Patents

Literature

56results about How to "Improve paste strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

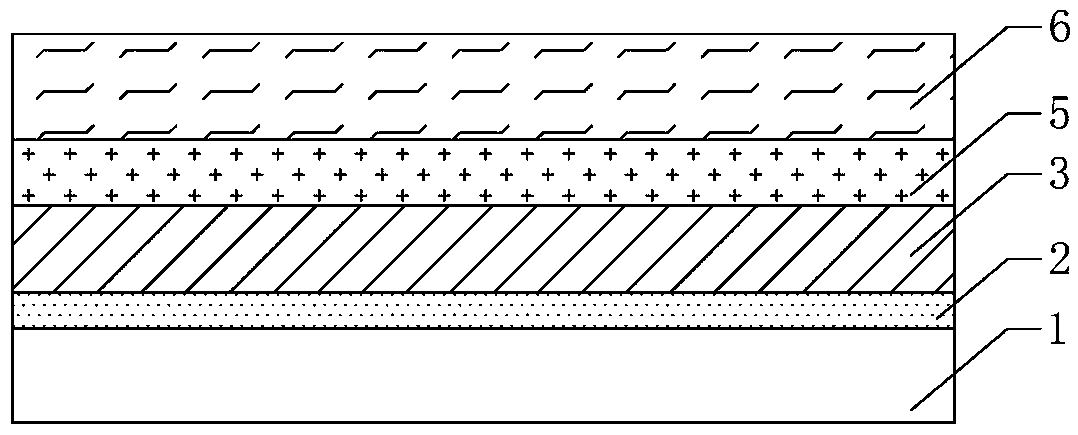

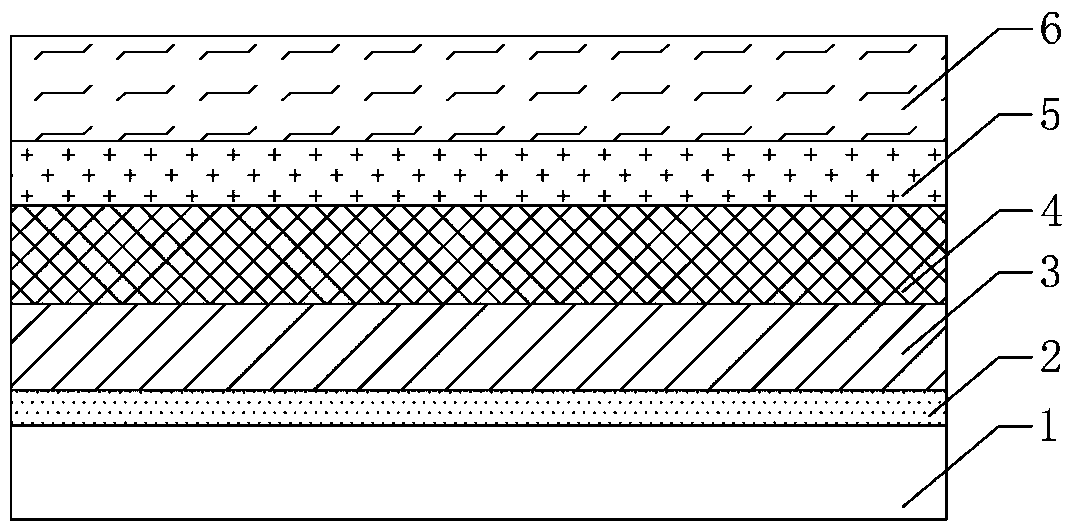

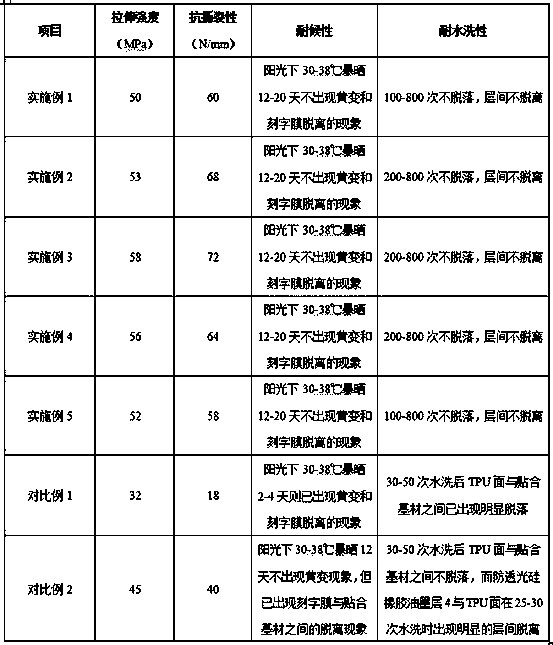

High elasticity silicone rubber heat transfer film and preparation method thereof

ActiveCN108690515AImprove water resistanceImprove processing efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSurface layer

The invention relates to the technical field of heat transfer films, and specifically relates to a high elasticity silicone rubber heat transfer film and a preparation method thereof. The high elasticity silicone rubber heat transfer film comprises following components from bottom to top: a bearing base material, a release layer, a silicone rubber surface layer, an interface bonding agent layer, and a TPU hot melt adhesive membrane; wherein the interface bonding agent layer is prepared an interface bonding agent, which comprises two resin components. The provided heat transfer film has the advantages of silicone rubber and TPU, such as excellent elasticity, high tearing resistant strength, weatherability, yellowing resistance, washing resistance, and the like. Layering is difficult to happen. Even if the heat transfer film is exposed under the sun, color change or fading is difficult to happen. The water washing fading rate is not more than 0.5%. When the color transfer film is washedwith materials with other colors, other materials will not be dyed easily. The stability is high. The heat transfer film can be easily adhered on multiple materials, the bonding strength is strong, the heat transfer film is not easy to peel off, the stability is good, the hand feeling is fine, the appearance is good, and the service life is long.

Owner:卢汉军

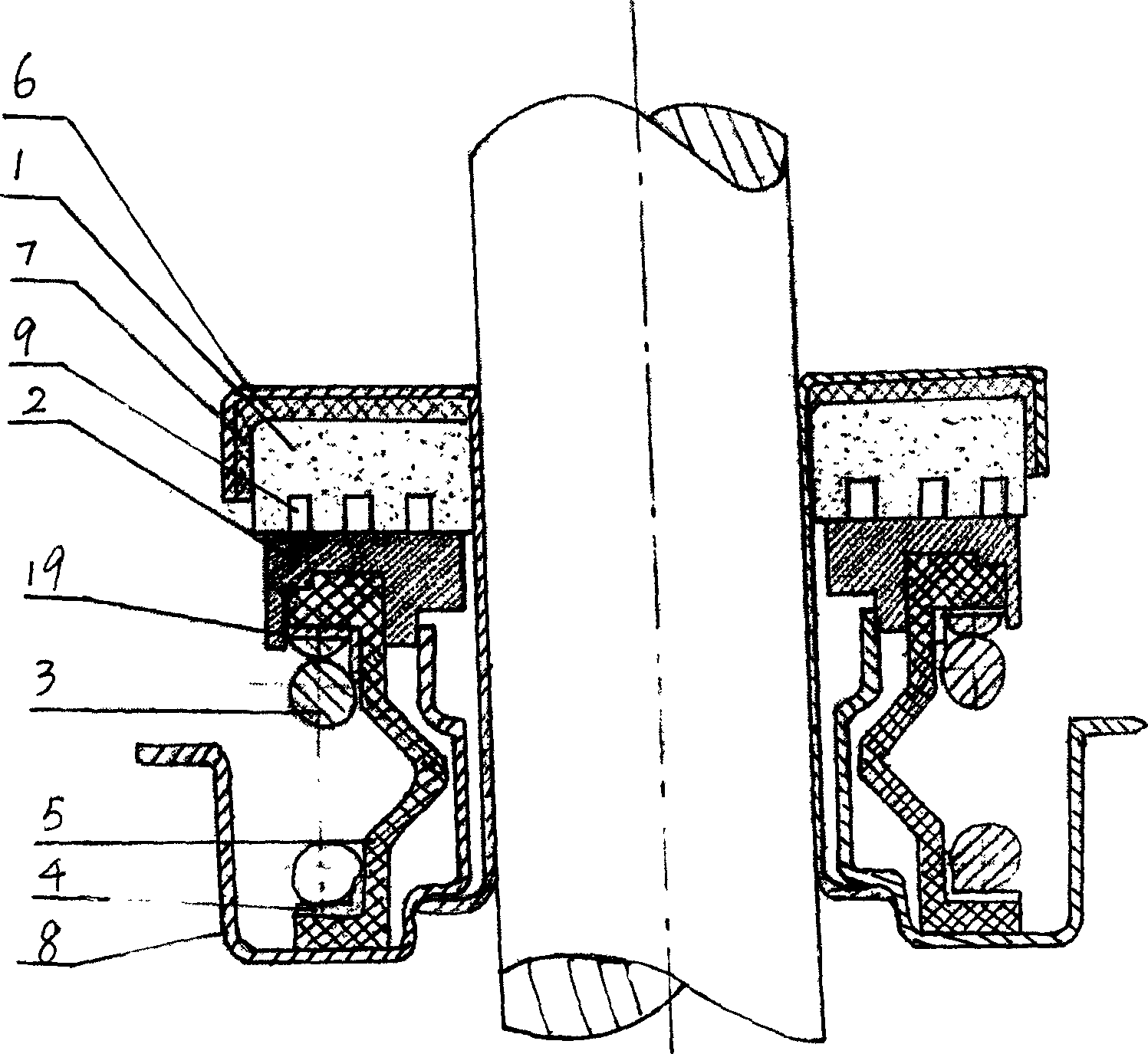

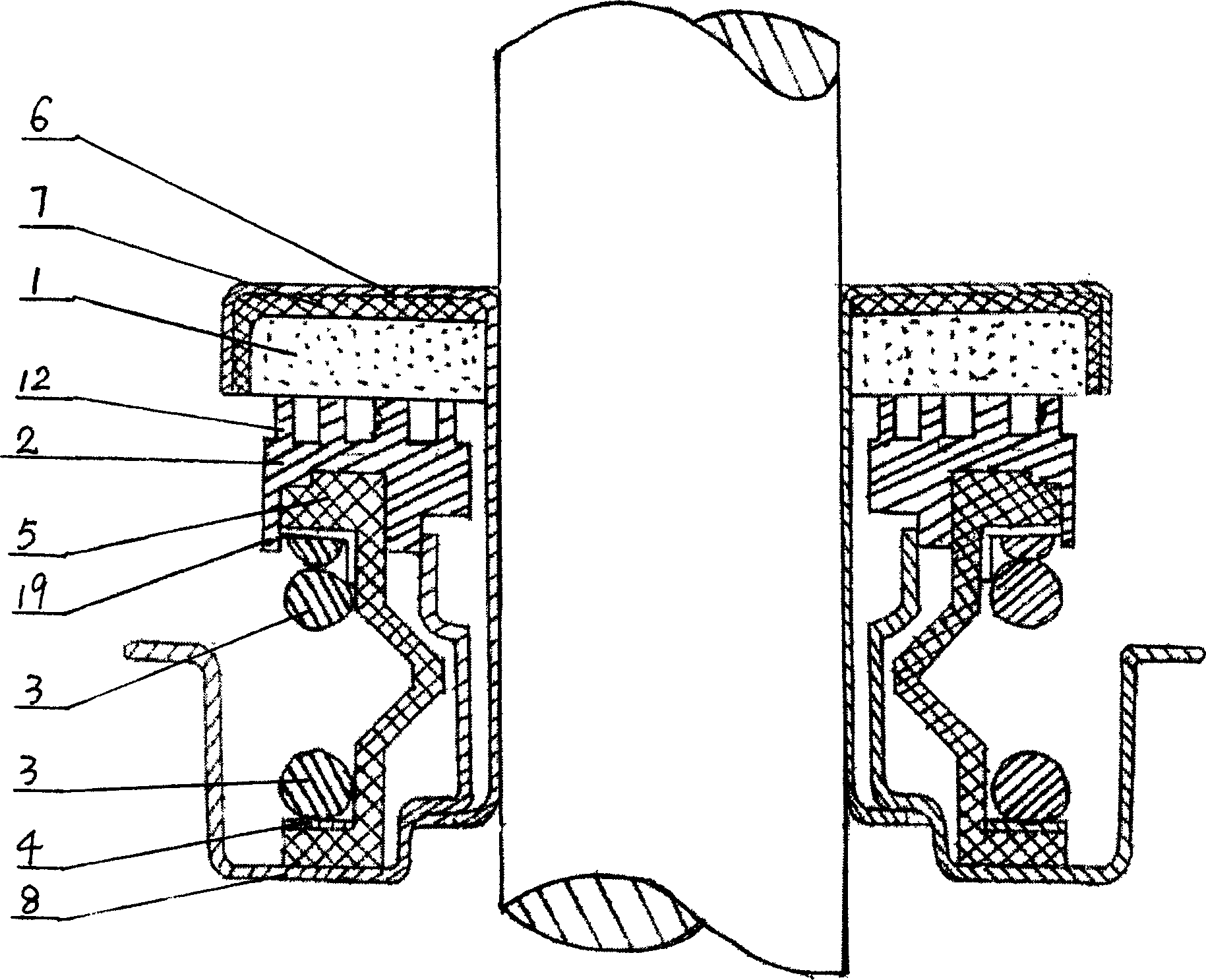

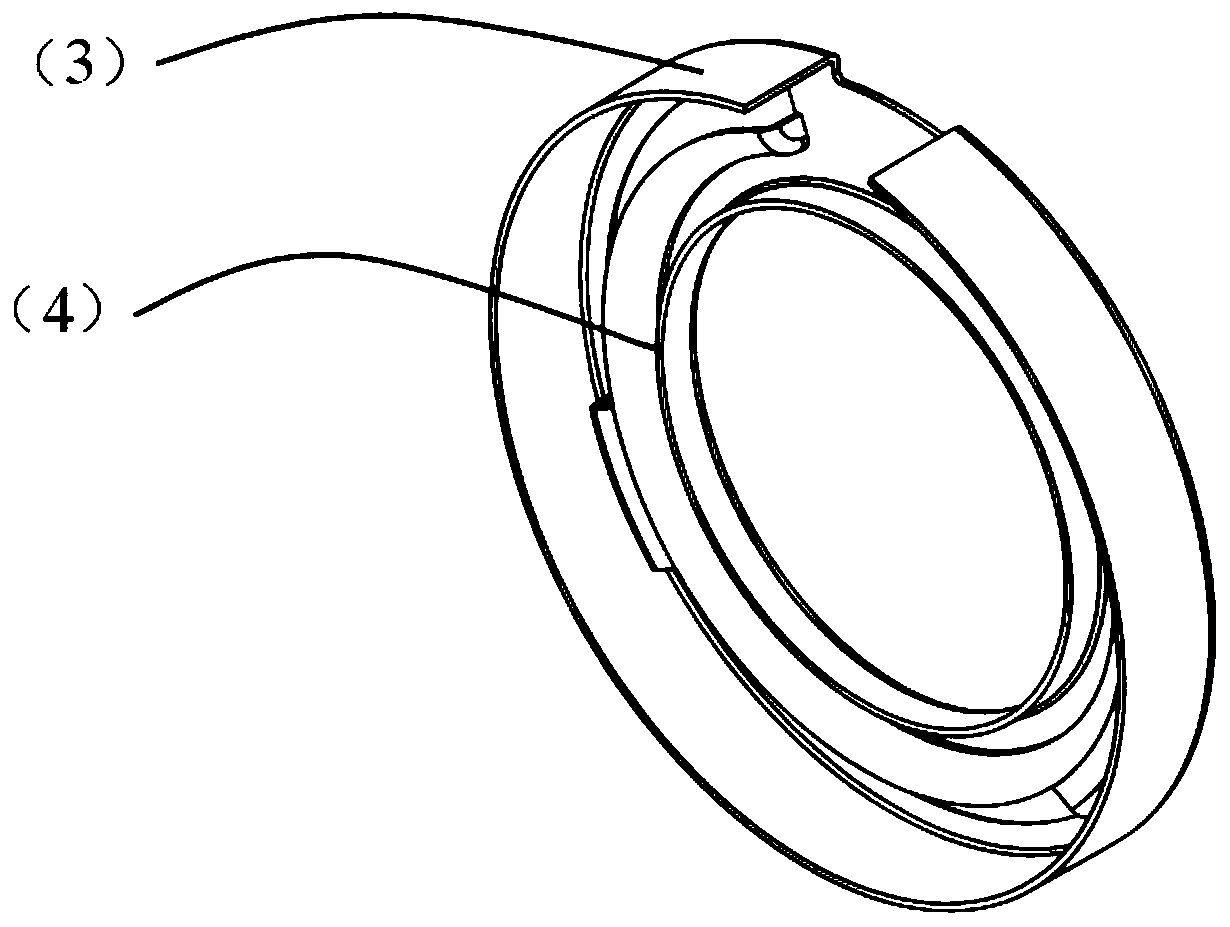

Leakless wear pump sealer

Owner:江雪忠

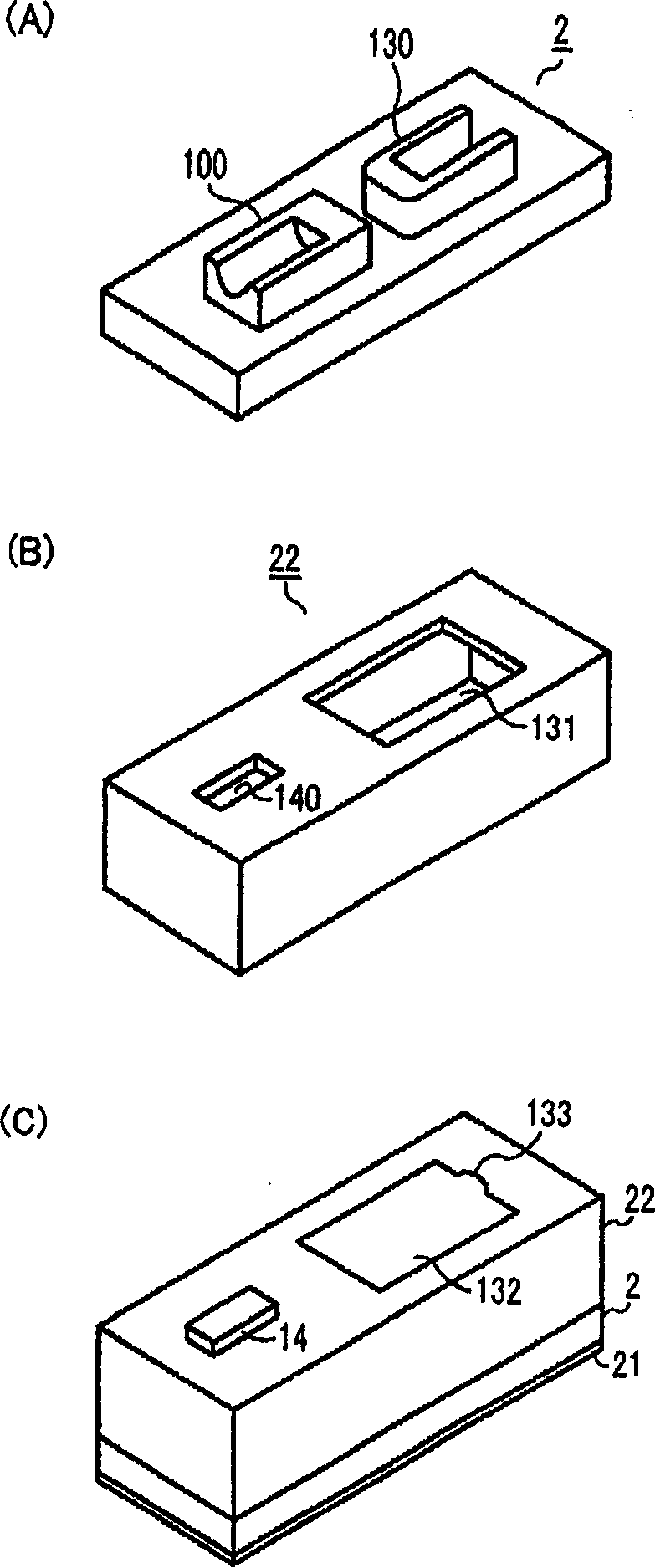

Method for mfg. plasma display

InactiveCN1719571AUniform bondingGood adhesionTube/lamp screens manufactureCold cathode manufactureFlexible circuitsDisplay device

This invention discloses a manufacture method for a plasma indicator, which adheres an ACF on a printed electrode of a glass base plate and puts the base plate on a crimp machine for pre-pressing the both sides at low temperature at the same time, then takes out the top layer of the ACF to keep its adhesion layer, a flexible PC film is adhered on the ACF of the printed electrode of the glass base plate then heats the both sides of the base plate at the same time and presses the place for placing the FPC film on the crimp machine tightly, finally, seals the FPC film and the glass base plate with a non-corrosive glue.

Owner:四川世纪双虹显示器件份有限公司

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

Method for flocking automotive interior side wall

InactiveCN105127071AHigh strengthInhibit sheddingLiquid surface applicatorsCoatingsAdhesiveFlame treatment

The invention discloses a method for flocking an automotive interior side wall. The method comprises the steps of flame treatment, glue spraying, flocking, drying, floating fluff removal, and the like, wherein during flame treatment, the plastic surface is carbonized by using strong oxidative flames, so that the roughness characteristic and cementing characteristic of the interior trim part surface are improved; then, an adhesive is sprayed on the surface, required to be flocked, of the interior trim part, a flocking cabinet is used to flock the interior trim part, high voltage static generated by a flocking machine is output to a flocking nozzle, fluff is input to the nozzle and is enabled to carry negative charge at the same time through the rotation of a fluff providing shaft in a fluff basket, the nozzle is moved near the interior trim part, and fluff flies to the interior trim part surface from the nozzle under the action of a high voltage electric field, and is vertically flocked on the surface coated with the adhesive; then, the flocked interior trim part is put on a drying line for drying. The invention has the following benefits: the method is used for flocking the interior trim part of a car, and has the advantages that the technology is simple, the flocking efficiency is high, fluff is high in scratch resistance, and the like.

