Patents

Literature

60results about How to "Effective suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for implementing video request program under cover network multicasting

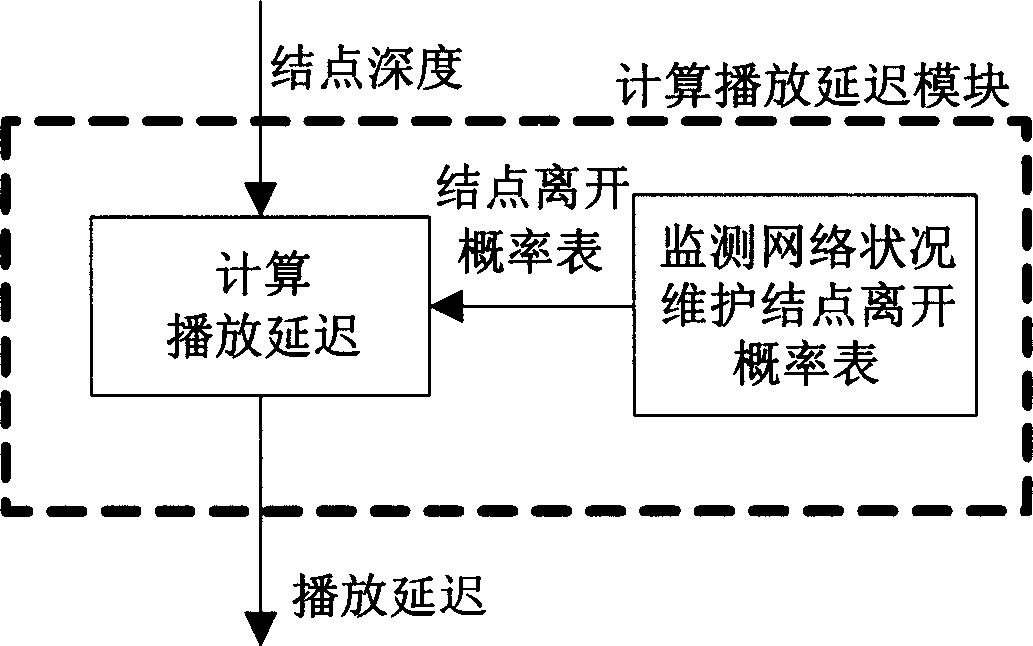

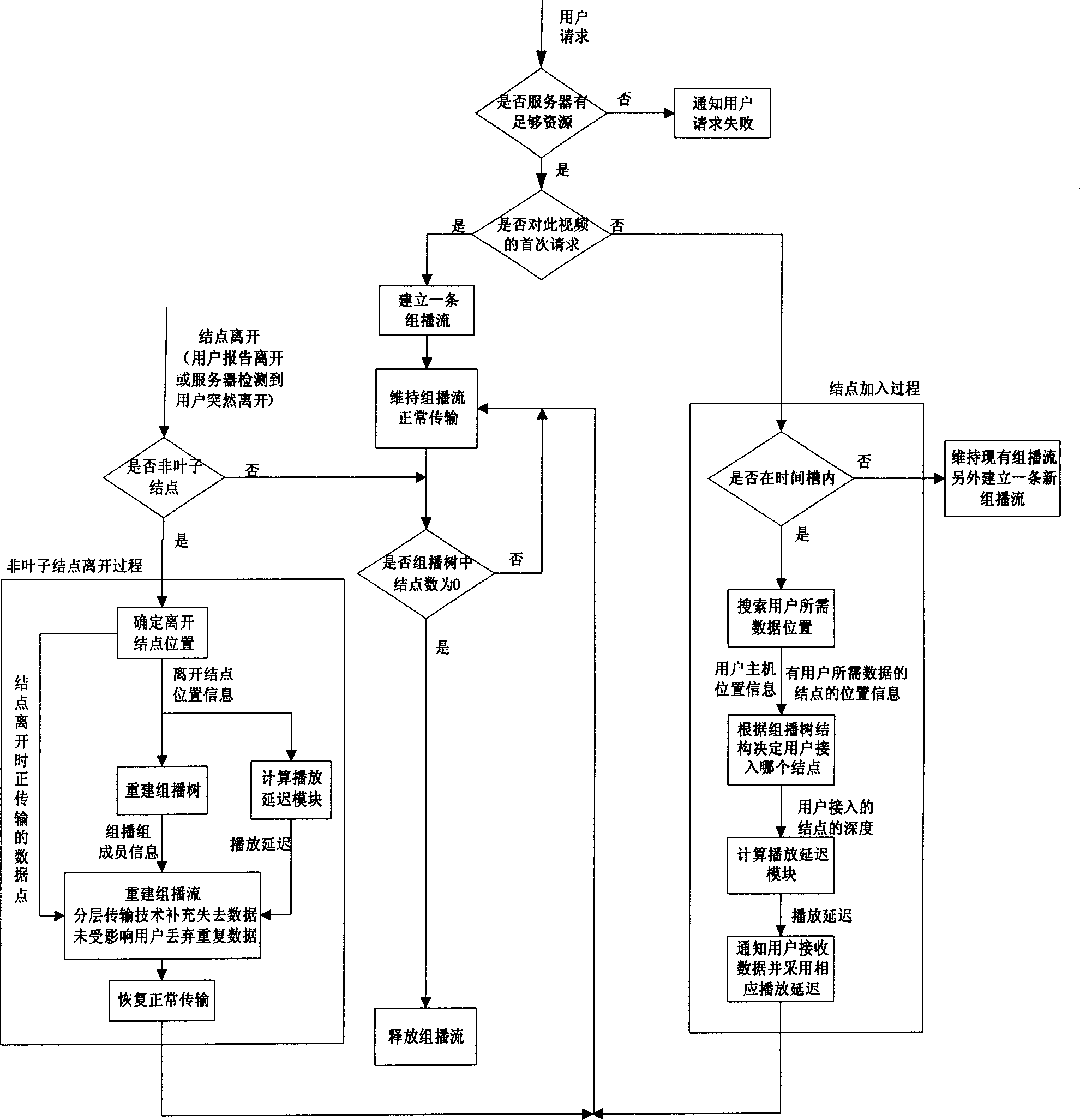

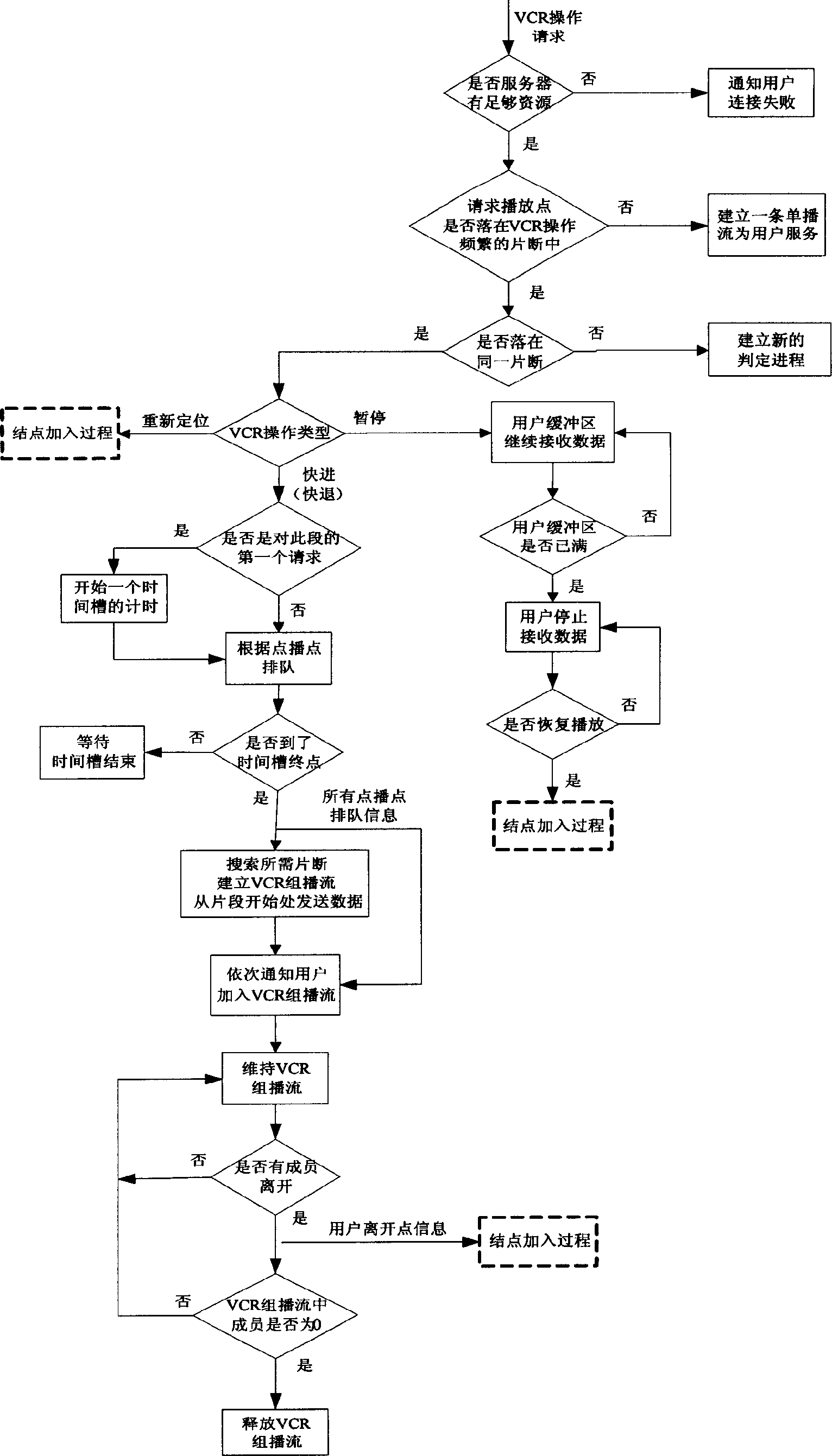

InactiveCN1719894AReduce the numberGuaranteed playback continuityTwo-way working systemsJunction pointFlow number

This invention relates to a video selection realization method under network multicast, in which, a video server sets up a multicast stream for users when a video program is selected for the first time, when a user asks for adding a same video junction point, different play delays are introduced, the small junction point play delay is close to the root junction point and large one is in a distance from the junction point a multicast VCR operation method is used to realize quick advance and quick retreat user VCR operation finishes to merge into suitable multicast stream in the multicast VCT operation set. This invention can add the optimized user waiting time, useless flow number and user buffer zone logic unblocks to ensure continuous play of VOD system reduce the streams for realizing VCR greatly.

Owner:BEIJING JIAOTONG UNIV +1

Emulsion stabilizer for the production of plant protein milk

InactiveCN101095475AImprove stabilityImprove emulsifying abilityFood preparationMilk substitutesEmulsionChemistry

The invention relates to an emulsion stabilizer for plant protein milk production. The comprised components and weight proportion are as follows: mono-fatty glycerin ester 10-20%, poly-glycerin fatty ester 4-8%, sodium alginate 3-6%, microcrystalline cellulose 60-75%, and sodium pyrophosphate 4-10%. The invention is characterized by increased floating stability, emulsifying ability and raw material usage rate. There is no deposition in preservative period, no apparent floating fatty circle when the product is used for plant protein milk production such as peanut milk, walnut milk and soybean milk, and the product quality is improved.

Owner:MASSON GROUP

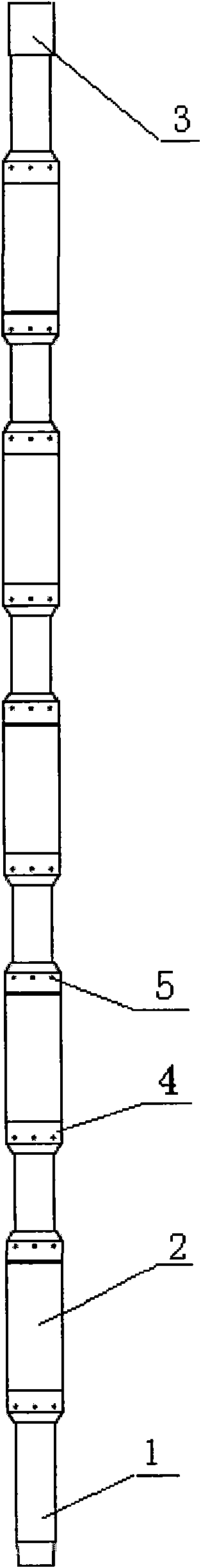

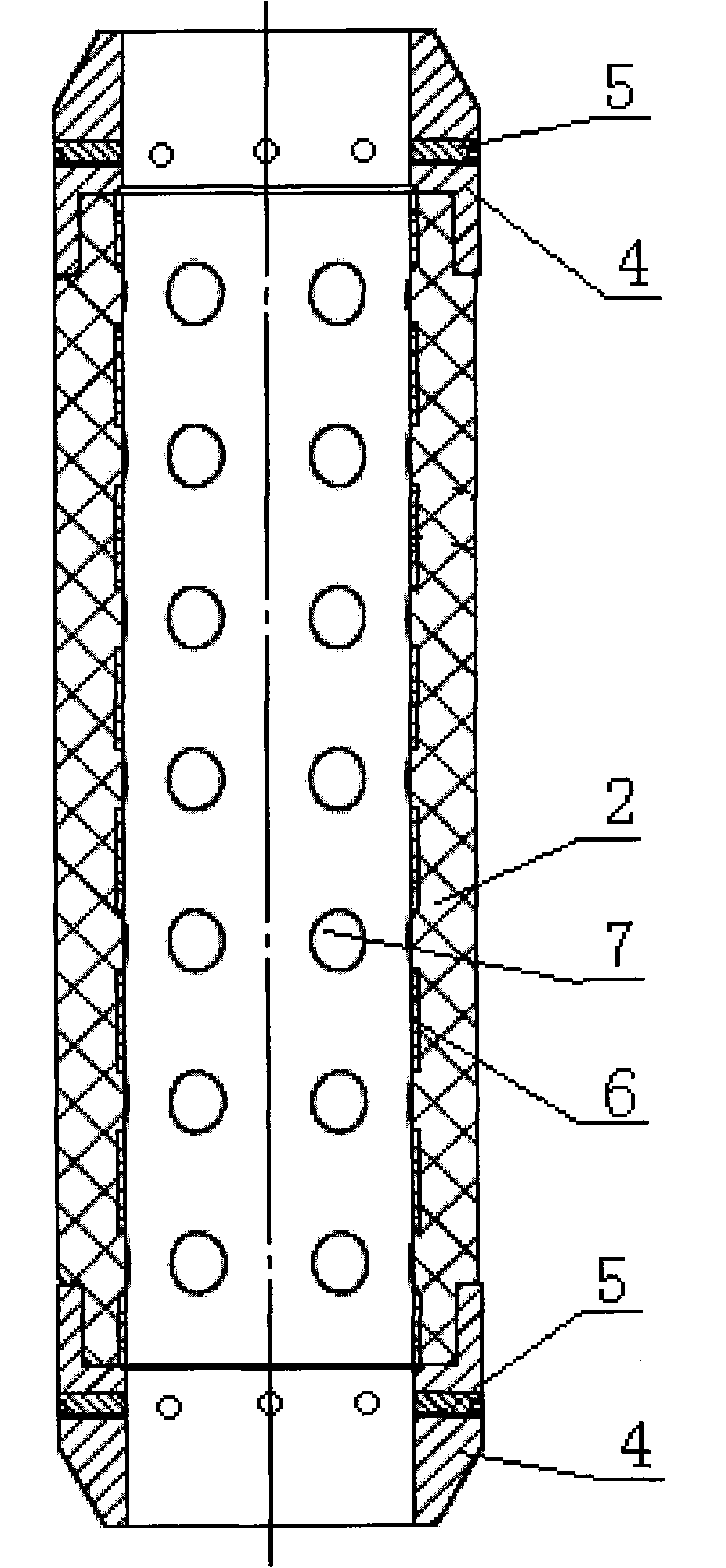

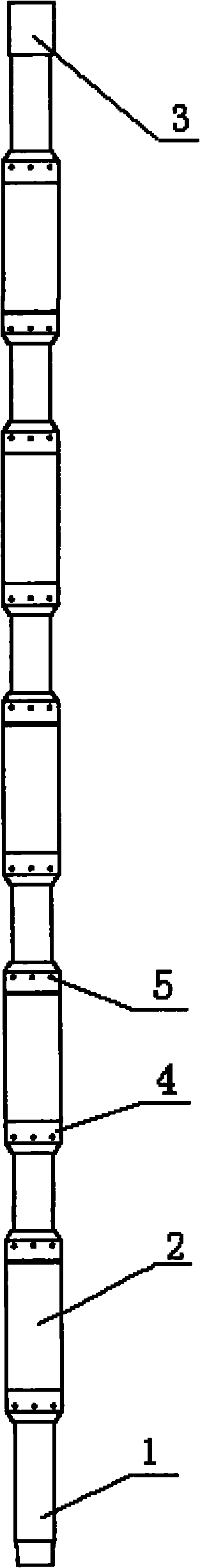

Underground self-expansion hanger

InactiveCN102071893ALarge diameterIncrease the diameterBorehole/well accessoriesVulcanizationAir Pollution Index

The invention discloses an underground self-expansion hanger, which is applied to oil development. An oil pipe or a casing which is commonly used in an oil field and is accordant with the air pollution index (API) standard is adopted; the outer wall of a pipe body is sleeved with 3 to 10 self-expansion rubber barrel components prefabricated by a vulcanization process in a plant; each self-expansion rubber barrel component consists of an inner bush and a self-expansion rubber barrel; through holes are uniformly distributed on the wall of the inner bush; self-expansion rubber barrels are vulcanized in the through holes; on a using field, the self-expansion rubber barrel components are sleeved on the outer wall of the pipe body; the distances between two adjacent self-expansion rubber barrel components are the same; pipe bodies at the two ends of each self-expansion rubber barrel component are sleeved with a limiting ring respectively; and the limiting rings are fixed on the pipe bodies through fastening bolts. The underground self-expansion hanger has the advantage that: under the condition that the oil pipe is not extracted, the hanger is seated and sealed and is hung in the oil pipe for realizing a well completion process.

