Leakless wear pump sealer

A water pump seal and seal ring technology, which is applied to pump components, pumps, and parts of pumping devices for elastic fluids, can solve problems such as shortening the service life of seals and seal failure, and achieve the elimination of unstable factors and extension Sealing cycle, eliminating the effect of increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

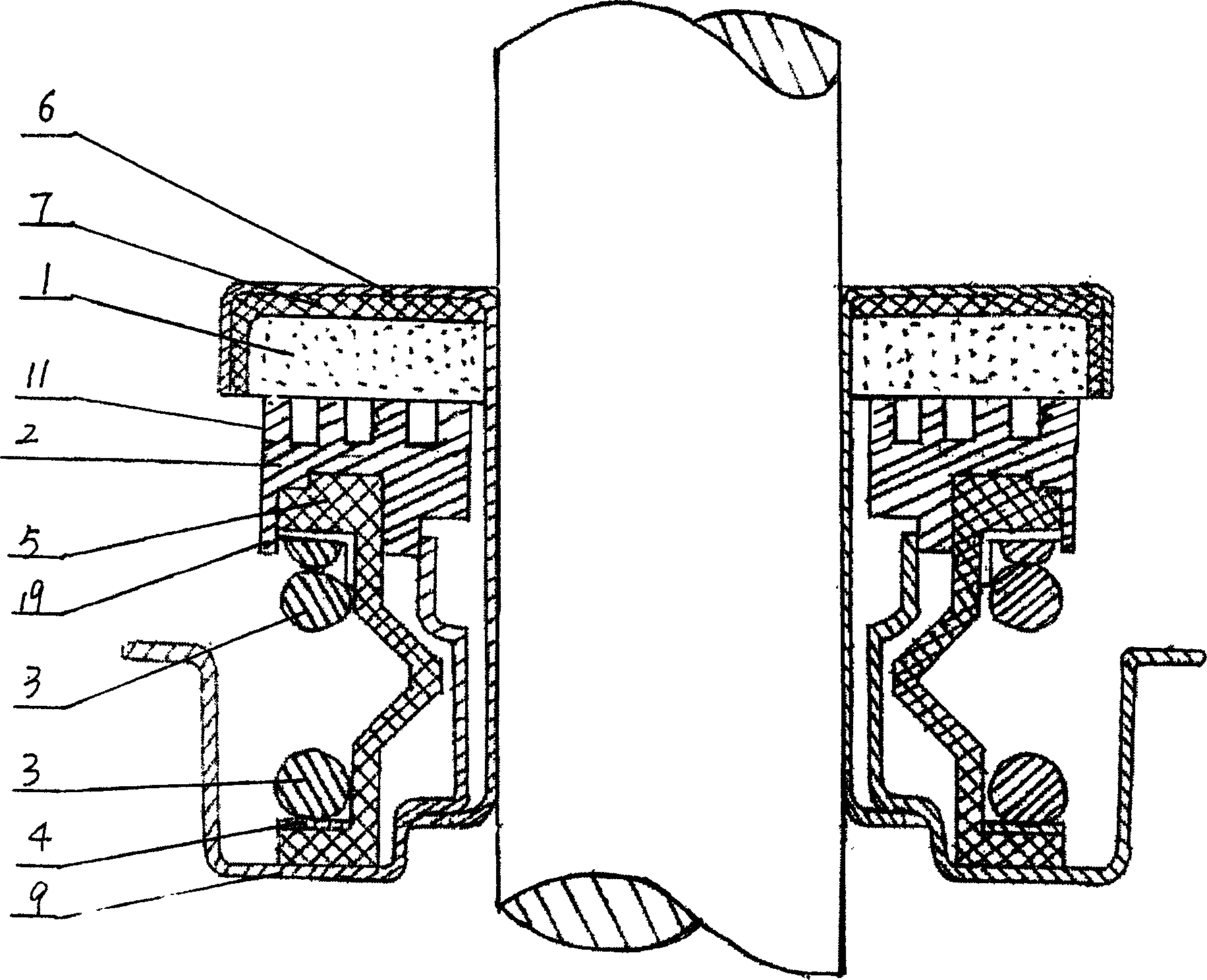

[0026] Such as figure 1 As shown, the seal of the present invention includes a moving ring body 1, a static ring body 2, a moving ring seat cover 6, a static ring seat cover 8, a moving ring sealing ring 7, a spring 3, a spring seat ring 4 and a rubber sealing sleeve 5. The moving ring body 1 is generally made of ceramic material or stainless steel metal material, and the static ring body 2 is generally made of graphite material, which is relatively soft. The moving ring body 1 is set on the moving ring seat cover 6 , and a moving ring sealing ring 7 is arranged between the moving ring body 1 and the moving ring seat cover 6 . The lower surface of the moving ring body 1 is closely matched with the upper surface of the static ring body 2, and three circles of deposition grooves are arranged on the contact surface of the moving ring body 1 and the static ring body 2, and the grooves are opened on the upper surface of the static ring body. On the surface, the annular groove 11 o...

