Patents

Literature

560results about How to "Small magnetic resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

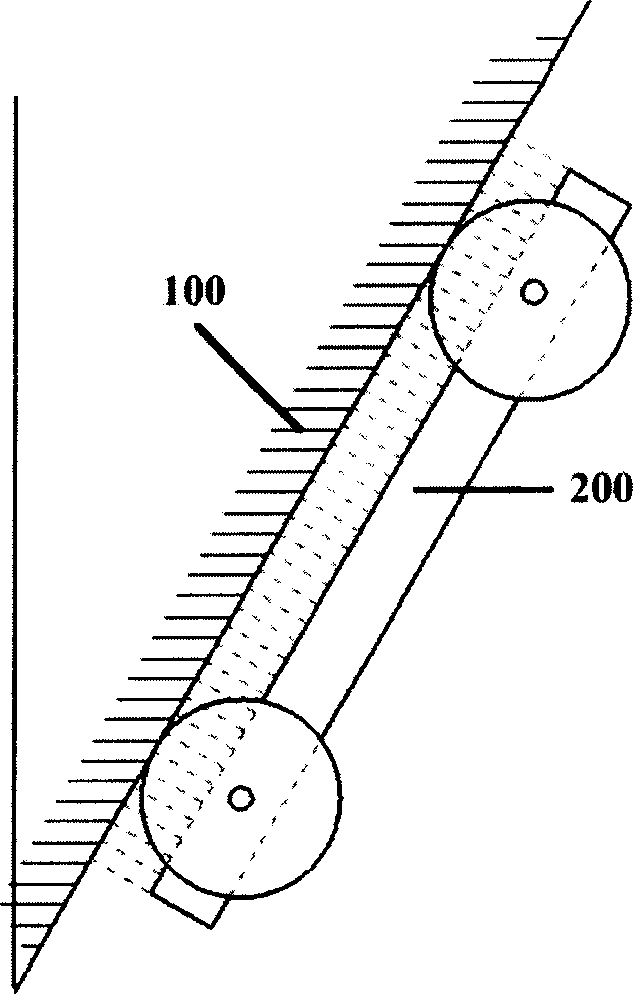

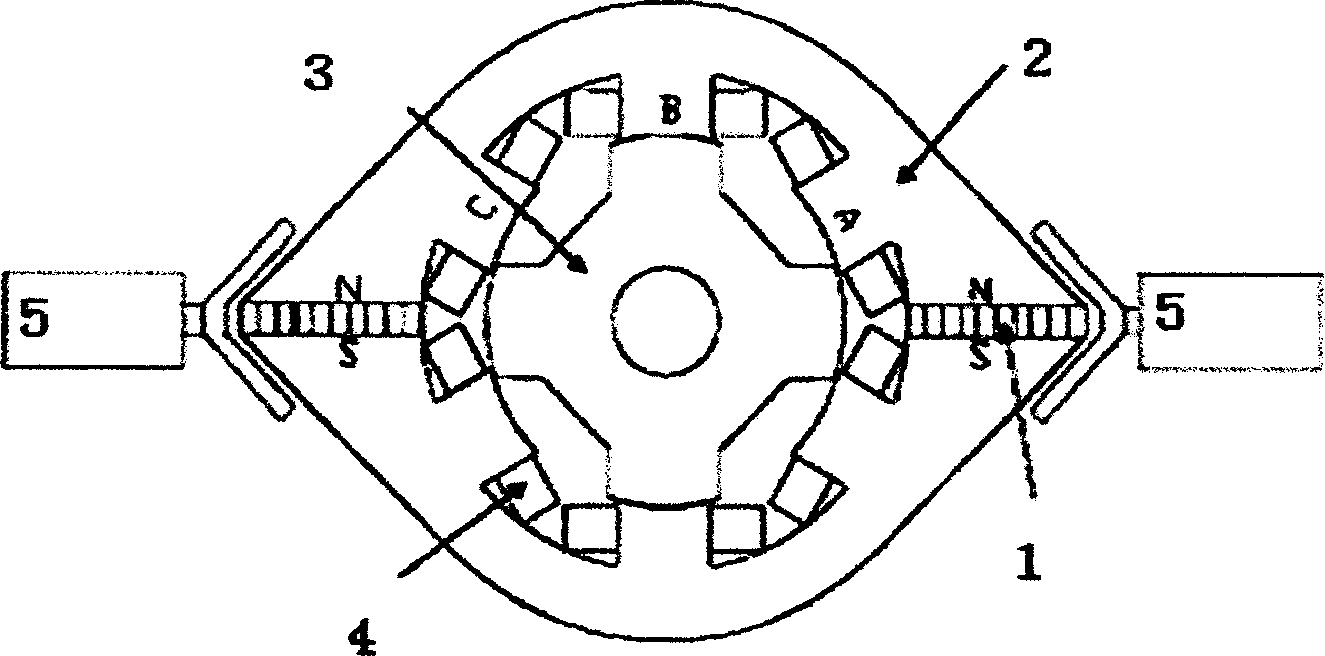

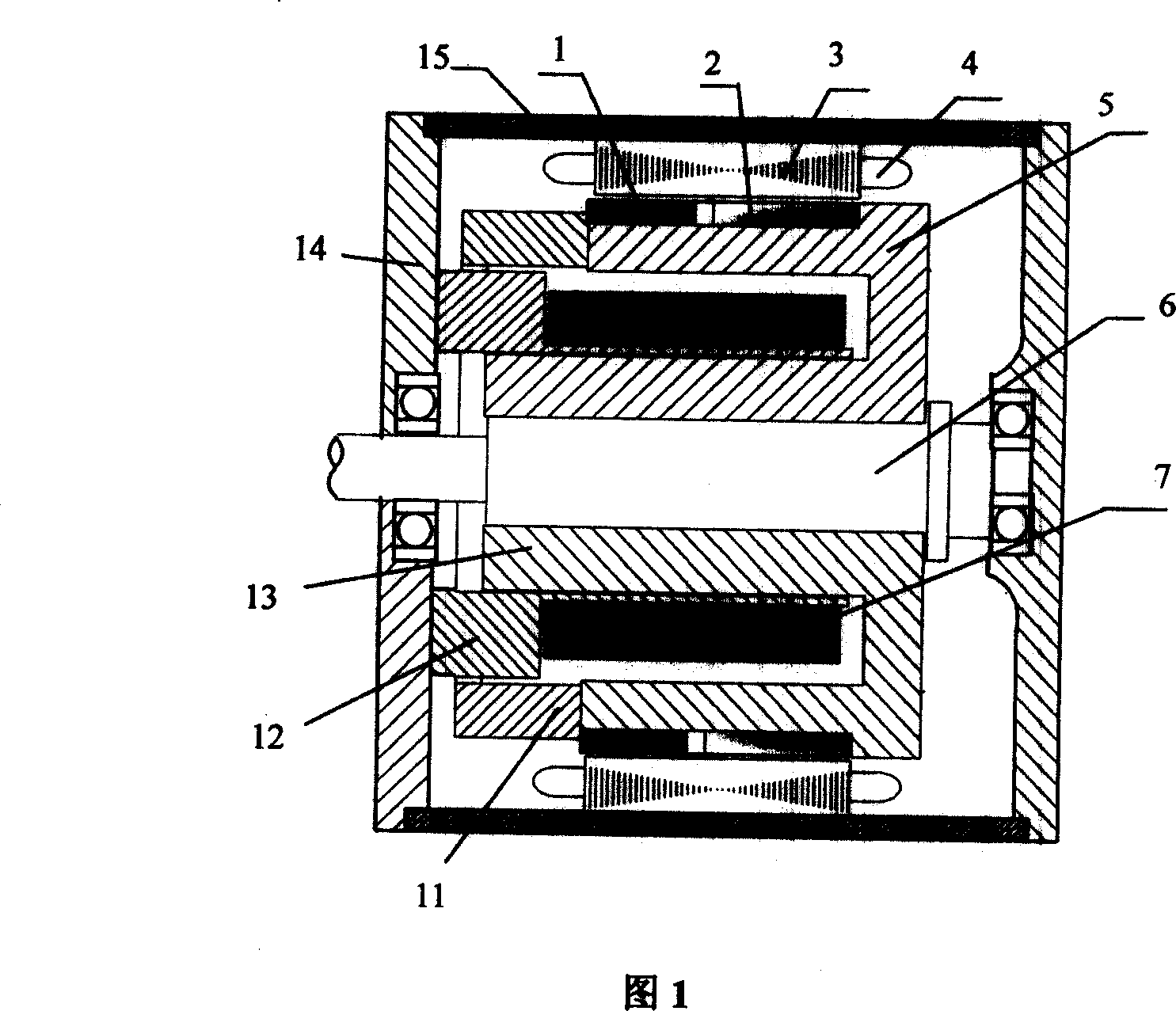

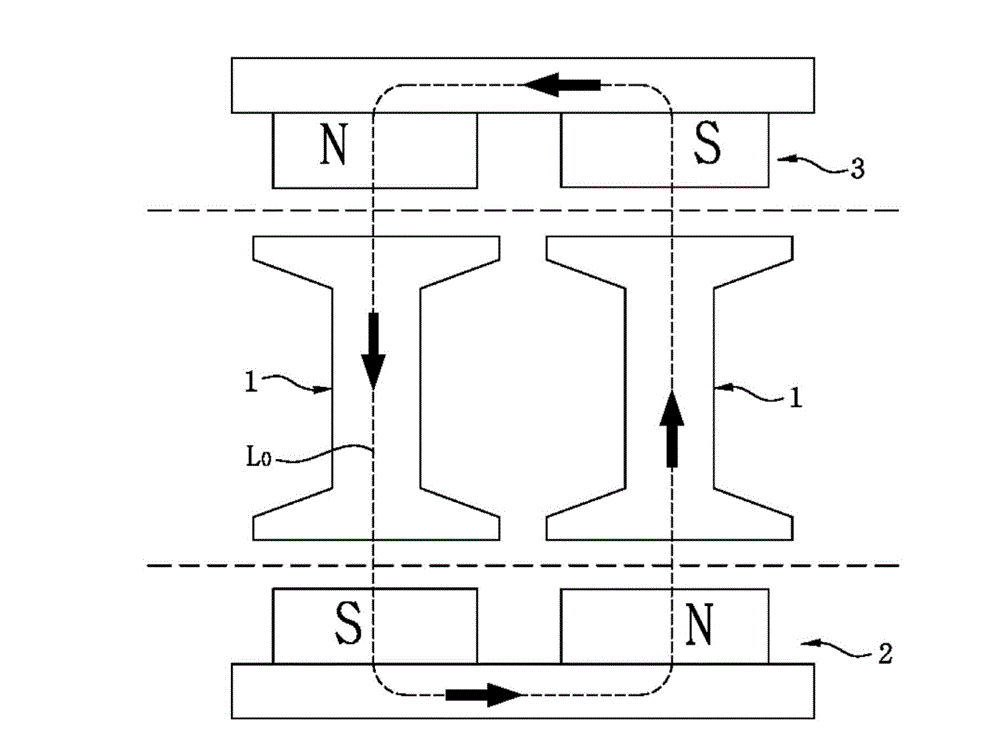

Non-contact magnetically adsorbed wall climbing robot

The present invention is non-contact magnetically adsorbed wall climbing robot, belongs to the field of robot design technology, and aims at providing robot with both high moving flexibility and great loading capacity. The non-contact magnetically adsorbed wall climbing robot includes wheeled moving mechanism and permanent adsorption mechanism. The wheeled moving mechanism includes chassis, driving mechanism and wheels, which are laid symmetrically, driven in differential mode, and turns on wall by means of the speed difference of the wheels. The permanent adsorption mechanism has no contact with the magnetically conducting wall surface, high magnetic energy utilization, and high adsorption capacity. The wall climbing robot has high loading capacity, high motion flexibility, especially high turning flexibility, and excellent application foreground.

