Patents

Literature

193 results about "Guanidine nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Guanidine nitrate is the chemical compound with the formula [C(NH₂)₃]NO₃. It is a colorless, water-soluble salt. It is produced on a large scale as high energy fuel used as gas generator and solid rocket propellant applications. Its more official name is guanidinium nitrate, but the incorrect term guanidine nitrate is widely used.

Extinguishment combination with hot gas sol

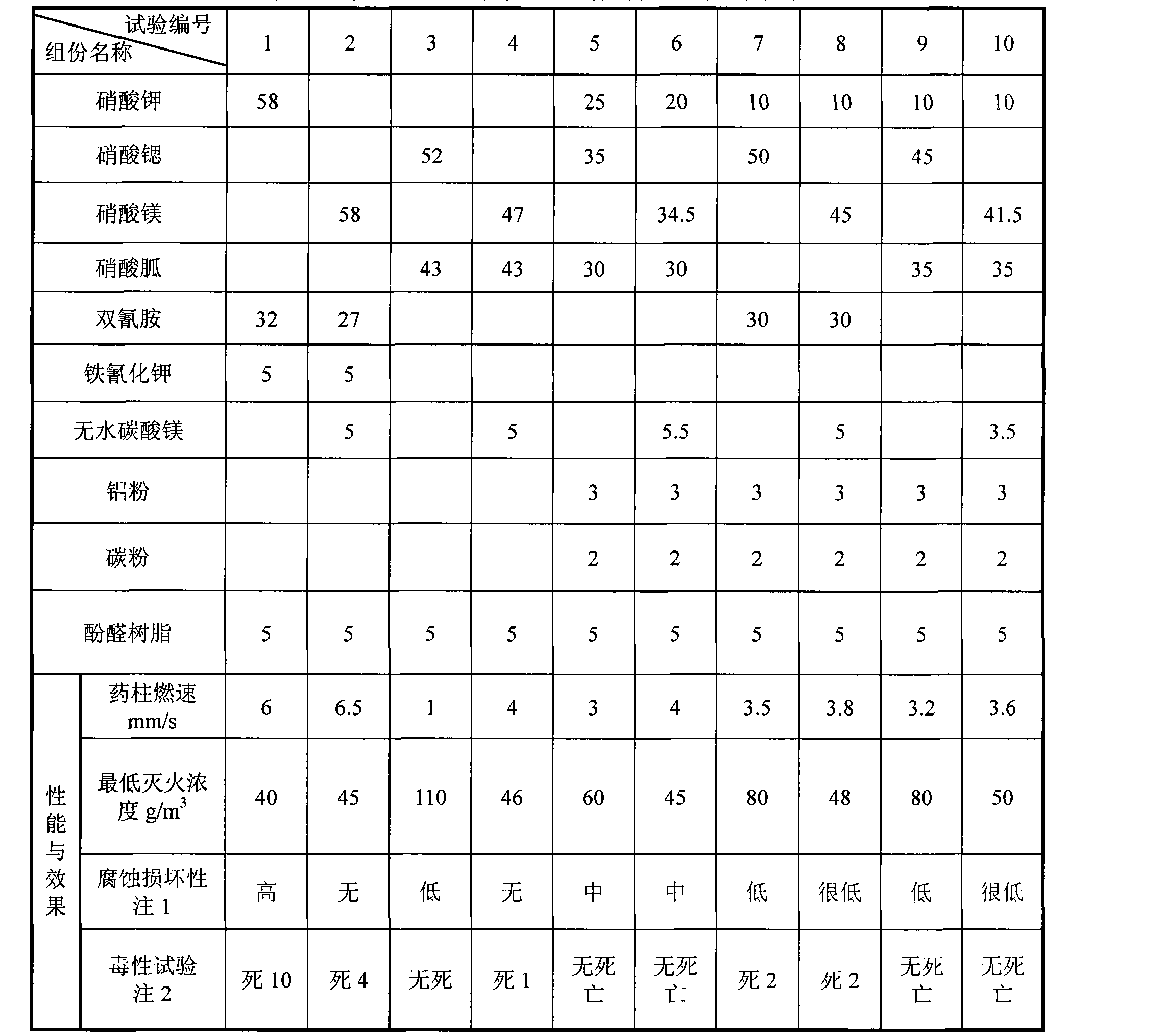

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Substituted basic metal nitrates in gas generation

A material for a pyrotechnic composition and related pyrotechnic compositions are provided in which the material includes a substituted basic metal nitrate including a reaction product of an acidic organic compound and a basic metal nitrate. A method for enhancing a burn rate of a gas generant composition and a burn rate enhanced gas generant composition including a reaction product of basic metal nitrate and tetrazoles, tetrazole derivatives, and combinations thereof, and a nitrogen-containing co-fuel such as guanidine nitrate are also disclosed. The burn rate enhance gas generant composition may optionally include an additional oxidizer such as basic copper nitrate.

Owner:AUTOLIV ASP INC

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1150952CStrong fire extinguishing functionRealize total flooding fire extinguishingFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, a lot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