Embodiment 2

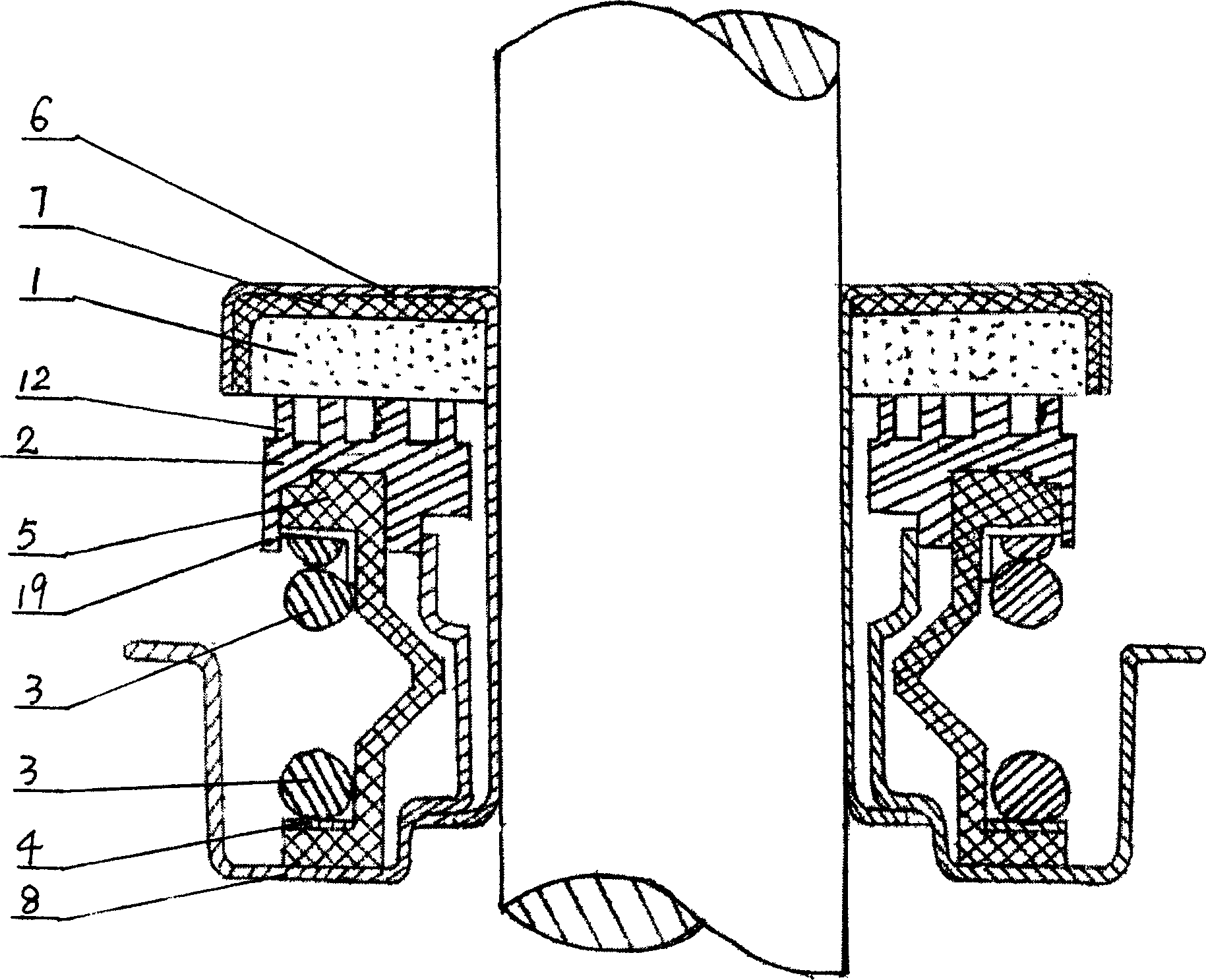

[0030] Such as image 3 As shown, the seal of the present invention includes a moving ring body 1, a static ring body 2, a moving ring seat cover 6, a static ring seat cover 9, a moving ring sealing ring 7, a spring 3, a spring seat ring 4 and a rubber sealing sleeve 5. The moving ring body 1 is generally made of ceramic material or stainless steel metal material, and the static ring body 2 is generally made of graphite material, which is relatively soft. The moving ring body 1 is set on the moving ring seat cover 6 , and a moving ring sealing ring 7 is arranged between the moving ring body 1 and the moving ring seat cover 6 . The lower surface of the moving ring body 1 is closely matched with the upper surface of the static ring body 2, and three circles of protruding rings are arranged on the contact surface of the moving ring body 1 and the static ring body 2, and the rings are arranged on the moving ring body on the lower surface of the . The height of the annular ring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com