Owner:TSINGHUA UNIV

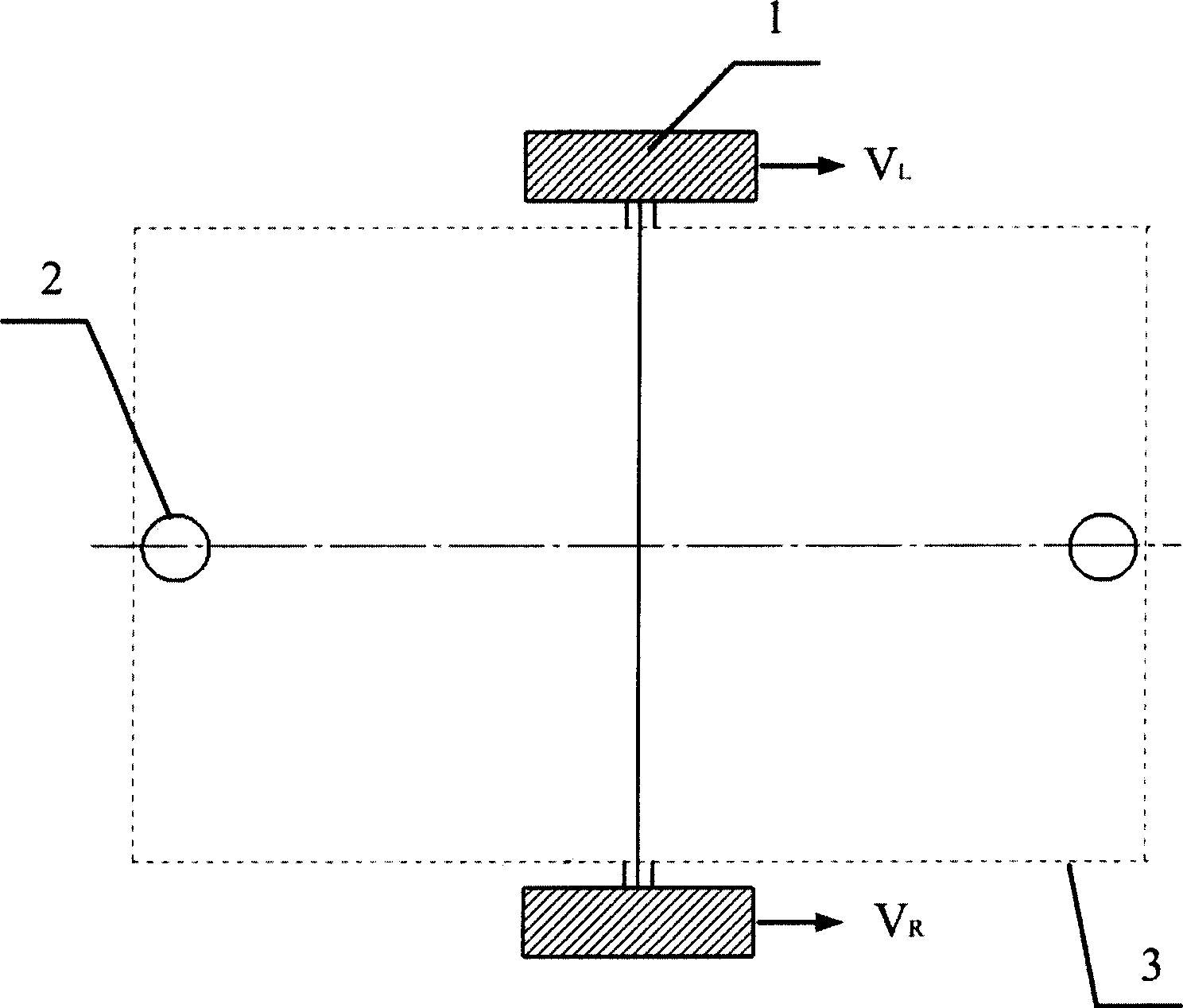

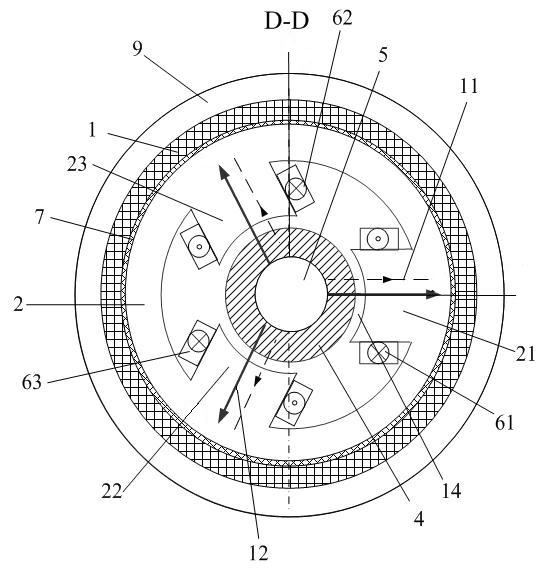

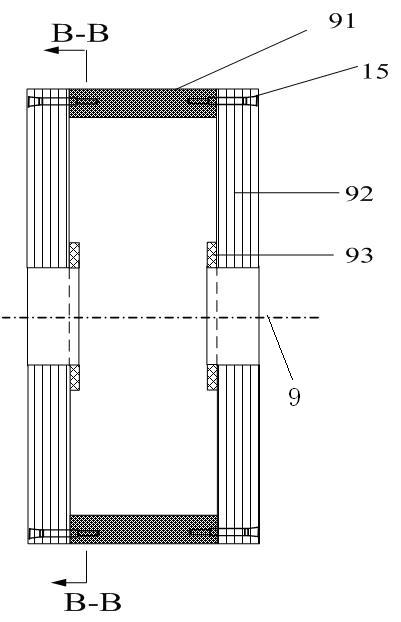

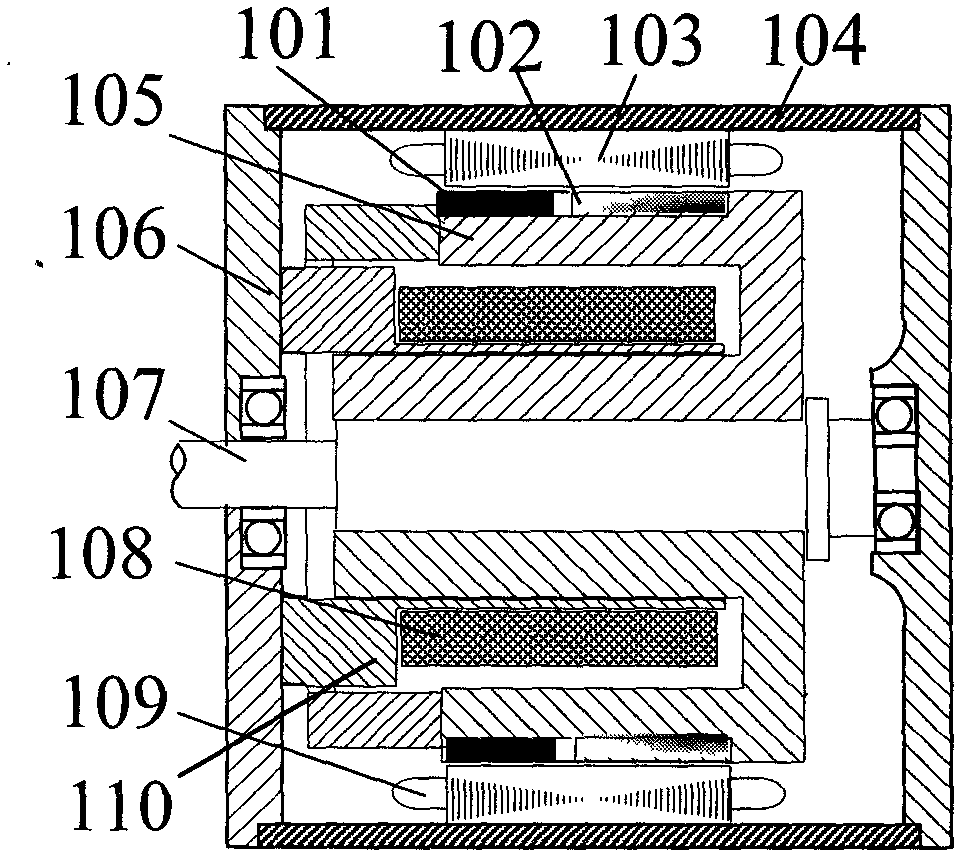

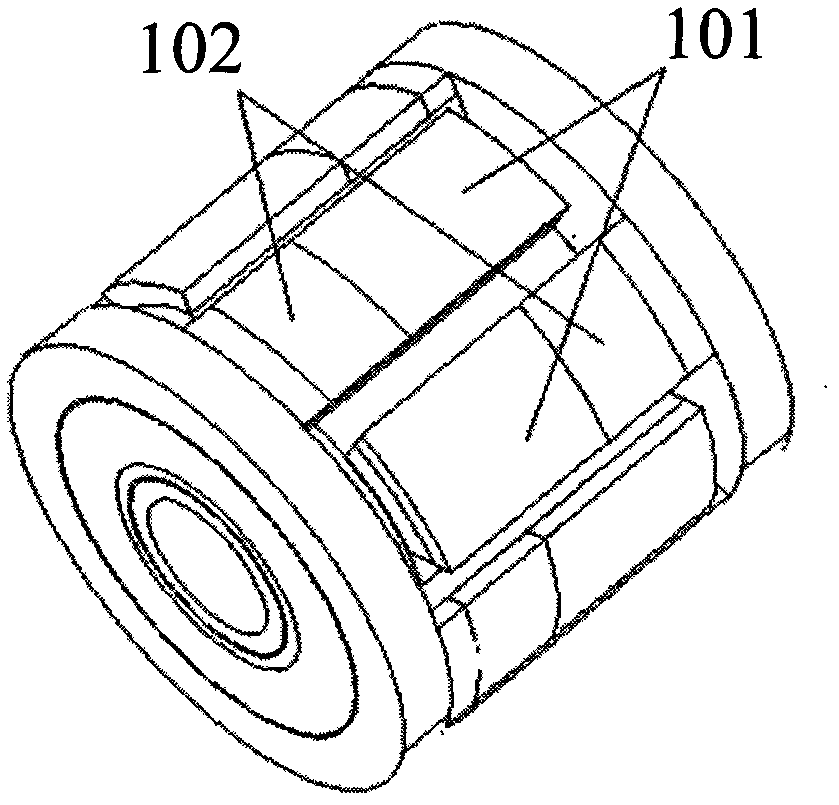

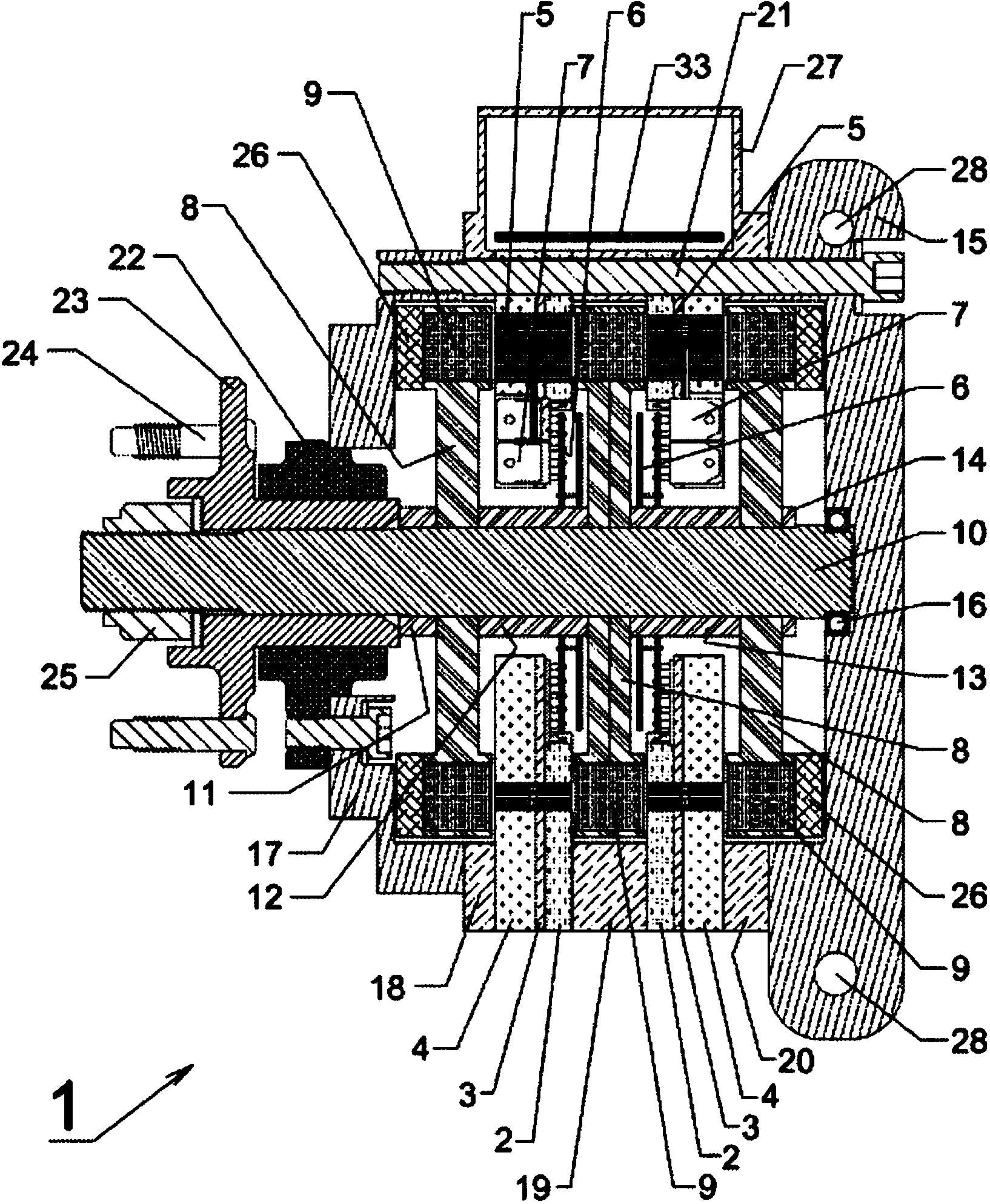

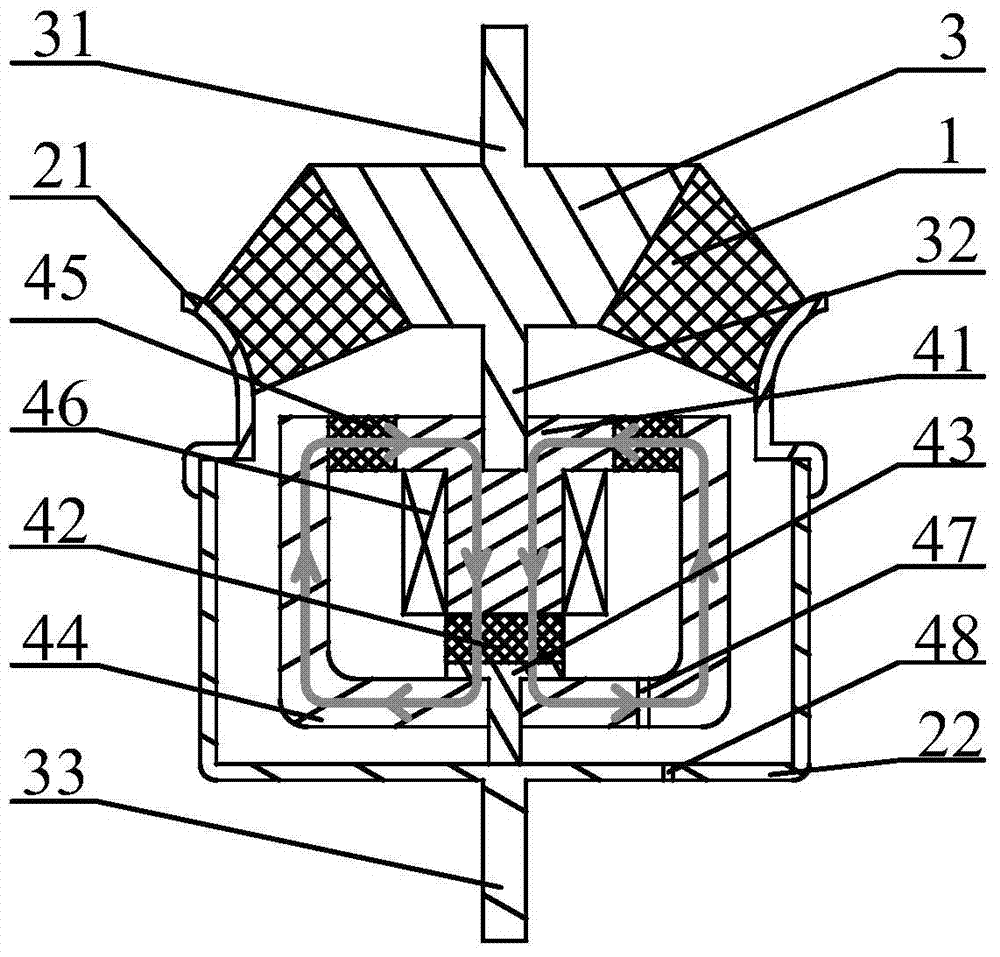

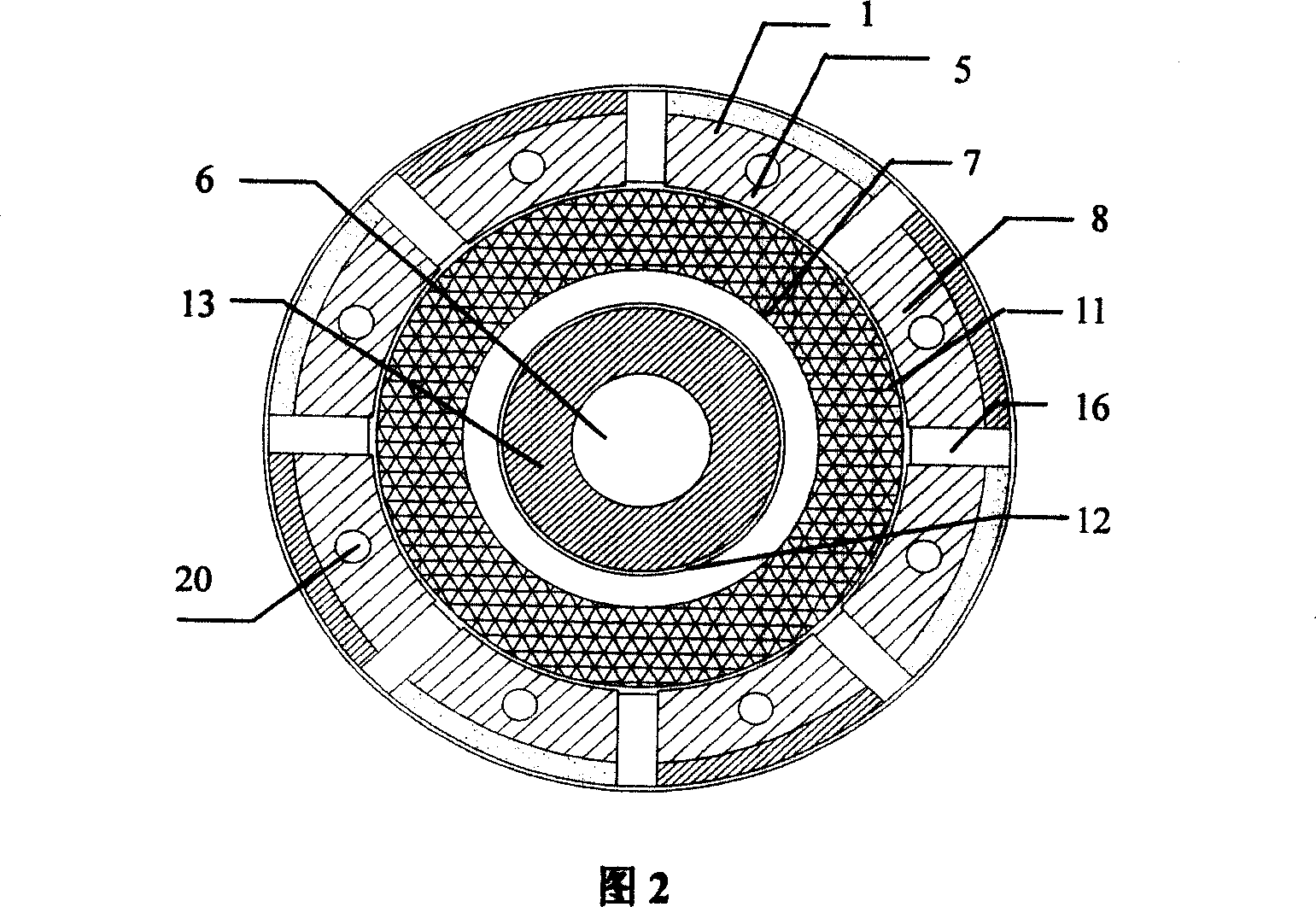

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

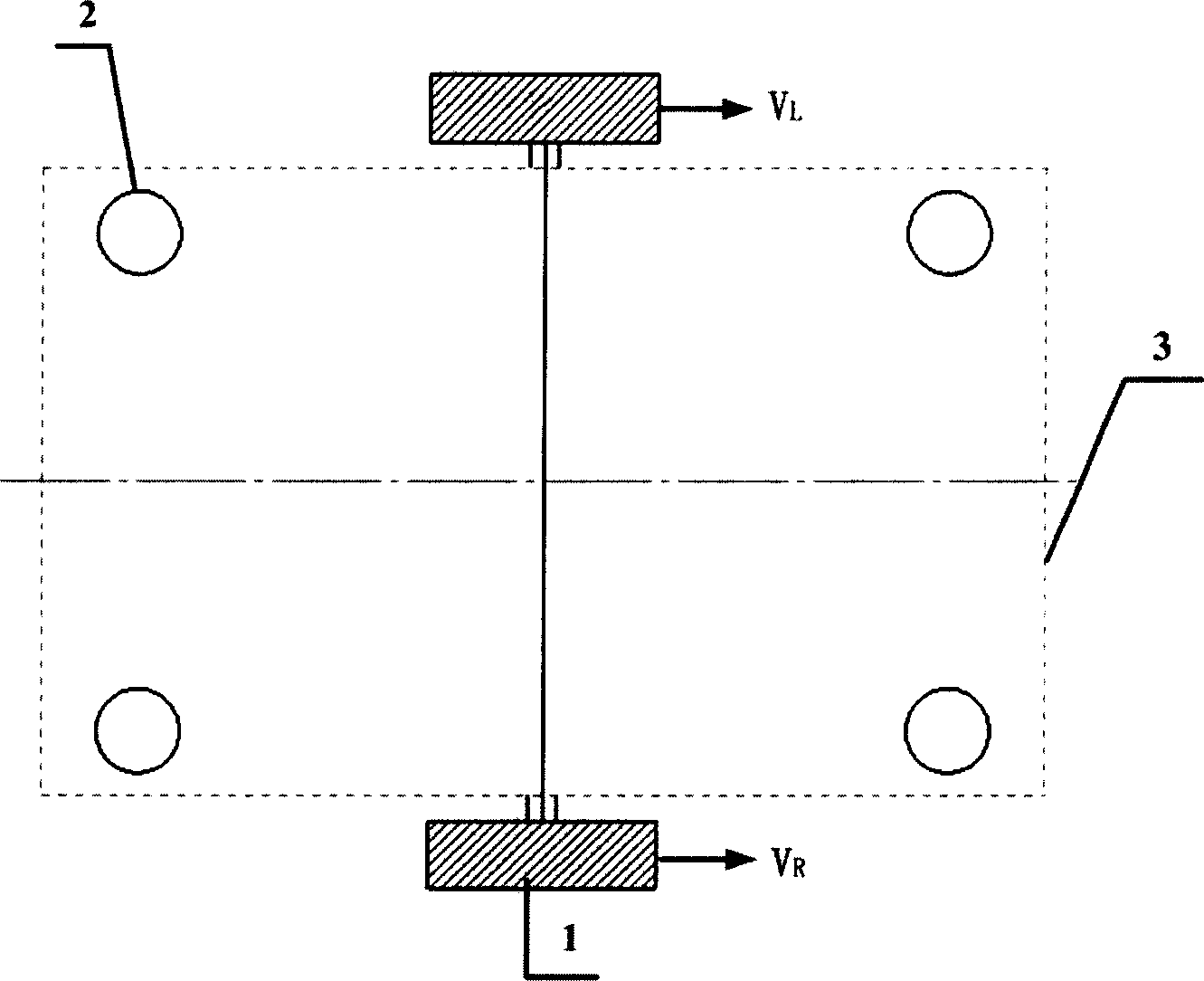

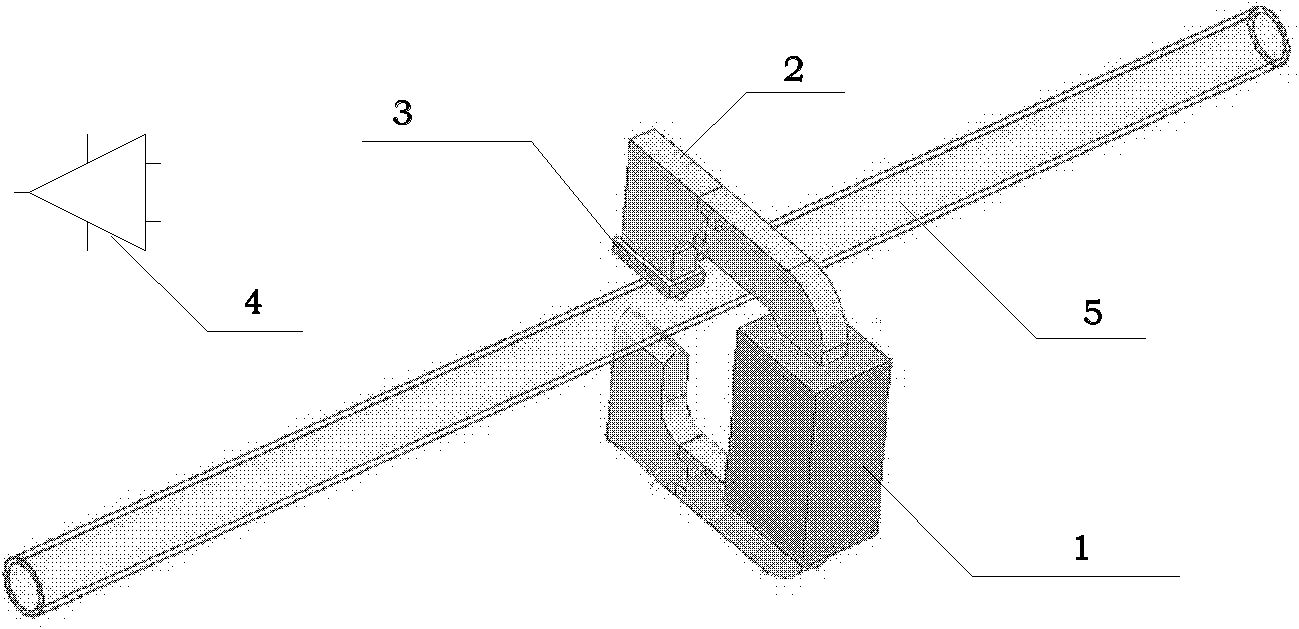

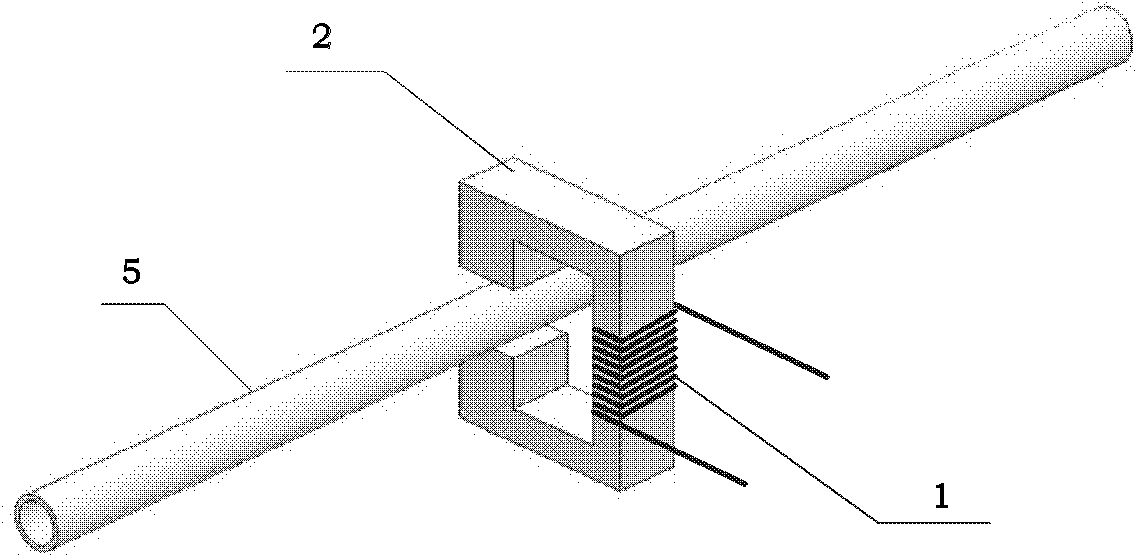

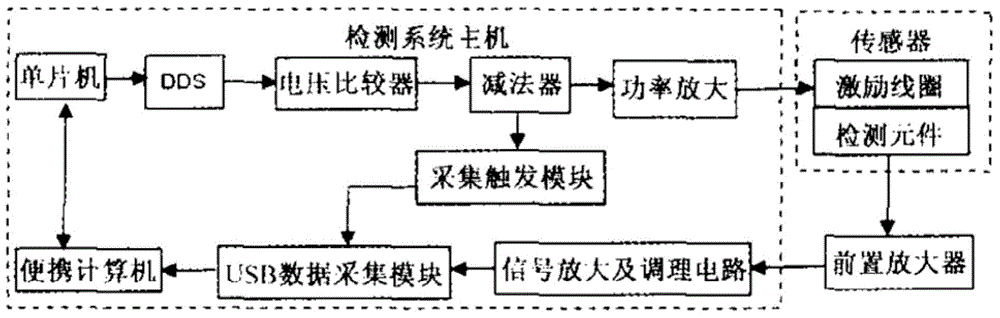

Radial magnetic field-based online abrasive grain monitoring sensor and monitoring method

InactiveCN102305755AHigh sensitivitySmall magnetic resistanceMaterial magnetic variablesMonitoring methodsCondensed matter physics

The invention discloses a radial magnetic field-based online abrasive grain monitoring sensor and monitoring method. The sensor comprises a magnetic field excitation source, an iron core, a detecting coil and an amplifying circuit, wherein a stable static magnetic field generated by the magnetic field excitation source forms a stable radial magnetic field by iron core optimization for being used for an oil pipe; and when an abrasive grain in the oil pipe generates inducing voltage by the detecting coil, the amplifying circuit carries out noise reducing and amplification processing output on the inducing voltage. The monitoring method comprises the following steps of: obtaining the induced voltage by the sensor; after processing the induced voltage by the amplifying circuit, obtaining an effective voltage signal; and confirming the motion speed, materials and size information of the abrasive grain by analyzing the waveform of the effective voltage signal. The invention uses the stable radial magnetic field as the monitoring magnetic field, optimizes the distribution of the magnetic field by an iron core, can effectively improve the sensitivity and precision of the sensor, is suitable for of the online abrasive grain monitoring of a hydraulic system and can provide service for the demand of state monitoring, fault diagnosis and service life prediction of the hydraulic system.

