Patents

Literature

154results about How to "Guaranteed mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

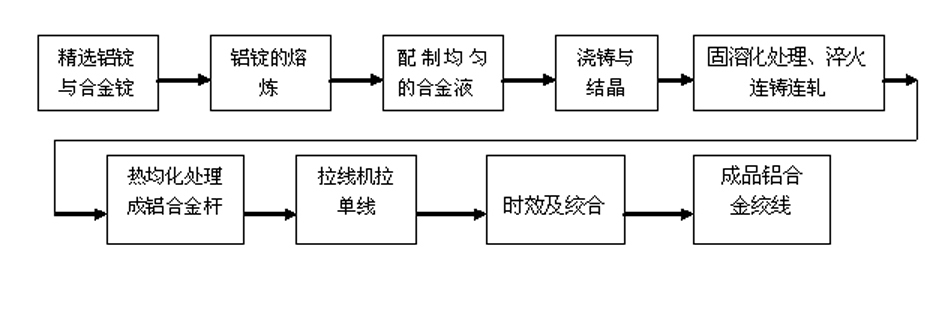

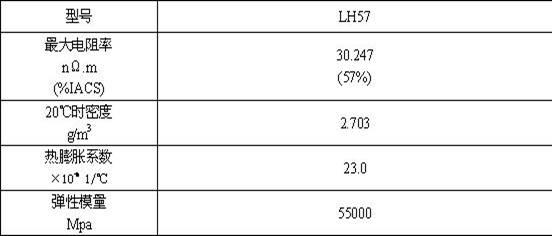

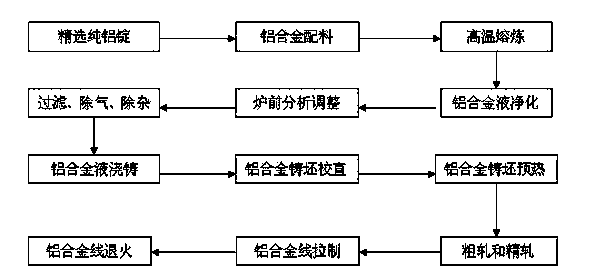

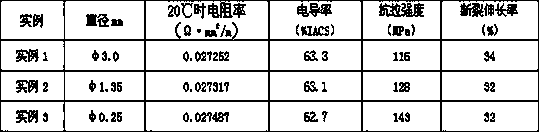

Method for manufacturing moderate intensity aluminium alloy wire with 57% electric conductivity

ActiveCN102041418AQuick checkControl contentSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthIngot

The invention provides a method for manufacturing a moderate intensity aluminium alloy wire with 57% electric conductivity, and relates to a method for manufacturing a moderate intensity aluminium alloy wire of which the electric conductivity reaches 57% (IACS), which comprises the following steps of: (1) selecting aluminum matrixes and aluminum moderate alloy ingots; (2) carrying out on-the-spot sample analysis and regulation; placing the selected aluminum ingots into a shaft furnace to be melted to obtain an aluminum liquid; and refining with a refining agent; (3) casting and crystallizing: enabling the aluminium alloy liquid in a tilting holding furnace to pass through a trough, and filtering with a ceramic filter plate, and adding a rear earth to ensure the rear earth content to be 0.05-0.15%; continuously casting in an aluminium alloy continuous casting machine to form the aluminium alloy ingots; and rolling the aluminium alloy ingots to obtain moderate intensity aluminium alloy rods by an aluminium alloy continuous mill; (4) solutionizing and quenching: carrying out homogenizing heat treatment on the aluminium alloy rods; and (5) drawing, ageing and twisting: drawing the aluminium alloy rods treated by the former process into the aluminium alloy wires with the required diameter on an aluminium alloy drawing machine, and twisting the aluminium alloy wires by using a frame-type wire twisting machine to manufacture the moderate intensity aluminium alloy wires with 57% electric conductivity in IACS.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

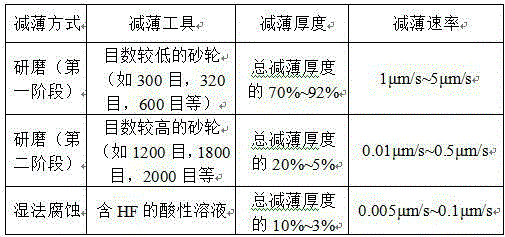

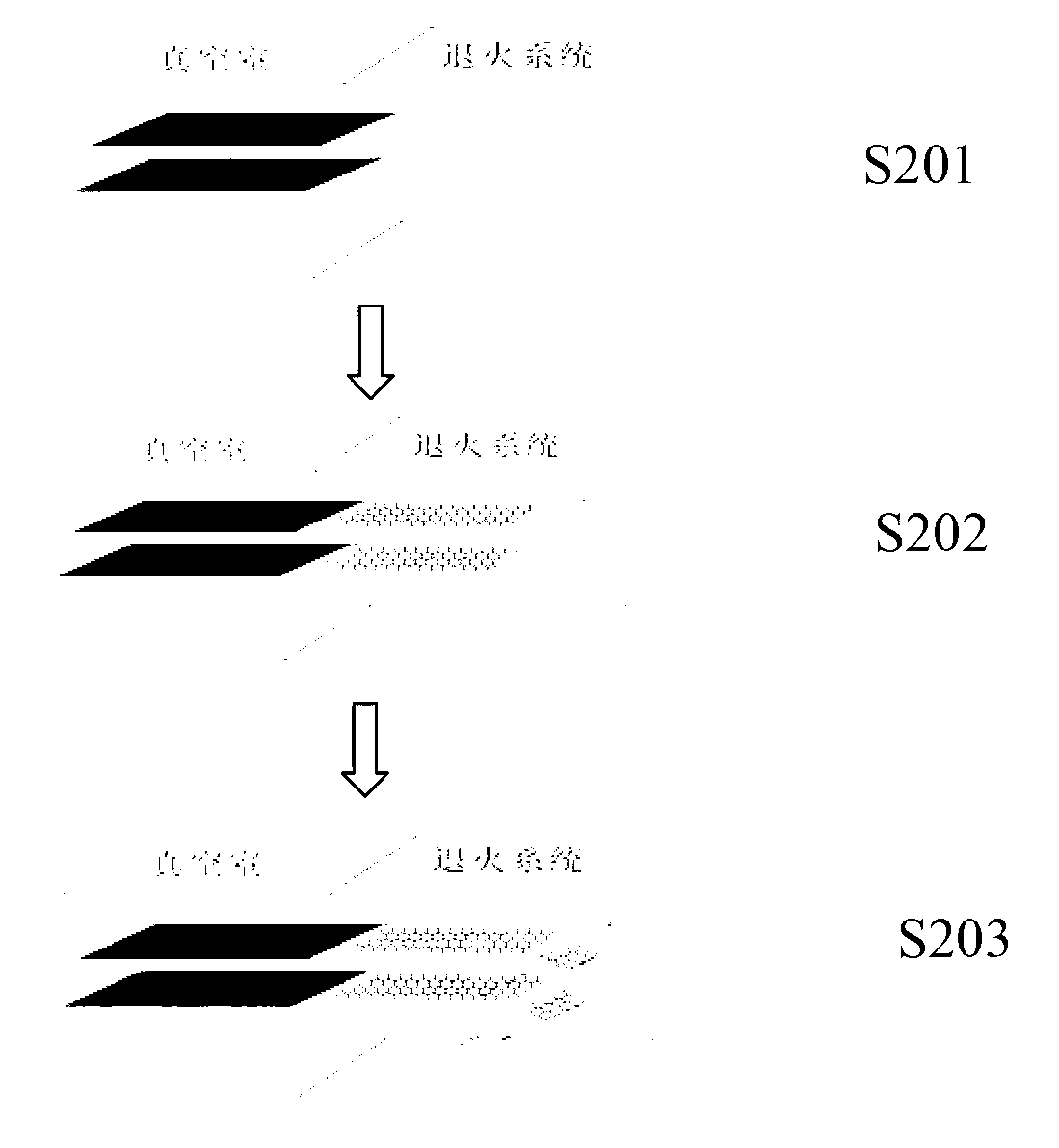

Silicon chip thinning method

ActiveCN103606517AGuaranteed mass productionReduce defectsSemiconductor/solid-state device manufacturingManufacturing technologyEtching

The invention belongs to semiconductor integrated circuit manufacture technology, and especially relates to a silicon chip thinning method. The silicon chip thinning method comprises a step 1 of arranging a protection material on the front side of a silicon chip; a step 2 of thinning the back side of the silicon chip in a phased grinding mode with a specific thinning process being divided into two phases; a step 3 of putting the silicon chip being thinned in the grinding mode into a corrosive liquid, and carrying out wet etching to the silicon chip through an abrasive wheel at a corrosion rate v3; and a step 4 of removing the protection material from the silicon chip. According to the invention, defects, of the silicon chip, generated in the thinning process are reduced, not only can a batch of silicon chips be thinned, but also back side defects and damaged layers caused by the thinning process are effectively reduced; the thickness proportions and the rates in the thinning process and the corrosion process can be subtly controlled, and therefore less defects and damages are generated on the surface of the silicon chip in the thinning process, and the effect of defect reduction is verified through ion implantation after the thinning process.

Owner:中国东方电气集团有限公司

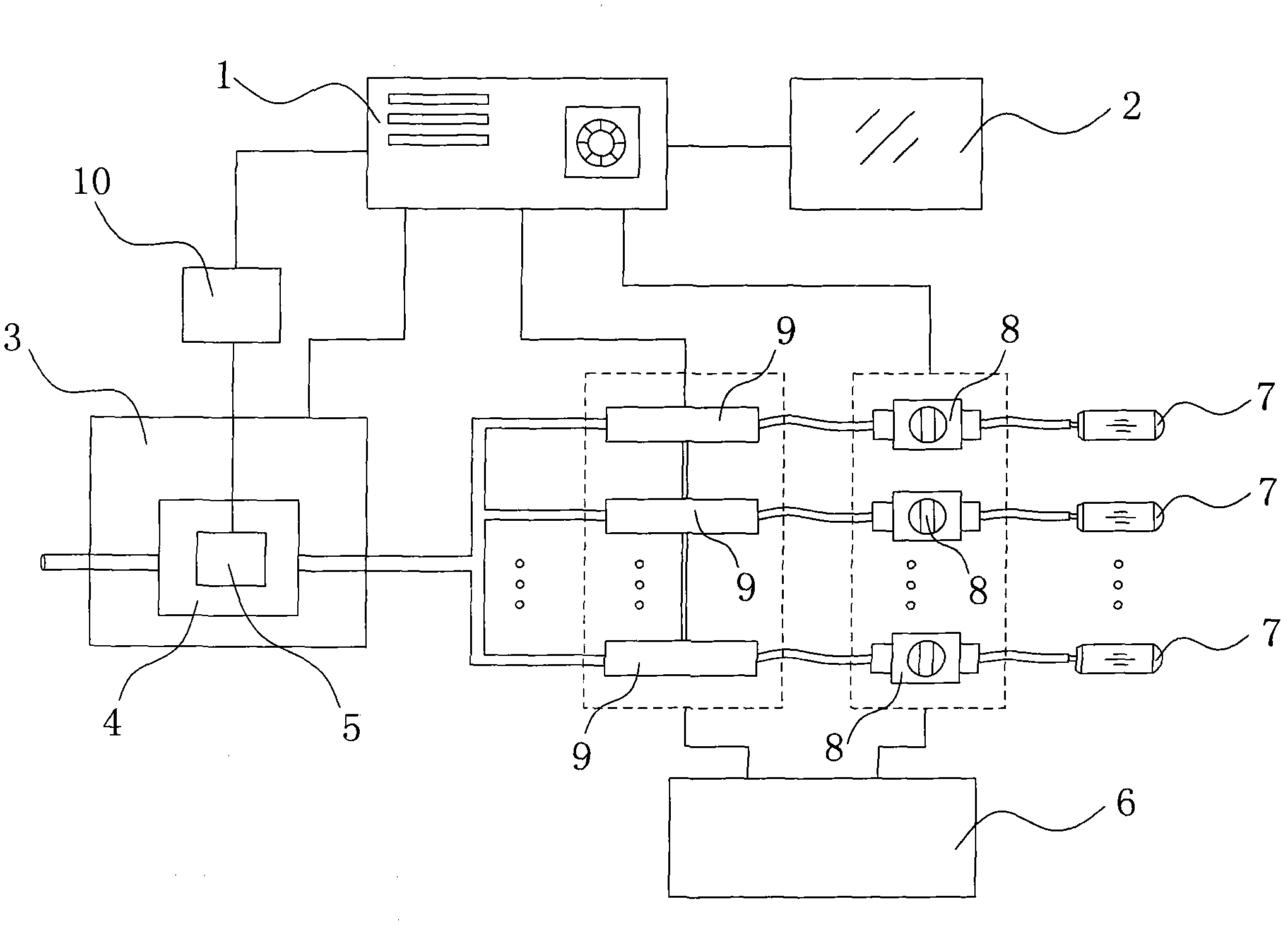

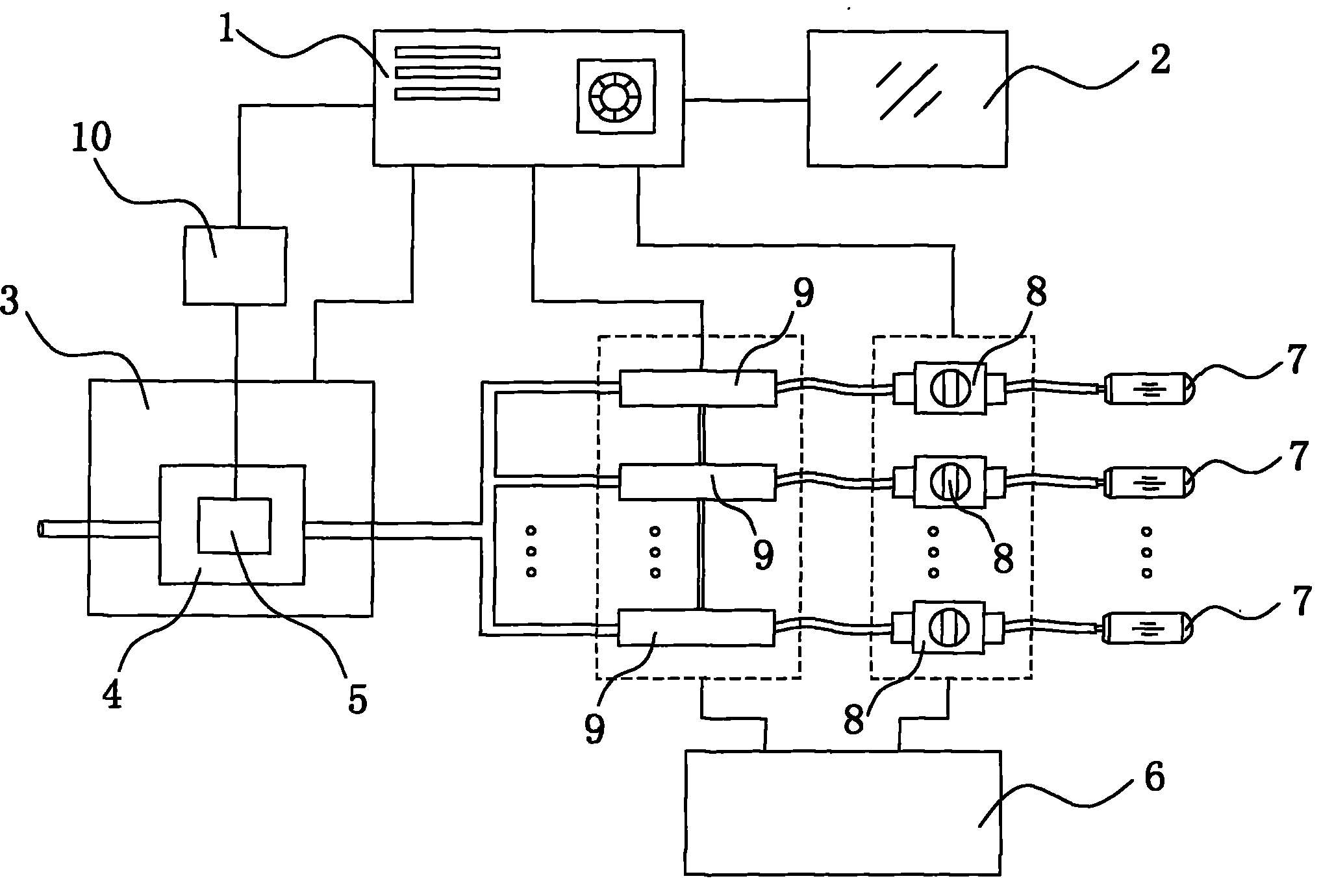

Automatic calibration system for gas sensor

InactiveCN102128861ARealize unattended operationGuaranteed mass productionMaterial analysis by electric/magnetic meansTemperature controlAutomatic control

The invention provides an automatic calibration system for a gas sensor. The automatic calibration system comprises a steel cylinder, a gas mass flow controller, a high- and low-temperature alternate experimental box, a sensor gas hood, a sensor data acquisition circuit and an industrial computer, wherein the steel cylinder, the gas mass flow controller and the sensor gas hood constitute an air distribution system; the industrial computer is connected with the high- and low-temperature alternate experimental box to produce different constant temperatures; the industrial computer is connected with the gas mass flow controller to generate set gas concentrations at different constant temperatures; and the industrial computer is connected with the sensor data acquisition circuit to acquire gas concentration response values of the gas sensor at different constant temperatures and transmit sensor calibration data to the gas sensor. The automatic calibration system has the advantages of scientific design, convenience for using, complete functions, automatic temperature control capability, automatic dynamic air distribution capability, automatic data acquisition capability, automatic data handling capability, high working efficiency and high reliability.

