Preparation method and device for graphene

A preparation device and graphene technology, applied in the graphene field, can solve problems such as hindering industrialization development, limiting preparation efficiency and output, and achieve the effects of ensuring mass production, improving production efficiency, and increasing production efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

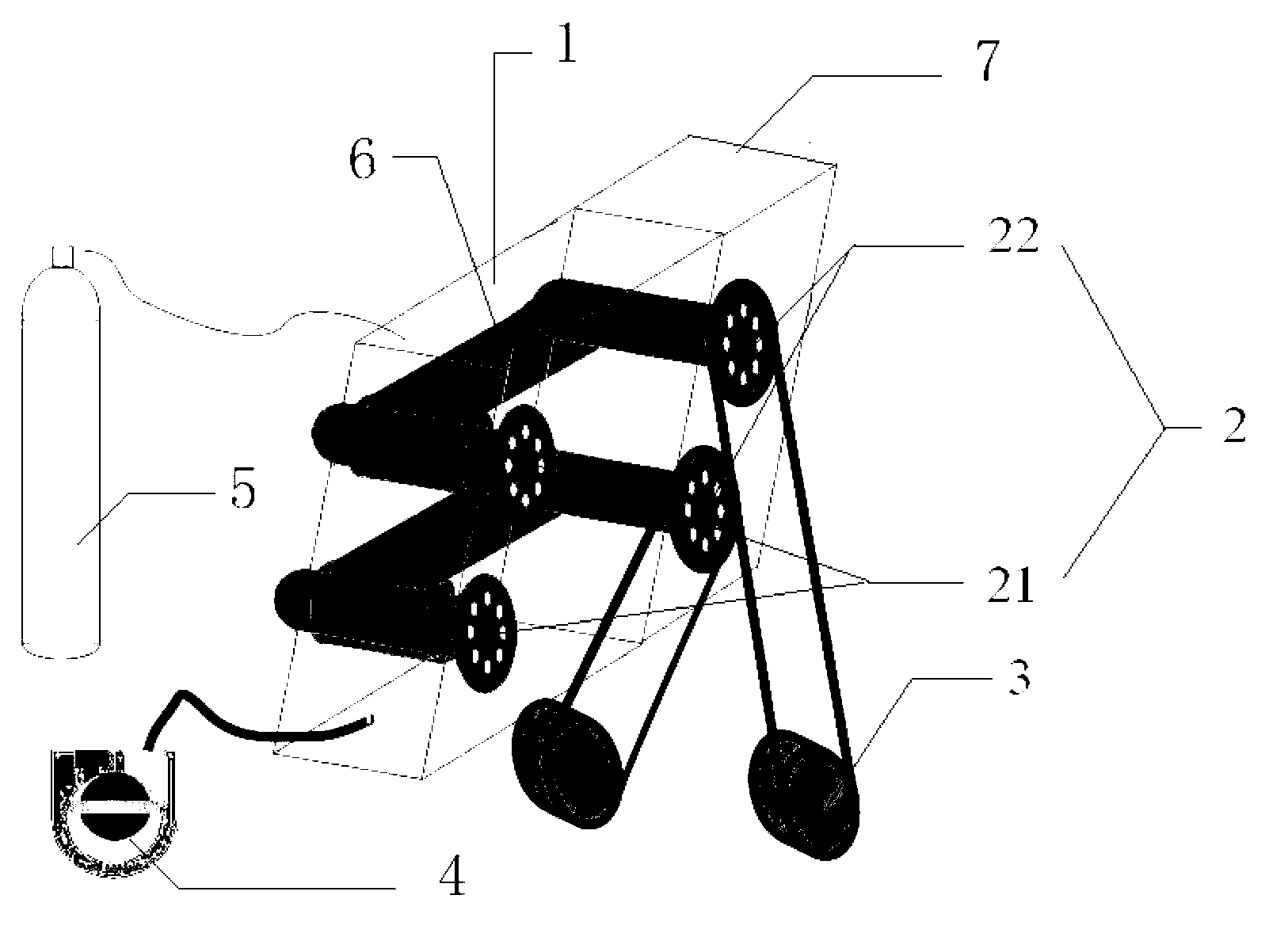

[0027] The invention provides a graphene preparation device, comprising:

[0028] air supply system;

[0029] a vacuum chamber connected to the gas supply system;

[0030] More than two sets of rollers arranged in the vacuum chamber, the rollers at least include a first roller and a second roller in the same direction of rotation, and the first roller and the second roller rotate around their respective axes ;

[0031] a driving device for respectively driving the rotation of the second roller;

[0032] The growth substrates respectively arranged on the roller group, one end of the growth substrate is wound on the first roller, and the other end is placed on the second roller, and the growth substrate can follow the movement of the second roller. turn and move;

[0033] An annealing system connected to the outlet of the vacuum chamber.

