Antibiotic dental prosthetic materials and preparation method thereof

A restorative material and dental technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of discoloration, less suitable monomers, and not durable, and achieve long-term antibacterial effects without destroying oral flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

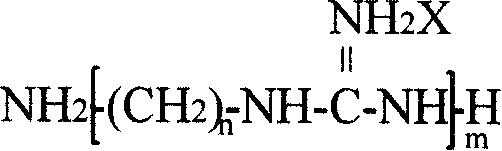

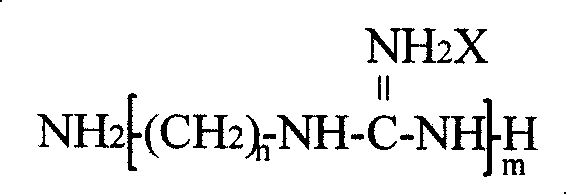

Method used

Image

Examples

Embodiment 1

[0026] Take 50 grams of bisphenol A type epoxy resin with an epoxy value of 0.22, dilute it with 5 grams of acetone, then add 2.7 grams of triethylenetetramine, 20nm-40nm SiO 2 Granules 12g, 1μm-3μm SiO 2 8 grams of granules, stir evenly. Take 3 grams of polyhexamethylenediamine guanidine hydrochloride, molecular weight 5000, heat up to 100°C-150°C, make it melt, slowly add into the system, and stir rapidly. After being evenly stirred, the mixture is injected into a specific mold, and cured at room temperature for 12 hours to obtain an antibacterial dental restorative material of the present invention.

Embodiment 2

[0028] Take 5 grams of polyethylenediamine guanidine carbonate, molecular weight 3000, heat up to 100°C-150°C, and make it melt. Add 50 grams of bisphenol F epoxy resin with an epoxy value of 0.3, 10 grams of phthalic anhydride, and 20nm-40nm SiO 2 Granules 12g, 1μm-3μm SiO 2 8 grams of granules, heated up and maintained at 120°C, and stirred quickly and evenly. The mixture is injected into a specific mold, heated to 150° C. for 5 hours and then cooled to obtain an antibacterial dental restorative material of the present invention.

Embodiment 3

[0030] Take 10 grams of polyhexamethylenediamine guanidine nitrate, molecular weight 1500, heat up to 100 DEG C-150 DEG C, make it melt. Add 50 grams of bisphenol S-type epoxy resin with an epoxy value of 0.5, 8 grams of maleic anhydride, and SiO of 20nm-40nm 2 Granules 12g, 1μm-3μm SiO 2 8 grams of granules, heated up and maintained at 120°C, and stirred quickly and evenly. The mixture is injected into a specific mold, heated to 160° C. for 5 hours, cured for 5 hours, and then cooled to room temperature to obtain an antibacterial dental restorative material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com