Owner:成都航天华涛汽车塑料饰件有限公司

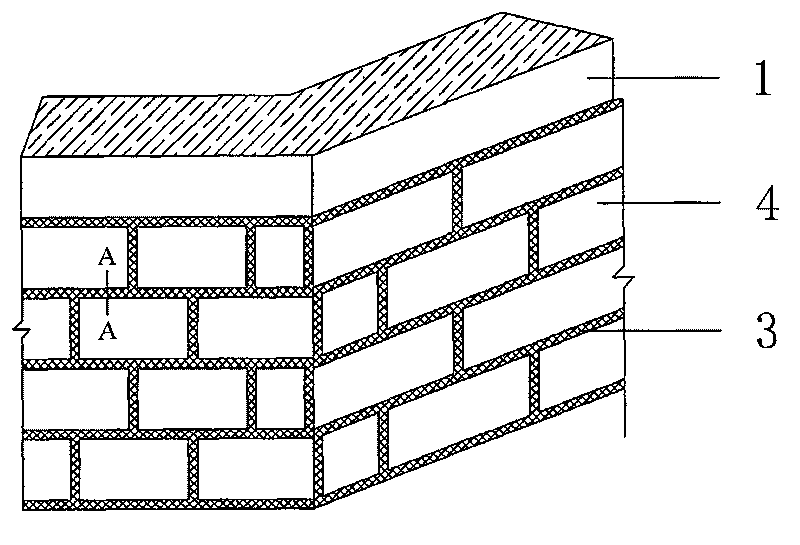

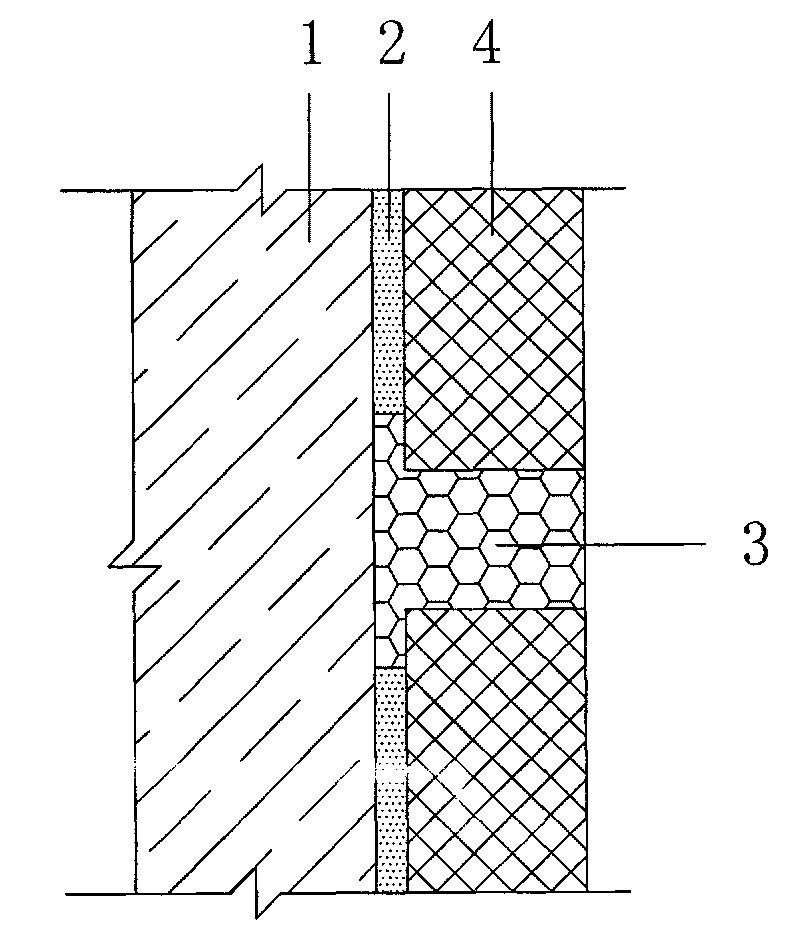

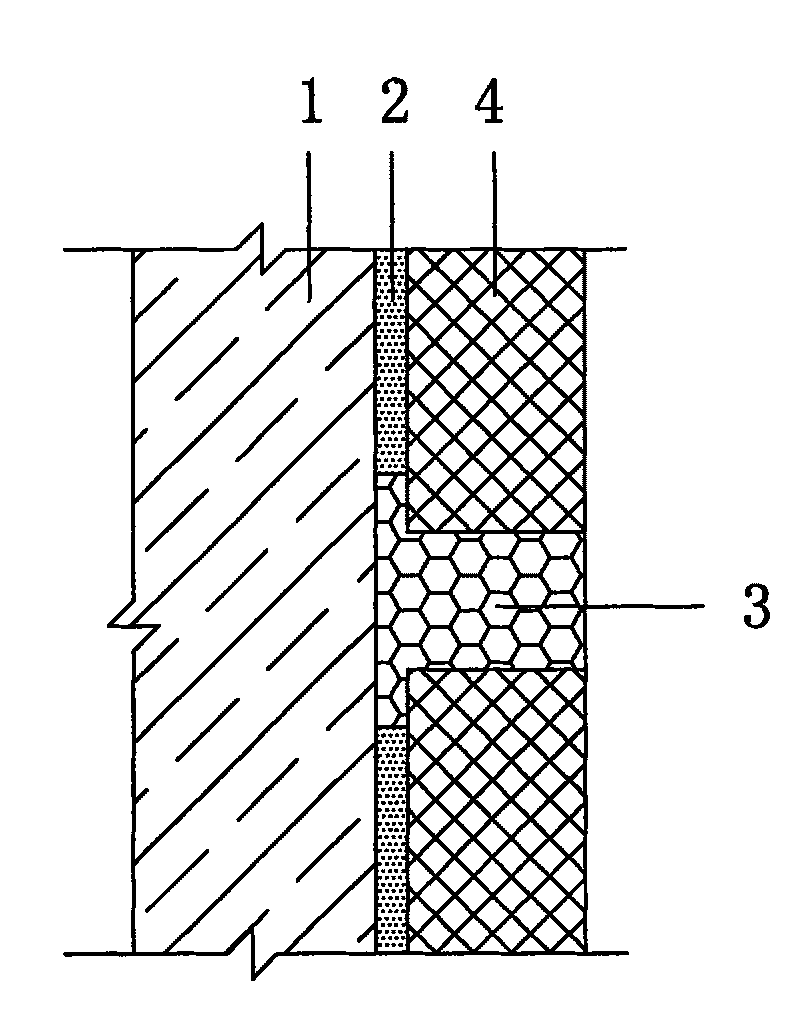

Construction technique for filling polyurethane hard bubbles in wall outer insulation layer

InactiveCN101748810AImprove paste strengthEasy to useWallsHeat proofingFreeze thawingInsulation layer

The present invention relates to a construction technique for filling polyurethane hard bubbles in a wall outer insulation layer. Insulation boards are glued to a base wall processed by an adhesive, the distance of 10 to 30mm is left from the adhesive between the insulation boards and the base wall to the circumferential edges of the insulation boards, and 10 to 100mm gaps are left between the insulation boards. When the adhesive glued to the insulation boards reaches more than 60% of the strength designed, polyurethane hard bubbles are poured in the gaps preset of the insulation boards to make polyurethane foamed and fill up the gaps. The outer surface of the polyurethane hard bubbles is abraded to be in the same plane with the outer surfaces of the insulation boards. Anti-crack mortar of about 3 to 8mm thickness is spread on the outer surfaces of the insulation boards, an alkali-proof net or a steel wire net is embedded, and an anti-crack mortar protective layer is made. The present invention has the advantages that the wall outer insulation layer forms a seamless whole body, quality problems, such as crack, seeping water freeze thawing, fall, etc can be thoroughly eliminated, the use time of the outer insulation layer is extended, and the fire-proofing grade of the outer insulation layer is improved.

