Wood floor and manufacturing process thereof

A manufacturing process and wood floor technology, applied in the field of wood floor and its manufacturing process, can solve the problems of low radial tension on the surface of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical solutions provided by the present invention more clearly, the present invention will be further described below in conjunction with specific examples.

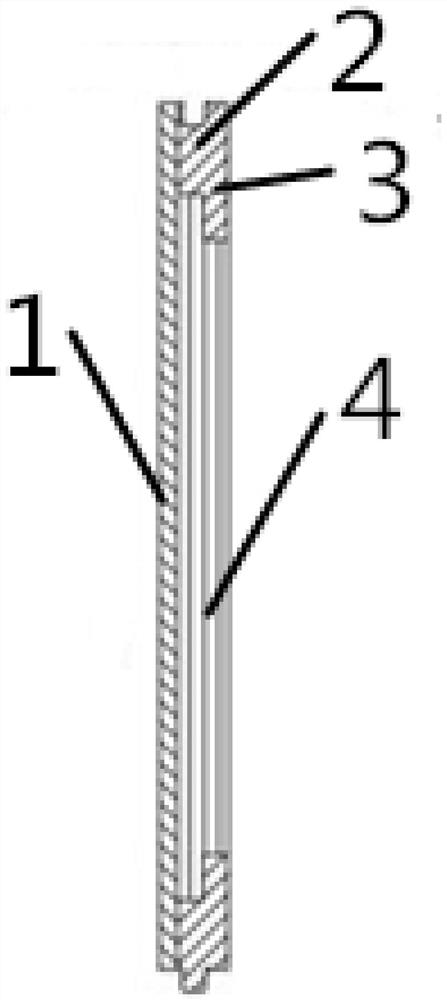

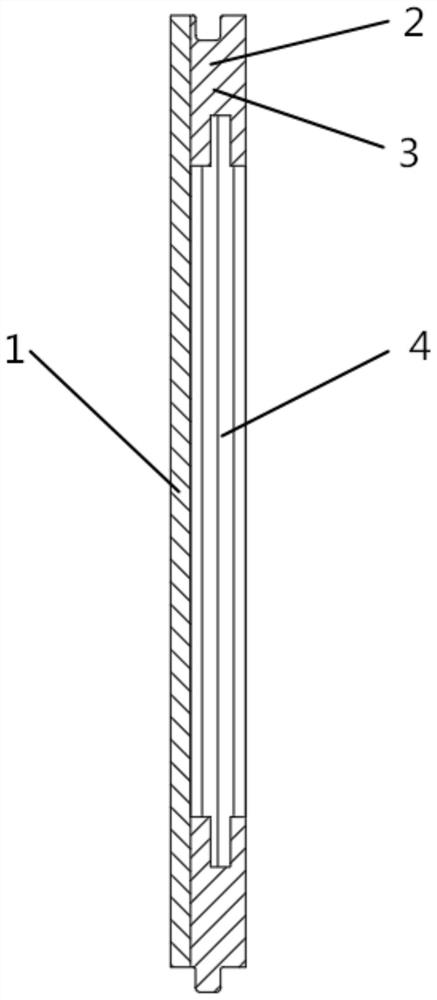

[0027] As shown in the figure, a wooden floor and its manufacturing process provided by the present invention have a length of 1220-3000mm, a width of 165-300mm, and a thickness of 12-18mm. The thickness direction is divided into an upper layer and a lower layer structure; the upper layer is a precious tree species : Thickness 1.0-6mm, the bottom layer (substrate) is pine or fir with a thickness of not less than 9-15mm, a wooden strip with a 10-30mm-frame and a support strip vertical or parallel to the frame edge in the frame spliced and glued together Timber; it is characterized in that the bottom layer includes a frame and supporting wooden bars, and the frame is located on both sides below the upper layer, and is fixedly connected with the upper layer; the supporting wooden bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com