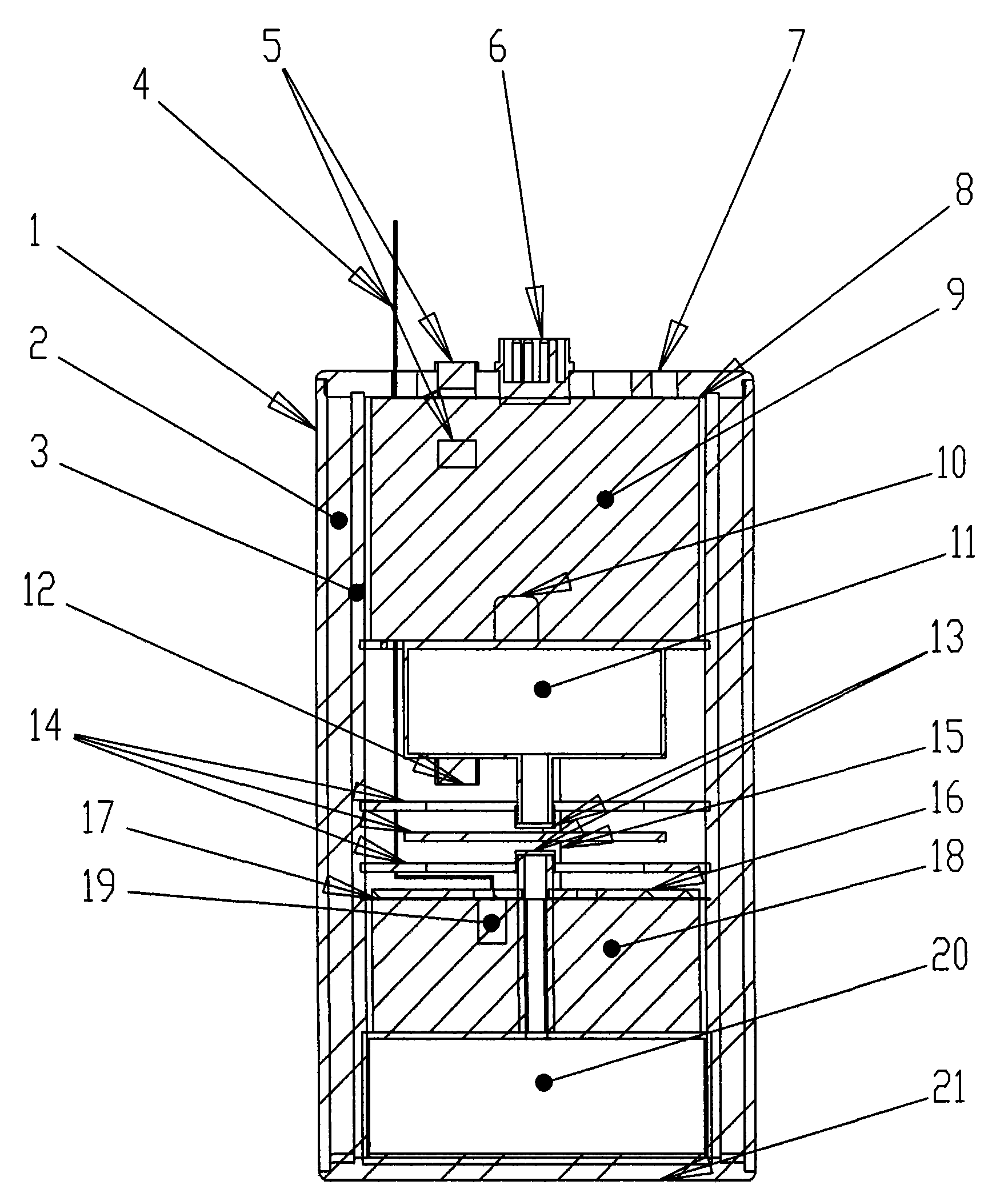

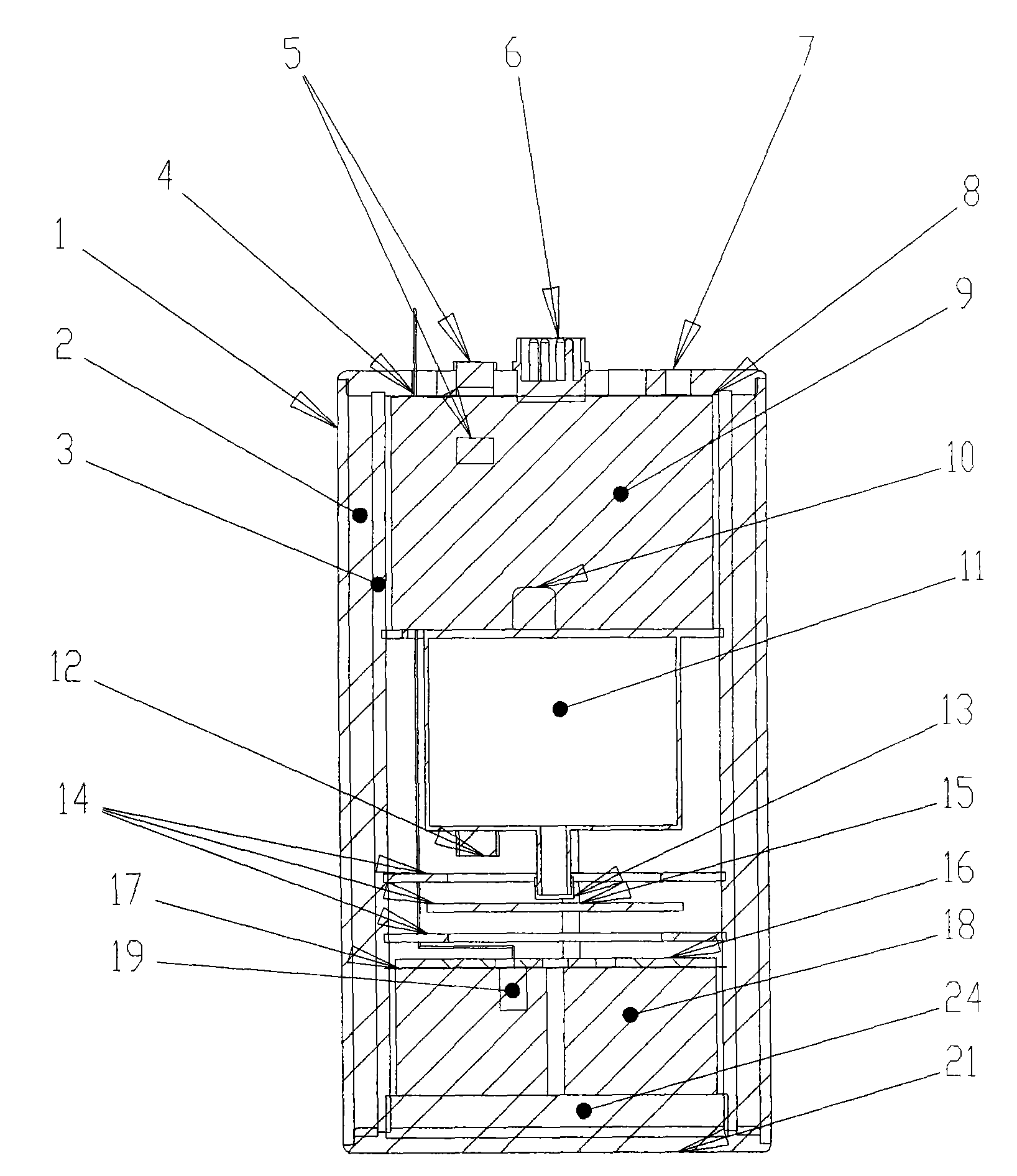

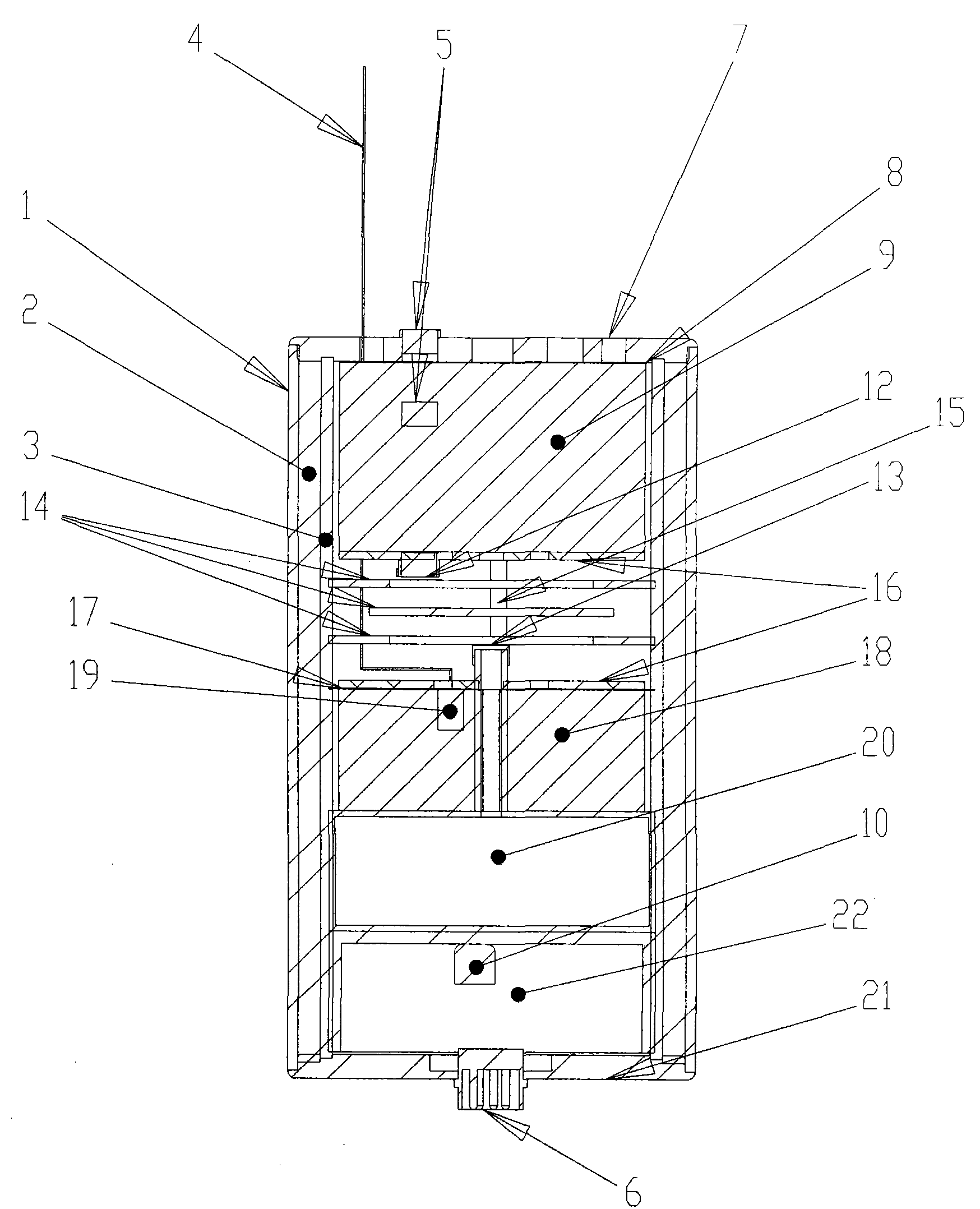

Steam hot aerosol fire-extinguishing composite and application method and fire extinguishing device thereof

ActiveCN101554520AWide variety of sourcesLess corrosiveFire rescueFire extinguisherSodium bicarbonateEpoxy

The invention provides a steam hot aerosol fire-extinguishing composite which contains 30-80wt percent of oxidant, 10-60wt percent of fuel additive and 2-30wt percent of cohesion solidification molding auxiliary agent. The oxidant can be one or more of the following substances: potassium salt, strontium salt, ammonium salt, magnesium salt, nitrocellulose and nitroglycerin; the fuel additive can be one or more of the following substances: azos, azoles, amino-guanidine nitrate, sodium bicarbonate, melamine, cyanoguanidine, carbamide, hexamine, triaminoguanidine nitrate, olefin, saccharose, aluminium powder, magnesite powder and magnesium-aluminium alloy power; the cohesion solidification molding auxiliary agent can be one or more of the following substances: phenol formaldehyde resin, ethoxyline resin, glycidyl azide, urethane rubber, hydroxyl-terminated polybutadiene, polyisobutylene, acetyl tributyl citrate, carboxymethyl cellulose, polyvinyl alcohol phenolic resin and acrylic resin. The invention also provides a fire extinguishing method and a fire extinguishing device adopting the composite. The invention has strong fire extinguishing capacity and fewer hazardous materials and can be applied to different places.

Owner:JIANGXI TSINGHUA IND CO LTD

Aluminum alloy surface phosphatizing fluid and phosphatizing method

InactiveCN101892479ALower working temperatureLess phosphating residueMetallic material coating processesSalicylic acidSodium hydroxide

