Double-stator/double-rotor motor and direct actuator for washer using same

一种驱动装置、双转子的技术,应用在机电装置、带有静止电枢和旋转磁体的同步电动机、电动组件等方向,能够解决低效率、磁力损失大、磁阻大等问题,达到减小磁阻、减小通路、节省时间和费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above objects, features, and advantages will become clearer from the detailed description below with reference to the accompanying drawings, so that those skilled in the art to which the present invention pertains will be able to easily implement the technical idea of the present invention.

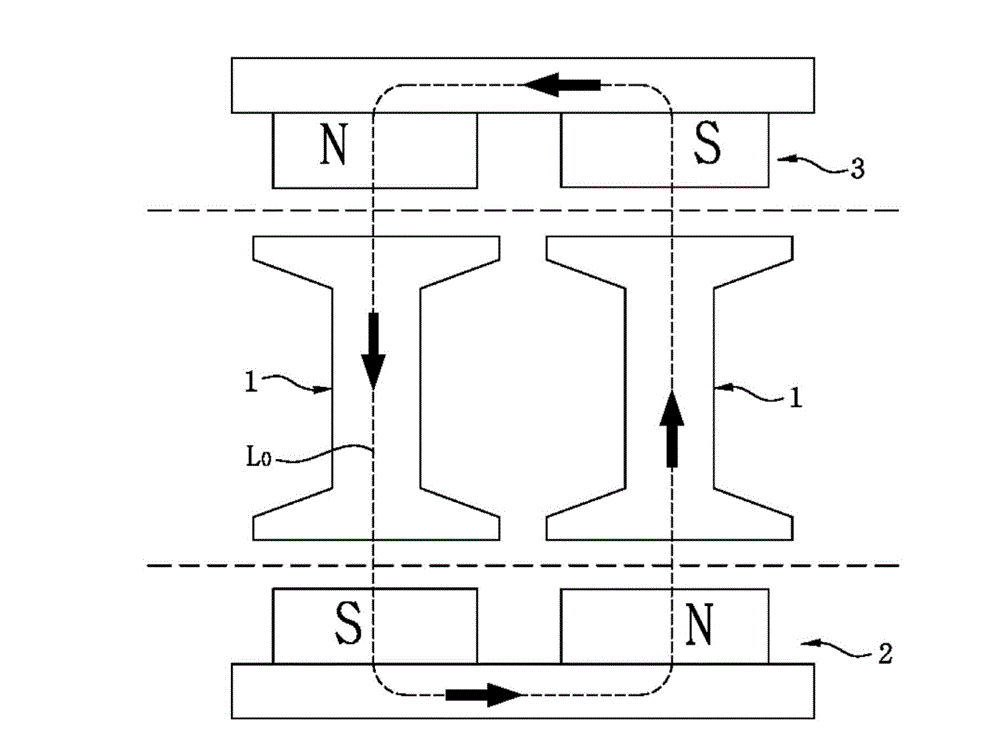

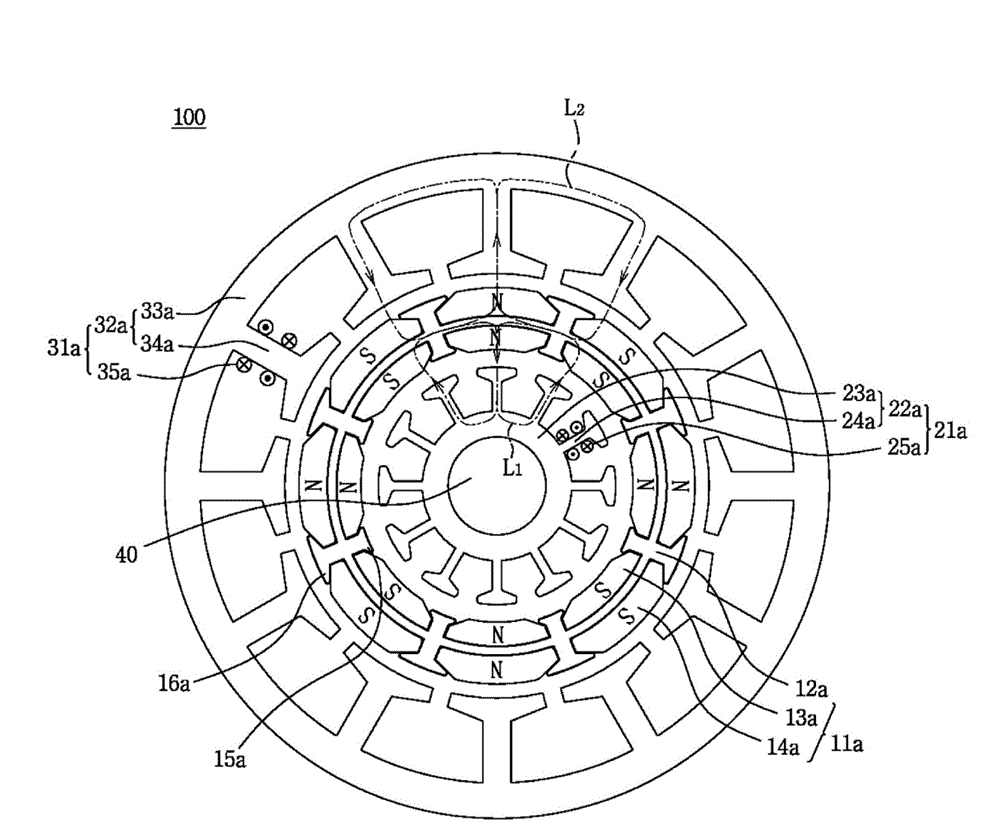

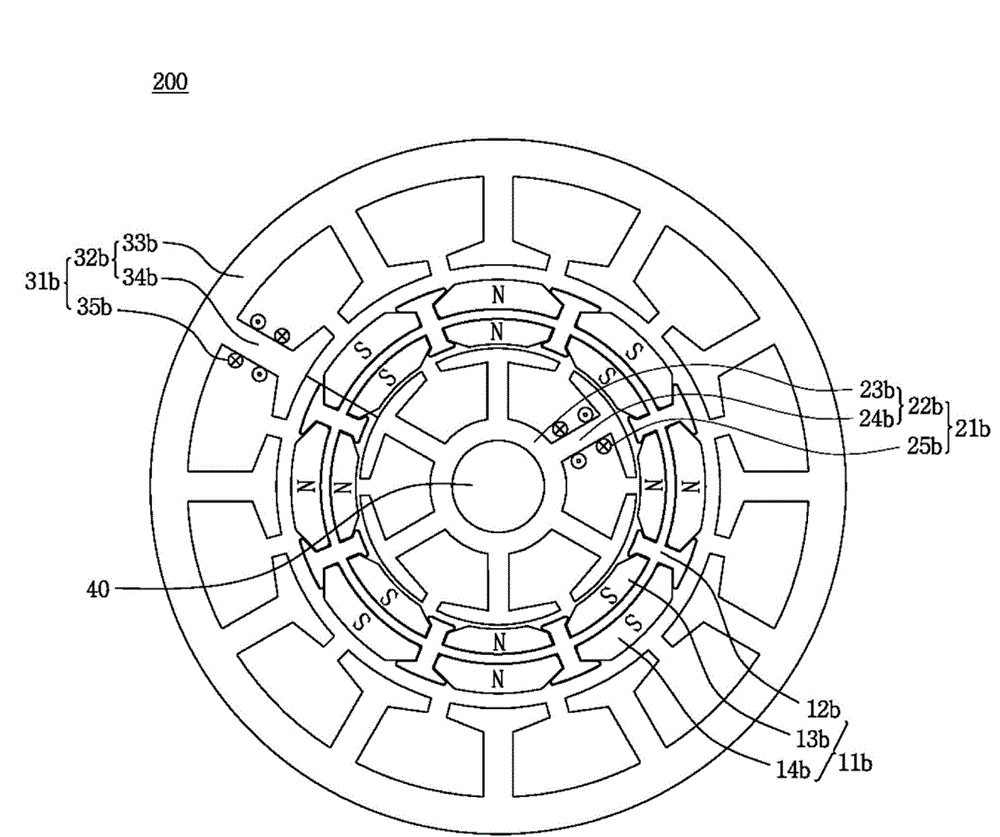

[0046] Before describing the embodiments of the present invention, it should be noted that the twin-stator / twin-rotor motor of the present invention is applied to a structure in which twin rotors are arranged between inner and outer stators.

[0047] Among them, even if an integrated rotor is arranged between the inner and outer stators in the twin-stator / double-rotor motor, in fact, the magnets required to form independent magnetic circuits for the inner and outer stators are installed inside the back yoke of the rotor. and outside, it is also possible to provide dual rotor functions facing the inner and outer stators respectively. In this twin-stator / double-rotor type motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com