Owner:南通华宏化工设备制造安装有限公司

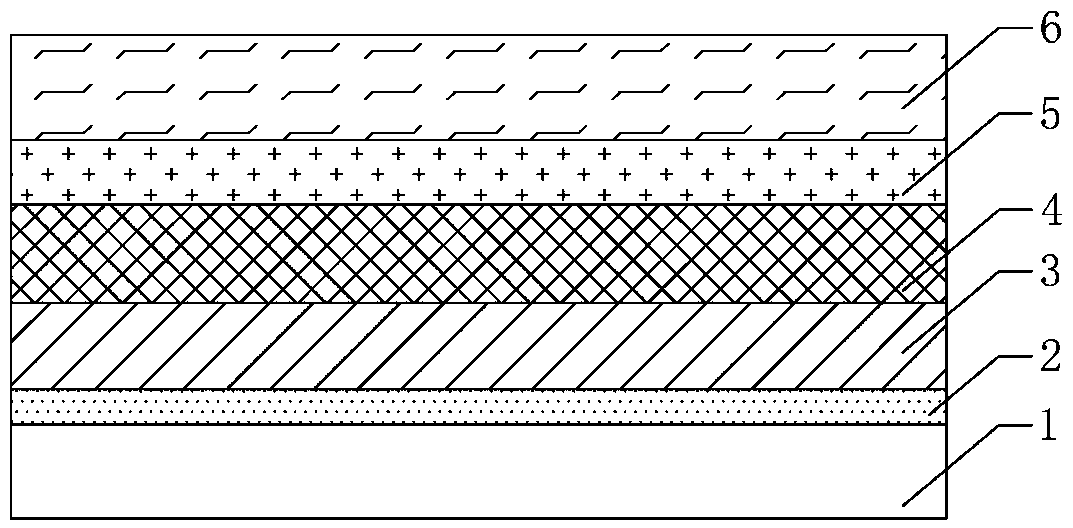

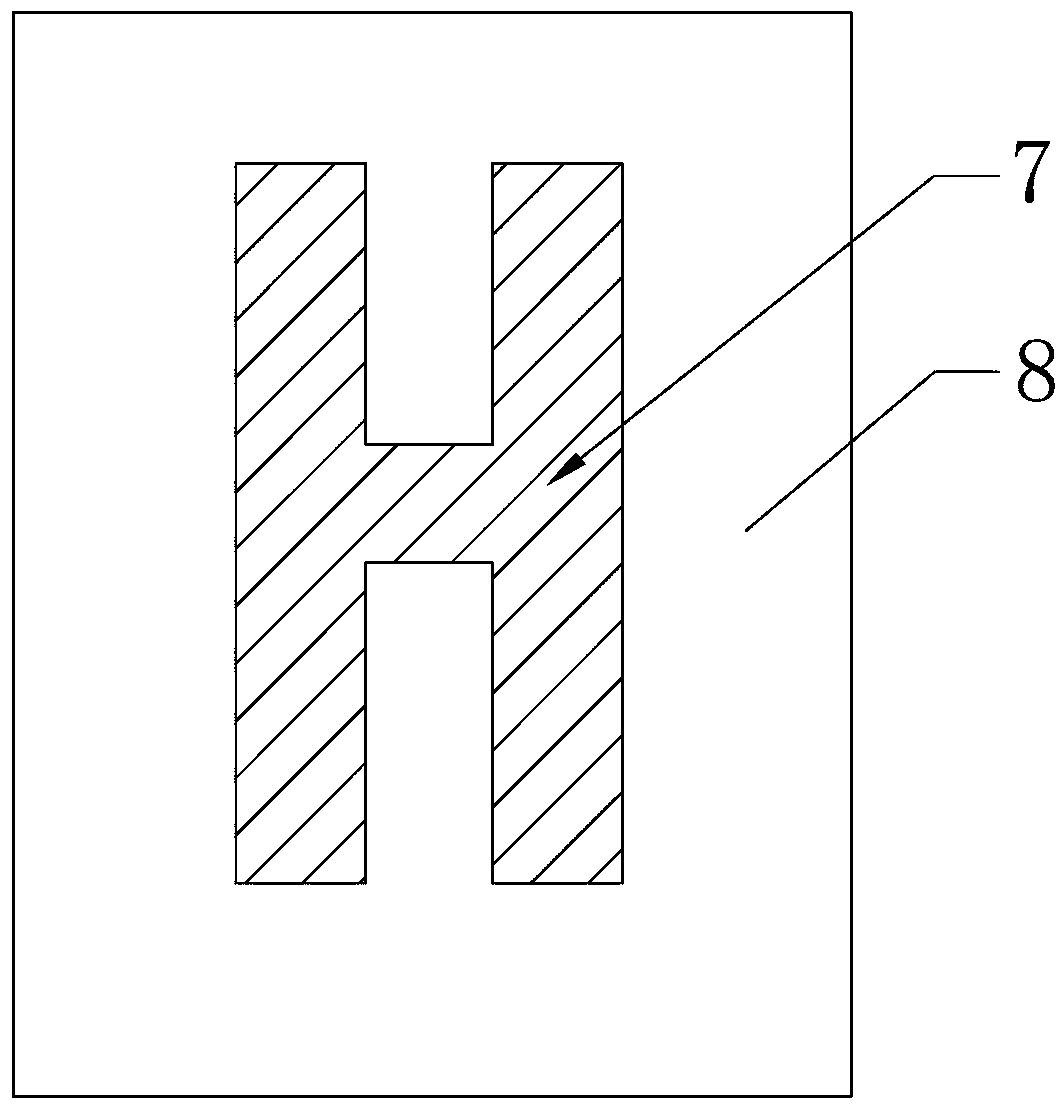

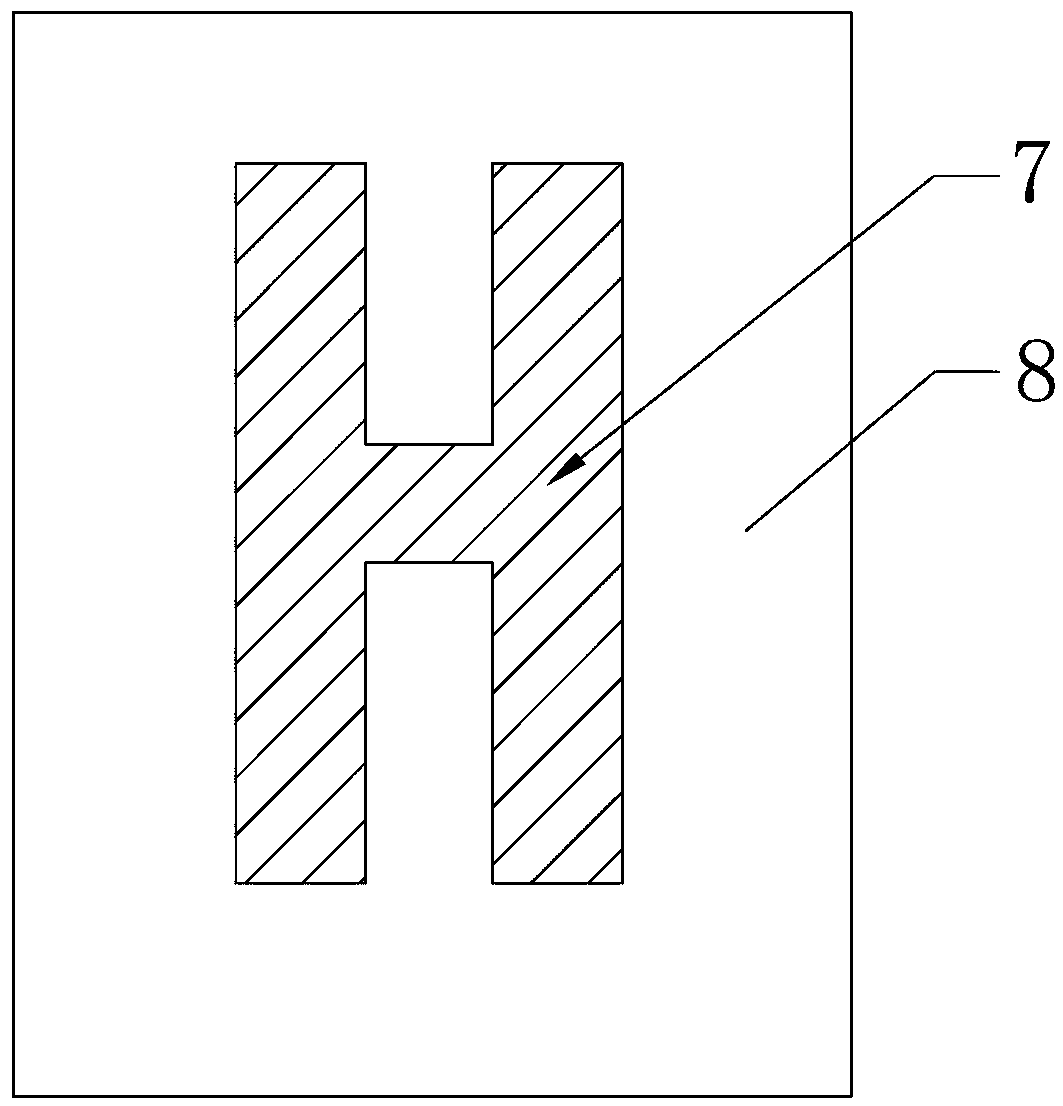

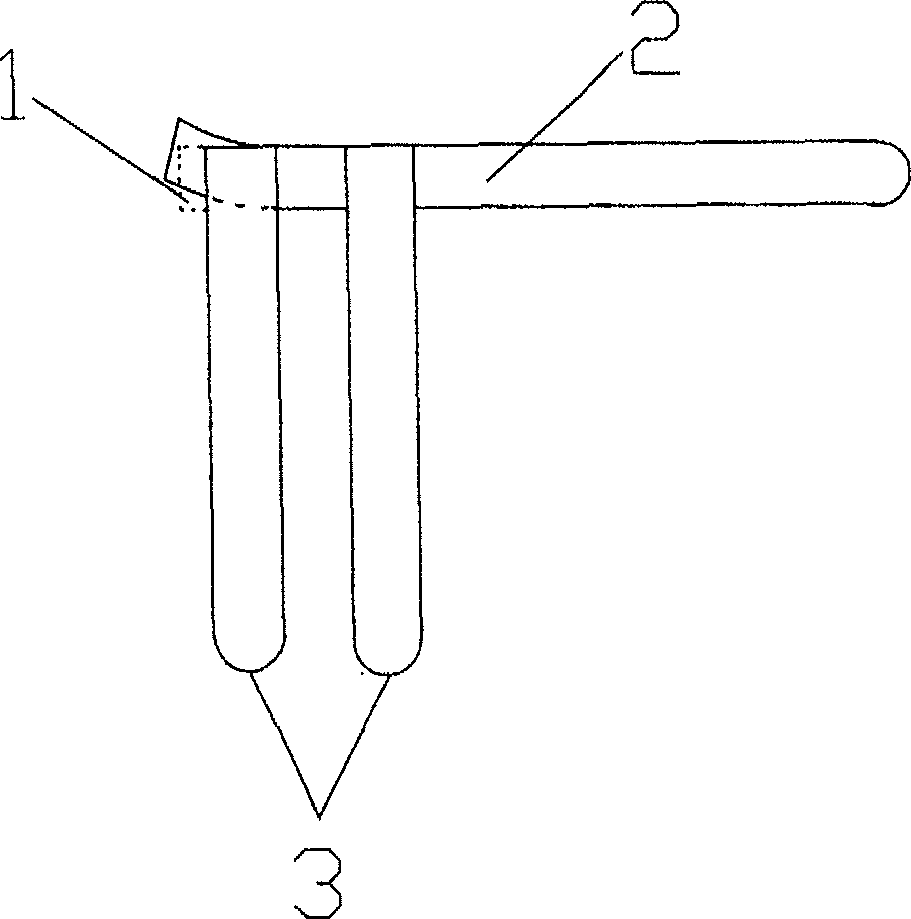

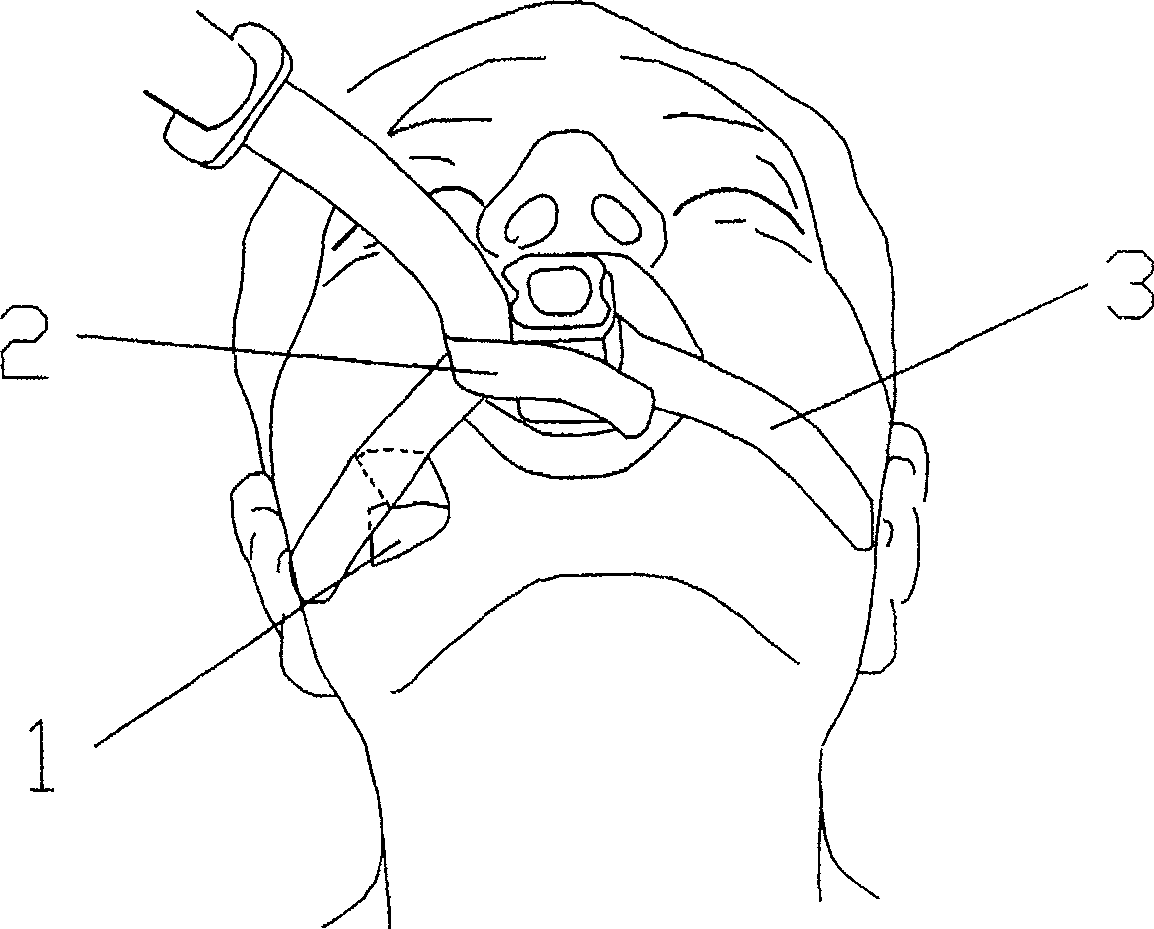

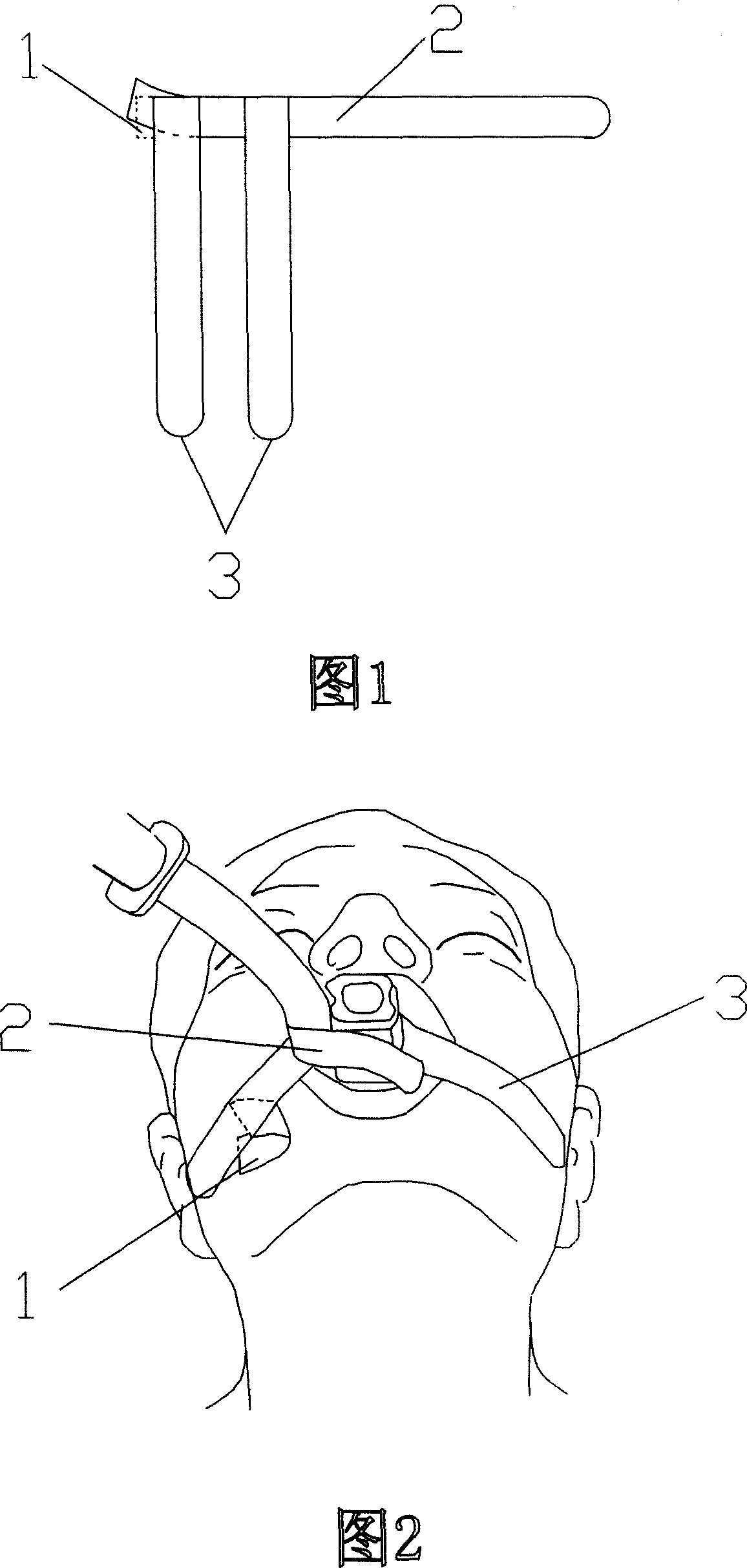

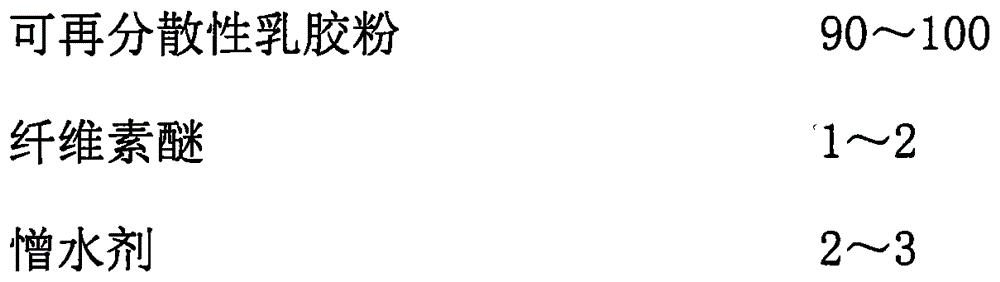

Trachea guide tube fixation adhesive tape

InactiveCN100500243CImprove paste strengthExcellent paste strengthTracheal tubesAdhesive dressingsTracheal tubeMedicine

The invention relates to a tracheal cannula fixing band, with wide clinic application. The invention is characterized in that the tracheal cannula is fixed with the band comprising a medical adhesive plaster and adhered liner, to form reverse-F shape via one horizontal adhesive plaster and two upright adhesive plasters. When in use, the liner is broken, and the horizontal adhesive plaster is coiled and fixed at the left of tracheal cannula (or tooth pad); two upright adhesive plasters are parallel at two sides whose heads are adhered with the longitudinal axle of tracheal cannula, and ends are adhered with the left and right faces, to fix the tracheal cannula. The invention has simple operation and wide application for fixing dual-chamber tracheal cannula, food tracheal cannula, or the like.

Owner:陈光忠

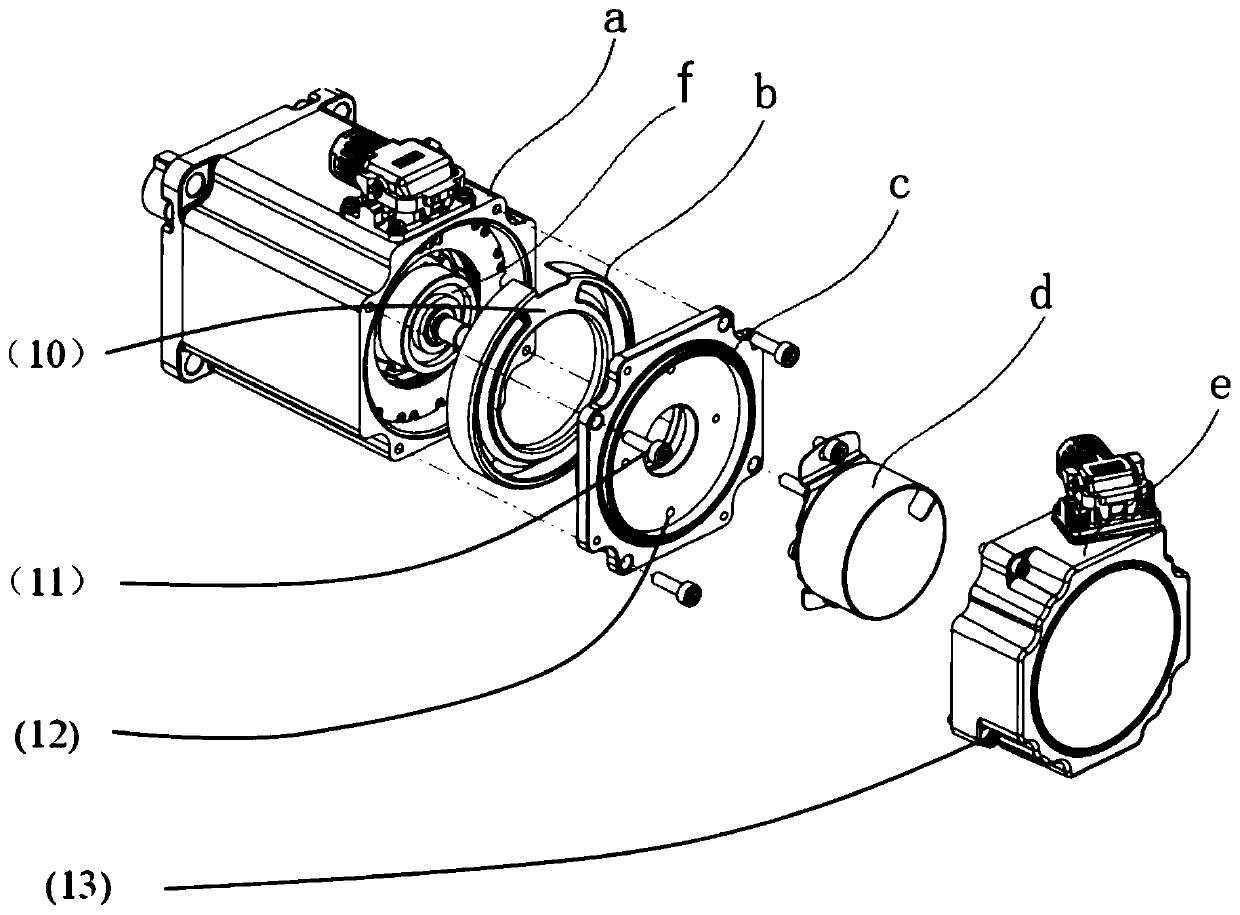

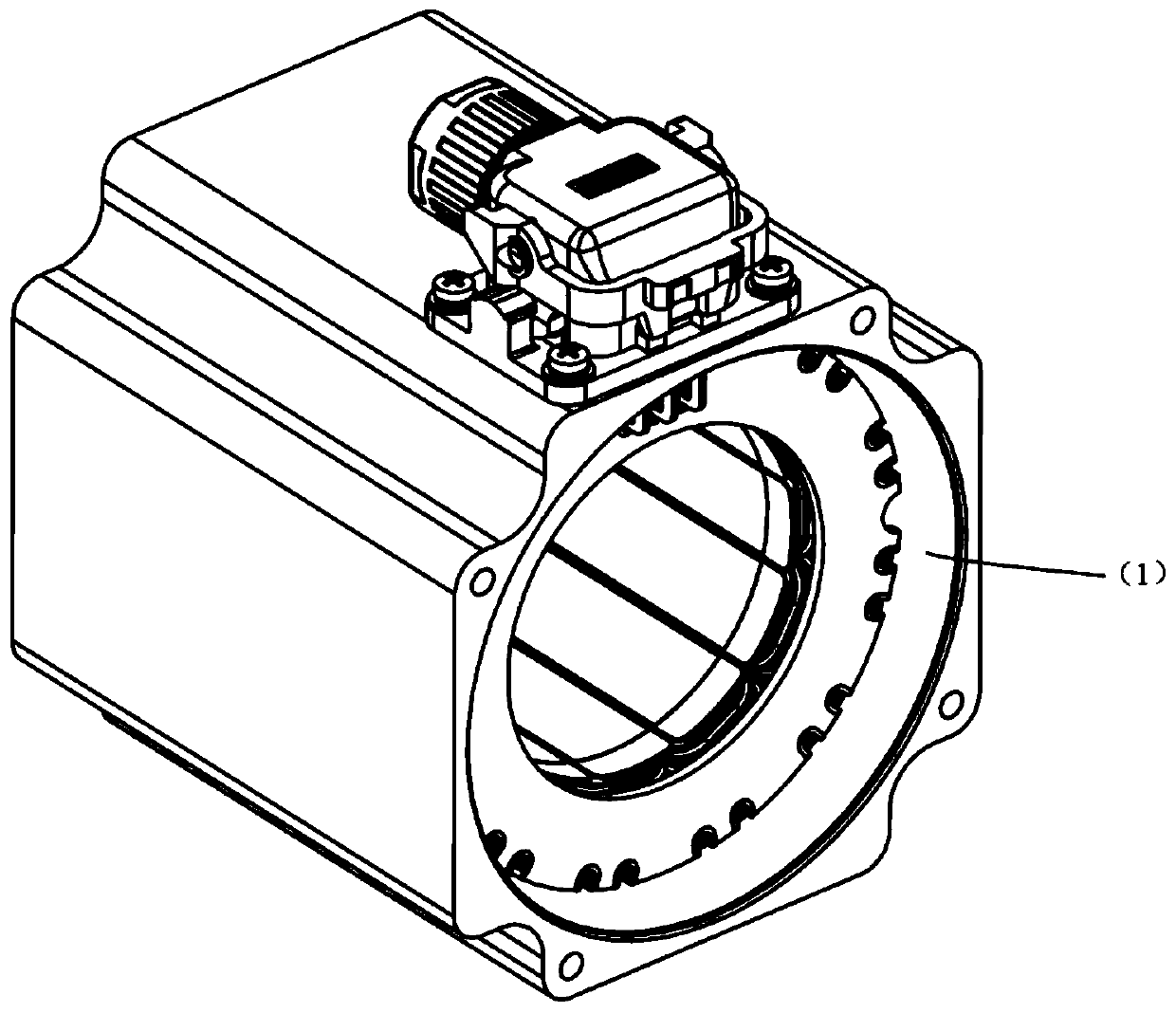

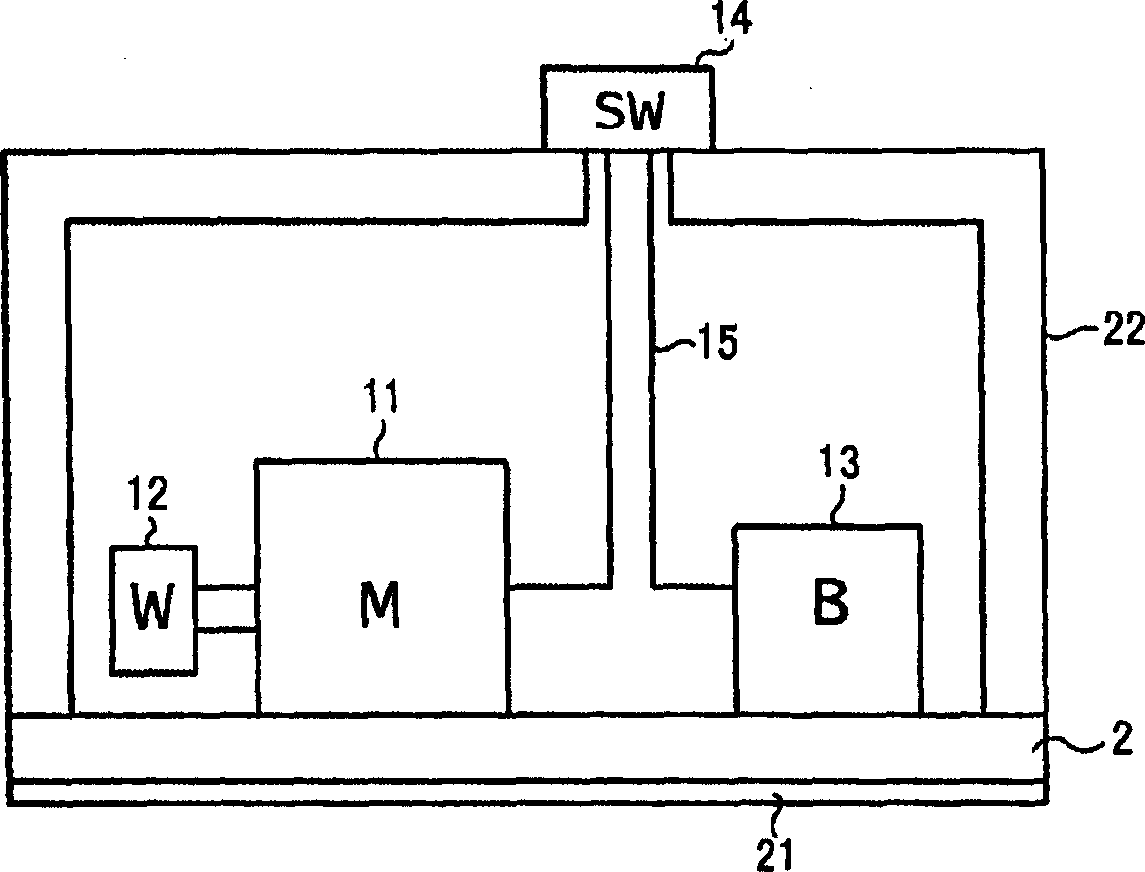

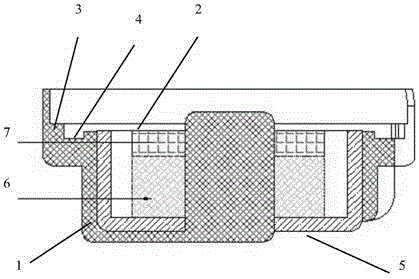

Servo motor

PendingCN109888938AShorten the lengthSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsEdge surfaceEngineering

The invention discloses a servo motor connecting structure for shortening length, which comprises a motor stator, an insulating end part, an end cover, a rear cover, an encoder and a motor rotor. Themotor stator is provided with a first spigot, the insulating end part is connected with the motor stator through a second spigot, and the insulating end part is fixed inside the motor stator through encapsulating epoxy resin; one surface of the insulating end part is a flange surface, a through hole is formed in the flange surface, the other surface of the insulating end part is a concave edge surface, and a first screw hole is formed in the concave edge surface; the end cover passes through the through hole via the first screw and is fixedly connected with the motor stator; the flange surfaceand the connecting end surface are both cambered surfaces protruding towards the motor stator, and the gap between the two cambered surfaces is 0.5 mm; a plurality of second screw holes are formed inthe concave edge surface of the insulating end part, the encoder is arranged in the concave edge surface of the insulating end part, and the end surface of the encoder is retracted into the concave edge surface; and a rear cover hole is fixedly connected with the concave edge surface of the insulating end part to form a sealing cavity, and the encoder is wrapped in the sealing cavity.