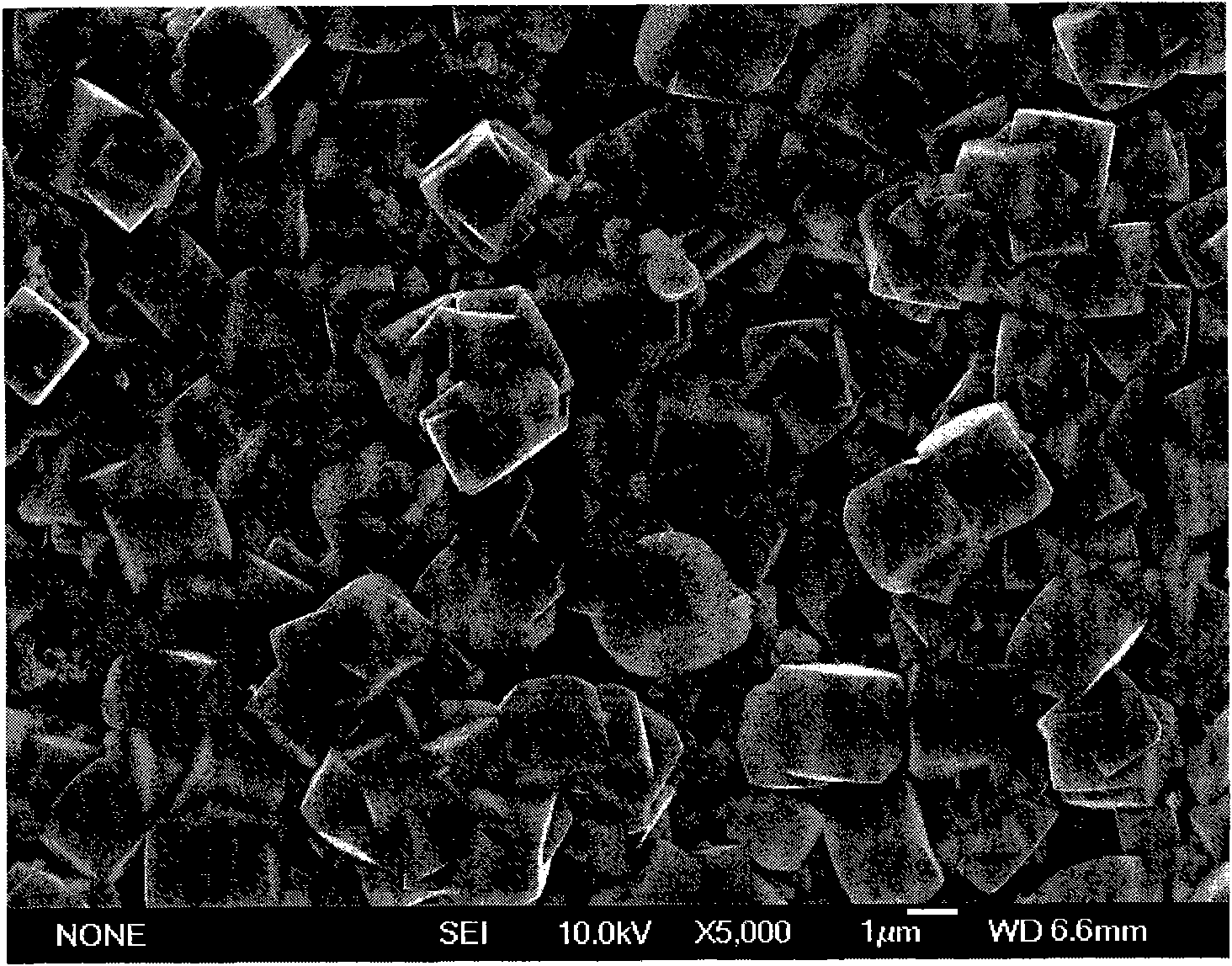

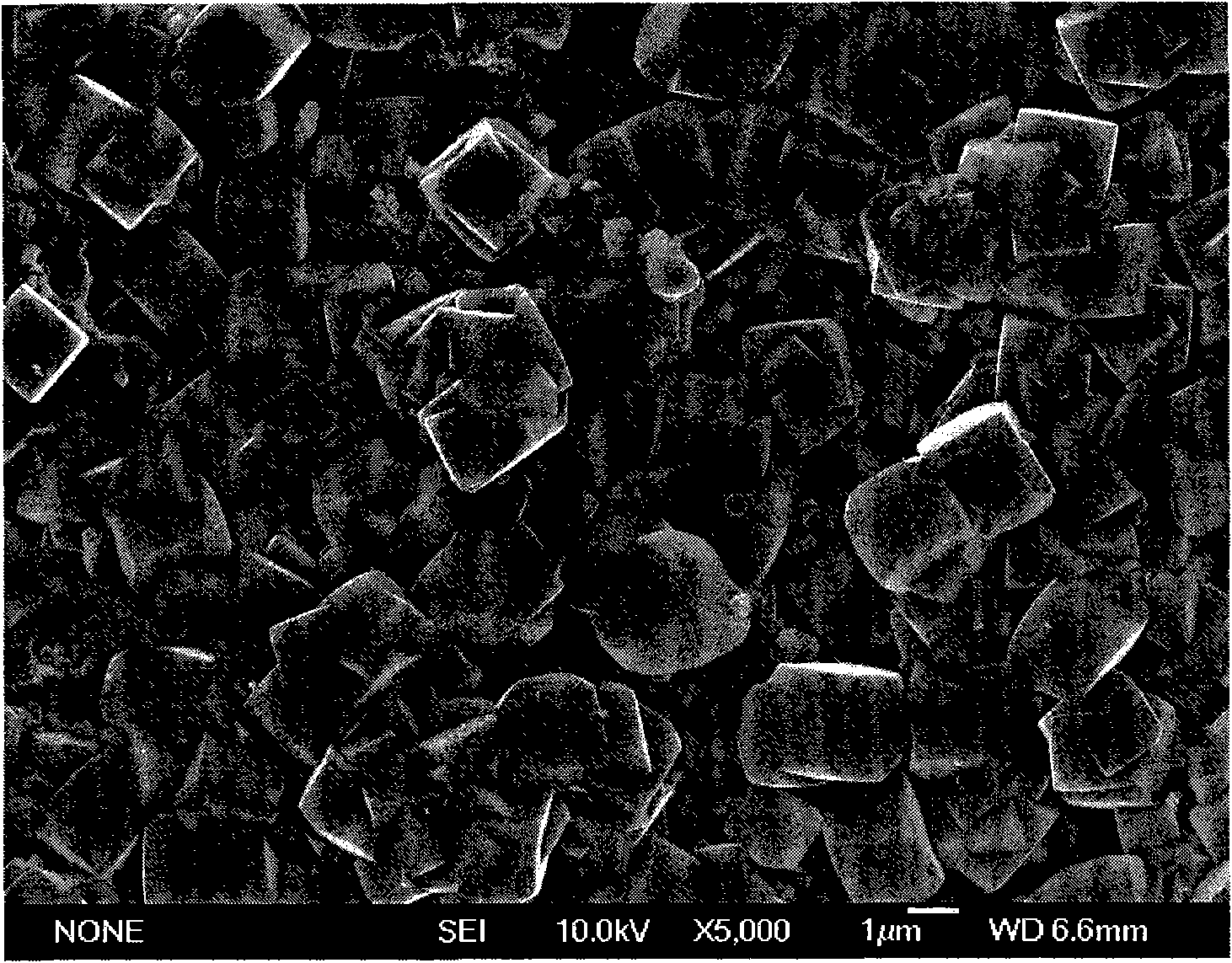

The invention relates to an aluminum alloy surface phosphatizing fluid and a phosphatizing method, belonging to the technical field of processing of chemical conversion coatings on metal surfaces. The method of the invention mainly comprises the following steps: (1) determining the formula of the phosphatizing fluid, wherein the formula comprises the following components and contents: 4.0-8.0g / L of Zn<2+>, 15.0-30.0g / L of PO4<3->, 1.5-1.8g / L of F<->, 0.7-0.9g / L of Ni<2+>, 1.0-1.2g / L of ammonium molybdate, 0.4-0.8g / L of guanidine nitrate and 0.2-0.6g / L of salicylic acid; preparing the phosphatizing fluid from deionized water, and regulating the pH value of the phosphatizing fluid to 3.5-3.7 by 30wt% of NaOH solution; (2) grinding and polishing an aluminum alloy sheet, removing grease by acetone, etching the aluminum alloy sheet by 0.1mol / L of sodium hydroxide solution, soaking the aluminum alloy sheet into 5g / L of surface adjustment fluid to carry out surface adjustment for 1-2min, and then, putting the aluminum alloy sheet into the phosphatizing fluid; (3) controlling the temperature of the phosphatizing fluid at about 40 DEG C, and carrying out phosphatizing reaction for 5min; and (4) cleaning the aluminum alloy sheet by deionized water, and drying the aluminum alloy sheet by hot air. The phosphatizing film formed after phosphatizing has better corrosion resistance and is uniform and compact.

Owner:SHANGHAI UNIV

Non-nitrine gas generating agent and production thereof

ActiveCN1644574AReduce dosageReduce generationExplosivesPressure gas generationParaffin waxGas composition

A non-laminated gas producing agent and its production are disclosed. The non-laminated gas producing agent consists of oxygen-enriched carbamidine nitrate 40-60% with granularity 0.5-6mu, basic copper nitrate 10-28% as oxidant with granularity 0.5-6mu, copperon oxide of catalyst with primary oxidant 15-30% with granularity 0.1-6mu, and clay or paraffin wax 0.1-3% as process assistant with granularity 1-20mu. The production is carried out by: breaking the materials, adding into mixer by proportioning, mixing, sieving by screen, adding water 10-30%, agitating, drying, sieving the dried materials by screen with 20-80 mesh to obtain medicine particles, pressing into tablets, and drying the tablets under 100-120deg.C for 1.5-2.5hrs with water content <0.4%. It achieves wide regulating range, high gas output efficiency, and clean gas composition.

Owner:HUBEI HANGPENG CHEM POWER TECH

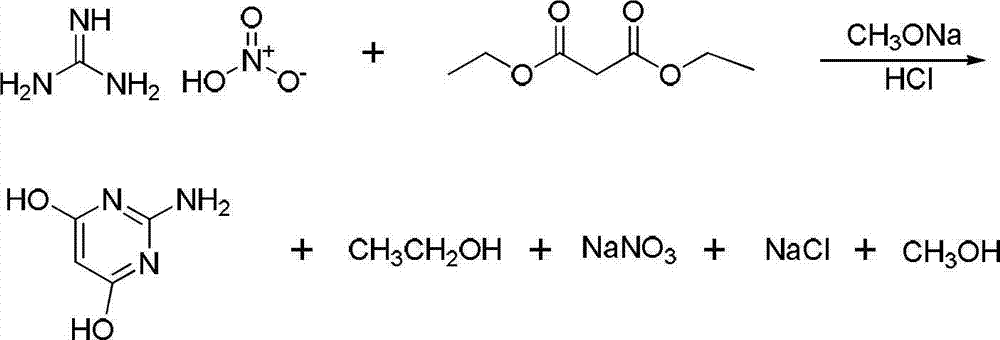

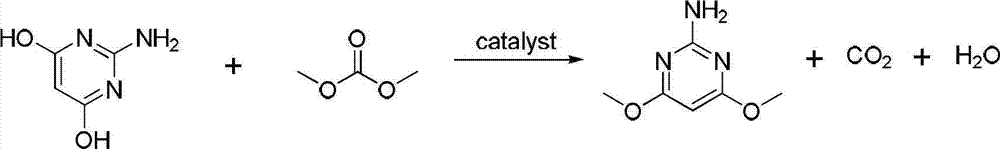

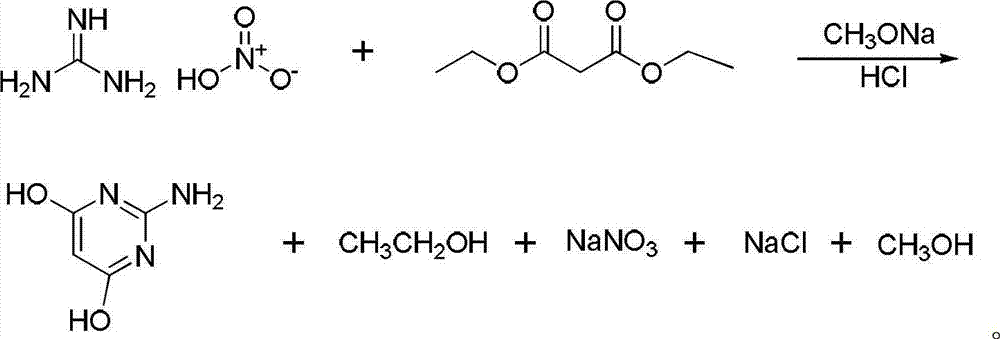

Method for synthesizing 2-amino-4,6-dimethoxypyrimidine

The invention relates to a method for synthesizing 2-amino-4,6-dimethoxypyrimidine serving as a fine chemical raw material. The method comprises the following steps of: performing cyclization and hydrolysis on guanidine nitrate, diethyl malonate, sodium methoxide, methanol and dimethyl carbonate serving as raw materials to generate 2-amino-4,6-dyhydroxypyrimidine, and performing methylation on the 2-amino-4,6-dyhydroxypyrimidine and dimethyl carbonate to generate the 2-amino-4,6-dimethoxypyrimidine. The raw materials are cheap; and the method is simple and convenient to operate, facilitates large-scale industrialized production, and has high application value. By using the dimethyl carbonate which is a green raw material as a methylation reagent, the reaction process is shortened, and generation of three wastes is greatly reduced; and because the route is shortened, the energy consumption is also reduced.

