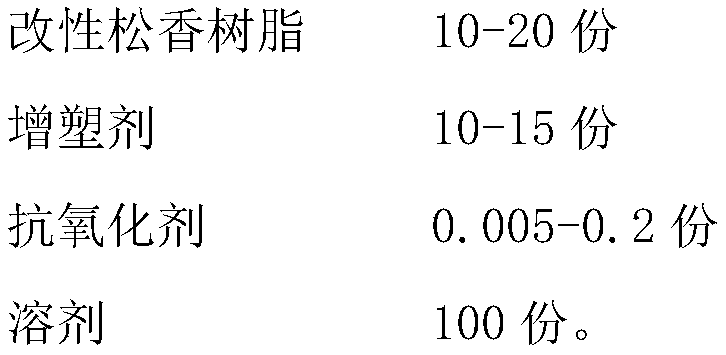

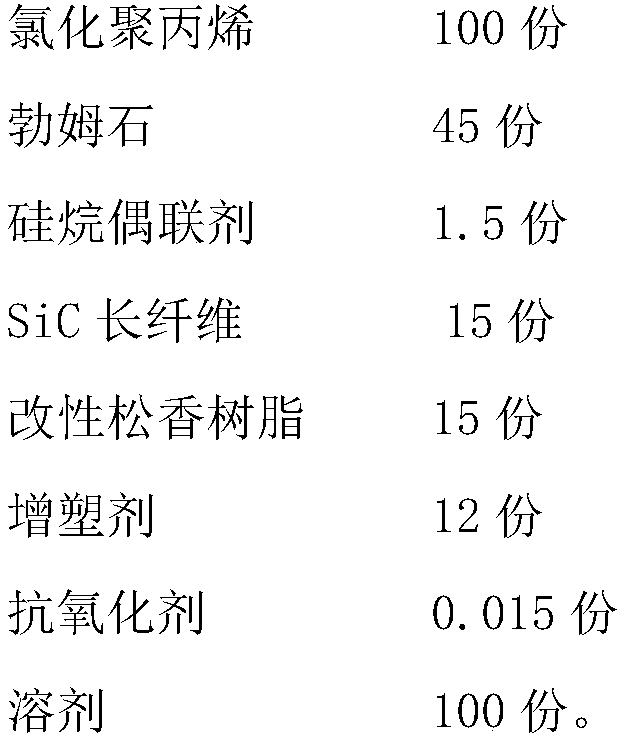

[0034] S4: Preparation of anti-slip coating: 100 parts of chlo...

Embodiment 2

[0038] The invention provides a method for manufacturing a flame-retardant non-slip woven bag, comprising the following steps:

[0039] S1: Blending and drying of raw materials: put polypropylene particles, calcium carbonate, and additives into a drying mixer and stir to dry;

[0040] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, is extruded into a film through the die, and passes through the water of 30-40 ℃ After cooling, the embryos are cut into filaments with a blade, and stretched through a drying plate to form flat filaments. After the flat filaments are heat-set, they are collected into rolls by a wire winding machine;

[0041] S3: Weaving process: weave the rolled flat yarn into a cylindrical woven bag through a circular loom, and after passing the inspection, wind up through a winder;

[0042] S4: Preparation of anti-slip coating: 100 parts of chlo...

Embodiment 3

[0046] The invention provides a method for manufacturing a flame-retardant non-slip woven bag, comprising the following steps:

[0047] S1: Blending and drying of raw materials: put polypropylene particles, calcium carbonate, and additives into a drying mixer and stir to dry;

[0048] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, is extruded into a film through the die, and passes through the water of 30-40 ℃ After cooling, the embryos are cut into filaments with a blade, and stretched through a drying plate to form flat filaments. After the flat filaments are heat-set, they are collected into rolls by a wire winding machine;

[0049]S3: Weaving process: weave the rolled flat yarn into a cylindrical woven bag through a circular loom, and after passing the inspection, wind up through a winder;

[0050] S4: Preparation of anti-slip coating: 100 parts of chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com