Owner:PETROCHINA CO LTD

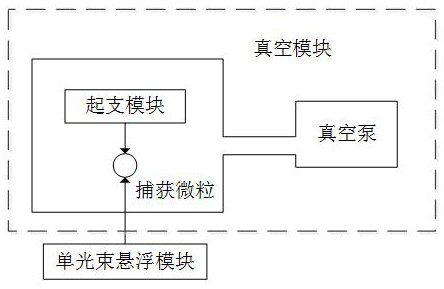

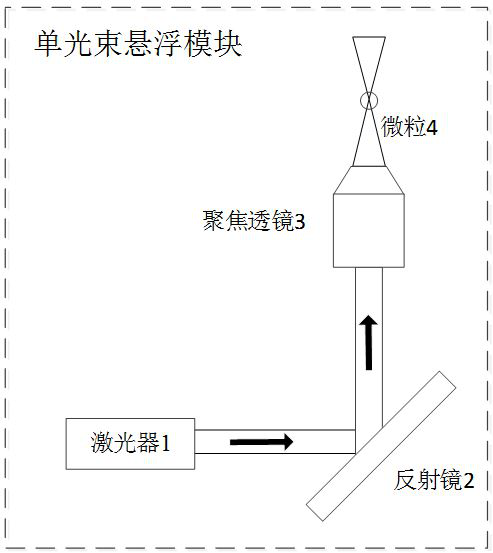

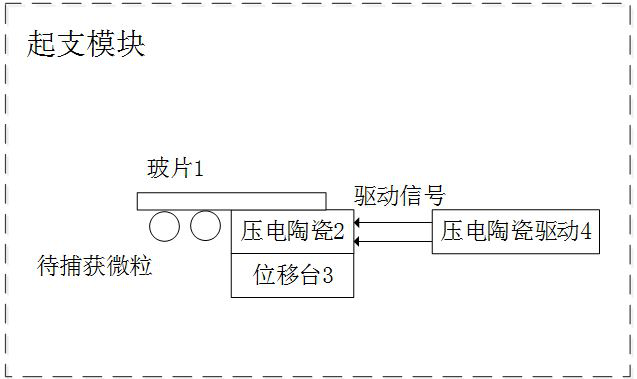

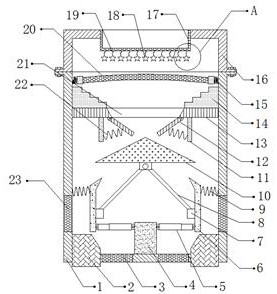

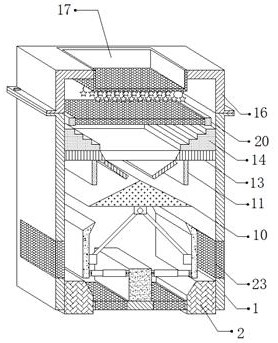

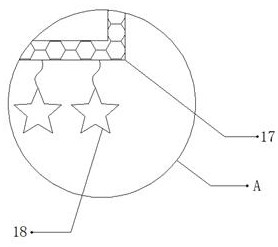

Method and device for suspending large-size particles based on photo-induced heating effect

The invention discloses a method and device for suspending large-size particles based on a photo-induced heating effect. The suspension device comprises a single-beam suspension module, a vacuum module and a supporting module, the single-beam suspension module is used for constructing focused laser transmitted from bottom to top, the laser acts on particles to be suspended, temperature differenceis generated on two sides of the particles, and generated photo-induced heating acting force can overcome the gravity of the particles to enable the particles to be suspended in the air; the vacuum module is used for controlling the air pressure around the suspended particles to maximize the photo-induced heating acting force, and the supporting module is used for initially supporting the particles to enable the particles to freely fall to a to-be-captured area. According to the invention, the suspension of particles is completed by using the photo-induced heating effect, the defect that traditional light trap suspension can only capture small-size particles is overcome, and the suspension capture of large-size particles can be realized.

Owner:ZHEJIANG UNIV

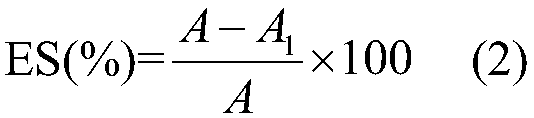

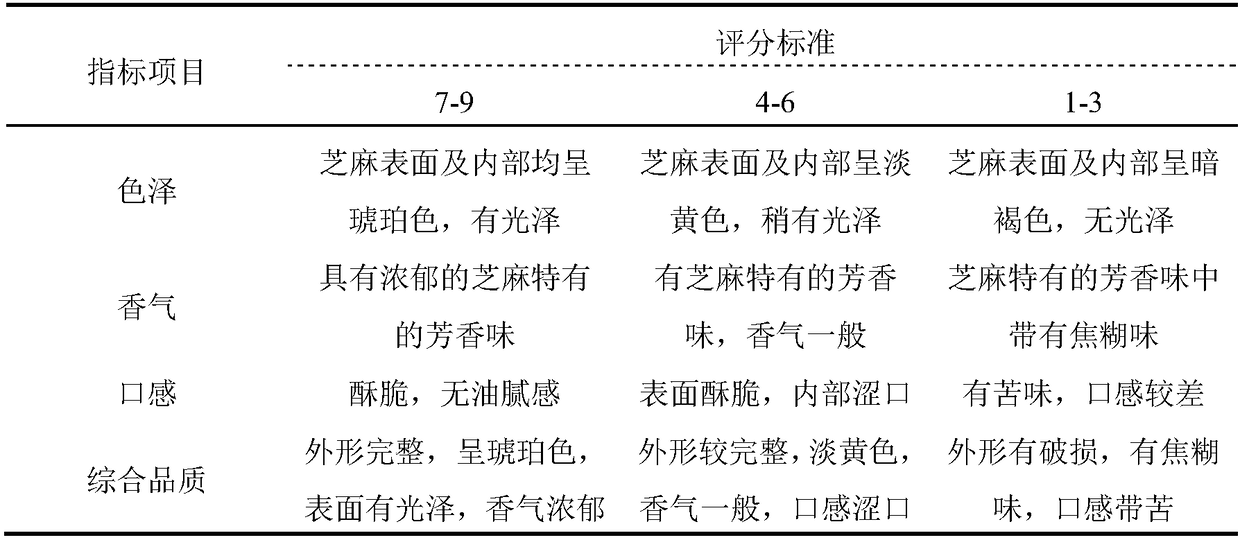

Sesame sauce and processing method thereof

The invention provides sesame sauce and a processing method thereof. The sesame sauce includes the following constituents in parts by weight: sesame 100, oil 6.5-7.5, an emulsifying agent 0.001-0.25,wherein the emulsifying agent includes the following constituents in parts by weight: sucrose esters 0.03-0.18 and monostearin 0.07-0.18. The sesame sauce is prepared by the method including the processes of roasting and grinding the sesame. According to the invention, through adopting a scientific formula and preparation process, the viscosity coefficient of the sesame sauce is increased from 2.3778 to 29.0216 and the stability coefficient of the sesame sauce is increased from 81.60% to 99.31%. Meanwhile, no oil phase is precipitated and yield is increased by about 23%.

Owner:HUAZHONG AGRI UNIV

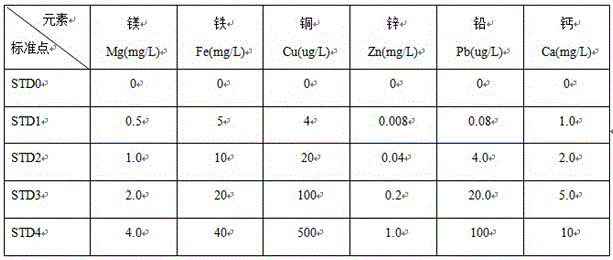

Detection method for microelements in peripheral blood

InactiveCN105738462ALow pollution rateImprove detection accuracyWithdrawing sample devicesPreparing sample for investigationBiologyPeripheral blood

The invention provides a detection method for microelements in peripheral blood. The detection method includes the following steps that 1, cleaning and disinfection are conducted; 2, a sample is acquired; 3, sample diluent is prepared; 4, detection liquid is prepared; 5, the concentration of the microelements is detected. A special acquisition tube is adopted for acquiring the sample in a scraping mode, the sample diluent is obtained by diluting an HNO3 and triton containing stock solution, and an inductively coupled plasma source mass spectrometer is applied to detecting the concentration of the microelements in the sample. The detection method for the microelements in the peripheral blood has the advantages that sample contamination is low, detection accuracy is high, the retention time of the sample is long, and the precision of the adopted instrument is high.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

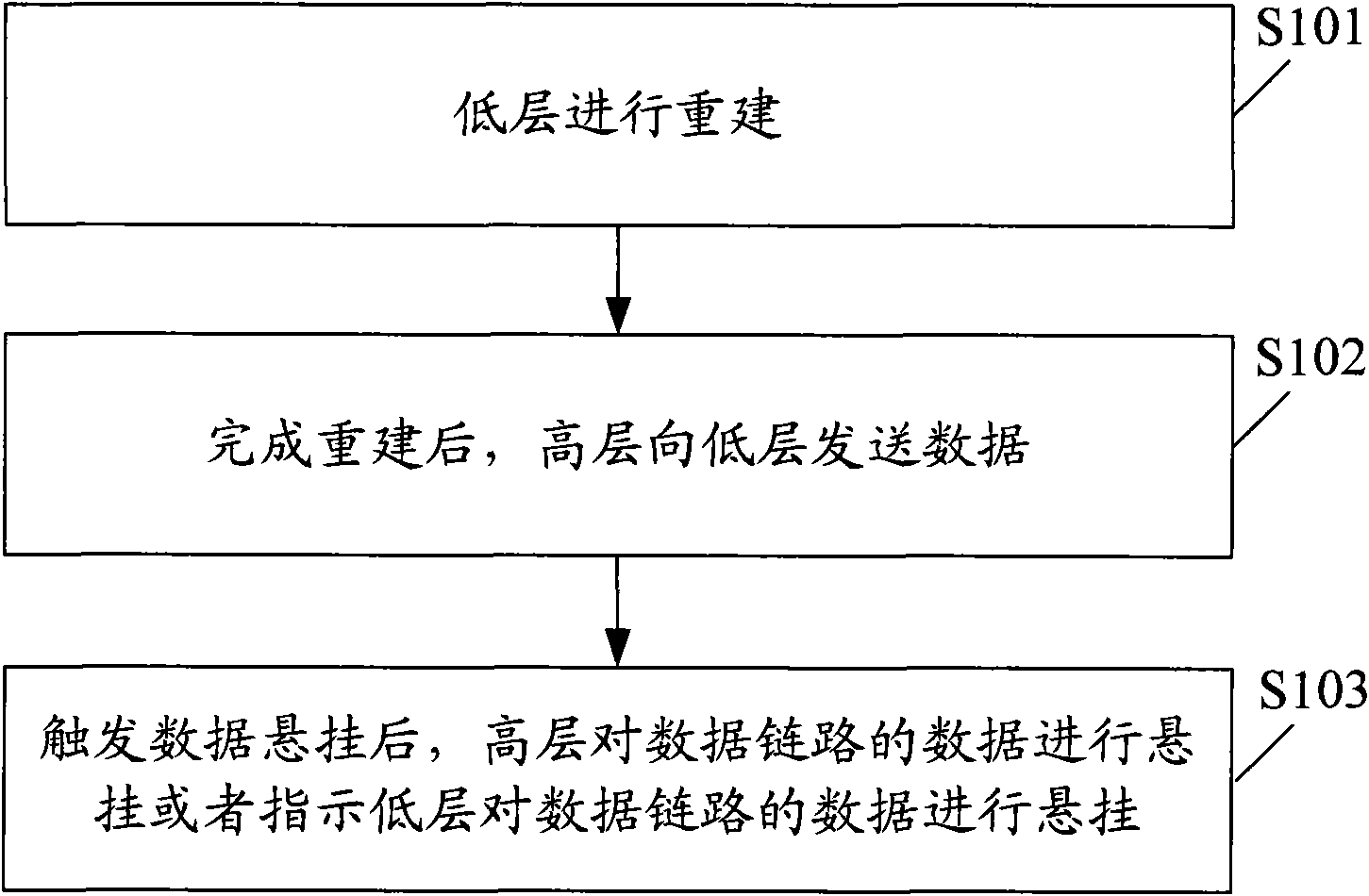

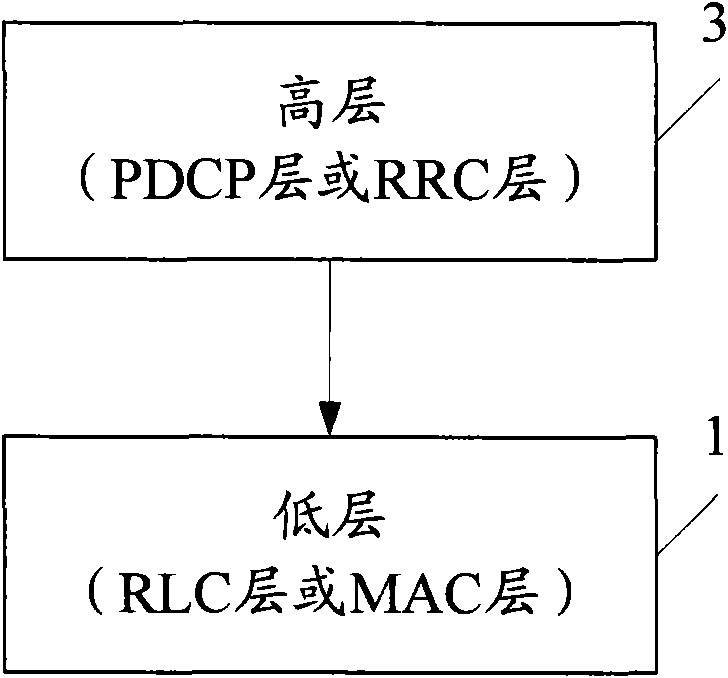

Method and equipment of data suspension

InactiveCN101686227AEffective suspensionEffective suspension controlError preventionControl dataComputer science

The embodiment of the invention discloses a method and equipment of data suspension, which relates to the technical field of communication and carries out effective data suspension in an EUTRAN system. The method comprises the following steps: a lower layer carries out reconstruction; after reconstruction is completed, a high layer transmits data to the lower layer; and after the data suspension is triggered, the high layer carries out suspension on the data of a data link or indicates the lower layer to carry out suspension on the data of the data link. The technical scheme provided by the embodiment of the invention can be widely applied in the EUTRAN system, carries out data suspension according to the functional characteristics of different protocol layers, and effectively controls thetransmission of the data.

Owner:HUAWEI TECH CO LTD

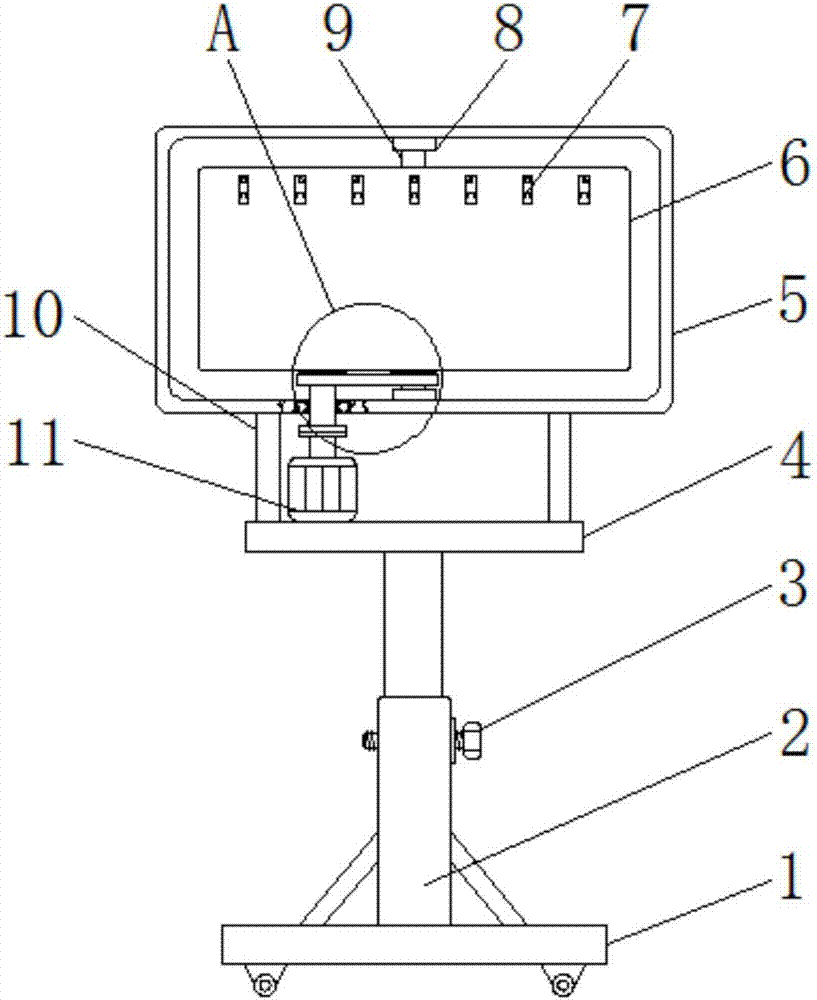

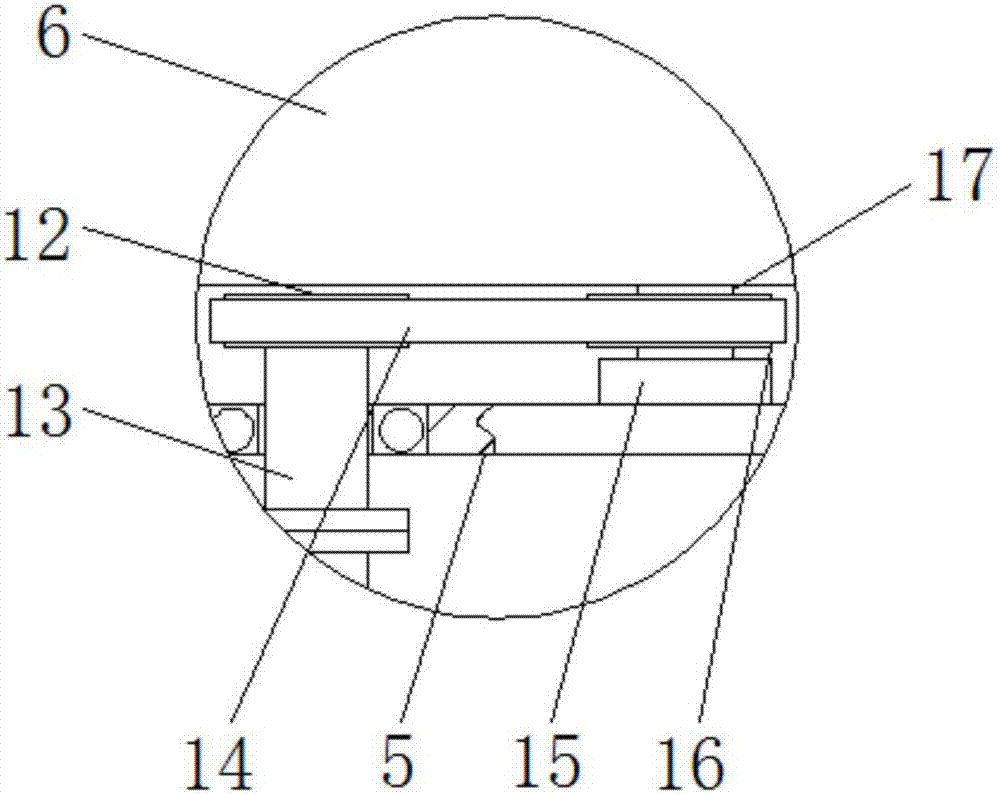

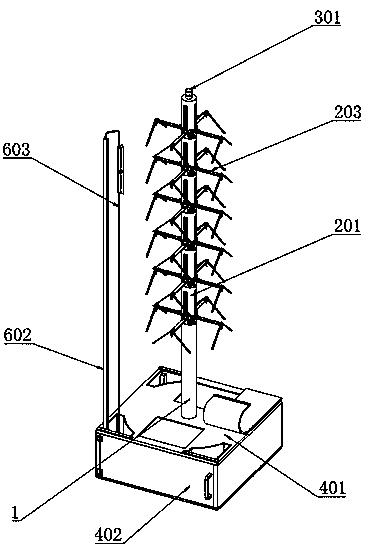

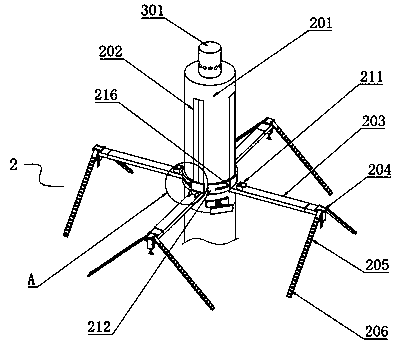

Textile display stand

InactiveCN107242735AEasy to displayImprove display effectShow shelvesShow hangersRotational axisDrive wheel

The invention discloses a textile display stand which comprises a base. An extensible rod is fixedly connected at the center of the top of the base, an adjusting button is arranged on the right side of the extensible rod, the top of the extensible rod is fixedly connected with a load bearing plate, a supporting rod is fixedly connected on each of two sides of the load bearing plate, and the tops of the supporting rods are fixedly connected with a display frame. Through matched using of a first bearing seat, a first rotating shaft, a forward-backward rotating frequency-variable motor, a driving wheel, a transmission shaft, a belt, a second bearing seat, a driven wheel and a second rotating shaft, angle of a display plate can be rotated effectively, so that textiles can be displayed from multiple angles, the problem that existing textile display stands cannot realize multi-angle display of textiles due to the fact that the existing textile display stands are fixed in angle during use is solved, great convenience is brought to textile displaying, and the textile display stand is suitable for popularization and use.