Owner:JIANGSU REPONT PESTICIDE FACTORY

Gas generating composition

InactiveUS6779464B1Nitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAmmonium perchlorate explosive compositionsNitroguanidinePerchlorate

A gas generating composition is obtained in which an amount of a combustion residue based on a unit amount of a gas generated is reduced.A gas generating composition comprising nitroguanidine, guanidine nitrate or a mixture thereof as a fuel and further an oxidizing agent. The oxidizing agent is a perchloric acid salt, a nitric acid salt or a mixture thereof, and when the oxidizing agent is ammonium perchlorate, a chlorine neutralizer is further incorporated.

Owner:DAICEL CHEM IND LTD

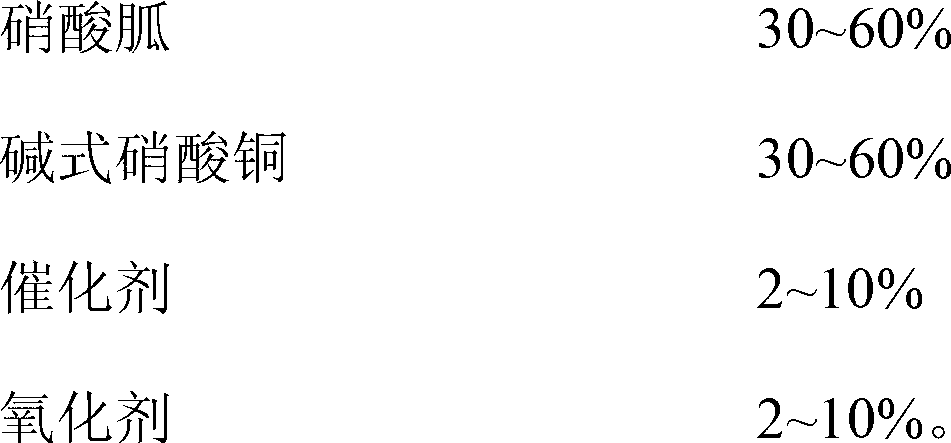

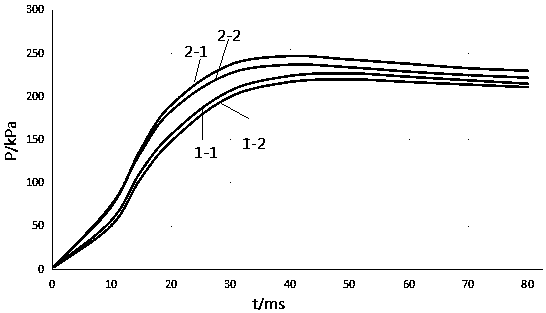

Anaerobic pressure-controlled heating agent and use thereof

InactiveCN102992926APharmacy formula is easy to getControllable burning rateExplosivesCombustionLiquid state

The invention relates to an anaerobic pressure-controlled heating agent, comprising the following components in percentage by mass: 30-60% of guanidine nitrate, 30-60% of basic copper nitrate, 2-10% of catalyst and 2-10% of oxidant. The anaerobic pressure-controlled heating agent can be used as a heating material for a carbon dioxide exploiter for a coal mine. The pharmaceutical formulation of the anaerobic pressure-controlled heating agent is simple, and easy to get; and the combustion speed is controllable, as well as is slow in air, and extremely fast in thin-oxygen or inert environments and even under a certain confining pressure, for example, the combustion speed can achieve 15-30 m / s in a liquid-state carbon dioxide airtight tube having a pressure of 7.0 MPa.

Owner:CCTEG CHINA COAL RES INST

Green process for producing nitroguanidine

InactiveCN101497579AEliminate vacuum distillation recovery processReduce decompositionOrganic chemistryOrganic compound preparationDecompositionFiltration

The invention relates to a green process for producing nitro guanidine, and belongs to the field of chemical engineering. The discontinuous nitrification method is adopted in the invention to prepare the nitro guanidine. The method particularly comprises that: guanidine nitrate is added in concentrated nitric acid while stirring, diluted by water and subjected to decompression and sucking filtration to separate out a crystal, so that the coarse product of the nitro guanidine is obtained; and the coarse product of the nitro guanidine is water-washed for more than four times to obtain the target product. The process is simple and saves the process of the decompression, distillation and recovery of the nitric acid, and the diluent uses water to replace the nitric acid, and the lowest reaction temperature is reduced from 60 DEG C to 30 DEG C, thereby lowering the decomposition of the nitro guanidine in the concentrated nitric acid, and the fastest reaction time is shortened from 3 hours to 20 minutes, and the production efficiency is greatly improved; due to the adoption of the discontinuous method, the prior idle production equipment can be used for production by simple modification; moreover, in the process, the content of the waste nitric acid is more than 45 percent, so that the nitro guanidine can be used as an oxidant and a neutralizer to produce various products such as sodium nitrate, oxalic acid, p-nitrodracylic acid and the like.

Owner:里程

High peformance gas generating compositions

ActiveUS20090255611A1Easily pressed into complex grainFew chip and voidCeramic shaping apparatusExplosive working-up apparatusBurn rateCopper nitrate

