Spiral promoting drier

A screw propulsion and dryer technology, applied in dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of loss of effective components, short survival time, inability to dry materials, etc., to reduce the burden, Novel structure and the effect of reducing churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

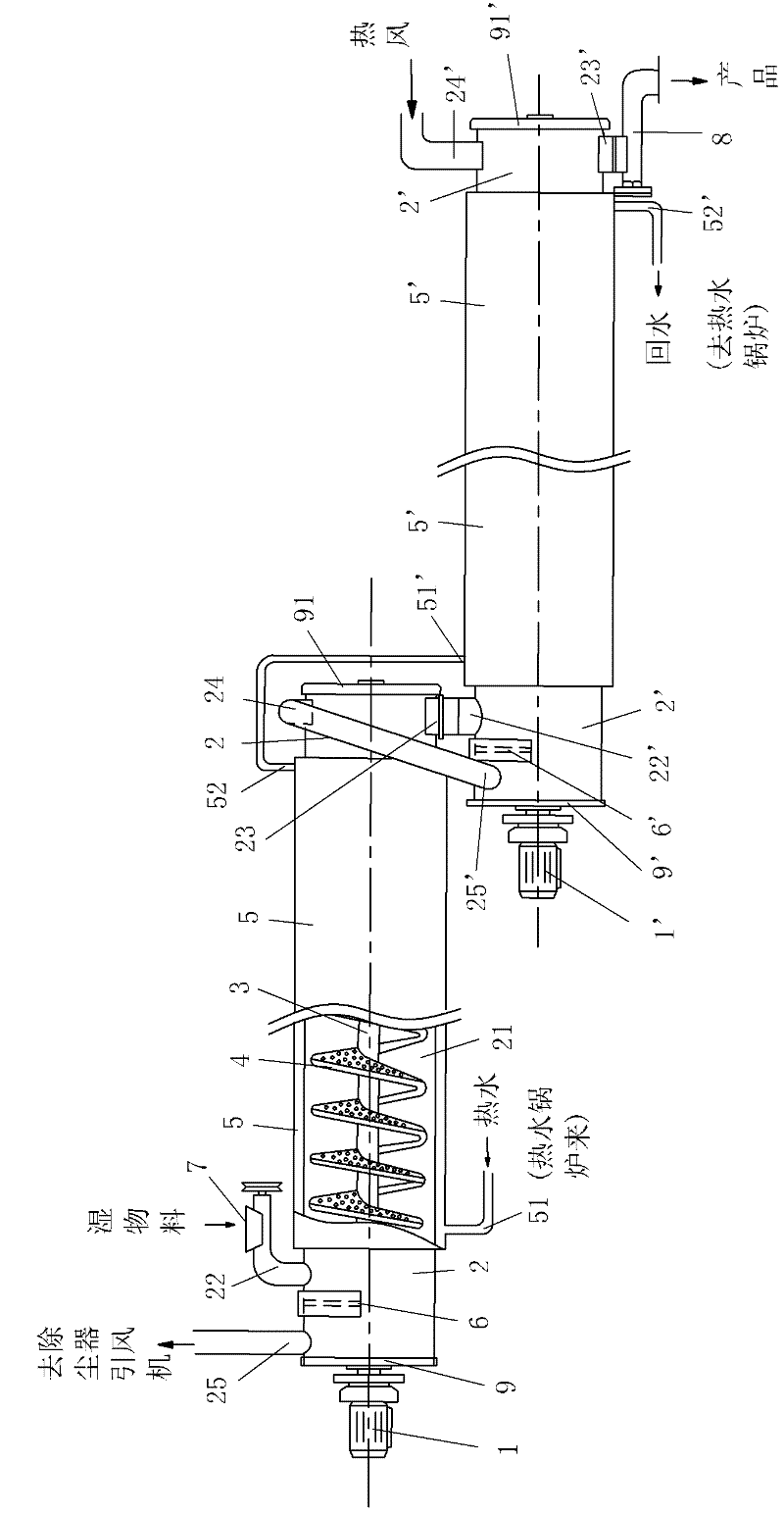

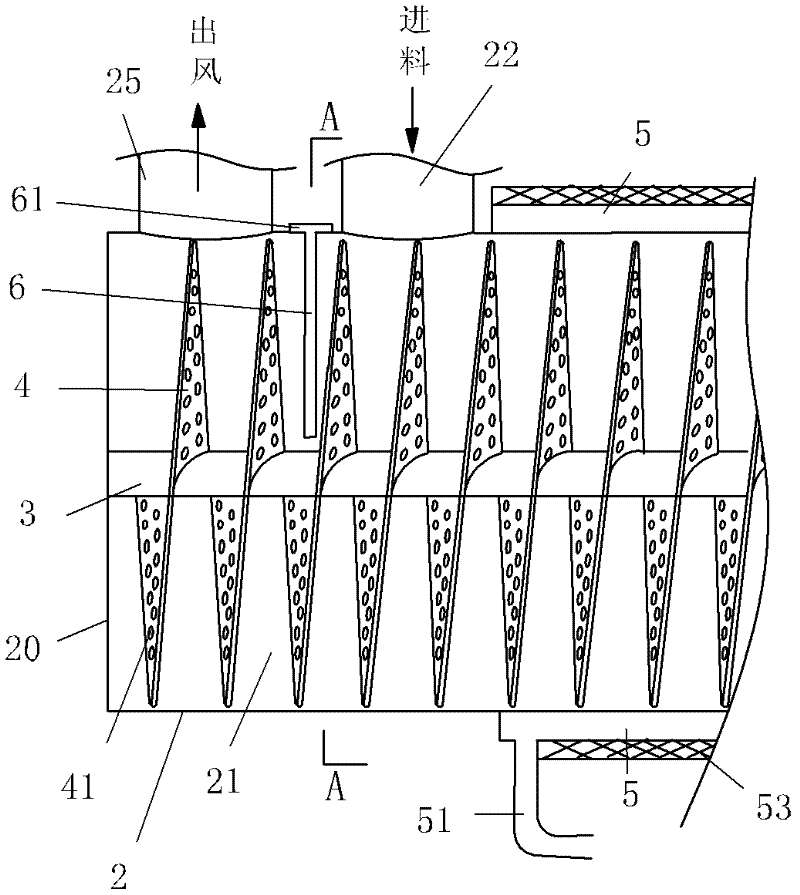

[0020] The structure of an embodiment of the screw propulsion dryer of the present invention, as figure 1 As shown, it consists of two identical screw propulsion units, a feed hopper 7 and a discharge pipe 8 with a screw discharge device.

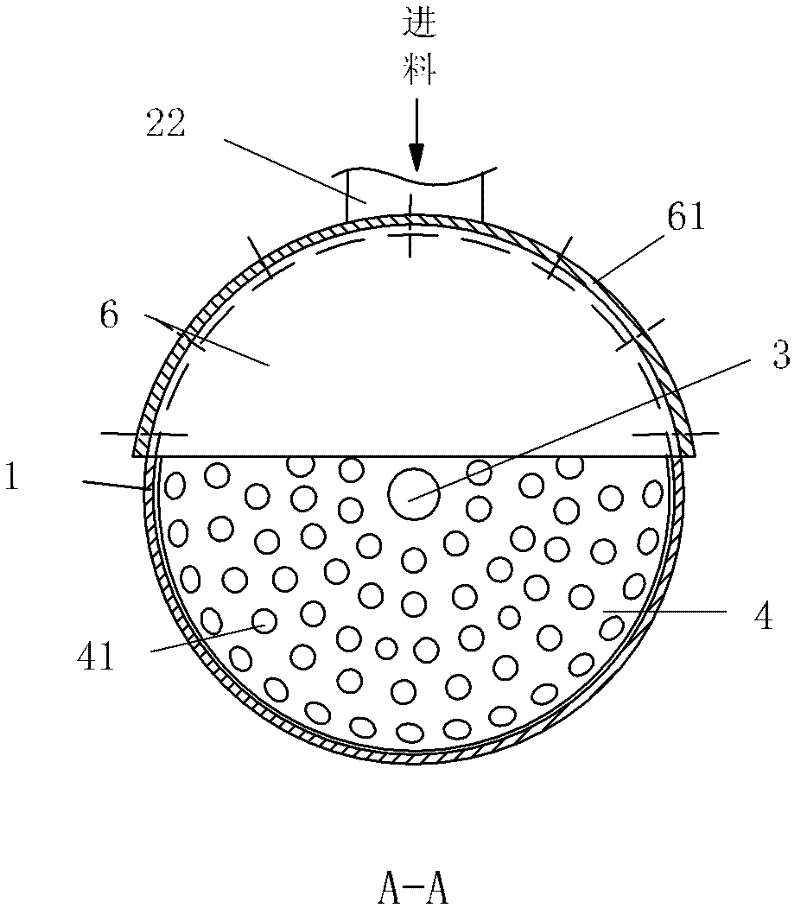

[0021] Taking the first screw propulsion unit as an example, a variable speed motor 1 is installed on the outside of its head, that is, the outside of the front end of the housing 2 . In the inner chamber 21 of the housing 2 , a spiral stirring shaft 3 is installed between the inner side of the center of the front end surface of the housing 2 and the inner side of the center of the rear end surface of the housing 2 . The rotating shaft of the variable speed motor 1 is connected with the screw stirring shaft 3 through a transmission mechanism and a square plug. A porous helical piece 4 that runs continuously through both ends of the helical stirring shaft 3 is coiled. A plurality of air holes 41 are uniformly and densely distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com