Owner:HENAN HANWEI ELECTRONICS

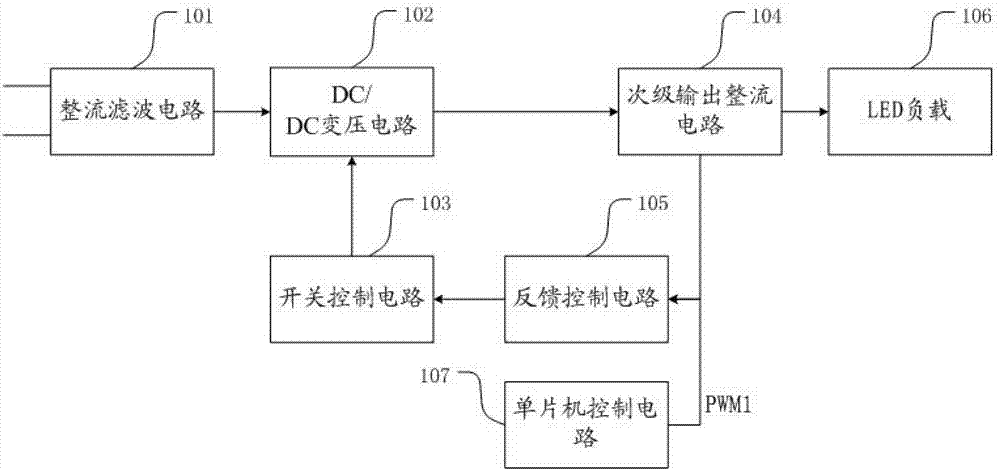

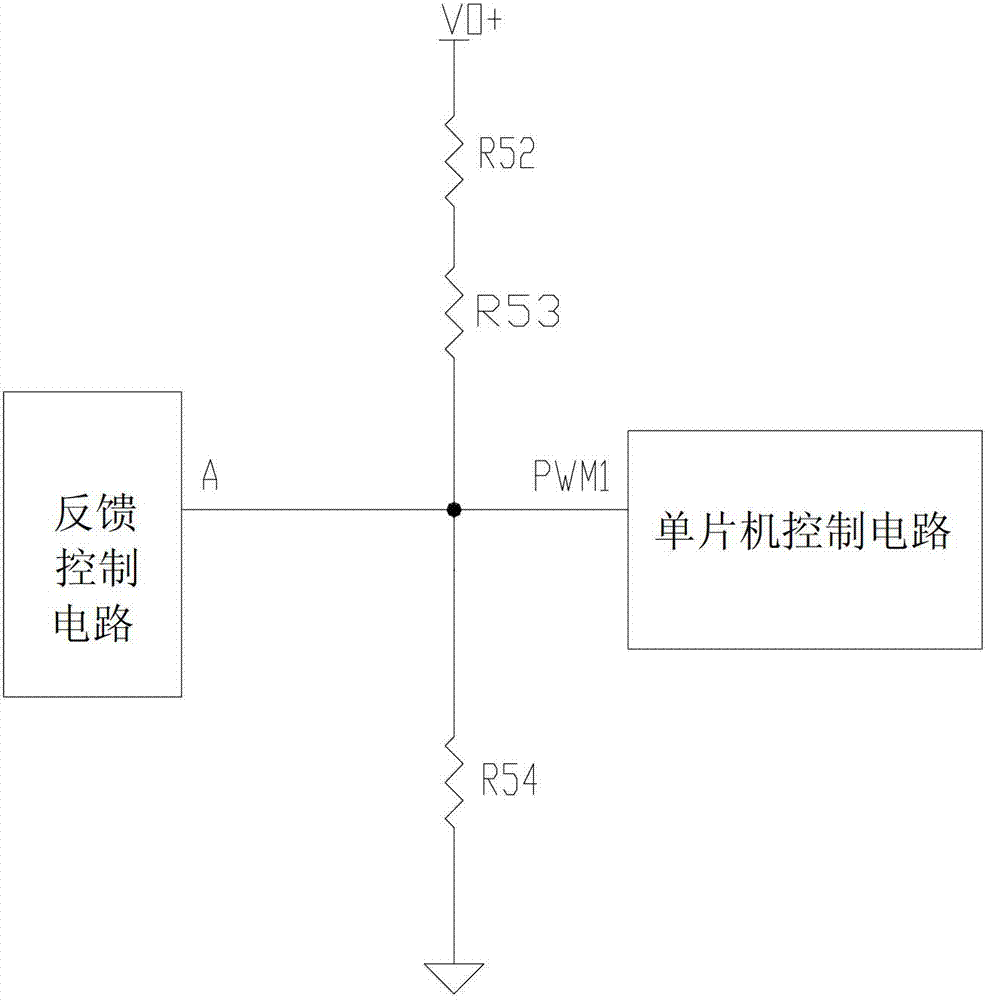

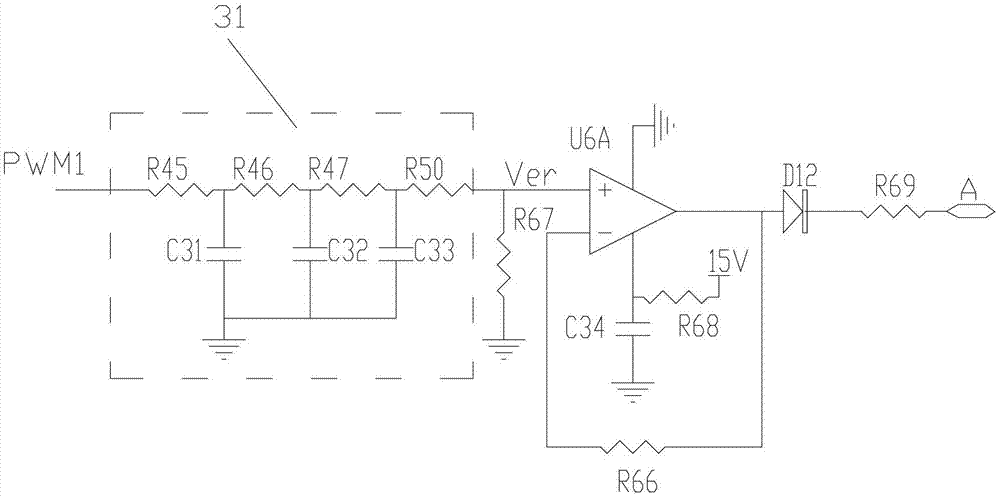

Driving power supply control circuit

InactiveCN102740572AReduce manpower and material costsIncrease productivityElectric light circuit arrangementPower flowControl circuit

The invention discloses a driving power supply control circuit. The driving power supply control circuit comprises a rectifier filter circuit, a DC / DC (Direct Current to Direct Current) transformation circuit, a switching control circuit, a feedback control circuit and a secondary output rectifier circuit. The feedback control circuit is connected between the secondary output rectifier circuit and the switching control circuit; the voltage sampling end of the feedback control circuit is connected with a singlechip control circuit; the singlechip control circuit is used for generating a control signal PWM1 to control a feedback voltage output of the feedback control circuit; and the singlechip control circuit can also be used for generating a load current control signal PWM2 for a load current control circuit to regulate the average of an output current cycle. According to the driving power supply control circuit provided by the invention, the mass production of a manufacturer can be ensured, the matching can be implemented only by carrying out program updating on a singlechip chip for different LED (Light-Emitting Diode) loads, the manpower and material cost is reduced, the production efficiency is improved and the supply quality is also ensured.

Owner:SHANXI ZHAOXIN ELECTRIC POWER EQUIP

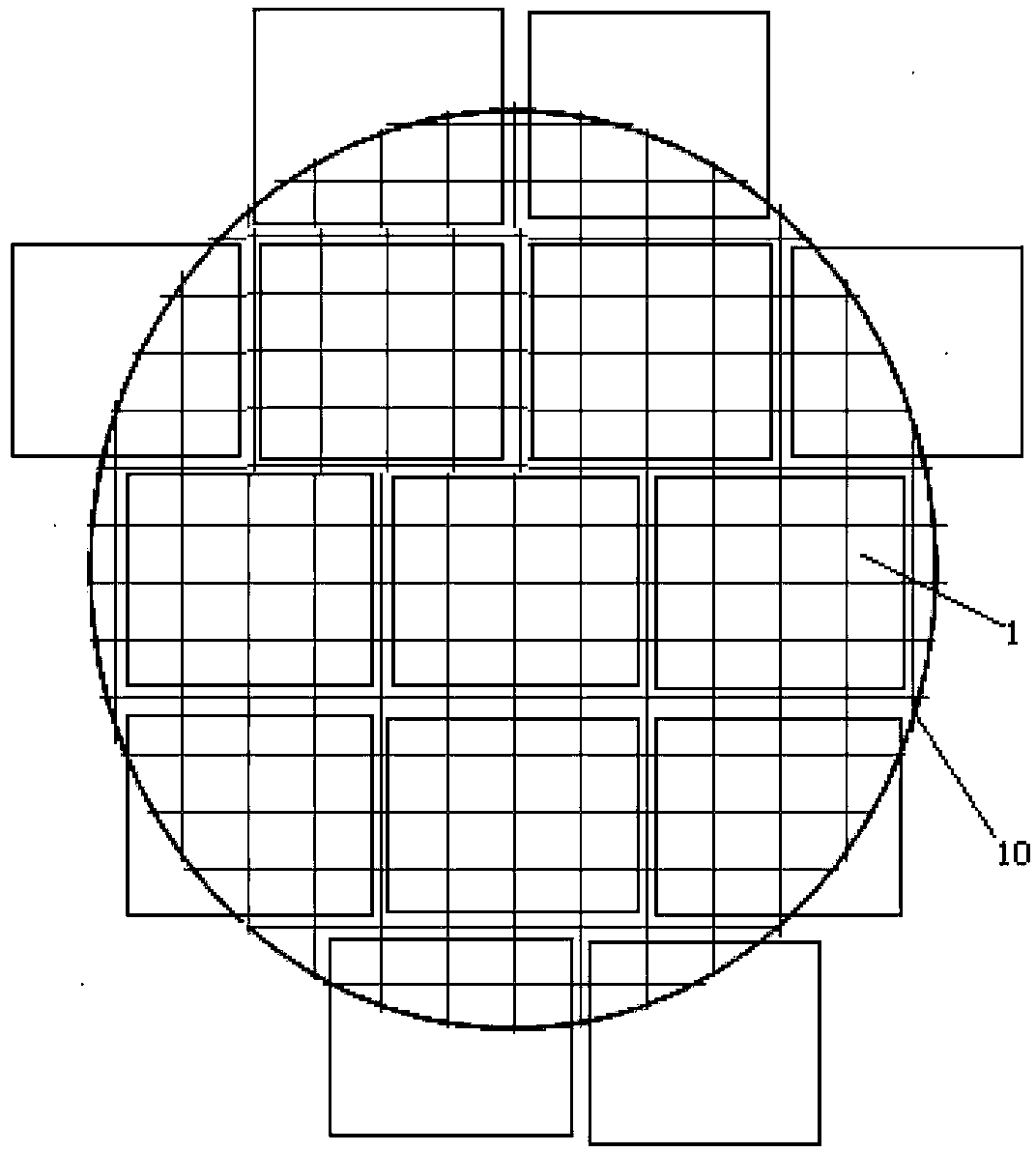

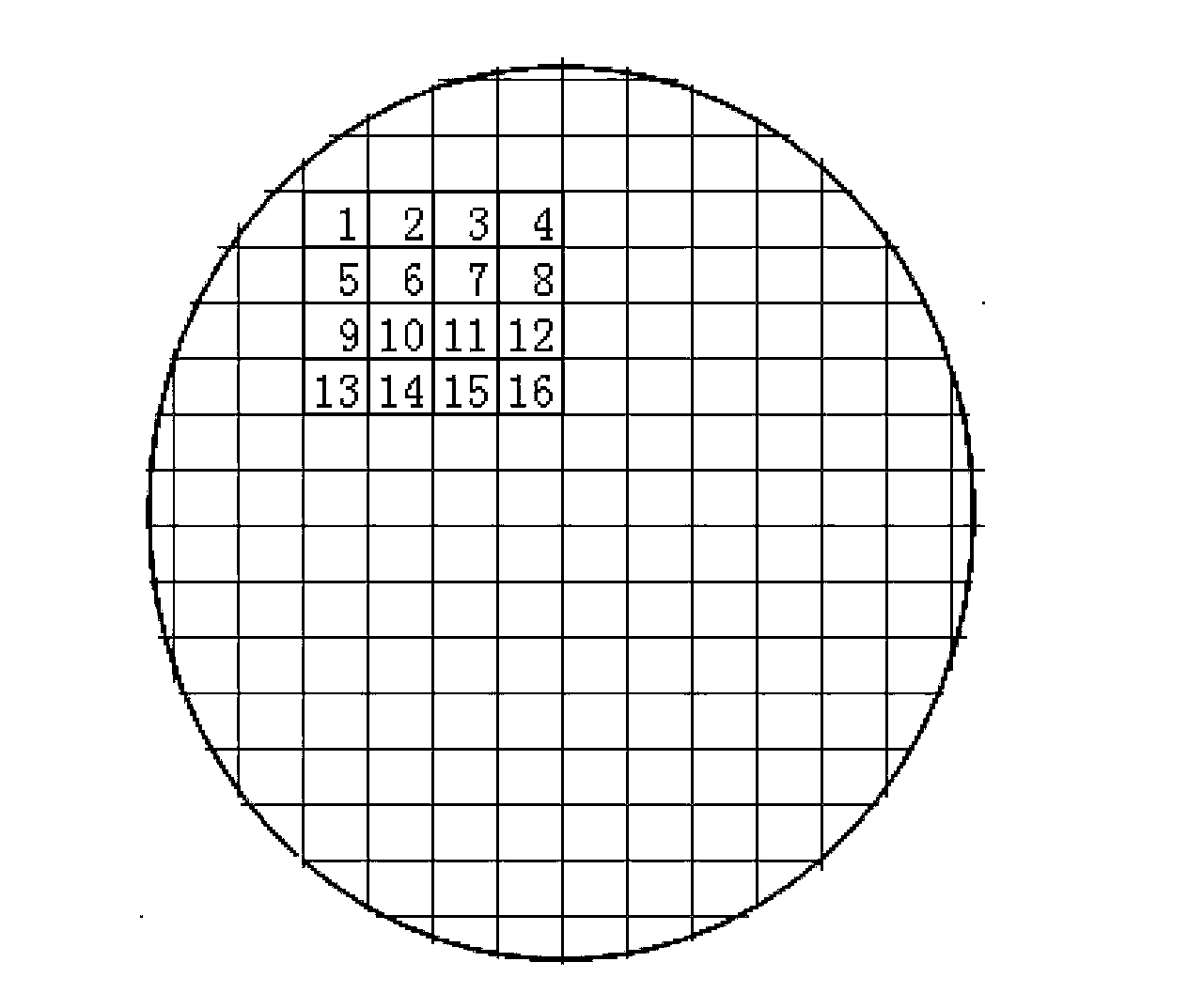

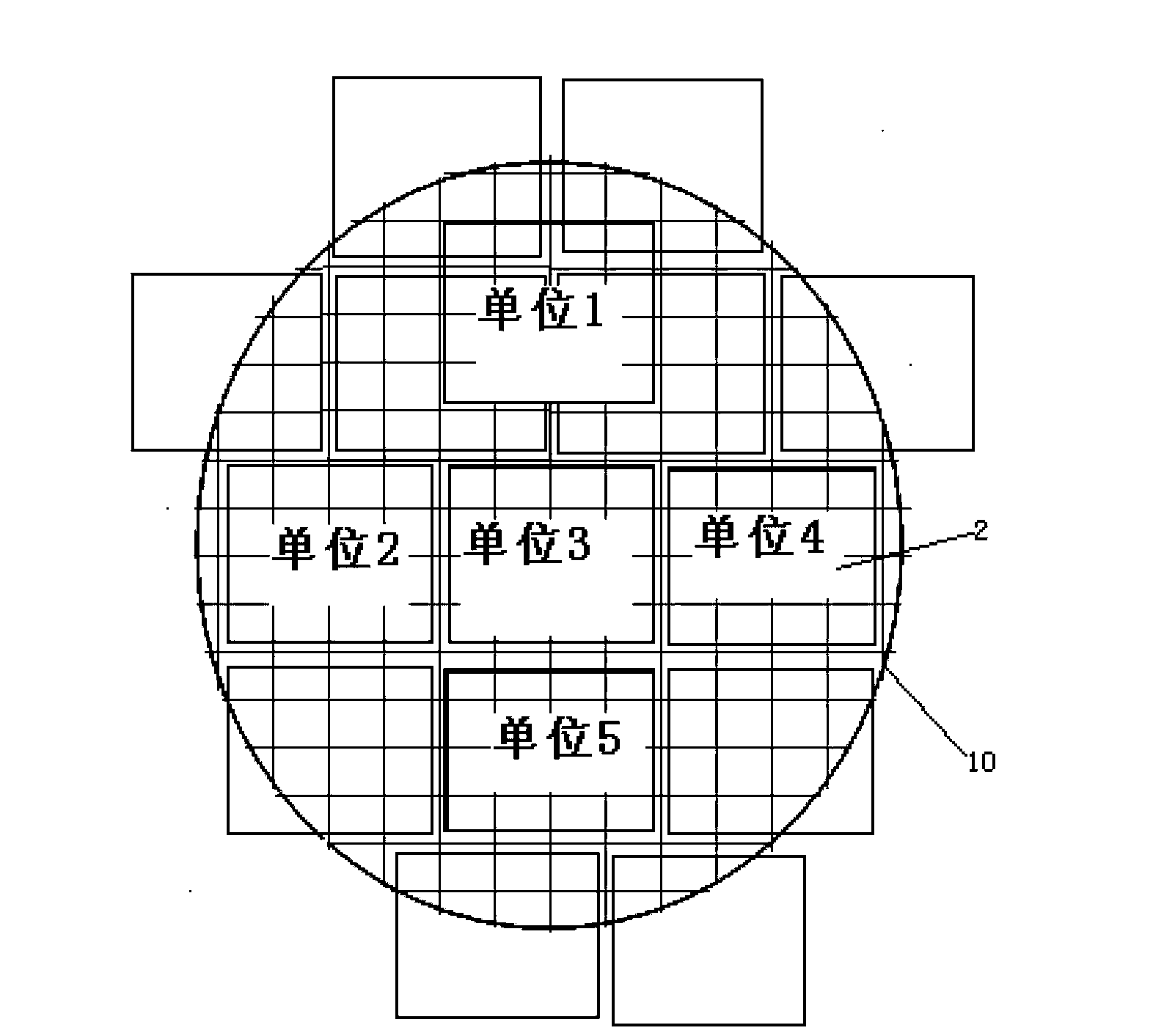

Adjustment method for parameters of chips on wafer

ActiveCN103855045AShorten test timeGuaranteed mass productionSemiconductor/solid-state device testing/measurementElectronic circuit testingSpecific testProbe card

The invention discloses an adjustment method for parameters of chips on a wafer. The method includes the following steps: step1: grouping all chips on a test wafer into a plurality of test units; step2: measuring a specific parameter of each chip in a specific test unit through a probe card so as to obtain eigenvalues of the parameters of all the chips in the test unit; step3: obtaining a mean value of the eigenvalues of the parameters of all the chips in the test unit and using the mean value of the parameters as an adjustment target value of all the chips in the test unit and at the same time writing the mean value of the parameters into the chips for being used in follow-up tests and normal work so as to complete adjustment of a specific test unit on the test wafer; step4: repeating the step 2 and step3 until adjustment of all test units on the test wafer is completed. The adjustment method for the parameters of the chips on the wafer is capable of ensuring the adjustment accuracy while ensuring large-scale mass production.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