Owner:DORNA TECH

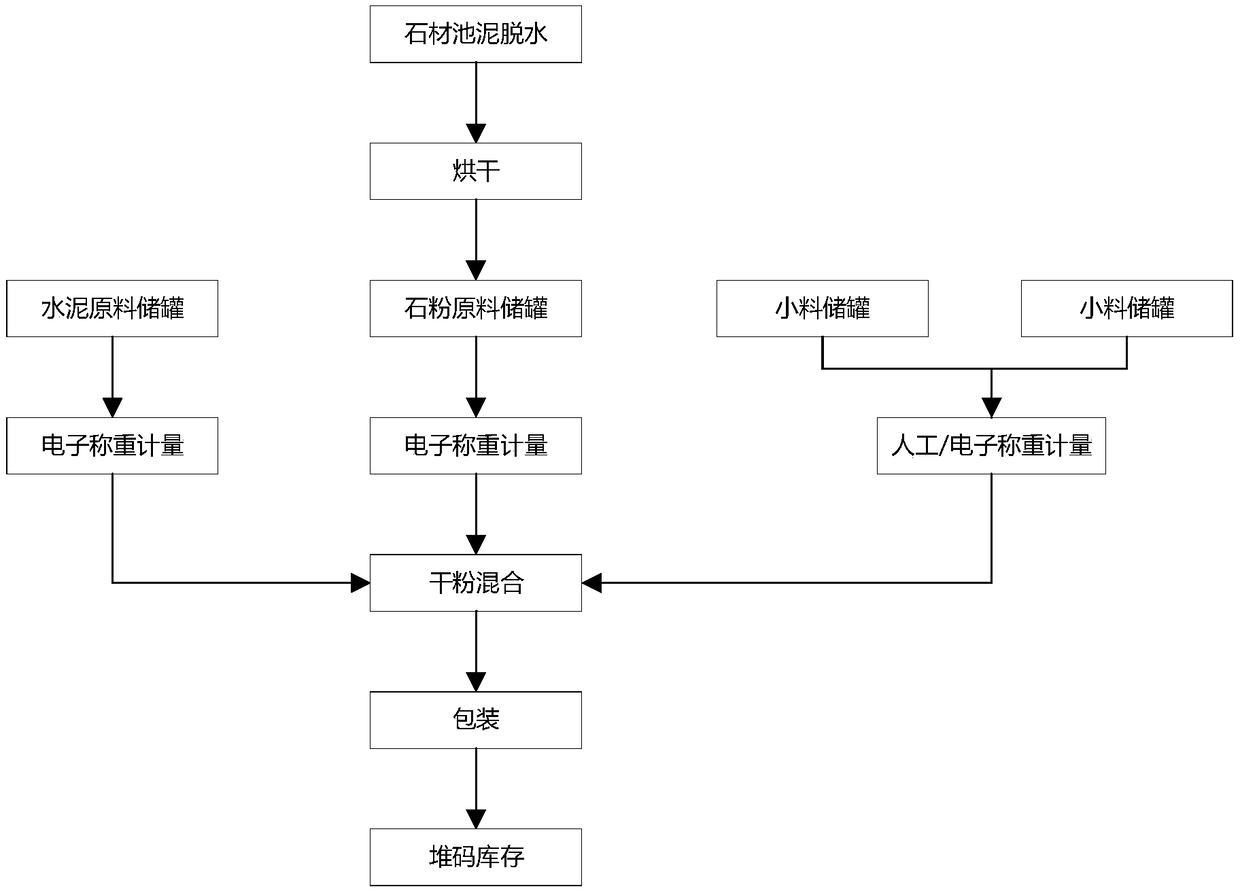

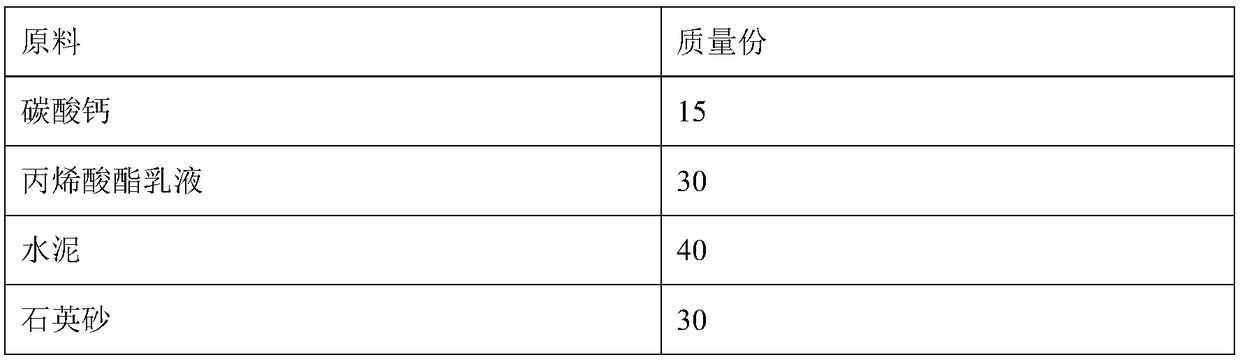

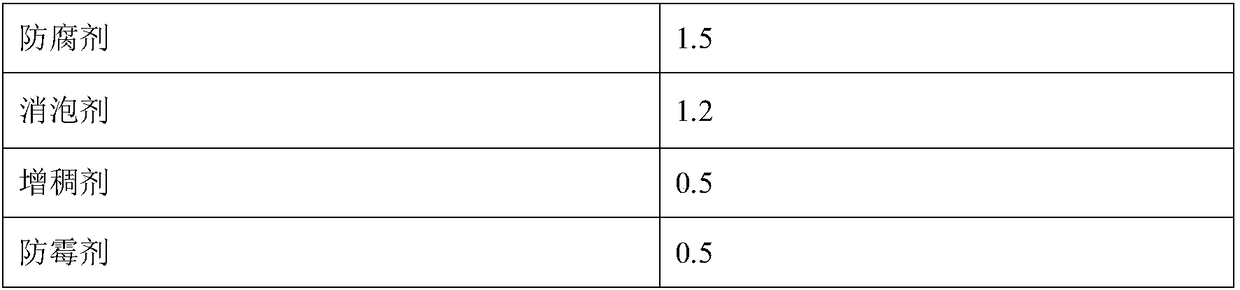

Marble back coating glue based on stone waste slurry material and preparation method of glue

The invention discloses marble back coating glue based on a stone waste slurry material and a preparation method of the glue. The marble back coating glue based on the stone waste slurry material consists of the following raw materials: a stone powder raw material, redispersible latex powder, cement, quartz sand, a preservative, a defoaming agent, a cellulose ether additive, a thickening agent andan anti-mildew agent. Meanwhile, the invention further discloses the preparation method of the marble back coating glue based on the stone waste slurry material. A large amount of waste slurry materials are generated in the stone processing industry, and the back coating glue required for marble stone decoration is prepared by making full use of the stone waste, and thus the environmental pollution caused by accumulation of the stone waste slurry material is solved, the use of the cement, the quartz sand and the like is reduced in the back coating glue production process, the pasting strengthof the stone and a base layer is improved, resources are comprehensively and efficiently utilized, and the purpose of environmental protection is achieved, so that the glue has a good application prospect.

Owner:广东同创科鑫环保有限公司

Trachea guide tube fixation adhesive tape

InactiveCN101011612AImprove paste strengthExcellent paste strengthTracheal tubesAdhesive dressingsTracheal tubeAdhesive

The invention relates to a tracheal cannula fixing band, with wide clinic application. The invention is characterized in that the tracheal cannula is fixed with the band comprising a medical adhesive plaster and adhered liner, to form reverse-F shape via one horizontal adhesive plaster and two upright adhesive plasters. When in use, the liner is broken, and the horizontal adhesive plaster is coiled and fixed at the left of tracheal cannula (or tooth pad); two upright adhesive plasters are parallel at two sides whose heads are adhered with the longitudinal axle of tracheal cannula, and ends are adhered with the left and right faces, to fix the tracheal cannula. The invention has simple operation and wide application for fixing dual-chamber tracheal cannula, food tracheal cannula, or the like.

Owner:陈光忠

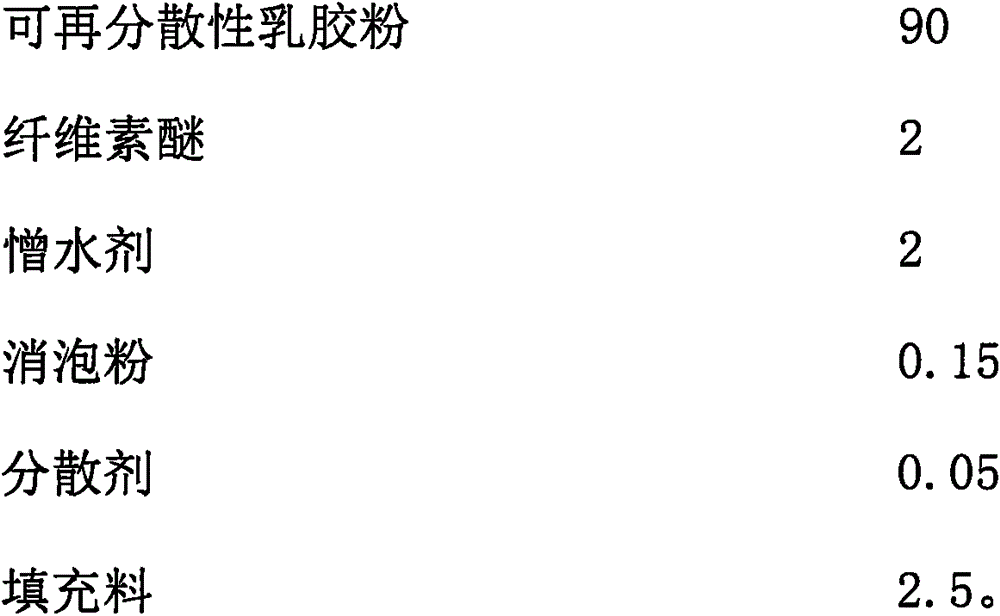

Adhesive powder for sticking waterproof rolls

InactiveCN104479591AImprove adhesionGood water retention and water resistanceCellulose adhesivesOther rubber adhesivesCelluloseEther

The invention discloses adhesive powder for sticking waterproof rolls. The adhesive powder is prepared from the following components in parts by weight: 90-100 parts of redispersible latex powder, 1-2 parts of cellulose ether, 2-3 parts of a water repellent, 0.05-0.15 part of defoaming powder, 0.05-0.15 part of a dispersing agent and 1.5-2.5 parts of a filling agent. The invention further discloses a construction method of the adhesive powder for sticking waterproof rolls. The adhesive powder is mixed with water and cement according to a ratio of 1:40:50, and the mixture can be directly coated on concrete or base layers to directly stick waterproof rolls. The adhesive powder disclosed by the invention has the advantages of high sticking strength, good adhesive force and good water retention and water resistance performance, is non-toxic and odorless, is environment-friendly, can be used for sticking various macromolecule waterproof rolls and is simple and convenient in construction, and the comprehensive cost is reduced.

Owner:XIAMEN LIKASAM WATERPROOF ENG

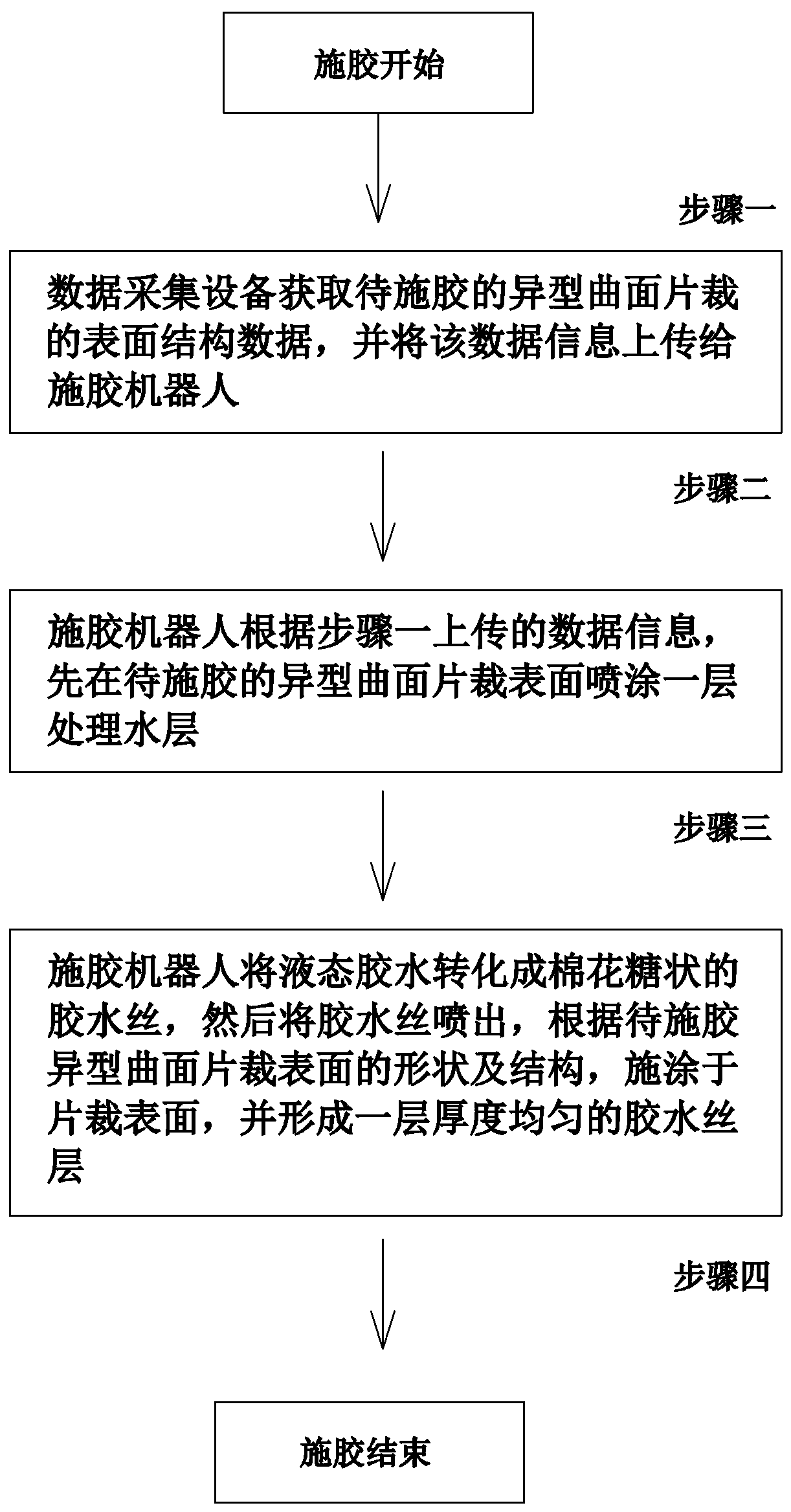

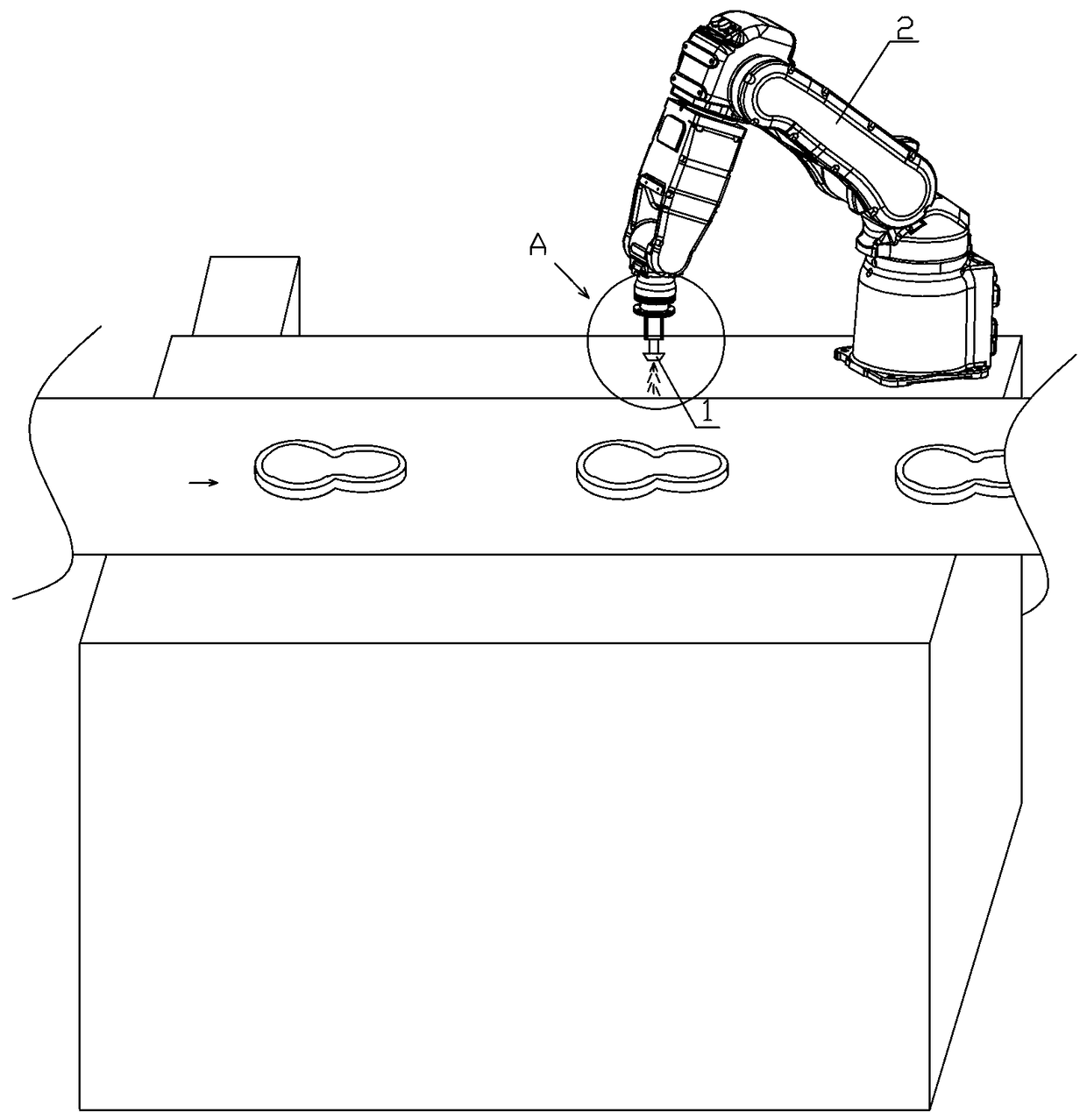

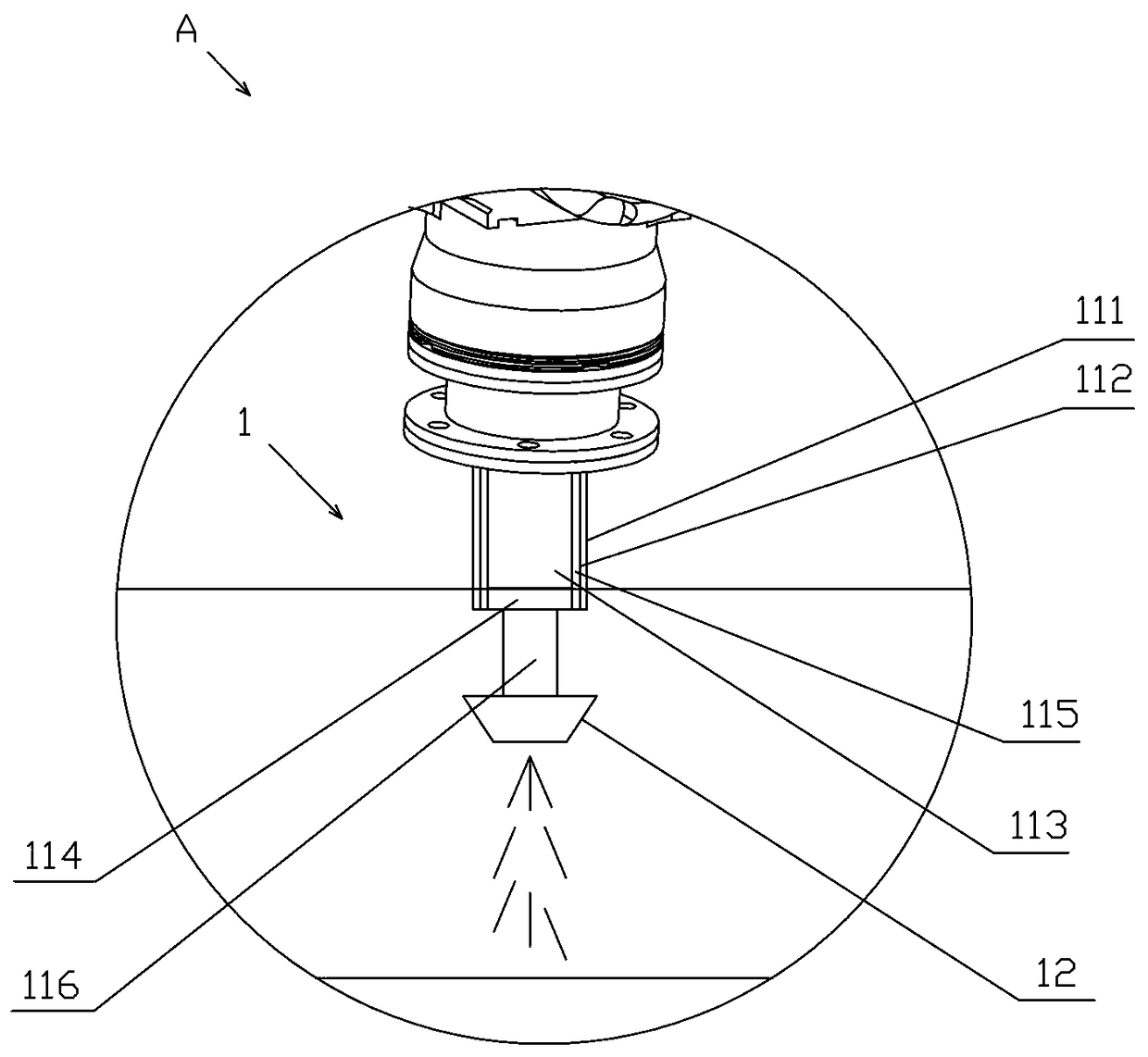

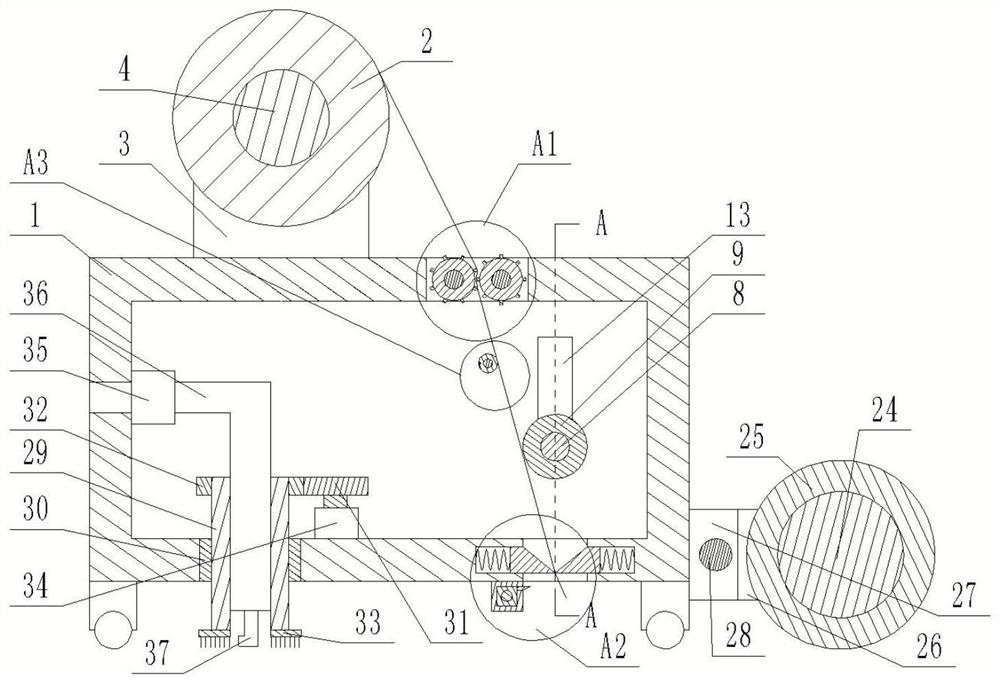

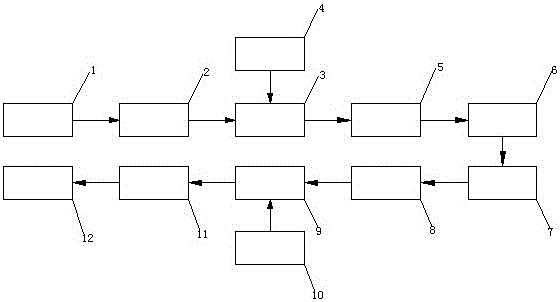

Intelligent glue application technology and equipment for special-shaped curved cutting piece for preventing glue solution accumulation and equipment thereof

PendingCN108720181AAvoid accumulationEasy to spread evenlyShoe gluingData acquisitionUltimate tensile strength

The invention discloses an intelligent glue application technology for a special-shaped curved cutting piece for preventing glue solution accumulation. The technology comprises the following steps: 1,acquiring surface structure data of special-shaped curved cutting pieces to be subjected to glue application; 2, spraying a treating water layer on the surface of the special-shaped curved cutting pieces to be subjected to glue application; and 3, transforming liquid glue into marshmallow-like glue threads by a glue application robot, ejecting the glue threads, applying glue onto the surfaces ofthe cutting pieces according to the shape and structure of the surfaces of the special-shaped curved cutting pieces to be subjected to glue application, and forming a glue thread layer having the uniform thickness. The invention further discloses intelligent glue application equipment for special-shaped curved cutting piece for preventing glue solution accumulation. According to the technology andequipment disclosed by the invention, the glue is easily and uniformly distributed and applied, the application thickness of the glue is easily controlled, excessive glue solution accumulation at recesses of the special-shaped upper cutting pieces is avoided, and the bonding strength of the glue is increased.

