Bearing lubricating grease filling device and filling method

A bearing lubricating and filling device technology, applied to lubricating parts, engine lubrication, engine components, etc., can solve the problems of low efficiency, high work intensity, and high difficulty in quality control, and achieve process requirements, convenient installation, and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

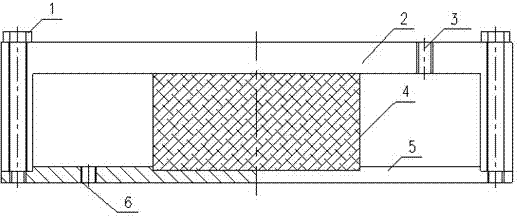

[0017] Such as figure 1 As shown, the bearing grease filling device is a box in which the bearing can be placed in the middle, on which is a cover plate 2 with a grease nozzle 3, and a base 5 with an oil outlet 6 below, the cover plate 2 and the base Between 5 is the core plate 4, and the two ends of the cover plate 2 and the base 5 protrude from the core plate 4, and the fastening screw 1 connecting the cover plate 2 and the base 5 is installed. The grease nozzle 3 can be connected with the grease nozzle of the grease filling tool. The bearing grease filling device can be designed into different specifications according to different bearings.

[0018] Such as figure 2 Shown, described bearing lubricating grease filling method comprises the following steps:

[0019] Putting in the bearing: Disassemble the fastening screw 1 of the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com