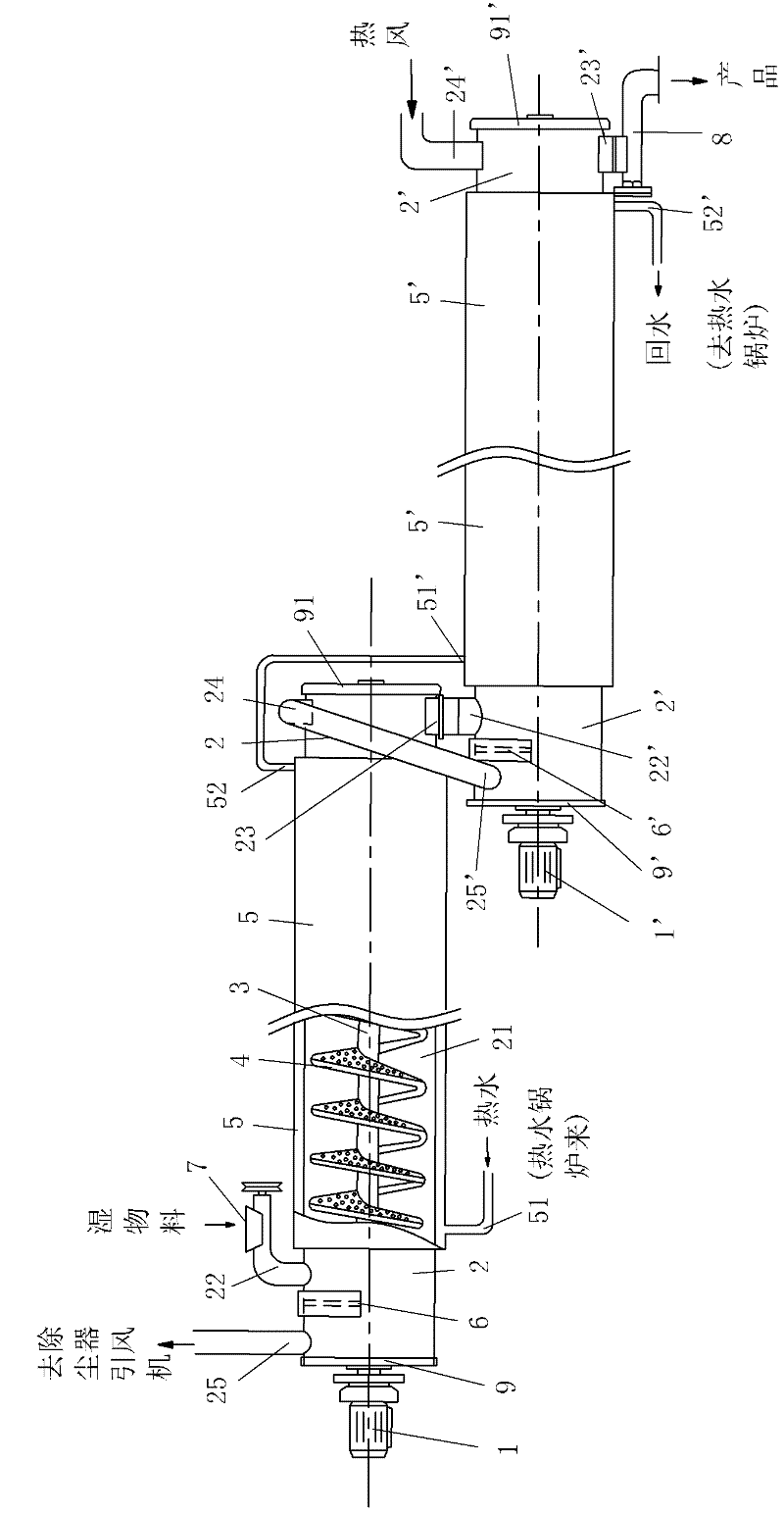

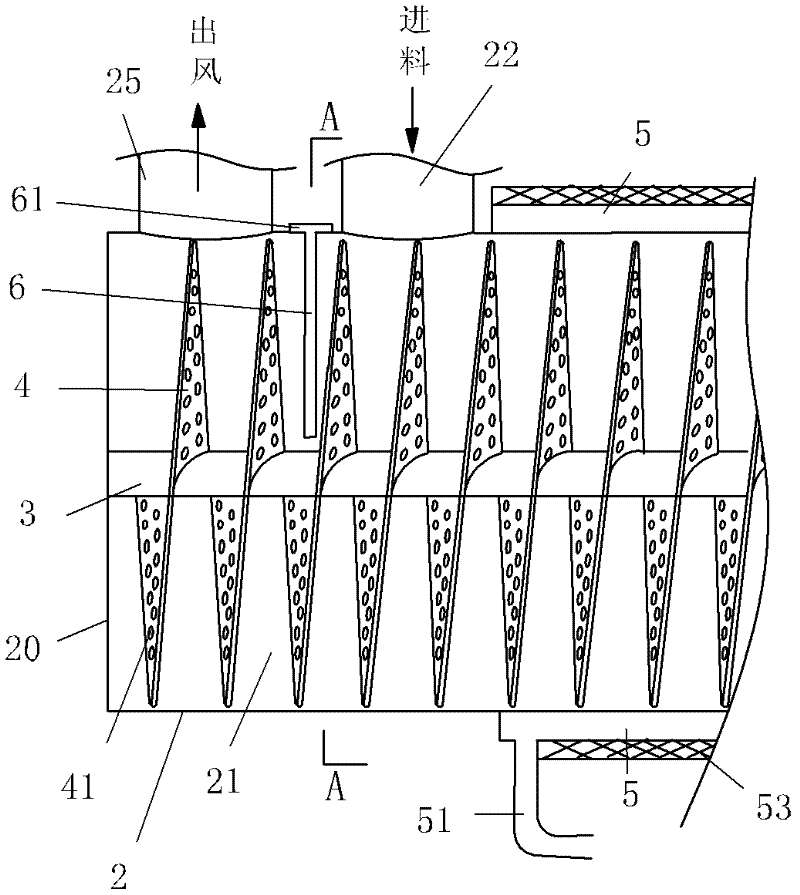

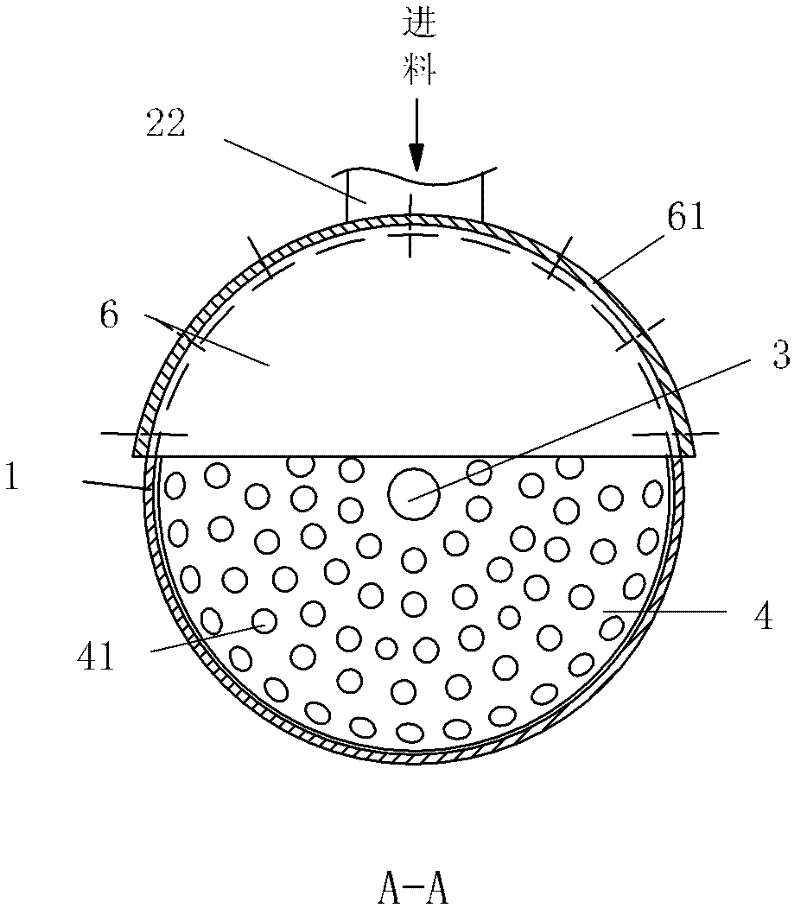

Spiral promoting drier

ActiveCN102305528APlay the role of lifting and throwingKeep dryDrying solid materials with heatHearth type furnacesMotor driveEngineering

The invention relates to a spiral promoting drier, and relates to a drying plant of a material having a biological active substance. The spiral promoting drier is characterized in that a spiral promoting unit body is provided with a shell and a motor, and the periphery of the shell is provided with a heat exchange sleeve with a heating medium inlet and a heating medium outlet; a motor drives a spiral agitator shaft arranged in the inner cavity of the shell, the upside of the front end side wall of the shell is provided with a feed port, and the downside of the rear end side wall of the shell is provided with a discharge hole; a multi-hole spiral piece winds on the spiral agitator shaft, wherein the multi-hole spiral piece penetrates through the two ends of the spiral agitator shaft and multiple air holes are evenly distributed on the multi-hole spiral piece; the upside of the front end side wall of the shell is provided with an air outlet arranged on the front of the feed port, and the upside of the rear end side wall of the shell is provided with an air inlet; the heating medium inlet is arranged on the front end part of the heat exchange sleeve, and the heating medium outlet is arranged on the rear end part of the heat exchange sleeve; and two or multiple spiral promoting unit bodies are connected in series so as to constitute the spiral promoting drier, the drying of a heat-sensitive material with complicated physical properties is solved in large production; and the spiral promoting drier provided by the invention is convenient for installation, transportation and adaptive to various areas.

Owner:FUZHOU LYUZHOU BIOCHEM CO LTD

Energy-saving high-elongation soft aluminum alloy wire and preparation method thereof

InactiveCN104032191AUniform compositionGuaranteed mass productionMetal/alloy conductorsImpurityEnergy analysis

The invention relates to an energy-saving high-elongation soft aluminum alloy wire and a preparation method thereof. The aluminum alloy wire is mainly composed of the following components in percentage by weight: 0.05-0.40% of Cu, 0.10-0.40% of Zr, 0.25-1.00% of Fe, 0.01-0.22% of Mg, 0.001-0.15% of Si, 0.05-0.15% of Y, 0.05-0.10% of Sc, and the balance of Al and other inevitable impurity elements. The amount of each element in the other inevitable impurity elements does not exceed 0.03%, and the total amount of all the other inevitable impurity elements does not exceed 0.15%. The aluminum alloy wire has the advantages of favorable creep resistance, high elongation percentage, favorable bending property and the like, is easy for machine-shaping, and can ensure the stability of the electrical connection.