Owner:SUZHOU YUANLING TEXTILE CO LTD

Oily sludge profile control agent and preparation method thereof

The invention discloses a sludge profile control agent and a preparation method thereof, wherein the sludge profile control agent comprises 0.1-0.5% of a thickener, 0.01-0.2% of a crosslinking agent,oily sludge and water. A surfactant group is introduced into thickener molecules, the oily sludge can be effectively suspended and dispersed, and the crosslinking agent is a hydroxymethyl amine solution. The preparation method comprises the steps of mixing clear water and the oily sludge in accordance with the proportion evenly, firstly adding the crosslinking agent and stirring evenly, then adding the thickener, continuing to stir to obtain the sludge profile control agent having good injection performance; the sludge profile control agent has controllable gelling time, has relatively strongsealing and plugging ability and salt tolerance, and achieves deep profile control; the profile control agent realizes utilization of resources of the oily sludge, has no use of phenol and aldehyde products, and is an environmental-protection type profile control agent.

Owner:PETROCHINA CO LTD

Suspension steel plate for treating cruciate ligament tibial avulsion fracture

The invention discloses a suspension steel plate for treating cruciate ligament tibial avulsion fracture. The suspension steel plate includes a first steel plate and a second steel plate. The first steel plate and the second steel plate can be buckled together, the bottom end of the first steel plate is fixedly connected with a clamping block, the bottom end of the clamping block is provided witha clamping groove, the left and right sides of the top end surface of the second steel plate are each provided with a third insertion groove, the third insertion groove is connected with the clampingblock through a gap, and the bottom end of the third insertion groove is provided with a first insertion groove. The suspension steel plate for treating cruciate ligament tibial avulsion fracture effectively fixes an injured part of a patient, so that the connection is convenient, the fixation is fast, and quick dismantling and quick mounting in urgent need can be achieved; due to the installationof two layers of steel plates, the injured part of the patient is effectively protected, the outer layer steel plate makes an object not be in contact with the injured part of the patient during theaccidental impact of the outside object, thereby avoiding secondary damage to the patient.

Owner:深圳市大豪斯智能科技有限公司

High-efficiency large-scale method for culturing algae

InactiveCN107746819APrevent precipitationExtended stayBacteriaUnicellular algaeLuminous intensityBiodiesel

The invention provides a high-efficiency large-scale method for culturing algae. The method comprises the following steps: pre-treating a culture pool and pre-treating water for cultivation, adding amedium in the culture pool, and inoculating the algae species in the culture pool according to inoculation density; performing real-time monitoring on algae groups size, and luminous intensity, temperature, and pH value in the culture pool as well as photochemical active index of algae cell PSII, and performing protection adjusting measurement according to the monitoring data. The method can realize effective suspension of algae at each growth period, and can efficiently use light, nutrition and CO2 to realize rapid growth. The obtained algae biomass can produce functional food, a food raw material, bait, a high added value secondary metabolite and biodiesel.

Owner:武汉藻尚健生物科技有限公司

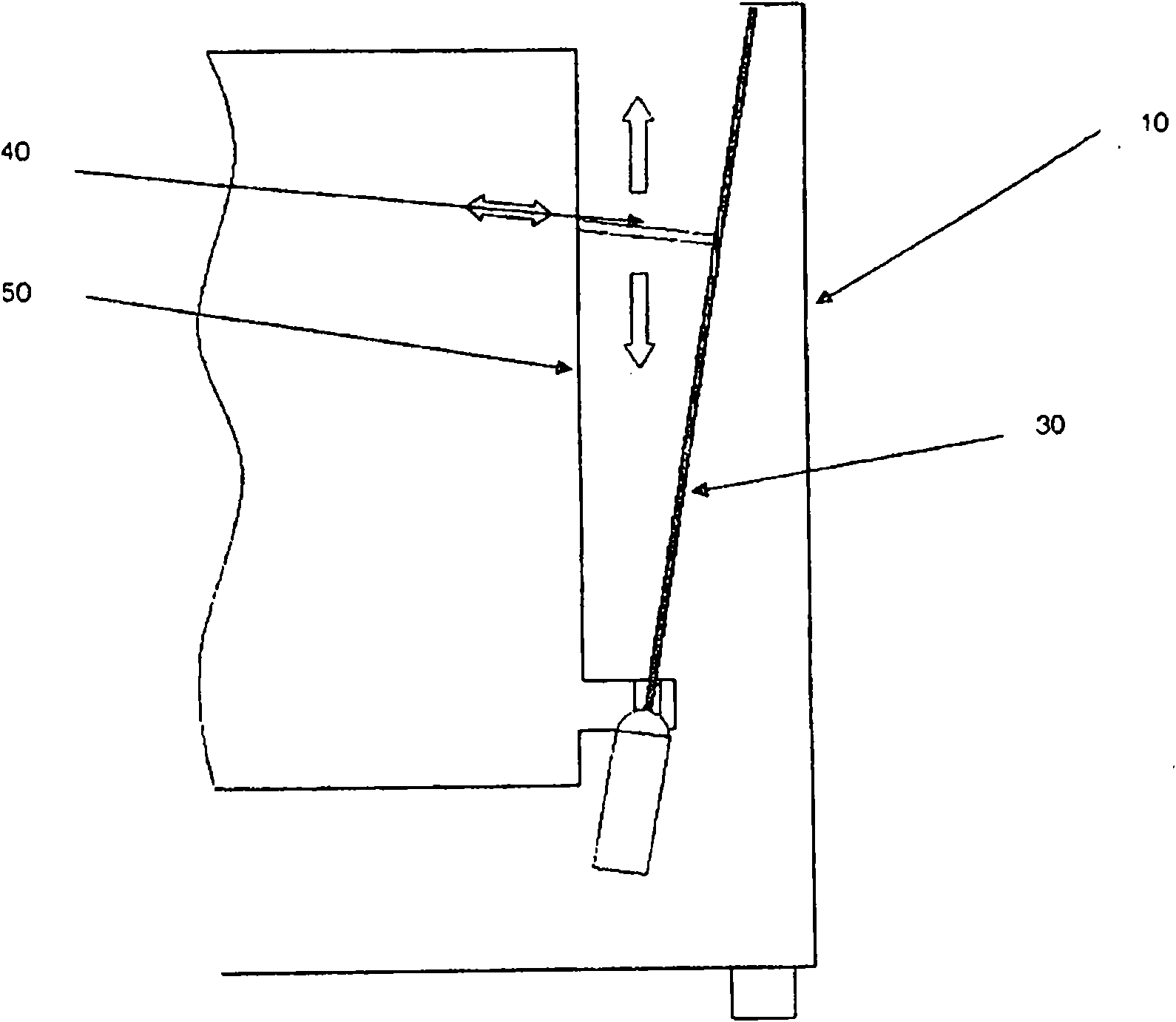

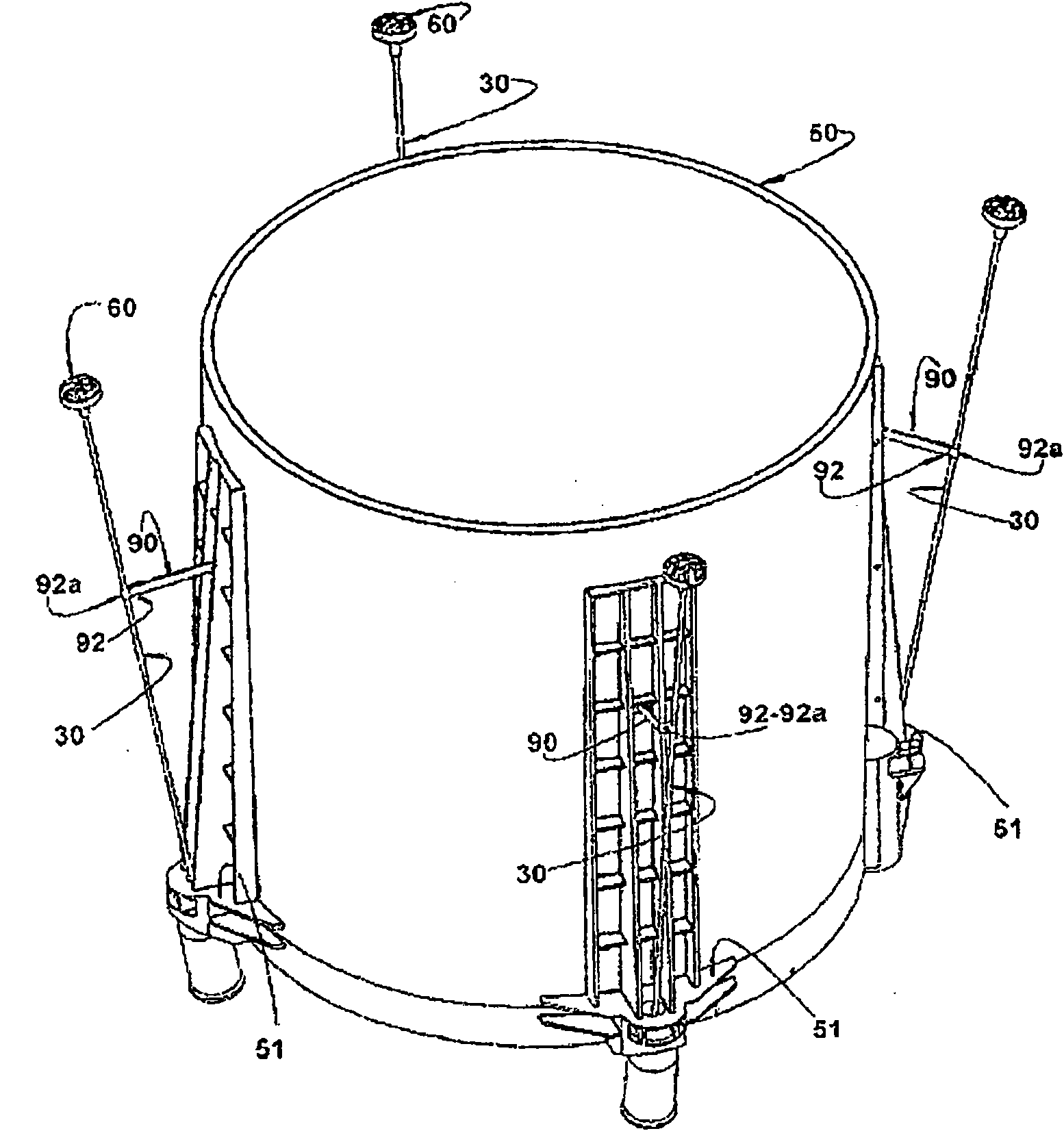

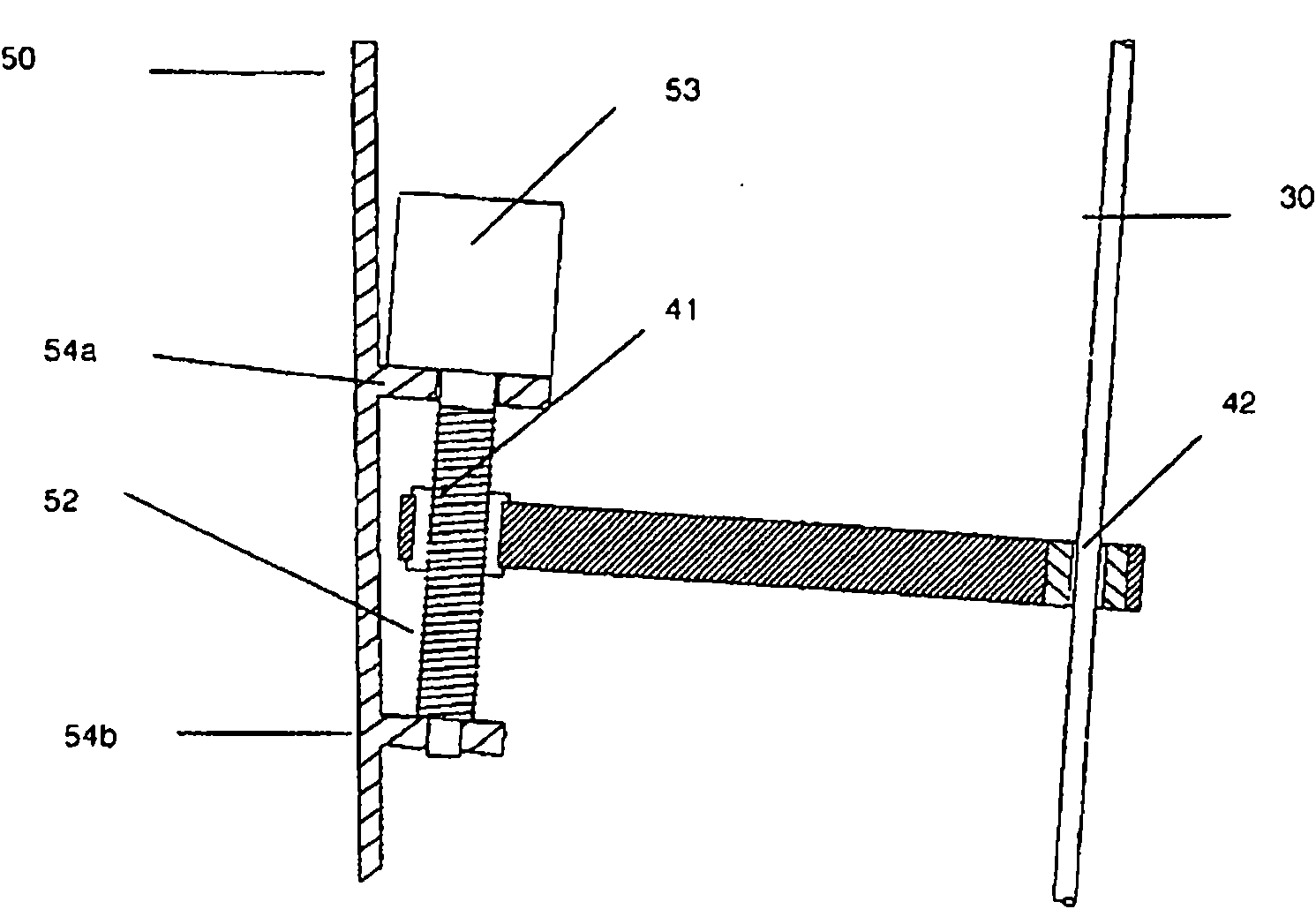

Suspension assembly for laundry machine

InactiveCN101899768AEffective suspensionSatisfactory performanceOther washing machinesWashing machine with receptaclesEngineeringLaundry

The present invention refers to a suspension assembly for laundry machines and, more specifically, to a suspension assembly for laundry machine comprising a washing liquid-containing tank suspended inside a structural housing. Said suspension assembly of the present invention comprises at least a suspension rod coupled to an upper portion of the inner wall of said housing and an lower portion of the outer wall of said tank; and at least a radial connection element with a first edge couplable to different positions of the outer wall of said tank and a second edge couplable to the suspension rod.