Owner:BEIHANG UNIV

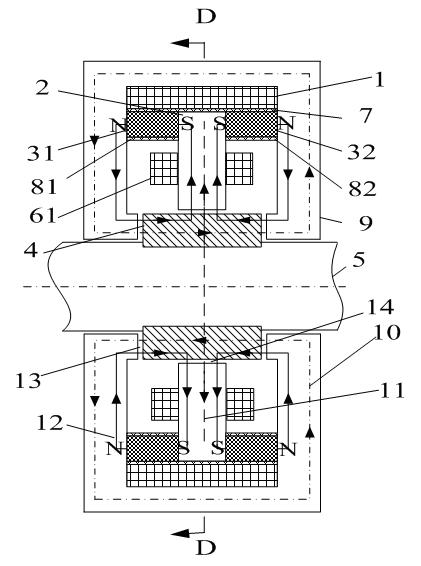

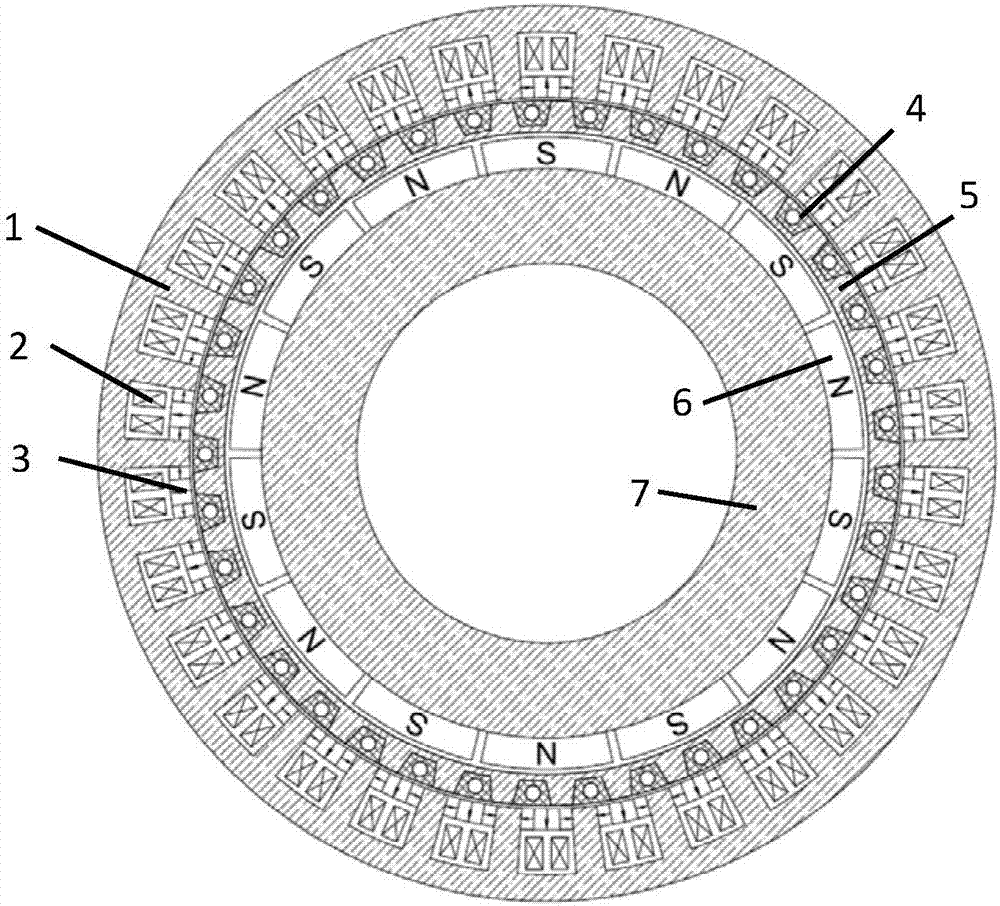

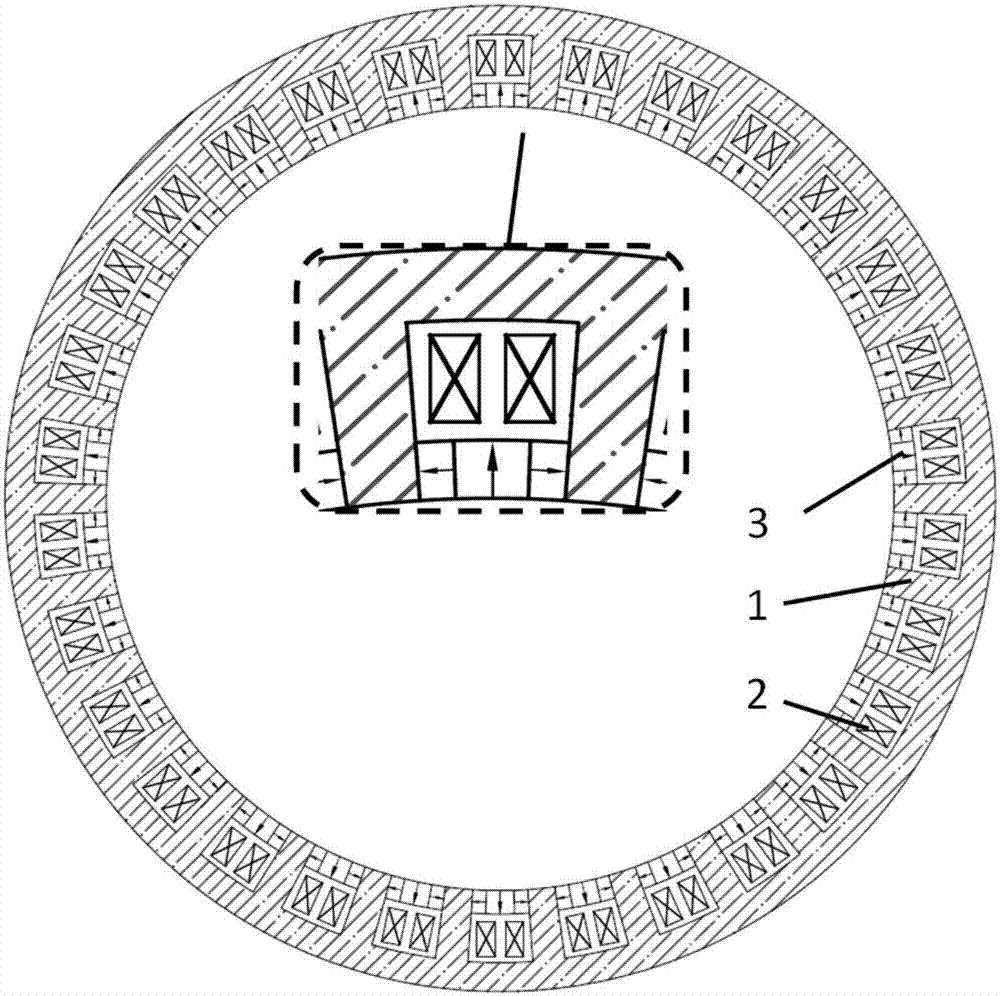

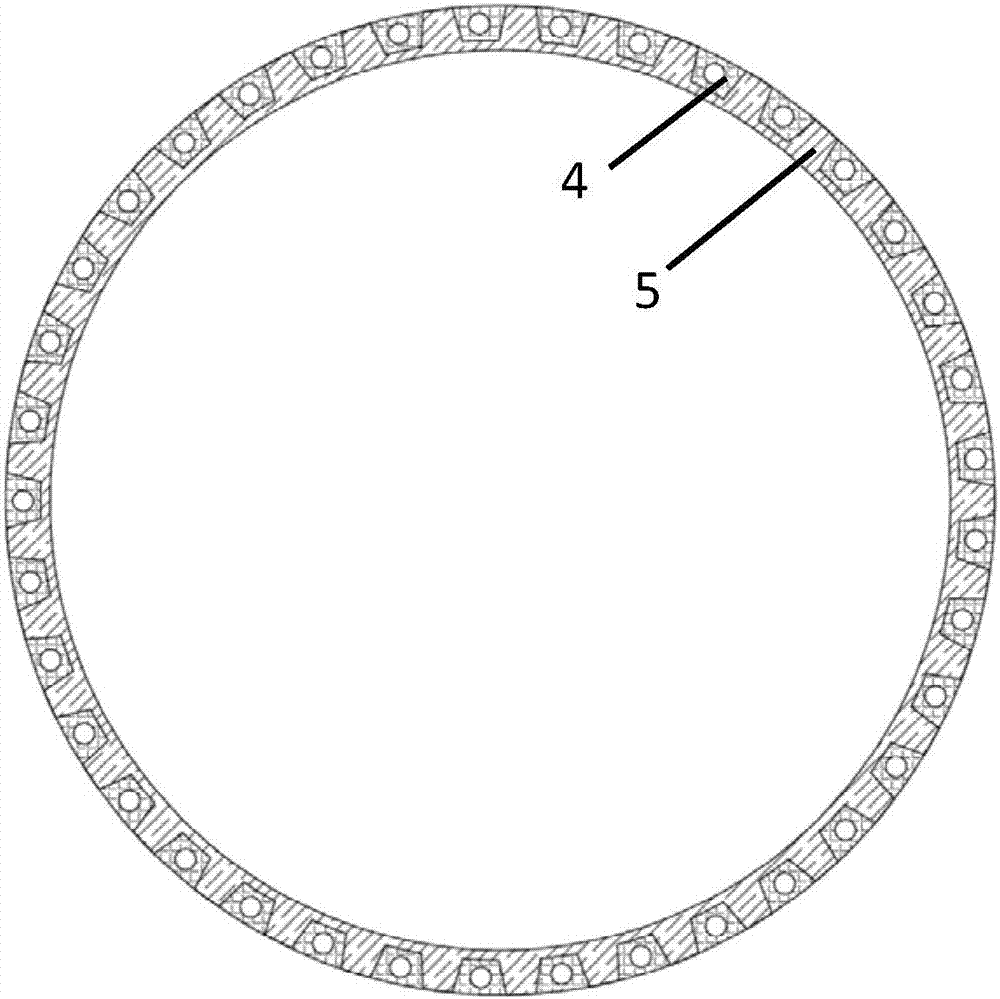

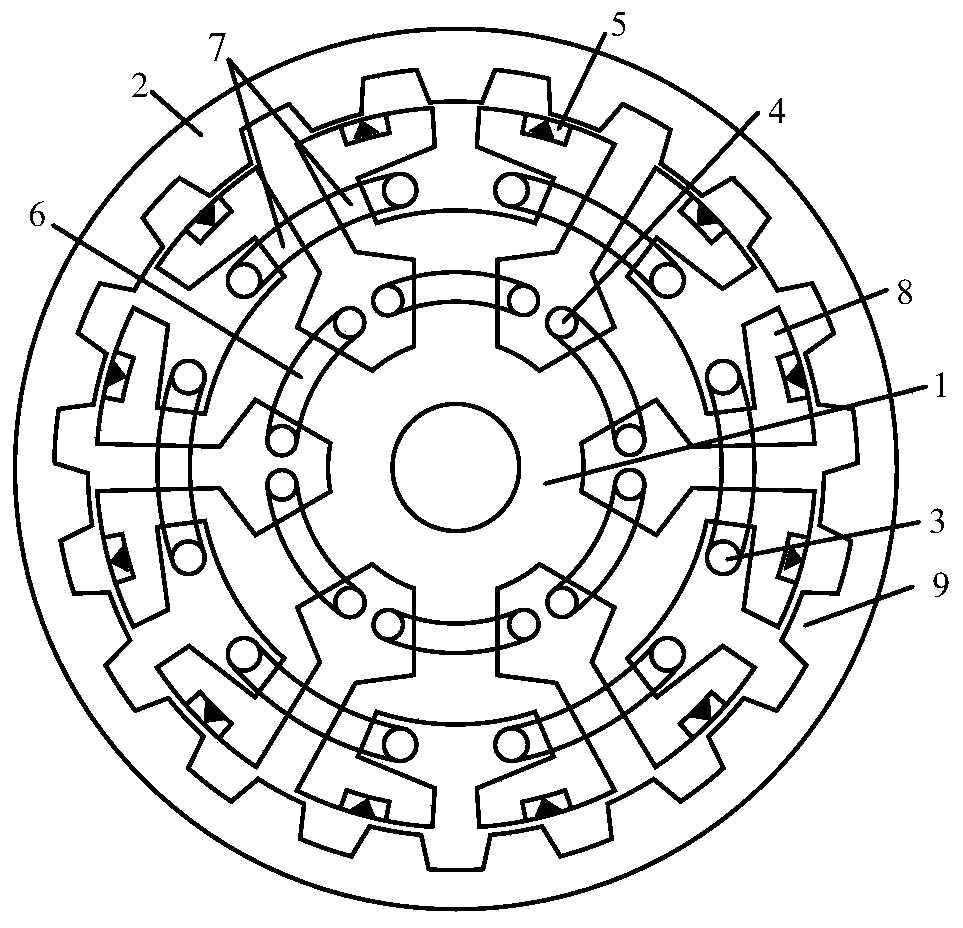

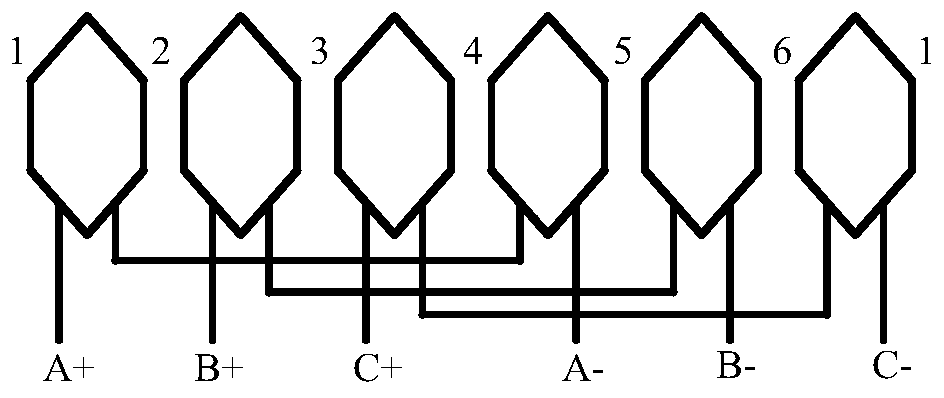

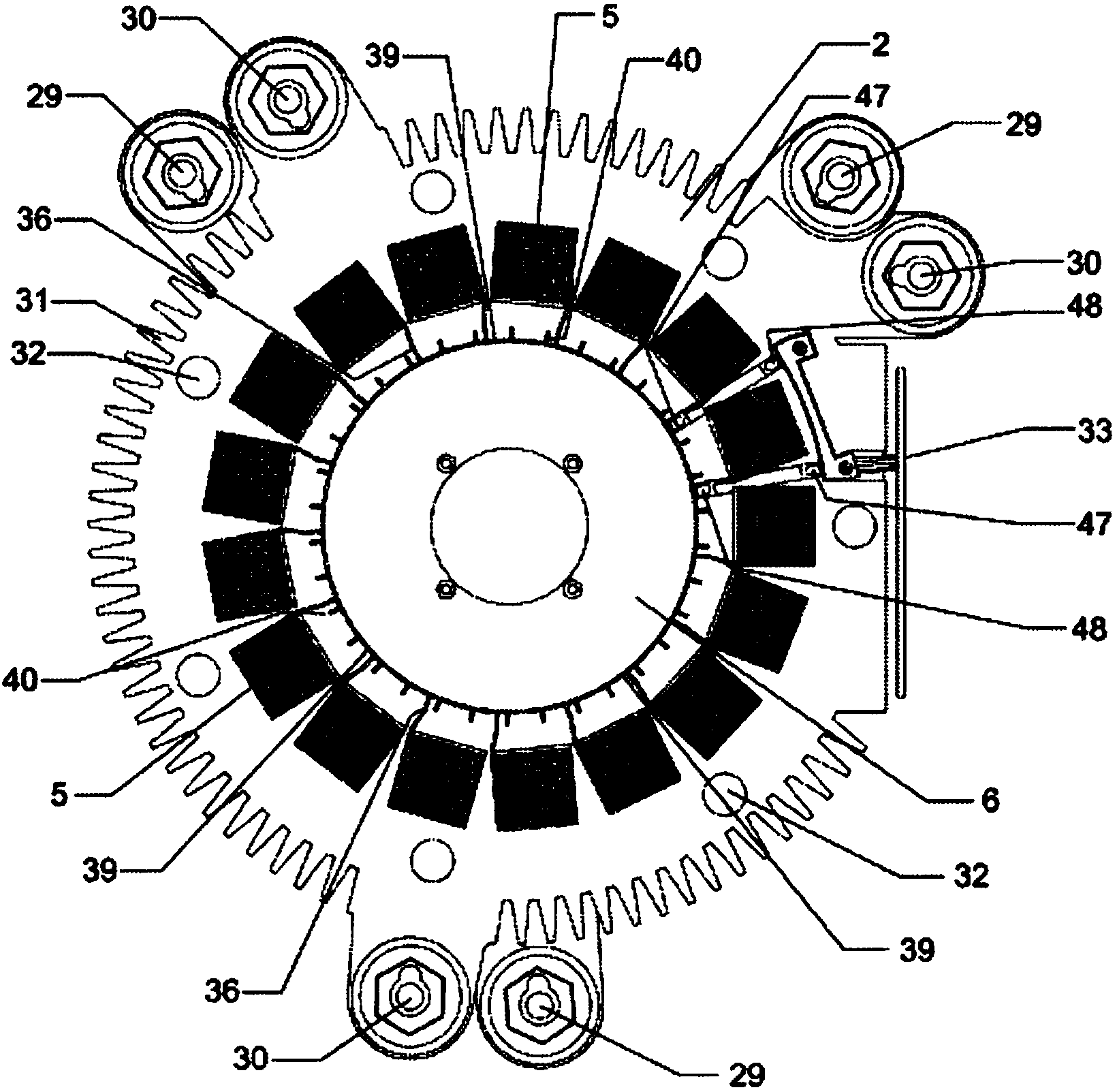

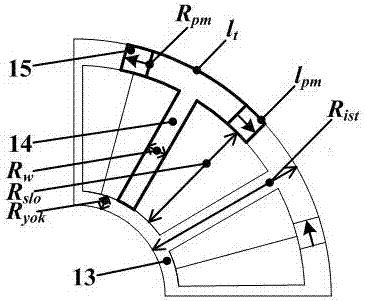

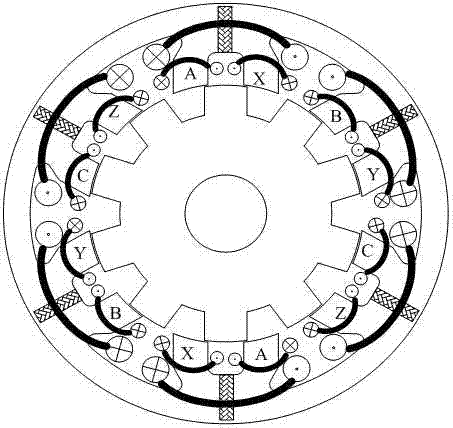

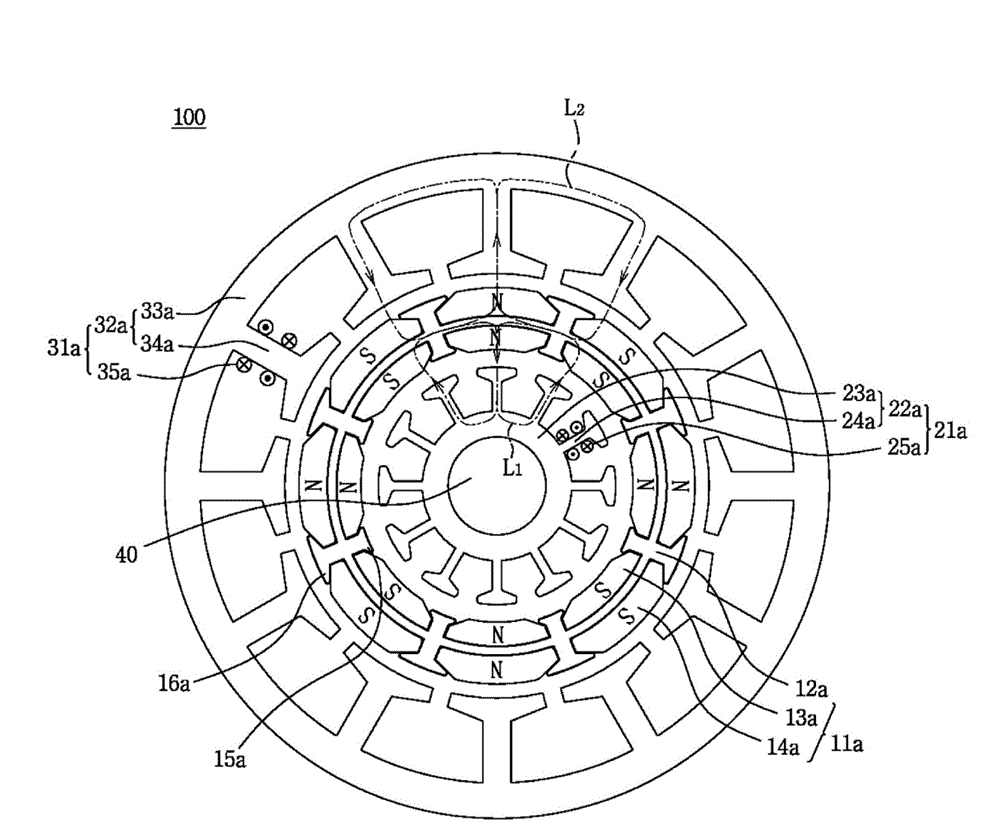

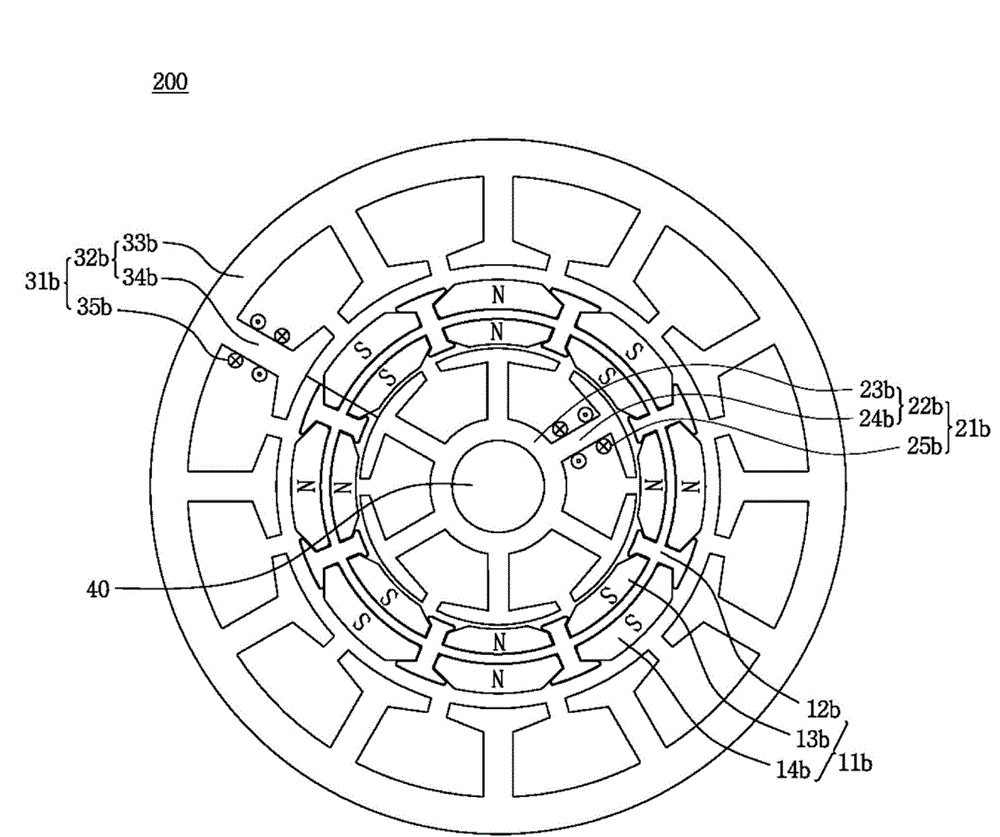

Magnetic gear composite motor

ActiveCN108011484AIncreased torque densityReduce Flux LeakageDynamo-electric machinesLow speedElectric machine

The invention discloses a magnetic gear composite motor. The magnetic gear composite motor comprises an outer stator, a modulation rotor and an inner rotor which are sequentially arranged in a concentrically nested manner from outside to inside, wherein air gaps are formed between the outer stator and the modulation rotor as well as between the modulation rotor and the inner rotor respectively; the outer stator is provided with a trapezoidal groove used for placing a fractional slot winding, and the groove opening is embedded with alternative-pole magnetic steel; the modulation rotor comprisesa plurality of magnet regulating yokes and a plurality of non-magnetic conductive materials embedded with punched holes respectively, and the adjacent magnet regulating yokes are embedded with the punched non-magnetic conductive materials therebetween; and the permanent magnet inner rotor comprises inner rotor permanent magnets and an inner rotor iron core which are concentrically nested to one another sequentially from outside to inside. According to the magnetic gear composite motor provided by the invention, a magnetic path of the magnetic gear motor on the stator is constructed through combining permanent magnets with different polarization directions, so that the magnetic path is enabled to be more efficient and reasonable, the flux leakage is reduced while low-speed and high-torquedirect drive output is realized, and the overall torque density and efficiency of the composite motor are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

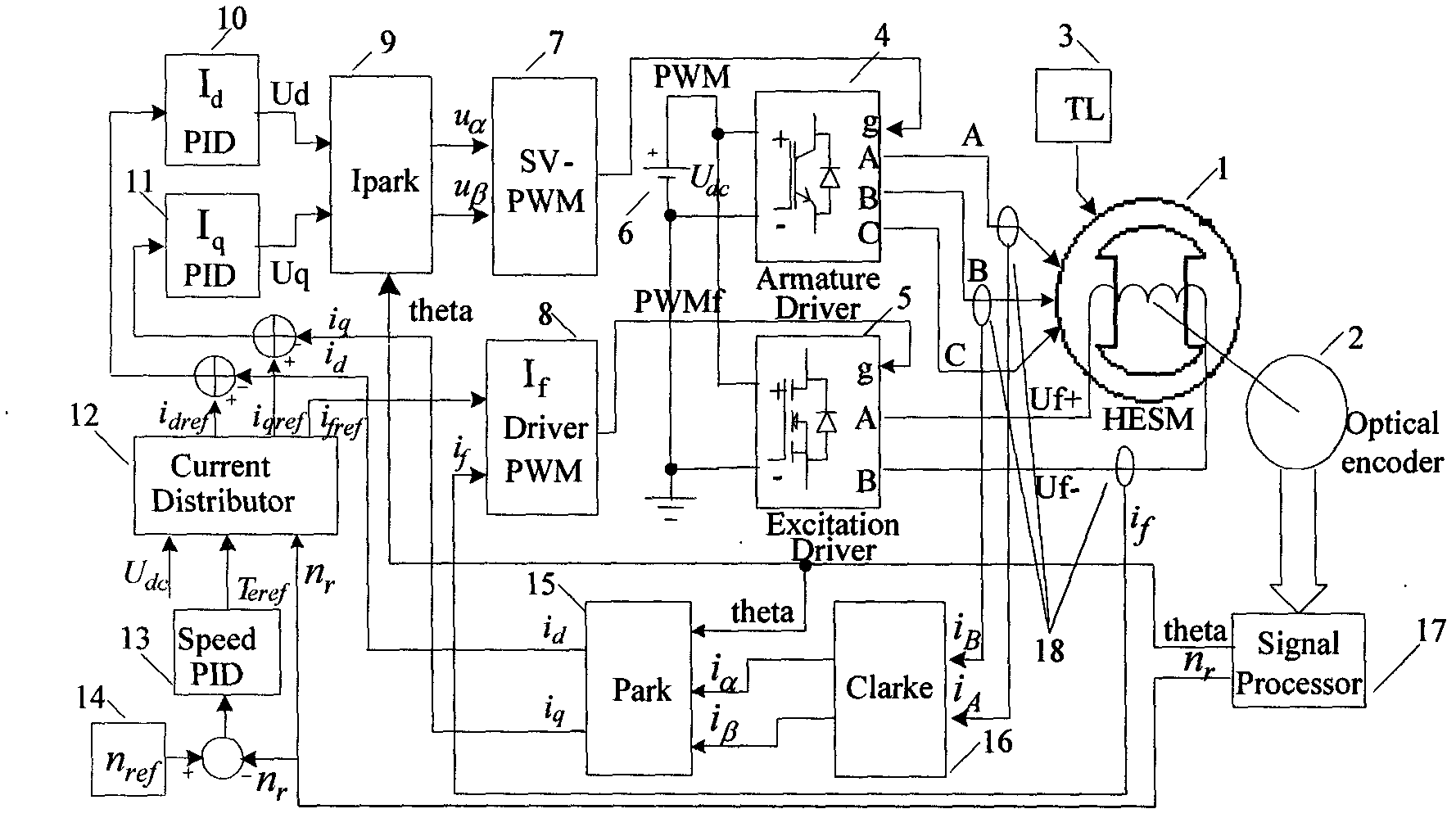

Novel speed regulating system suitable for driving electric automobile and current distributing method

InactiveCN102545766ANo risk of permanent demagnetizationThe risk of permanent demagnetization will notElectronic commutation motor controlVector control systemsPhase currentsProportion integration differentiation

The invention discloses a novel speed regulating system suitable for driving an electric automobile, which comprises the following steps: collecting phase currents iA, iB and exciting current if from an HESM (hybrid excitation synchronous machine) motor main circuit; collecting a real-time rotating speed nr from the HESM motor; obtaining d-q-axis currents id and iq after transforming the collected phase currents; comparing d-q-axis currents id and iq respectively with d-axis reference current idref and q-axis reference current iqref obtained from a current distributer and carrying out PID (proportion integration differentiation) operation, carrying out a reverse Park transformation and a space vector voltage pulse width modulation and outputing a pulse signal to control conduction and disconnection of a power tube corresponding to a armature driving module, and outputing the exciting current if and