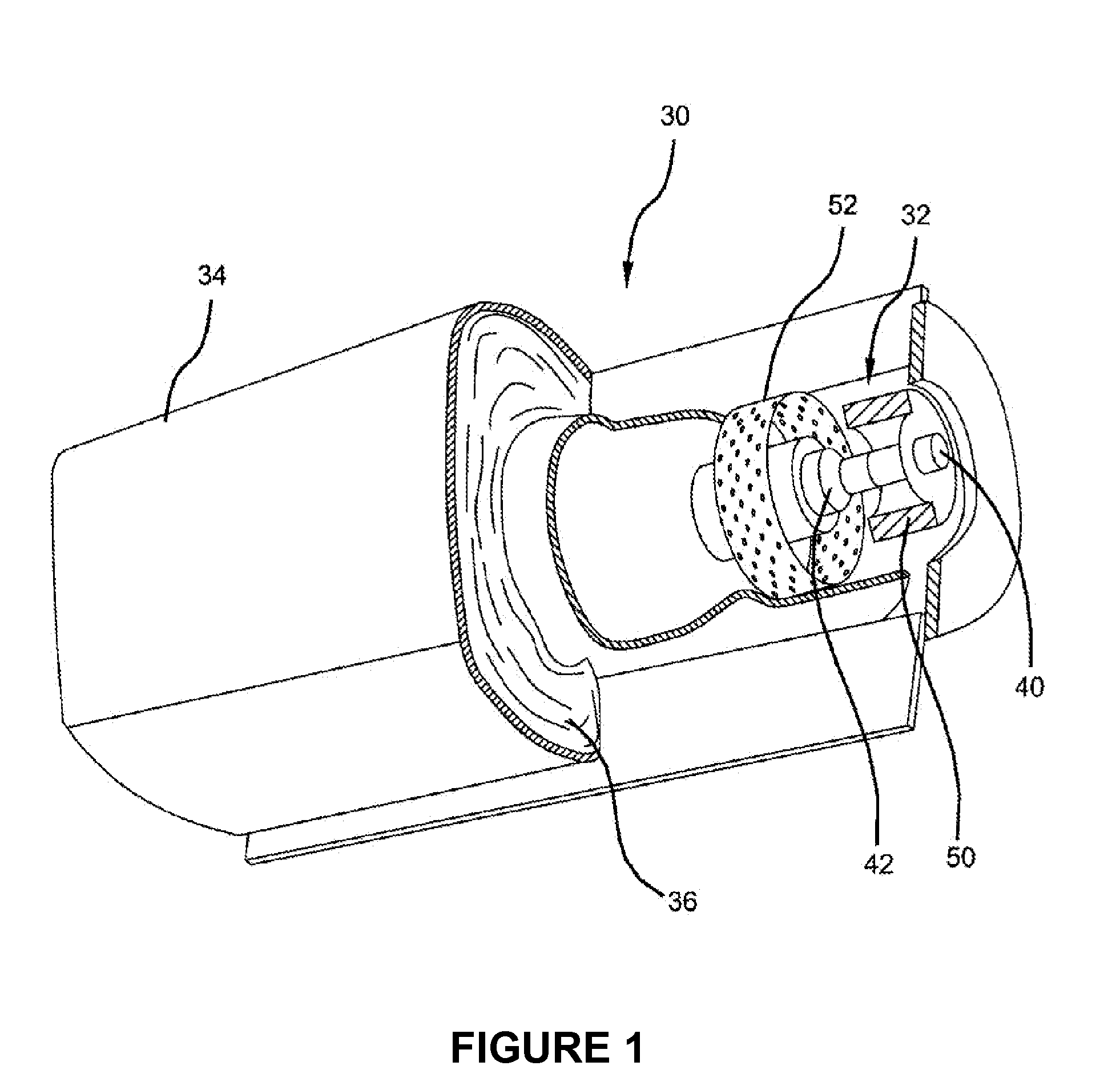

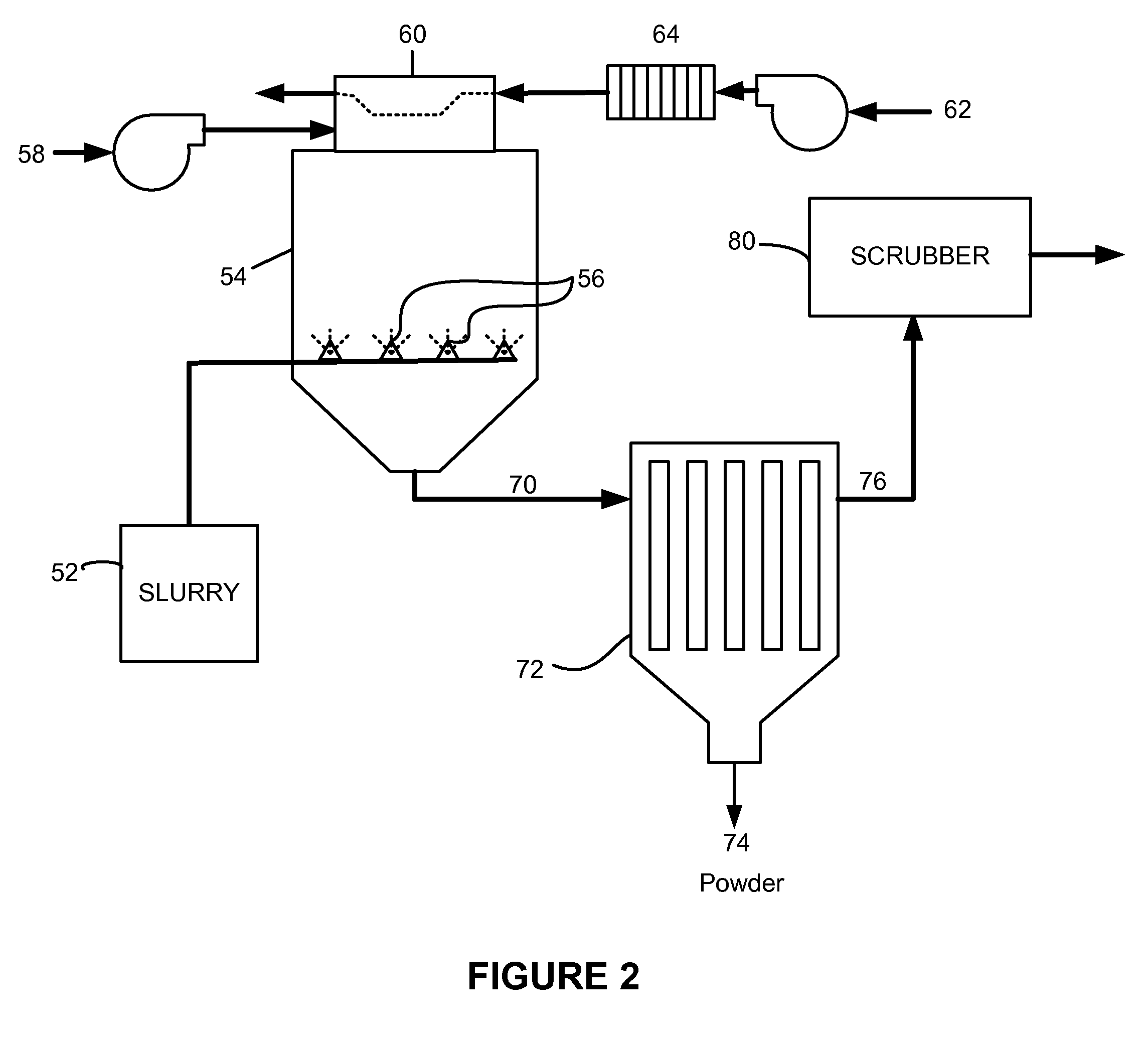

Compositions and methods relating to gas generants used in inflatable restraint systems. The gas generant grains formed via spray drying techniques of the present disclosure provide superior performance, including high burn rates and high gas yields. Further, processing of the gas generant grain products can be streamlined. Such gas generants include by way of non-limiting example, guanidine nitrate, basic copper nitrate, and a secondary oxidizer, such as potassium perchlorate.

Owner:AUTOLIV ASP INC

Gas generating agent for automobile safe gasbag and preparing method thereof

InactiveCN101234943AEasy to mold and releaseImprove adsorption capacityPressure gas generationCarboxymethyl celluloseSesquioxide

The invention discloses an automobile airbag gas generating agent and a preparation method thereof. The invention is characterized in that 30 to 50 percent of guanidine nitrate, 5 to 20 percent of basic cupric nitrate, 10 to 25 percent of strontium nitrate, 3 to 10 percent of ammonium perchlorate, 2 to 6 percent of iron sesquioxide, 2 to 10 percent of sodium carboxymethyl cellulose and 2 to 5 percent of caoline taken in accordance with the weight percentages are mixed thoroughly; after distilled water is added, the mixture is heated and kneaded and cooled for granulation; obtained particles are then dried and sieved to get the gas generating agent. Raw materials for products to be made with the method of the invention are easy to acquire and have low prices. The production process is safe and conducive to safety of automobile occupants and also to environment protection.

Owner:烟台安泰德汽车安全系统有限公司

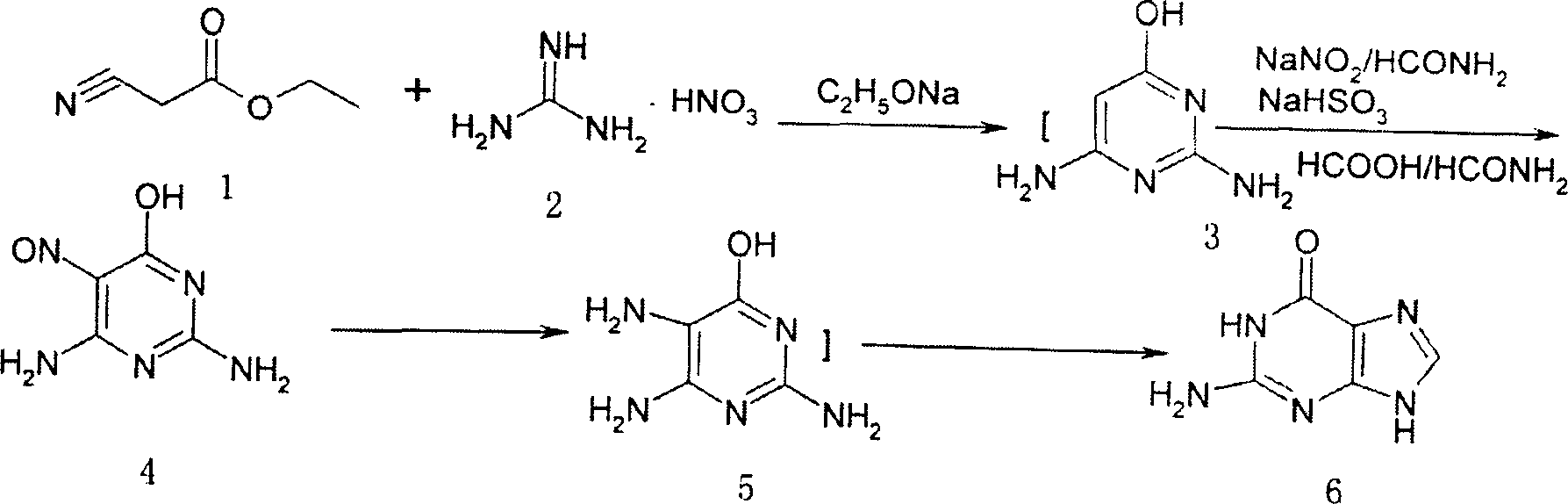

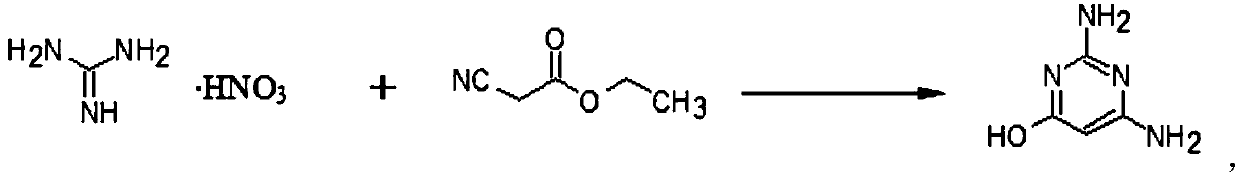

Guanine one-pot synthesis method

The invention discloses a synthesis method for guanine, which includes the following steps: carrying out a cyclization reaction of guanidine nitrate and ethyl cyanoacrylate to obtain the compound of 2, 4-diamino-6-hydroxypyrimidine in formamide solvent, adding sodium nitrite, formamide and concentrated formic acid in turn, and carrying out nitrosation and reduction reaction with reducing agent and cyclization reaction to obtain the final product. The invention is the use of ''one-pot'', and the raw materials are fat chain ethyl cyanoacrylate and guanidine nitrate, which are directly from market, cheap and easy to get, without need of separation and purification of pyrimidine intermediates. Guanine is prepared by one step through effective control of reaction conditions, feeding sequence and ratio. The product is purified through adjusting pH, which has high yield and is easy to operate.

Owner:SHANGHAI INST OF PHARMA IND

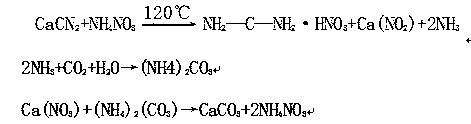

Process for producing guanidine nitrate

InactiveCN102304065AGuaranteed Alkalinity RequirementsQuality improvementOrganic chemistryOrganic compound preparationPhysical chemistrySide reaction

The invention relates to a process for producing guanidine nitrate, which comprises the following steps: reacting ammonium nitrate and dicyandiamide, which serve as raw materials, obtaining a guanidine nitrate product after reaction, cooling the guanidine nitrate product to obtain solid guanidine nitrate, crushing and grinding to obtain a finished product. The process is characterized in that continuous circulating ammonia gas is added into the reaction solution as an assistant in a reaction process. In the processing procedure of each produced guanidine nitrate, the ratio of ammonia gas to ammonium nitrate to dicyandiamide in reaction is (5-10)kg:1,000kg:500kg. The ammonia gas serves as an alkaline protective agent in the reaction solution to improve the quality of the coarse guanidine nitrate formed by an initial reaction and improve the stability of the product. The decomposition of dicyandiamide and other side reaction caused by the decomposition of dicyandiamide in an improper environment are prevented. The reaction speed and efficiency are increased.