Owner:FUJIAN TIEGONG INTELLIGENT ROBOT CO LTD

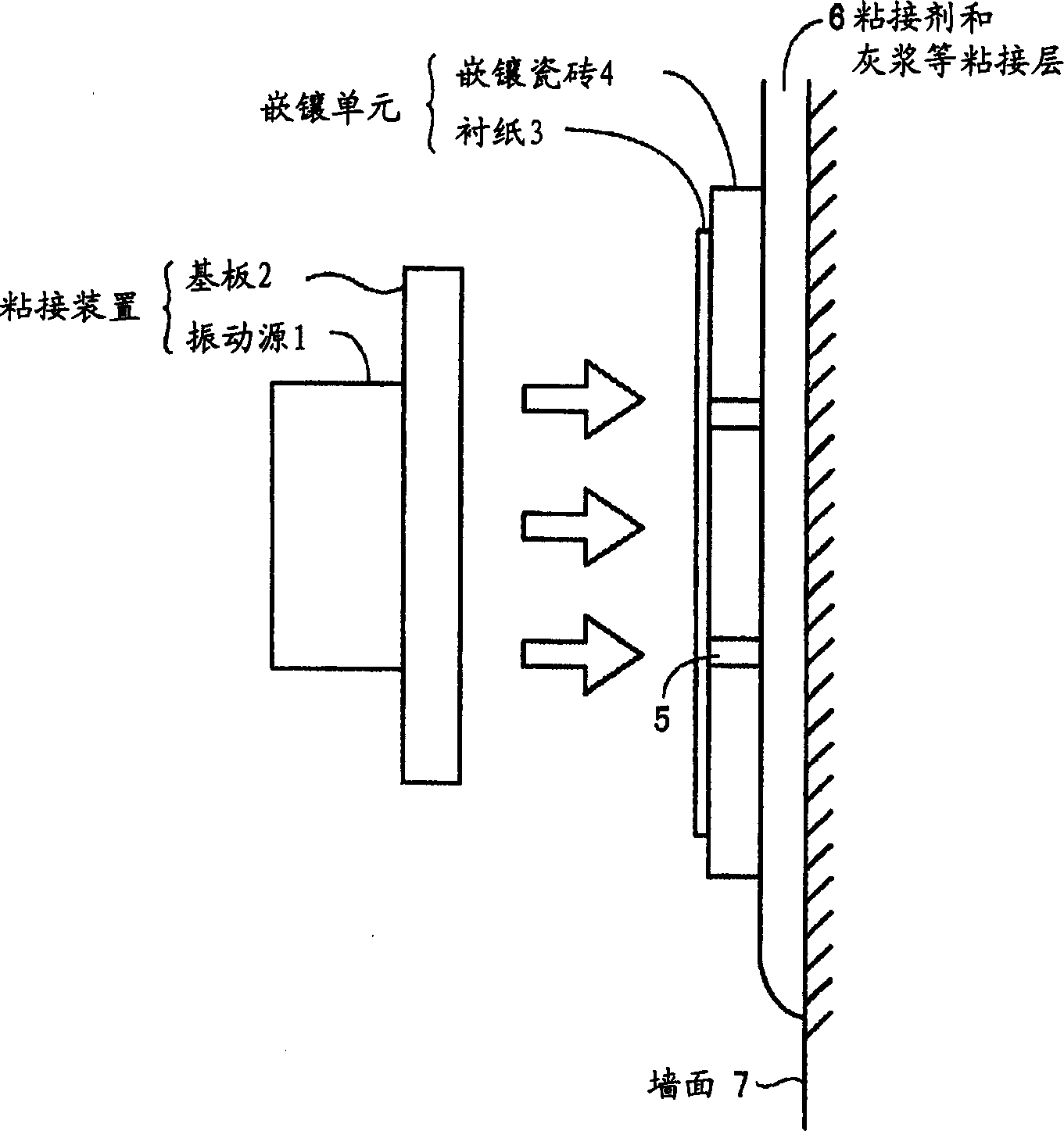

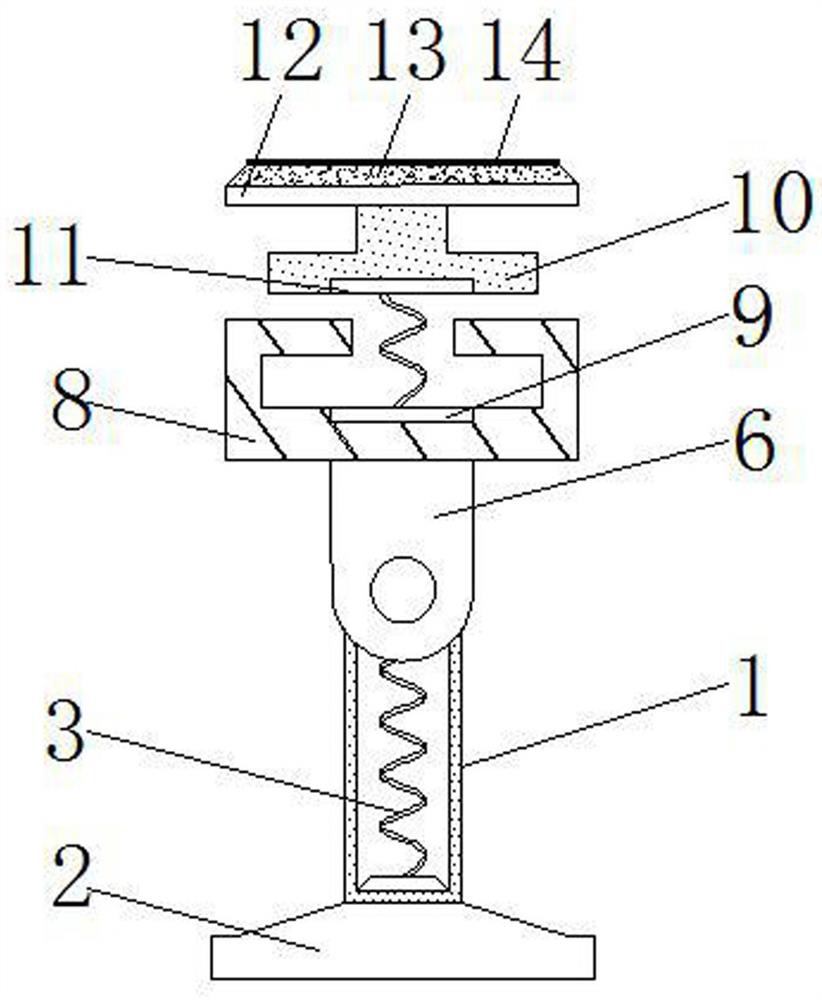

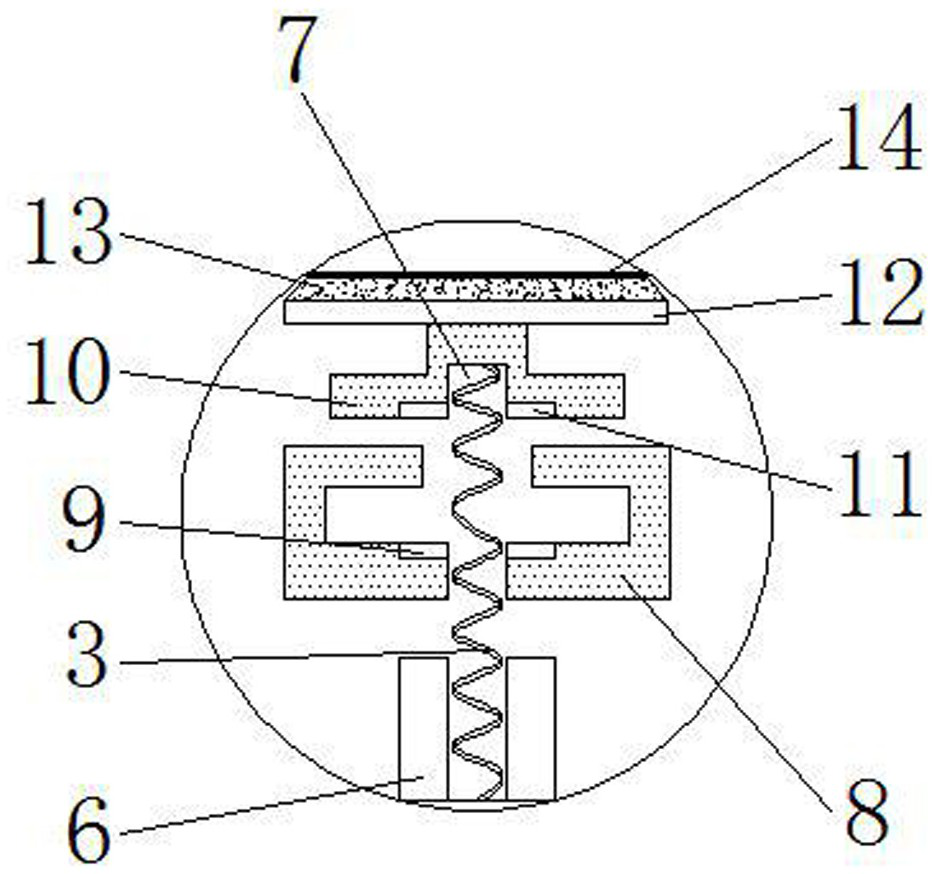

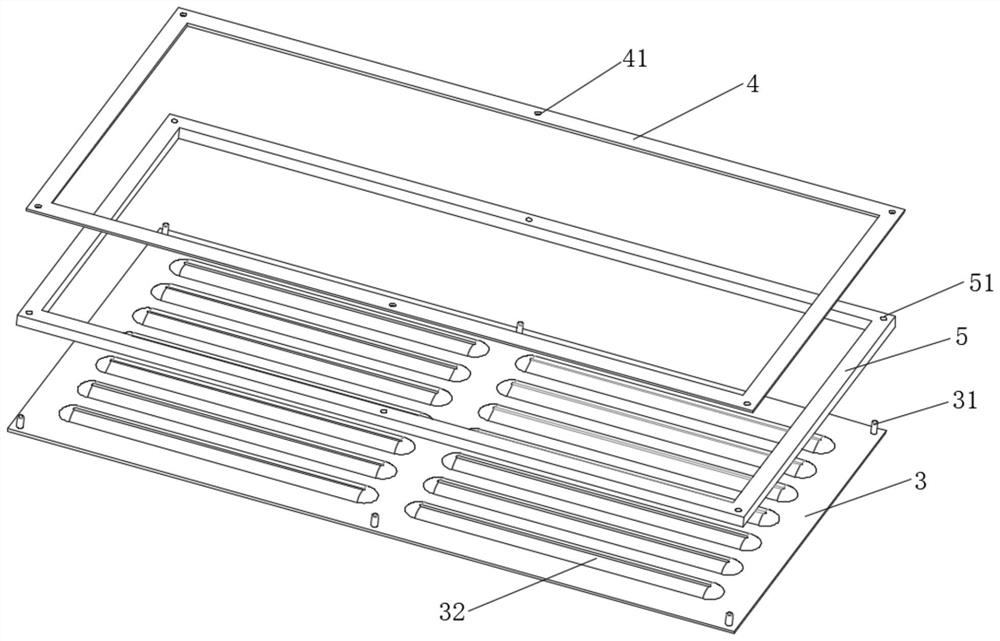

Mosaic ceramic tile unit vibrating binder

A vibration sticking machine for sticking the inlaid ceramic tile unit onto the surface of wall or floor features that under the action of vibration source, its base plate can generate mechancial vibration and transfer the vibration force to said inlaid ceramic tile unit in order to stick it via adhesive layer onto the wall (or floor) surface. Said inlaid ceramic tile unit is composed of several inlaid ceramic tiles and a lining paper which can be removed. Its advantage is uniform pressure.

Owner:新优有限公司

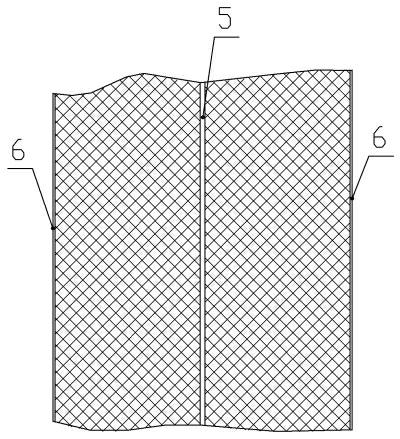

Improved anti-crack pressing and pasting device for asphalt concrete pavement crack diseases

PendingCN113250062AImprove stabilityAvoid shakingRoads maintainenceStructural engineeringRoad surface

The invention discloses an improved anti-crack pressing and pasting device for asphalt concrete pavement crack diseases, which is characterized by comprising a movable shell, an anti-crack pasting body, a transmission mechanism, a pressing and pasting mechanism and a cleaning mechanism, the transmission mechanism comprises a clamping seat, a clamping shaft, an extrusion shaft, an extrusion sleeve and a convex block; the clamping seats are arranged on the two sides of the top face of the movable shell respectively, the clamping shaft is detachably connected between the two clamping seats, one end of the anti-crack patch body is arranged outside the clamping shaft in a sleeving mode, a feeding hole is formed in the top face of the movable shell, the two extrusion shafts are arranged in the feeding hole, and the two extrusion shafts are arranged in the movable shell. The extrusion shafts are sleeved with the extrusion sleeves, the multiple protruding blocks are arranged on the outer walls of the extrusion sleeves in the circumferential direction, and the two extrusion sleeves are meshed with each other through the protruding blocks; the pressing and pasting mechanism is arranged in the movable shell, and the multiple cleaning mechanisms are longitudinally arranged and arranged on the side, away from the cutting assembly, of the bottom of the movable shell.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

Gummed paper

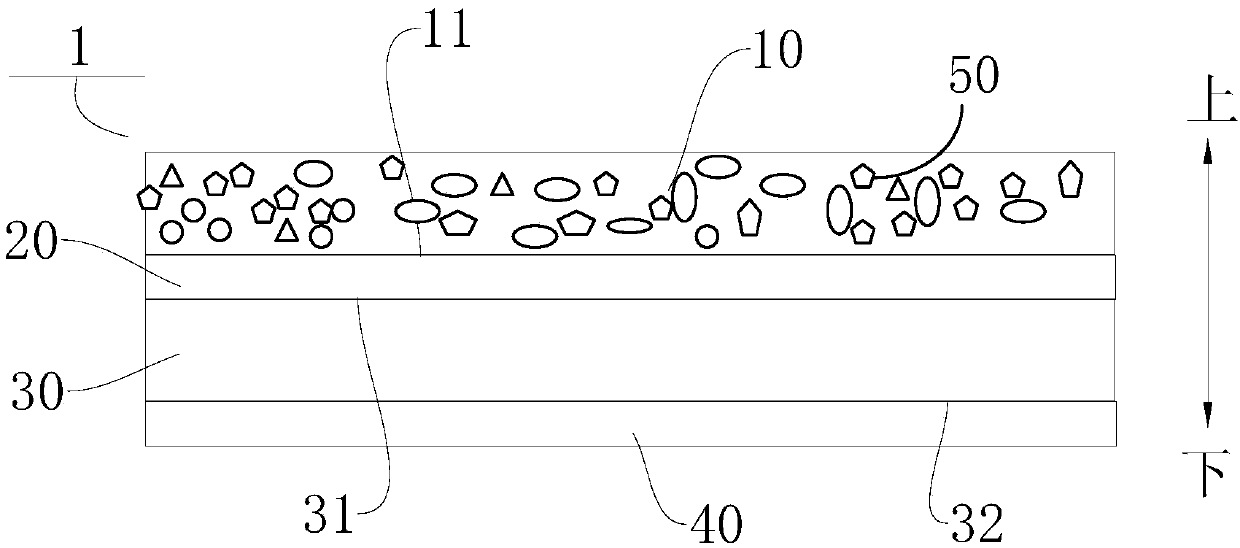

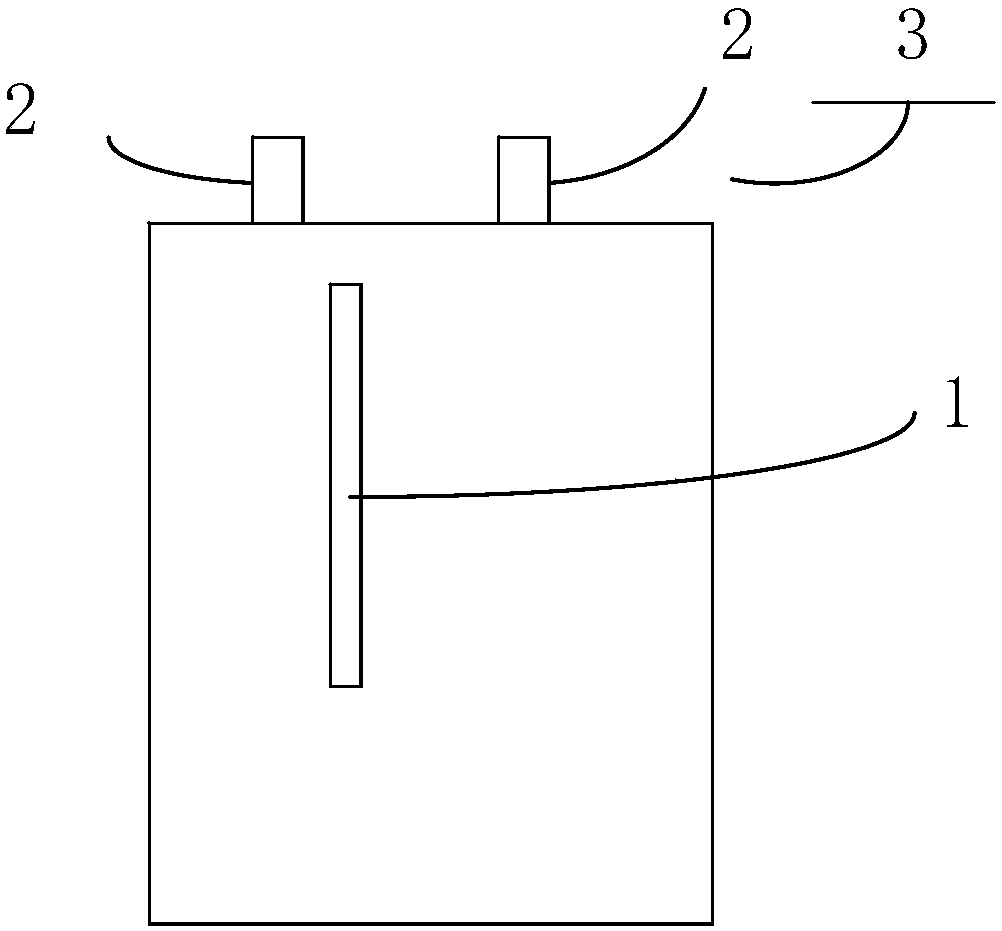

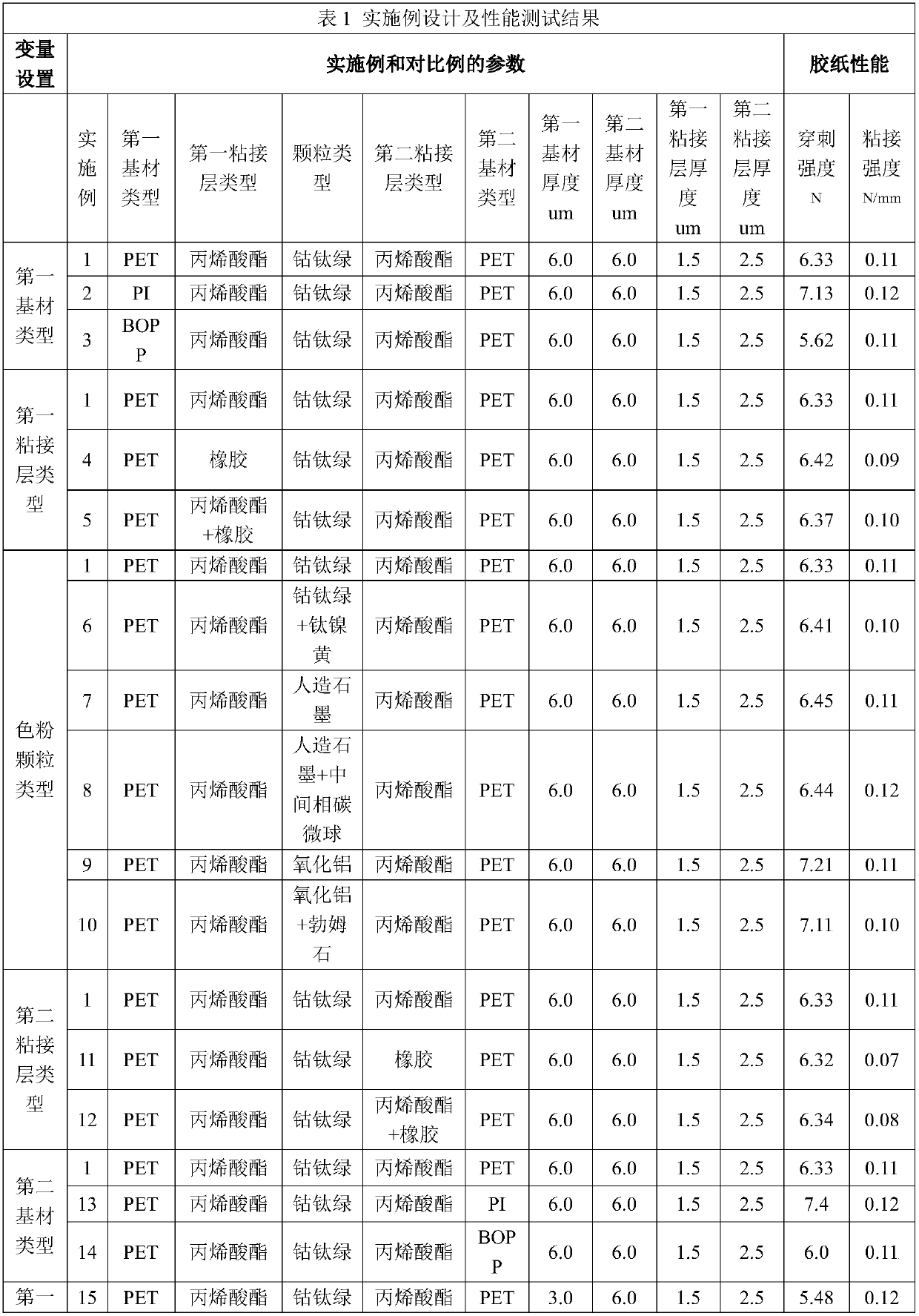

InactiveCN110380122AGood adhesive strength and puncture strengthImprove puncture strengthFinal product manufactureElectrolyte accumulators manufactureComposite structureBonding strength

The invention discloses gummed paper, and the gummed paper comprises a first base material, a first bonding layer and a second bonding layer, wherein the first bonding layer comprises particles. The first bonding layer is arranged between the first base material and the second bonding layer, and the first bonding layer is in contact with the first base material. The gummed paper is of a multi-layer composite structure, the bonding strength of the gummed paper can be improved through the multi-layer composite structure, the gummed paper is not prone to falling off, and the puncture strength ofthe gummed paper is improved.