the exciting reference current ifref through an exciting driving signal generating module to control conduction and disconnection of the power tube corresponding to the exciting driving module, wherein the HESM motor adopts a dual-stator structure, an armature winding is arranged on an outer stator, and an inner stator is provided with an exciting winding; the motor rotor is configured as a claw pole shape, a permanent magnetic steel and a magnetizing iron core are in staggered arrangement on the claw pole, and the area rate of the permanent magnetic steel to the magnetizing iron core is 2:1.

Owner:HENAN INST OF ENG

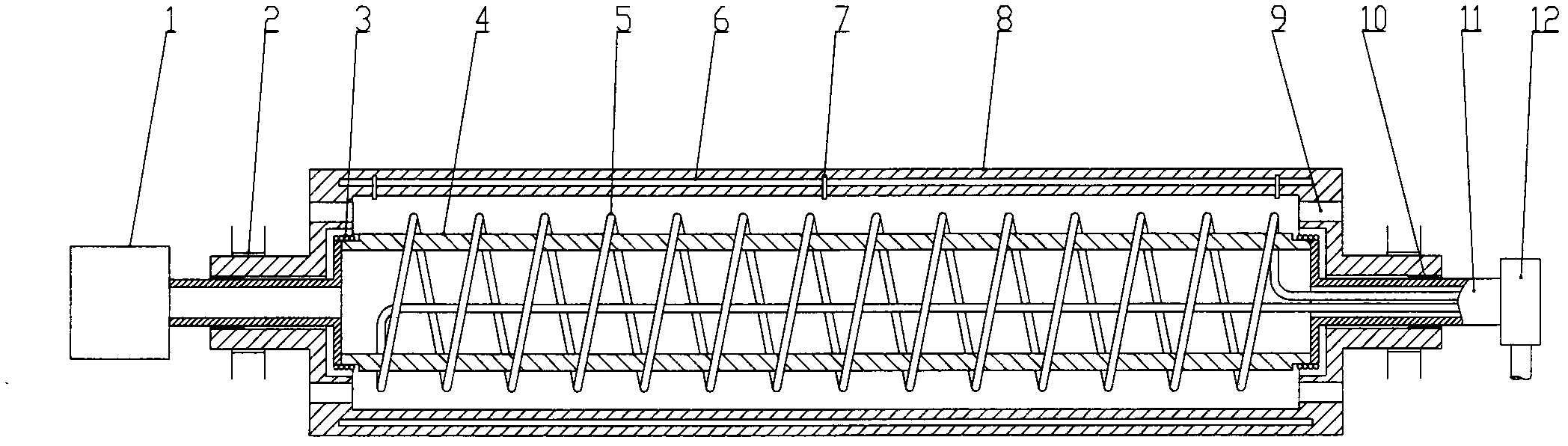

Electromagnetic induction heating roller

InactiveCN102325395AReduce pollutionReduce fireCoil arrangementsInduction heating apparatusElectricityKerosene

The invention discloses an electromagnetic induction heating roller in which high-frequency electromagnetic induction coils are arranged. The main body is a hollow roller body; a magnetism conductive iron core is arranged in the roller body; one end of the magnetism conductive iron core is connected with a cable connector through a half shaft; a heating coil wound on the magnetism conductive iron core is led into the roller body via the cable connector; a compensative heating coil wound on both ends of the magnetism conductive iron core is led into the roller body via the cable connector; a layer of water-filled isolating cavity is arranged in the wall of the roller body; and the surfaces of both ends of the roller body are respectively provided with a plurality of air holes for exhausting heat. The heating roller which is produced by utilizing the electromagnetic induction heating principle can replace various other heating rollers which are still used in a large quantity at present. Compared with the currently used steam heating, resistance wires, electric heating tubes or method for heating the surface of the heating roller with hot kerosene, the electromagnetic induction heating roller can save more electricity consumption and increase the temperature stability and precision of the roller surface.

Owner:张家港市弘扬机械设备有限公司

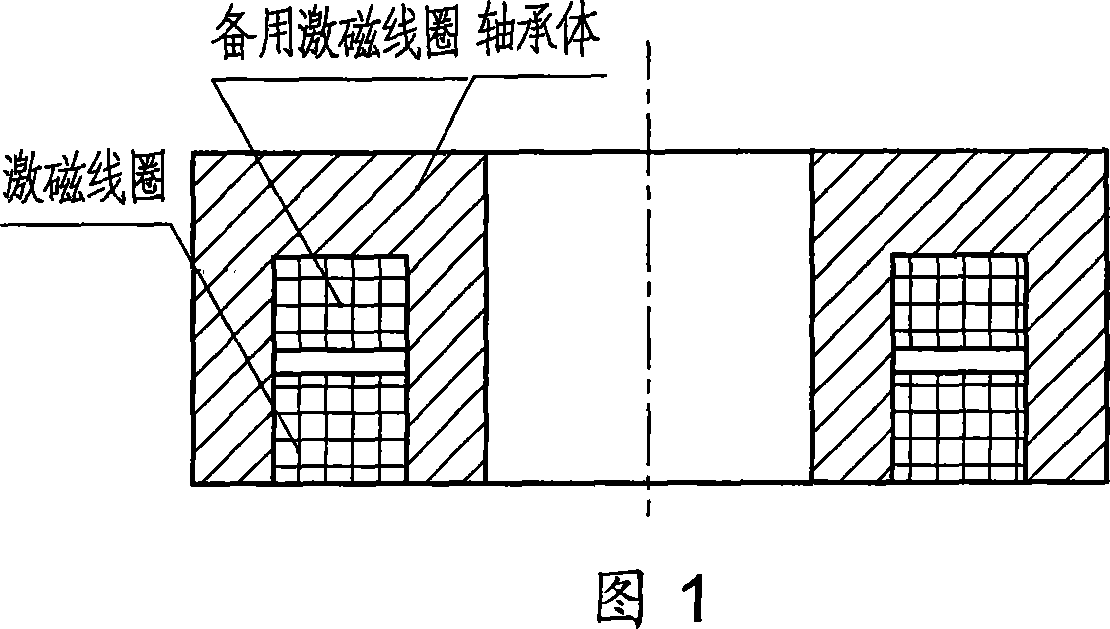

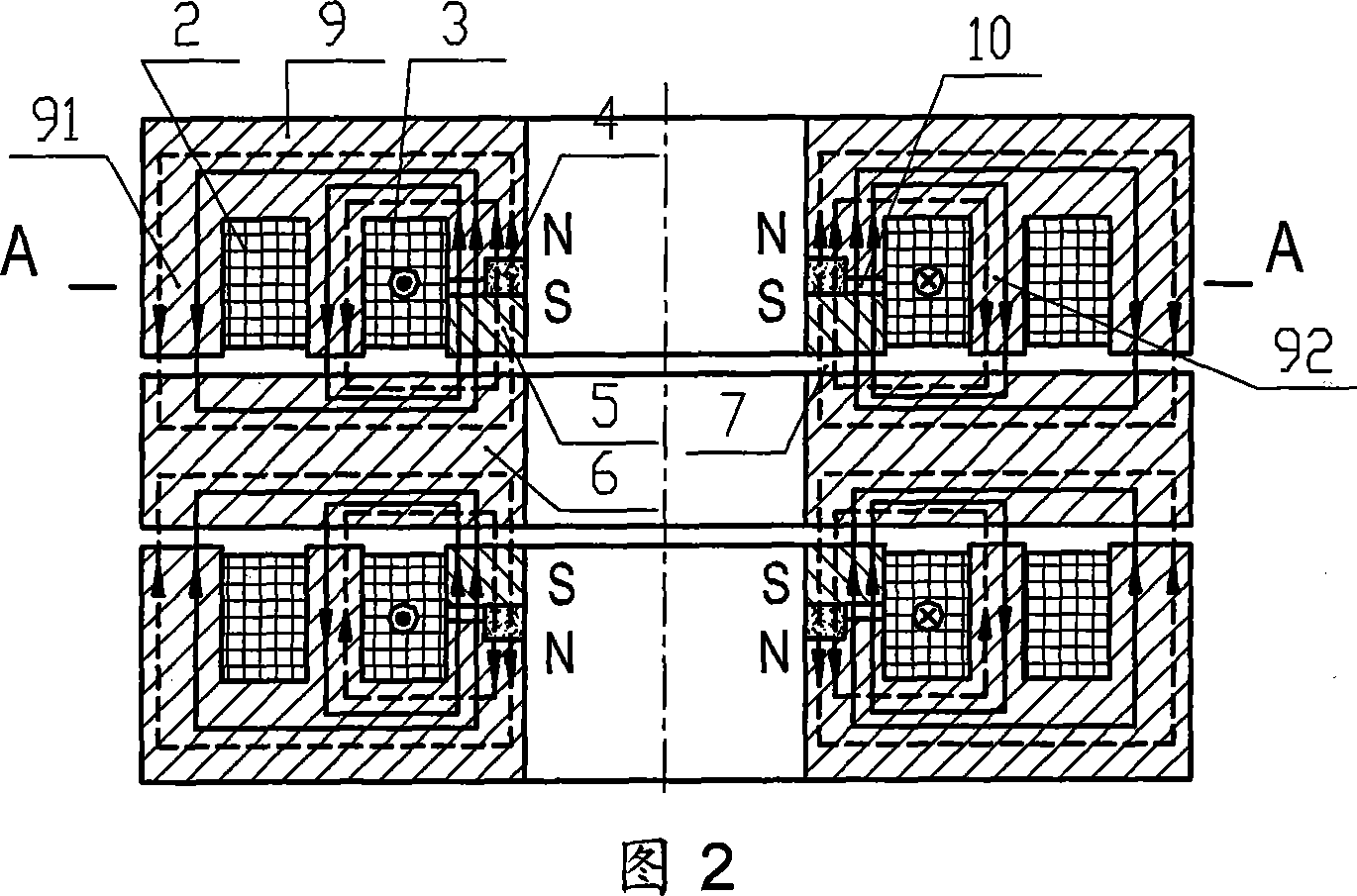

Low power consumption axial magnetic bearing with redundant structure

A low power axial magnetic bearing with redundant structure is characterized in that it is composed of bearing body, exciting coils, permanent magnet, magnetic ring, air gap, auxiliary air gap and suspension body. The permanent magnet clings to the bearing body to generate bias flux, the magnetic ring clings to the permanent magnet and forms the auxiliary air gap with the bearing body, the air gap is formed among the magnetic ring, the bearing body pole and the suspension body to generate bias flux, the bearing body is winded with two groups of the exciting coils to generate control flux, the exciting coil, the permanent body and the magnetic ring are formed to redundant axial magnetic bearing stators relative to each other. The invention realizes the redundancy for the structure of the permanent bias axial magnetic bearing, prevents the electromagnetic magnetic path from passing the internal part of the permanent body, and reduces the exciting current. The invention has high reliability and low power consumption, and can work as non-contact support for the rotating components in the flywheel and other devices.