Owner:WHIRPOOL SA

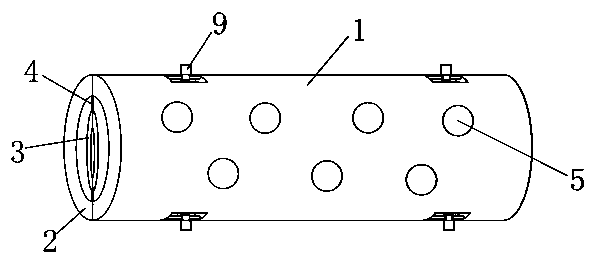

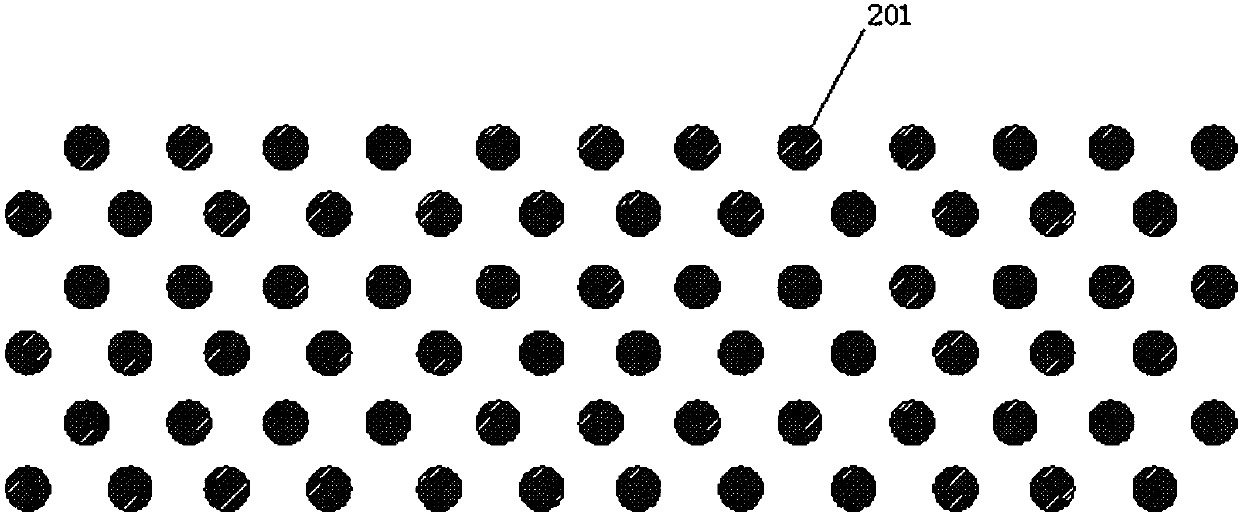

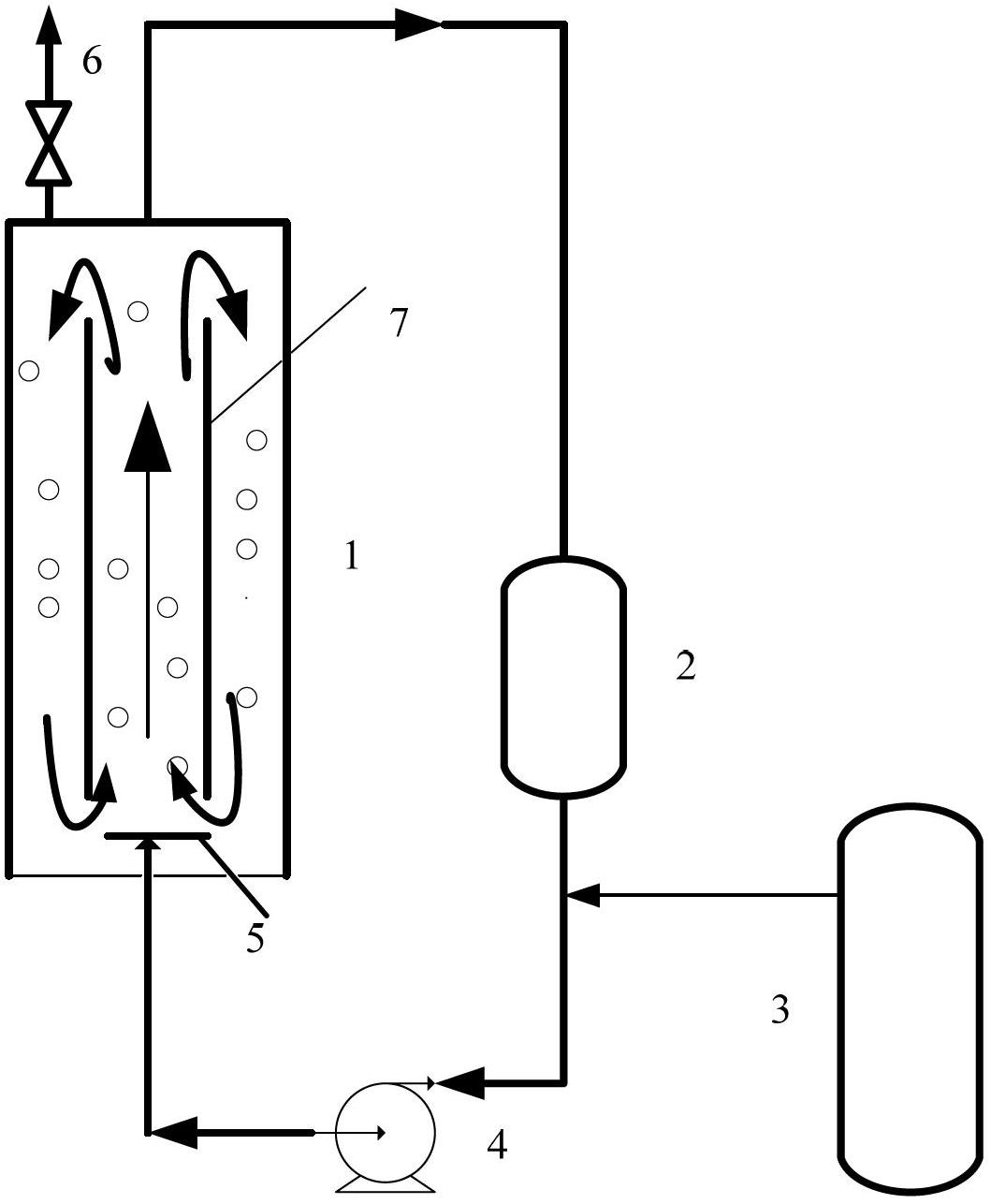

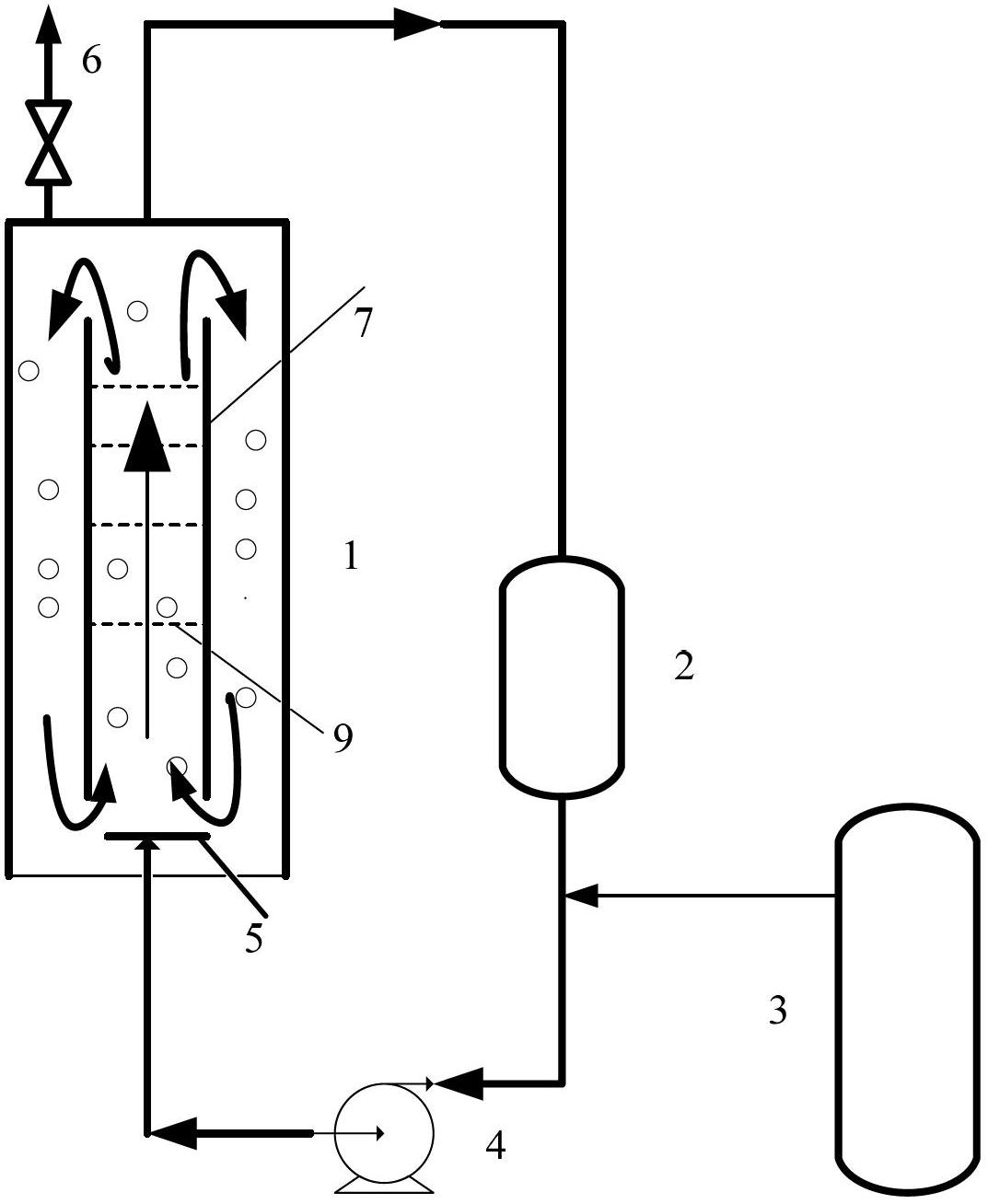

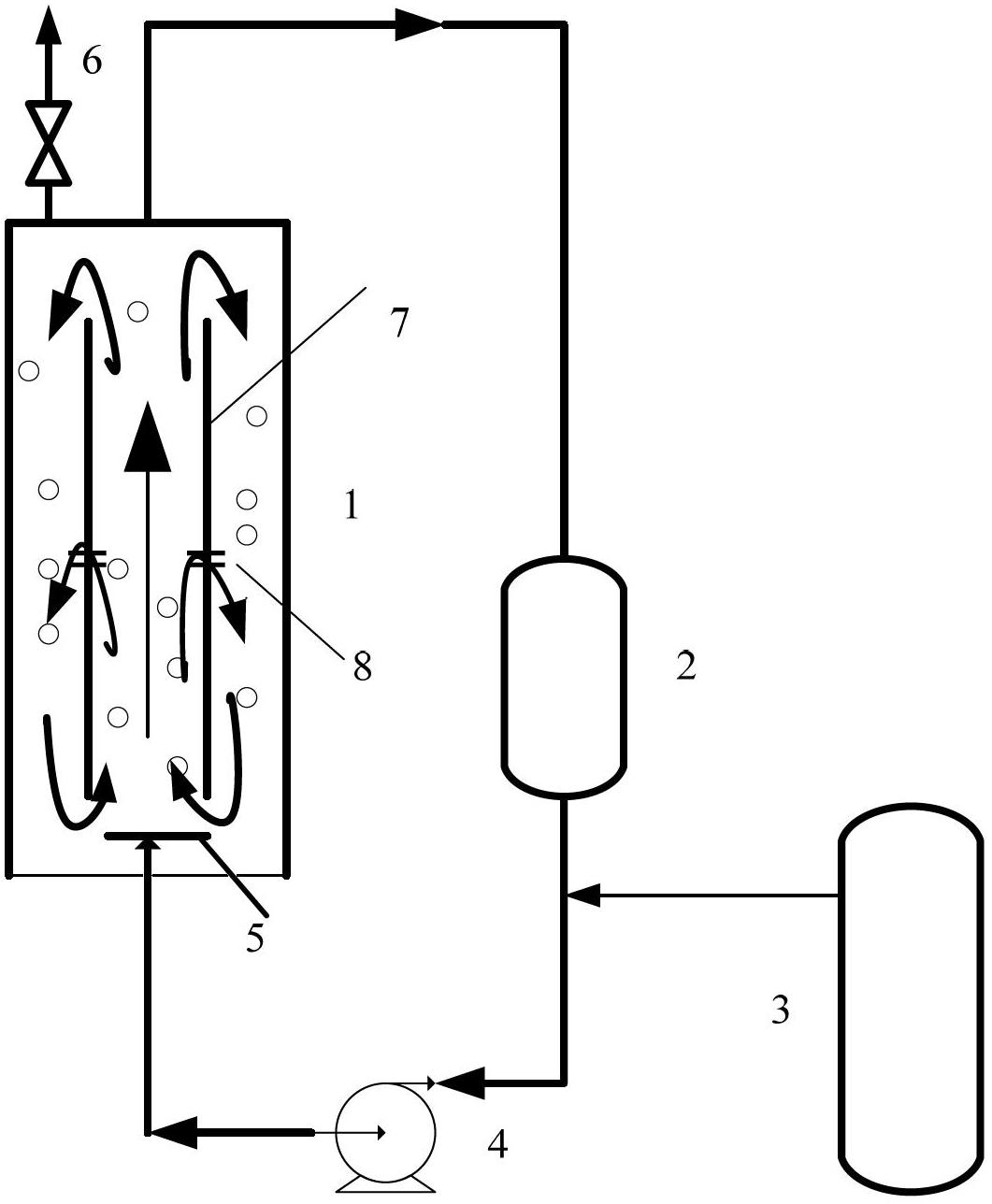

Method for copolymerizing carbon dioxide and propylene oxide with circulation flow reactor

The invention belongs to the field of chemical engineering technique and equipment, and particularly relates to a method for continuously producing polycarbonate by copolymerizing carbon dioxide and propylene oxide with a circulation flow reactor. The method comprises the following steps: introducing dry inert gas to replace atmosphere and remove water in the circulation flow reactor; adding propylene oxide, catalyst and carbon dioxide; copolymerizing the carbon dioxide and the propylene oxide under certain temperature and pressure to generate polycarbonate; and separating to obtain the aliphatic polycarbonate product, wherein the unreacted raw materials and gas are redistributed into the circulation flow reactor for cyclic utilization. The circulation flow reactor comprises a reactor shell, a raw material gas inlet, a gas distributor, a guide flow cylinder, a liquid feed port and a gas outlet, wherein a multilayer large-pore screen can be arranged in the guide flow cylinder, so that the circulating flow is divided into at least two stage when the pores of the guide flow cylinder wall are opened. The invention has the advantages of simple structure, low investment, good gas-liquid contact, good mass transfer, short time, high efficiency and the like, and is convenient to operate.