Owner:JIANGSU CHANGFENG CABLE

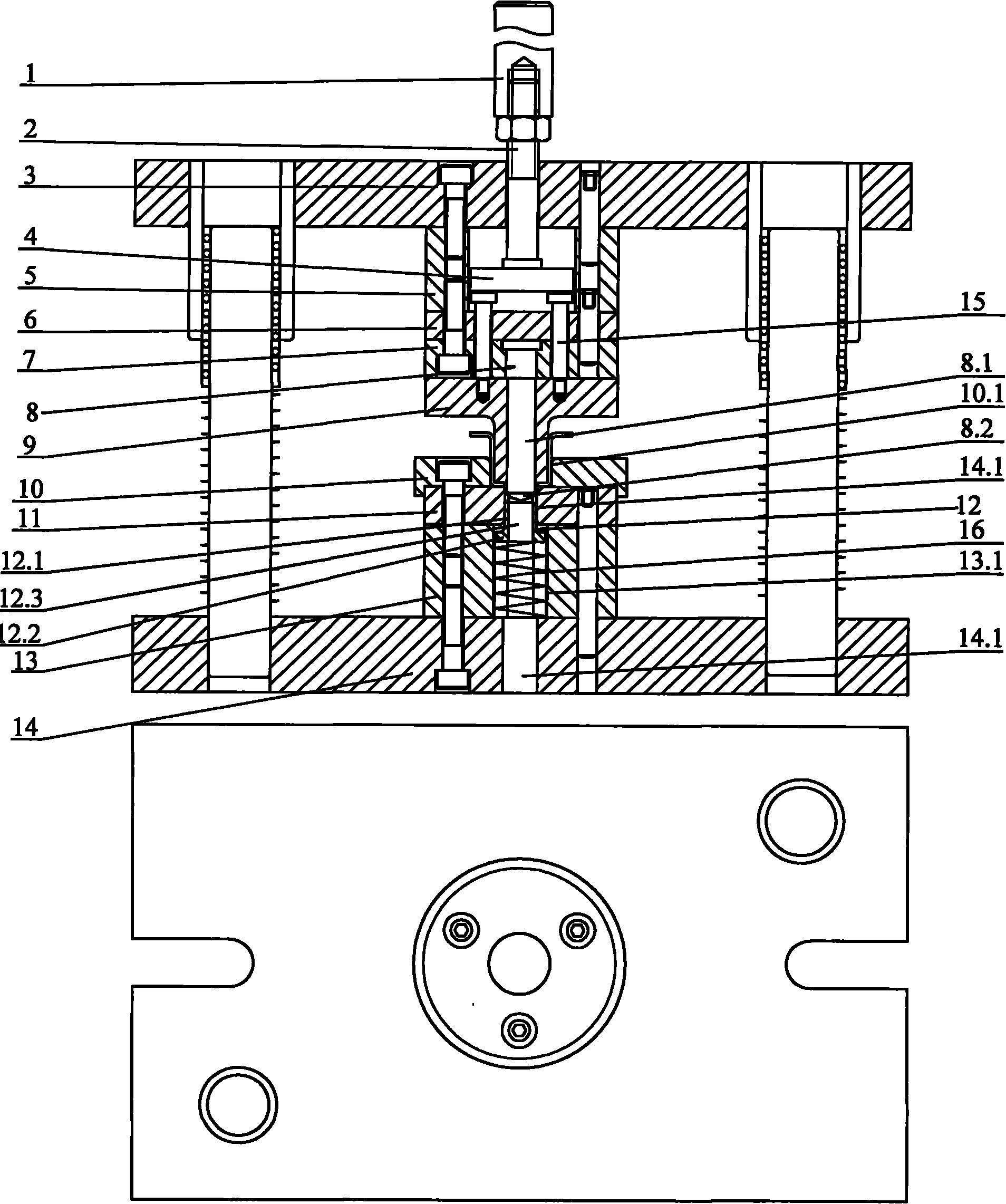

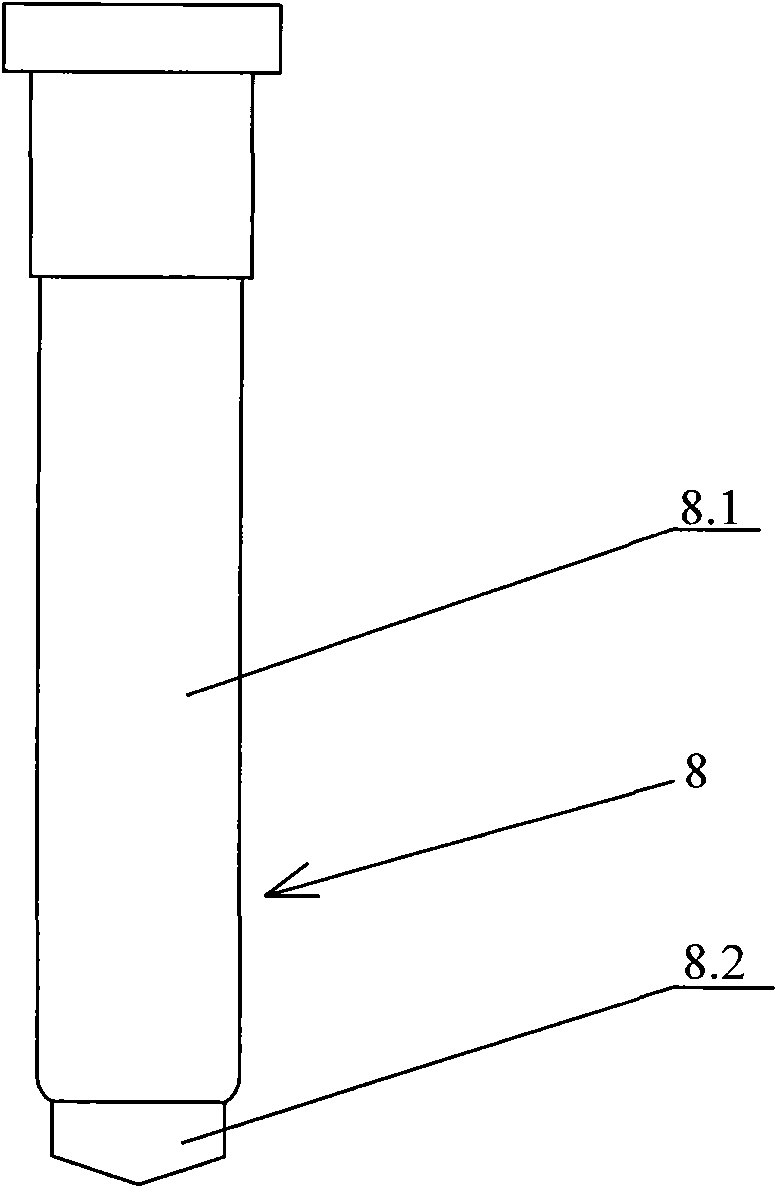

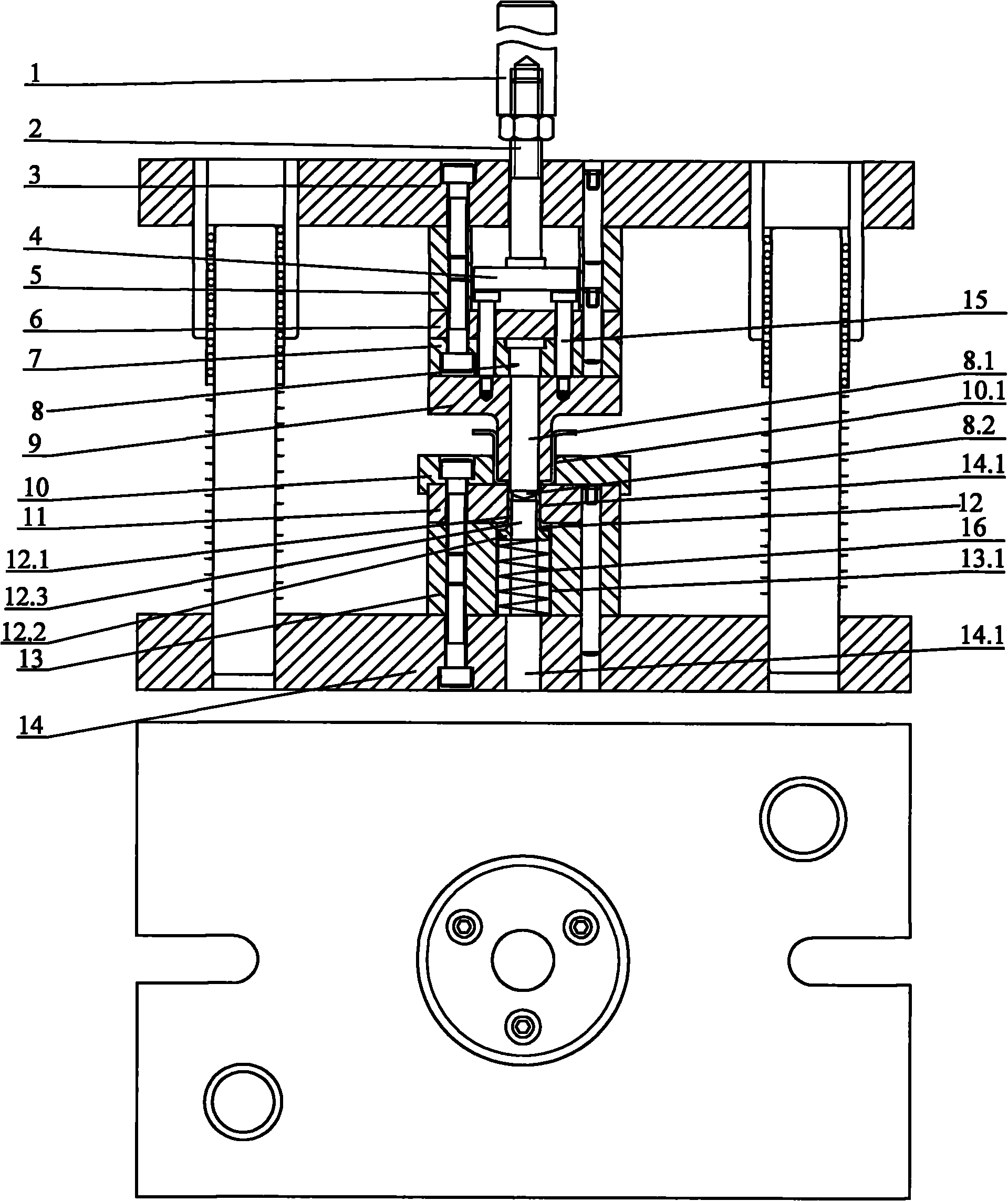

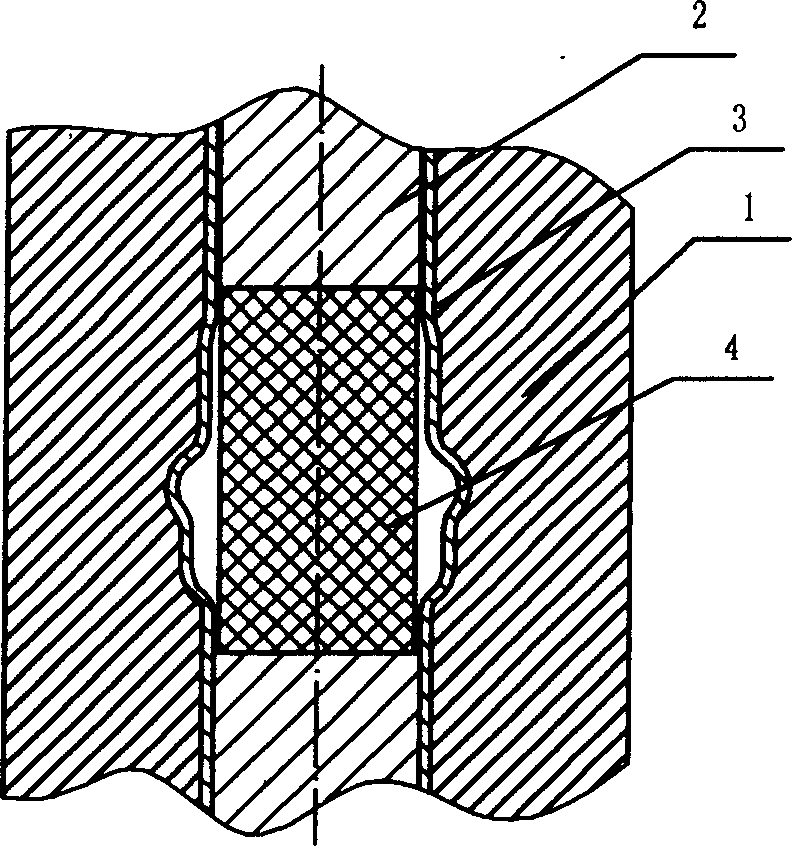

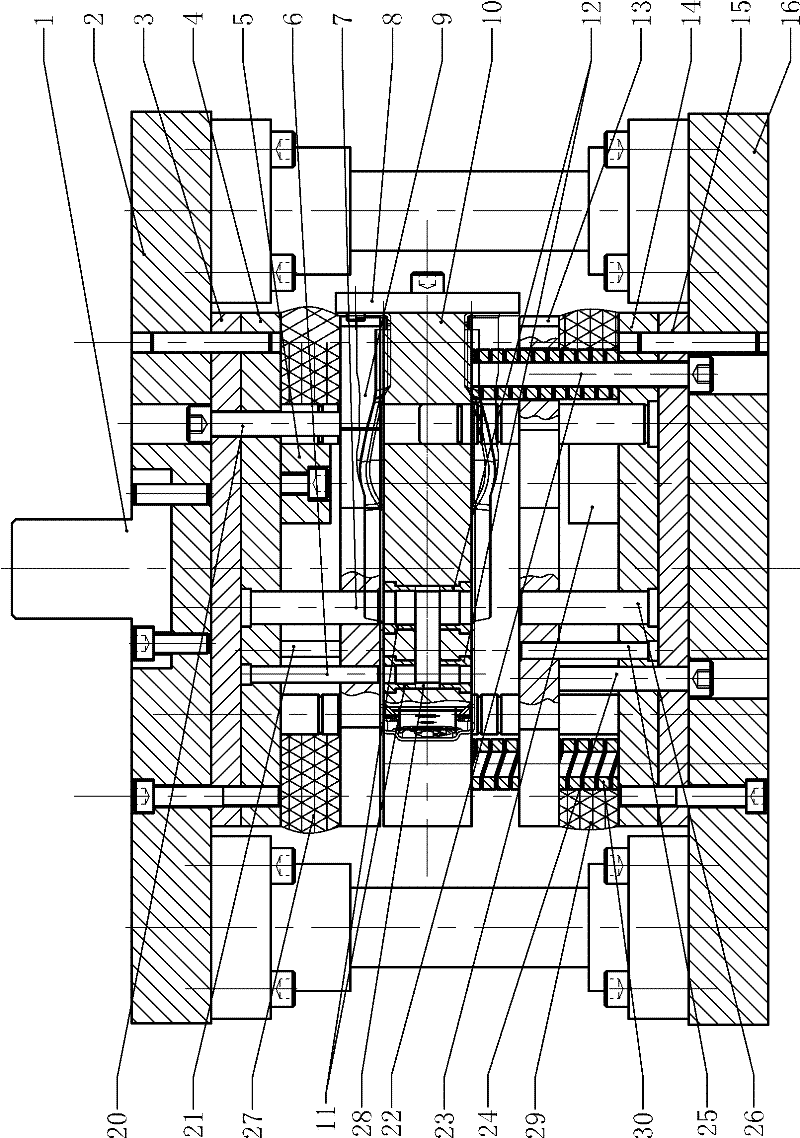

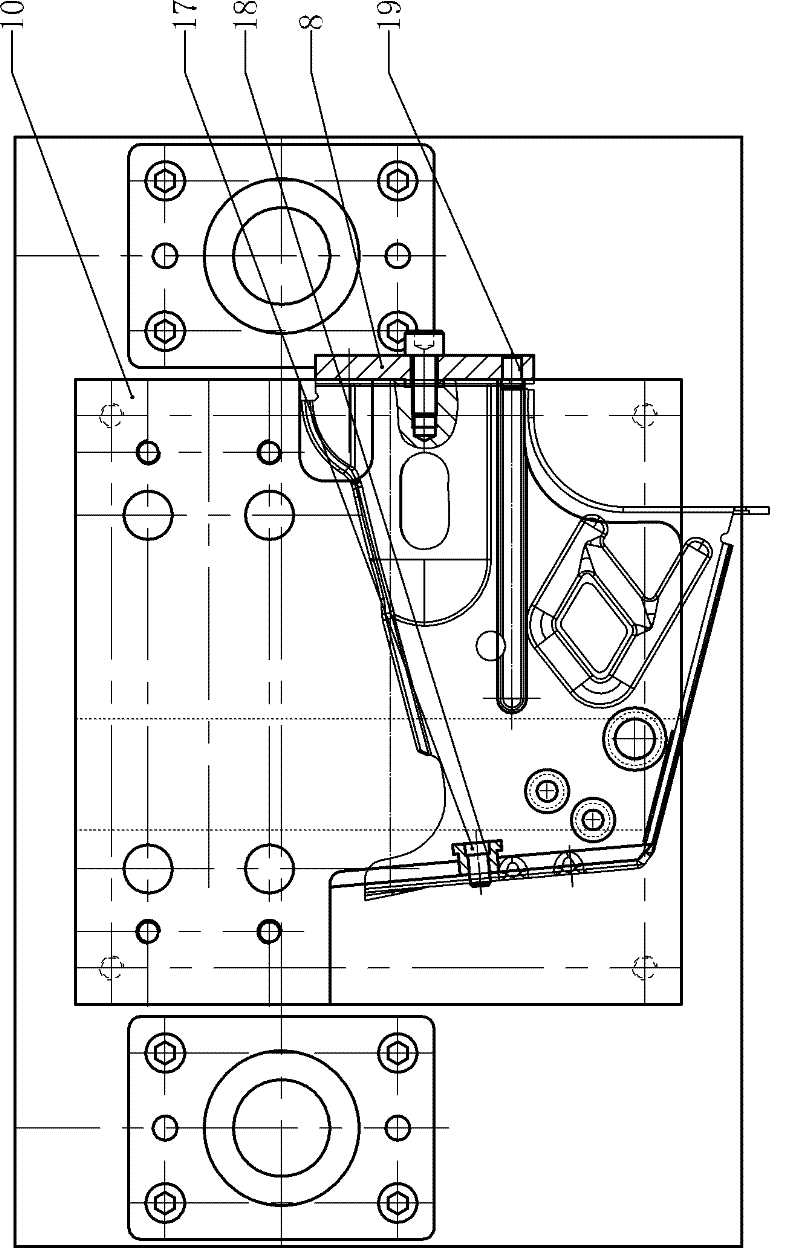

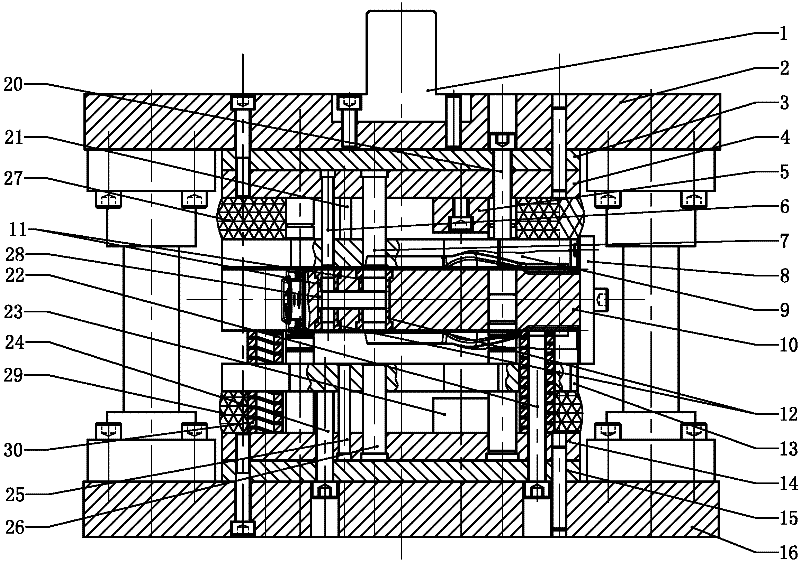

Punching/hole flanging die for internal supporting tube of auto shock absorber

ActiveCN101829733AIncrease productivityGuaranteed sizeShaping toolsPerforating toolsPunchingFlanging

The invention relates to a punching / hole flanging die for an internal supporting tube of an auto shock absorber, which is characterized in that an upper template is provided with a mounting hole, and a knock-out pin is slipperily arranged in the mounting hole, the top of the knock-out pin is provided with a knock-out pin sleeve, and the bottom of the knock-out pin is fixedly provided with a knock-out block, the lower surface of the upper template is fixedly provided with an punch holder, an upper padding plate and a top clamping plate, an integrated jack is arranged in both the upper padding plate and the top clamping plate, and an insert-column is slipperily connected in the jack, the bottom of the insert-column is fixedly provided with a stripper plate, and the bottom of the stripper plate is connected with a discharge convex head, the top clamping plate is fixedly provided with a male die, the upper surface of an lower template is provided with a lower padding plate, a female die and a positioning block, and a punching female die is arranged below the male die, the male die comprises an upper male die section and a lower male die section, the lower male die section is integrally connected at the bottom of the upper male die section, the upper male die section and the lower male die are coaxial, and the diameter of the lower male die section is less than that of the upper male die section. The punching / hole flanging die can greatly improve the production efficiency and guarantee the product size after being put into practical production.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

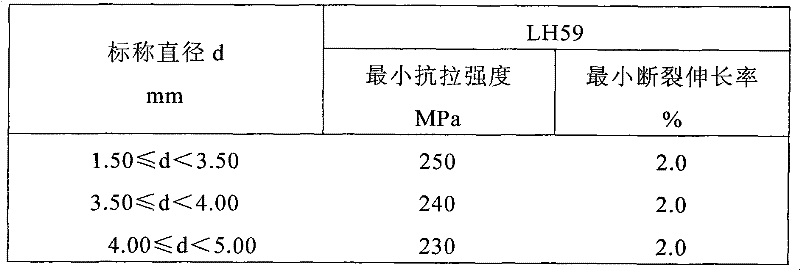

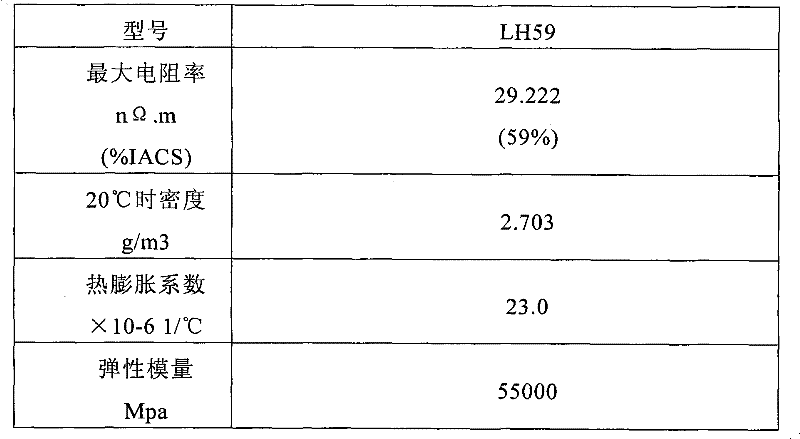

Manufacture method of medium-strength aluminum alloy wire with electrical conductivity of 59 percent

ActiveCN102453819AControl contentGuaranteed mass productionSingle bars/rods/wires/strips conductorsMetal/alloy conductorsManganeseImpurity

The invention provides a manufacture method of a medium-strength aluminum alloy wire with electrical conductivity of 59 percent. The method comprises the following steps of: A, preparing molten aluminum by selecting an aluminum ingot as a raw material, wherein the aluminum ingot comprises the following impurities in percentage: less than or equal to 0.08 percent of silicon, less than or equal to 0.16 percent of iron, less than or equal to 0.01 percent of copper, less than or equal to 0.015 percent of titanium, vanadium, chromium and manganese, and less than or equal to 0.03 percent of other impurities; B, melting the alloy liquid to realize that the silicon is controlled to be between 0.40 and 0.55 weight percent, magnesium is controlled to be between 0.35 and 0.50 weight percent, and copper is controlled to be between 0.020 and 0.040 weight percent in the alloy liquid; C, casting into an aluminum alloy ingot; D, rolling into a medium-strength aluminum alloy rod; E; drawing into a medium-strength aluminum alloy single wire; and F, twisting to form a medium-strength aluminum alloy wire finished product with electrical conductivity of 59 percent. The medium-strength aluminum alloy wire with electrical conductivity of 59 percent manufactured by adopting the method has higher tensile strength than that of an aluminum wire and higher electrical conductivity than that of a common aluminum alloy conductor, can replace a steel-core aluminum conductor, and can be used as a lead wire of a long-span transmission circuit.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Preparation method of macromolecule resin composite bipolar plate for ion exchange membrane fuel battery

The invention belongs to the fuel battery technique, relating to a method for preparing proton exchange membrane fuel battery with high polymer resin composite bipolar plate. The preparing method comprises: adding globular graphite in 70-80wt%, thermoplastic polyimide resin in 15-25wt%, coupling agent (KH-560) in 0.5-1.5wt% and polar plate fiber reinforcing agent (staple carbon fiber) in 3-10wt% into mixing machine to be mixed for 15-35 minutes; mixing and heating to 80-100Deg. C, to be put into the mould which has been heated to 80-100Deg. C; the vacuum degree of vacuum hydraulic presser is -0.085MPa, the compression molding temperature of mixed material is controlled in 120-180Deg. C, the compression molding pressure is 0.5-15MPa, and the warm-keeping time of composite dipolar plate in the hydraulic presser is controlled in 2-50 minutes; the product is demoulded and laid into oven for final treatment while the temperature is in 80-180 Deg. C, and the time is 0.2-2 hours, then extracting the product to be cooled in room temperature to attain the final product. The quality index of invention can meet the standard of composite bipolar plate of proton exchange membrane fuel battery.

Owner:ZHEJIANG UNIV

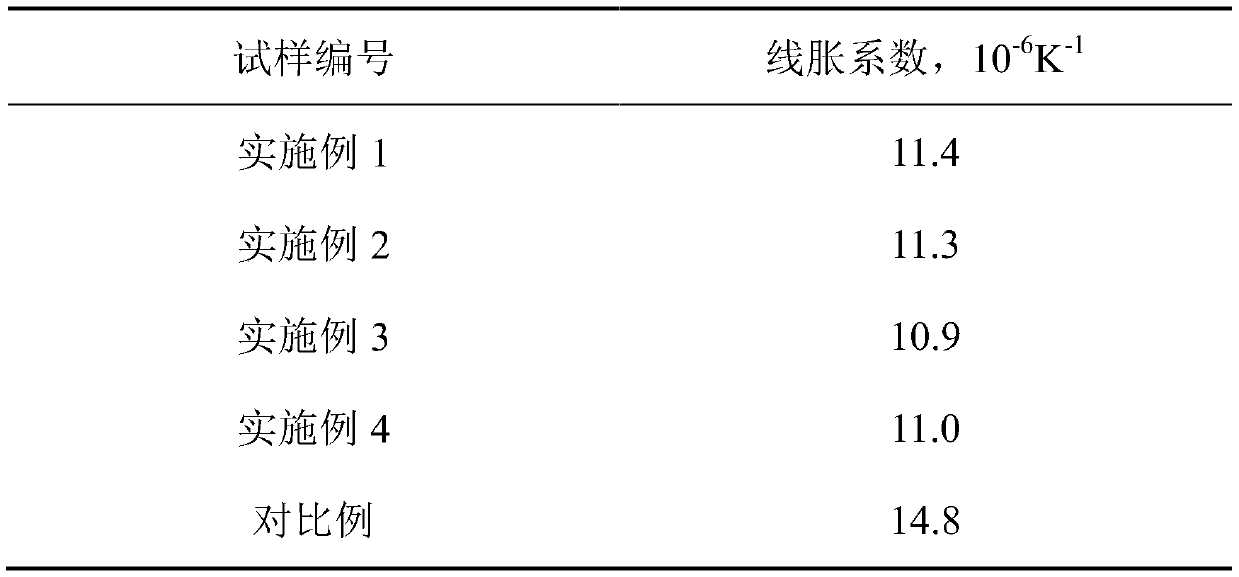

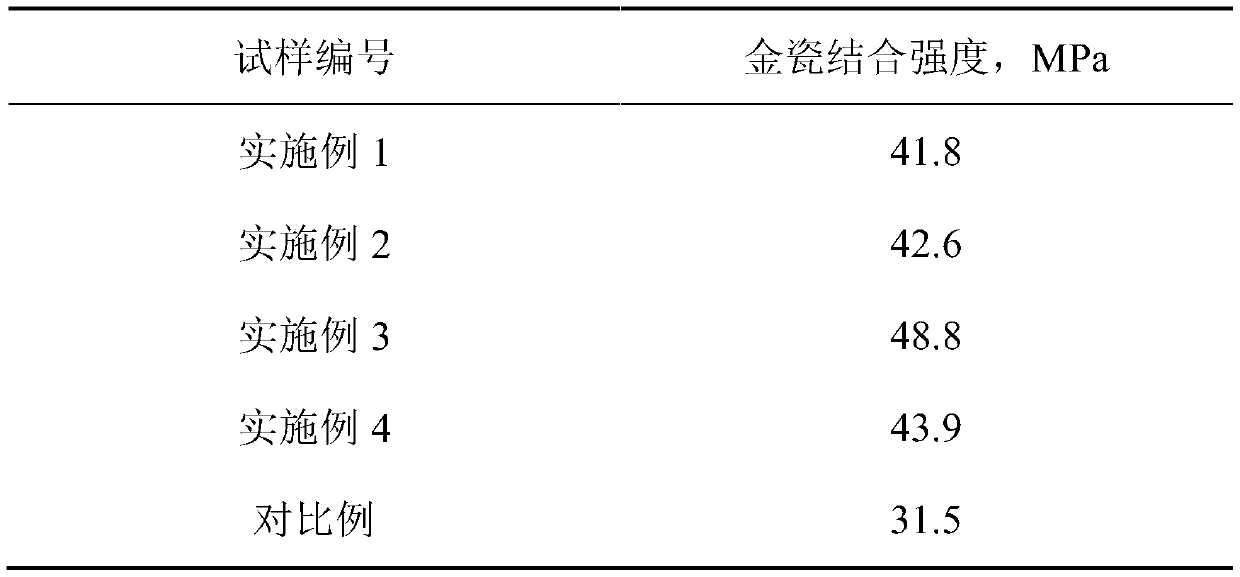

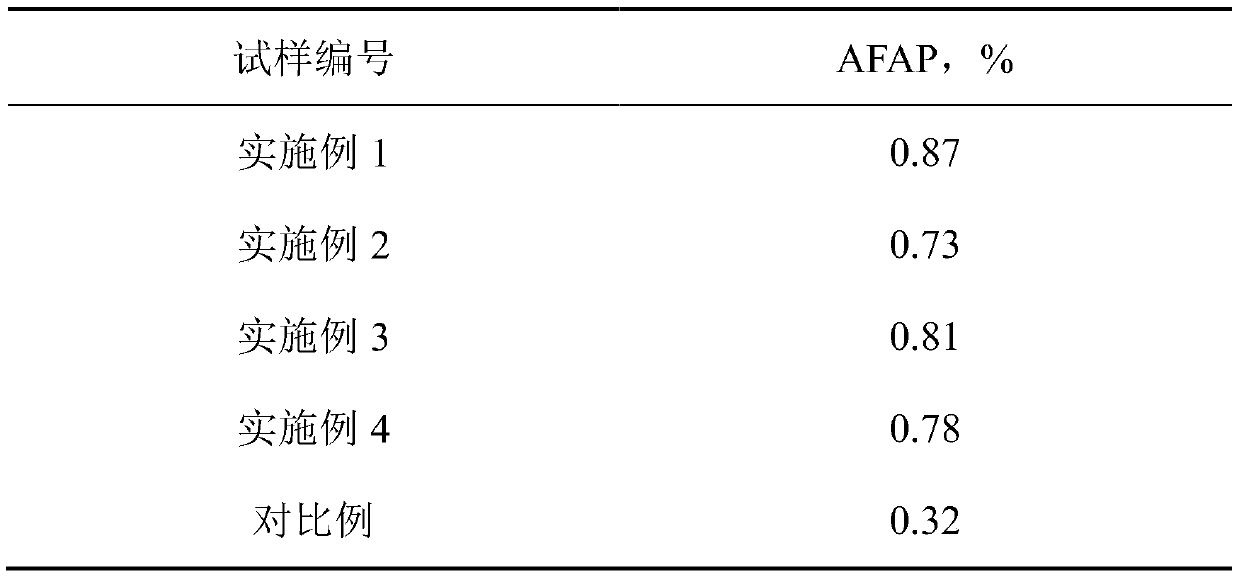

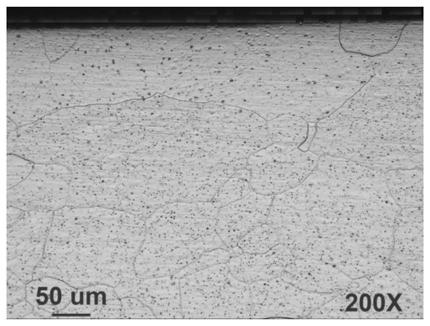

Cobalt-chromium-tungsten-molybdenum alloy powder for biomedical 3D printing and preparation method thereof

InactiveCN111014706ADoes not introduce inclusionsWill not introduce the situationAdditive manufacturing apparatusArtificial teeth3d printSelective laser melting

The invention discloses a preparation method of cobalt-chromium-tungsten-molybdenum alloy powder for biomedical 3D printing. The cobalt-chromium-tungsten-molybdenum alloy powder comprises the following components of, in percentage by weight of 60%-78% of Co, 20%-30% of Cr, 3.0%-7.0% of W, 2.0%-6.0% of Mo, smaller than or equal to 1.0% of Si, smaller than or equal to 0.02% of Be, smaller than or equal to 0.02% of Cd, smaller than or equal to 0.1% of Ni and the balance impurities, and the invention further discloses the preparation method of the cobalt-chromium-tungsten-molybdenum alloy powder for biomedical 3D printing. The powder prepared through the method is high in sphericity degree, good in fluidity, free of satellite powder, high in apparent density, smooth in powder surface and concentrated in particle size distribution and is suitable for SLM (selective laser melting) and other 3D printing technologies, and the prepared 3D printing forming part is low in linear expansion coefficient, high in gold-ceramic bonding strength and high in residual ceramic AFAP.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