Owner:NINGDE AMPEREX TECH

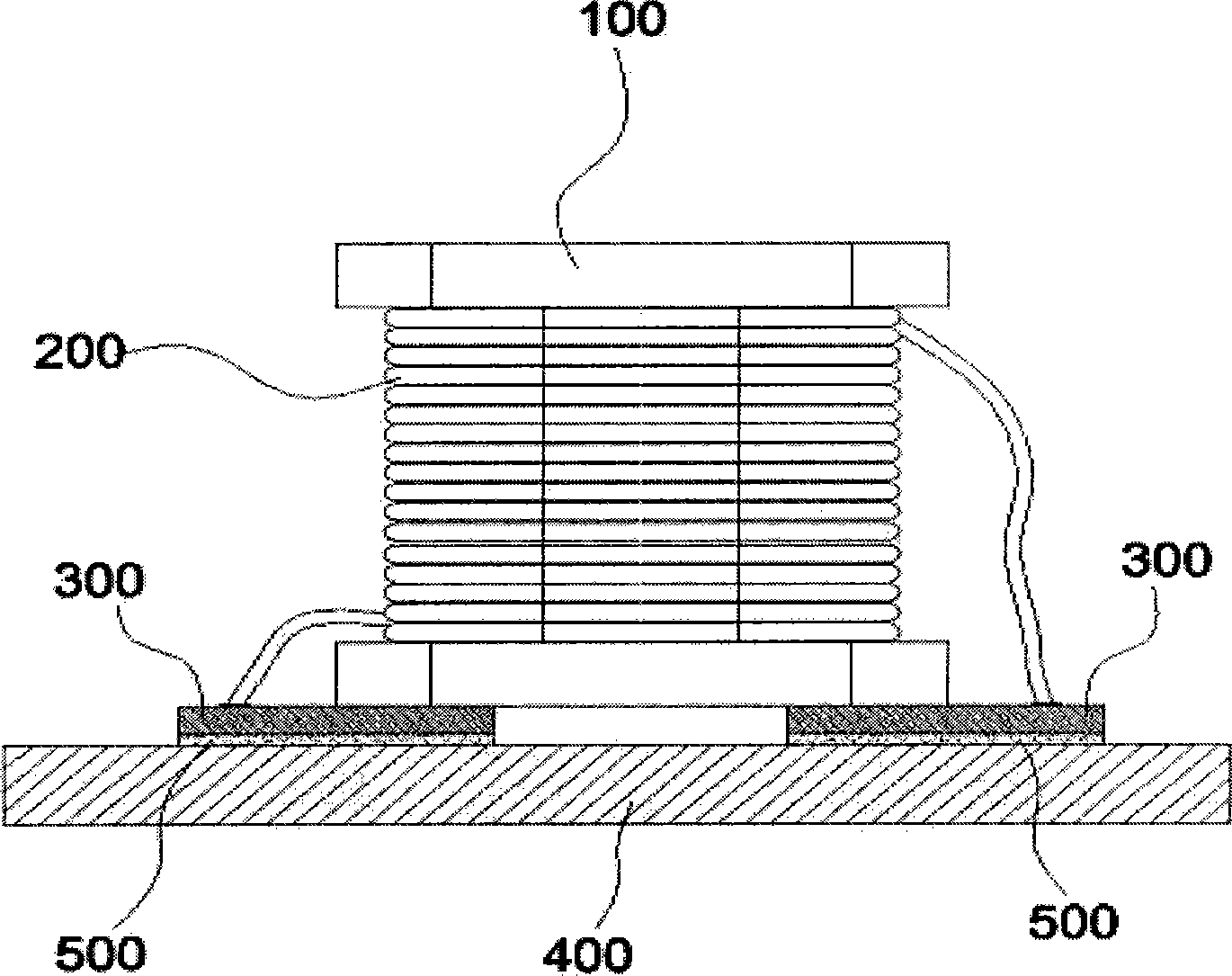

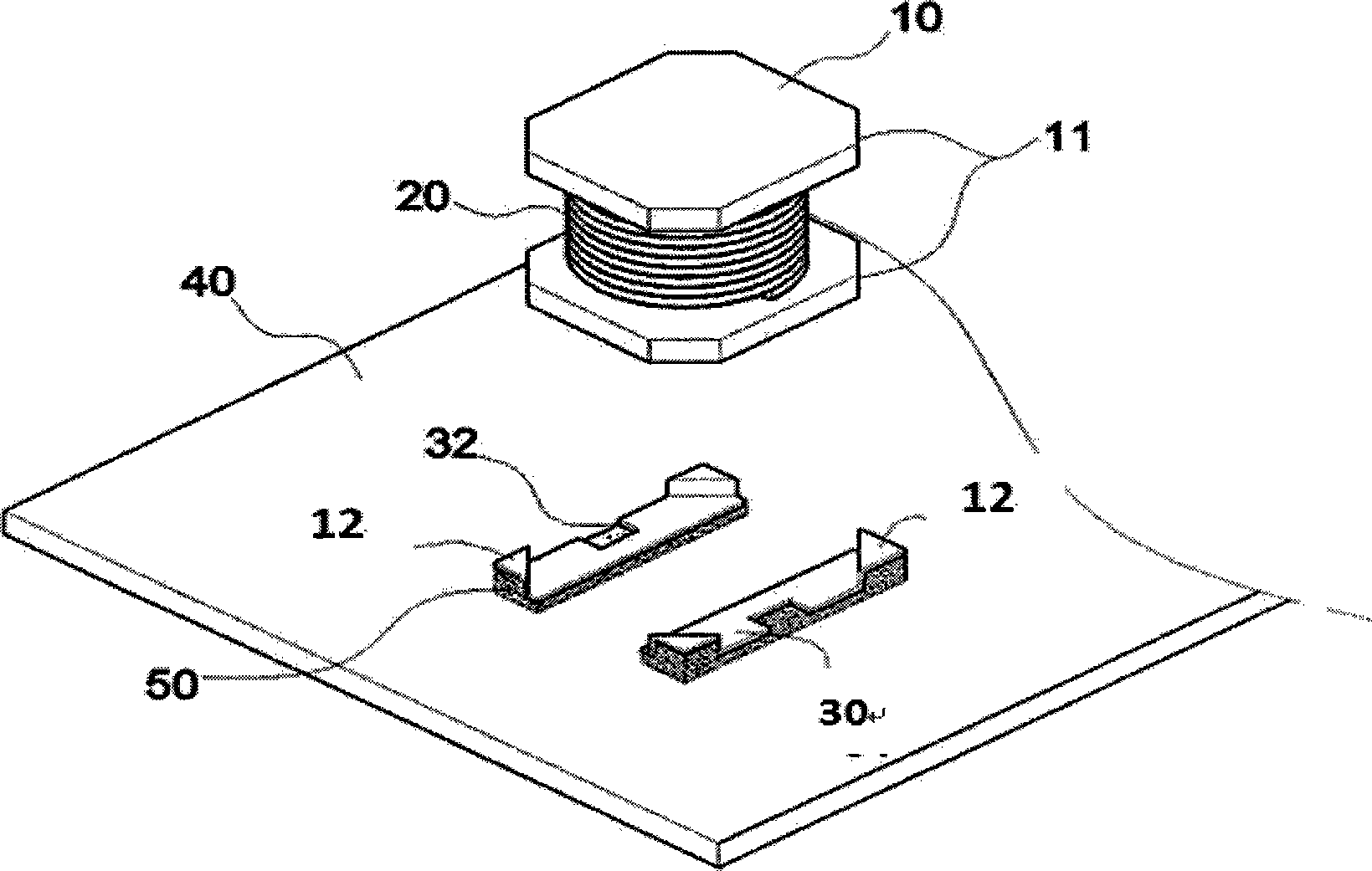

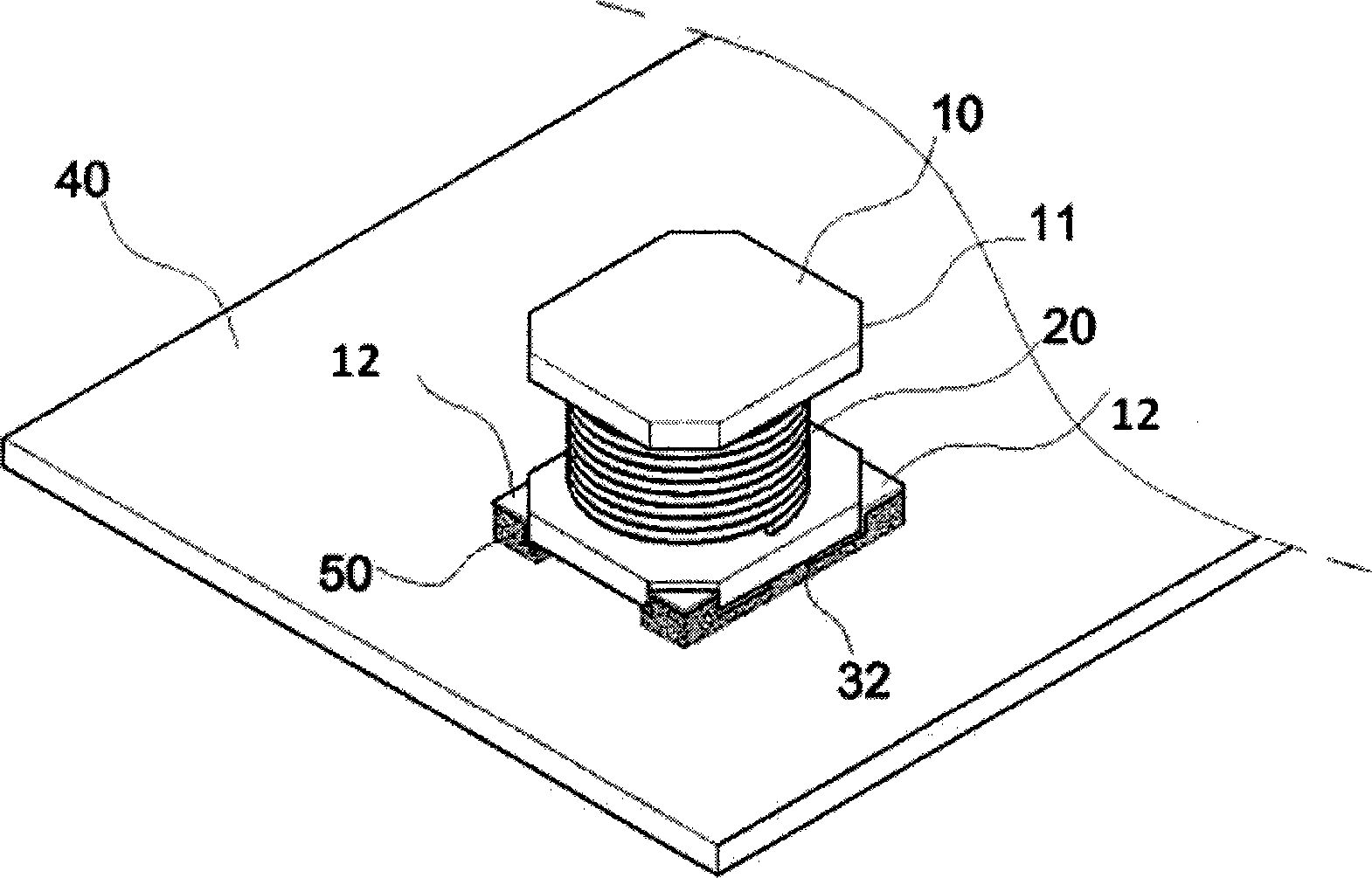

Multiple-inductor terminal

InactiveCN102637512AFirmly connectedIncrease contact areaTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresCopper wireComputer module

The invention provides a multiple-inductor terminal comprising a magnetic core wound with a copper wire and a terminal, wherein the copper wire is connected with the terminal; the upper part of the outer end of the terminal is provided with a bulge; the lower bottom surface of the magnetic core is connected with the surface of the terminal; and the lower part of the magnetic core is provided with a surface which is jointed with the inner side of the bulge of the terminal. The multiple-inductor terminal has the characteristics of stable adhesion, high heat dissipation efficiency and no circuit board module restriction.

Owner:COIL MASTER ELECTRONICS

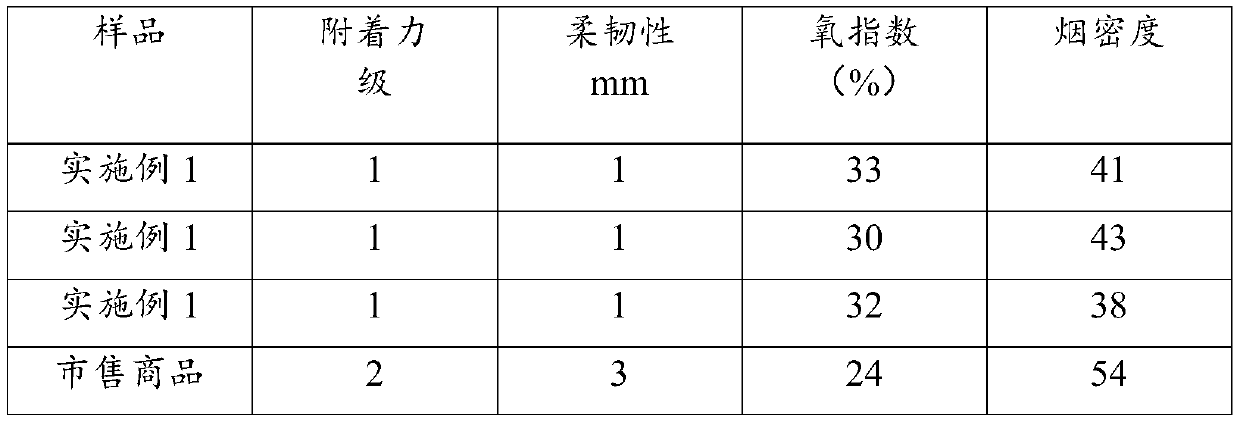

Low-stress epoxy resin intumescent fireproof coating material

PendingCN111548662AImprove adhesionImprove paste strengthFireproof paintsEpoxy resin coatingsFiberPolymer science

The invention relates to a low-stress epoxy resin intumescent fireproof coating material. The material comprises a component A and a component B. The component A specifically comprises the following components in parts by weight: 35-50 parts of modified epoxy resin; 5-13 parts of a diluent; 8-15 parts of a charring agent; 6-10 parts of a flame retardant; 3-6 parts of a foaming agent; and 8-15 parts of a solvent. The component B specifically comprises the following components in parts by weight: 35 to 45 parts of curing agent; 12 to 20 parts of amino-terminated polysulfide rubber; 40 to 50 parts of pigment filler; 23 to 35 parts of refractory fiber; and 3 to 10 parts of solvent. According to the low-stress epoxy resin intumescent fireproof coating material of the invention, the organosilicon-modified epoxy resin matrix, the curing agent and the amino-terminated polysulfide rubber are combined, so that the adhesive force of the matrix can be obviously enhanced, and the bonding strength and shrinkage resistance of the coating can be remarkably improved; and no benzene toxic solvent is used in the formula, so that the coating material is more environment-friendly; and various flame retardants, pigments, fillers and charring agents are combined in the formula, so that a flame-retardant effect is remarkably improved.

Owner:竺浩亮

A display stand for mobile phone sales

ActiveCN107172248BImprove securityEasy to fixStands/trestlesTelephone set constructionsDisplay boardHot melt

The invention discloses a mobile phone sales display support. The mobile phone sales display support comprises a fixed pedestal rod, an antitheft chain, a slide rail fixed block and a display board; the bottom end of the fixed pedestal rod is connected to the pedestal; the antitheft chain is installed on the inner side of the fixed pedestal rod; a rotation shaft passes through the fixed pedestal rod and is connected to a rotation fixed head; wire arrangement holes are arranged on the top of the fixed pedestal rod; the slid rail fixed block is fixedly connected to the rotation fixed head; the slid rail fixed block is connected to the sliding block; an iron block is arranged on the lower end of the sliding block; the display board is connected to the sliding block; and an adhesive layer is formed on the upper end surface of the display board. The mobile phone sales display support adopts an antitheft chain and a resistance layer and the antitheft chain goes through all wire arrangement holes and finally connects to the sliding block, which make the display support more beautiful and safe; adhesive strength of an adhesive layer of a hot melt adhesive material is high, and the hot melt adhesive material does not damage the housing of the mobile phone, good in safety and does not interfere with operation experience of a user.

Owner:扬州市杭集创意设计园有限公司

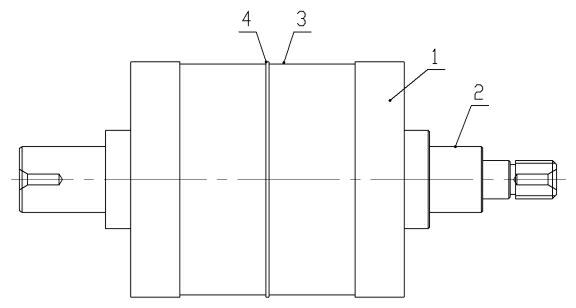

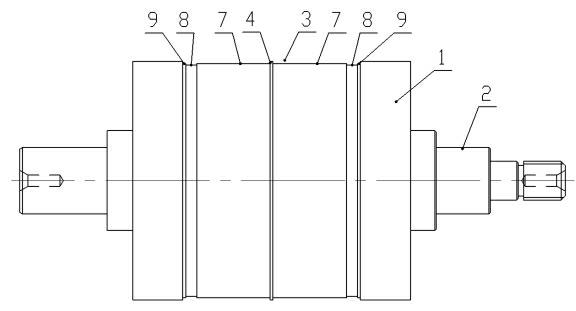

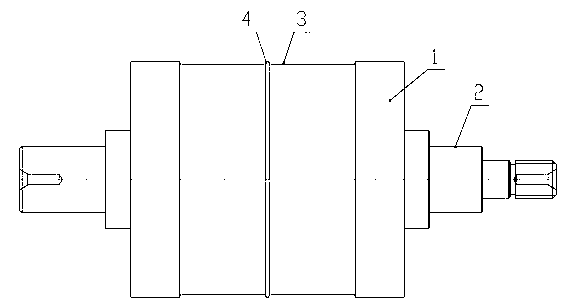

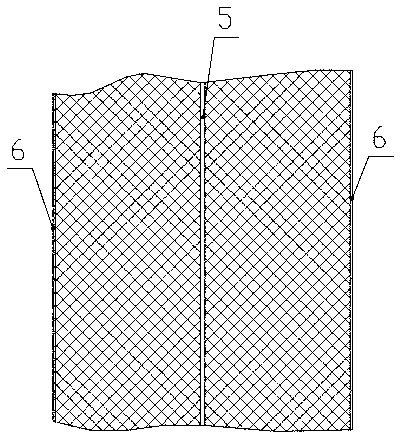

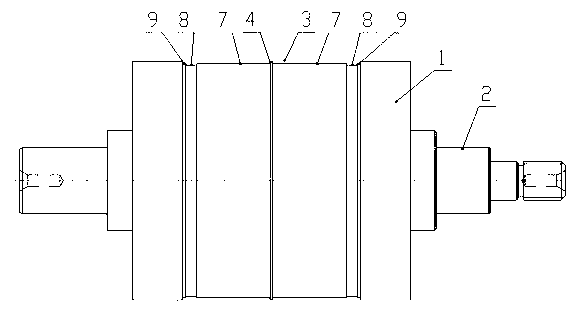

Gum control roller of cigarette making and tipping machine combination

ActiveCN102429321APrevent air leakageHigh bonding strengthCigarette manufactureEngineeringUltimate tensile strength

The invention discloses a gum control roller of a cigarette making and tipping machine combination, comprising a roller and a rotary shaft which is arranged on the centre of the roller, wherein the circumferential surface of the roller is provided with a groove, and the centre of the groove is provided with an annular convex edge. The surface of the groove is respectively provided with a first annular gum coating strap, a second annular gum coating strap and a third annular gum coating strap in turn from the convex edge to the two sides. The gum control roller designs the gum coating quantityof the tipping paper which meets the twisting requirements according to the twisting technology, and coats a thin gum on the middle part to reduce the gum scale of cutters; the gum control roller increases the gum coating quantity in the joint area of the cigarette and the filter tip and improves the bonding strength, so the cigarette cannot leak the air; and the edge of the tipping paper is coated with little gum coating quantity, so that the curling sides of the tipping paper caused by the shortage gum quantity of the part can be compensated.

