Aluminum alloy with high quality oxidation effect and high strength and preparation method thereof

An aluminum alloy and aluminum alloy ingot casting technology is applied in the field of high-quality oxidation effect and high-strength aluminum alloy and its preparation, and can solve the problems of streaks, low aluminum alloy strength, and insufficient aluminum alloy strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

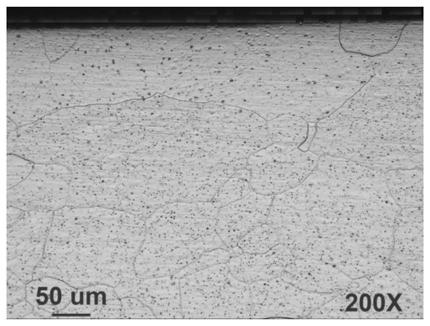

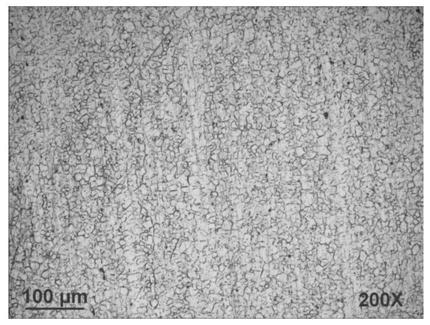

Image

Examples

Embodiment 1

[0051] The composition of aluminum alloy: Si is 0.55%, Mg is 2.7%, Fe is 0.12%, Cu is 0.65%, Mn is 0.12%, Cr is 0.0080%, Ti is 0.01%, other single impurity elements are ≤0.05, and the balance is Al.

[0052] A method for manufacturing a high-quality oxidation effect high-strength aluminum alloy, comprising the following steps:

[0053] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0054] (2) Heating the aluminum ingot to 760°C for melting, then adding magnesium ingot and intermediate alloy, stirring and melting to obtain aluminum alloy liquid I;

[0055] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0056] (4) putting the aluminum alloy liquid II into the launder, and then adding a grain refiner for on-line grain refinement treatment to ...

Embodiment 2

[0062] The composition of aluminum alloy: Si is 0.6%, Mg is 2.5%, Fe is 0.15%, Cu is 0.55%, Mn is 0.08%, Cr is 0.0080%, Ti is 0.01%, other single impurity elements are ≤0.05, and the balance is Al.

[0063] A method for manufacturing a high-quality oxidation effect high-strength aluminum alloy, comprising the following steps:

[0064] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0065] (2) Heating the aluminum ingot to 760°C for melting, then adding magnesium ingot and intermediate alloy, stirring and melting to obtain aluminum alloy liquid I;

[0066] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0067] (4) putting the aluminum alloy liquid II into the launder, and then adding a grain refiner for on-line grain refinement treatment to o...

Embodiment 3

[0073] The composition of aluminum alloy: Si is 0.5%, Mg is 2.5%, Fe is 0.18%, Cu is 0.75%, Mn is 0.18%, Cr is 0.0080%, Ti is 0.0050%, other single impurity elements are ≤0.05, and the balance is Al.

[0074] A method for manufacturing a high-quality oxidation effect high-strength aluminum alloy, comprising the following steps:

[0075] (1) Prepare materials according to the above mass percentages, wherein aluminum and magnesium adopt aluminum ingots and magnesium ingots;

[0076] (2) Heating the aluminum ingot to 760°C for melting, then adding magnesium ingot and intermediate alloy, stirring and melting to obtain aluminum alloy liquid I;

[0077] (3) Adding a refining agent to the aluminum alloy liquid I, and then introducing argon gas to refine the aluminum alloy liquid, removing slag, and standing to obtain aluminum alloy liquid II;

[0078] (4) putting the aluminum alloy liquid II into the launder, and then adding a grain refiner for on-line grain refinement treatment to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com