Owner:BEIJING RISUN TECH CO LTD

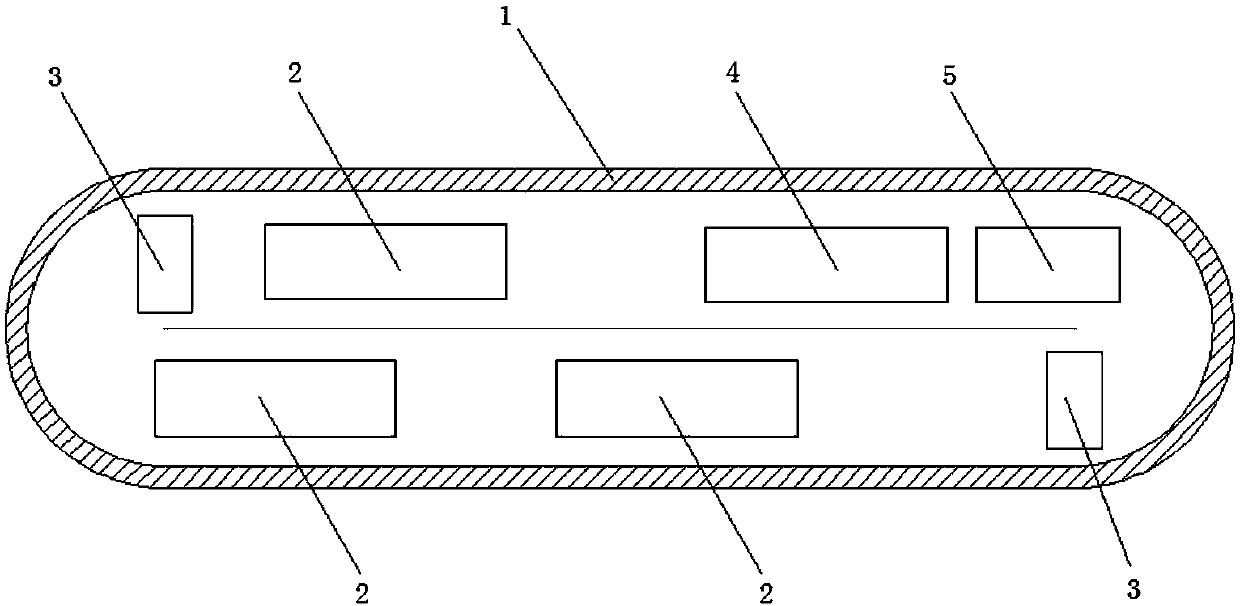

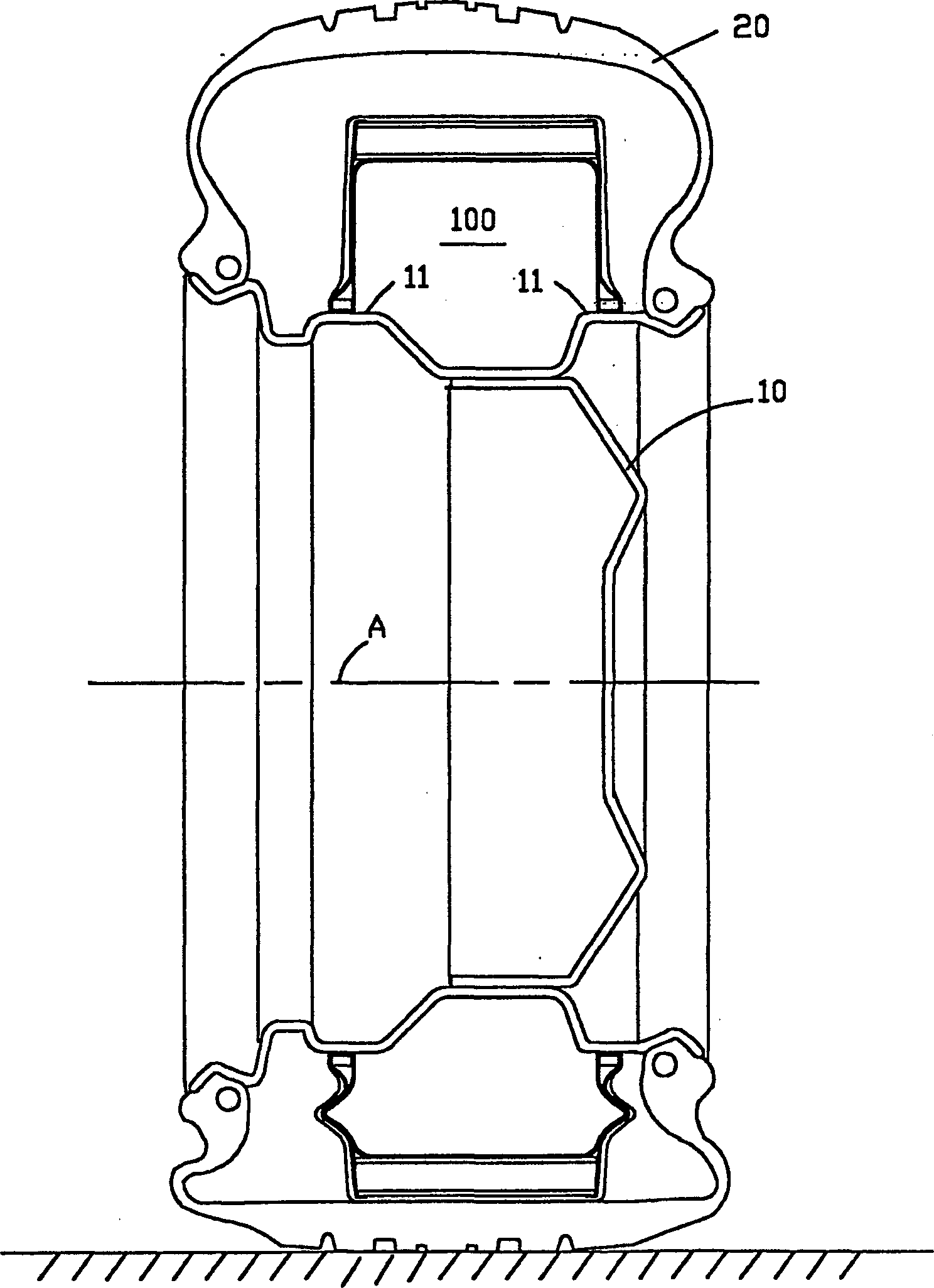

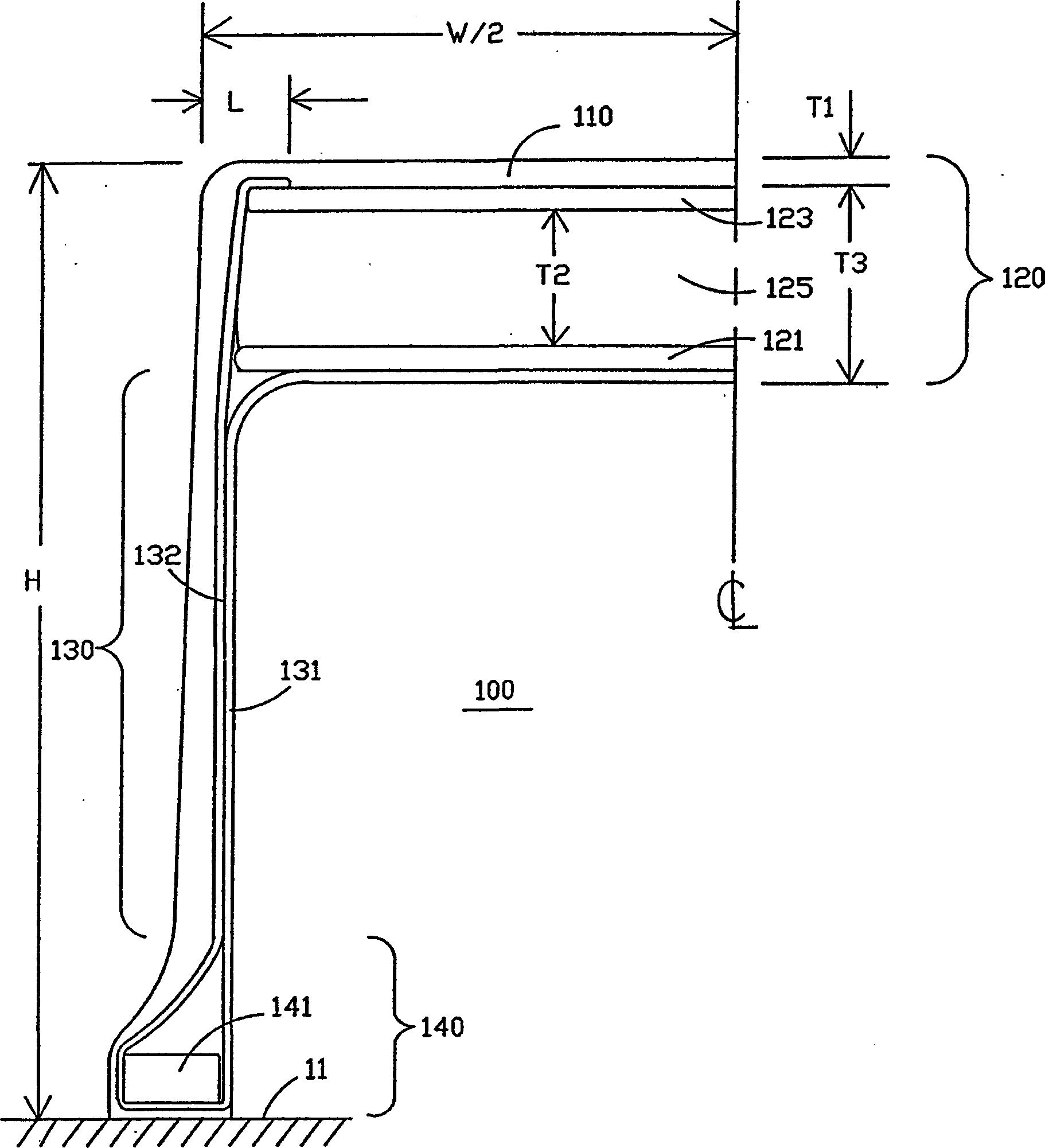

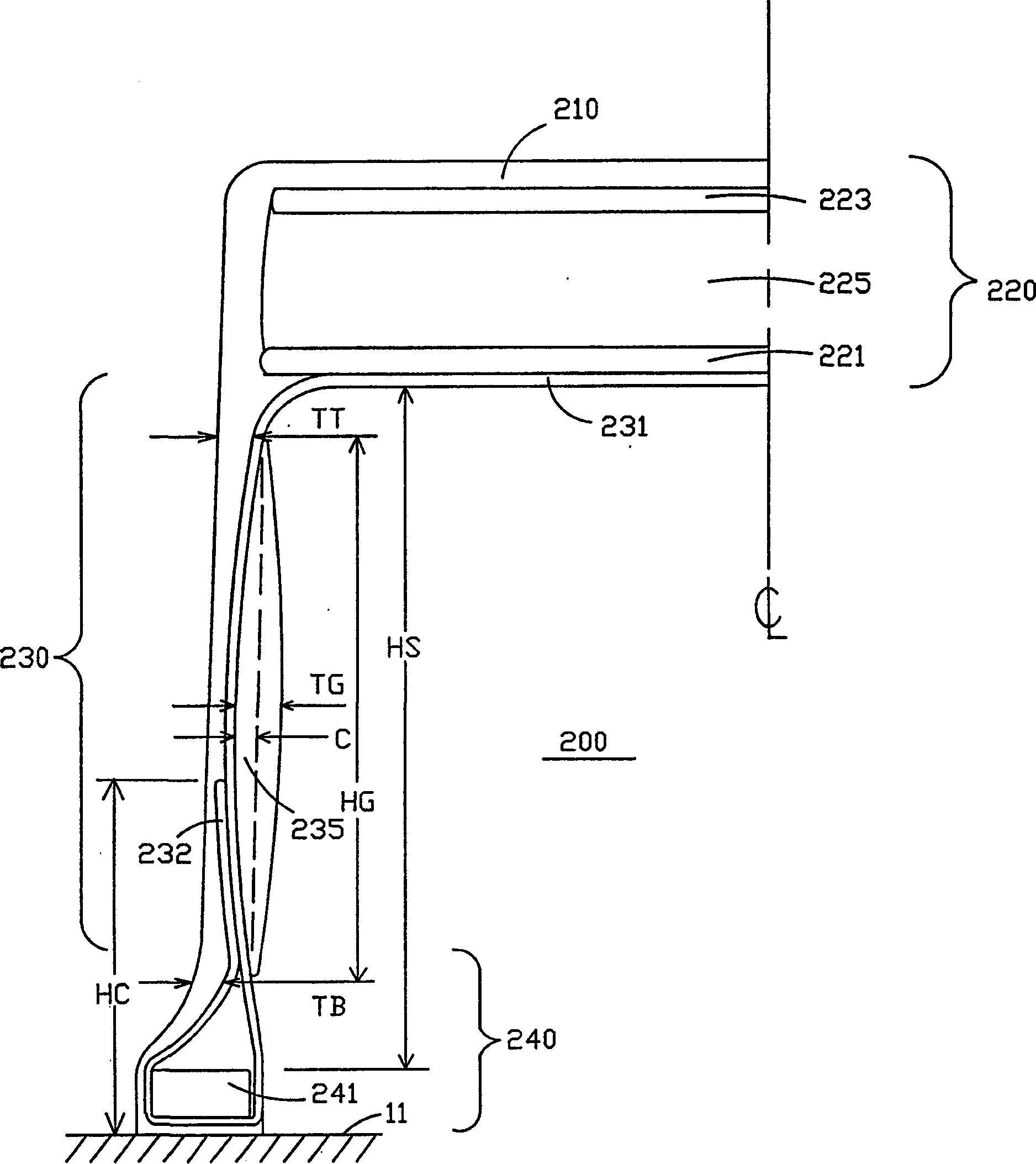

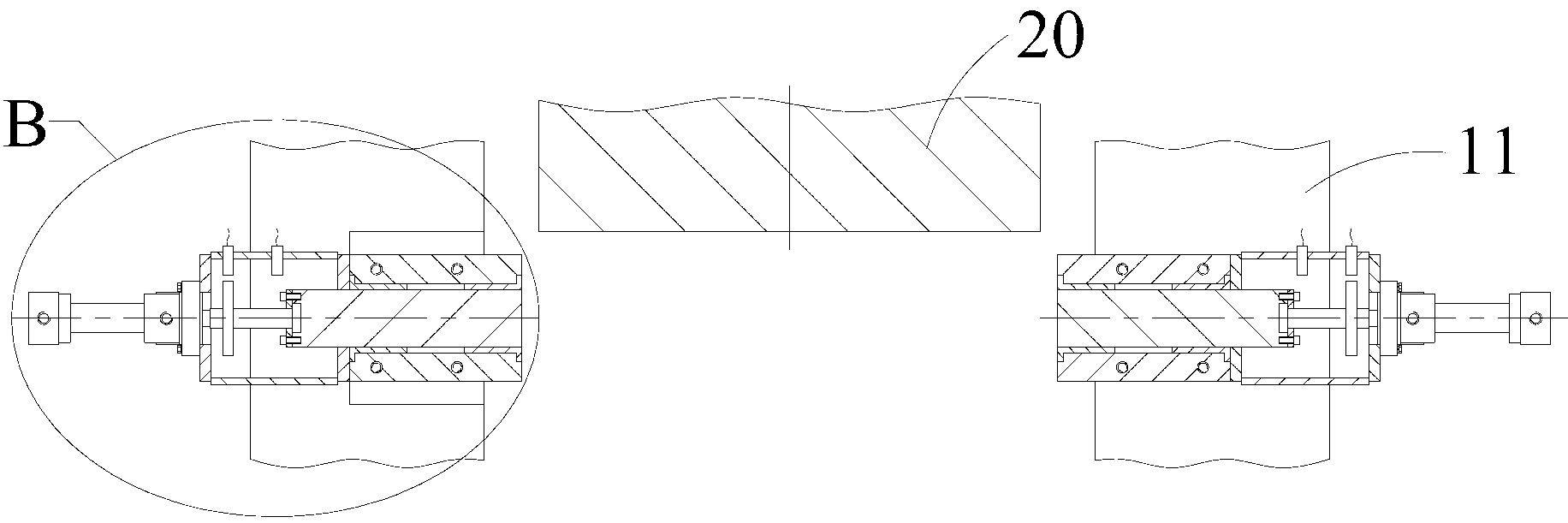

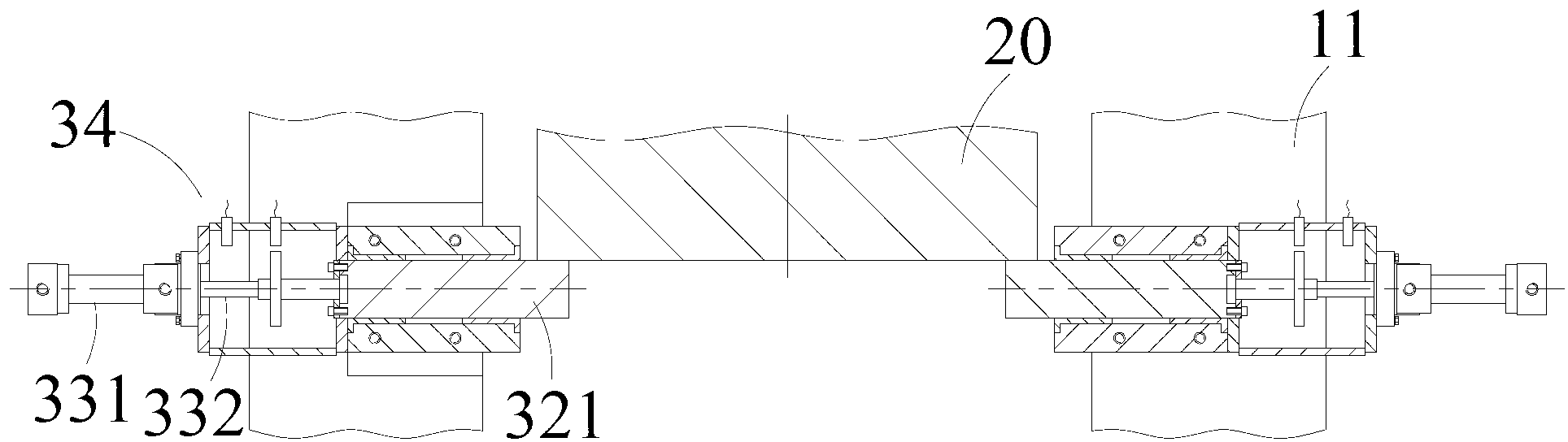

Runflat insert for tire

InactiveCN1545455AImprove performanceGentle bendSpecial tyresPneumatic tyre reinforcementsEngineeringMechanical engineering

A runflat insert (200) for enabling a vehicle to run for limited duration on a deflated tire (20), is mounted in an assembly comprising a pneumatic tire (20) and a wheel rim (10), and said insert is mounted inside the tire and secured to the wheel rim. The insert (200) has improved characteristics in load carrying, vehicle handling, mass, and shock transmission. Such a runflat insert (200) comprises an outer, reinforced annular band (220) that is coupled with a sidewall portion (230) having little resistance to compressive loads, and the sidewall portion (230) terminates in a base member (240) fitted around the wheel rim (10) for securing the insert (200) to the rim (10).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

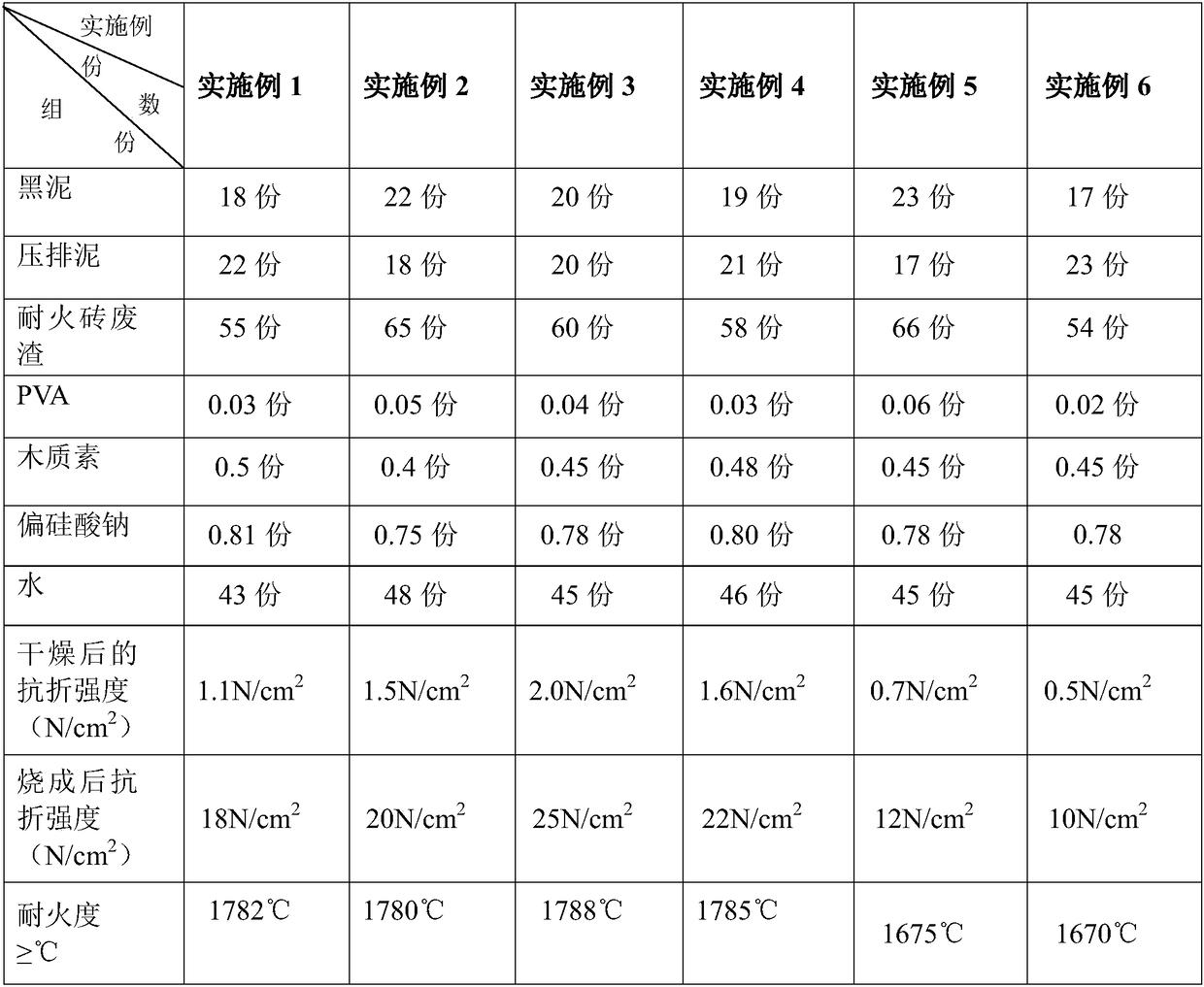

Low-cost preparation process of environment-friendly high-temperature brick and the high-temperature brick

ActiveCN108516847AEnergy saving and environmental protection in the preparation processHigh strengthCeramic materials productionClaywaresSodium metasilicateFire brick

A low-cost preparation process of an environment-friendly high-temperature brick and the high-temperature brick. The preparation process includes steps of: 1) mixing the raw materials including, by weight, 18-22 parts of black mud, 18-22 parts of pressure-discharged mud, 55-65 parts of waste residue of refractory bricks, 0.03-0.05 parts of PVA, 0.4-0.5 parts of lignin, 0.75-0.81 parts of sodium metasilicate and 43-48 parts of water, ball-milling the mixture to form slurry, and spray-drying the slurry to obtain a high-temperature brick powder material; 2) placing the high-temperature brick powder material in a pressing mould to press-shape the high-temperature brick powder material, and sintering the material in a kiln to obtain a finish product. The high-temperature brick not only has high-temperature fireproof effect but also is higher in strength, can be repeatedly used, is greatly reduced in preparation cost, is more environment-friendly and energy-saving, and has simple preparationprocess.

Owner:FOSHAN DONGPENG CERAMIC +2

Purple potato and tremella suspension beverage and preparation method thereof

The invention relates to a preparation method of a purple potato and tremella suspension beverage, which comprises the following specific steps of: (1) pretreating purple potatoes to obtain purple potato mud; (2) preparing original purple potato juice by using an enzyme method; (3) clarifying the original purple potato juice to obtain clarified original purple potato juice; (4) preparing tremellafruit grains; (5) blending the clarified original purple potato juice with the tremella fruit grains to obtain the purple potato and tremella suspension beverage. The purple potato and tremella suspension beverage is bright purple and has coordinated fragrance and clear and smooth taste, and fruit grains are stably and uniformly suspended. In the purple potato and tremella suspension beverage prepared by the method, the content of soluble solids is greater than or equal to 7%, the content of total acids is about 0.1-0.5%, the viscosity is 8.702*10<3> mPa.s, the content of anthocyanin is greater than or equal to 5 mg / 100 mL, the fruit grains are uniformly suspended, and the purple potato and tremella suspension beverage contains 12 amino acids among which 7 amino acids are essential to human bodies.

Owner:HEFEI UNIV OF TECH

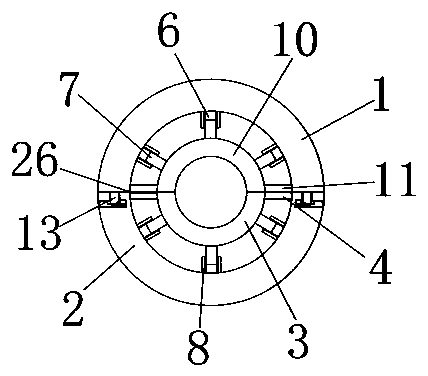

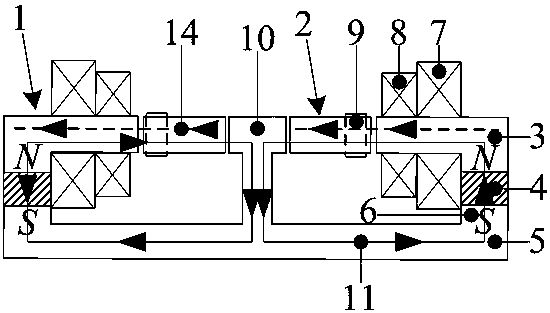

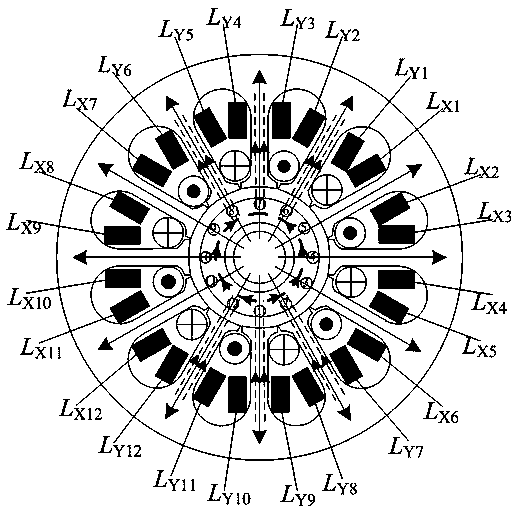

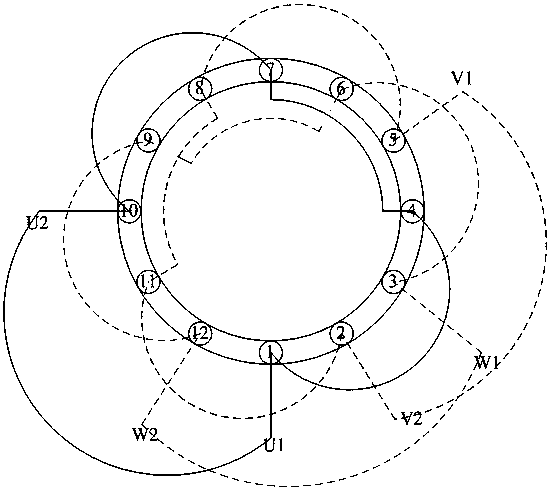

Stator permanent magnet-biased sheet-shaped inner-rotor bearingless asynchronous rotor

ActiveCN108712044ASmall magnetic resistanceEffective suspensionAsynchronous induction motorsWindings conductor shape/form/constructionCouplingConductor Coil

The invention discloses a stator permanent magnet-biased sheet-shaped inner-rotor bearingless asynchronous rotor. The stator permanent magnet-biased sheet-shaped inner-rotor bearingless asynchronous rotor comprises a stator and a rotor, wherein the rotor is arranged in an inner circle of the stator, the stator comprises a stator core, an axially-magnetized annular permanent magnet and an iron corebridge, a stator groove is formed in the stator core, a suspension winding and a torque winding are arranged in the stator groove, a T-shaped cylindrical boss is arranged at a middle part of the ironcore bridge and protrudes inwards, the rotor is a hollow thin circular post, an outer side air gap exists between the rotor and the stator core, an inner side air gap exists between the rotor and theT-shaped boss, a rotor groove is formed in a surface of the outer side air gap of the rotor, a guide strip is casted into the groove or a winding is wound around the groove, and the pole pairs of thewinding are different from those of the suspension winding. The stator permanent magnet-biased sheet-shaped inner-rotor bearingless asynchronous rotor is compact in structure and is simple to control, no coupling is generated between a suspension force and torque, and axial passive control and radial active control are performed.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

