High-elasticity silicone rubber lettering film and preparation method and application method thereof

A silicone rubber, high-elasticity technology, applied in applications, adhesives, household appliances, etc., can solve the problems of short service life, poor softness, and reduced appearance, and achieve the effect of long service life, moderate peeling performance, and not easy to fade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

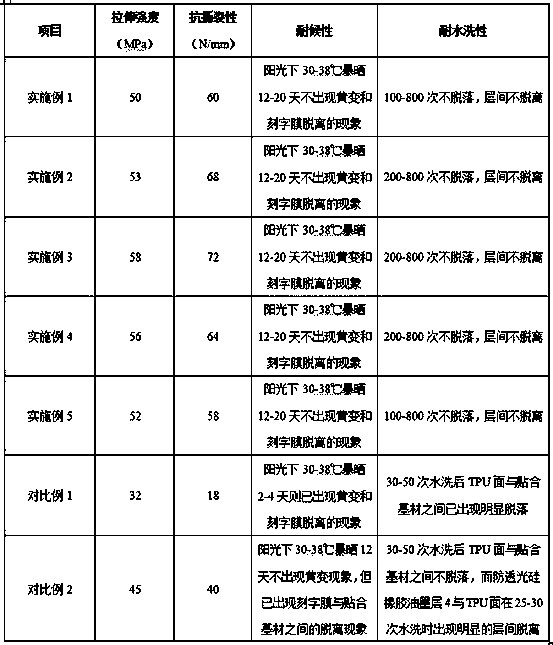

Embodiment 1

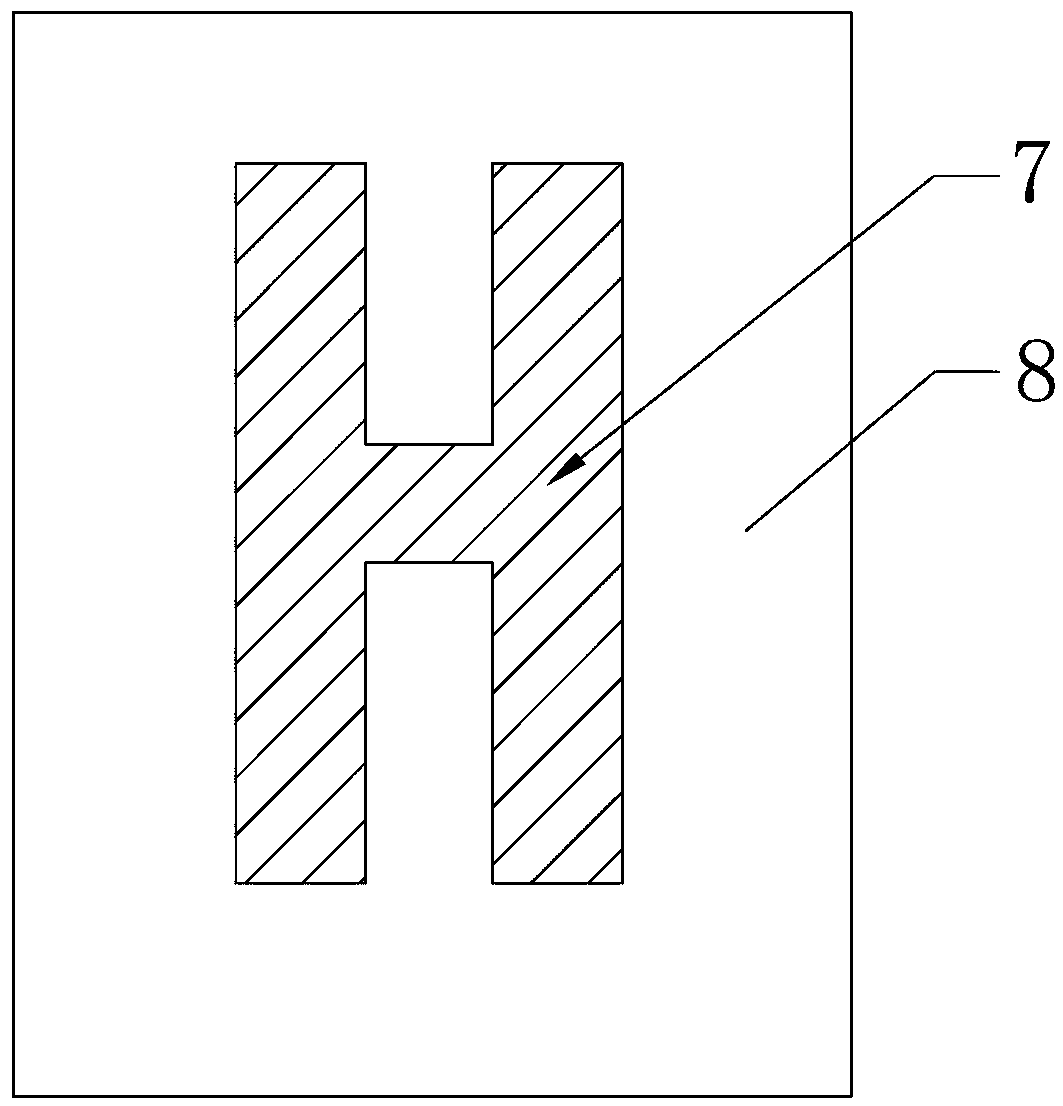

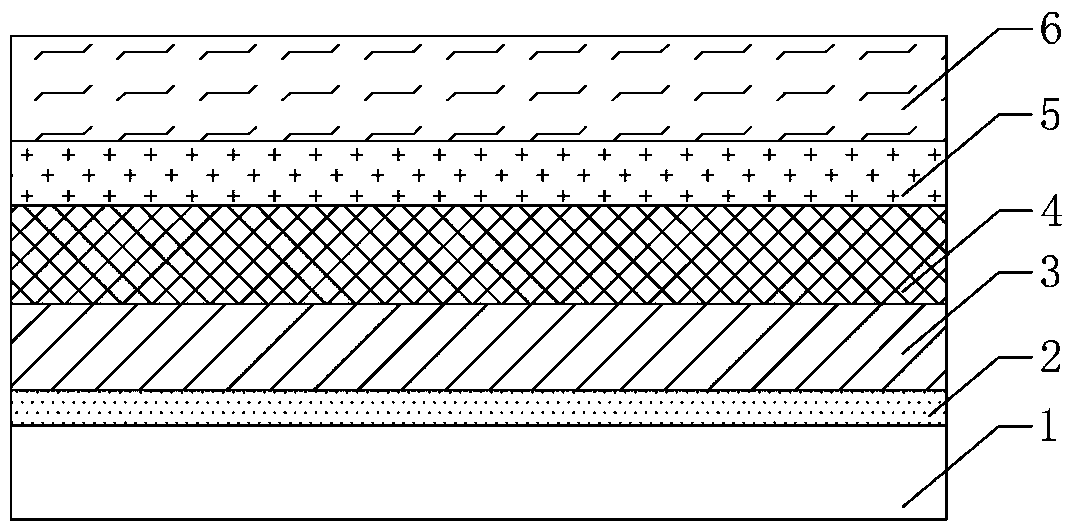

[0092] A kind of highly elastic silicon rubber lettering film, said high elastic silicon rubber lettering film comprises a bearing substrate 1, a release layer 2, a surface silicon rubber ink layer 3, an anti-translucent silicon rubber ink layer 4, which are connected sequentially from bottom to top. The adhesive interface agent layer 5 and the TPU hot melt adhesive film 6; the adhesive interface agent layer 5 is made of an adhesive interface agent, and the adhesive interface agent is an adhesive interface agent with two resin components.

[0093] The bearing substrate 1 is a polyester matte film with a thickness of 0.08mm; the thickness of the release layer 2 is 0.8 μm, the thickness of the surface silicone rubber ink layer 3 is 25 μm, and the anti-translucent silicone rubber ink The thickness of the layer 4 is 35 μm, the thickness of the adhesive interface agent layer 5 is 10 μm, and the thickness of the TPU hot melt adhesive film 6 is 80 μm.

[0094] The release layer 2 is ...

Embodiment 2

[0118] The difference between this embodiment and above-mentioned embodiment 1 is:

