Gummed paper

A technology of adhesive tape and adhesive layer, applied in the direction of sustainable manufacturing/processing, climate sustainability, non-aqueous electrolyte battery, etc. Meet the needs and other issues, achieve the effect of good adhesion strength and puncture strength, and improve the puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

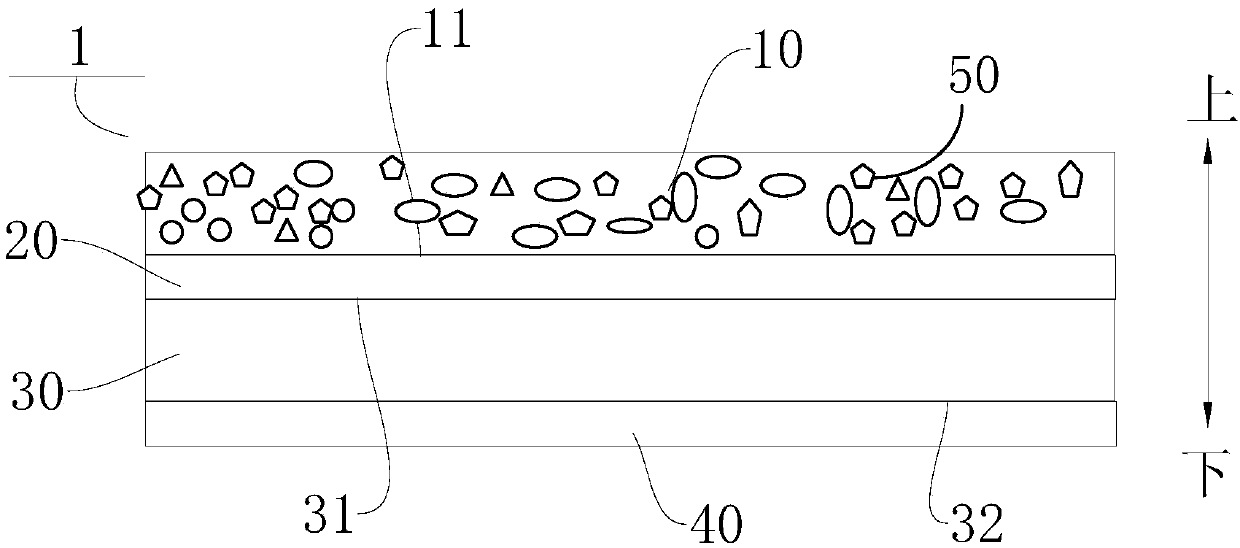

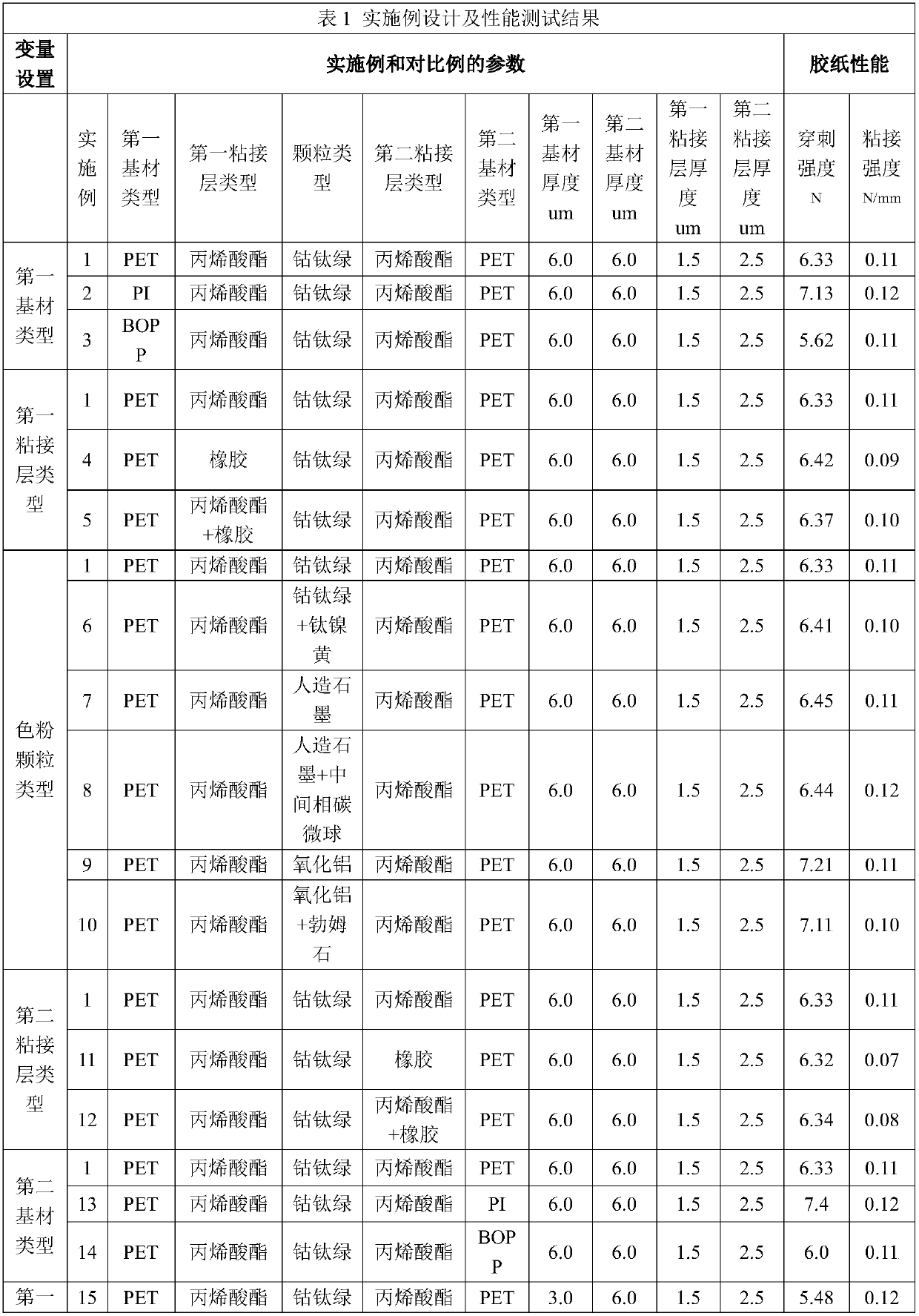

[0035]Corona treatment is performed on the first surface 11, the second surface 31, and the third surface 32, and the cobalt titanium green is uniformly dispersed in the first adhesive layer (acrylate), and then scraped by a doctor blade, uniformly Coated on the surface of the first substrate (polyethylene terephthalate PET), after passing through a tunnel furnace at 120°C for 2 minutes, rolling and compounding the second substrate (polyethylene terephthalate PET) ), the rolling pressure is 20kg. The second adhesive layer (acrylate) was coated on the surface of the second substrate by scraping with a doctor blade, passed through a tunnel oven at 120°C for 2 minutes, then rewound, and aged at 60°C for 2 hours. The first substrate, the first adhesive layer, the second substrate, and the second adhesive layer are combined to obtain an adhesive tape, wherein the thickness of the first substrate is 6um, the thickness of the first adhesive layer is 1.5um, and the second The thickne...

Embodiment 2

[0037] The preparation method is the same as in Example 1, except that the first surface 11, the second surface 31 and the third surface 32 are subjected to plasma treatment, and the first base material is polyimide (PI), wherein cobalt titanium green The content of a bonding layer is 20%, and the particle size is 1um.

Embodiment 3

[0039] The same preparation method as in Example 1, the first surface 11, the second surface 31 and the third surface 32 are subjected to plasma treatment, the difference is that the first substrate is biaxially oriented polypropylene (BOPP), wherein cobalt titanium green is The content in the first adhesive layer is 20%, and the particle size is 1um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com