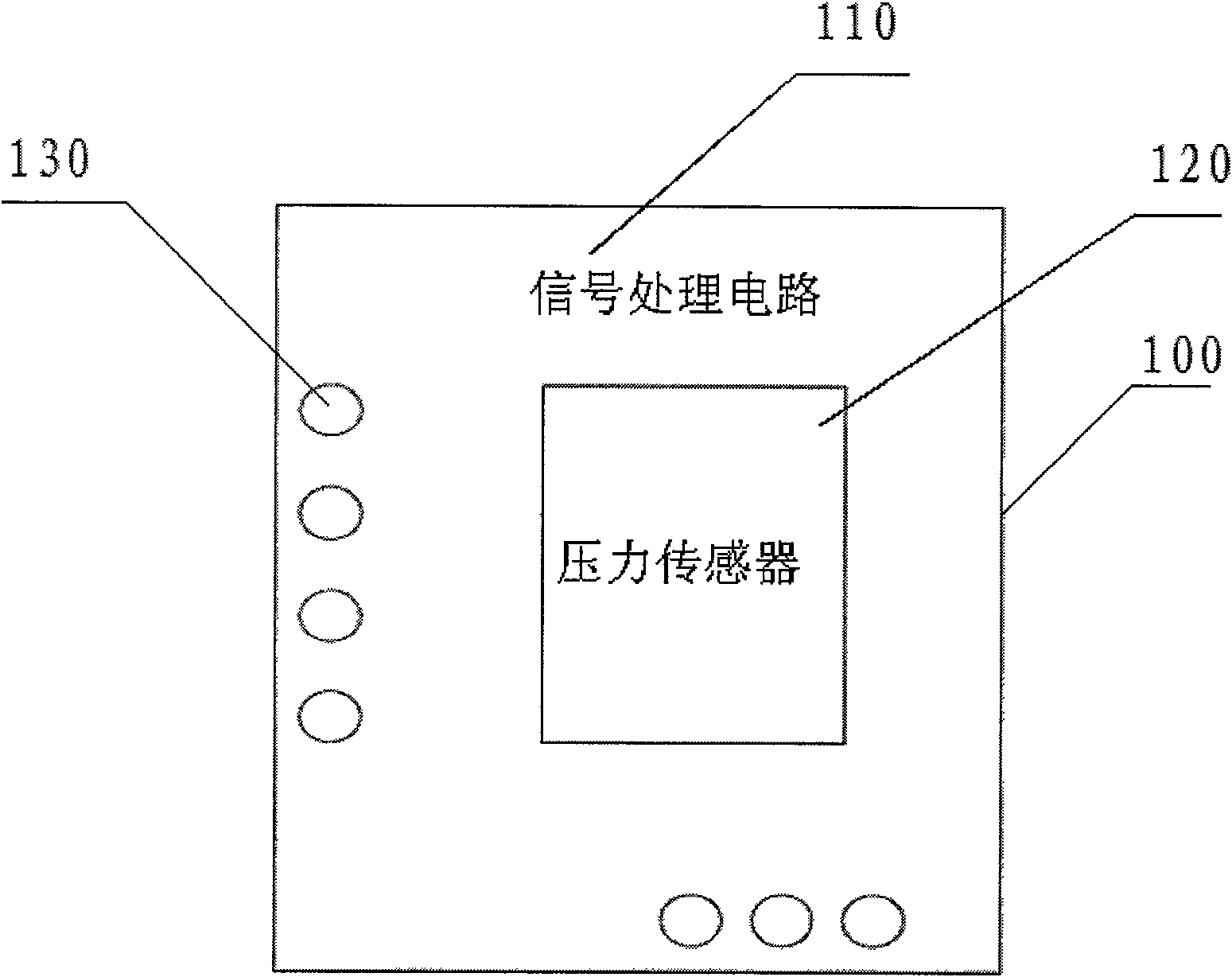

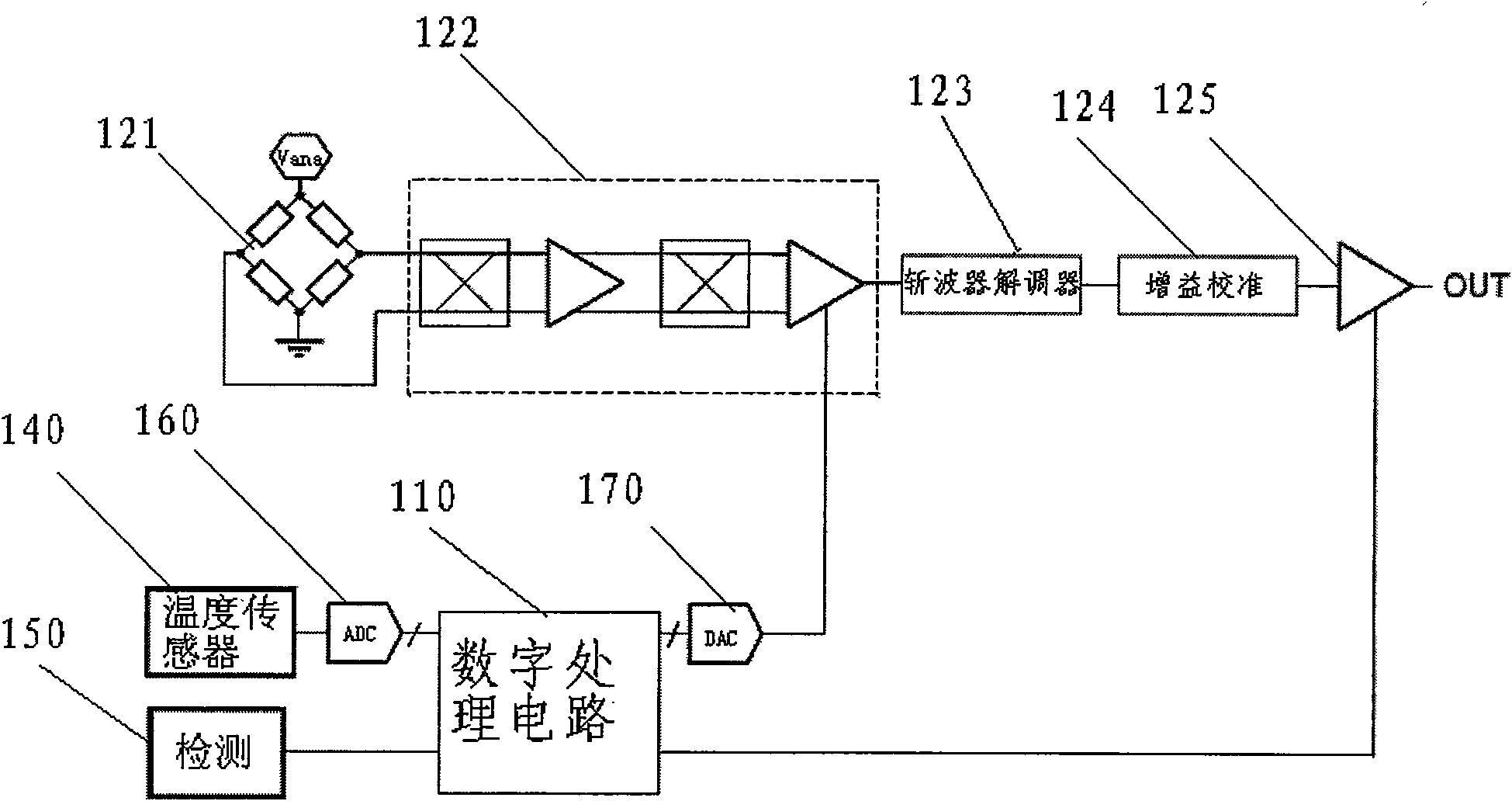

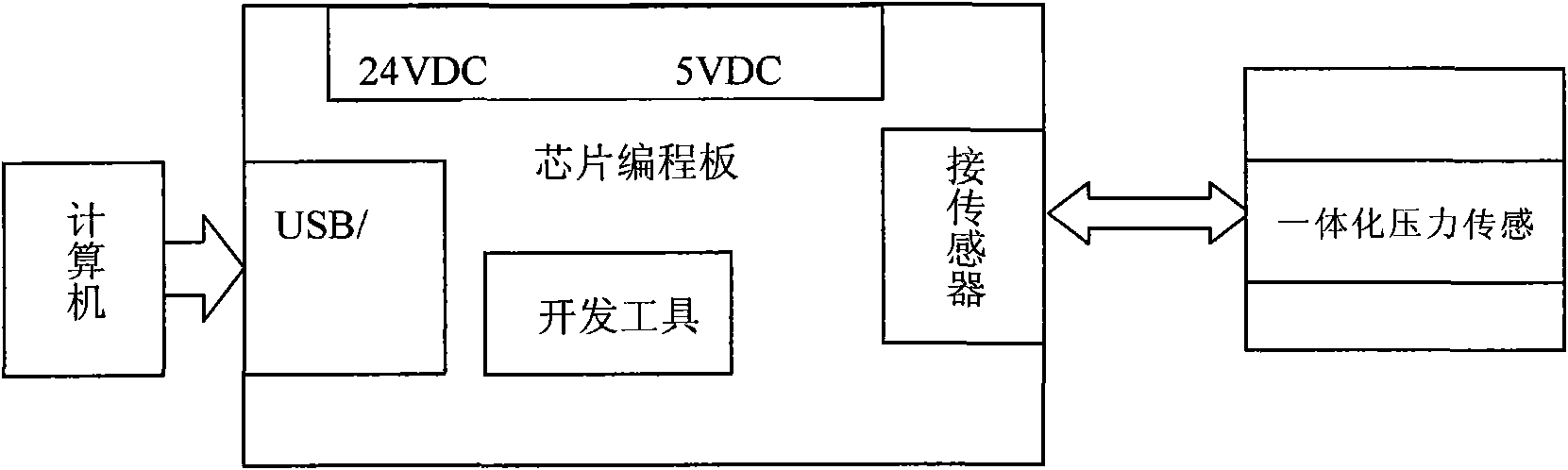

Programmable pressure sensor

InactiveCN101644612AReduce the impactImprove stabilityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsDigital signal processingAutomatic control

The invention discloses a programmable pressure sensor which comprises a chip and a chip programming plate for realizing chip programming, wherein the chip is provided with a programmable signal processing circuit and a pressure sensor, the input end of the signal processing circuit is connected with the output end of the pressure sensor, one end of the chip programming plate is connected with a USB communication port of a computer and a computer, and the other end of the chip programming plate is connected with the signal processing circuit of the chip. By adopting the process structure thatthe pressure sensor and a digital signal processing circuit are integrated by a MEMS technology, the programmable pressure sensor of the invention reduces the influence on the sensor signal from outside, improves stability and lowers the production cost, simultaneously realizes that a large-scale and friendly man-machine interface is convenient for a user to carry out standardization on the sensor, and has the advantages of simple structure, small volume, light weight and long service life and the like, and can be widely used in the automatic control environments of various industries relatingto water resources and hydropower, railway transportation, intelligent building, production automatic control, spaceflight, military project and other industries.

Owner:苏州中崟传感股份有限公司 +3

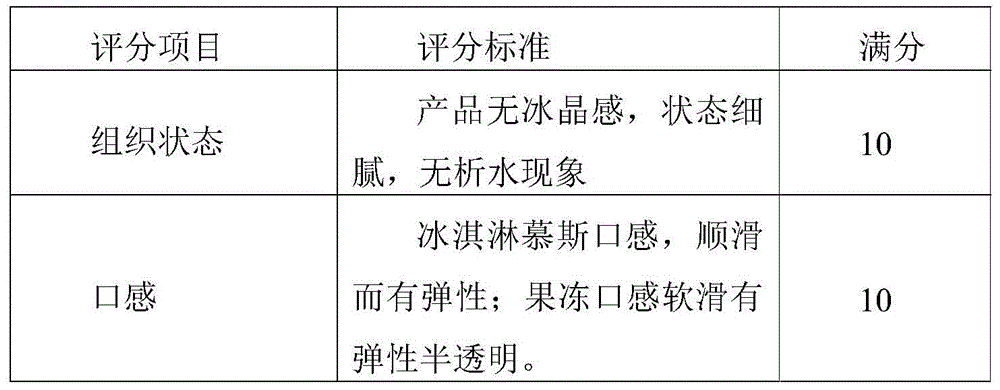

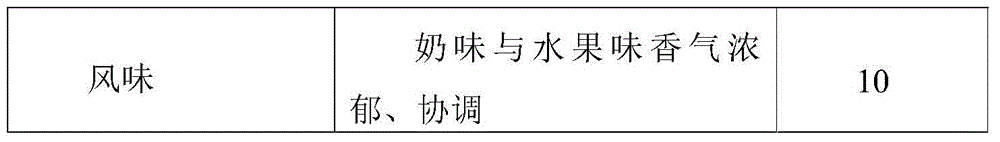

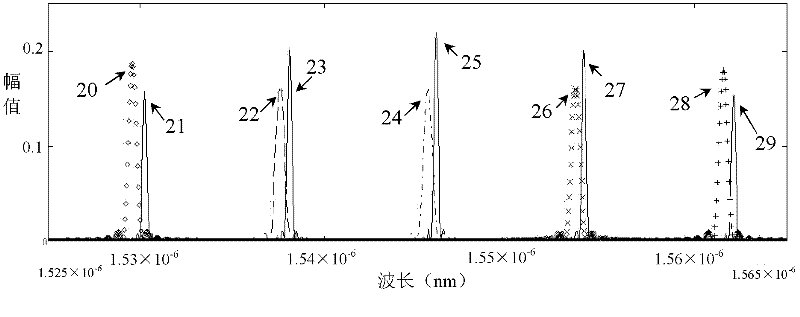

Thickening agent, frozen dessert and preparation method thereof

ActiveCN105707402AIncrease temperatureReduce lossesFood freezingFood ingredient as thickening agentMolten stateGellan gum

The present invention discloses a frozen dessert. A frozen dessert thickening agent includes gellan gum and carrageenan, optionally further comprises xanthan gum and locust bean gum, and optionally further comprises sodium alginate. The frozen dessert is flexible and unique in taste, has a taste of ice cream mousse when eaten at a freezing condition (-3 DEG C to -8 DEG C), and has a taste of jelly when eaten at a molten state (at room temperature).

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

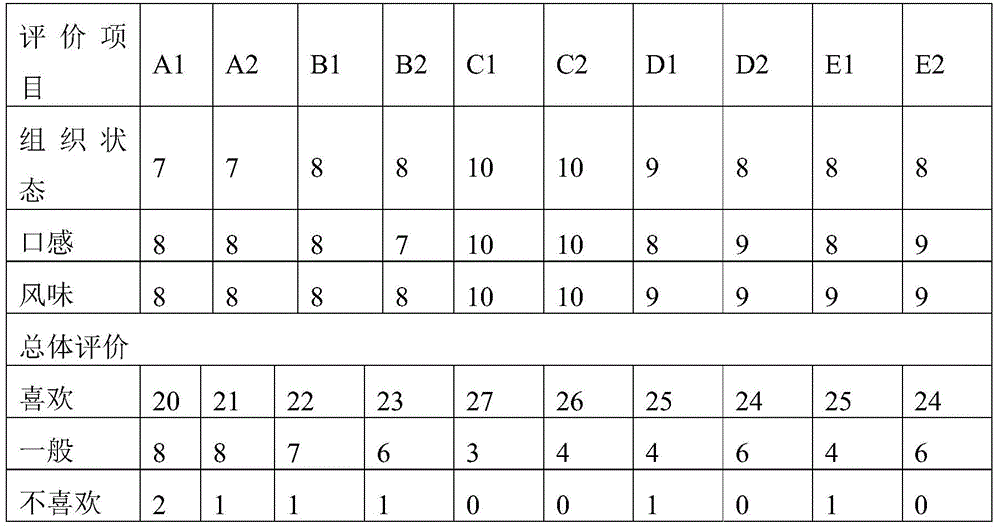

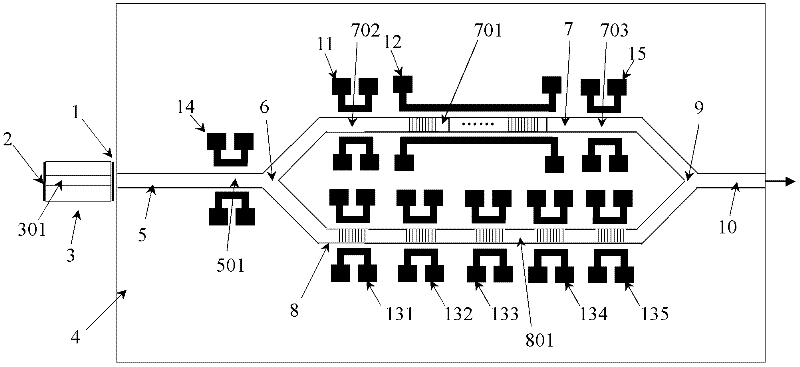

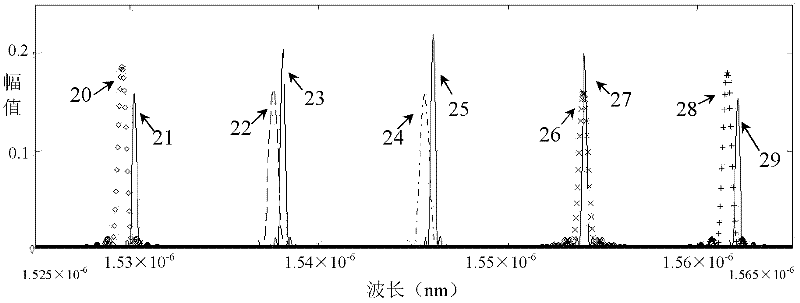

Wavelength-tunable laser based on March-Zehnder interferometer and reflecting grating

InactiveCN102646926AImplement step by stepImprove continuityLaser optical resonator constructionLaser output parameters controlGratingPhotonic Chip

The invention discloses a wavelength-tunable laser based on a March-Zehnder interferometer and a reflecting grating. The wavelength-tunable laser comprises an active gain chip and a passive photonic chip. A waveguide in the passive photonic chip comprises an input waveguide, a first coupler, a second coupler, a first waveguide arm, a second waveguide arm and an output waveguide. A laser generation phase regulating section is arranged on the input waveguide. A first reflecting mirror section is arranged on the first waveguide arm. A second reflecting mirror section is arranged on the second waveguide arm. A laser coupling phase regulating section is arranged between the first coupler and the first reflecting mirror section or the second reflecting mirror section. A laser power phase regulating section is arranged between the second coupler and the first reflecting mirror section or the second reflecting mirror section. Each section is provided with an electrode. By alternatively changing the waveguide refraction index of the first reflecting mirror section or the second reflecting mirror section and further regulating the laser generation phase regulating section, the incremental tuning of laser output wavelength is realized. The wavelength-tunable laser based on the March-Zehnder interferometer and the reflecting grating has the advantages that the output wavelength can be continuously or selectively changed and a very wide wavelength range can be covered.

Owner:SICHUAN MARS TECH

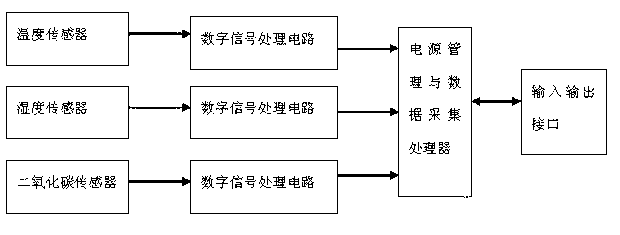

Integrated sensor

InactiveCN103278196AEasy CalibrationImprove stabilityMitigation of undesired influencesDigital signal processingGreenhouse

The invention relates to an integrated sensor which comprises a circuit board, temperature sensors, a humidity sensor, a carbon dioxide sensor and digital signal processing circuits are arranged on the circuit board, and the temperature sensors, the humidity sensor and the carbon dioxide sensor are connected with one digital signal processing circuit respectively to form an integral structure. Due to the integrated design technology, the temperature sensors, the humidity sensor, the carbon dioxide sensor and the digital signal processing circuits are designed to a module, nonlinear correction and temperature compensation of signals output by the sensors reduce influences of the outside world on the signals of the sensors, stability is improved, and production cost and installation and maintenance cost are reduced. The integrated sensor has the advantages of being simple in structure, small in size, light in weight, long in service life and the like. The integrated sensor can be widely applied to data collection of different types of agricultural greenhouse environments and intelligent agricultural production.

