Stator permanent magnet-biased sheet-shaped inner-rotor bearingless asynchronous rotor

A technology of permanent magnet bias and asynchronous motors, which is applied in asynchronous induction motors, electromechanical devices, electrical components, etc., and can solve problems such as control strategy constraints, large magnetic circuit reluctance, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

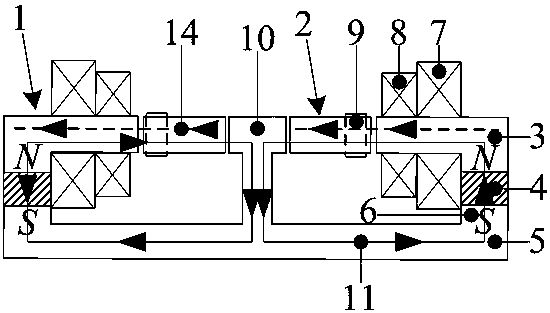

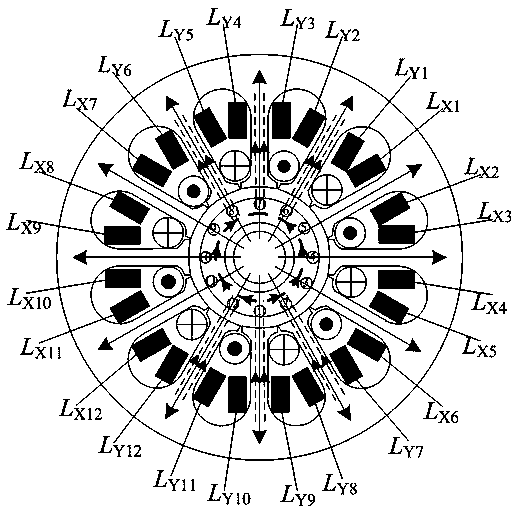

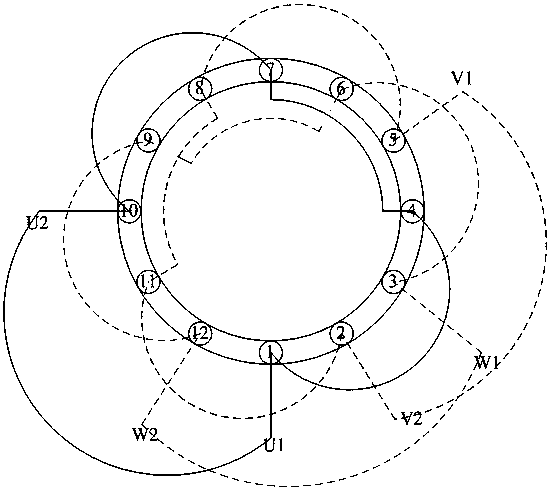

[0018] Such as Figures 1 to 6 As shown, a three-phase motor with 12 stator slots, 1 suspension winding pole pair, and 2 torque winding pole pairs is used as an example to describe in detail:

[0019] A bearingless asynchronous motor with a stator permanent magnet bias plate inner rotor, including a stator 1, a rotor core 2 located in the inner ring of the stator 1, the stator 1 includes a stator core 3, an axially magnetized annular permanent magnet 4 and an iron core Bridge 5, the main body of the iron core bridge 5 is a circular plate, and the edge of the circular plate is provided with a circle of upwardly protruding annular boss 6, and the annular permanent magnet 4 is laminated and fitted on the annular boss 6. The lower end surface of the stator core 3 is laminated with the upper side of the annular permanent magnet 4, and a stator slot is opened on the stator core 3, and a suspension winding 7 and a torque winding 8 are arranged in the stator slot; the iron core The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com