Owner:SUZHOU WUGAN PHARMA

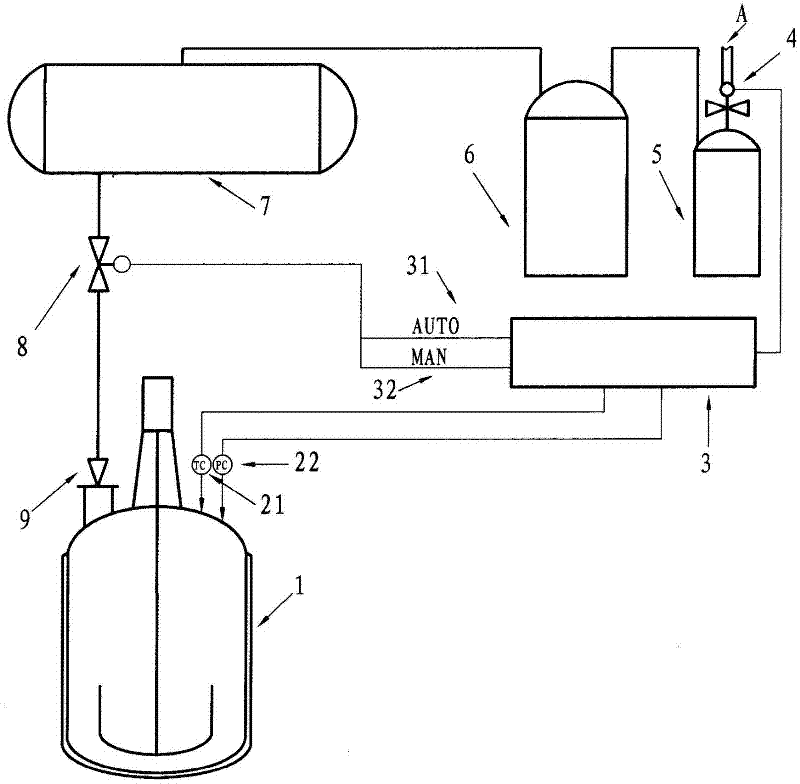

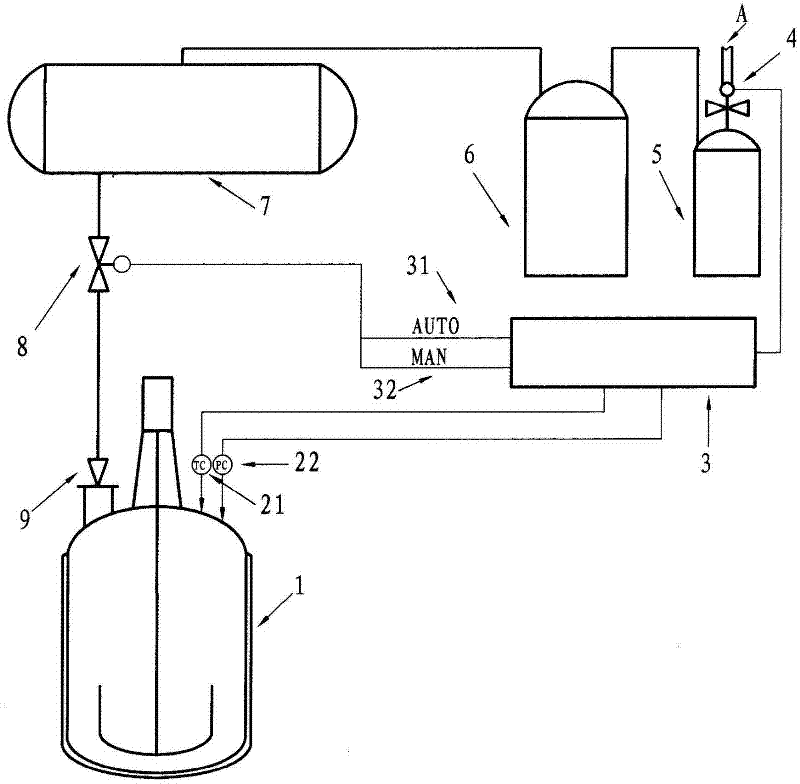

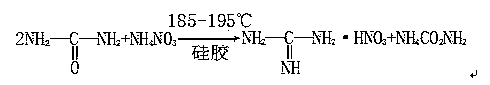

One-step safety production method of guanidine nitrate

InactiveCN102408358AReduce aggregationReduce sublimationOrganic chemistryOrganic compound preparationDecompositionSilica gel

The invention discloses a one-step safety production method of guanidine nitrate. The guanidine nitrate product is prepared through the following steps: adding ammonium nitrate, urea and a catalyst which is silicon dioxide or inorganic silica gel or aluminum oxide into a reaction kettle, heating to ensure that urea and ammonium nitrate are molten; controlling the temperature of the reaction liquid in the reaction kettle to maintain a reaction at the temperature; and cooling after the reaction, adding process water, heating the solution, performing hot filtering, recycling the catalyst, cooling the filtrate, filtering out a wet product, and drying the wet product to obtain the finished guanidine nitrate product. Ammonium nitrate is excess, thus urea can be completely reacted, side reactions such as the polymerization or sublimation of urea and decomposition can be reduced, the product yield can be increased and simultaneously the product quality can be increased. The production method has safety; and in order to ensure that the reaction has higher safety, the reaction kettle is connected with a temperature-pressure integrated fire device. The content of the obtained guanidine nitrate can meet the standard of the high-class product. The method has the advantages of simple technology and cheap and common raw material, and is economical and efficient.

Owner:河北克尔化工有限公司 +1

Production process of guanidine nitrate

InactiveCN102924337AHigh yieldOrganic chemistryOrganic compound preparationMolten stateThermal insulation

The invention discloses a production process of guanidine nitrate. Ammonium nitrate and dicyandiamide serving as raw materials are reacted to make guanidine nitrate. The production process is characterized in that a batch feeding mode is adopted, ammonium nitrate and dicyandiamide are mixed and then added into a reaction kettle in batches, the feeding times is 5-10, and the feeding reaction temperature is controlled to be 130-140 DEG C; when feeding of one batch of raw materials is finished and a reaction mixture is in a molten state and the reaction temperature is 130-140 DEG C, a next batch of raw materials are added until feeding of the reaction raw materials is finished; after feeding is finished, thermal insulation reactions are continued to be performed for 30-60min at 145-155 DEG C until an addition reaction is over, then the temperature is continued to be warmed to 210-220 DEG C within 20-30min, and guanidine nitrate products are obtained when a cracking reaction is over after reaction for 30min. The production process has the advantages that by batch feeding and by controlling corresponding feeding temperature and feeding amount well, the aim of improving the yield coefficient of guanidine nitrate is achieved, the content of the produced guanidine nitrate is larger than 92%, and the mol yield coefficient is larger than 96%.

Owner:NANTONG TENDENCI CHEM

Agent combination of safe fireworks and fire cracker

InactiveCN1431182AAvoid low temperature decomposition disadvantagesHigh melting pointExplosivesFireworksUrea nitrateFireworks

A high-safety composite charge for firecrackers or fireworks is prepared from oxidant (metallic oxides including Fe2O3, Fe3O4, copper oxide, manganese oxide, etc and organic alkali nitrate including urea nitrate, guanidine nitrate, etc.) sulfate compound, aluminium powder, pearlite powder and charcoal powder. The said sulfate compound is ferrous sulfate as gas expanding agent, which is treated through dewatering, pulverizing, surface treating, and neutralizing. Its advantages are high safety, and high performance in sound, light and colors.

