Multiple-inductor terminal

A multi-inductance and terminal technology, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problems of unstable paste and poor compatibility, achieve stable paste, improve heat dissipation efficiency, save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

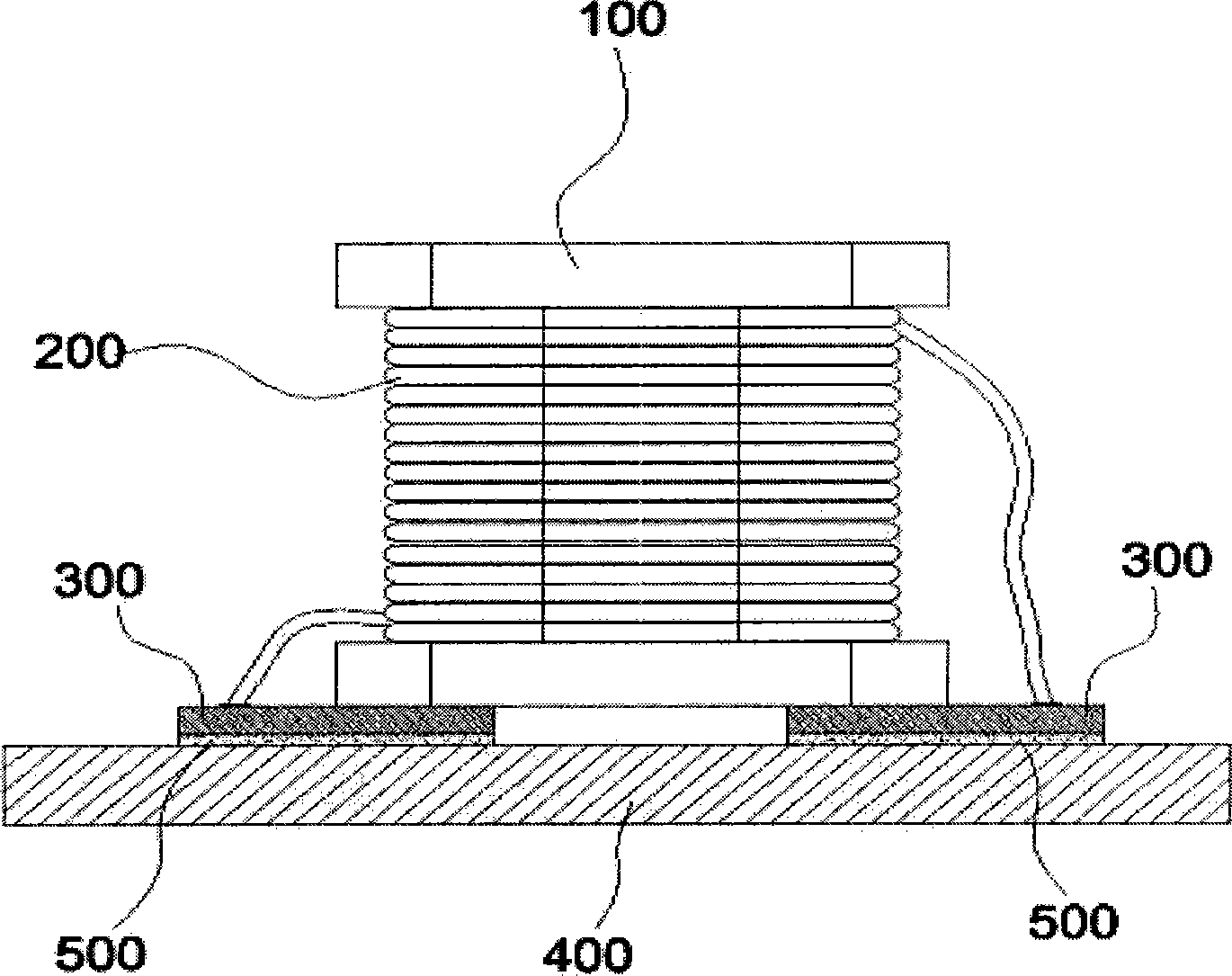

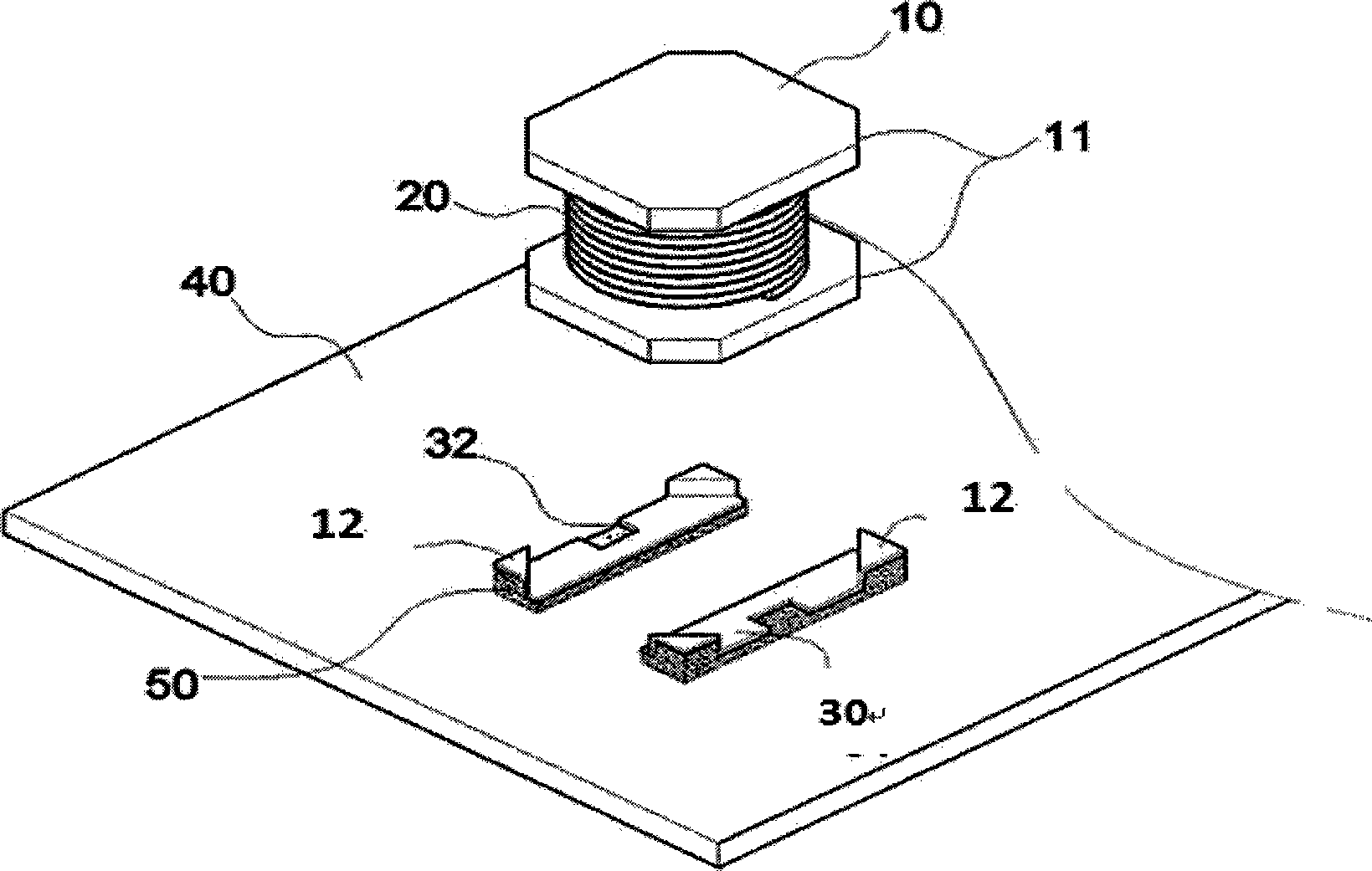

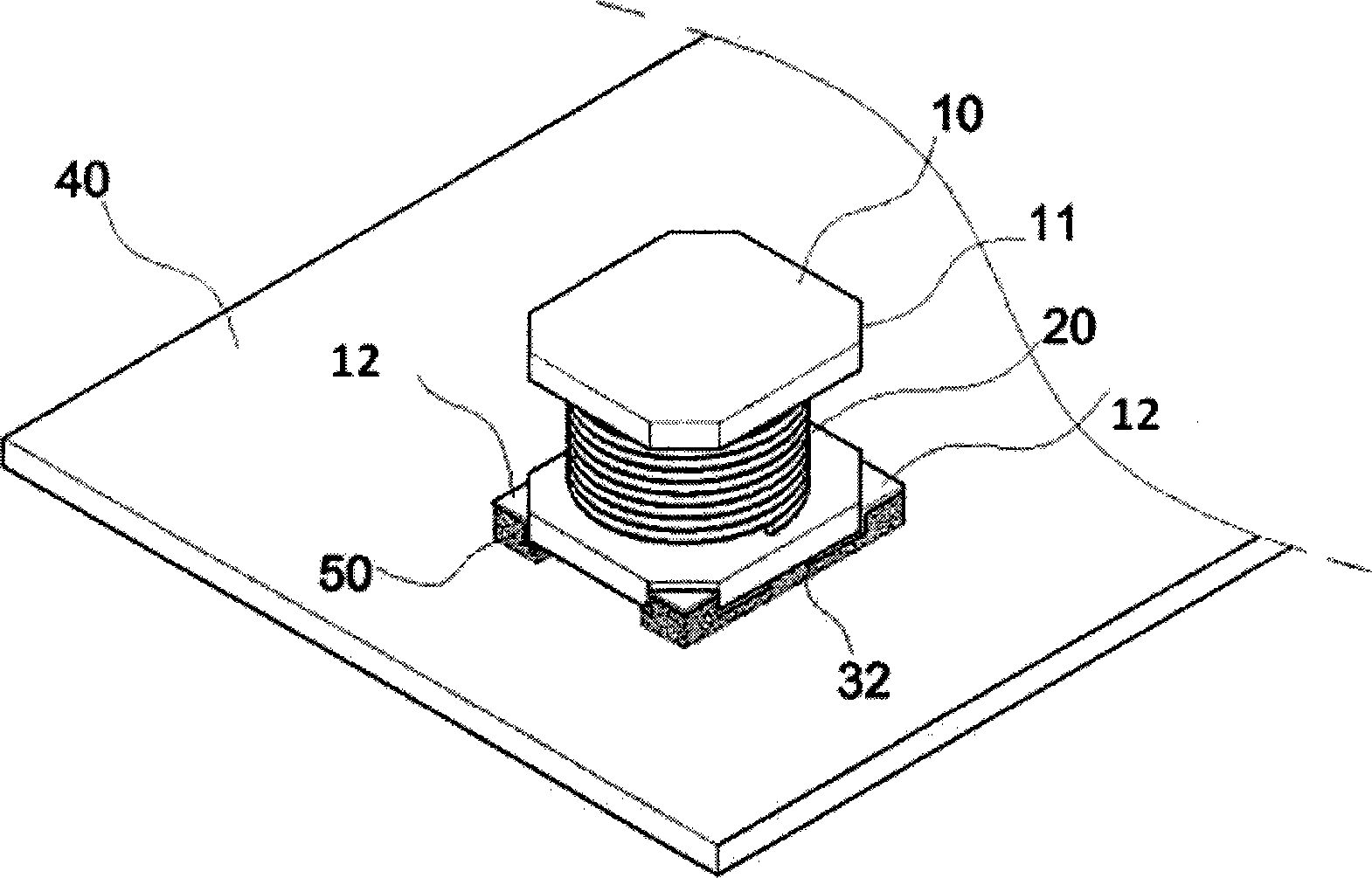

[0017] Such as Figure 2 to Figure 4 As shown, the present invention includes a magnetic core 10 and a terminal 30 wrapped with a copper wire 20, the copper wire 20 is connected to the terminal 30, the upper part of the outer end of the terminal 30 is a protrusion 12, and the bottom surface of the lower part of the magnetic core 10 is connected to the surface of the terminal 30, The lower portion of the magnetic core 10 is provided with a surface 11 that engages with the inner side of the protrusion 12 of the terminal 30 . In the actual installation process, the bottom surface of the magnetic core 10 is glued to the surface of the terminal 30, the side surface 11 of the magnetic core 10 is glued to the inner side of the protrusion 12 of the terminal 30, and then the bottom surface of the terminal 30 is pasted by solder 50. Paste on the circuit board 40. In order to increase the sticking strength between the terminal 30 and the circuit board 40, the bottom surface of the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com