Owner:BEIHANG UNIV

Disk type wind-mill generator

InactiveCN1905331ANot easy to produceImprove efficiencyMagnetic circuit rotating partsShaftsElectric machineElectrical polarity

The invention is a disc wind power generator, where a stator is composed of windings without ferromagnetic material; a permanent magnet fixed on a rotor spindle is a rotating body with the rotor spindle as axis and corresponds to permanent magnets fixed in the upper and lower casings, the opposite surfaces has the same polarity and there is a gap between them; the generating line of the rotating body is a curve or a broken line or an oblique line. Because eliminating iron core, the magnetic resistance is reduced. Because eliminating bearing, it forms air suspension between the rotor spindle and the stator, reducing no-load resisting torque, raising efficiency of motor and implementing breeze power generation; the permanent magnet whose generating line is a curve or a broken line or an oblique line makes the rotor spindle able to automatically align and reset.

Owner:林修鹏

Wide governing, double salient pole, mixed excitation brushless dynamo and weak magnet control method thereof

InactiveCN1601855AWide range of constant power speed regulationSmall magnetic resistanceMagnetic circuit stationary partsDC commutatorMagnetic orientationDynamo

The motor includes following structure: DC exciting coil are setup between armature windings on stator; corresponding permanent magnet is setup at outboard of the DC exciting coil; there is bridge of guiding magnetism between DC exciting coil and the permanent magnet; direction of magnetic field is along circumferencial direction in motor. Method of mixed excitation of combining permanent magnetism excitation with electricity excitation is adopted in weak magnetism control method for controlling excitation of motor. The method increases regulating range by using smaller electricity excitation, suitable to application needed of changing speed in large range.

Owner:SOUTHEAST UNIV

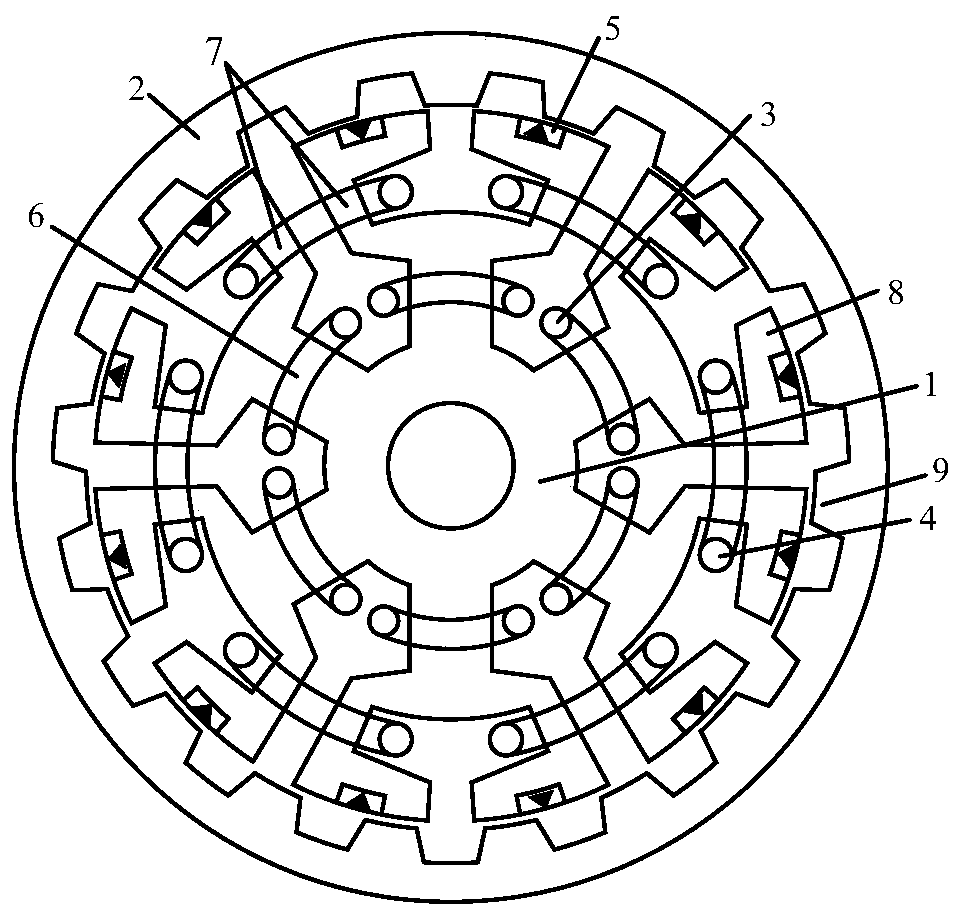

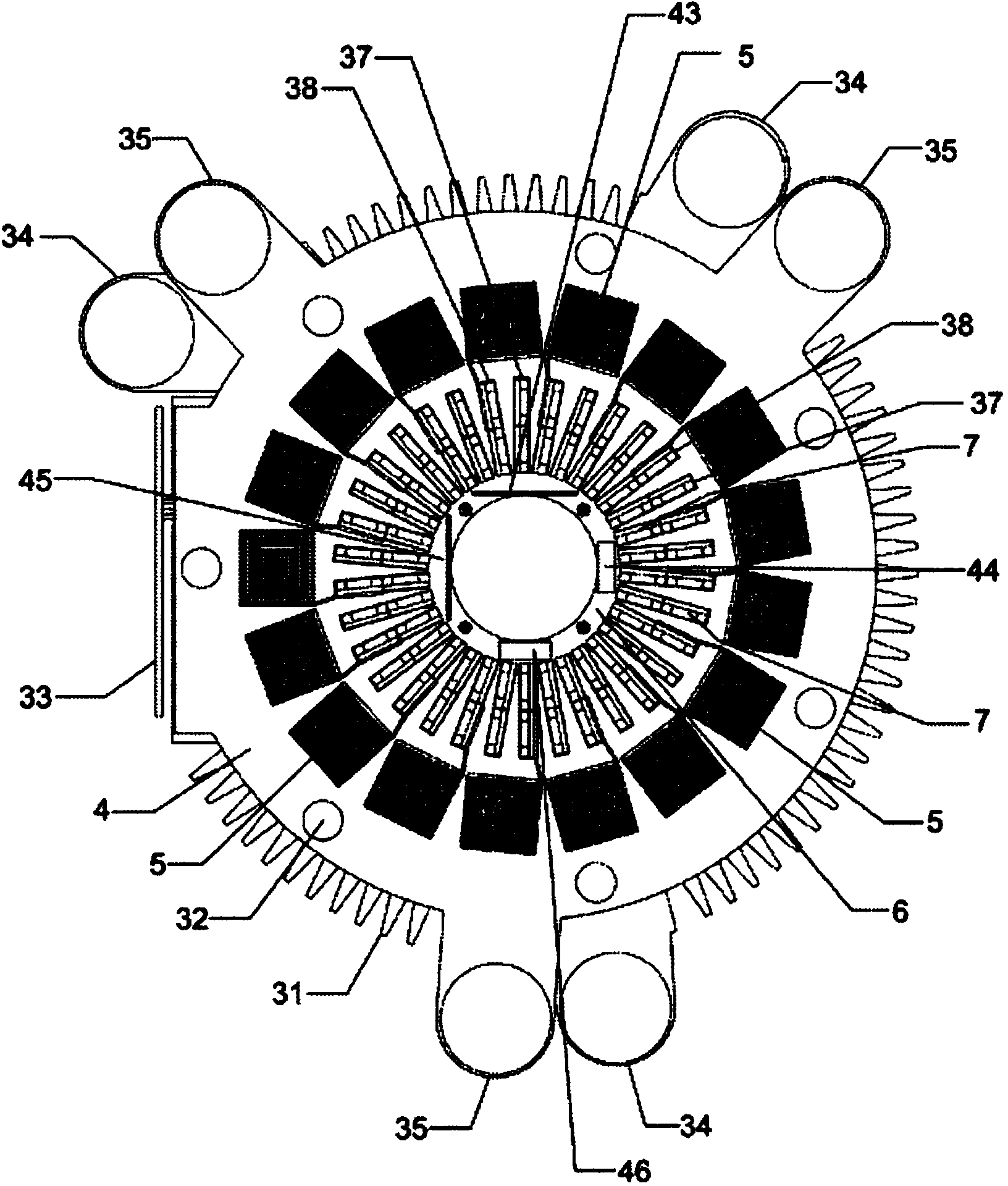

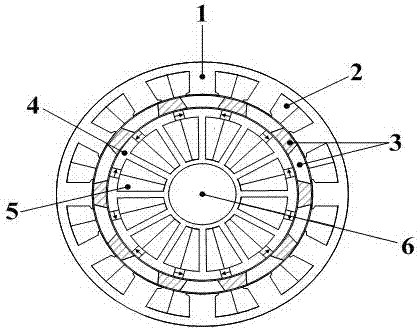

Magnetic field modulation hybrid excitation motor and multi-working-wave design method thereof

ActiveCN111509941AIncreased working air gap areaIncrease output torqueSynchronous machine detailsMagnetic circuit stationary partsMagnetoEngineering

The invention discloses a magnetic field modulation hybrid excitation motor and a multi-working-wave design method thereof. The motor comprises a stator and a rotor, wherein the stator comprises a stator iron core, two sets of windings and permanent magnets, the two sets of windings comprise an armature winding and an exciting winding, the stator iron core is designed as an open slot, one set of windings is distributed in the open slot of the stator iron core, and is wound on one stator tooth in a centralized manner, the outer surface of each stator tooth is provided with a groove, the other set of windings is placed in the groove of the stator tooth, each stator tooth is split into two modulation teeth through the groove, one permanent magnet is placed on each modulation tooth, the otherwinding is wound on two adjacent modulation teeth formed by splitting different stator teeth in a centralized mode, and the magnetizing direction of the permanent magnets is consistent with or opposite to the direction of a magnetic field formed by the excitation winding on the modulation teeth. According to the invention, the permanent magnet magnetomotive force and the excitation magnetomotive force are connected in parallel on the magnetic circuit and are independent from each other, so that the risk of irreversible demagnetization caused by the introduction of an excitation current permanent magnet is avoided, and the effective exertion of the magnetic regulation capability is ensured.

Owner:JIANGSU UNIV

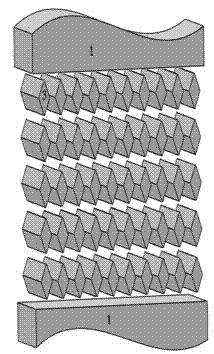

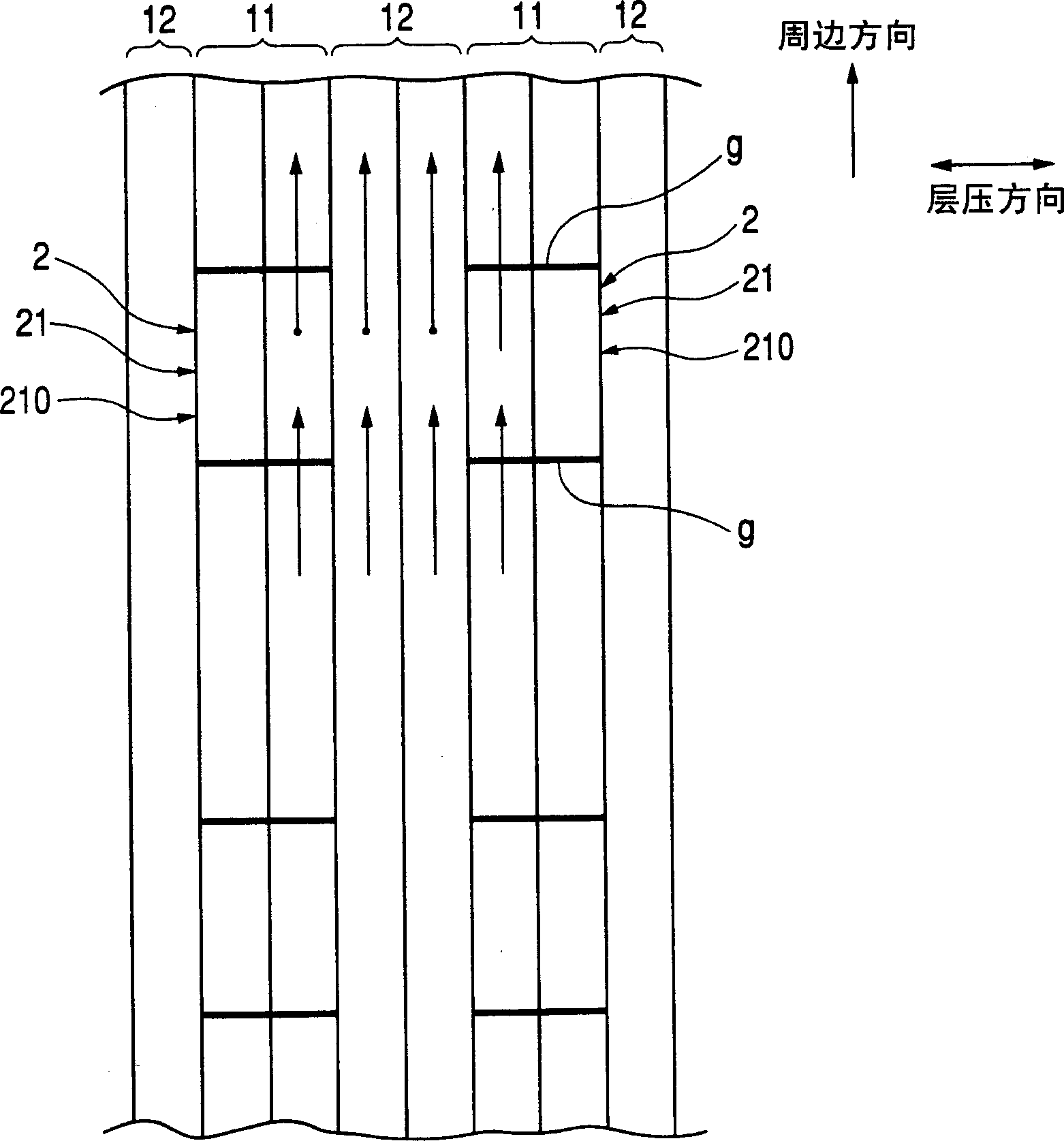

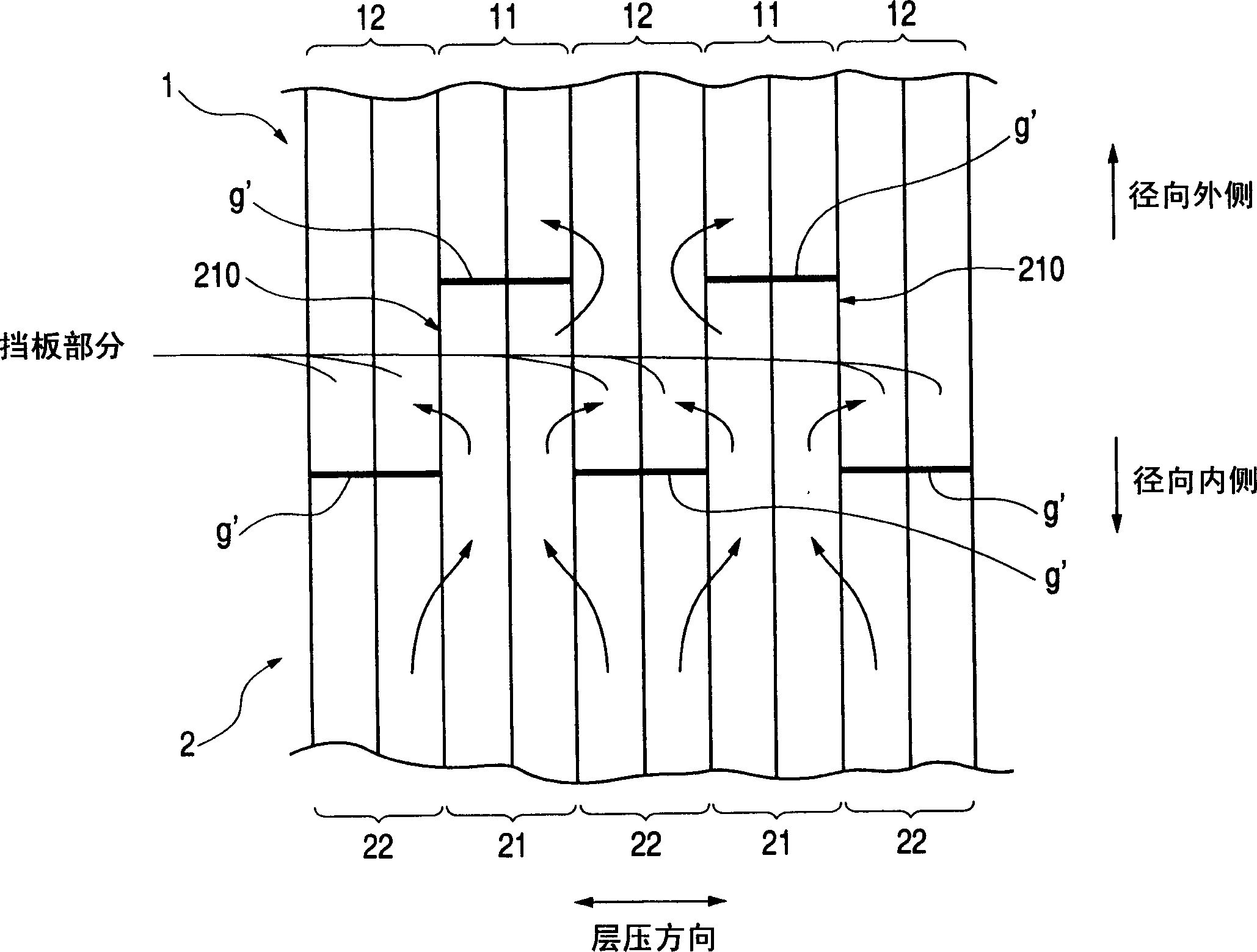

High-gradient magnetic flux converging medium for high intensity magnetic separator

InactiveCN102335638AHigh recovery rateRaise the magnetic field gradientHigh gradient magnetic separatorsMagnetic field gradientLower limit

The invention discloses a novel high-gradient magnetic flux converging medium for a high intensity magnetic separator. The high-gradient magnetic flux converging medium comprises non-magnetic conducting metal plates and a magnetic conducting medium rod, wherein a cross section of the magnetic conducting medium rod has a shape of equilateral rhombus; the rhombic magnetic conducting medium rod is fixed between the two non-magnetic conducting metal plates, thereby forming a separating medium box; the two non-magnetic conducting metal plates are embedded into a separating space of the magnetic separator in a parallel mode and are in suitable size; and two long-end vertex angles (acute angles) of the equilateral rhombic magnetic conducting medium rod are subjected to chamfering treatment. The high-gradient magnetic flux converging medium provided by the invention has the advantages that a gradient of a magnetic field in a magnetic path is high, magnetic resistance is small and energy consumption is saved; the high-gradient magnetic flux converging medium has the advantages of being free from 'magnetic short circuit' phenomenon and being difficult to block during an ore grain recycling process; and the high-gradient magnetic flux converging medium is specially suitable for recycling fine weak-magnetic ore grains and an effective grain level recycling lower limit can reach 5 microns.