Owner:刘琼吾 +1

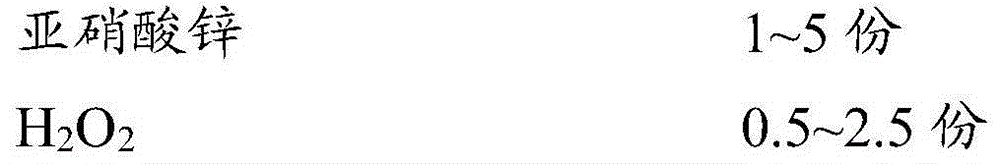

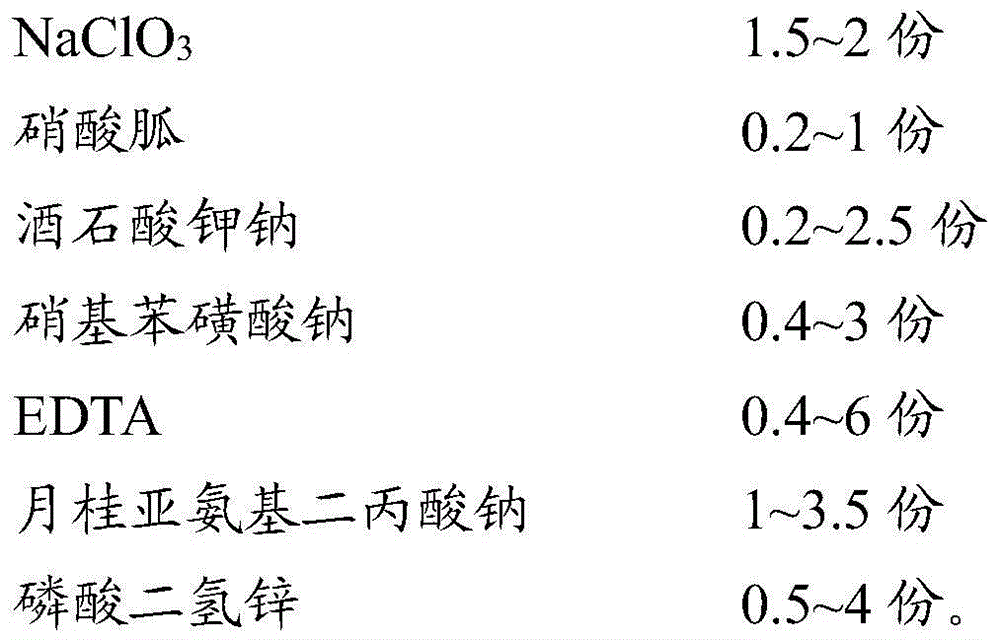

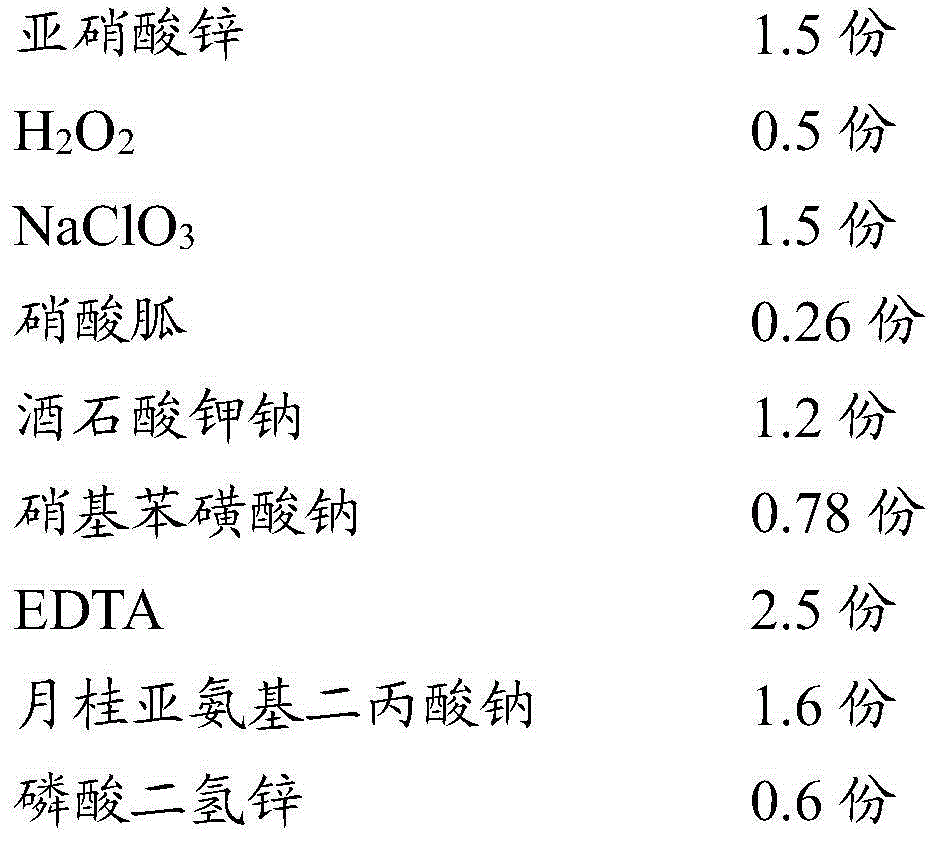

Zinc-system phosphating solution additive and use method thereof

The invention provides a zinc-system phosphating solution additive and a use method thereof and belongs to the field of industrial phosphating solution. The zinc-system phosphating solution additive comprises an inorganic promoter, an organic promoter, ligand, a buffering agent and a surface active agent, wherein the inorganic promoter is zinc nitrite, NaClO3 and H2O2; the organic promoter is tartrate, guanidine nitrate and nitrobenzene sulfonate; the ligand is organic carboxylate; and the surface active agent is sodium lauriminodipropionate and zinc dihydrogen phosphate. The zinc-system phosphating solution additive is suitable for preparing low-temperature phosphating solution; and due to matching use of the organic promoter and the inorganic promoter, the film-forming speed is fast; due to complexing of the ligand and metal cations, the crystalline grain is refined, simultaneously the deposited slag of the phosphating solution is reduced, the quality of the phosphating film is guaranteed, and the film layer is uniform and fine; due to the buffering agent and the surface active agent, the phosphating solution has better corrosion resistance, and the adhesive force between all metal parts and a coating layer is enhanced. The additive is wide in application range, low in cost and convenient in use, is energy-saving and environmental-friendly, and is beneficial to industrial production.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

Phosphorization processing liquid for surface of carbon steel and nickel plating enclosure method

InactiveCN101693993ALower working temperatureLess phosphating residueSuperimposed coating processRare earth ionsCarton

The invention relates to a phosphorization processing liquid for the surface of carbon steel and a nickel plating enclosure method, belonging to the technical field of chemical conversion film processing for the surface of metal. The phosphorization processing liquid comprises the following components: 2.0-7.0 g / L ZnO, 10-40 g / L PO4<3->, 2.0-17 g / L NiSO4*6H2O, 0.4-0.8 g / L of guanidine nitrate, 10-30 g / L of sodium nitrate and 0.4-0.8 g / L of Ce<4+> rare-earth ions, and the pH value of the phosphorization processing liquid is 2.7-2.9. The nickel plating enclosure method comprises the following steps: polishing a carbon steel sheet, removing oil by using acetone, soaking the carbon steel sheet in 5 g / L of surface correction liquor for surface correction, and then putting the carton steel sheet into the phosphorization processing liquid; controlling the temperature of the phosphorization processing liquid to be about 45 DEG C and carrying out phosphorization reaction for 15 mins; cleaning and blowing for drying after the phosphorization reaction; placing the phosphorized carbon steel sheet into nickel plating liquid, and plating nickel for 1 minute at room temperature and constant current; and cleaning and blowing for drying after nickel plating enclosure is finished. A phosphorization film generated after phosphorization treatment and nickel plating enclosure treatment has better corrosion resistance, and a generated film is uniform and compact.

Owner:SHANGHAI UNIV +1

Microcrystalline phosphating solution for brake block hardware

InactiveCN101348906AImprove pollutionLittle pollutionMetallic material coating processesPhosphateNitrobenzene

The invention provides a pollution-free microcrystalline phosphating treatment solution for brake pad hardware, which is mainly made from the following raw materials in portion by weight: 40 to 50 portions of zinc nitrate, 22 to 30 portions of zinc dihydrogen phosphate, 30 to 40 portions of Mazhev salt (manganous dihydrogen phosphate), 1.5 to 2 portions of guanidine nitrate, 1.5 to 2 portions of sodium m-nitrobenzene sulfonate, 1 to 2 portions of sodium tripolyphosphate, 2 to 4 portions of tartaric acid, 2 to 3 portions of sulfosalicylic acid, 1.5 to 2.5 portions of citric acid and 1,000 to 1,200 portions of water. The solution is used for the blackening-phosphating treatment of the surface of iron hardware, and has the characteristics of fast phosphorization, good performances, little environmental pollution, low cost, etc. The treatment solution has the advantages of fine phosphatized crystals of phosphating films, uniform color in consistent black and good corrosion resistance. Especially, as the treatment solution chooses the raw materials with little environmental pollution and high efficiency, the treatment solution acquires excellent effects in both phosphatization and environmental protection through optimized combination and reasonable proportioning.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

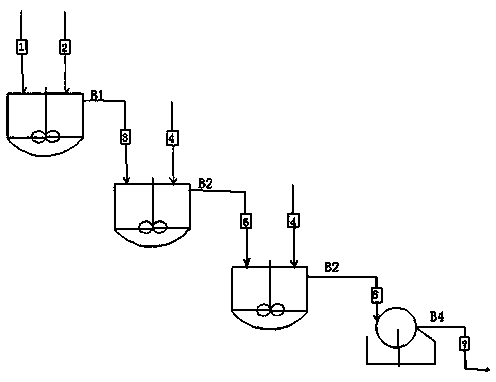

Continuous synthesis process of guanidine nitrate

ActiveCN103450048AEasy to operateQuality improvementOrganic chemistryOrganic compound preparationPhysical chemistryReaction temperature

The invention discloses a continuous synthesis process of guanidine nitrate. The method comprises the following steps: (1), continuously adding materials into a melting kettle according to a proportion, controlling the temperature of the melting kettle, overflowing the materials to enter a primary reaction kettle after the materials are molten; (2), controlling the temperature and the retention time of the primary reaction kettle, continuously ventilating an ammonia gas into the primary reaction kettle, and overflowing the reacted materials to enter a secondary reaction kettle; and (3), controlling the temperature and the retention time of the secondary reaction kettle, continuously ventilating the ammonia gas into the secondary reaction kettle, and cooling, slicing and packaging the reacted materials to obtain a guanidine nitrate finished product. The synthesis process disclosed by the invention is continuously carried out for the whole process and stable to operate, so that the operation strength is greatly lowered, the product yield is high, the quality is good and the yield is high.

Owner:NANTONG TENDENCI CHEM

Production technology of nitroguanidine

The invention discloses a production technology of nitroguanidine. The nitroguanidine serves as a raw material, a nitroguanidine crude product is obtained after sulfuric acid dehydration, ice water hydrolysis and liquid ammonia neutral reaction, and ammonium sulfate in filtrate is recycled through multiple-effect evaporation. The technology has the advantages that the prepared nitroguanidine has a molar yield higher than 95% and a content larger than 97%, and three wastes seldom exist.

Owner:NANTONG TENDENCI CHEM

Black phosphating liquid and use method thereof

ActiveCN102953055AStrong corrosion resistanceFast film formationMetallic material coating processesO-Phosphoric AcidHydroxylamine sulfate

The invention belongs to the technical field of metal surface treatment, and particularly relates to black phosphating liquid for phosphating the surface of alloy steel which does not need to be acid cleaned in preliminary treatment. The black phosphating liquid comprises components with the following weight percentage: 2 percent to 5 percent of acidic manganese phosphate, 2 percent to 4 percent of diammonium hydrogen phosphate, 1 percent to 3 percent of cobalt nitrate, 1 percent to 2 percent of guanidine nitrate, 0.5 percent to 1.5 percent of hydroquinone, 0.2 percent to 1 percent of hydroxylamine sulfate, 0.5 percent to 2 percent of phosphoric acid with the mass concentration being 80 percent to 90 percent, and the rest is pure water. Due to the use of the black phosphating liquid, the operation is simple, the stability is good, the film forming speed is high, a formed film is fine and uniform, the color is black, the film forming strength is high, the corrosion resistance is strong and the like, and the black phosphating liquid is applicable to the surface treatment of alloy steel parts of various models.

Owner:CHANGSHA WOER METAL SURFACE TECH

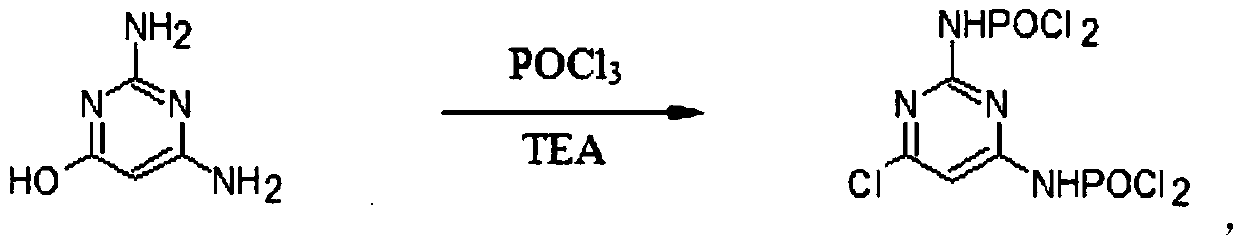

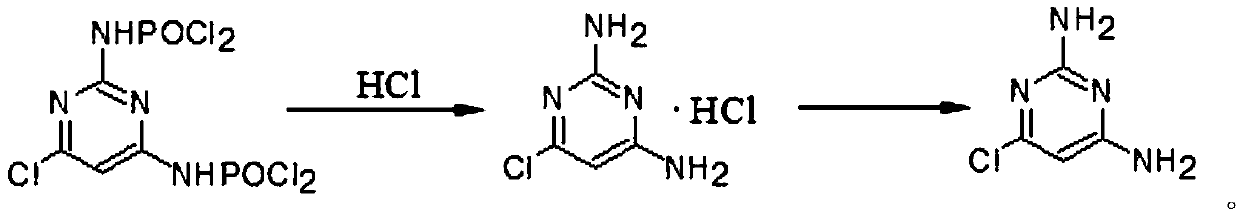

Method for synthesizing 2,4-diamino-6-chloropyrimidine

The invention discloses a method for synthesizing 2,4-diamino-6-chloropyrimidine. According to the method, methyl cyanoacetate, guanidine nitrate and sodium methoxide serve as raw materials to react with one another to obtain 2,4-diamino-6-hydroxypyrimidine, and then 2,4-diamino-6-hydroxypyrimidine is chloridized with POCl3 in the presence of triethylamine to obtain 2,4-diamino-6-chloropyrimidine.Compared with the prior art, the situation that the whole reactant is neutralized to generate and precipitate a large amount of phosphate is avoided, the product purity is improved, the product yieldis increased, the situation that a solvent is used for refining DACP is avoided, the process is greatly simplified, the cost is reduced, the yield is increased, and the method has the advantages of being high in yield, easy to operate and high in safety and is a very effective process suitable for industrialized mass production.