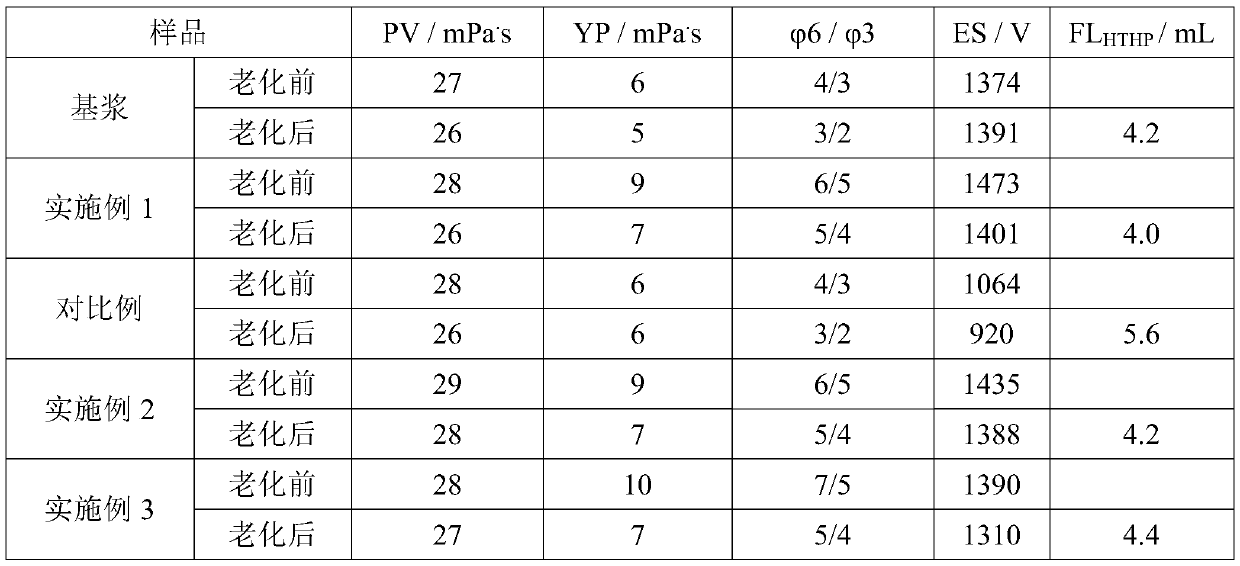

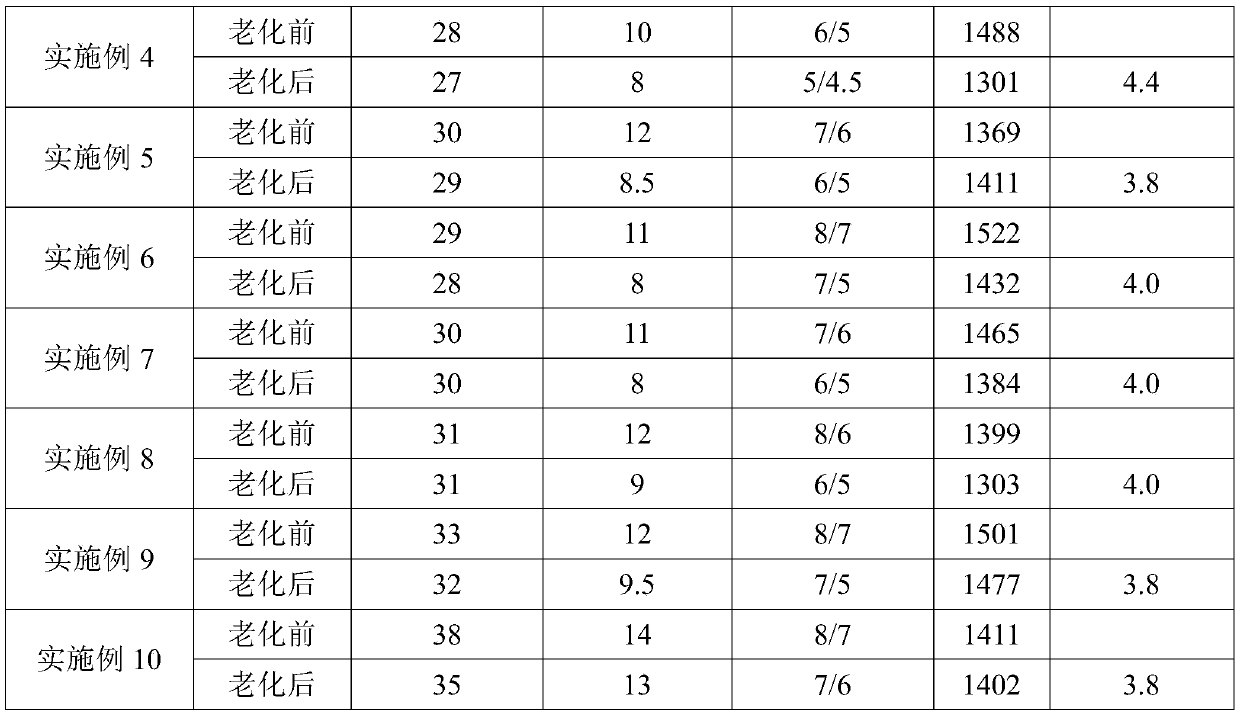

Flow pattern regulator for synthesizing base drilling fluid, and preparation method thereof

ActiveCN110746944AImprove liquidityImprove emulsion stabilityEsterified saccharide compoundsSugar derivativesPolymer sciencePtru catalyst

The invention discloses a flow pattern regulator for synthesizing a base drilling fluid, and a preparation method thereof. The flow pattern regulator is alkyl glucosamide containing two or more glucose chain segments, which is generated by reacting fatty acid or fatty acid methyl ester with glucose methylamine. The preparation method specifically comprises the following steps: adding glucose methylamine and binary or polybasic fatty acid / acid ester into a polar solvent, heating the obtained solution to 140-150 DEG C under the action of a sodium alcoholate catalyst, carrying out a reflux reaction for 4-5 h, evaporating away the polar solvent until no liquid drops out, cooling the obtained material to obtain a waxy solid, and drying and crushing the waxy solid to obtain the product. The flowpattern regulator for synthesizing the base drilling fluid has a low toxicity and is easy to degrade, and the molecular chain of the flow pattern regulator has a large number of polar groups such ashydroxyl groups and acylamino groups, so that the flow pattern regulator is prone to associating in a water-in-oil emulsion to form a weak gel form, so solid-phase particles are effectively tackifiedand suspended in a low-flow-rate state; and the gel state can be easily damaged under the action of external force such as pumping, so the drilling fluid recovers good fluidity, and increase of the mechanical drilling speed and improvement of the flushing capacity to the well wall are benefited.

Owner:CNPC BOHAI DRILLING ENG +1

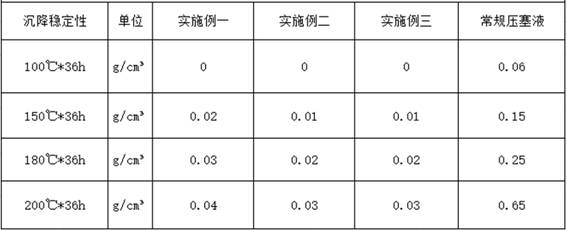

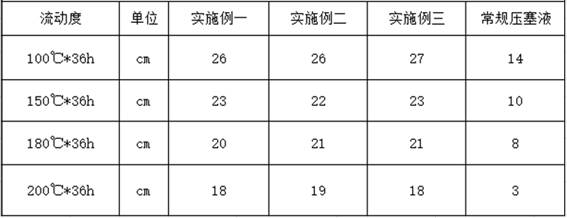

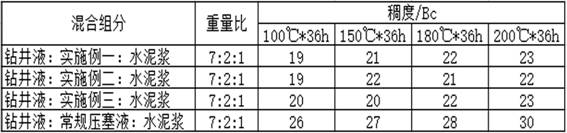

Well cementation method for high-temperature oil-gas well

ActiveCN113338849AEffective suspensionSuspendedFlushingDrilling compositionThermodynamicsWell cementing

The invention relates to a well cementation method for a high-temperature oil-gas well. The well cementation method sequentially comprises the following steps that (1) a casing string is placed in a well hole; (2) a cement head is installed on a top joint, and a rubber plug is arranged in the upper portion of the cement head; (3) drilling fluid is fed into an inner cavity of a casing, ascends along the annulus of the well hole and flows back to the ground, and rock debris is cleaned; (4) prepad fluid is injected into the casing string; (5) cement paste is injected into the casing string until the cement paste reaches the well cementation design amount; (6) the rubber plug is released, a cement truck injects tamponade fluid through a tamponade fluid inlet, and the tamponade fluid pushes the rubber plug to move downwards; (7) the drilling fluid is injected for paste replacement, the drilling fluid pushes the tamponade fluid to move downwards, the rubber plug pushes the cement paste to move downwards, the cement paste enters the annulus of the well hole from a float shoe and then pushes the prepad fluid to ascend, and the prepad fluid pushes the drilling fluid to ascend; and (8) the rubber plug stops moving downwards when moving downwards to a spoiler of a float collar, collision pressure is generated, a mud pump is turned off immediately, and at the moment, the cement paste returns to a preset well section and enters a waiting-for-cement state. The well cementation quality is good, and well logging of an electrical logging instrument can be smoothly carried out after well cementation.

Owner:中石化石油工程技术服务有限公司 +1

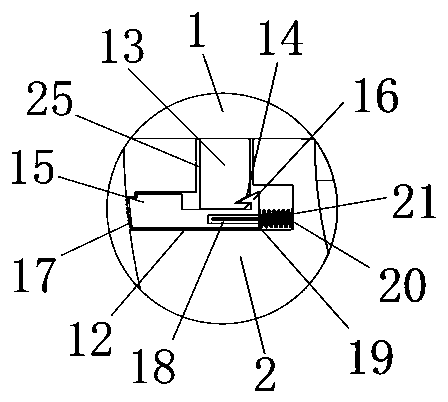

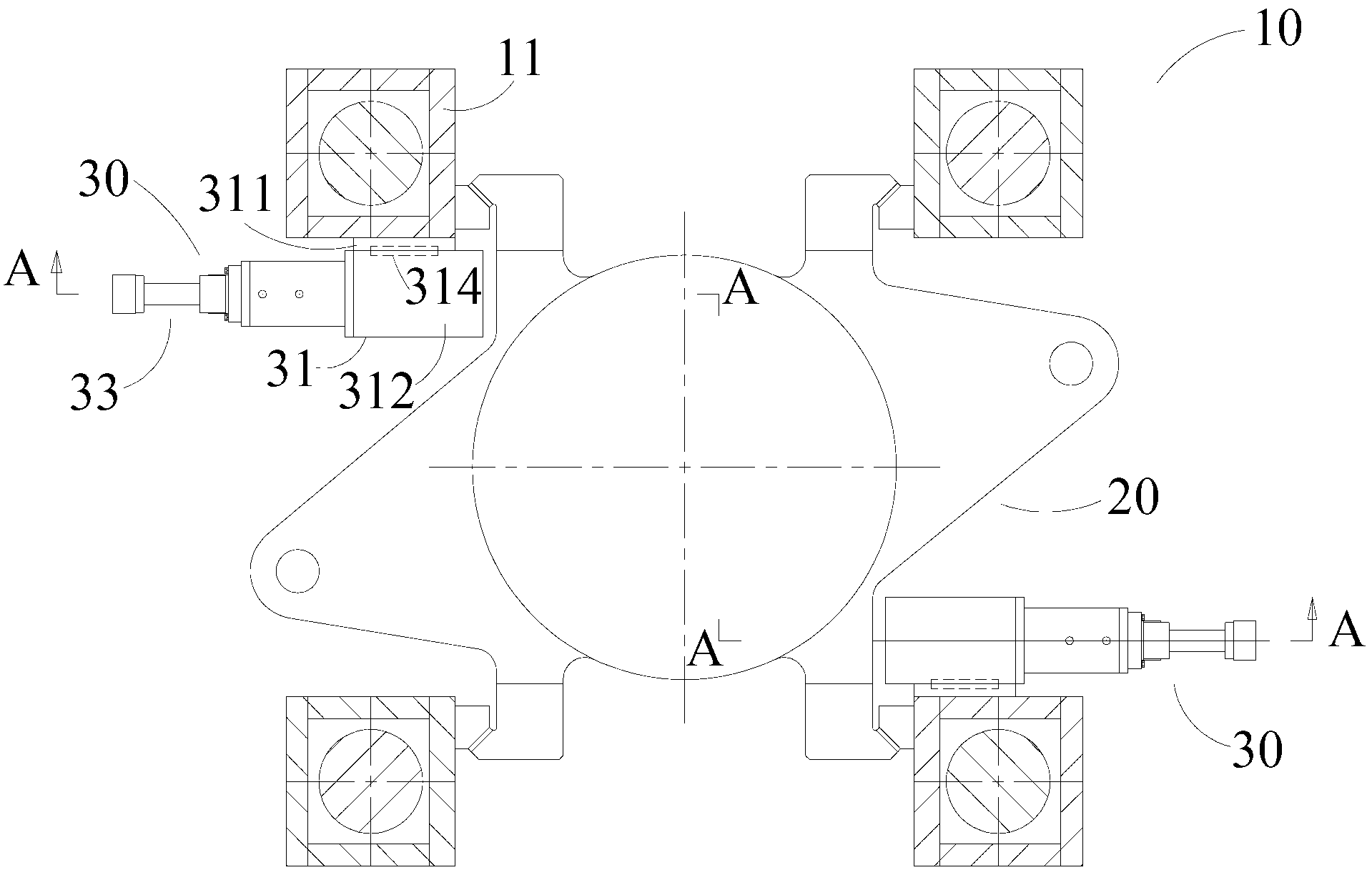

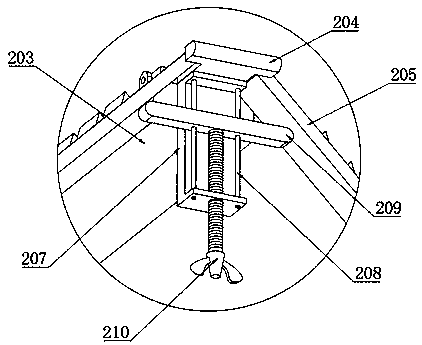

Extrusion beam suspension device and vertical extruder

The invention provides an extrusion beam suspension device and a vertical extruder. The extrusion beam suspension device is used for supporting an extrusion beam of the vertical extruder, and comprises a fixed part, a movable part and a driving part, wherein the fixed part comprises a seat body; the seat body is fixedly connected with a stand column of the vertical extruder; the movable part comprises a pin shaft; the pin shaft is movably arranged in the seat body; the driving part is used for driving the pin shaft to move; when the pin shaft is not exposed out of the seat body, the pin shaft is not in contact with the extrusion beam, and the extrusion beam is in a working state; and when at least part of the pin shaft is exposed out of the seat body, the extrusion beam is supported by the pin shaft, and is in a suspension state.

Owner:TAIYUAN HEAVY IND

Water-based cleaning agent with strong dispersing capacity, and cleaning method thereof

ActiveCN111040888AQuick wetQuickly wets and penetratesInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsLipid formationChlorobenzene

The invention provides a water-based cleaning agent with strong dispersing capacity, and a cleaning method thereof, wherein the cleaning agent comprises narrow-distribution fatty alcohol-polyoxyethylene ether and a nonionic surfactant. According to the invention, the cleaning agent prepared by the preparation method has strong cleaning capability on granular pollutants wrapped by rosin or other lipid compounds, can effectively remove pollutants in difficult-to-clean positions such as deep holes, blind holes and the like, and is simple and stable in components, free of layering, not prone to volatilization and decomposition, free of corrosion effect on welding spots, is wide, inexpensive and easily-available in raw materials, low in cost, low in waste liquid treatment cost, free of toxic substances such as sulfur, chlorine, benzene, heavy metals and the like, and low in harm to human bodies and the environment; the cleaning process is easy to operate, free of residues, high in cleanliness and bright in welding spot; and the application field is wide, and the application prospect is good.

Owner:CHONGQING UNIV OF TECH

Telescopic coat hanger

PendingCN110656475ASafe to useImproved rotatabilityTextiles and paperLaundry driersRound barEngineering

The invention discloses a telescopic coat hanger which comprises a round bar. A plurality of coating hanging mechanisms are mounted at the top end of the round bar, a plurality of cylinders are mounted at the top end of the round bar, the bottom of a storage slot is rotatably connected with a telescopic bar through a rotating shaft, recesses on two sides of an I-shaped piece are rotatably connected with coat hanging bars through rotating shafts, the middles of limited posts are slidably connected with adjusting bars, an arc-shaped frame is welded on the side surface of each cylinder facing oneside of the bottom of the corresponding storage groove, arc-shaped door plates are slidably connected in the arc-shaped frames through first reset springs, a T-shaped bar is welded at one end of eacharc-shaped door plate, and adjusting grooves are formed in the middles of the arc-shaped frames. According to the coat hanger, angles of the coat hanging bars are adjusted by moving the adjusting bars upwards, the coat hanging bars can be effectively hung according to different types of clothes, a plurality of coat hanging bars can be stored into the storage grooves, and appropriate number of andappropriate position of coat hanging bars can be selected and used by a user as required.

Owner:桑滨

Emulsion stabilizer for the production of plant protein milk

InactiveCN101095475BEffective emulsification and dispersionWill not affect the tasteFood preparationMilk substitutesFatty acid glycerol estersPyrophosphate

The invention relates to an emulsion stabilizer for plant protein milk production. The comprised components and weight proportion are as follows: mono-fatty glycerin ester 10-20%, poly-glycerin fattyester 4-8%, sodium alginate 3-6%, microcrystalline cellulose 60-75%, and sodium pyrophosphate 4-10%. The invention is characterized by increased floating stability, emulsifying ability and raw material usage rate. There is no deposition in preservative period, no apparent floating fatty circle when the product is used for plant protein milk production such as peanut milk, walnut milk and soybean milk, and the product quality is improved.

Owner:MASSON GROUP

Solid-liquid separation device applied to sewage treatment system

The invention discloses a solid-liquid separation device applied to the sewage treatment system. The device comprises a box body, water outlets are formed in the two sides of the outer wall of the bottom of the box body, first filter screens are fixedly connected to the inner walls of the two water outlets, a plurality of filter holes are formed in the outer walls of the two sides of the box body,a box cover is fixedly connected to the outer wall of the top of the box body, a water inlet is formed in the outer wall of the top of the box cover, a filter cone is fixedly connected to the inner wall of the water inlet, a fixing block is fixedly connected to the inner wall of the bottom of the box body, telescopic rods are connected to the outer walls of the two sides of the fixing block through hinges, and extrusion plates are connected to the outer walls of one sides of the two telescopic rods through hinges. According to the device, solid waste can be subjected to extrusion treatment, the situation that the device cannot effectively conduct solid-liquid separation on the sewage due to the fact that the impact strength of the sewage is weak can be prevented, the solid waste doped inthe sewage can be retained on the second guide plate, and the situation that the solid waste falls off from the hanging piece due to water flow can be prevented.