[0034] see figure 1 , figure 1 Schematic diagram of the structure of the graphene preparation device provided by the present invention...

Embodiment 1

[0061] Select a copper foil with a purity of 95%, a width of 10 cm, and a length of 100 m as the growth substrate, put the above copper foil into a container filled with acetone, ultrasonically clean it 3 times, each time for 3 minutes, and then put the copper foil into a container filled with acetone. In a container of isopropanol, ultrasonically clean it twice, each time for 3 minutes, then put the copper foil into a container filled with deionized water, and ultrasonically clean it twice, each time for 3 minutes. Then take out the copper foil, dry it with nitrogen, put the copper foil in a blast drying oven, and bake it at 70° C. for 30 minutes. Put two sets of rollers in a vacuum chamber with a length of 10m, a width of 50cm, and a height of 1m. One end of the copper foil is placed on the roller connected to the drive system, and the rest is wound on the other roller. The copper foil is in the vacuum chamber.

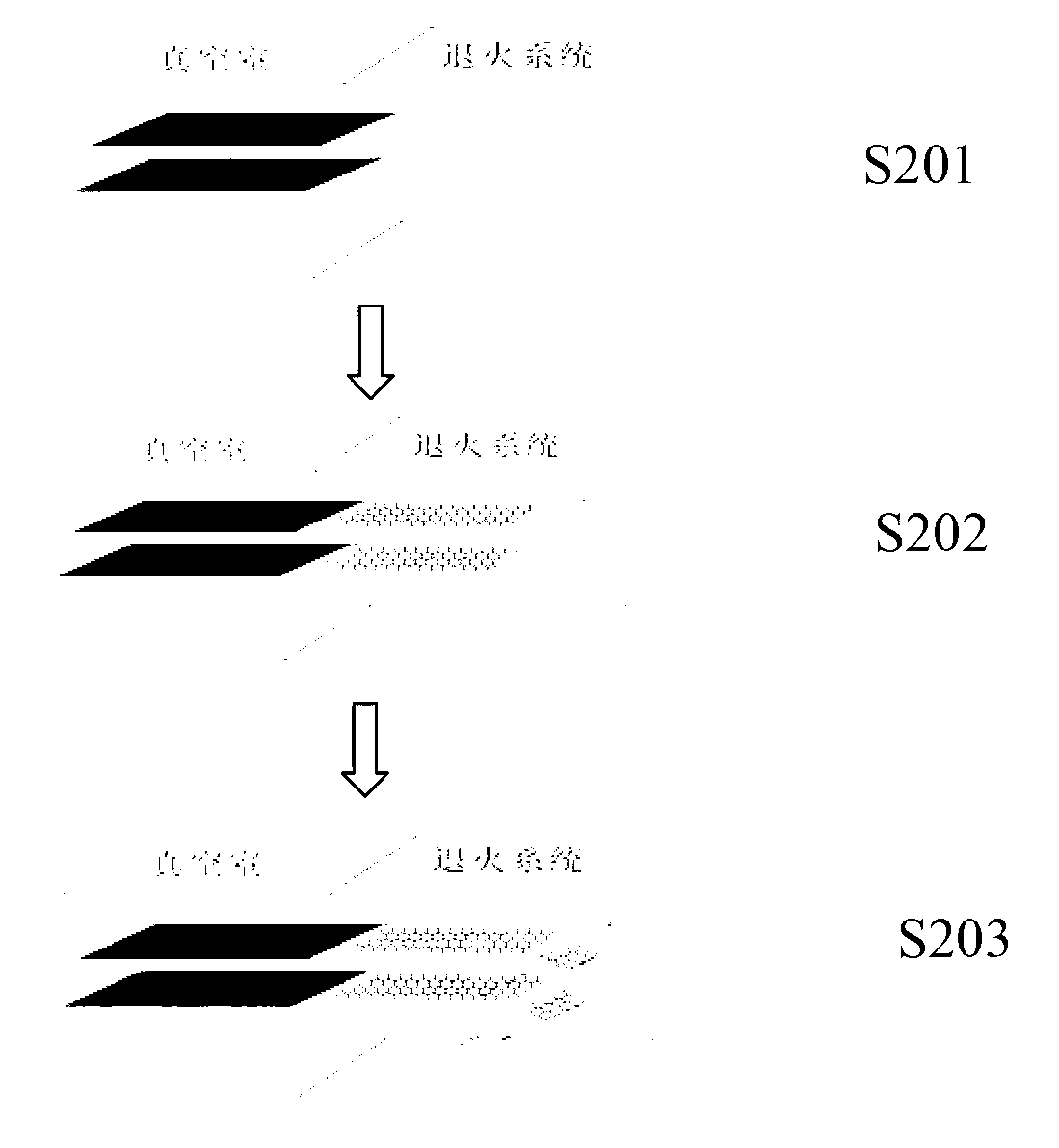

[0062] After the vacuum chamber is evacuated to a vacuum degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com