Owner:KUNMING UNIV OF SCI & TECH

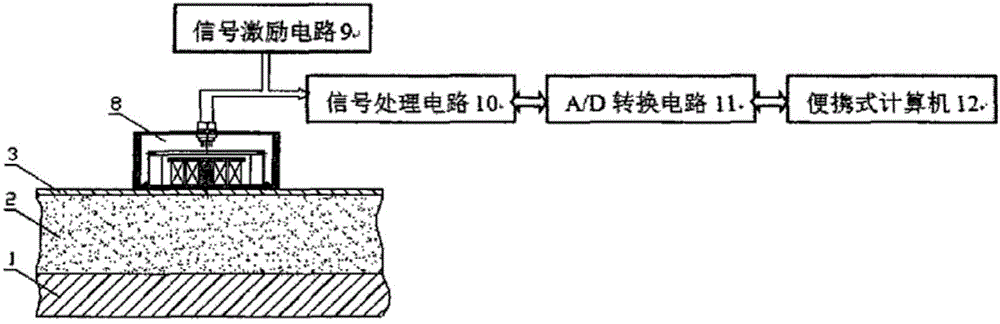

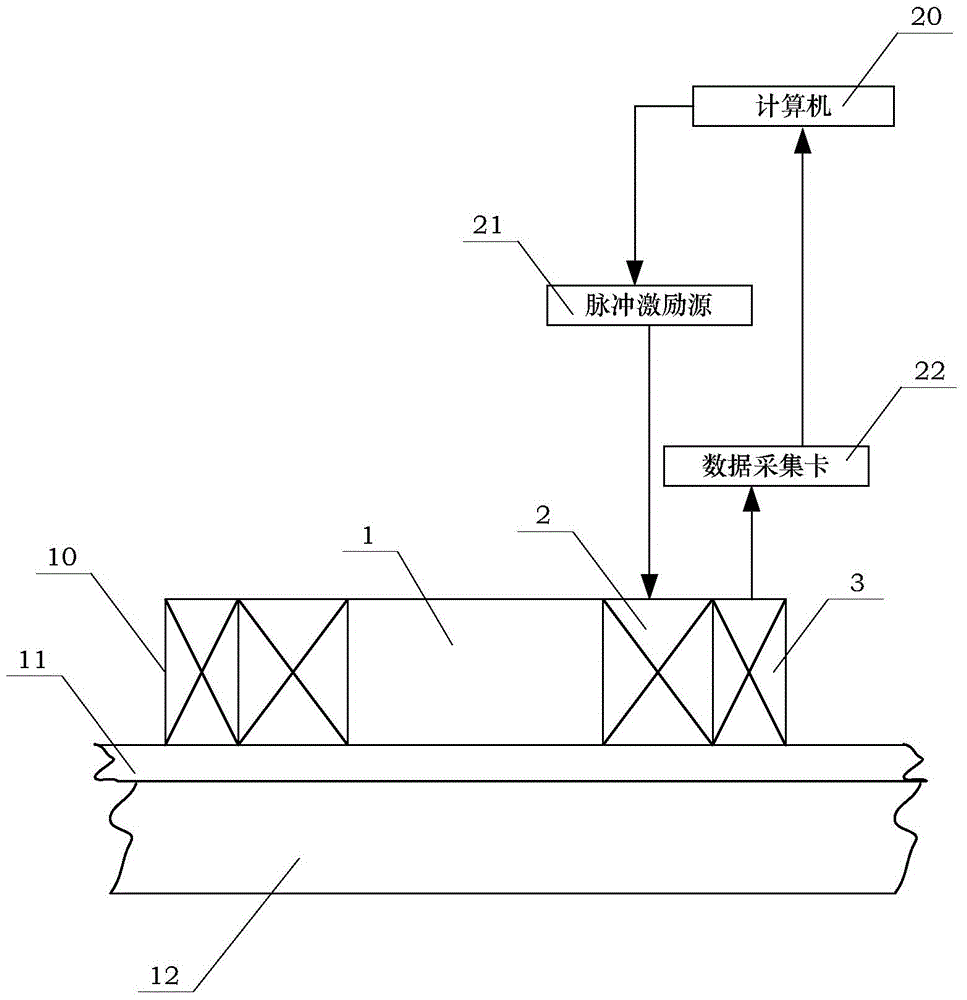

Pulse eddy electromagnetism nondestructive detection method based on probe with iron core coil

ActiveCN104155361ASmall magnetic resistanceEasy to detectElectrical/magnetic thickness measurementsMaterial magnetic variablesDiffusionHigh lift

The invention discloses a pulse eddy electromagnetism nondestructive detection method based on a probe with an iron core coil. The probe consists of an iron core bundle, an excitation coil and a detection coil, wherein the iron core bundle is arranged in the center of the excitation coil; the detection coil is arranged outside the excitation coil. When the probe with the iron core coil is adopted to perform pulse eddy detection on a part, a strong pulse magnetic field of a dense space can be generated, an excitation magnetic field is increased, the signal to noise ratio of a signal is increased, and pulse eddy detection on a component with a relatively large wall thickness can be achieved under a relatively high lift-off condition. When a pulse eddy electromagnetism nondestructive detection system based on the probe with the iron core coil is adopted for detection, the influence of the pulse eddy field inside the iron core to the detection signal can be measured according to a probe time constant tau s. When tau s is greatly smaller than a part diffusion time constant tau e, the influence of the pulse eddy field inside the iron core to the detection signal can be ignored, the function of the probe with the iron core coil can be approximated to be linear amplification of the detection signal, and thus the signal processing difficulty is reduced.

Owner:BEIHANG UNIV

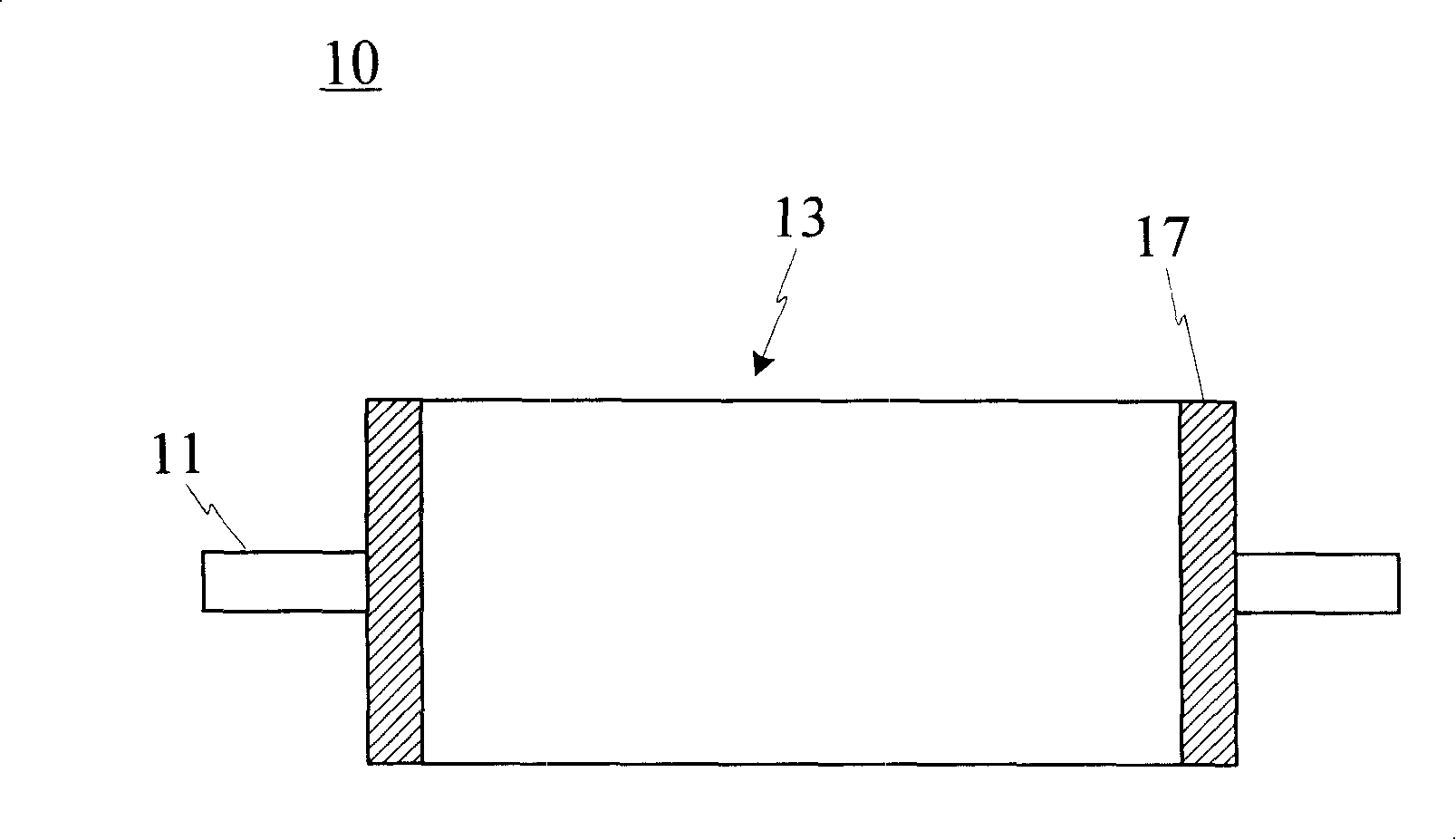

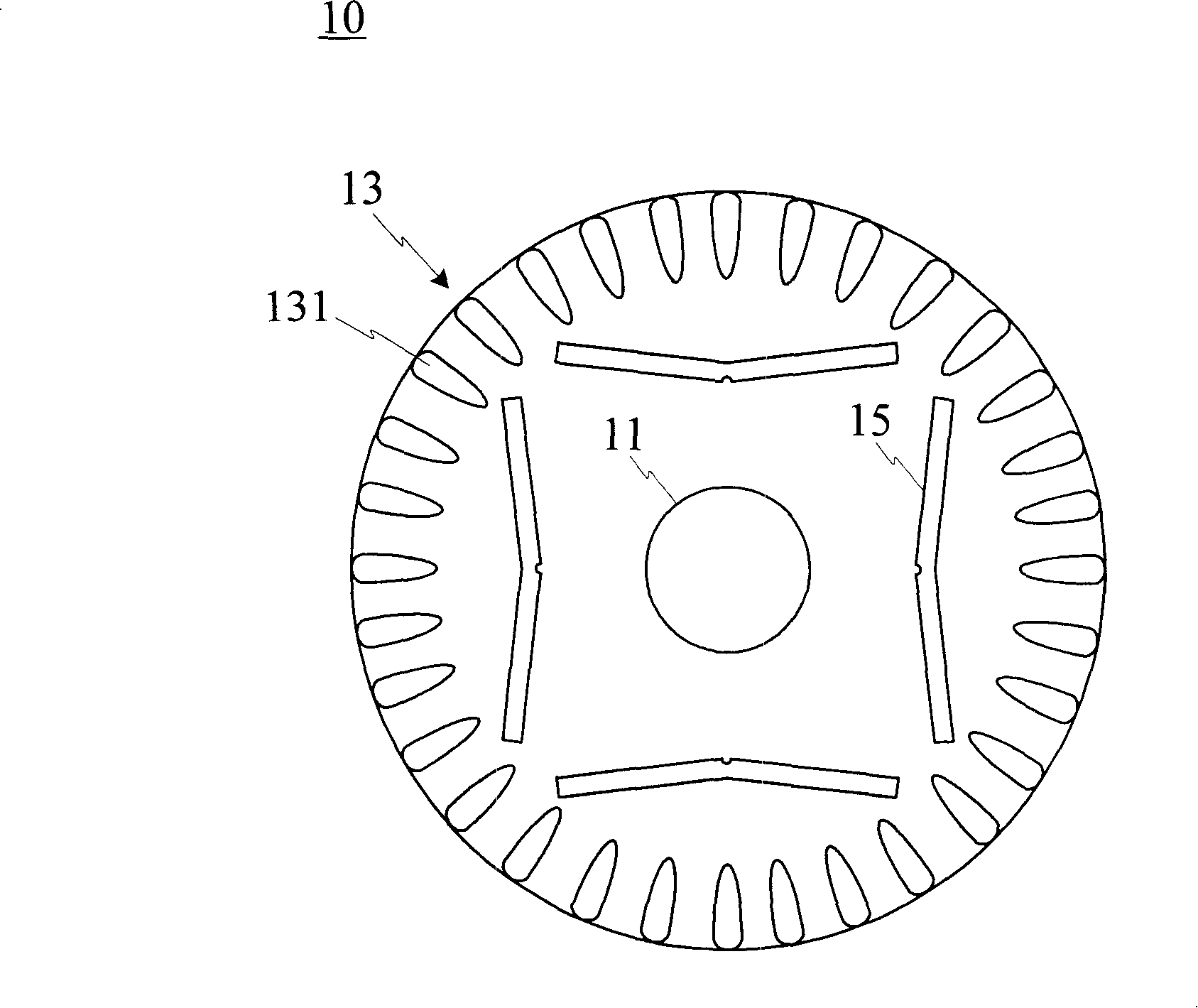

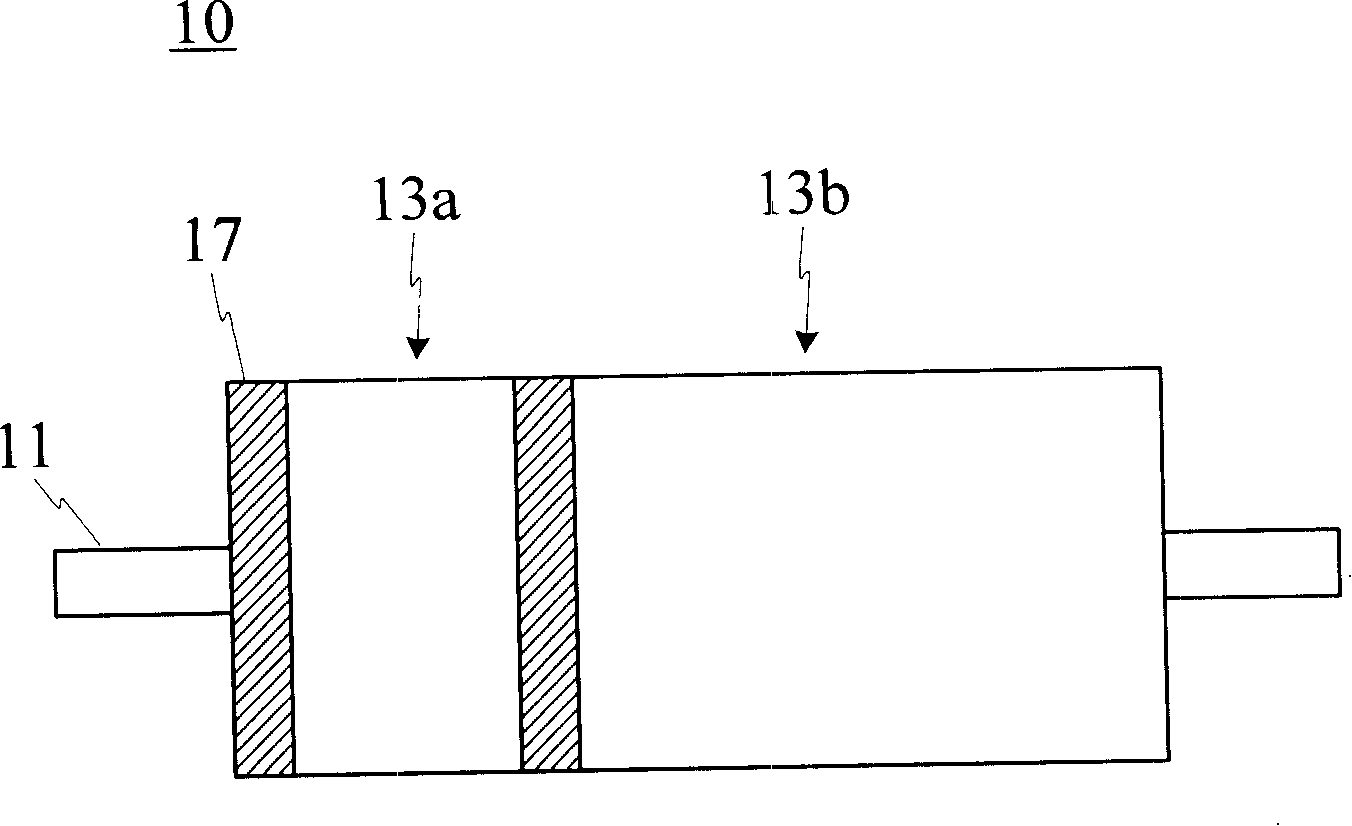

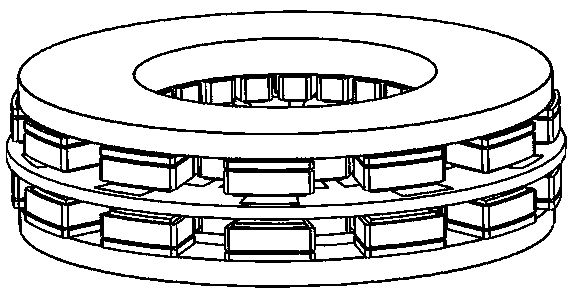

Electric motor/generator

ActiveCN103931081AExtended service lifeSmall magnetic resistanceAssociation with control/drive circuitsMagnetic circuit rotating partsEngineeringElectric generator

Certain embodiments are directed to devices, methods, and / or systems that use electrical machines. For example, certain embodiments are directed to an electrical machine comprising: at least one stator at least one module, the at least one module comprising at least one electromagnetic coil and at least one switch, the at least one module being attached to the at least one stator; at least one rotor with a plurality of magnets attached to the at least one rotor, wherein the at least one module is in spaced relation to the plurality of the magnets; and the at least one rotor being in a rotational relationship with the at least one stator, wherein the quantity and configuration of the at least one module in the electrical machine is determined based in part on one or more operating parameters; wherein the at least one module is capable of being independently controlled; and wherein the at least one module is capable of being reconfigured based at least in part on one or more of the following: at least one operating parameter during operation, at least one performance parameter during operation, or combinations thereof. Other embodiments are also disclosed.