Owner:刘海容

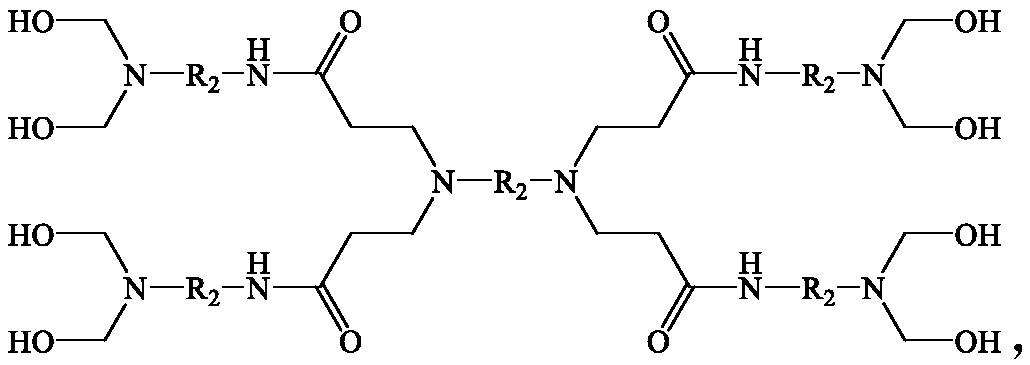

Anti-dandruff traditional Chinese medicine oil mixture conditioning shampoo

InactiveCN107951751ASafe to useStrong antibacterial effectCosmetic preparationsHair cosmeticsHair washingAntibacterial effect

The invention provides a traditional Chinese medicine anti-dandruff conditioning shampoo. The shampoo comprises a cleansing surfactant, a water-insoluble anti-dandruff agent and / or an anti-itch agent,a conditioning agent, traditional Chinese medicine oil and a suitable carrier. Compared with the prior art, the shampoo has the advantages that the shampoo is safe and convenient to use, water-insoluble hair treatment compounds are effectively suspended, the hair is effectively cleaned, the water-soluble and water-insoluble hair treatment compounds are effectively conveyed to the hair and scalp,and the hair is also effectively conditioned; moreover, the volatile traditional Chinese medicine oil is selected and used and can quickly and automatically volatilize after participating in compoundconveying in the hair washing process so that the traditional Chinese medicine oil can assist in hair shaping after hair washing and cause no other dust adhesion. The shampoo can effectively achieve hair conditioning, have a great antibacterial effect and control the continued generation of dandruff.

Owner:佛山市洛克威特科技有限公司

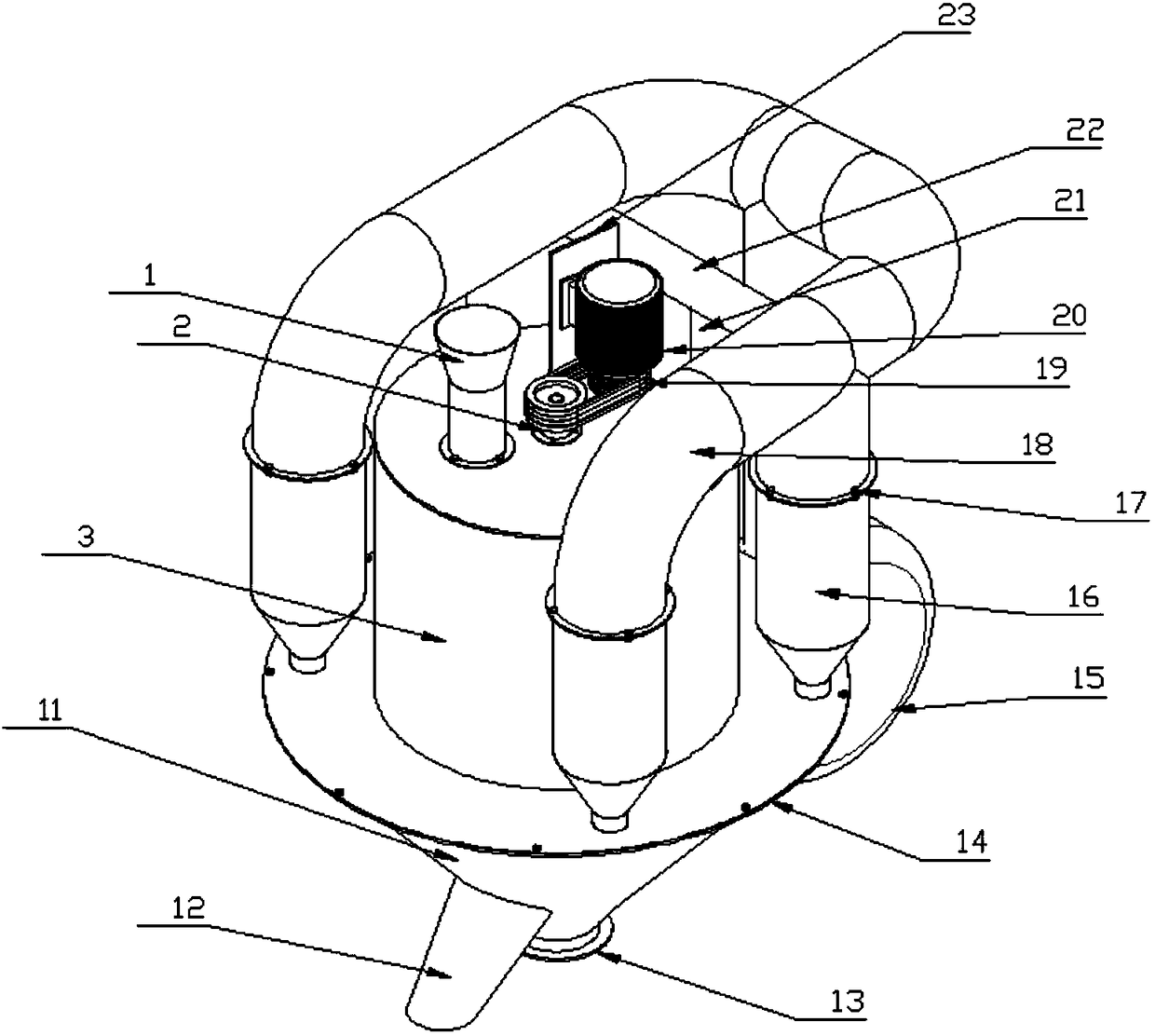

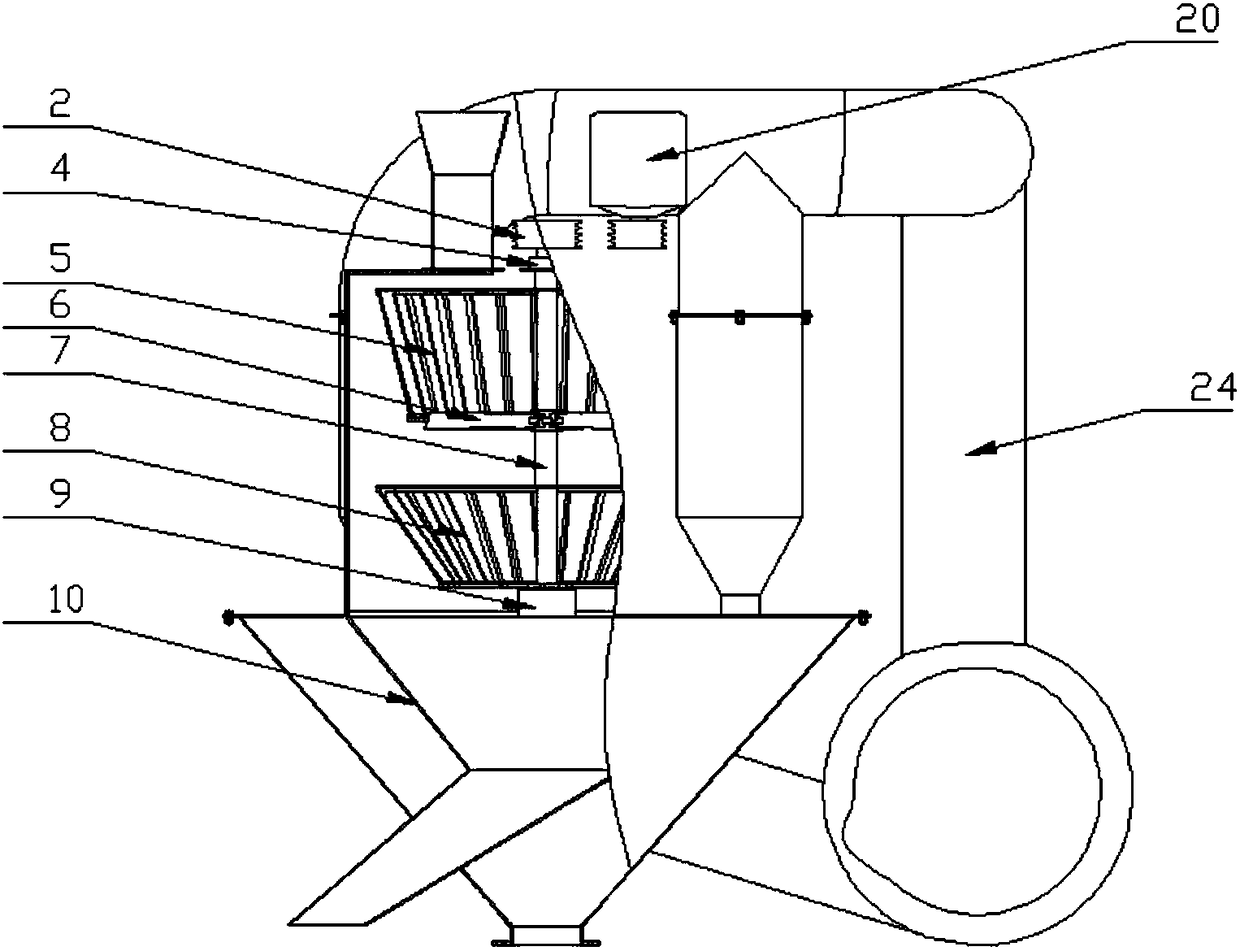

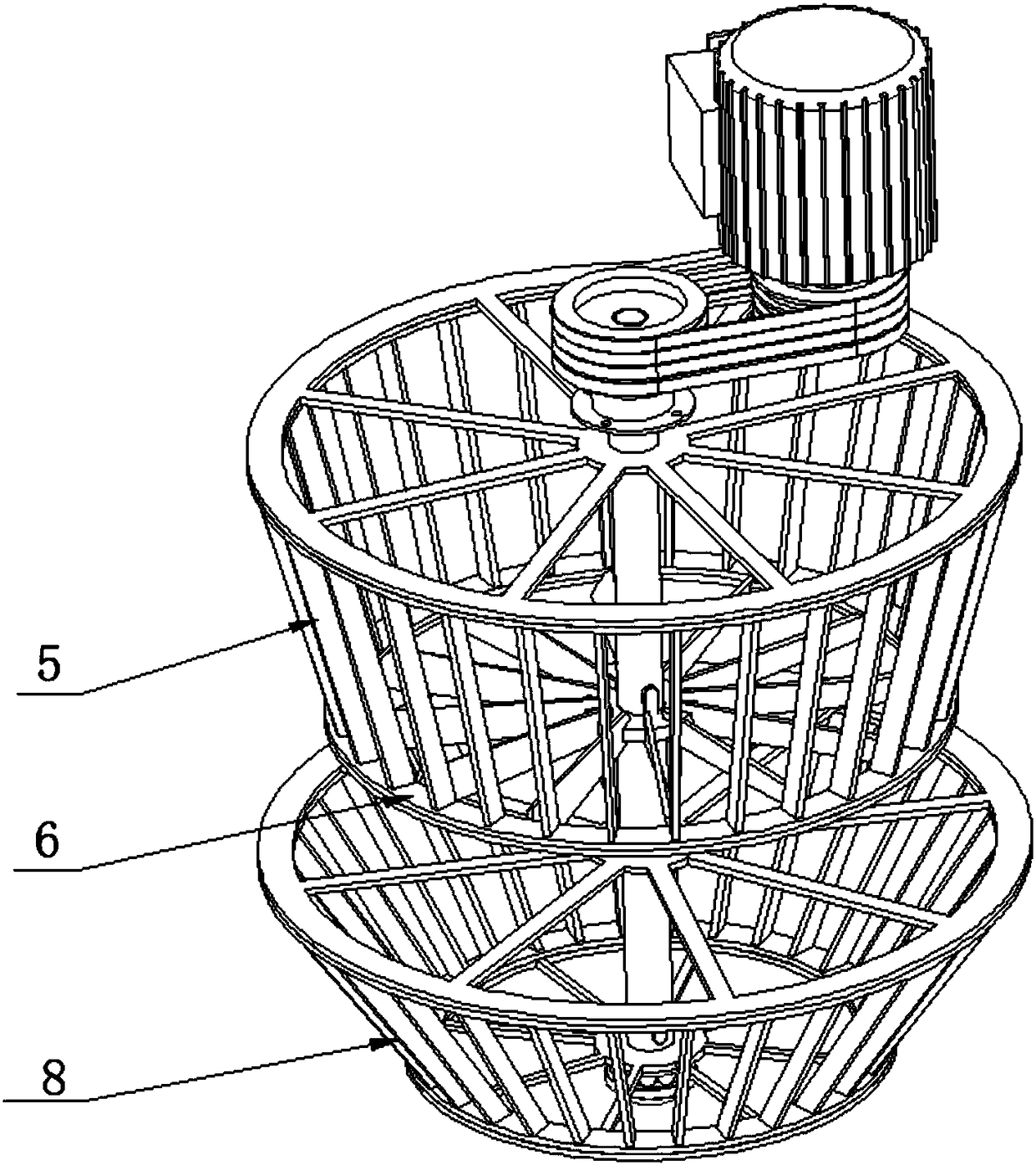

Efficient cyclone-type powder selecting machine

PendingCN108465636AEffective suspensionEasily brokenGas current separationCycloneMaterial scattering

The invention provides an efficient cyclone-type powder selecting machine. The efficient cyclone-type powder selecting machine comprises a powder selecting box, an upper cage-type rotor, a material scattering disc, a lower cage-type rotor, a fine powder collecting cylinder, a screening tube and a flow dividing tube; the lower side of a driven belt wheel is provided with a bearing through cover connected with a rotating shaft in a sleeved joint mode, and the lower side of the bearing through cover is provided with the upper cage-type rotor connected with the rotating shaft in a sleeved joint mode; the lower side of the upper cage-type rotor is provided with the material scattering disc connected with the upper cage-type rotor through a bolt, and the lower side of the material scattering disc is provided with the lower cage-type rotor connected with the rotating shaft in a sleeved joint mode; and the middle of the upper side of a fine powder flow guiding tube is provided with the flow dividing tube connected with the fine powder flow guiding tube in a welded mode, and the lower end of the middle of the flow dividing tube is provided with the screening tube connected with the powder selecting box. Through improvement in the structure, combined with the prior art, the efficient cyclone-type powder selecting machine has the advantages that the structure is excellent, the practicability is high, the screening range is stable, and the separating efficiency is high, thus the problems and defects existing in an existing device are solved and overcome, and the purpose of better practicability is achieved.