Owner:苏州中崟传感股份有限公司 +3

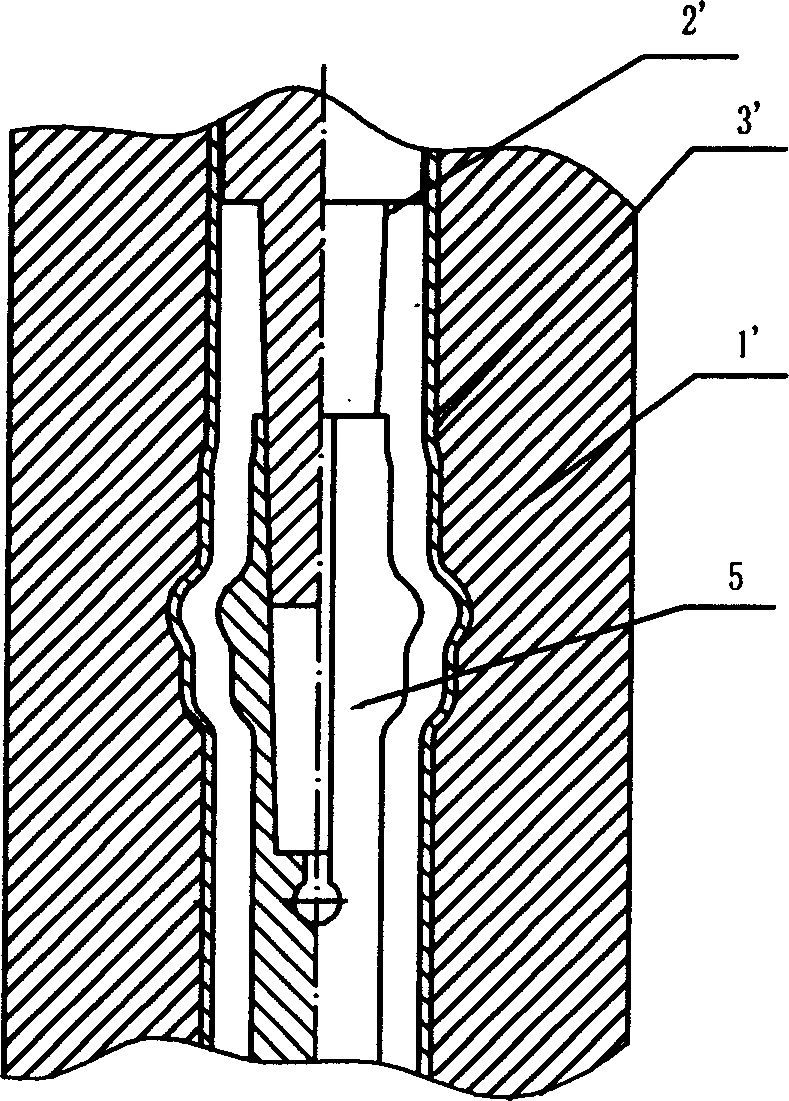

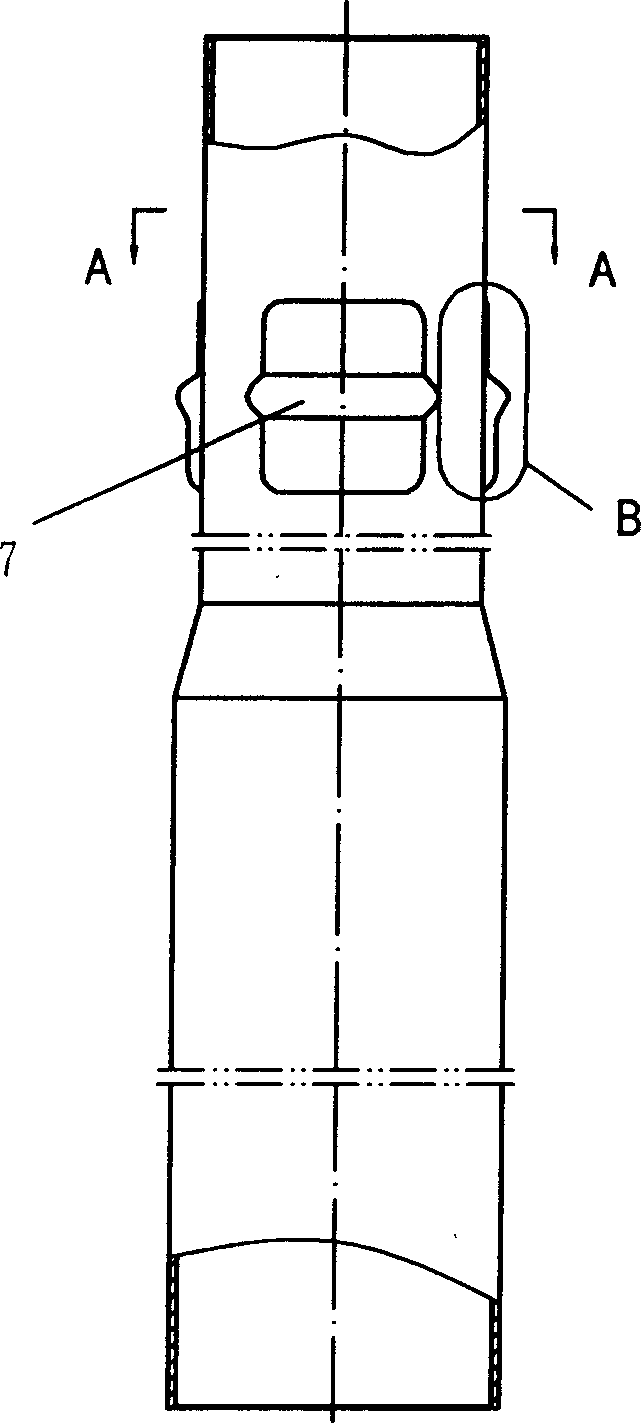

Three-boss flexible expanding die of vibration damper liquid-storage cylinder and expanding process

The invention discloses a three protruding platform bulge mould for processing the liquid tube of shock-reducer. The bulge mould includes a bulge die and a upper press die. The shape of bulge model cavity is matching with the shape of the three-projection-platform on the liquid storage tube. The characteristic is that there is bugle soft die in the bulge shape cavity and the bugle soft die is under the upper pressing die and it is made up of flexible material. The process of bulging shape is: put preparative workpiece straight into bulge die cavity, and put the soft die into the workpiece and then tighten the bulge die; The upper press soft die extrudes the workpiece to make workpiece full of bugle die and the workpoece is deformed along shape of bulge die. The invention has the characteristic of reasonable design, reduced production cost, advanced eligibility of product, simple process of machining, short machining cycle.

Owner:杭州福鼎交通器材有限公司

Storable low temperature cured powder coating and preparation method thereof

InactiveCN101709164AGood storage stabilityLong storage timePowdery paintsEpoxyLow temperature curing

The invention discloses a storable low temperature cured powder coating and a preparation method thereof. The powder coating mainly comprises 30 to 40 percent of epoxy resin, 19 to 29 percent of modified polyester resin, 0.5 to 1.2 percent of acrylic acid, 0.08 to 0.15 percent of phosphite ester, 20 to 38 percent of pigment and filler, 0.2 to 3 percent of W-187 low temperature curing agent, and 0.15 to 0.6 percent of curing accelerator. The method for preparing the powder coating comprises the following steps: mixing, heating, melting, extruding, tabletting, cooling, crushing, ACM-crushing and sieving all the raw materials to achieve the fineness of 180 meshes, and packing a finished product. The storage time of the powder coating is greatly prolonged, and the curing temperature is reduced; the powder coating has excellent performance, and is widely applied to surface coating and painting of hardware, electric appliances, home appliances, automobiles, furniture, mechanical equipment and the like; the energy is reduced and the using cost is reduced, so the production cost of enterprises is reduced; and the method ensures the large-scale production of the enterprises, and increases the economic benefits of the enterprises.

Owner:FUJIAN WANAN IND

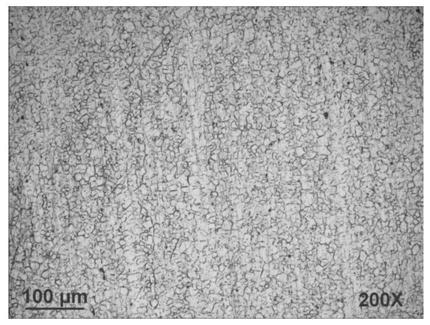

Manufacturing method of carbon steel wire with diameter of 0.05 mm

ActiveCN109940054AImprove plastic deformationInhibit expansionFurnace typesHeat treatment furnacesWork in processUltimate tensile strength

The invention discloses a manufacturing method of a carbon steel wire with a diameter of 0.05 mm. The manufacturing method comprises the steps of raw material selection-primary semi-finished steel wire cold drawing-primary semi-finished steel wire continuous heat treatment-secondary semi-finished steel wire cold drawing-secondary semi-finished steel wire continuous heat treatment-ternary semi-finished steel wire cold drawing-ternary semi-finished steel wire continuous heat treatment-finished steel wire drawing-finished steel wire inspection. The stress is eliminated to recover plasticity through the drawing combination mode and three times of heat treatment; through optimization of heat treatment parameters and specific drawing routes, the metal deformation under high compression ratio isadapted to, so that the smooth drawing process can be effectively guaranteed; through plastic deformation in the whole process, the diameter of the steel wire can be smoothly reduced; meanwhile, the tensile strength of a product is continuously improved, and the strength reaches above 2300 MPa to meet the requirements of appearance, surface quality, mechanical performances and toughness of the steel wire product; and meanwhile, the batch production is realized, and the product quality is guaranteed.

Owner:GUIZHOU WIRE ROPE

Punching die for car accelerator pedal bracket

The invention relates to a punching die for concentric holes on both sides of an automobile accelerator pedal bracket. An upper fixing plate is fixed under the upper template, an upper punch is fixed on the upper fixing plate, and a first post is slidably fitted on the upper fixing plate. An upper unloading plate is fixed at the lower end of a column, and an upper unloading reset rubber is arranged between the upper unloading plate and the upper fixing plate; a lower fixing plate is fixed on the lower template, and a lower punch is fixed on the lower fixing plate. The second post and the third post are slidingly fitted on the fixed plate, the upper end of the third post is fixed with a lower unloading plate, and a lower unloading reset rubber is arranged between the lower unloading plate and the lower fixing plate, and the second post The column passes through the lower unloading plate, the upper end of the second inserted column is fixed with a floating concave formwork, and a return spring is arranged between the floating concave formwork and the lower fixing plate. The invention adopts the floating concave template to process the concentric holes on both sides of the automobile accelerator pedal bracket, has stable punching force, prolongs the service life of the concave mold and reduces the cost of the mold.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

