Gum control roller of cigarette making and tipping machine combination

A technology for controlling rubber rollers and units, which is applied in the fields of application, tobacco, and cigarette manufacturing, etc., can solve the problems of fixed film thickness, large differences in the suction of base paper, and poor sticking of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

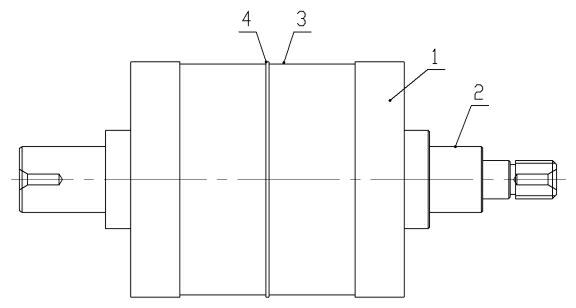

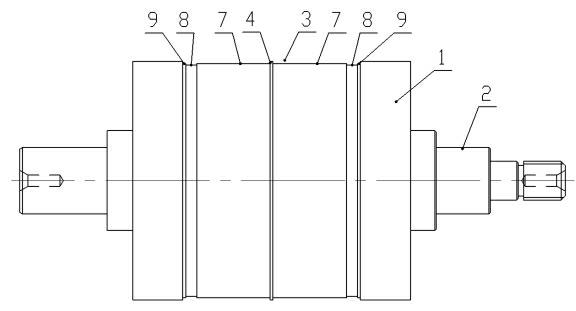

[0017] Embodiment one: if image 3 As shown, the control rubber roller of the coiling unit of the present invention is an ordinary flat rubber roller, including a roller 1 and a rotating shaft 2 pierced in the center of the roller 1, and the circumferential surface of the roller 1 is provided with a groove 3, and the center of the groove 3 A circular rib 4 is provided, and the surface of the groove 3 is respectively provided with a first rubber-coated annular belt 7 , a second rubber-coated annular belt 8 and a third rubber-coated annular belt 9 on both sides from the rib 4 . Groove 3 has a width of 60mm, rib 4 has a width of 1mm, the first glue-coated ring-shaped belt 7 has a width of 21.5mm and a depth of 0.025mm, the second glue-coated ring-shaped belt 8 has a width of 7mm and a depth of 0.035mm, and the third glue-coated ring-shaped belt 8 has a width of 7mm and a depth of 0.035mm. The rubber annular belt 9 has a width of 1mm and a depth of 0.02mm.

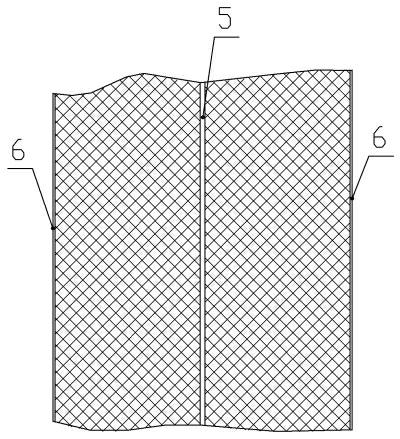

[0018] Tipping paper ...

Embodiment 2

[0019] Embodiment two: if Figure 5 As shown, the difference from the first embodiment is that the first rubber-coated annular belt 7 is provided with a rubber-coated annular spacer belt composed of at least two elongated protrusions 13 . The setting of the glue-coated annular interval belt not only saves the amount of glue applied to the glue-coated tipping paper without affecting the rubbing process, but also saves the cost accordingly.

[0020] Tipping paper is used as Figure 5 Cotton roller gluing shown as Figure 6 shown, with Figure 4 The difference is that the corresponding part 14 of the rubber-coated annular spacer belt on the first glue-coated endless belt 7 which is composed of at least two elongated protrusions 13 on the tipping paper has no glue film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com