Process for producing guanidine nitrate

A production process, the technology of guanidine nitrate, applied in the field of guanidine nitrate production process, can solve problems such as side reactions and dicyandiamide decomposition, and achieve the effects of improving stability, speeding up reaction speed and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

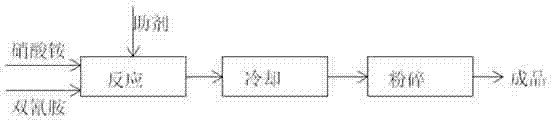

[0009] figure 1 A production process of guanidine nitrate is shown, and its process steps are: use ammonium nitrate and dicyandiamide as raw materials, react, obtain guanidine nitrate product after the reaction, carry out cooling treatment to it, obtain guanidine nitrate solid, and then crush After processing and grinding, the finished product is obtained. During the reaction, continuous circulation of ammonia gas is added to the reaction solution as an auxiliary agent.

[0010] Specifically, in the reaction solvent of each part of guanidine nitrate, the mass distribution of the ammonia gas additive with ammonium nitrate and dicyandiamide during the reaction is: 1000Kg of ammonium nitrate, 500Kg of dicyandiamide, and 5-10Kg of ammonia gas.

[0011] In the reaction process of the reaction auxiliary ammonia gas of the present invention, the method of circulating injection is adopted to ensure that the reaction solution is alkaline, and the volatilization of the gas can also tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com