Owner:江西开元生物医药科技有限公司 +1

Gas generating agent composition, method for preparing same, application of gas generation agent composition and gas generator

InactiveCN107698415AKeep shapeForm-retaining agents do not work wellPedestrian/occupant safety arrangementNon-explosive/non-thermic compositionsStrontium titanateCopper nitrate

The invention relates to a gas generating agent composition, a method for preparing the same and a gas generator with the gas generation agent composition. The gas generating agent composition comprises, by weight, 40%-60% of guanidine nitrate, 25%-40% of alkali copper nitrate, 1%-20% of strontium nitrate, 1%-10% of ammonium perchlorate, 5.5%-10% of strontium titanate and 0.6%-10% of talc powder.The gas generating agent composition, the method and the gas generator have the advantages that the strontium titanate and the talc powder are jointly used as shape keeping agents, synergistic effectscan be realized by the strontium titanate and the talc powder, accordingly, pre-combustion shapes of tablets can be effectively kept after the tablets are combusted, and gas bags can be prevented from being burnt due to melting and splashing of the combusted tablets; the strontium nitrate is used as an auxiliary oxidizing agent, the usage amount of the alkali copper nitrate is reduced, and accordingly molten copper residues can be reduced; the ammonium perchlorate is used as an ignition performance regulator, accordingly, the low-temperature ignition performance of the gas generating agent composition can be obviously improved, the combustion speeds can be increased, and the gas generating agent composition mainly can be used for gas generators for supplementary restraint systems of automobiles.

Owner:HUBEI HANGPENG CHEM POWER TECH

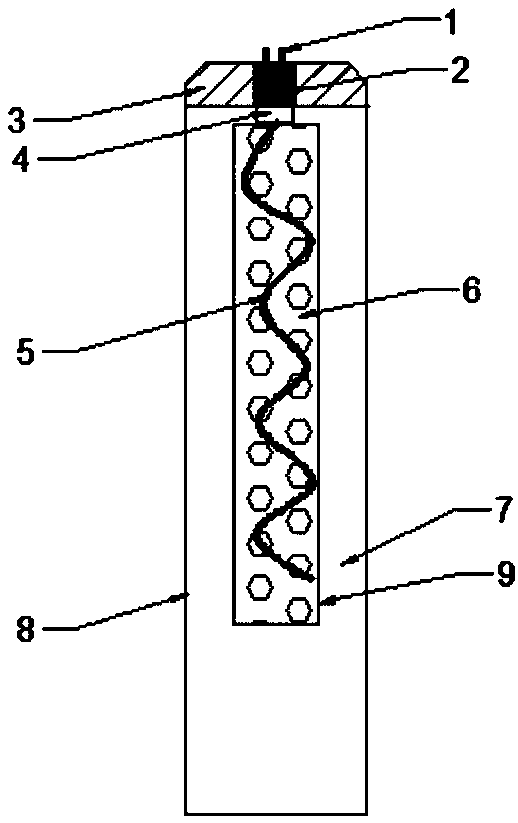

High-burning rate gas generating agent and granulation method thereof

ActiveCN107840772ABurn fasterMeet performance needsExplosivesPressure gas generationCopper nitrateBurn rate

The invention discloses a high-burning rate gas generating agent and a granulation method thereof. The granulation method comprises adding guanidine nitrate, basic copper nitrate, auxiliaries and water into a container, carrying out heating under control of the temperature in a range of 70-90 DEG C, stirring to disperse the mixture through a dispersing device to obtain a uniform mixture, drying the mixture through an atomizing device to obtain dry particles 1, finishing the dry particles 1 to obtain particles 2, drying the particles 2 to obtain particles 3, and tabletting the particles 3. Thehigh-burning rate gas generating agent has a high combustion speed and satisfies the performance requirements of side gasbags to a generating device with special speed requirements. The granulation method can reduce a raw material cost, is free of drying and crushing treatment on raw materials before use, guarantees full contact and mixing of components, improves product stability and consistency,realizes full dissolution of soluble raw materials through a heating dissolution method, utilizes a basket mill and unbaked wet basic copper nitrate to grind and disperse so that a uniform material is obtained, is easy to operate and has high production efficiency.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

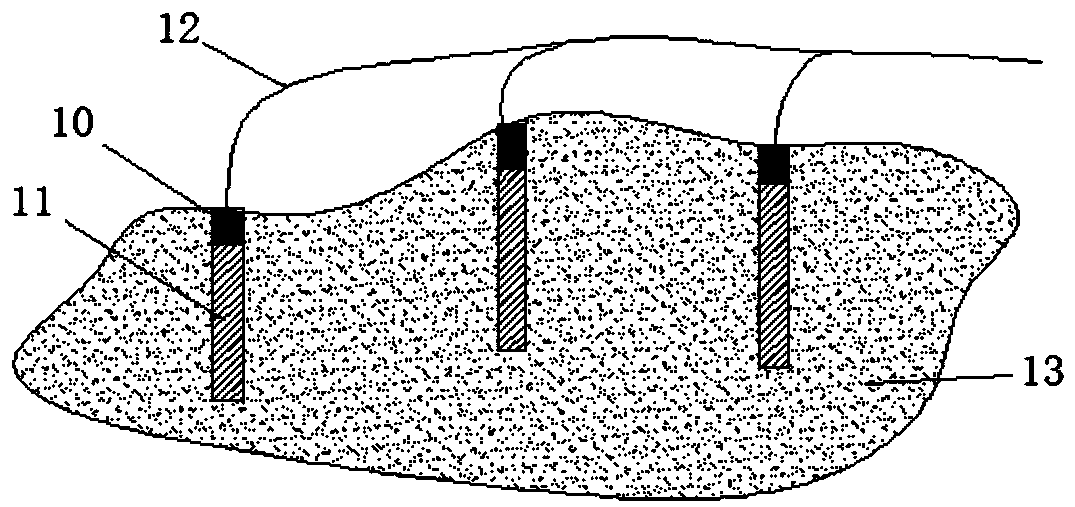

Air bag restraint system gas generant based cracking barrel and near-people blasting method thereof

ActiveCN108827086AReduce security risksReduce vibration effectsBlasting cartridgesBlastingCombustionPlasticizer

The invention relates to an air bag restraint system gas generant based cracking barrel and a near-people blasting method thereof. The cracking barrel comprises a gas generant shell and a gas generant, wherein the gas generant needs certain pressure to trigger combustion; the gas generant comprises an oxidant, an acrylate cross-linking agent, a plasticizer, a vinyl trisilane lubricant, a combustion agent guanidine nitrate and a catalyst iron oxide; the gas generant shell has certain pressure therein, is further equipped with a resistance wire; the resistance wire is connected with a plug through a delayer outside the gas generant shell; and pins for connecting external circuits are further arranged on the plug. The cracking barrel cannot trigger and combust the safe environment-friendly type gas generant under atmospheric pressure, and is convenient and efficient to operate.

Owner:WUHAN UNIV OF TECH

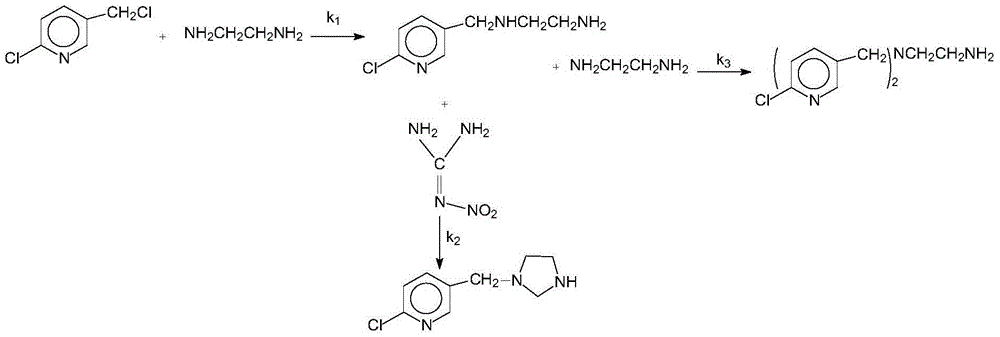

Method for synthesizing imidacloprid employing cascade reaction

The invention discloses a method for synthesizing imidacloprid employing cascade reaction. The method comprises the following steps: with 2-chlorine-5-chloromethyl pyridine, ethidene diamine and guanidine nitrate as raw materials, mixing 2-chlorine-5-chloromethyl pyridine, ethidene diamine and guanidine nitrate with a certain amount of solvent ethanol; adding a little of ionic liquid as a catalyst, controlling the pH value of the reaction process to be about 6 with a little of hydrochloric acid; heating, warming, and slowly dropwise adding a certain amount of ethidene diamine, reacting, heating for a certain period of time, stopping heating, and cooling to a room temperature; and purifying and drying to obtain an imidacloprid product. Due to adoption of one-pot cascade reaction, an intermediate product 2-degree amine is high in activity, and easily forms a heterocyclic ring together with nitroguanidine; byproducts can be prevented; and the high-purity imidacloprid is synthesized. Compared with an original two-step technology, the method for preparing the imidacloprid disclosed by the invention is simple in reaction step; the yield and the purity of the product are greatly improved; the yield reaches more than or equal to 95%; the purity of a reaction product through gas chromatography reaches more than or equal to 90%.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com