Solid-liquid separation device applied to sewage treatment system

A sewage treatment system and solid-liquid separation technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of the efficiency of sewage solid-liquid separation, etc., to facilitate solid-liquid separation, increase impact force, The effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

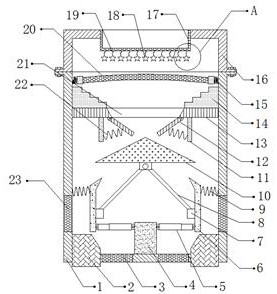

[0030] refer to Figure 1-3 , a solid-liquid separation device applied to a sewage treatment system, comprising a box body 1, both sides of the outer wall of the bottom of the box body 1 are provided with drainage outlets, and the inner walls of the two drainage outlets are connected with a first filter screen 3 by bolts , the outer walls on both sides of the box body 1 are provided with a plurality of filter holes 23, the top outer wall of the box body 1 is connected with a box cover 16 by bolts, and the top outer wall of the box cover 16 is provided with a water inlet, and the inner wall of the water inlet is connected by bolts A filter bucket 17 is connected, and the bottom inner wall of the box body 1 is connected with a fixed block 4 by bolts, and the outer walls on both sides of the fixed block 4 are connected with telescopic rods 5 by hinges, and the outer walls of one side of the two telescopic rods 5 are connected by hinges. An extruded plate 6 is connected, and a fix...

Embodiment 2

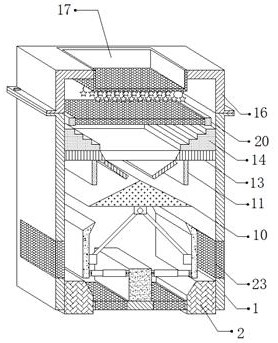

[0039] refer to Figure 4-5 , a solid-liquid separation device applied to a sewage treatment system. Compared with Embodiment 1, this embodiment has two rotating shafts 24 connected by bearings between the inner walls of the opposite sides of the box body 1, and the two rotating shafts 24 Located between the support plate 13 and the second filter screen 20 , blades 25 are connected to the outer walls of the two rotating shafts 24 by bolts, and the outer walls of the blades 25 are provided with a plurality of barbs 26 .

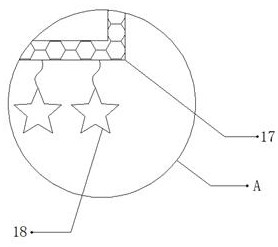

[0040] Working principle: when in use, the sewage that needs solid-liquid separation is filled into the interior of the box 1 through the filter bucket 17, and the sewage is initially treated through the filter bucket 17, and the impurities mixed in the sewage can be suspended on the pendant through the pendant 18 18, in order to carry out solid-liquid separation to sewage, the shape of pendant 18 is star shape, can effectively hang solid waste, prevents that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com