Owner:CHINA TOBACCO HENAN IND

Wood floor and manufacturing process thereof

PendingCN111805676AImprove paste strengthSolve size deformationWood working apparatusFlooringLap jointRabbet

The invention discloses a wood floor and a manufacturing process thereof. The wood floor structurally comprises an upper layer and a bottom layer which are sequentially arranged from top to bottom, wherein the upper layer is made of veneer and adopts precious tree species; the bottom layer is a base material and is made of pine or Chinese fir. The wood floor is characterized in that the bottom layer comprises frames and a supporting batten, and the frames are positioned on the lower two sides of the upper layer; and the supporting batten is located on one sides of the frames, and is connectedwith the frames by rabbet s. According to the wood floor and the manufacturing process thereof, the wood floor is structurally formed by lap joint of unique closed or open rabbets between the frames and the supporting batten, and radial pulling force of the surface of the veneer can be enhanced; meanwhile, a reinforcing agent is added during glue blending, and vacuum heat treatment is used, so that bonding strength of the floor can be further enhanced, flatness of the floor surface can be improved, and the problem of dimensional deformation of the floor after water absorption is also solved; the gluing steps can be reduced by structural stability, and the environmental effect is improved; and the supporting batten can be made of waste lumber materials, so that the production cost is effectively reduced.

Owner:SINO MAPLE JIANGSU CO LTD

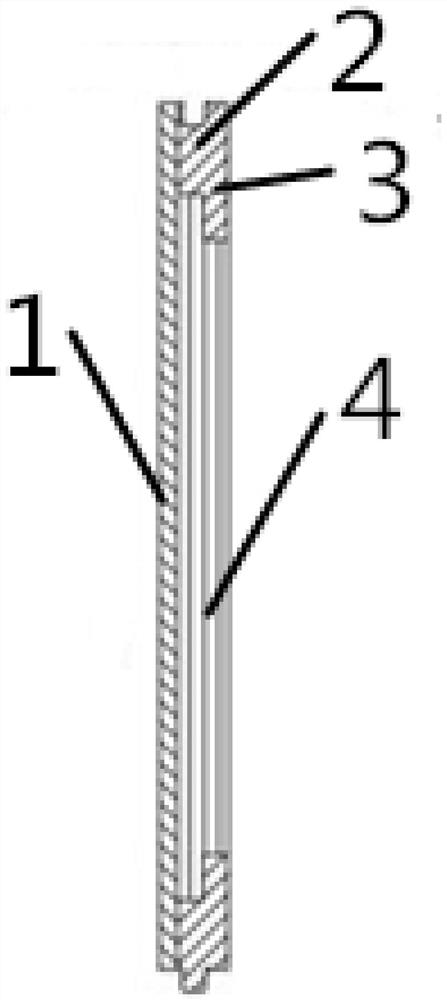

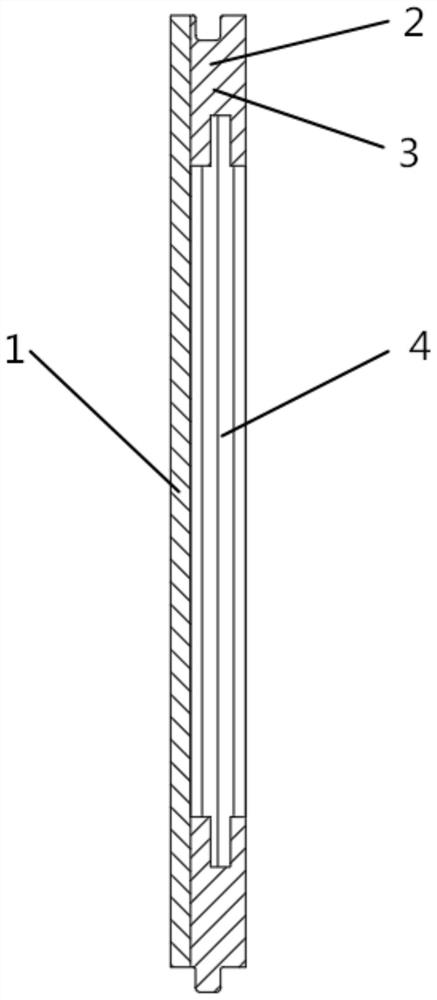

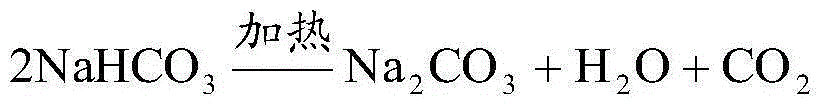

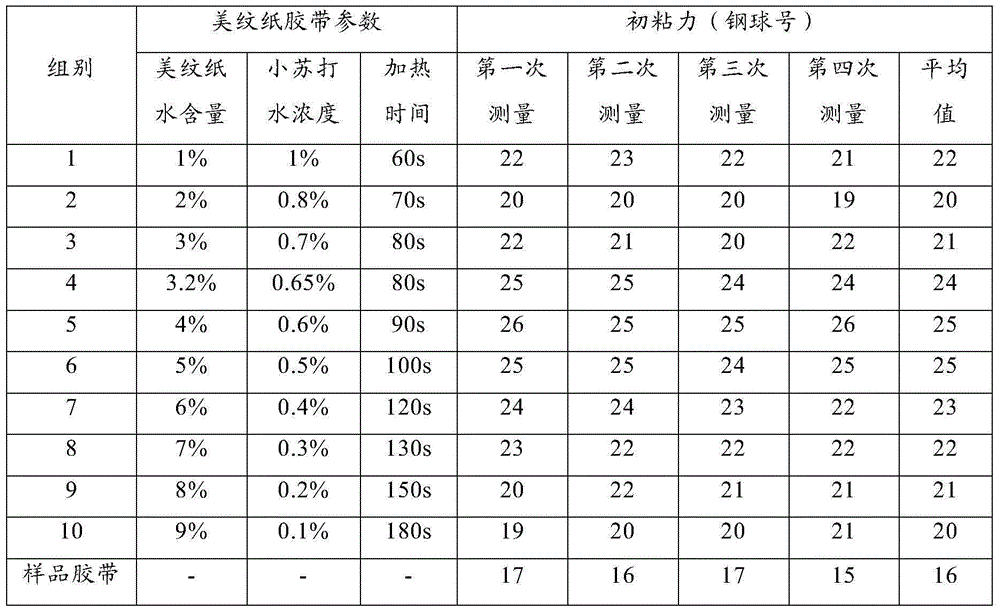

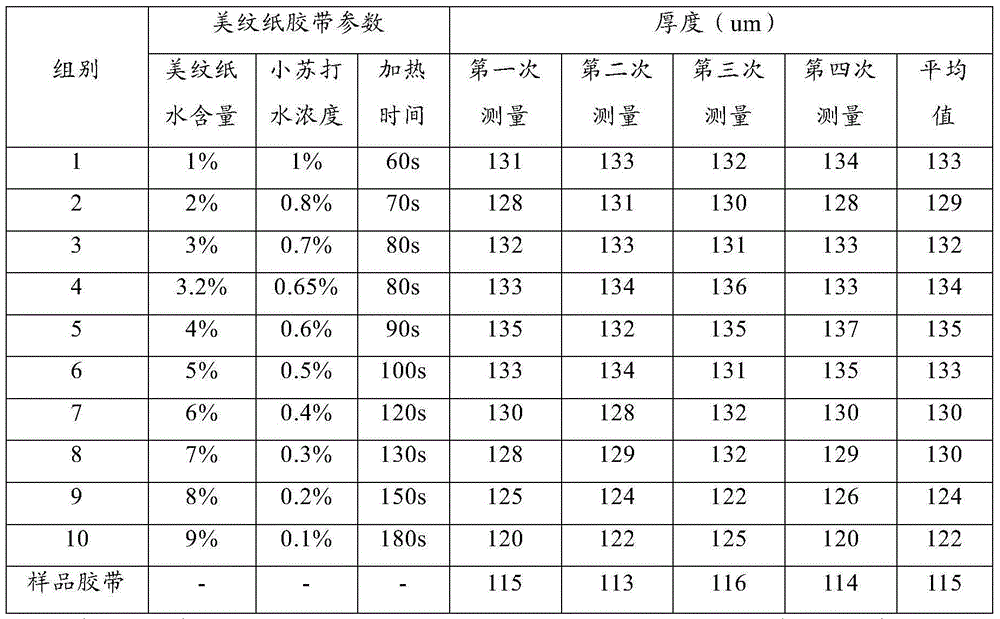

Manufacturing process for hot-melt textured adhesive tape

ActiveCN105802530AReduce manufacturing costIncreasing the thicknessFilm/foil adhesivesHot meltPulp and paper industry

The invention relates to a manufacturing process for a hot-melt textured adhesive tape. The process comprises the following steps: by utilizing baking soda water as a medium, controlling space humidity through a humidity controller, allowing the adhesive-coating surface of textured paper to form a layer of a baking soda water contained thin film, then uniformly coating an adhesive on the surface of the textured paper containing the baking soda water contained thin film, decomposing the baking soda water into water and carbon dioxide under heating through a heating device, subjecting an adhesive layer to expansion at high temperature, and allowing carbon dioxide and vapor to penetrate through the adhesive layer and evaporate so as to obtain a porous foam-like adhesive layer. The manufacturing process provided by the invention improves thickness and initial adhesion of a hot-melt adhesive, reduces production cost, and does not cause environmental pollution.

Owner:江苏晶华新材料科技有限公司

Gum control roller of cigarette making and tipping machine combination

ActiveCN102429321BPrevent air leakageHigh bonding strengthCigarette manufactureUltimate tensile strengthPaper sheet

The invention discloses a gum control roller of a cigarette making and tipping machine combination, comprising a roller and a rotary shaft which is arranged on the centre of the roller, wherein the circumferential surface of the roller is provided with a groove, and the centre of the groove is provided with an annular convex edge. The surface of the groove is respectively provided with a first annular gum coating strap, a second annular gum coating strap and a third annular gum coating strap in turn from the convex edge to the two sides. The gum control roller designs the gum coating quantityof the tipping paper which meets the twisting requirements according to the twisting technology, and coats a thin gum on the middle part to reduce the gum scale of cutters; the gum control roller increases the gum coating quantity in the joint area of the cigarette and the filter tip and improves the bonding strength, so the cigarette cannot leak the air; and the edge of the tipping paper is coated with little gum coating quantity, so that the curling sides of the tipping paper caused by the shortage gum quantity of the part can be compensated.

Owner:CHINA TOBACCO HENAN IND

Mineral composite decorative board and preparation method thereof

PendingCN114033116ARich and realistic color without fadingBright, rich, lifelike and non-fadingCovering/liningsCeramic shaping apparatusPolymer adhesiveMining engineering

The invention discloses a mineral composite decorative board which comprises a mineral synthetic finish coat, an anti-crack reinforcing net and a mineral synthetic base material. The mineral synthetic finish coat is adhered to the upper surface of the mineral synthetic base material through a high-molecular polymer adhesive; the anti-cracking reinforcing net is arranged between the mineral synthetic finish coat and the mineral synthetic base material; the mineral synthetic finish coat is made of inorganic mineral particles; a facing material blocking frame is arranged on the side wall of the mineral synthetic finish coat; a base material blocking frame is arranged on the side wall of the mineral synthetic base material; a plurality of veneer material blocking frame positioning holes are respectively formed in the periphery of the veneer material blocking frame; a plurality of base material blocking frame positioning holes are respectively formed in the periphery of the base material blocking frame; and a plurality of template positioning pins are respectively arranged on the periphery of the mineral synthetic base material. According to the invention, the mineral composite decorative board has the characteristics of light weight, high strength, ultra-long service life, aging resistance, fire resistance, insulation, water resistance, moisture resistance, heat insulation, sound insulation, energy conservation and environmental protection.

Owner:河南科镁隆实业有限公司

Clothes hanger PE pipe compositing process

The invention relates to a clothes hanger PE pipe compositing process. The clothes hanger PE pipe compositing process comprises the steps that 1, a steel belt is discharged out of an unreeling machine and corrected through a steel belt correcting device; 2, the corrected steel belt passes through an extrusion die, at the moment, resin is extruded through an extruder located at the same side as the extrusion die at the same time, and the resin is arranged outside the steel belt in a wrapping manner, so that belt materials are formed; 3, reinforcing ribs of the belt materials obtained after preliminary shaping are subjected to secondary shaping through a shaping die, and meanwhile, cooling is conducted through cooling water of a shaping table; 4, the cooled belt materials are blown to be dry through blowers, and then the belt materials are pulled to a winding machine through a traction machine; 5, a sizing material is extruded through an extruder located at the upper end of the winding machine and bonded to one side of each belt material output through the winding machine, and then a clothes hanger PE pipe is formed through a formation cage; and 6, the formed clothes hanger PE pipe output through the formation cage is cut through a cutting machine. The clothes hanger PE pipe compositing process has the beneficial effects that bonding strength among the belt materials in the clothes hanger PE pipe is high; and the steel material and the resin are composited well.

Owner:NANTONG YUEDA KNITTING GARMENT

Method for mfg. plasma display

InactiveCN100452276CUniform bondingGood adhesionTube/lamp screens manufacturePrinted circuit assemblingFlexible circuitsDisplay device

Owner:四川世纪双虹显示器件份有限公司

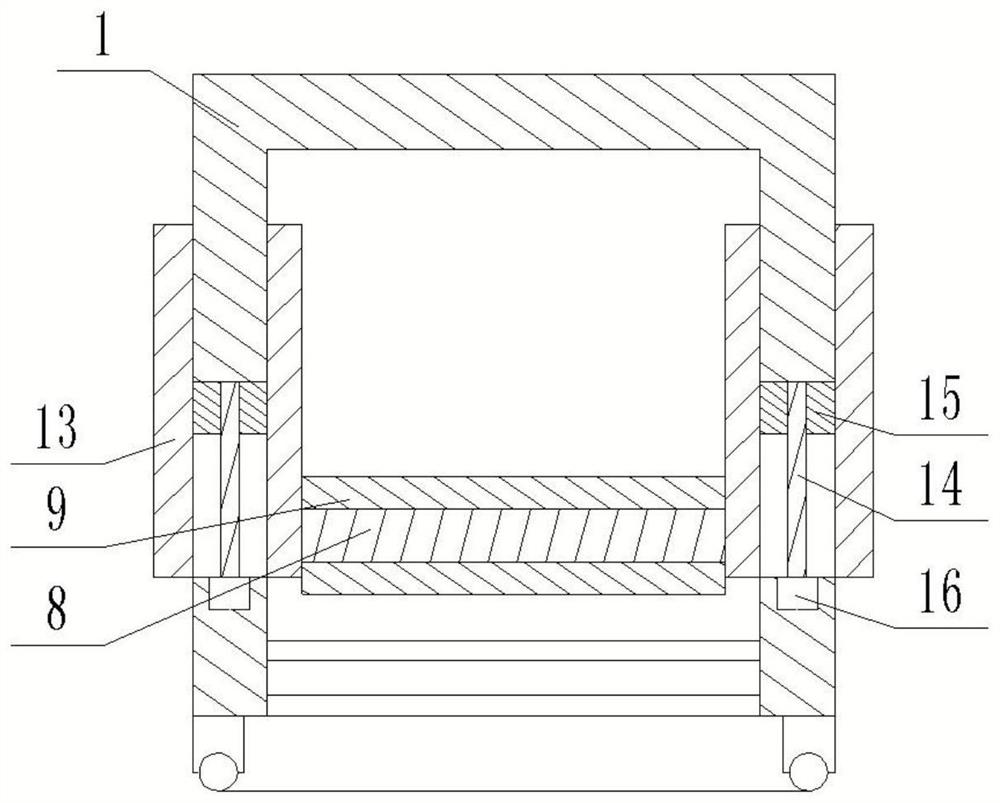

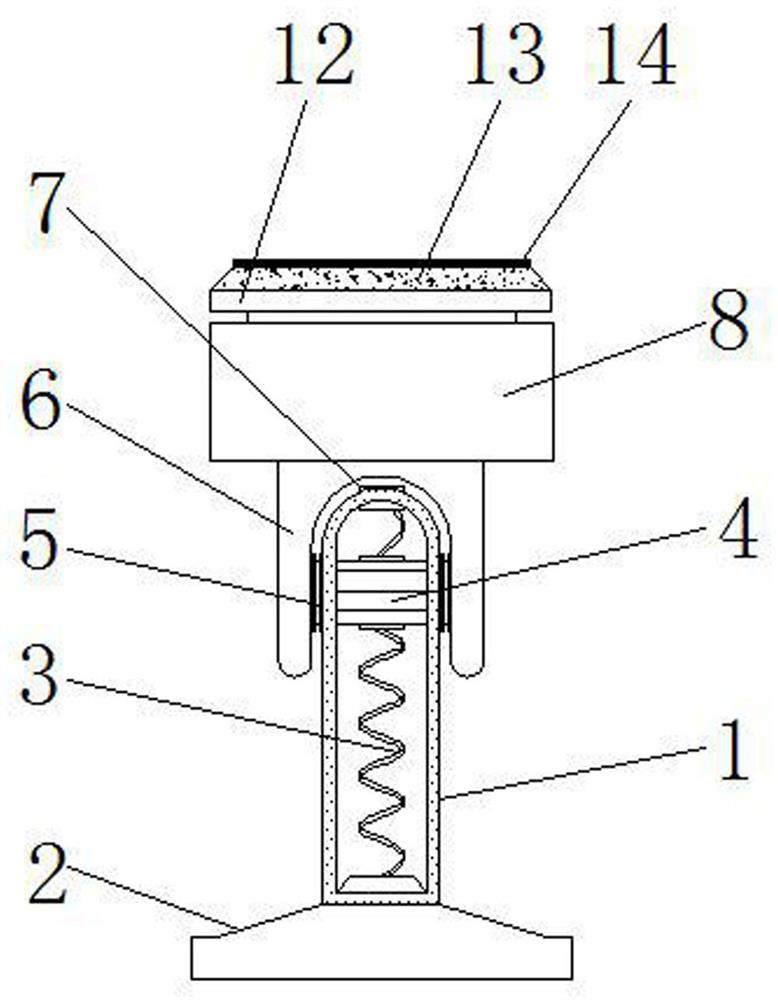

Hot-melt loudspeaker support and manufacturing method thereof

InactiveCN105072515AIncrease widthPaste width increasedTransducer casings/cabinets/supportsManufacturing technologyEngineering

The invention relates to the technical field of loudspeaker box manufacture and especially to a hot-melt loudspeaker support. The hot-melt loudspeaker support comprises a support body in which a support chamber is disposed. The periphery of the hot-melt loudspeaker support is provided with a damping cloth or net plane. The damping cloth or net plane is provided with an air vent. A stepped table is circumferentially disposed on the inner side of the support chamber under the damping cloth or net plane. A glue staying groove is circumferentially disposed on stepped table. The hot-melt loudspeaker support saves labor and material cost and improves efficiency. An increase in the width of the damping cloth or net plane increases the pasting width of a PCB and the damping cloth or net plane and the pasting intensity of the damping cloth or net plane and the PCB. Just U iron is required to be subjected to injection molding and a magnet and a washer are not required to be subjected to injection molding. The magnet and the washer are assembled after the injection molding is performed and then hot melt is performed by a three-dimensional hot-melt machine such that a required support is achieved. As a result, fraction defective can be greatly reduced.

