Organically modified polystyrene board and preparation method thereof

A polystyrene board and expandable polystyrene technology, which is applied in the field of building materials, can solve the problems of unfavorable modified polystyrene board use, complicated and complicated production process, unstable production process, etc., and achieves the effect of thermal insulation and energy saving. Good, good thermal insulation effect, convenient process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

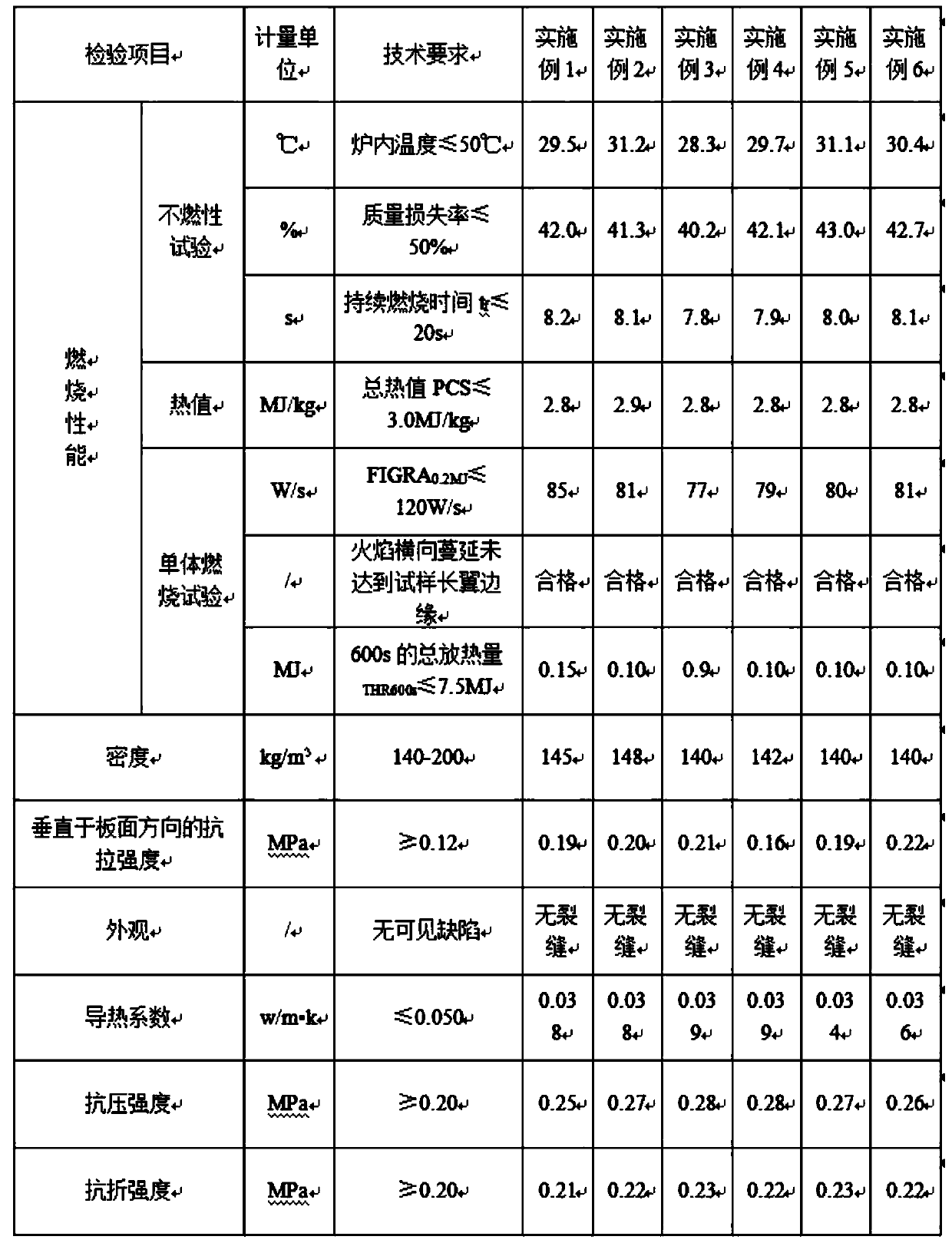

Examples

Embodiment 1

[0028] Example 1: An organically modified polystyrene board and its preparation method

[0029] (1) Accurately weigh each raw material component according to the formula: expandable polystyrene 13kg, magnesium oxide 62kg, magnesium chloride 62kg, organosilicon defoamer 0.90kg, magnesium sulfate 1.80kg, magnesite modifier 0.6kg, color pulp 3.20kg;

[0030] (2) Turn on the dispersing mixer and turn on the agitator, put the weighed expandable polystyrene and the color paste into the dispersing mixer until the expandable polystyrene and the color paste are mixed evenly to obtain a mixture;

[0031] (3) Turn on the steam foaming machine, put the above mixture into the steam foaming machine for pre-foaming, keep the steam pressure at 0.5MPa, and foam for 3 minutes to obtain colored expandable polystyrene. 14kg / m 3 , and then dry the colored expandable polystyrene;

[0032] (4) Put the dried colored expandable polystyrene into the sheet forming mold, keep the steam pressure at 0.6...

Embodiment 2

[0036] Embodiment 2: A kind of organically modified polystyrene board and its preparation method

[0037] (1) Accurately weigh each raw material component according to the formula: expandable polystyrene 11kg, magnesium oxide 65kg, magnesium chloride 65kg, coupling agent 1.10kg, phosphoric acid 2.20kg, magnesite modifier 0.30kg, color paste 2.80kg ;

[0038] (2) Turn on the dispersing mixer and turn on the agitator, put the weighed expandable polystyrene and the color paste into the dispersing mixer until the expandable polystyrene and the color paste are mixed evenly to obtain a mixture;

[0039] (3) Turn on the steam foaming machine, put the above mixture into the steam foaming machine for pre-foaming, keep the steam pressure at 0.6MPa, and foam for 3 minutes to obtain colored expandable polystyrene. 16kg / m 3 , and then dry the colored expandable polystyrene;

[0040] (4) Put the dried colored expandable polystyrene into the sheet forming mold, keep the steam pressure at ...

Embodiment 3

[0044] Example 3: An organically modified polystyrene board and its preparation method

[0045] (1) Accurately weigh each raw material component according to the formula: expandable polystyrene 12kg, magnesium oxide 64kg, magnesium chloride 64kg, silicone defoamer 1.00kg, phosphoric acid 2.00kg, magnesite modifier 0.50kg, color paste 3.00kg;

[0046] (2) Turn on the dispersing mixer and turn on the agitator, put the weighed expandable polystyrene and the color paste into the dispersing mixer until the expandable polystyrene and the color paste are mixed evenly to obtain a mixture;

[0047] (3) Turn on the steam foaming machine, put the above mixture into the steam foaming machine for pre-foaming, keep the steam pressure at 0.7MPa, and foam for 4 minutes to obtain colored expandable polystyrene. 17kg / m 3 , and then dry the colored expandable polystyrene;

[0048] (4) Put the dried colored expandable polystyrene into the sheet forming mold, keep the steam pressure at 0.6MPa t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com