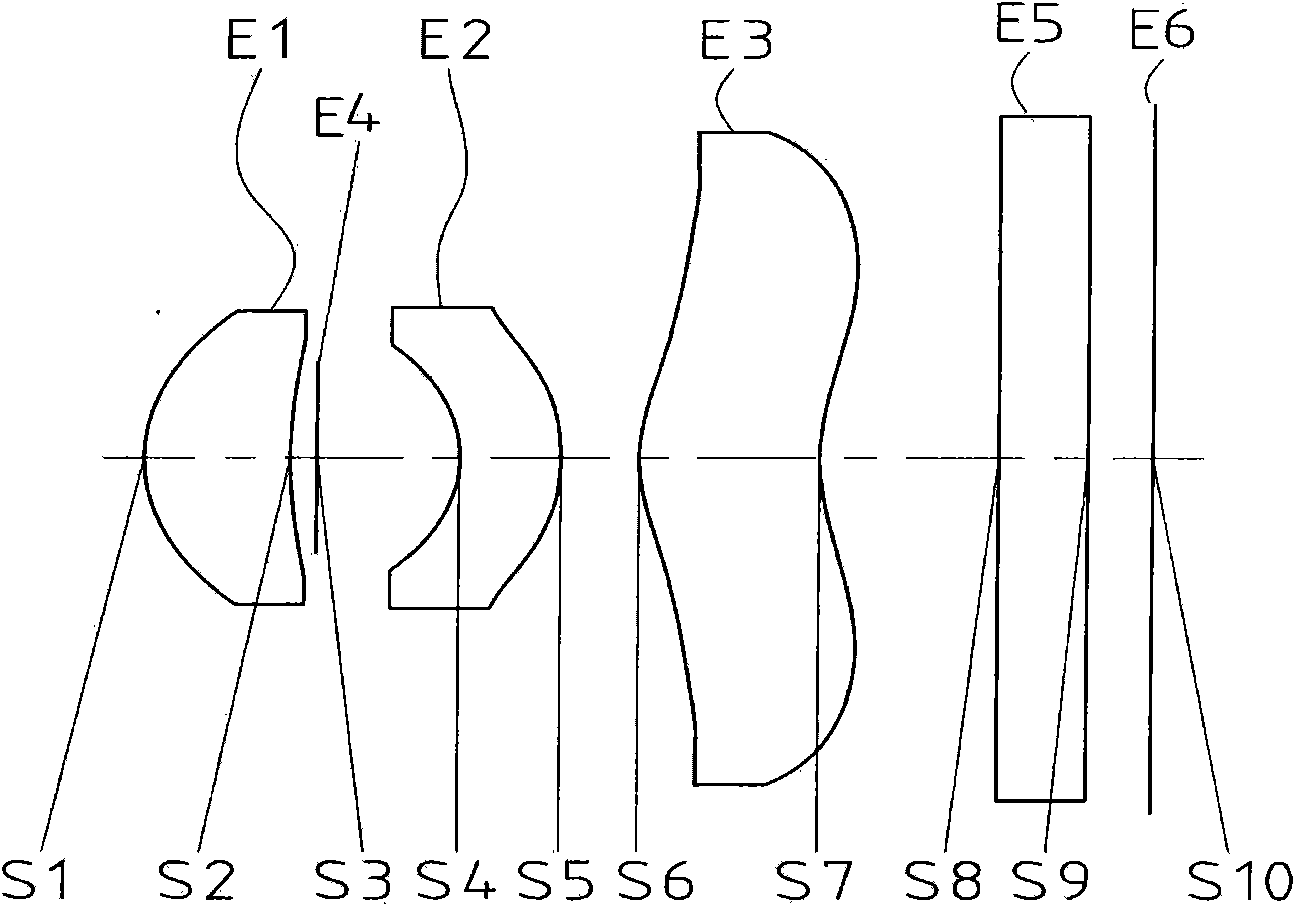

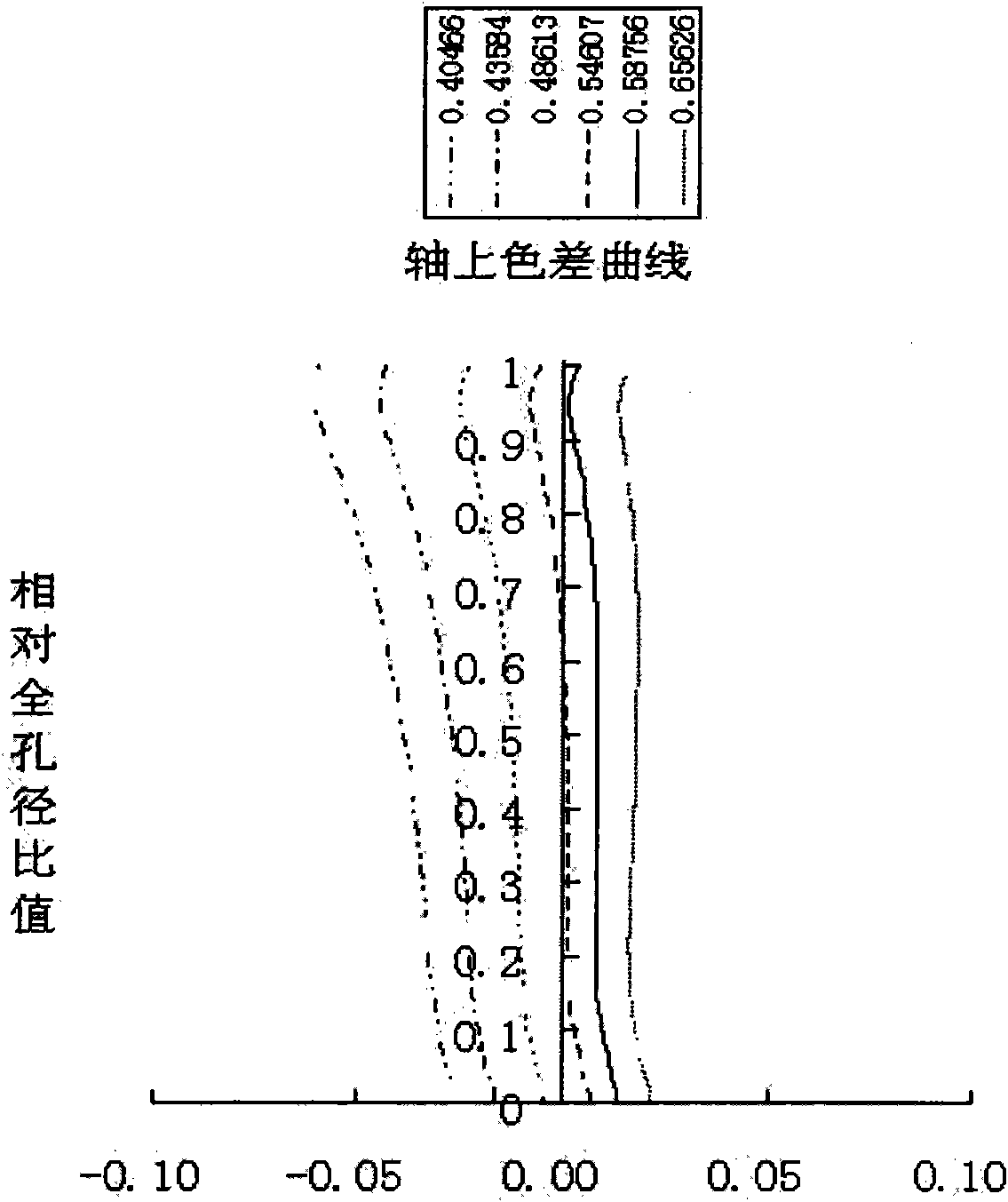

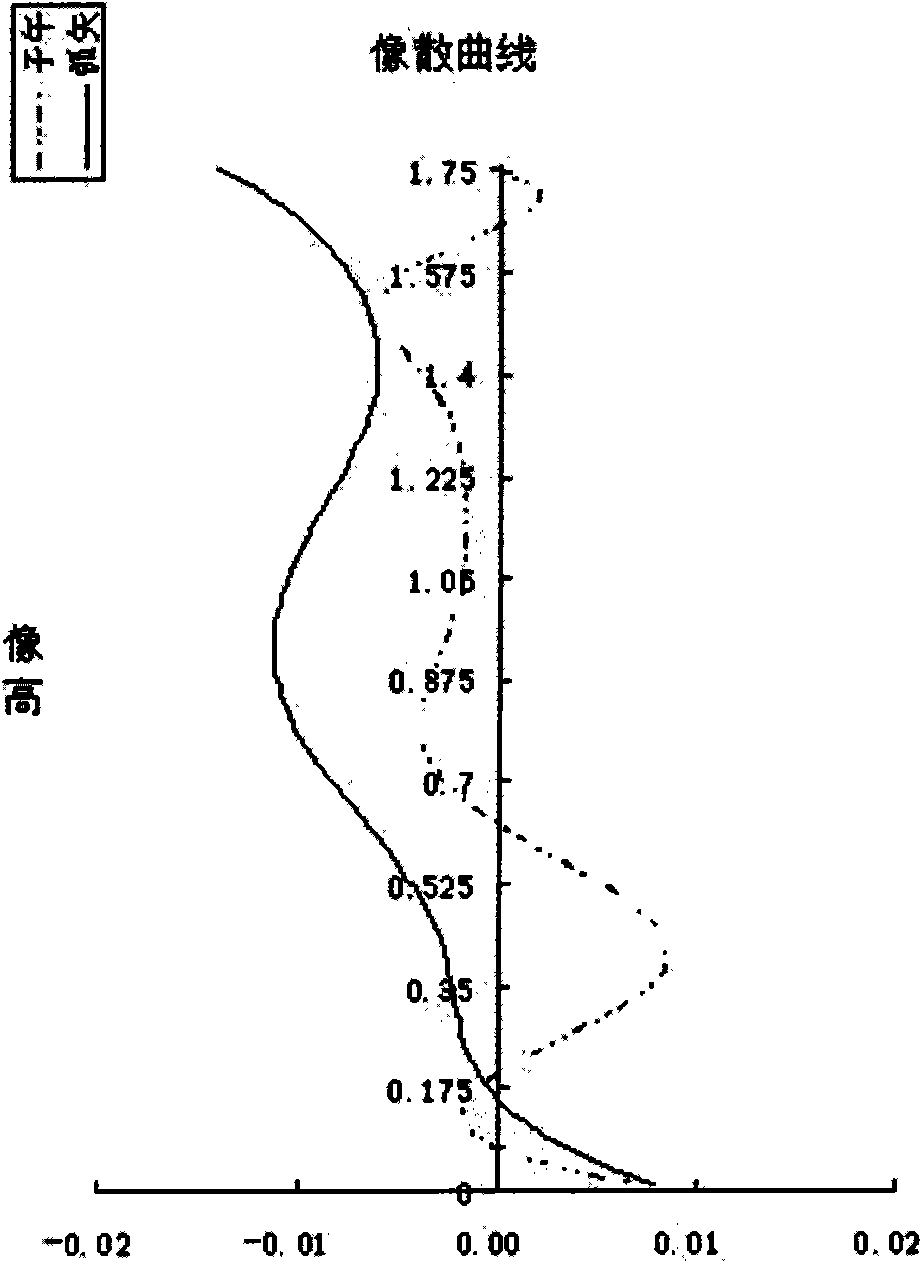

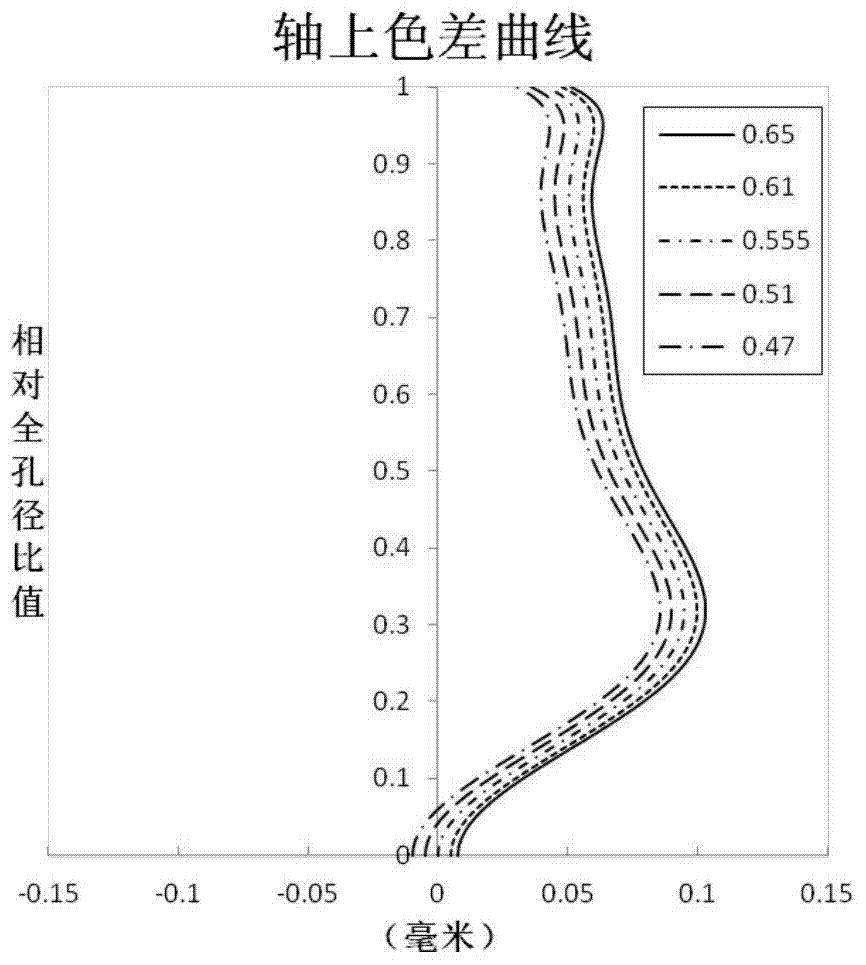

Micro pickup lens

InactiveCN101846793AImprove resolutionHigh image qualityOptical elementsCamera lensHigh volume manufacturing

The invention discloses a micro pickup lens, which comprises three non-spherical lenses and a diaphragm. The diopters of the lenses are positive, negative and positive respectively, wherein the lenses meet the following expressions that: VP1 is more than 50 and VP2 is less than 35; and in the expressions, the VP1 and the VP2 are abbe numbers of the first lens and the second lens respectively. Due to the adoption of a non-spherical lens combination mode, the micro pickup lens improves the resolution capability of the whole group of lenses and ensures that the lenses have good imaging quality; and meanwhile, due to the design of reasonable optical parameters, the lens has lower tolerance sensitivity, improves the tolerance, can realize stable quality in mass production, and achieves good technical effect.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

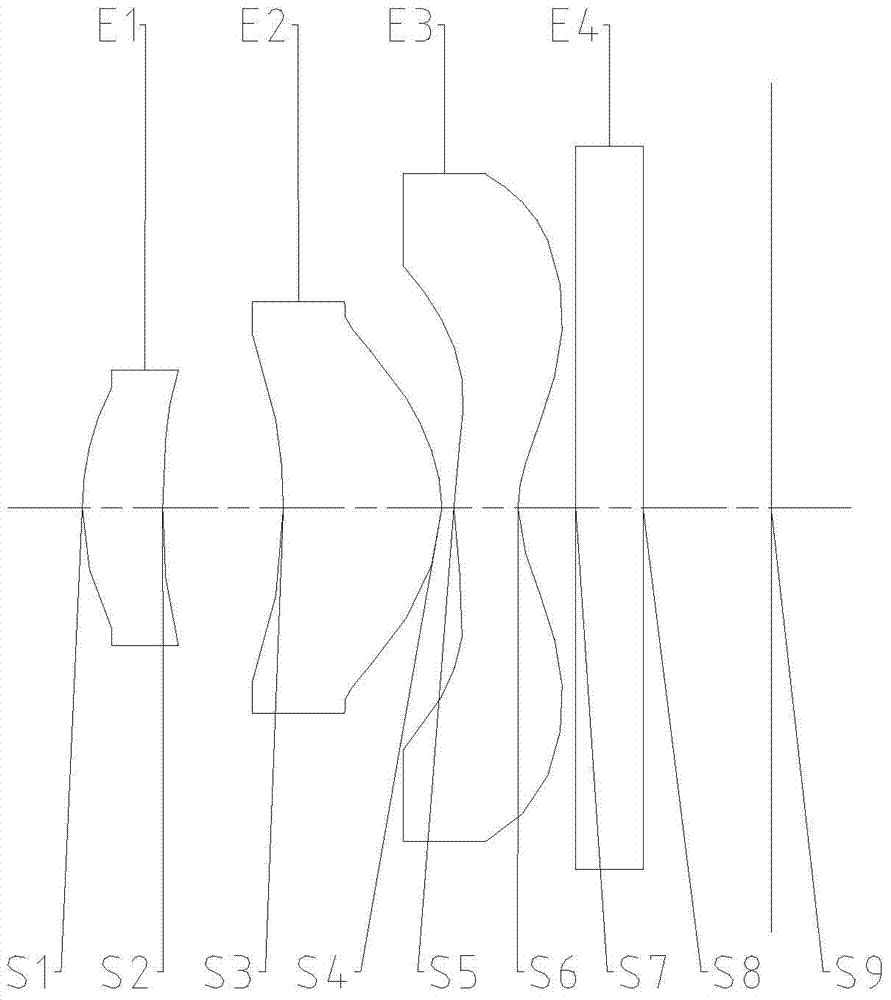

Miniature imaging lens

ActiveCN103941380AHigh image qualityReduce quality problemsOptical elementsCamera lensImaging quality

The invention provides a miniature imaging lens. The miniature imaging lens is characterized by comprising three lens bodies, wherein the first lens body is a positive focal power lens body; the second lens body is a positive focal power lens body with a concave object surface side and a convex image surface side; the third lens body is a negative focal power crescent lens body with a convex object surface side, and the image surface side of the third lens body is provided with at least one inflection point. The miniature imaging lens meets the inequations: 25<V2-V3<45, 1.5<f1 / f2<2.5 and 0.55<ImgH / TTL<0.75. According to the miniature imaging lens, the three aspheric lens bodies are adopted, the system length of the lens is effectively reduced, compatibility between field angles and image quality is fully considered, and excellent imaging quality of the lens on the condition of great visual angles is guaranteed; in addition, the miniature imaging lens is low in tolerance sensitivity through reasonable focal power distribution, ensures mass production of products and achieves a good technical effect.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

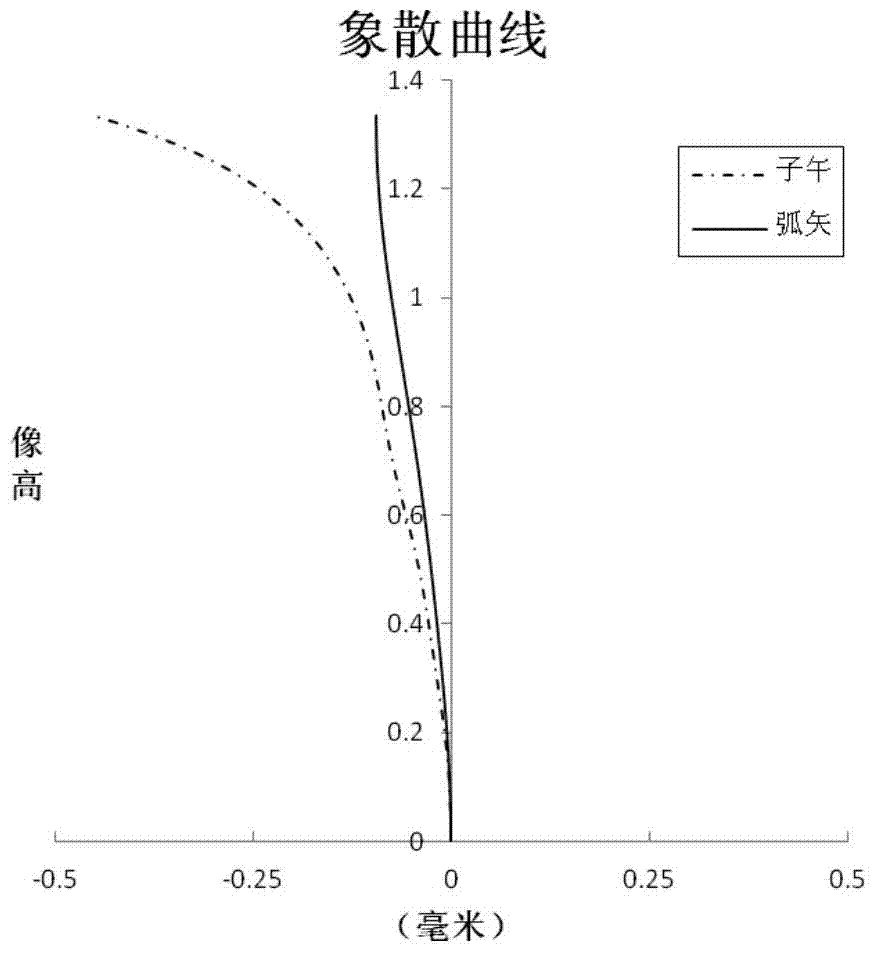

Server memory signal detection design method

InactiveCN104268042AGuaranteed mass productionAchieve reliabilityDetecting faulty computer hardwareMemory bankFile comparison

The invention discloses a server memory signal detection design method and relates to the field of computer communication. The server memory signal detection design method includes that distributing a memory bank without quality problem for a main board to be detected, wherein the memory bank has the maximum frequency and capacity capable of being supported by the main board; connecting a power supply chip of a memory power supply VDD on the main board with a CPU through an I2C bus; after starting the system, enabling the CPU to set the initial voltage value of the memory power supply VDD through the I2C bus; connecting each memory bank inserted in the main board with the CPU through an SMBUS bus, wherein after starting the system, the CPU servers as the main control end for memory signals, the CPU uses different data packet sending modes to enter signal connectivity test and inter-symbol interference test between signals, and the CPU uses a read-in data and read data comparison mode; regulating the power supply voltage and memory frequency of the memory, and continuously reading in and reading memory random data under the system so as to obtain the data reading and reading-in stability under voltage undulation and the data reading and reading-in stability under different memory frequencies.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

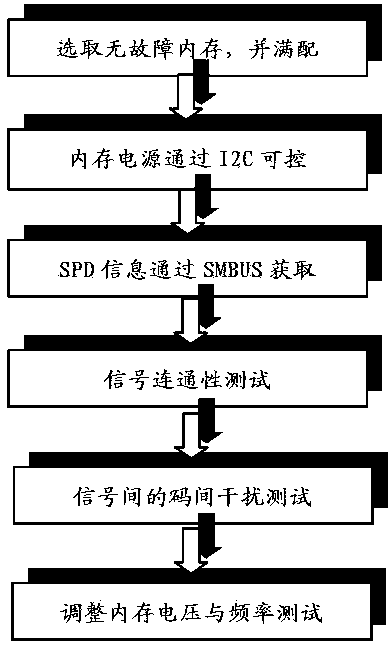

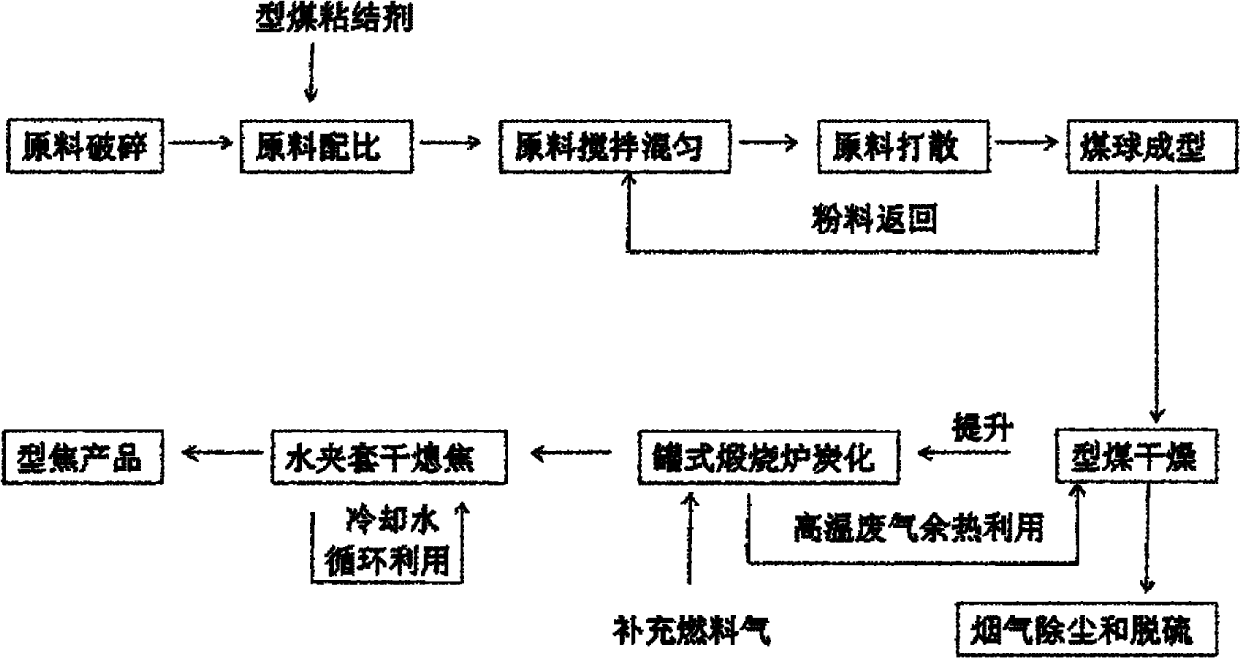

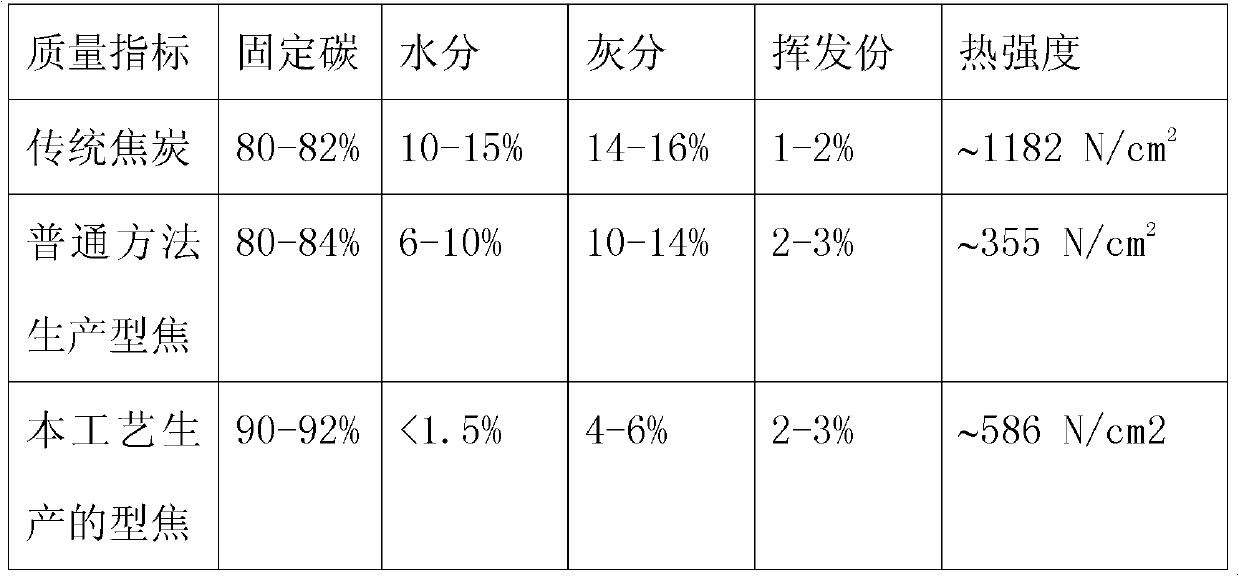

Production method of formed coke

ActiveCN102079982AIncrease the drying processHigh calorific valueCoke quenchingEnergy inputEngineeringWater jacket

The invention discloses a production method of formed coke. In the method, the working procedure of drying formed coke is added, thus the carbonization time can be shortened, the calorific value of dry distillation gas can be increased, and the large-scale production of formed coke can be ensured; an external combustion type carbonization furnace is used in the carbonization process, the carbonization equipment has long flue stroke, the residence time of flue gas is long and the thermal efficiency is high; the quantity of heat can be adjusted to ensure the carbonization quality of the formed coke; the integration of carbonization and dry quenching can be realized, energy-saving analysis is performed on the energy requirement and supply of the carbonization process and a specific energy-saving scheme is provided; a specific temperature control scheme of the carbonization process is provided particularly for the carbonization of formed coke prepared from calcium carbide; and a novel water jacket is used for dry quenching, thus the water content of the formed coke product can be reduced, the water pollution can be prevented, the energy can be saved and the strength of formed coke canbe increased. The formed coke produced by the method meets the quality requirements, the operating cost is low, the floor space is small, the investment is less, the technology and equipment are mature and the industrial and large-scale production can be realized.

