Improved anti-crack pressing and pasting device for asphalt concrete pavement crack diseases

A technology for asphalt concrete and pavement cracks, applied in the field of pavement crack treatment, can solve problems such as increased labor and inconvenience, and achieve the effects of saving raw materials, avoiding shaking, and reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

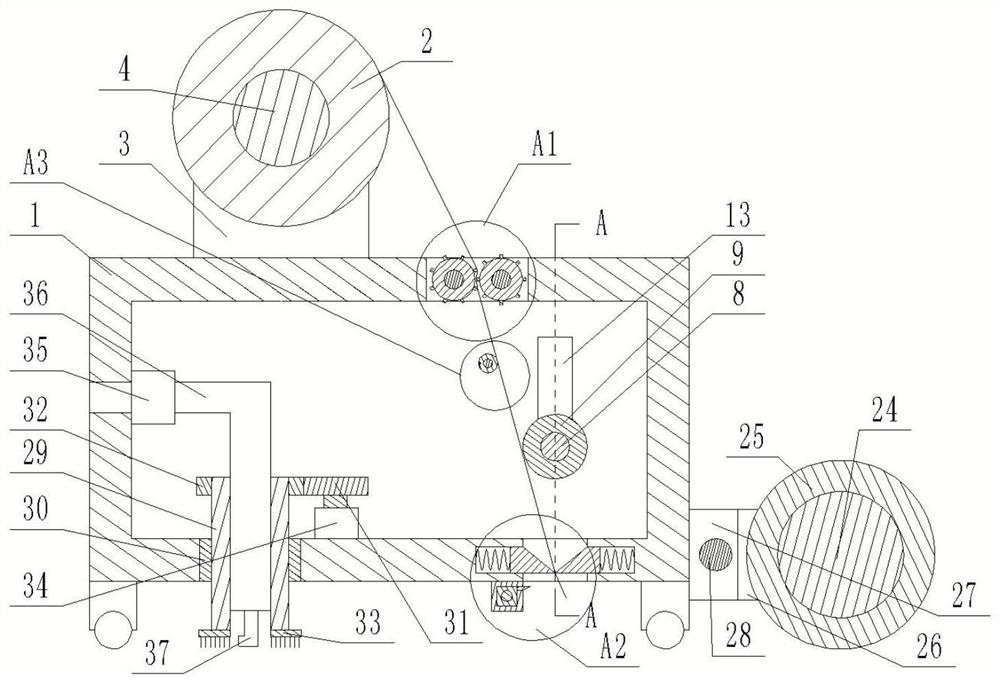

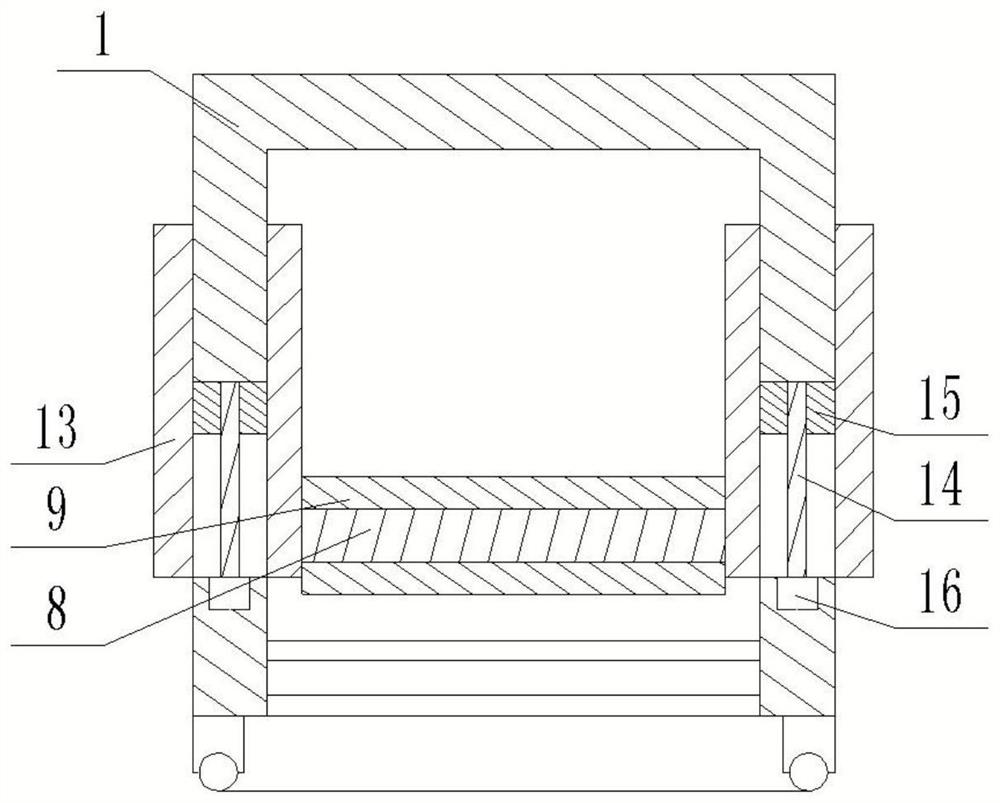

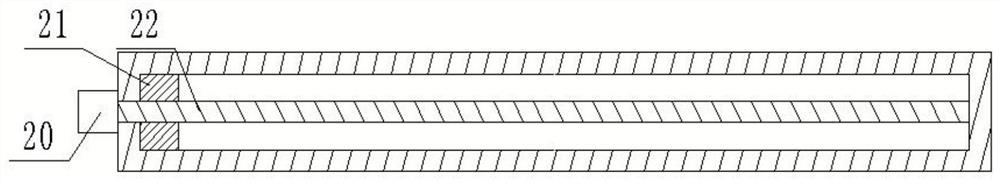

Method used

Image

Examples

Embodiment 2

[0072] refer to Figure 7-9 , in order to adapt to different specifications of anti-crack stickers, in this embodiment 2, the clamping seat 3 and the clamping shaft 4 in the above embodiment 1 can be replaced by a receiving assembly, which includes a receiving motor 38, a two-way screw 39. Sliding seat 40, lifting motor 41, lifting screw 42, lifting bushing 43, lifting seat 44, distance adjustment cylinder 45, distance adjustment shaft 46, hinge shaft 47, hinge rod 48, ejector rod 49 and positioning ring 50;

[0073]The top surface of the mobile housing 1 is provided with a slide groove, and the two-way lead screw 39 is arranged in the slide groove, and one end of the two-way lead screw 39 is rotationally connected with one side of the slide groove. The other end of 39 runs through the groove wall on the other side of the sliding groove and is affixed to the output end of the receiving motor 38, and the two-way lead screw 39 is respectively provided with a forward thread and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com