Underground self-expansion hanger

A self-expanding, hanger technology, applied in the direction of wellbore/well components, earthwork drilling, etc., can solve the problems of unsuitable for on-site storage, unsuitable for transportation, storage, etc. The effect of simplicity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Taking a downhole self-expanding hanger as an example, the present invention will be further described in detail.

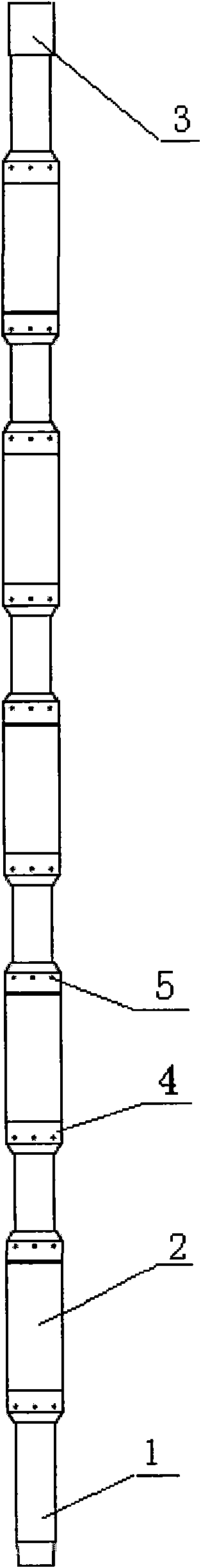

[0019] refer to figure 1 The downhole self-expanding hanger of the present invention is mainly composed of a pipe body 1, a self-expanding rubber tube 2, a collar 3, a limit ring 4, a fastening bolt 5 and an inner bushing 6. Body 1 is 5 1 / 2 "API casing, the outer diameter is 139.7mm, the length is 6.4m. There are 5 1 / 2 "API standard external thread, a coupling 3 is threaded at one end of the pipe body 1.

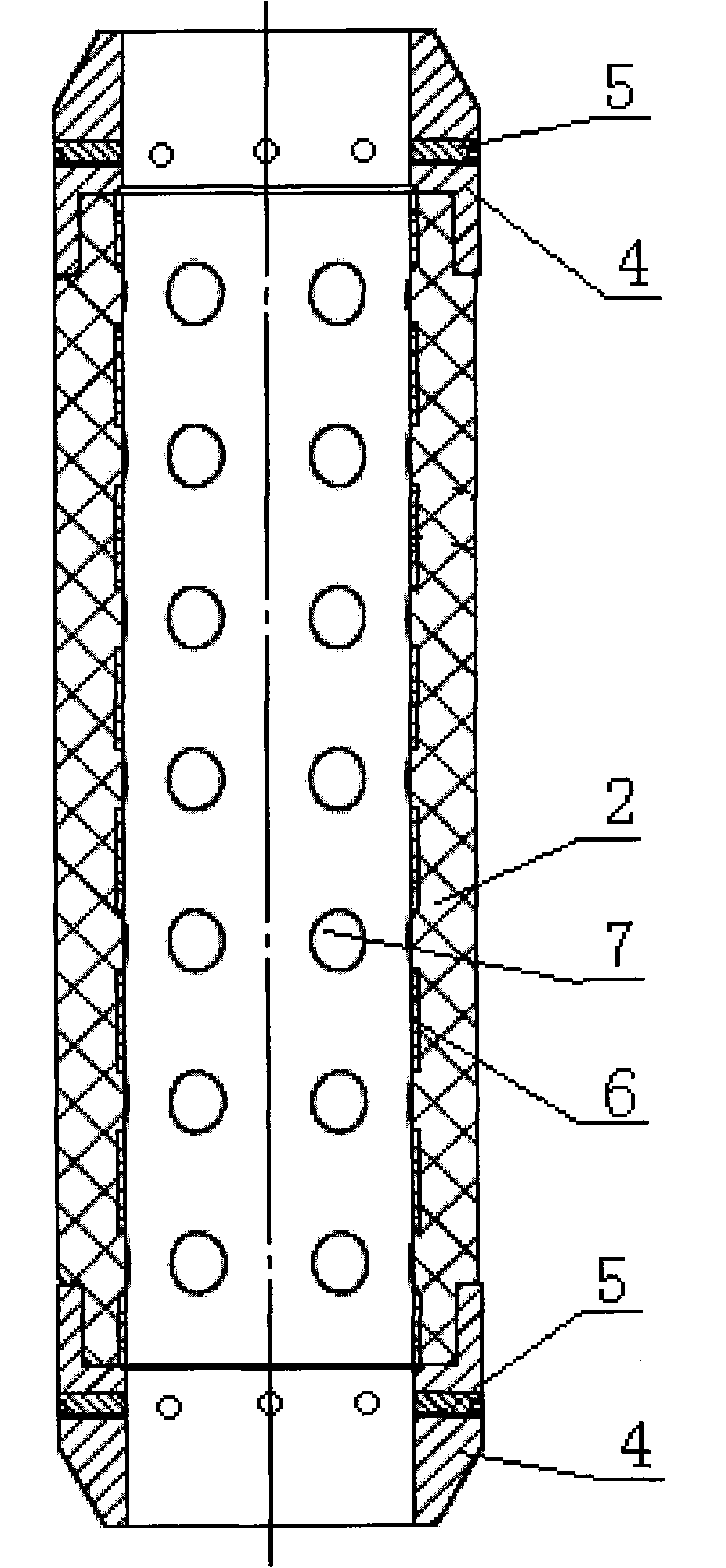

[0020] Five self-expanding rubber cylinder assemblies are sheathed on the outer wall of the pipe body 1, and the self-expanding rubber cylinder assemblies are prefabricated in the factory by vulcanization process. refer to figure 2 . The self-expanding rubber cylinder assembly is composed of an inner bushing 6 and a self-expanding rubber cylinder 2, the self-expanding rubber cylinder 2 is vulcanized on the outer wall of the inne...

Embodiment 2

[0023] Embodiment 2: The main difference from Embodiment 1 is: the pipe body 1 is 2 7 / 8 "API oil pipe, the outer diameter is 72.6mm. There are 2 ends at the two ends of the pipe body 1 7 / 8 "API standard external thread. The inner diameter of the inner liner 6 is 73.2mm, and the outer diameter is 76.2mm. The thickness of the self-expanding rubber cylinder 2 is 18mm. The material used by the self-expanding rubber cylinder 2 is oil self-expanding rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com