Owner:LANZHOU JIAOTONG UNIV

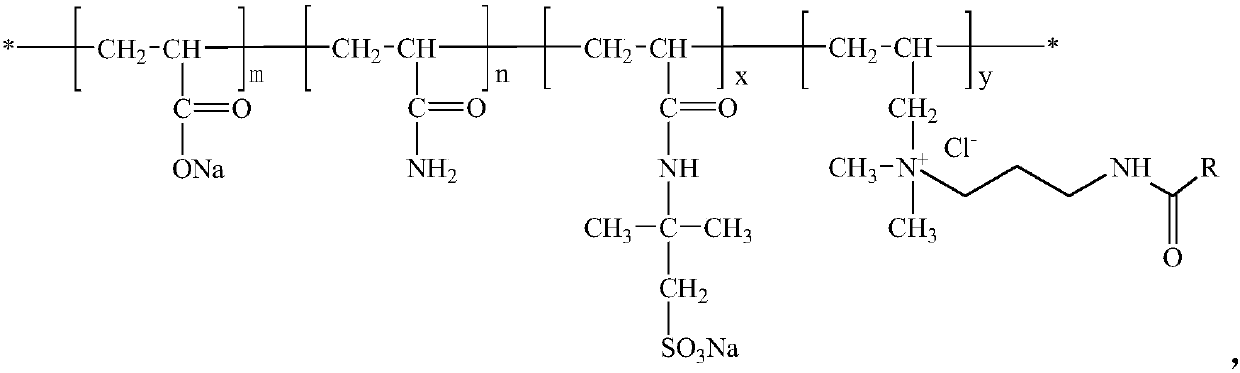

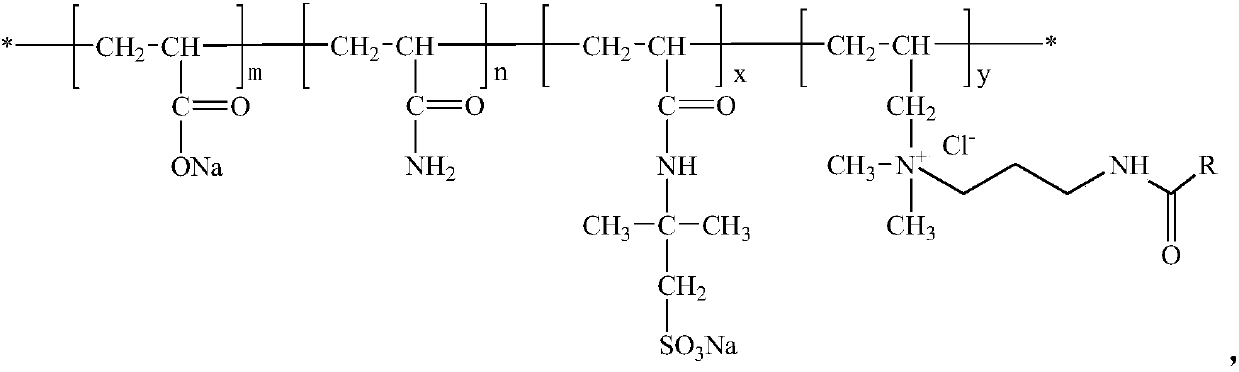

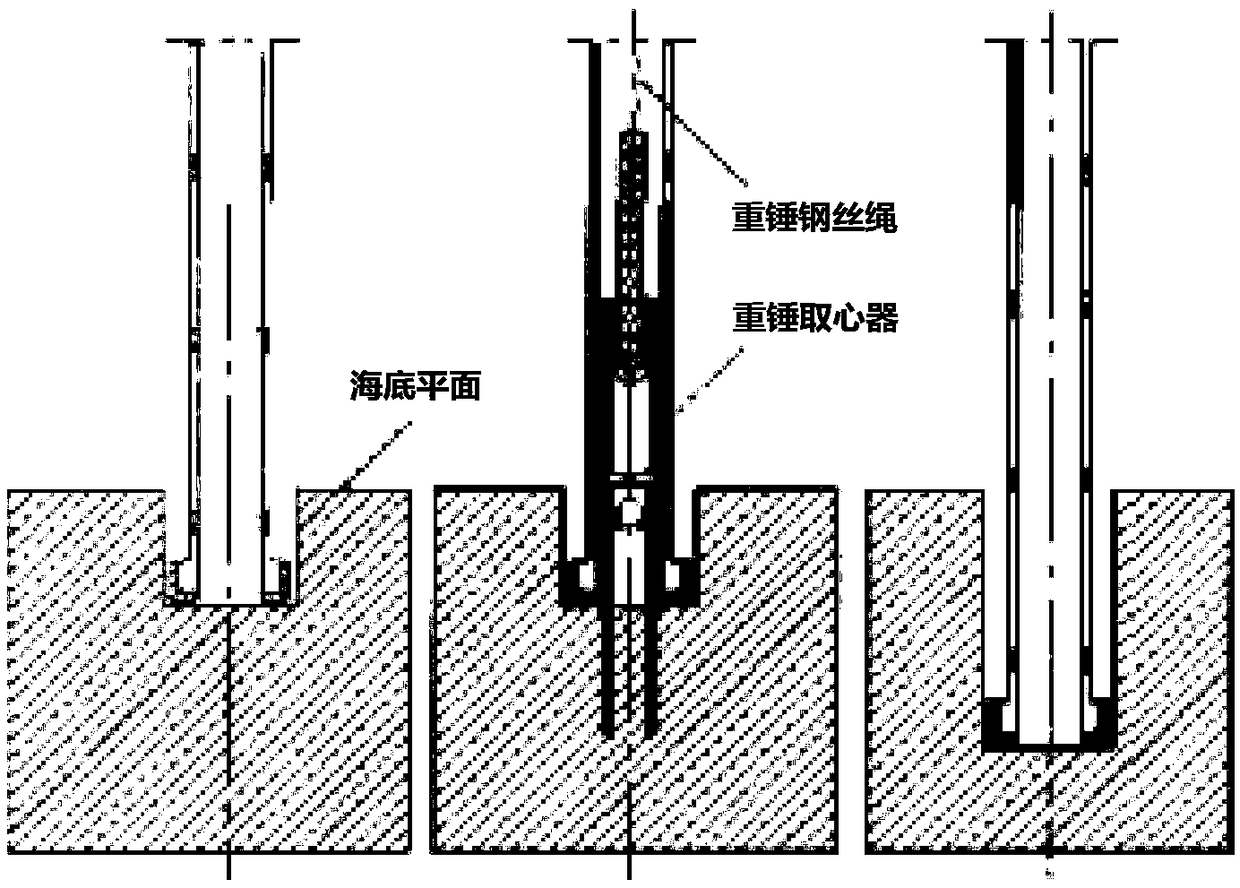

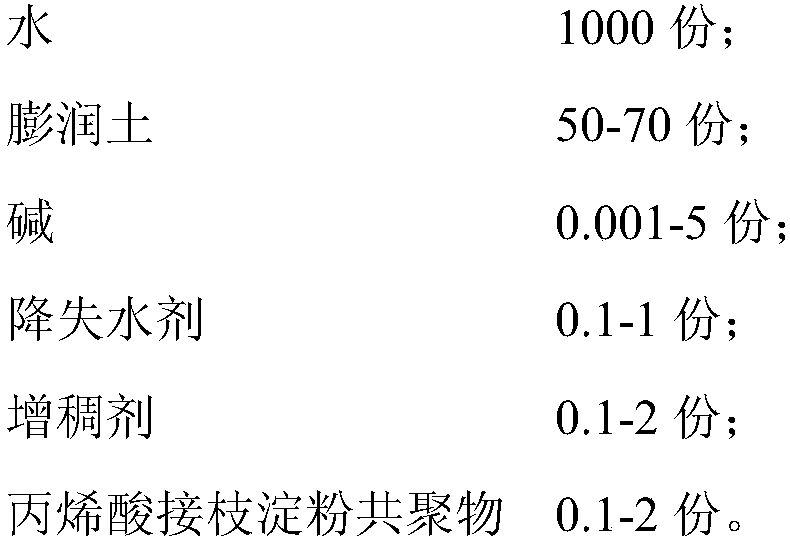

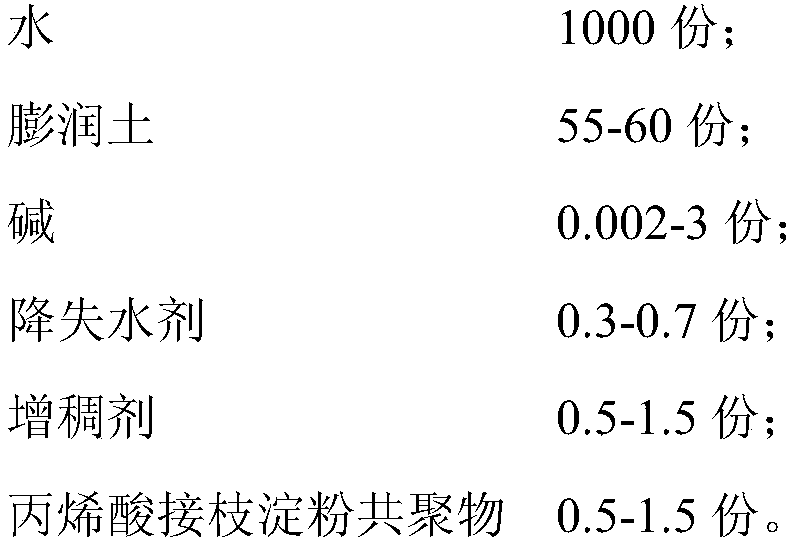

Marine quaternary formation drilling fluid

InactiveCN108611079AWall protection effect is goodEffective suspensionDrilling compositionCopolymerOpen hole

The invention belongs to the technical field of drilling, and provides marine quaternary formation drilling fluid. The fluid is prepared from, by weight, 1000 parts of water, 50-70 parts of bentonite,1-5 parts of alkali, 0.1-1 part of fluid loss additive, 0.1-2 parts of thickener and 0.1-2 parts of acrylic grafted starch copolymer. The invention further provides a method for preparing the marinequaternary formation drilling fluid and application thereof in the drilling and core removal process of the marine quaternary formation. The marine quaternary formation drilling fluid has excellent wall protection performance, and in the process of open hole core removal of the marine quaternary loose formation, the problems that hole walls of sand formation easily collapse, sand gushing and drillbit burying occur, hole walls of water-sensitive muddy formation are reduced in diameter, the bottoms of holes are not clean and the like are better solved.

Owner:中石化石油工程技术服务有限公司 +1

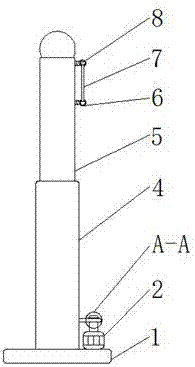

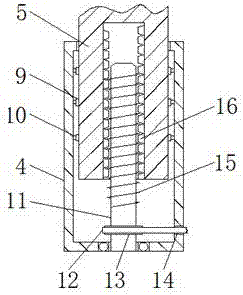

Adjustable-height marine flagpole

InactiveCN107097902AHeight adjustableEasy to useVessel superstructuresVessel mastsDrive wheelEngineering

The invention discloses an adjustable-height marine flagpole. The pole includes a mounting plate, wherein the top of the mounting plate is provided with a positive and negative rotation motor at right side, and a top shaft surface of the positive and negative rotation motor is sleeved with a drive wheel; the center of the mounting plate is provided with a lower bar body, and the center of an inner cavity bottom of the lower bar body is movably connected with a rotating shaft, the surface bottom of which is sleeved with a driven wheel, and meanwhile, the drive wheel is in a transmission connection with the driven wheel through a belt. By arranging the positive and negative rotation motor, the rotating shaft, the belt, the driven wheel, a through hole, a forward-spinning thread and a reversed-spinning thread to cooperate with the drive wheel for use, the adjustable-height marine flagpole can effectively adjust the height of flagpole, thereby improving the use effect of the flagpole, and solving the problem that during use, a same flagpole can not be reused in ships of different sizes and the universality of the flagpole is decreased due to the unchangeable height of the flagpole.

Owner:丁庆慈

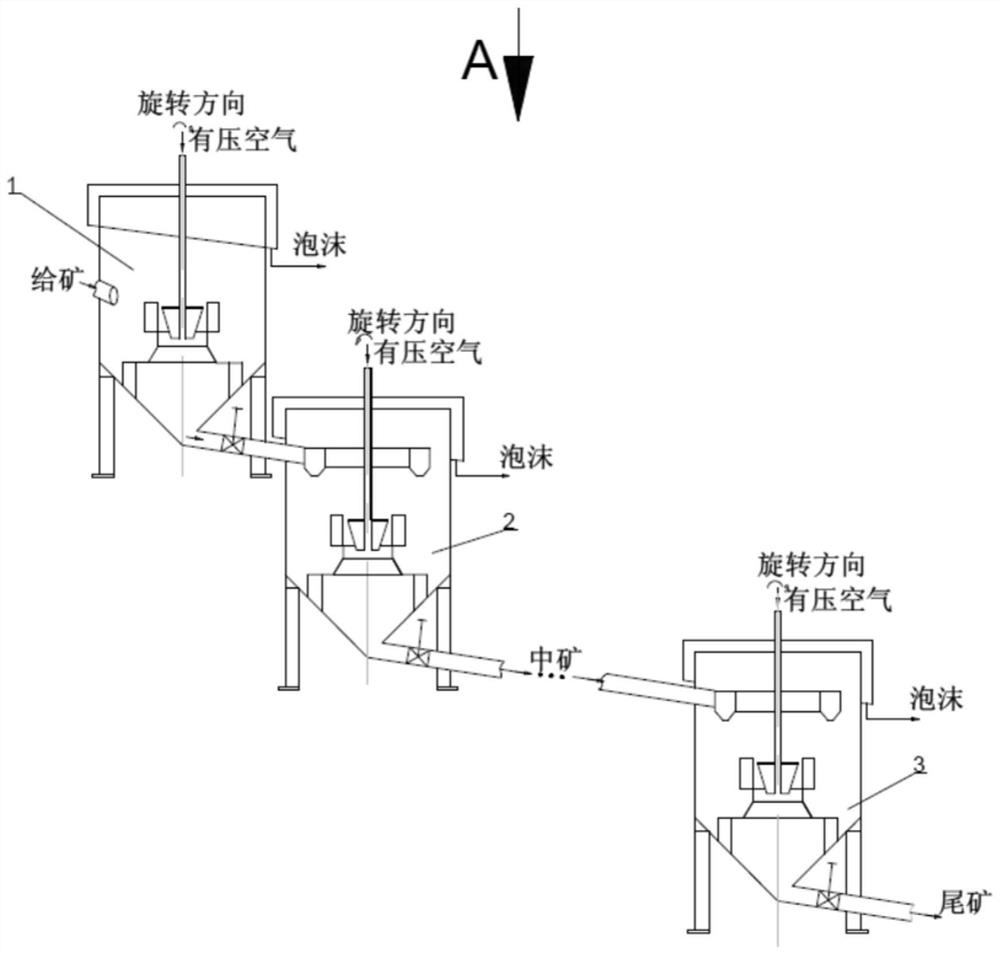

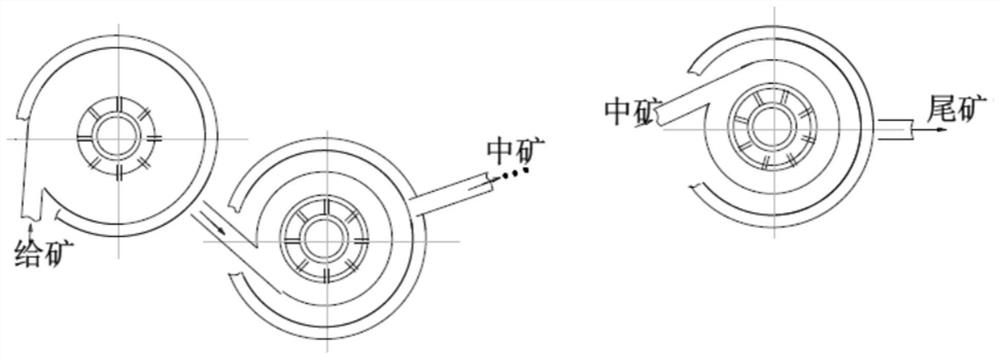

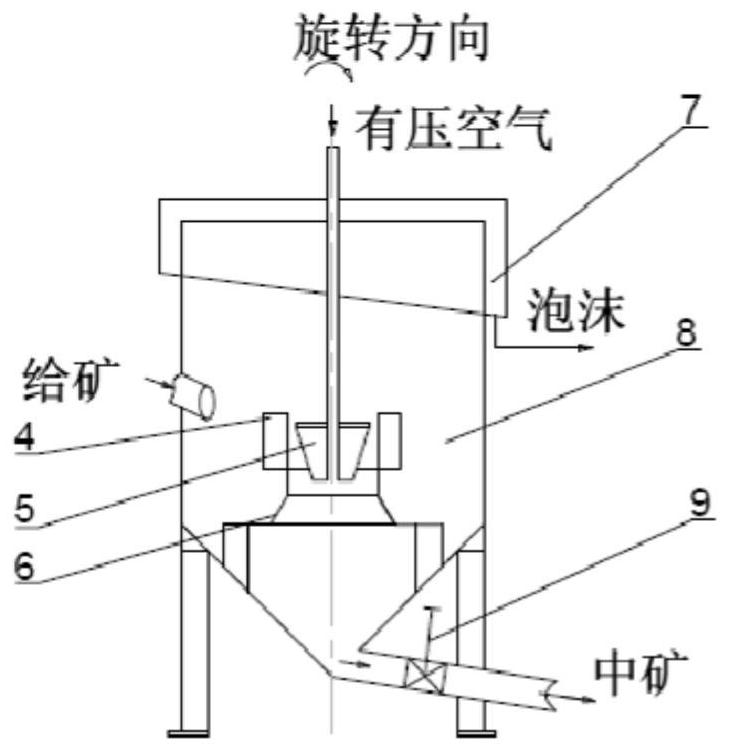

A complete set of high concentration flotation machine

The invention discloses a high-concentration flotation machine set. The machine set includes an ore feeding flotation machine, multiple middle flotation machines and a tail floatation machine which are connected with one another in sequence, an ore slurry feeding pipe tangentially feeds ore slurry to the upper portion of the side face of an impeller in the ore feeding flotation machine from a groove body of the ore feeding flotation machine, a bottom flow of the ore feeding flotation machine is adopted as a middling tangent line and fed to the middle flotation machines, a bottom flow of each middle flotation machine is tangentially fed into the next middle flotation machine from the bottom of the previous middle flotation machine, and the bottom flow of the last middle flotation machine istangentially fed into the tail flotation machine from the bottom of the last middle flotation machine. The middle flotation machines are staggered and tangentially distributed for ore feeding; the impeller of the ore feeding flotation machine rotates clockwise; the first connected middle flotation machine rotates counterclockwise, the second middle flotation machine rotates clockwise, and all themiddle flotation machines are sequentially staggered. The flow feeding direction is same as the rotation direction of the impeller, and a bottom flow discharge pipe is radially arranged along the groove body. Under a high-concentration ore feeding condition, effective bubble dispersion, particle suspension, uniform ore distribution, collision between the particles and bubbles, concentration of the ore slurry and the like in one flotation machine are achieved, the purpose of high-concentration sorting is achieved, and the effects of saving water and medicaments, shortening workflow configuration, saving energy and reducing energy consumption are achieved at last.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD +1

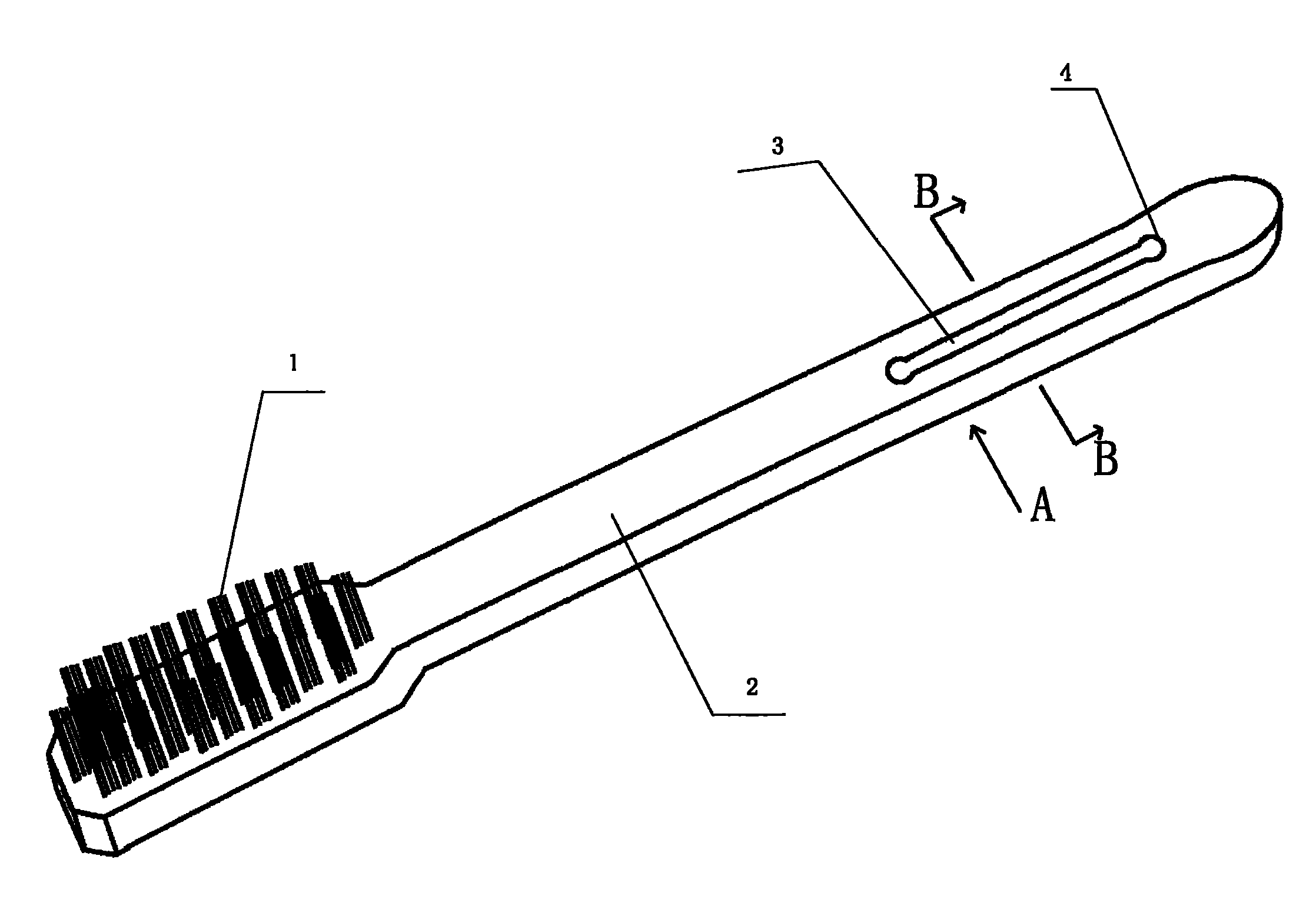

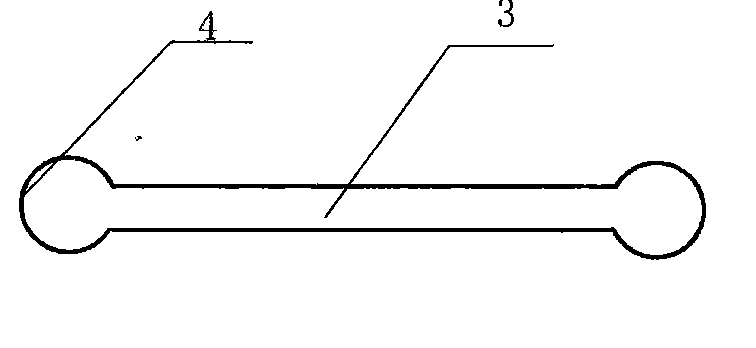

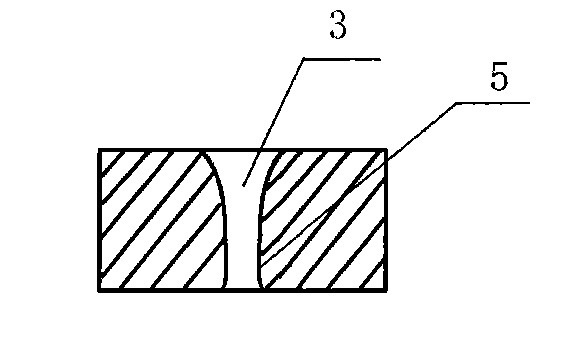

Toothbrush capable of extruding toothpaste tube

InactiveCN101785600AImprove cleanlinessGood effectBrush bodiesHolders and dispensersBristleToothpaste

The invention discloses a toothbrush capable of extruding a toothpaste tube. The toothbrush comprises a toothbrush body, one end of the toothbrush body is provided with bristles (1), the other end of the toothbrush body is arranged as a toothbrush handle (2), the toothbrush handle (2) is provided with a strip-shaped extrusion hole (3), both ends of the extrusion hole (3) are arranged as concave surfaces (4), and the inner wall of the rest part of the extrusion hole (3) is arranged as convex surface (5). The toothbrush can extrude out the residual toothpaste in the toothpaste tube in order to avoid waste, use is convenient and quick, and moreover, the material cost for fabricating the toothbrush handle is reduced as well.

Owner:孙来东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com