Owner:YIBIN TIANYUAN GRP CO LTD

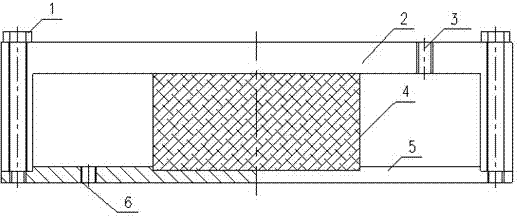

Bearing lubricating grease filling device and filling method

InactiveCN103032666AGuaranteed cleanlinessThe add process is cleanConduits/junctionsEngineeringNozzle

The invention discloses a bearing lubricating grease filling device and a filling method, and solves the technical problems that the quality control difficulty is high, the working intensity is large and the efficiency is low in the prior art. The bearing lubricating grease filling device is a box which can be used for placing a bearing in the middle part; a cover plate with an oil filling nozzle is arranged on the device; a base with an oil outlet is arranged at the lower part of the device; a core plate is arranged between the cover plate and the base; and a fastening screw for connecting the cover plate and the base is arranged on the part where two ends of the cover plate and the base extend out the core plate. The bearing lubricating grease filling method is used for filling by adopting the bearing lubricating grease filling device; and the method specifically comprises the following steps of: placing the bearing into the bearing lubricating grease filling device; covering the cover plate of the bearing lubricating grease filling device, and mounting the fastening screw; and filling oil. By the device and the method, the cleanness of the lubricating grease is guaranteed; the bearing is filled to be full; the time and labor are saved; the technical requirements are satisfied; the cost is low; and the mass production of products can be guaranteed.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

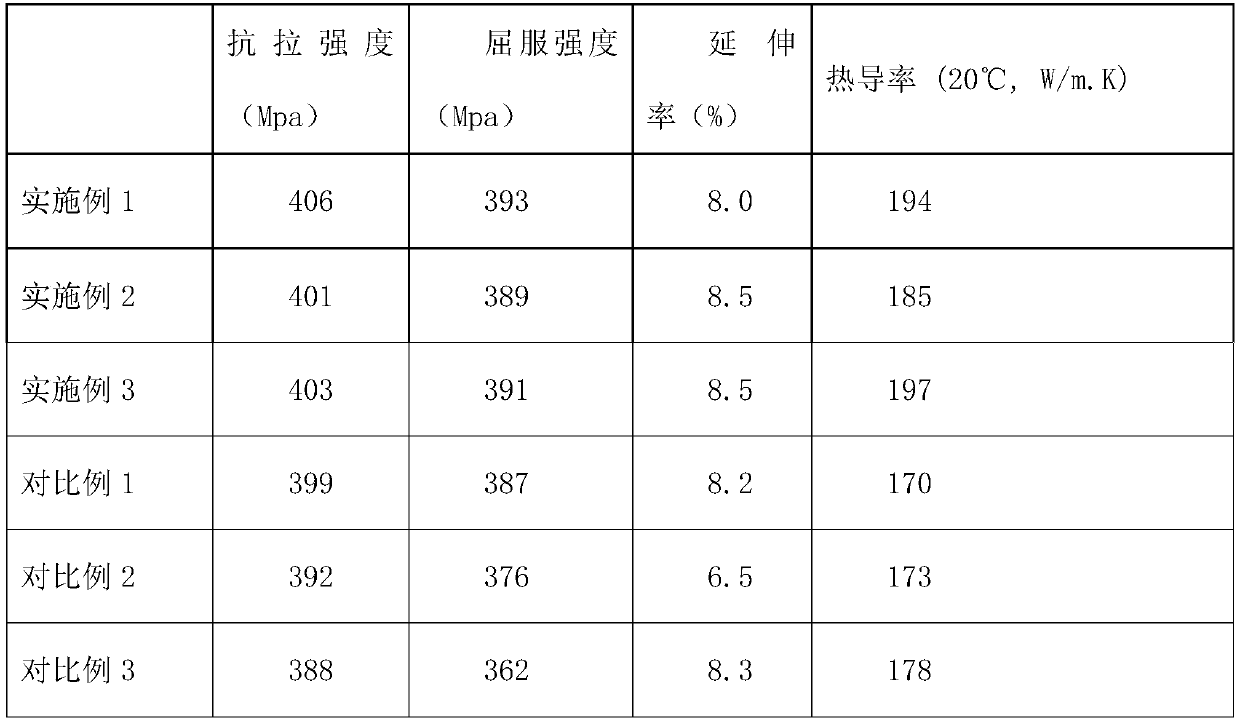

Aluminum alloy with high quality oxidation effect and high strength and preparation method thereof

The invention relates to the technical field of nonferrous metals, and discloses an aluminum alloy with a high quality oxidation effect and high strength. The aluminum alloy comprises the following components of, in percentage by mass, 0.50%-0.60% of Si, 2.2%-2.8% of Mg, less than or equal to 0.20% of Fe, 0.55%-0.75% of Cu, less than or equal to 0.01% of Cr, less than or equal to 0.30% of Mn, lessthan or equal to 0.03% of Ti, and the balance Al. The invention further discloses a preparation method of the aluminum alloy, the preparation method comprises the steps that an aluminum ingot is heated, and then a magnesium ingot and an intermediate alloy are added to obtain aluminum alloy melt I; a refining agent is added into the aluminum alloy melt I, and argon is introduced to refine the aluminum alloy melt I to obtain aluminum alloy melt II; the aluminum alloy melt II is put into a flow groove, and then a grain refiner is added to carry out on-line grain refining treatment to obtain aluminum alloy melt III; the aluminum alloy melt III is cast under the condition of 680 - 730 DEG C to obtain an aluminum alloy ingot A; segmented multi-stage homogenization treatment is carried out on the aluminum alloy ingot A to obtain an extruded aluminum alloy C; and artificial aging treatment is carried out on the aluminum alloy C. The aluminum alloy has the advantages that the yield strength islarge and reaches 400 MPa or above, the binding force of an oxidation film is strong, and the oxidation effect is in high quality.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

Novel sweet inhibitor co-crystal and preparation method thereof

The invention discloses a novel sweet inhibitor co-crystal and a preparation method thereof. The preparation method comprises the following steps: heating and concentrating a solution containing glucose under reduced pressure at 120-125 DEG C to obtain a supersaturated solution, and controlling the solid content at 80-85%; and adding a sweet inhibitor while stirring in a constant-temperature waterbath at 70-80 DEG C, adding the supersaturated solution, carrying out high-speed rotary crystallization, and performing centrifugal dewatering and drying to obtain the co-crystal containing the sweetinhibitor. The glucose-sweet inhibitor co-crystal is added into foods, so that the caking problem is remarkably improved, namely, uniform mixing is easier to form compared with a manner of directly adding the sweet inhibitor in a powder state, and the homogeneity, dispersity, solubility and emulsibility of the sweet inhibitor are improved.

Owner:GUANGZHOU WELBON BIOLOGICAL TECH

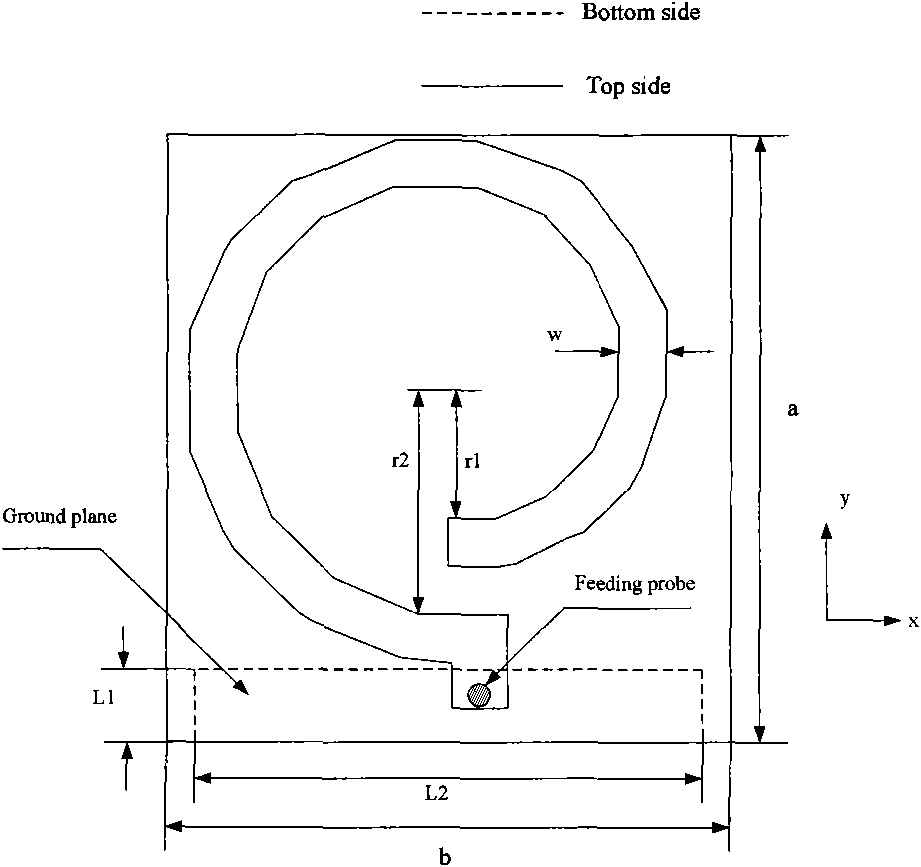

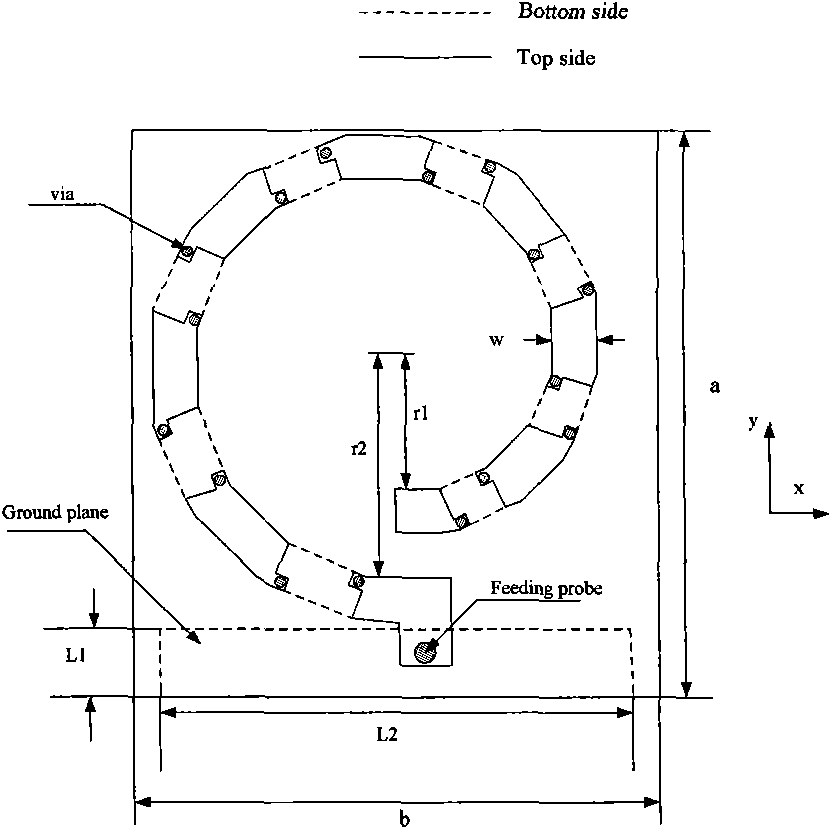

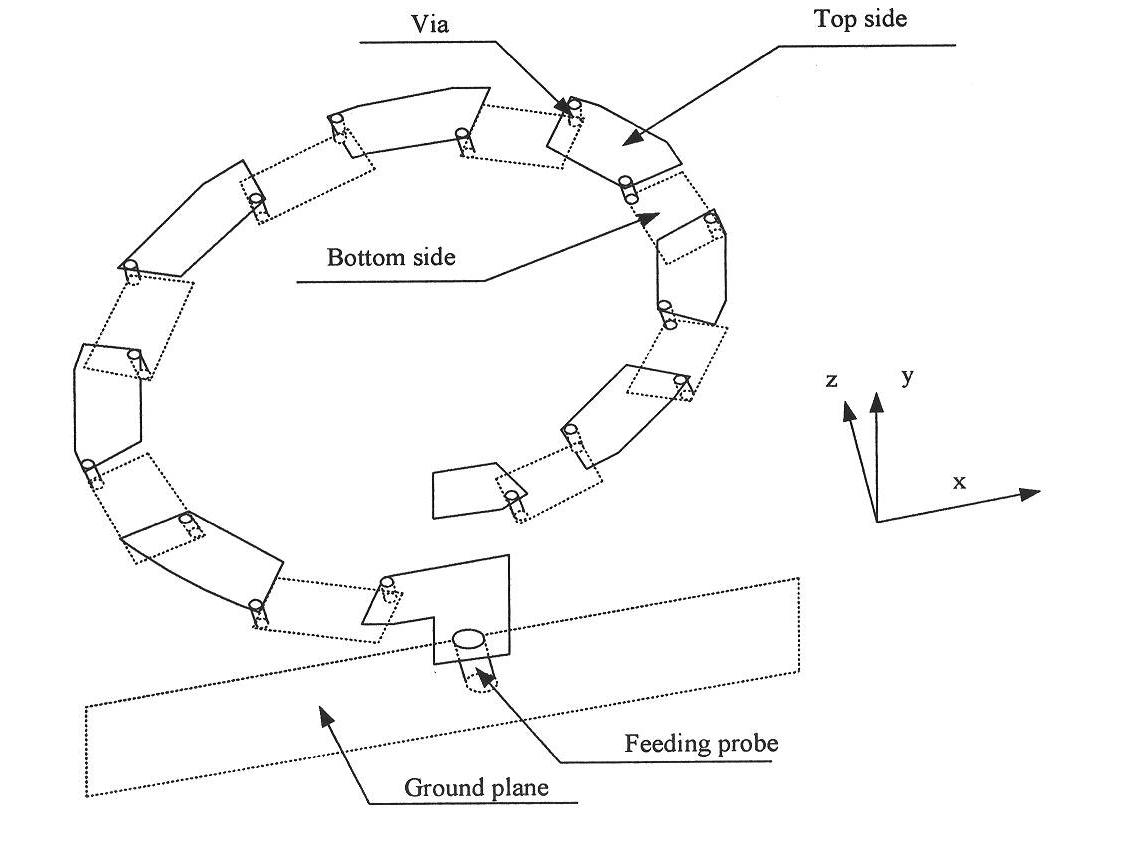

New method for miniaturization design of planar helical antenna

InactiveCN102035075ASmall sizePrecise processingRadiating elements structural formsAntenna earthingsReduced sizeHelical antenna

The invention discloses a new method for effectively reducing the size of a planar helical antenna, in particular to the design of an improved planar helical antenna. A general helical antenna patch is cut into a plurality of small segments, small metal segments are alternately arranged on an upper layer and a lower layer of a medium board and the patch segments of the upper layer and the lower layer are made to communicate through metal probes. By increasing the number of the metal probes, the antenna has reduced resonance frequency points and reduced size. The simple single-ring spiral patch antenna and corresponding four novel antenna structures designed by adopting the method are manufactured. Shown by simulation and the analysis of experimental results, the more segments are cut, the more probes are adopted, the greater the reduction degree of the antenna size is, and the size of the antenna is reduced by more than 80 percent. The antenna of the type has the advantages of small size, light weight and easy processing, is a novel low-cost miniaturized planar antenna and has wide application prospects.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Double-roller rolling strip steel machine side seal board surface recombination coating

InactiveCN101259517AStrong adhesionNot easy to fall offFoundry mouldsFoundry coresSodium BentoniteAlcohol

The invention discloses a surface compound dope of the side sealing plate of a double-roll cast-rolling strip mill. The compound dope consists of the following components: 50 to 70 percent of black lead, 5 to 15 percent of bentonite, 10 to 15 percent of high-alumina fly, 7 to 10 percent of colophony and 8 to 10 percent of alcohol according to mass proportion. The compound dope of the invention resists the high temperature of 1500 to 1700 DEG C, has the high adhesive attraction, is hard to fall off, improves the service life of the side sealing plate, reduces the maintaining cost, ensures the commercial production in batch, increases the economic benefits and has no effects on the components and the quality of strip steel.

Owner:戚建明

High-conductivity high-strength aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, and discloses a high-conductivity high-strength aluminum alloy. The high-conductivity high-strength aluminum alloy comprises, by mass,0.60%-0.80% of Si, 0.85%-0.95% of Mg, 0.04%-0.13% of Fe, 0.55%-0.75% of Cu, 0.04%-0.13% of Mn, less than or equal to 0.0050% of Cr, 0.01%-0.04% of B, 0.0010%-0.0080% of Ti, and the balance Al. The invention further discloses a preparation of the high-conductivity high-strength aluminum alloy. The preparation method comprises the following steps that 1, materials are prepared according to the masspercentage; 2, an aluminum ingot is heated to 730 DEG C-780 DEG C for melting, the magnesium ingot and an intermediate alloy are added to obtain a first aluminum alloy liquid; 3, a refining agent is added, and argon is introduced to refine to obtain a second aluminum alloy liquid; 4, the second aluminum alloy liquid is put into a flow groove so as to obtain a third aluminum alloy liquid; 5, casting is performed to obtain an aluminum alloy ingot A; 6, homogenization treatment is performed to obtain an aluminum alloy ingot B; 7, the aluminum alloy ingot B is heated to 500 DEG C-550 DEG C for extrusion forming to obtain an extruded aluminum alloy C; and 8, artificial aging treatment is performed. According to the high-conductivity high-strength aluminum alloy, the yield strength of the aluminum alloy is further increased, the yield strength is 380 MPa or above, and the conductivity is 180 (20 DEG C, w / m.K), and the oxidation effect is high.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

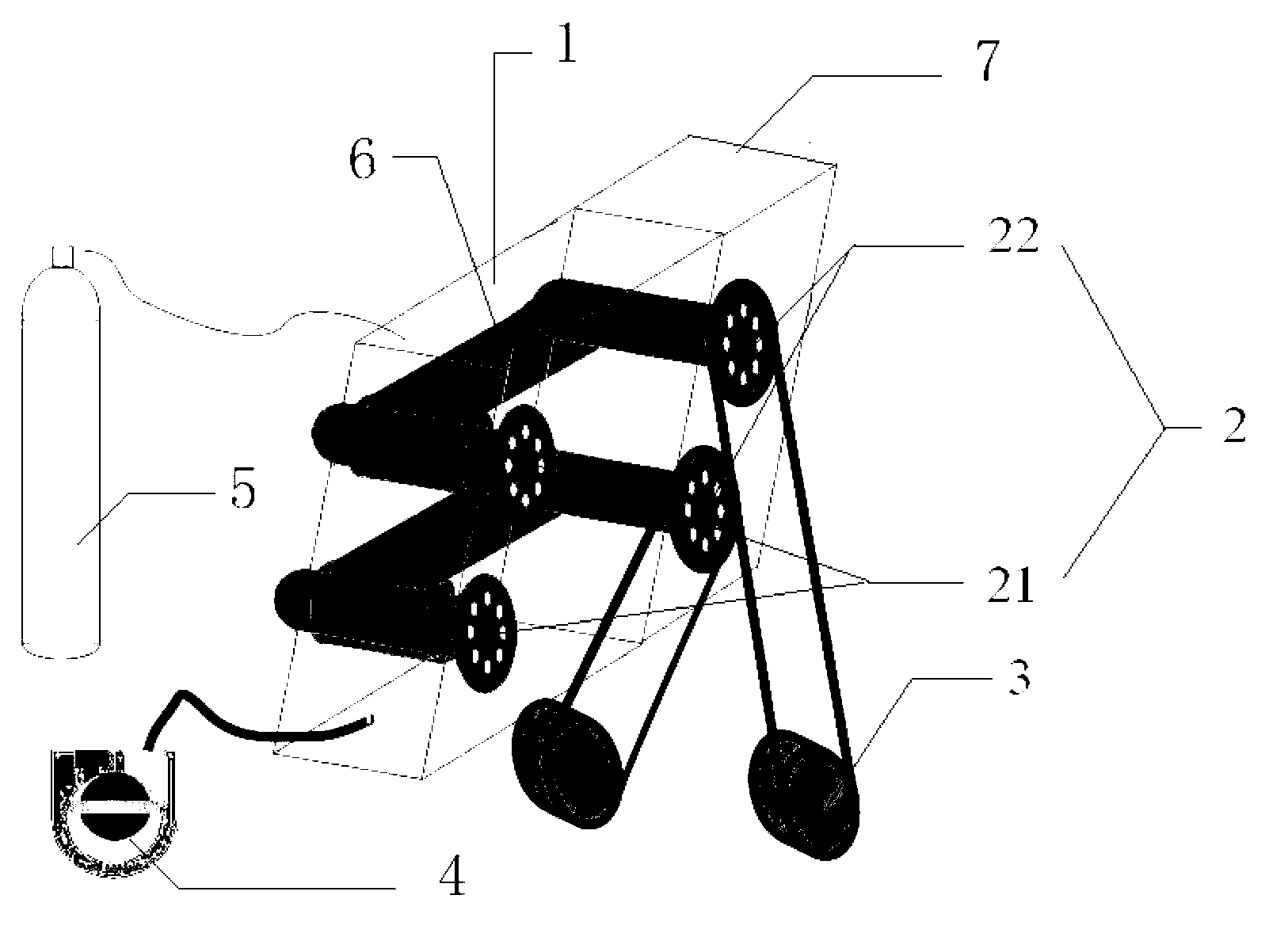

Preparation method and device for graphene

The invention provides a preparation device for graphene. The preparation device for the graphene comprises an air supply system, a vacuum chamber, more than two groups of drum sets, driving systems, growth substances and an annealing system, wherein the vacuum chamber is connected with the air supply system; the more than two groups of drum sets are arranged in the vacuum chamber, and each group of drum sets at least comprises a first drum and a second drum which rotate in the same direction; the driving systems are used for respectively driving the second drums to rotate; the growth substances are respectively formed on the drum sets; one ends of the growth substances are wound on the first drums while the other ends of the growth substances are arranged on the second drums in a lapping manner; the growth substances can move along with the rotating of the second drums; and the annealing system is connected with an outlet of the vacuum chamber. By adopting the preparation method and the preparation device for the graphene, provided by the invention, the massive and continuous production of the graphene can be realized, and therefore, the production efficiency and output of the graphene can be improved, and the industrialization development of the graphene is further promoted.

Owner:CHONGQING GRAPHENE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com