Energy-saving high-elongation soft aluminum alloy wire and preparation method thereof

An aluminum alloy wire and aluminum alloy technology, applied in the field of aluminum alloy wires, can solve the problems of low conductivity, inability to be used as cable conductors and electromagnetic wires, poor extensibility, etc., and achieve the effects of uniform composition, good crystalline state and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

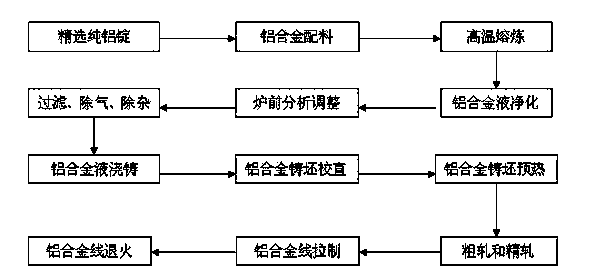

Method used

Image

Examples

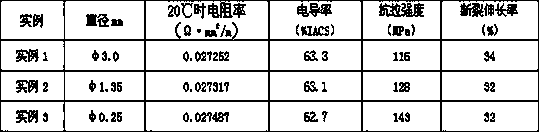

Embodiment 1

[0026] (1) Select the aluminum ingot for remelting with the grade of Al99.70, and the impurity content is required to be Si≤0.08%, Mn+Ti+V+Cr≤0.03%, and each other impurity≤0.03%.

[0027] (2) Ingredients are prepared according to the weight percentage of each component, among which Cu, Zr, Fe, Mg, Y, and Sc are respectively selected from aluminum-copper master alloy, aluminum-zirconium master alloy, aluminum-iron master alloy, aluminum-magnesium master alloy Master alloys, aluminum-yttrium master alloys, aluminum-scandium master alloys.

[0028] (3) Weigh the selected Al99.70 aluminum ingots, put them into the shaft furnace for high-temperature melting, and the molten aluminum flows into the holding furnace, and then add aluminum-iron intermediate alloy, aluminum-copper The master alloy, aluminum-zirconium master alloy, aluminum-magnesium master alloy, aluminum-yttrium master alloy and aluminum-scandium master alloy are alloyed, and the controlled temperature of the aluminum ...

Embodiment 2

[0039] (1) Select the aluminum ingot for remelting with the grade of Al99.70, and the impurity content is required to be Si≤0.08%, Mn+Ti+V+Cr≤0.03%, and each other impurity≤0.03%.

[0040] (2) Ingredients are prepared according to the weight percentage of each component, among which Cu, Zr, Fe, Mg, Y, and Sc are respectively selected from aluminum-copper master alloy, aluminum-zirconium master alloy, aluminum-iron master alloy, aluminum-magnesium master alloy Master alloys, aluminum-yttrium master alloys, aluminum-scandium master alloys.

[0041] (3) Weigh the selected Al99.70 aluminum ingots, put them into the shaft furnace for high-temperature melting, and the molten aluminum flows into the holding furnace, and then add aluminum-iron intermediate alloy, aluminum-copper The master alloy, aluminum-zirconium master alloy, aluminum-magnesium master alloy, aluminum-yttrium master alloy, and aluminum-scandium master alloy are alloyed, and the temperature of the aluminum liquid is ...

Embodiment 3

[0052] (1) Select the aluminum ingot for remelting with the grade of Al99.70, and the impurity content is required to be Si≤0.08%, Mn+Ti+V+Cr≤0.03%, and each other impurity≤0.03%.

[0053] (2) Ingredients are prepared according to the weight percentage of each component, among which Cu, Zr, Fe, Mg, Y, and Sc are respectively selected from aluminum-copper master alloy, aluminum-zirconium master alloy, aluminum-iron master alloy, aluminum-magnesium master alloy Master alloys, aluminum-yttrium master alloys, aluminum-scandium master alloys.

[0054] (3) Weigh the selected Al99.70 aluminum ingots, put them into the shaft furnace for high-temperature melting, and the molten aluminum flows into the holding furnace, and then add aluminum-iron intermediate alloy, aluminum-copper The master alloy, aluminum-zirconium master alloy, aluminum-magnesium master alloy, aluminum-yttrium master alloy and aluminum-scandium master alloy are alloyed, and the controlled temperature of the aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com