Owner:朝阳聚声泰(信丰)科技有限公司

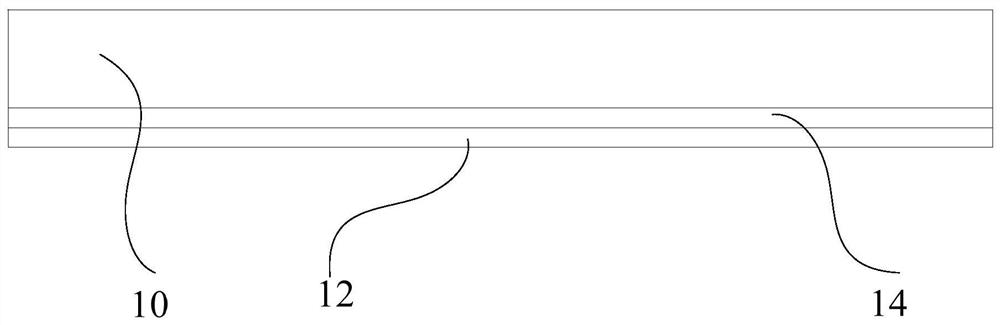

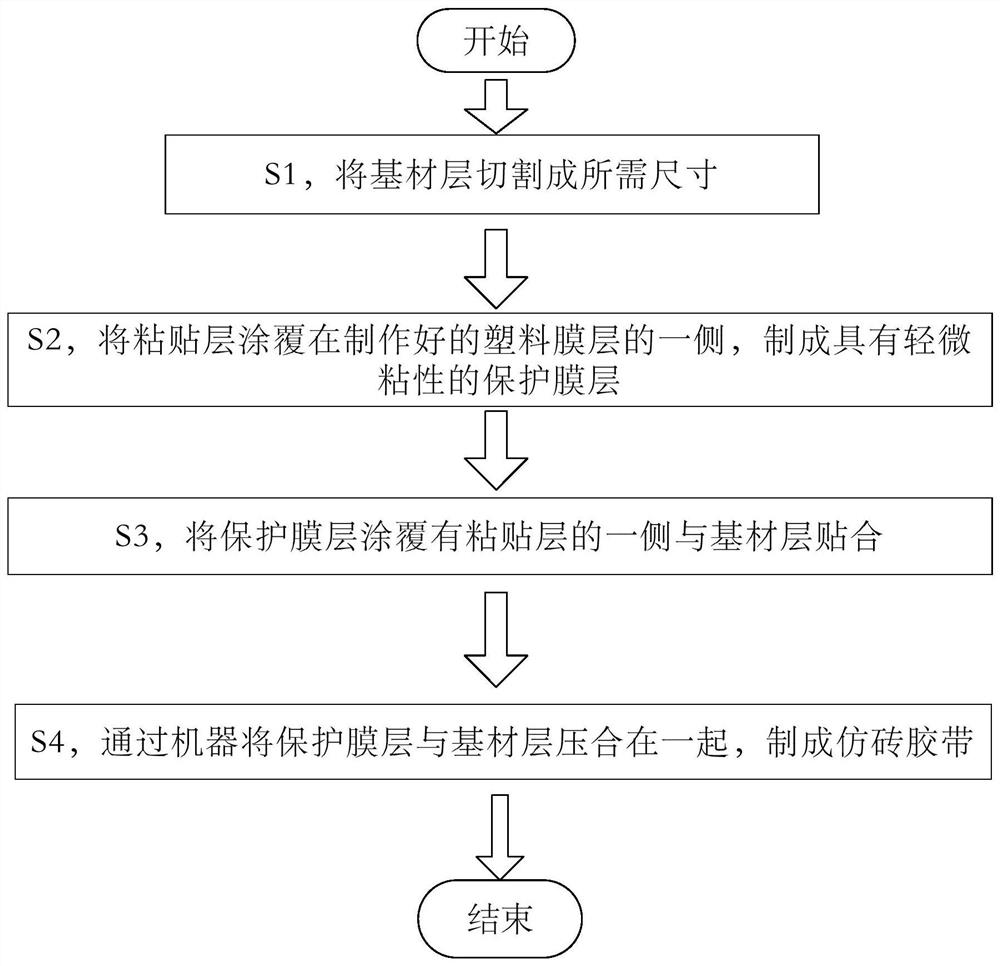

Brick-imitating adhesive tape

PendingCN112126361AQuick decorationEasy to manufactureFilm/foil adhesivesUnsaturated alcohol polymer adhesivesAdhesive beltPlastic film

The invention provides a brick-imitating adhesive tape, which is prepared by the steps of S1, cutting a base material layer into a required size to meet the use requirements of customers so as to facilitate sticking; S2, coating one side of a manufactured plastic film layer with a bonding layer to manufacture a protective film layer with slight viscosity so as to facilitate direct combination of the plastic film layer and the base material layer; S3, attaching the side, which is coated with the bonding layer, of the protective film layer to the base material layer to form the brick-imitating adhesive tape so as to facilitate decoration of a wall body; and S4, laminating the protective film layer and the base material layer together through a machine so as to increase the adhesion degree between the plastic film layer and the base material layer of the brick-imitating adhesive tape, thereby avoiding the problem that the base material layer loses the viscosity due to falling of the plastic film layer. The bonding layer is directly coated on the surface of the plastic film layer, and then the plastic film layer is directly attached to the base material layer, so that the operation steps of sticking on the base material layer for many times, cutting the bonding layer and the like are replaced, the production cost is reduced, and the production cost does not exceed the budget.

Owner:沈阳德鑫包装材料有限公司

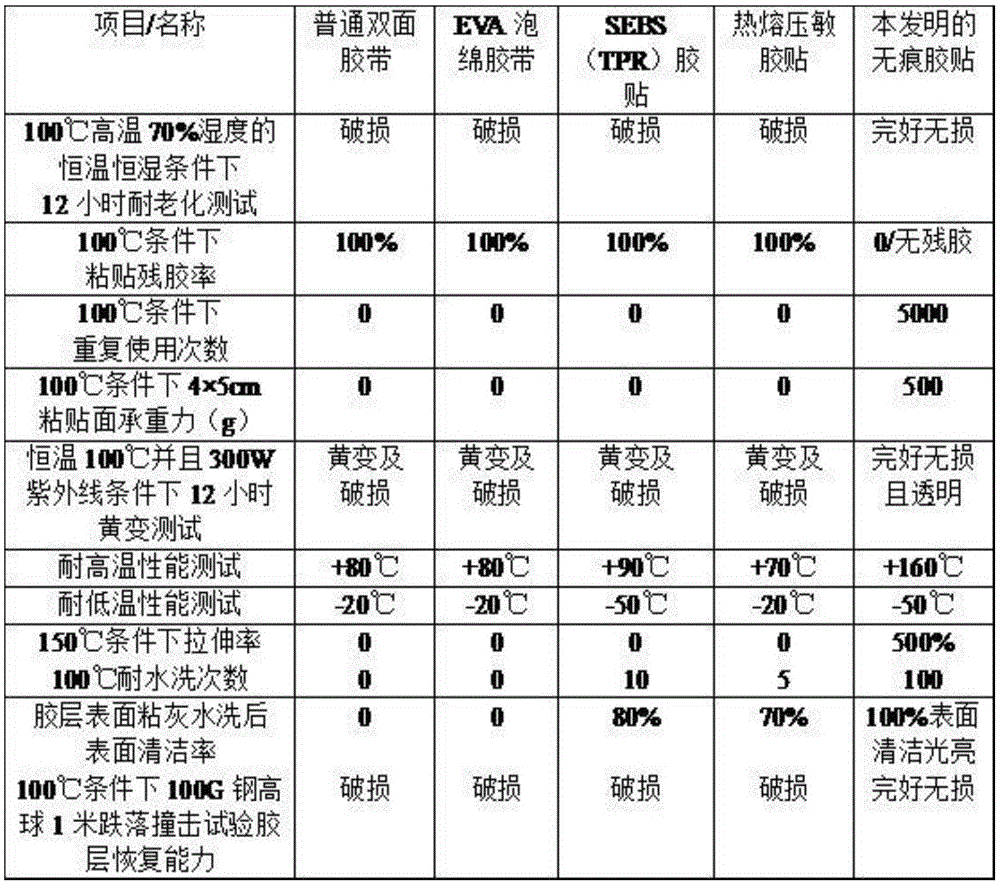

A kind of polyurethane synthetic resin for preparing non-trace adhesive tape and non-trace adhesive tape prepared by using it

ActiveCN103937197BWill not cause secondary pollutionPreparation of raw materials is environmentally friendlyFilm/foil adhesivesPolyureas/polyurethane adhesivesEpoxyNatural resin

Owner:DONGGUAN XUCHEN ENVIRONMENTAL PROTECTION TECH CO LTD

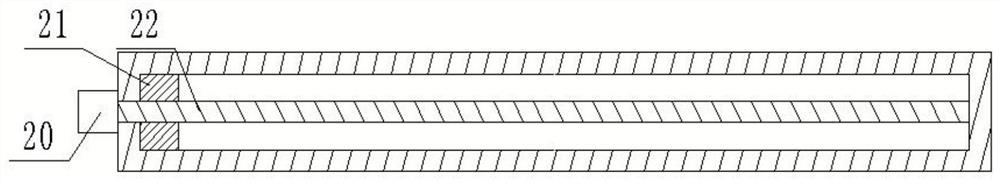

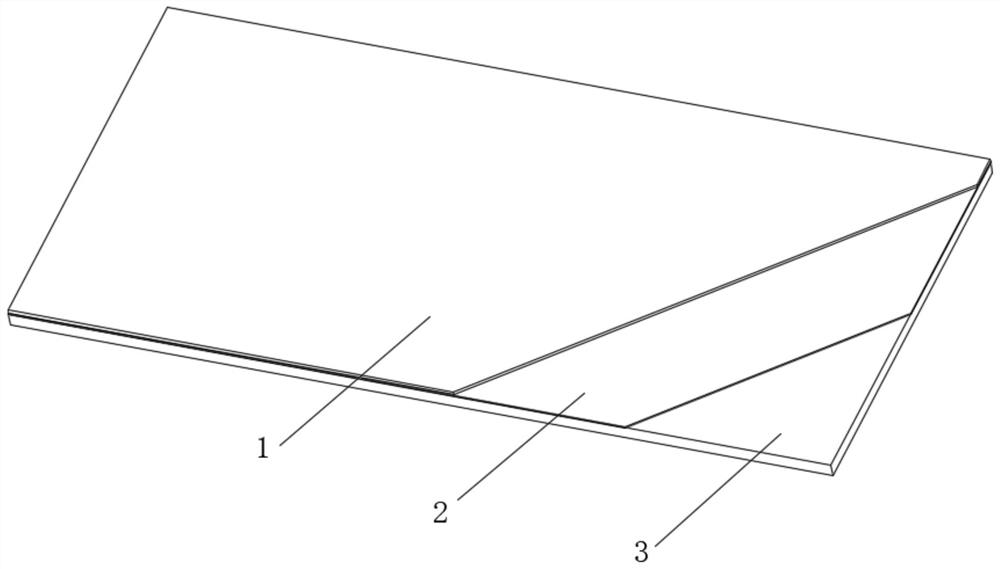

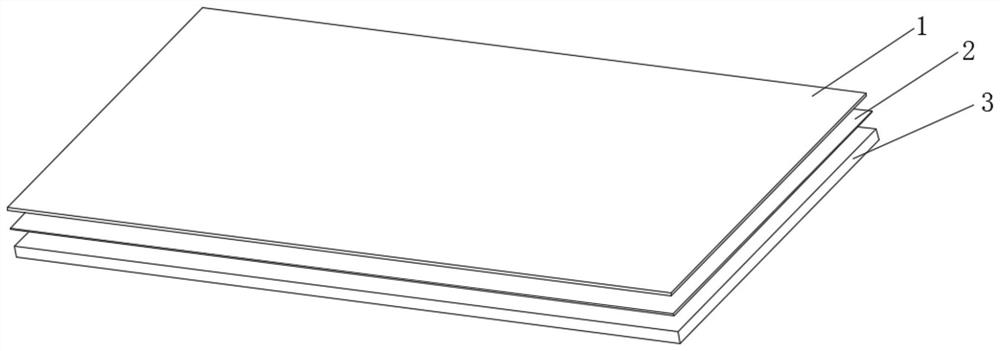

Manufacturing method of polarizer

ActiveCN102466835BExcellent optical propertiesImprove paste strengthLamination ancillary operationsSynthetic resin layered productsAcrylic resinBonding process

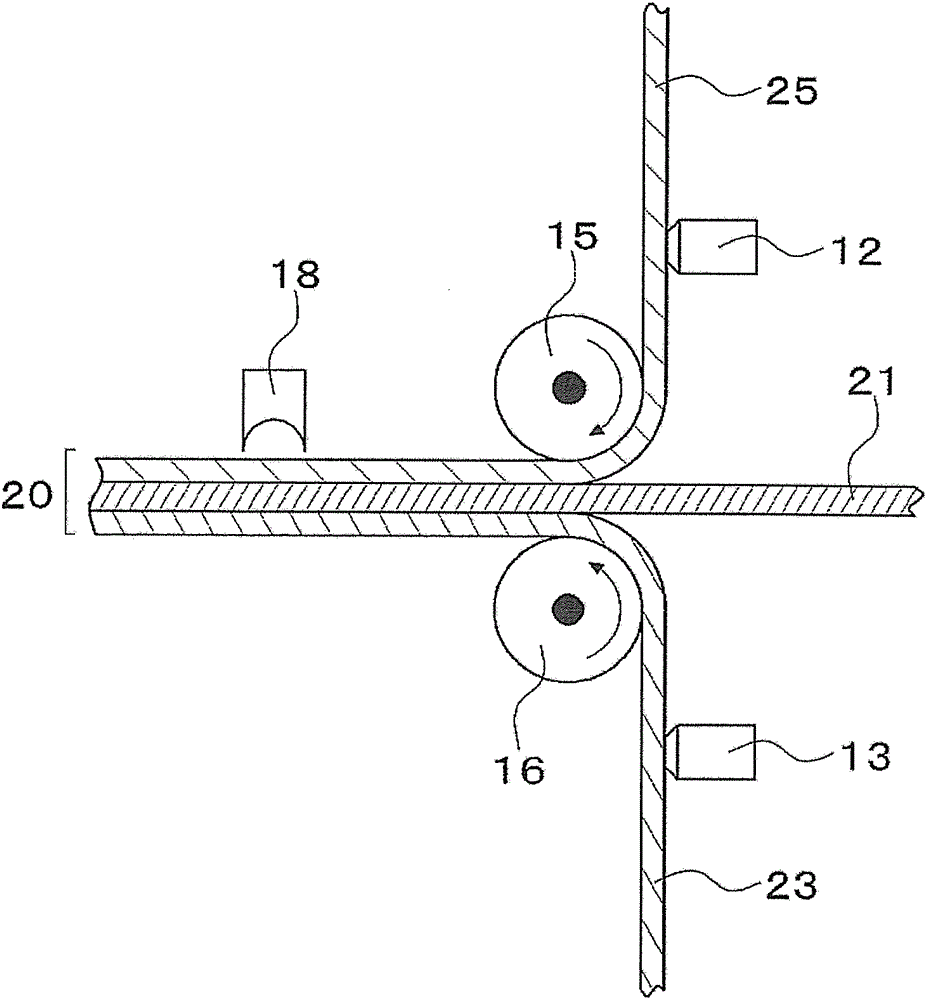

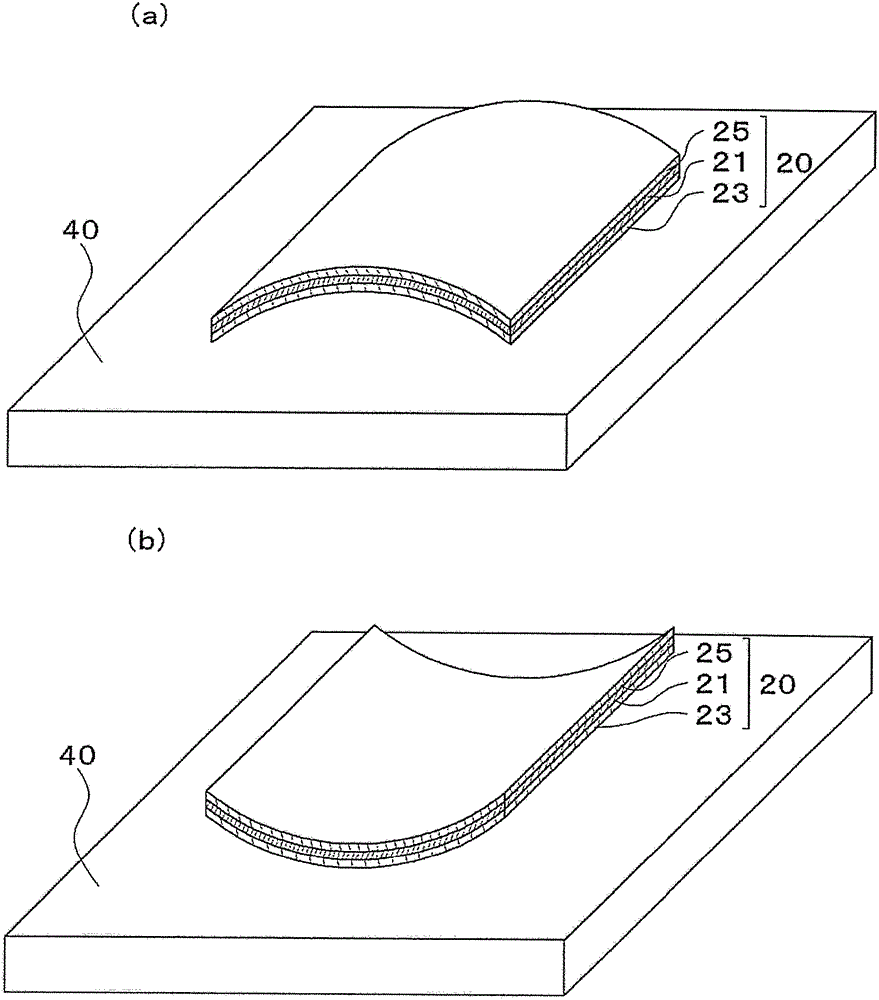

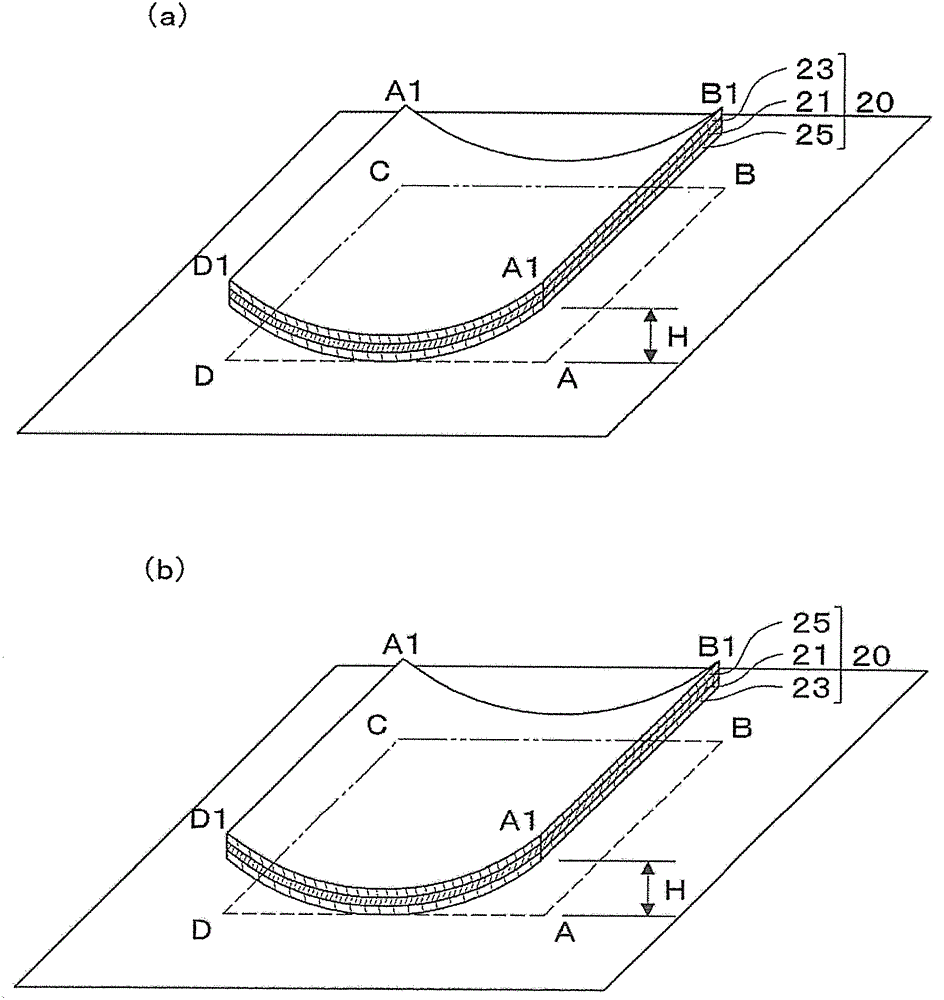

Provided is a method for producing a polarizing plate. The method includes the following steps: (A) a material film delivery process, wherein a film is delivered in a way that a polarizing film is clamped by a acrylic resin film and a transparent resin film; (B) a bonding process, wherein the film is bonded through clamping of the laminated bodies of the film by a first bonding roller and a second bonding roller, the first bonding roller is used for being contacted and rotating with the acrylic resin film, and the second bonding roller is used for being contacted and rotating with the transparent resin film; and (C) a solidifying process, so that a bonding agent is solidified. During the bonding process (B), in a way that the contraction stess of the laminated bodies of the acrylic resin film is larger than that of the laminated bodies of the transparent resin film, the two films are bonded onto a polarizing plate under a condition that tension is applied to the two films.

Owner:SUMITOMO CHEM CO LTD

Adhesive powder with large adhesive strength and good toughness and for pasting waterproof coils

InactiveCN106318275AImprove paste strengthStrong adhesionNon-macromolecular adhesive additivesCellulose adhesivesHydroxypropylmethyl celluloseBuilding material

An adhesive powder with large adhesive strength and good toughness and for pasting waterproof coils belongs to the technical field of building materials. The adhesive powder comprises 110-120 parts of re-dispersible latex powder, 10-50 parts of water, 5-15 parts of hydroxypropyl methyl cellulose, 0.07-0.10 parts of an antifoaming agent, 5-8 parts of a filler, 0.05-0.15 parts of a bactericide, 5-15 parts of quartz powder and 0.2-0.6 parts of a vinyl acetate-ethylene copolymer. The adhesive powder has the advantages of high pasting strength, high adhesion, good water retention property, good water prevention performance, non-toxicity, tastelessness, greenness and environmental protection, use in pasting of various polymeric waterproof coils, simplicity in construction, and comprehensive cost reduction.

Owner:杜义勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com