[0119] The bearing substrate 1 is a polyester matte film with a thickness of 0.09mm; the thickness of the release layer 2 is 0.9 μm, the thickness of the surface silicone rubber ink layer 3 is 28 μm, and the anti-translucent silicone rubber ink The thickness of the layer 4 is 38 μm, the thickness of the adhesive interface agent layer 5 is 11 μm, and the thickness of the TPU hot melt adhesive film 6 is 90 μm.

[0120] The release layer 2 is obtained by coating the frosted surface of the polyester frosted film with a release liquid and drying it. The release liquid is composed of a water-based fluorine release liquid and water in a weight ratio of 1:48. composition of the mixture.

[0121] The surface silicone rubber ink layer 3 is made of surface silicone rubber ink, and the surface silicone rubber ink includes 98 parts of silicone rubber color ink and 4 parts of liquid platinum vulcanizing ag...

Embodiment 3

[0144] The difference between this embodiment and above-mentioned embodiment 1 is:

[0145] The bearing substrate 1 is a polyester frosted film with a thickness of 0.10 mm; the thickness of the release layer 2 is 1.0 μm, the thickness of the surface silicone rubber ink layer 3 is 30 μm, and the anti-translucent silicone rubber ink The thickness of the layer 4 is 40 μm, the thickness of the adhesive interface agent layer 5 is 12 μm, and the thickness of the TPU hot melt adhesive film 6 is 100 μm.

[0146] The release layer 2 is obtained by coating the frosted surface of the polyester frosted film with a release liquid and drying it. The release liquid is composed of a water-based fluorine release liquid and water in a weight ratio of 1:50 composition of the mixture.

[0147] The surface silicone rubber ink layer 3 is made of surface silicone rubber ink, and the surface silicone rubber ink includes 100 parts of silicone rubber color ink and 3 parts of liquid platinum vulcanizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com