Owner:AXIFLUX HLDG

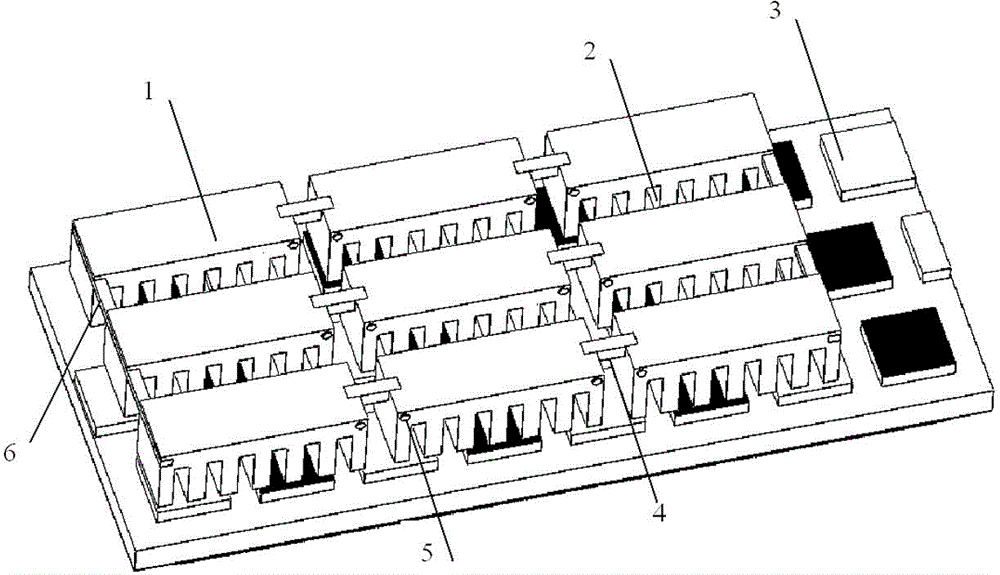

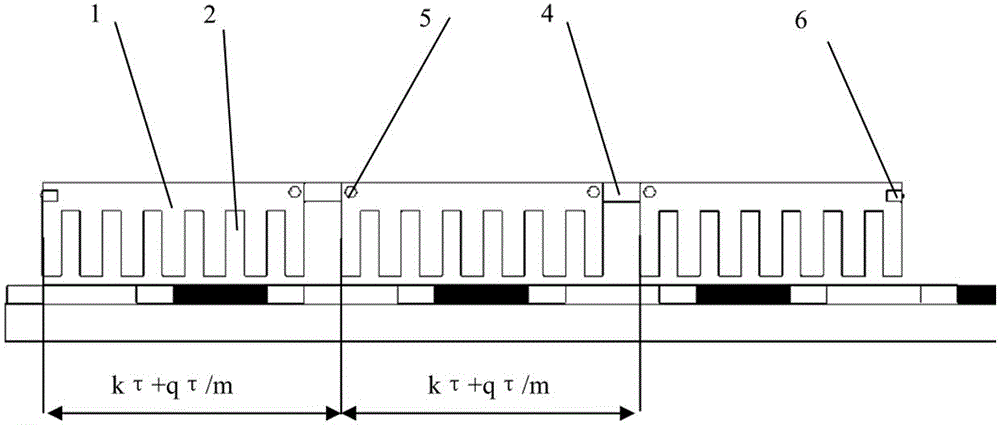

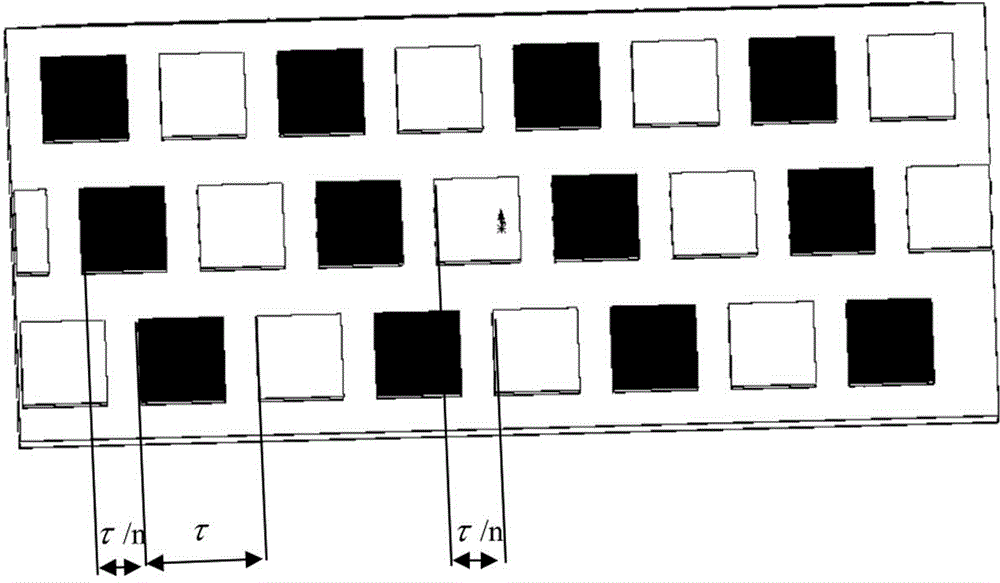

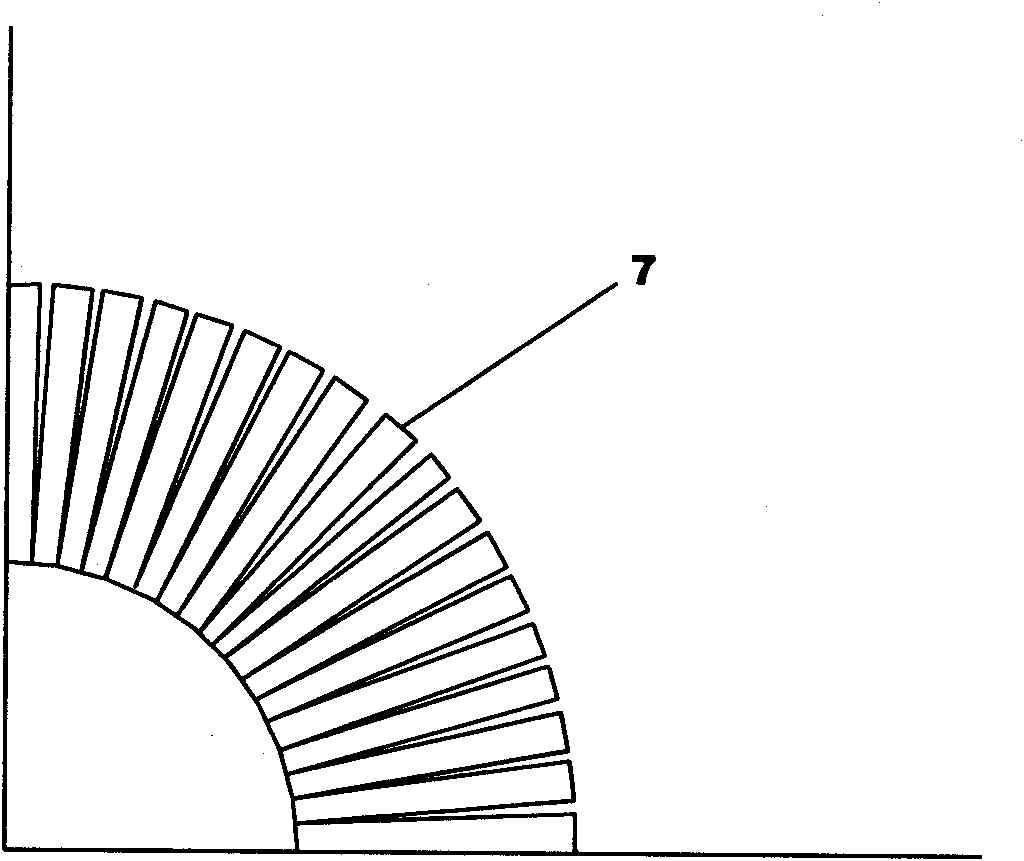

Low-thrust fluctuation matrix combined iron core primary permanent magnet linear synchronous motor

InactiveCN104410245ASmall magnetic resistanceSimple transmission structurePropulsion systemsMagnetPermanent magnet linear synchronous motor

The invention provides a low-thrust fluctuation matrix combined iron core primary permanent magnet linear synchronous motor. The motor is composed of a plurality of independent type iron core primaries; the plurality of independent iron core primaries are arranged on secondaries at the bottom of the independent iron core primaries according to a form of transverse-and-longitudinal m*n matrix and are in rigid connection with the secondary through non-magnetic materials so as form an integrated body; each independent iron core is independently powered by a concentrated winding, and independence between each other can be ensured; and each independent type iron core primary is provided with a coil winding. According to a permanent magnet linear synchronous motor which adopts a concentrated winding and is provided with short iron core primaries, the invention provides the matrix combined iron core primary permanent magnet linear synchronous motor. According to the low-thrust fluctuation matrix combined iron core primary permanent magnet linear synchronous motor, the magnetic resistance fluctuation amplitude of the motor can be greatly reduced, and the average thrust of the motor can be increased manyfold, and the fluctuation amplitude of the motor can be reduced, and the performance of the motor can be improved.

Owner:SHENYANG POLYTECHNIC UNIV

Double-stator hybrid excitation motor with T-type core inner stator

ActiveCN107222075ASolve the problem of mutual limitation of installation spaceImprove space utilizationMagnetic circuit stationary partsDc currentConductor Coil

The invention discloses a double-stator hybrid excitation motor with a T-type core inner stator. A center rotor is coaxially arranged in the middle of an outer stator and an inner stator. 12 T-type teeth are uniformly distributed along the circumferential direction of the inner stator yoke of the inner stator. The T-type teeth are sleeved with excitation windings. The top of each T-type tooth is near the center rotor. An inner stator slot is formed between every two adjacent T-type teeth. An arc permanent magnet is embedded fixedly between the tops of every two T-type teeth. The permanent magnets are magnetized along the tangential direction, and every two adjacent permanent magnets are magnetized in opposite directions. The inner and outer diameters of the permanent magnets are equal to the inner and outer diameters of the tops of the T-type teeth. The excitation windings are wound on the vertical parts of the T-type teeth of the inner stator, and thus, an electric excitation magnetic field connected in parallel with a permanent magnetic field is formed. The electric excitation magnetic field does not demagnetize the permanent magnets. When direct currents in different directions are fed to the excitation winding, the electric excitation magnetic field and the permanent magnetic field interact with each other to strengthen or weaken the magnetism.

Owner:LELING HETIAN ELECTRIC VEHICLE PARTS CO LTD

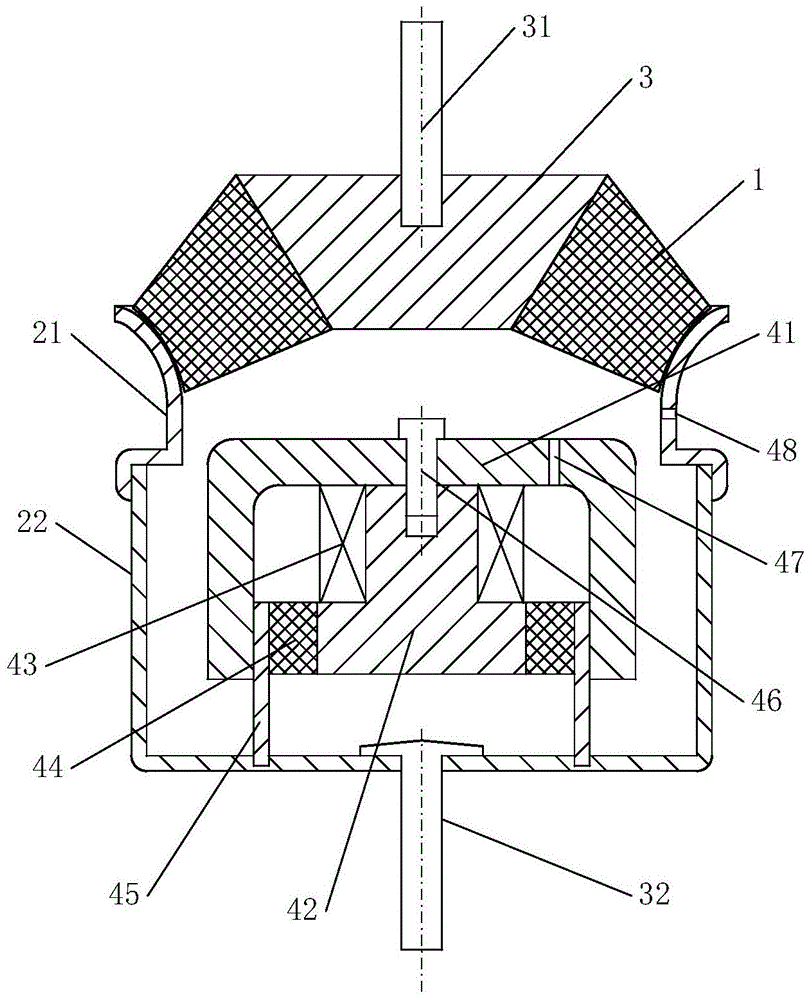

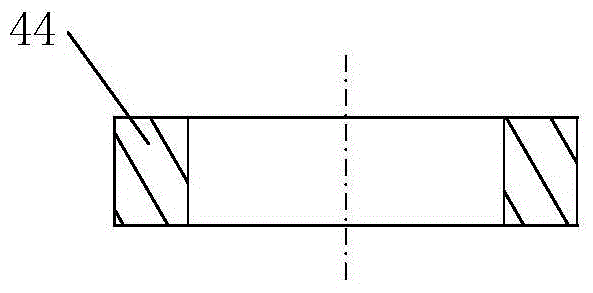

Paralleling model semi-active vibration isolator

ActiveCN104747651AIncrease stiffnessReduce stiffnessSpringsShock absorbersRotary machineMechanical engineering

The invention discloses a paralleling model semi-active vibration isolator. The vibration isolator is characterized in that a cylindrical upper shell is arranged, a rubber main spring is plugged in a top end opening of the upper shell, a main spring framework penetrates through the rubber main spring and is provided with an upper connection stud and a lower connection stud, the upper connection stud is connected with a main vibrating object, the lower connection stud is connected with a column-shaped iron core where an excitation coil is wound, the column-shaped iron core is supported in a magnetism conduction sleeve through a cutting magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, the two ends of the magnetorheological elastomer are extruded to be connected with the top of a T-shaped support and the bottom end of the iron core, and the T-shaped support penetrates through the magnetism conduction sleeve and is fixedly connected; the upper shell is connected with a lower shell, the lower end of the T-shaped support is fixedly connected with the lower shell, and the bottom of the lower shell is provided with a connection bolt used for being connected with a basal body. By means of the vibration isolator, vibrating energy transmitted by a rotary machine to the basal body can be effectively reduced, vibration of relative parts of the rotary machine is reduced, and the service life of the rotary machine and a system of the rotary machine is prolonged.

