Mosaic ceramic tile unit vibrating binder

A technology of inlaying ceramic tiles and pasting devices, which is applied in the direction of architecture and building construction, and can solve problems such as uneven pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

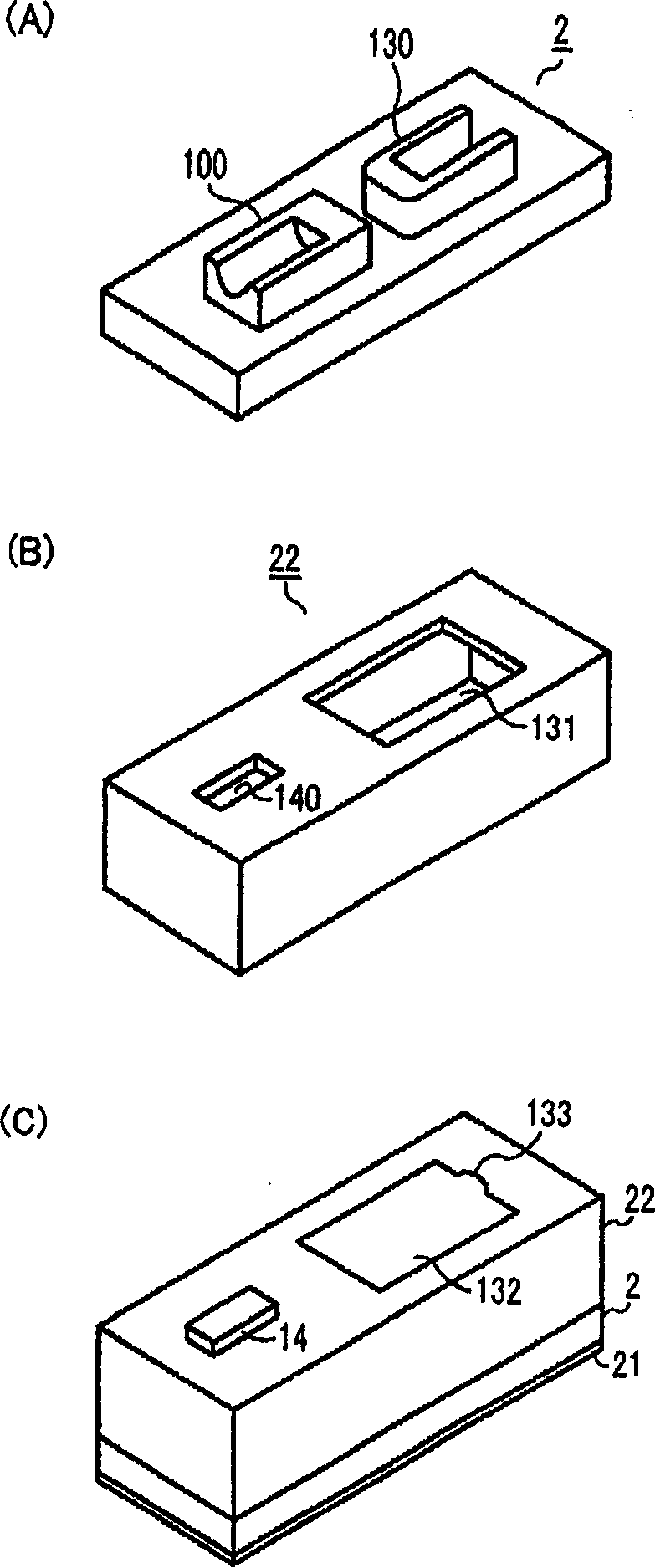

[0017] Embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

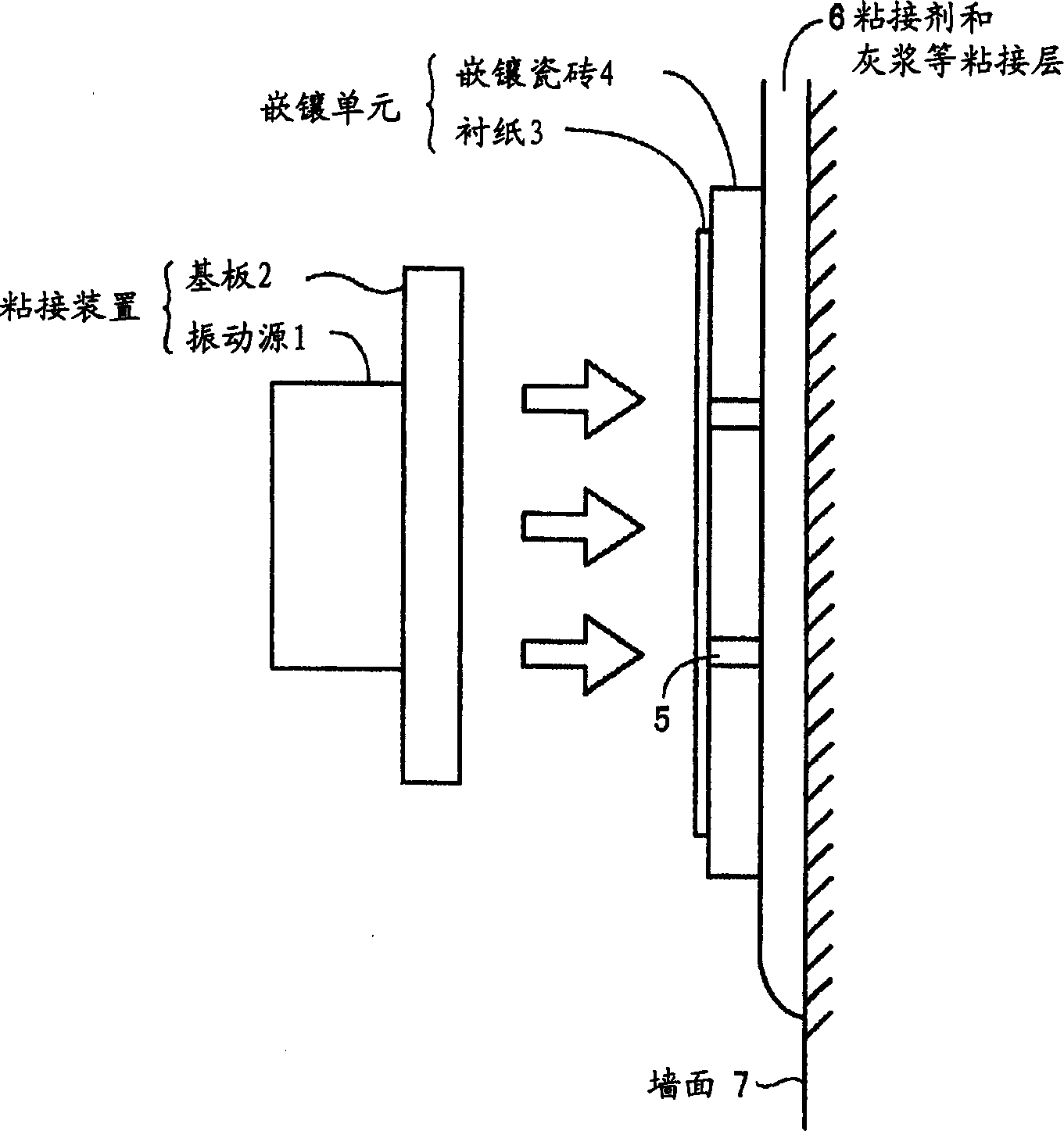

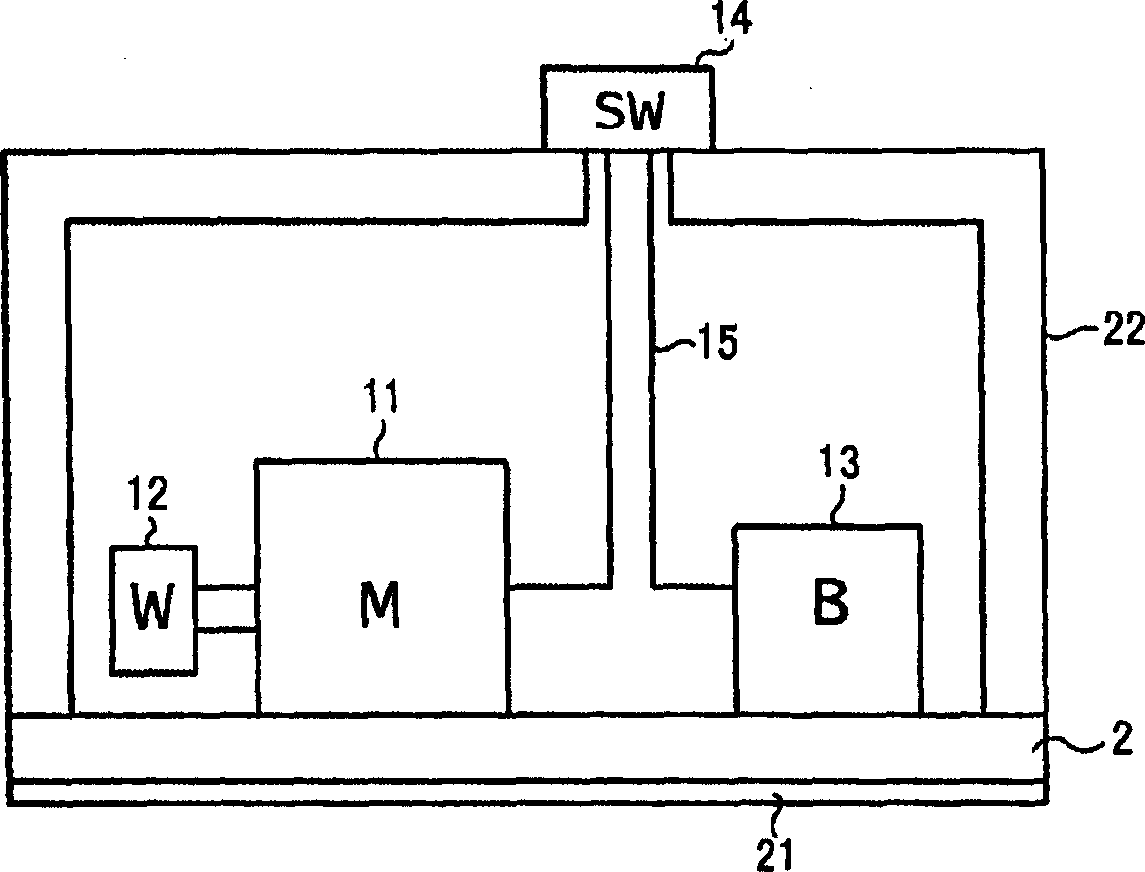

[0018] figure 1 It is a schematic cut-away view of the mosaic tile unit vibration pasting device of the present invention, schematically describing the situation in which the mosaic tile unit is pasted on the wall (including the floor surface etc.) 7 . The vibrating pasting device is composed of a vibration source 1 and a substrate 2 on which the vibration source 1 is installed. The mechanical vibration of the vibration source 1 is transmitted to the substrate 2 in contact with the vibration source 1 . Vibration source 1 can be battery internal power supply type, also can be the external power supply type that is powered by the external power supply outside the vibration sticking device, because battery, switch, wiring etc. are all very simple, so not shown in the figure.

[0019] Hold this vibrating pasting device (the device cover is not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com