Owner:HEFEI UNIV OF TECH

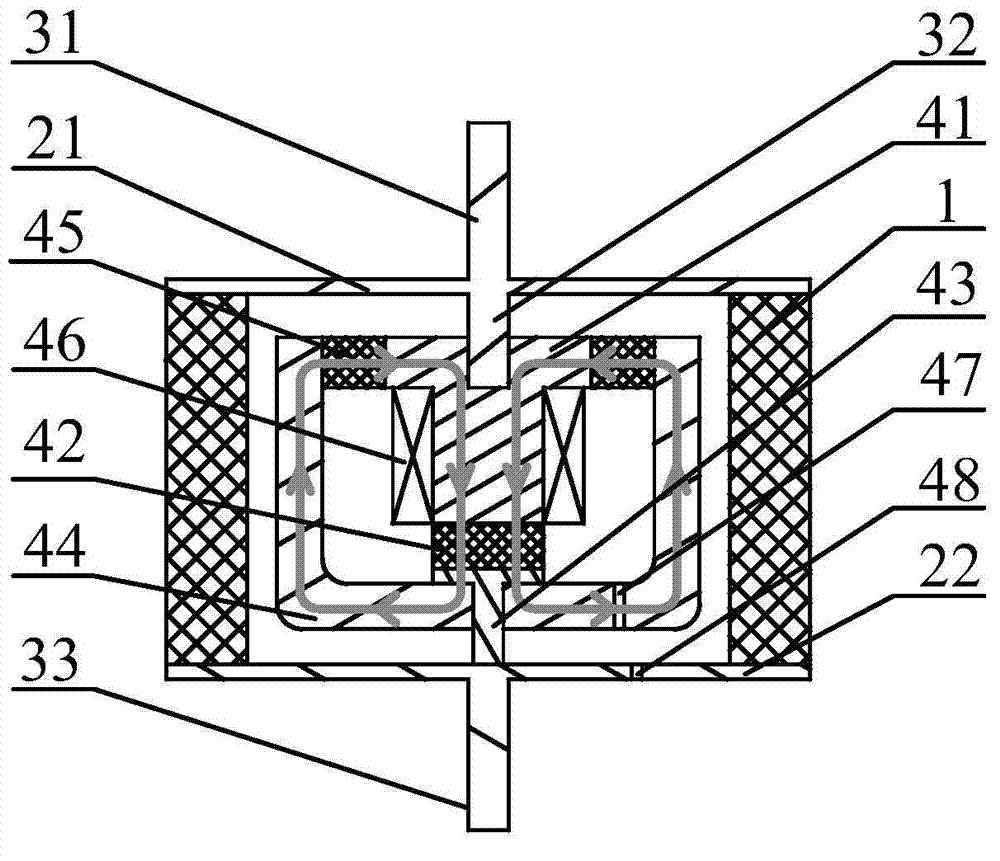

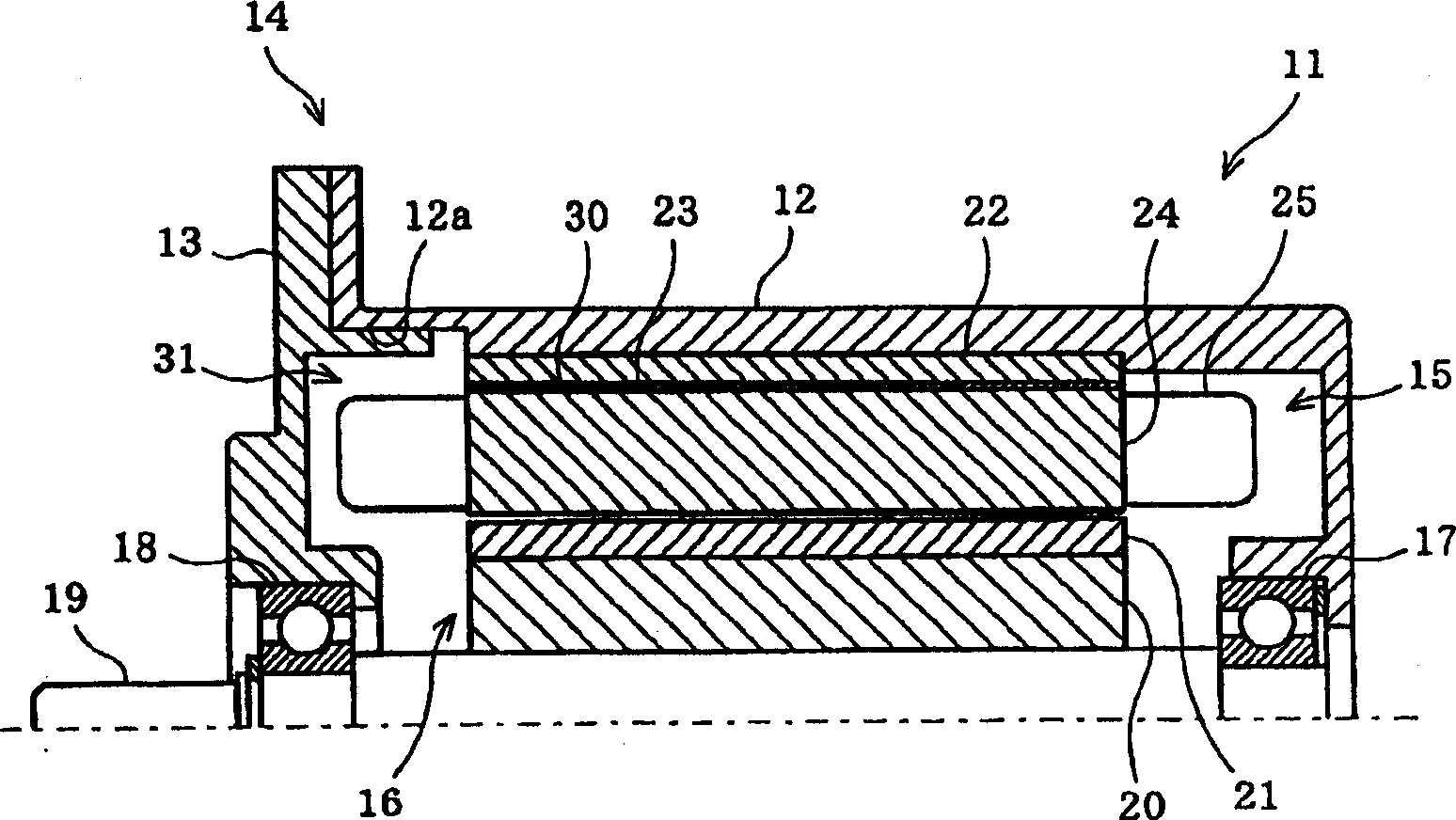

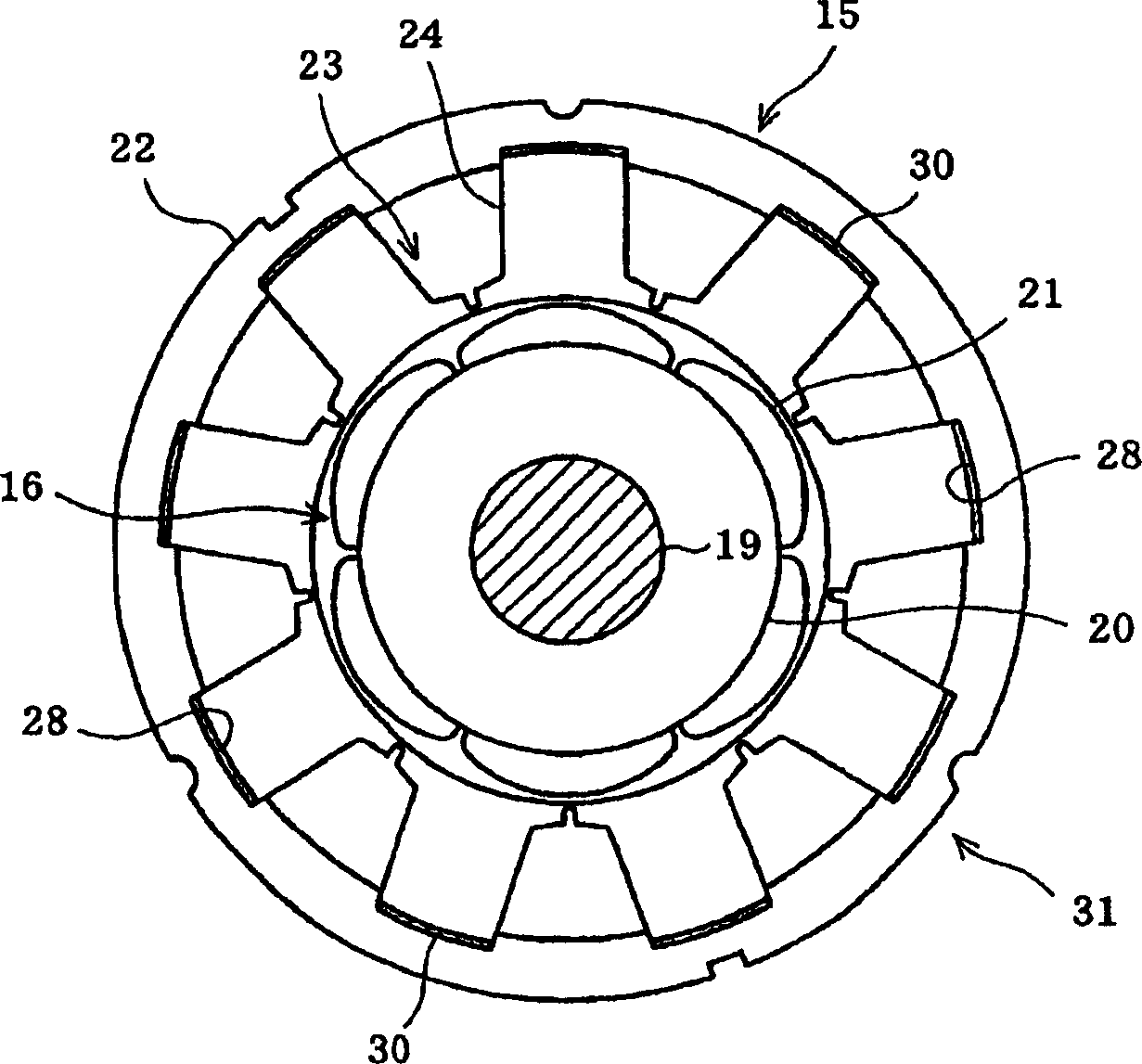

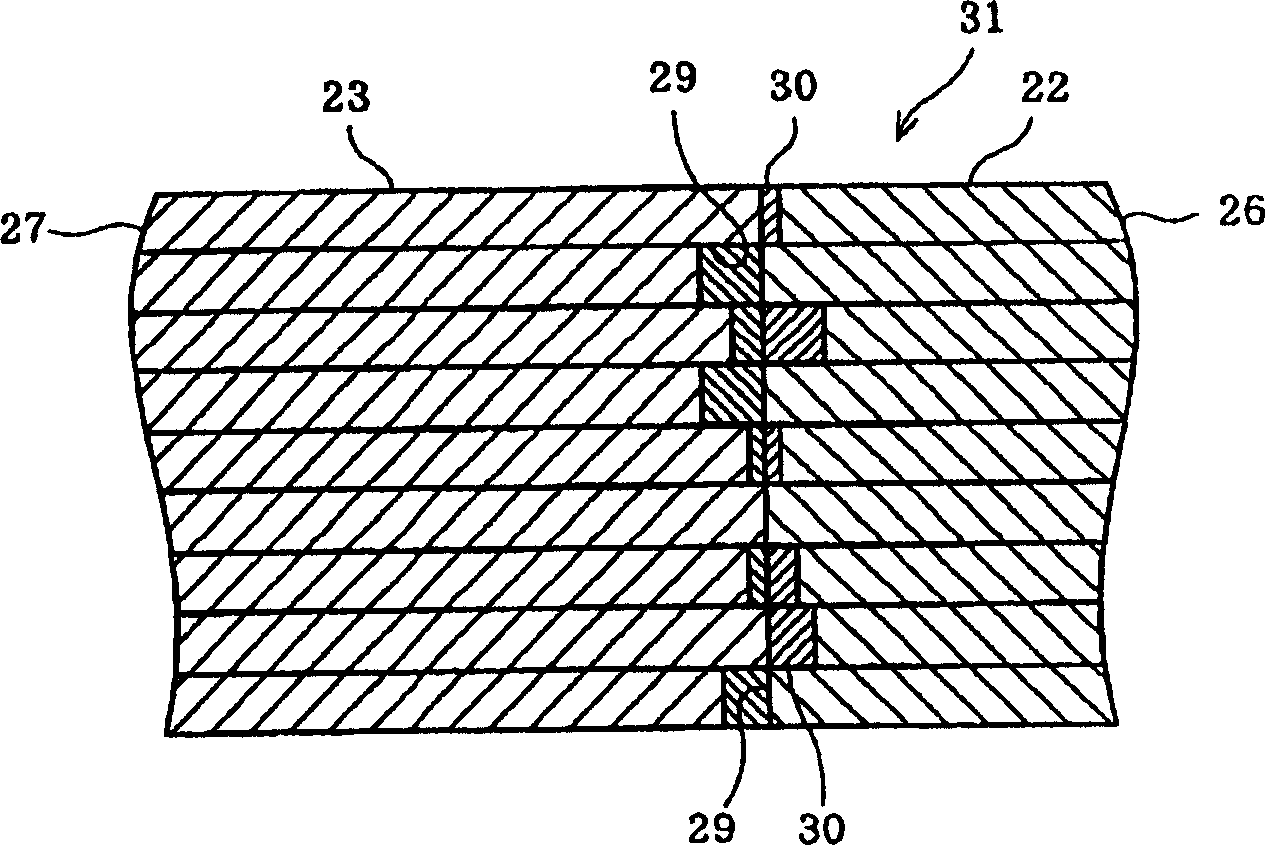

Combined stator core for electic rotary machinery

InactiveCN1514527ASmall magnetic resistanceReduce the number of gapsMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringMechanical engineering

Owner:DENSO CORP

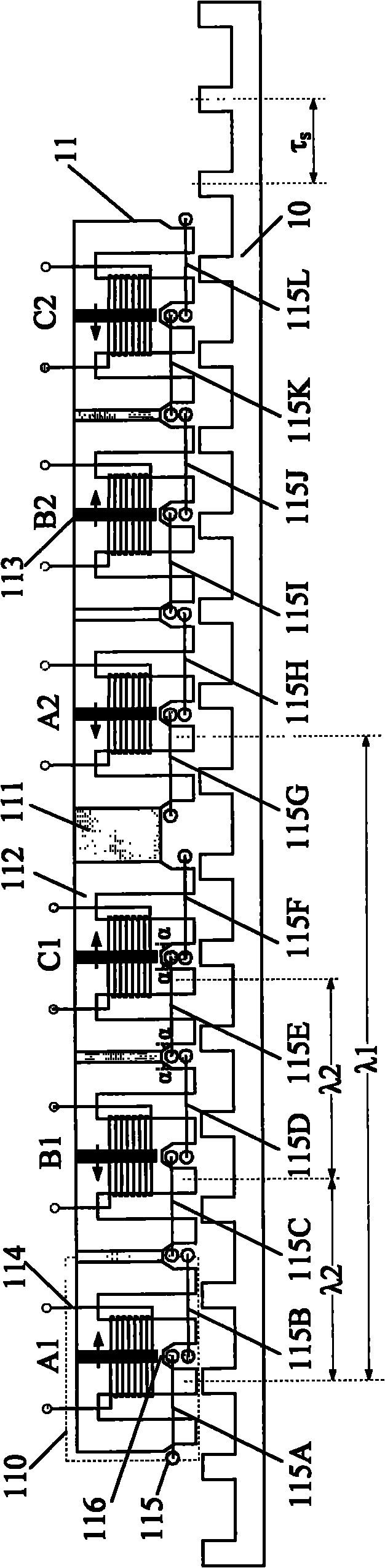

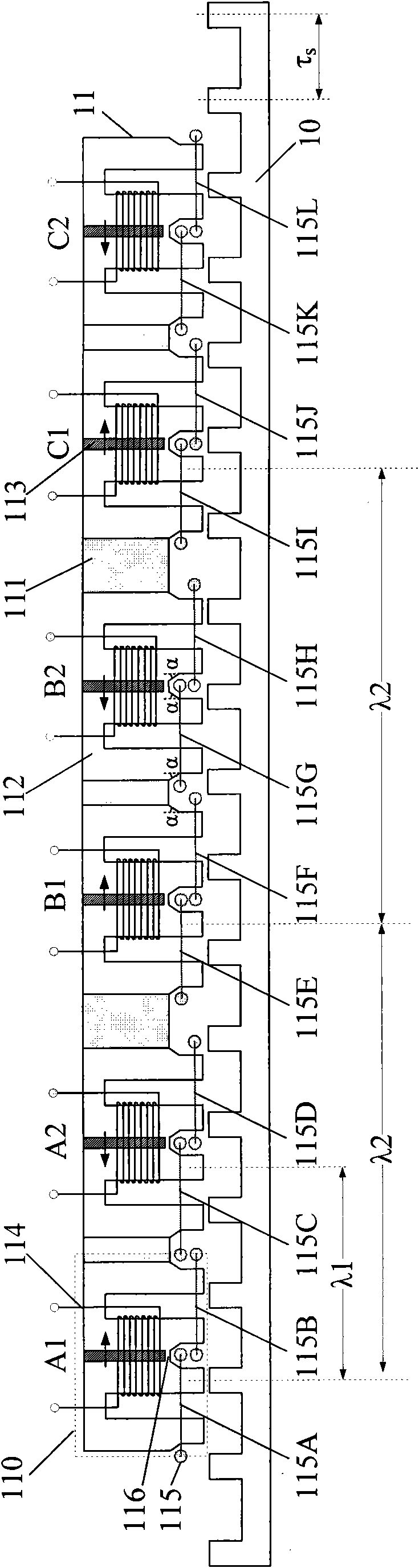

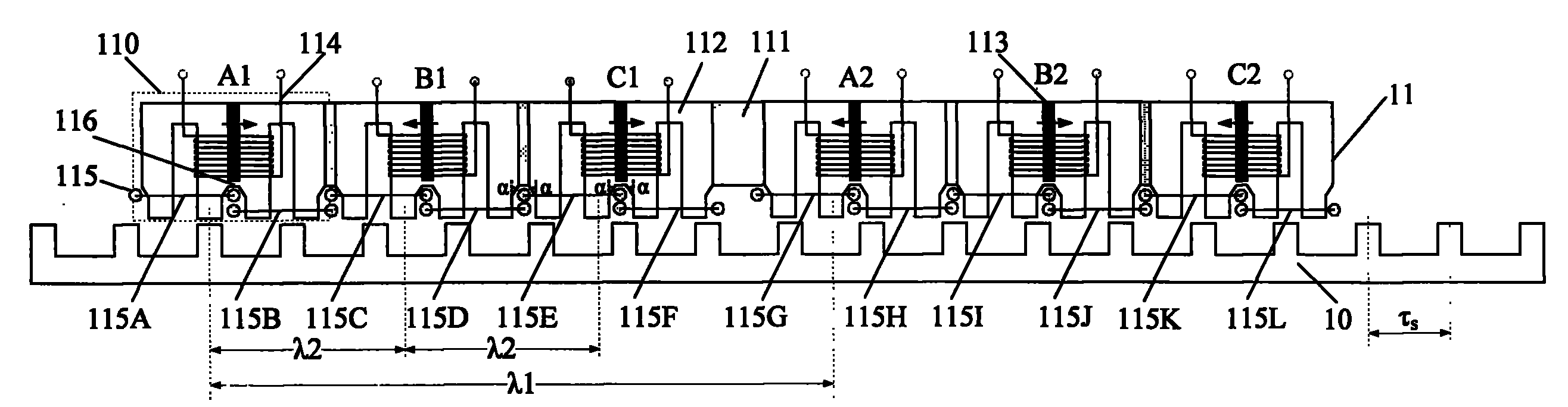

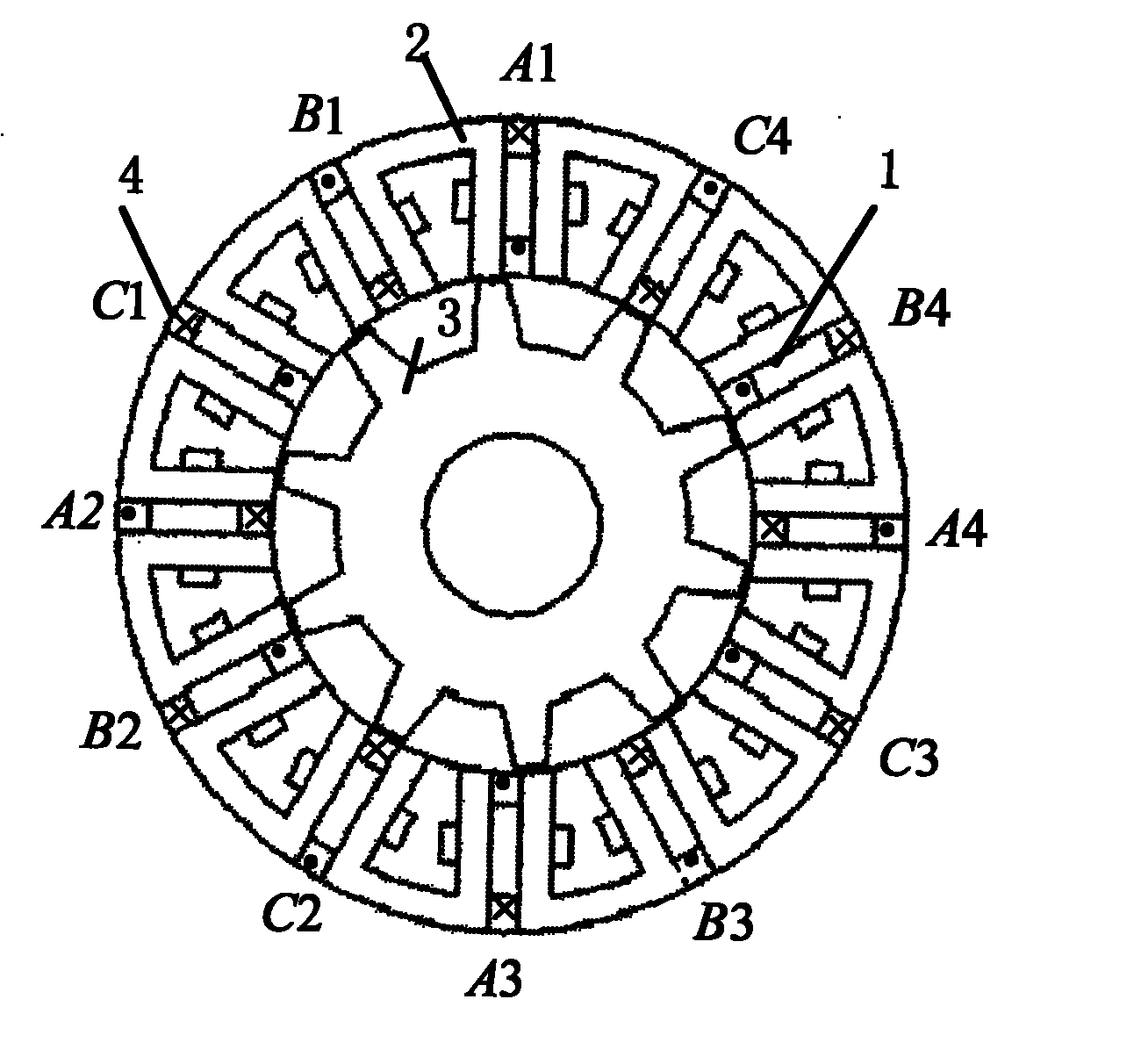

Complementary modular hybrid excited linear motor

InactiveCN101834512AStrong power densityImprove power densityPropulsion systemsRelative displacementElectric machine

The invention provides a complementary modular hybrid excited linear motor comprising a stator and a rotor. Both the stator and the rotor are in salient-pole structures, and an air gap is left between the stator and the rotor; the rotor comprises 2m E-type modules, wherein m is the number of the phases of a motor; the relative displacement Lambda 1 of two in-phase E-type modules is equal to (n+ / -1 / 2) Taus, and the relative displacement Lambda 2 of two out-phase E-type modules is equal to (j+ / -1 / m) Taus, wherein the Taus is the polar distance of the stator, and the n and the j are positive integers; each E-type module comprises two U-shaped magnetic teeth, a permanent magnet, an armature winding and an exciting winding, wherein the two U-shaped magnetic teeth are connected by a magnetic bridge, and the exciting winding is arranged and sleeved on the top of the U-shaped magnetic teeth. The magnetic bridge structure for the linear motor can supply the additional access for the exciting winding so that the reluctance of the circuit for the electrically exciting magnetic field can be reduced and the flux of the linkage for the armature winding can be greatly reduced by using smaller exciting current. The linear motor has strong magnetic field weakening capacity and high efficiency.

Owner:SOUTHEAST UNIV

Vibration isolator with active vibration absorbing ability

The invention discloses a vibration isolator with an active vibration absorbing ability. The vibration isolator with the active vibration absorbing ability is provided with a barrel-shaped upper shell, a rubber main spring is blocked in a top end opening of the upper shell, a main spring framework runs through the rubber main spring, a connecting stud is arranged at the top of the main spring framework, and the upper end of the connecting stud is used for connecting with a base body; the vibration isolator with the active vibration absorbing ability is provided with a lower shell connected with the upper shell, a shearing sleeve is fixed on the bottom plate of the lower shell, a column-shaped iron core is supported in the shearing sleeve through a magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, a magnet exciting coil winds the column-shaped iron core, and the magnetorheological elastomer works in a shearing mode; a magnetic conductive mass block is firmly connected with the iron core; a connecting bolt is arranged at the bottom of the lower shell for connecting with a main vibration object. The vibration isolator with the active vibration absorbing ability is capable of effectively lowering the vibration energy transmitted to the base body from a rotating mechanism, reducing the vibration of related parts of the rotating mechanism and improving the service life thereof.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

Motor and rotor structure thereof

ActiveCN101227127AImprove efficiencyReduce lossesMagnetic circuit rotating partsAsynchronous induction motorsInduction motorDrive motor

A motor which can automatically start comprises a starting portion and an operating portion, wherein the starting portion is divided into a squirrel-cage type induction motor, while the operating portion is divided into a permanent type motor, the starting portion and the operating portion are separately arranged along the same axis, and wire windings thereof are respectively connected with a alternating-current power supply, the wire winding on the starting portion can be provided with a switch, when the starting portion drives the motor to achieve a synchronous speed, the operating portion is used to keep a synchronous operation of the motor and can close the starting portion to reduce copper loss.

Owner:TECO ELECTRIC AND MACHINERY

Compound excitation amorphous alloy axial flux motor

ActiveCN109217597AAchieve regulationEasy to adjustMagnetic circuit rotating partsMagnetic circuit stationary partsAlloyHigh power density

A hybrid magnetic field controllable axial flux motor comprises two amorphous alloy stators and a rotor arrange between that two stators; The stator core of stator is divided into three parts along the radial direction, which are stator core in permanent magnet region, stator core in magnetic isolation region and stator core in electric excitation region. The armature winding of the permanent magnet region is arranged on the stator core of the permanent magnet region; The armature winding of the electric excitation region is arranged on the stator core of the electric excitation region; A permanent magnet and a ferromagnetic pole are embedded on the rotor bracket of the rotor part, respectively corresponding to the stator iron core of the electric excitation region and the stator iron coreof the permanent magnet region in the axial direction. The utility model has the advantages of simple manufacture, low loss, high power density and wide range of weak magnetic field expansion speed.

Owner:SHENYANG POLYTECHNIC UNIV

Motor and connector for semiconductor

InactiveCN1881745AIncrease effective fluxHigh outputMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringSemiconductor

An electric motor includes a stator including a stator core made of a plurality of split cores joined to each other and a stator winding wound on the stator core, and an admixture interposed in a joint between the split cores and comprising a binder mixed with a granular magnetic substance.

Owner:KK TOSHIBA

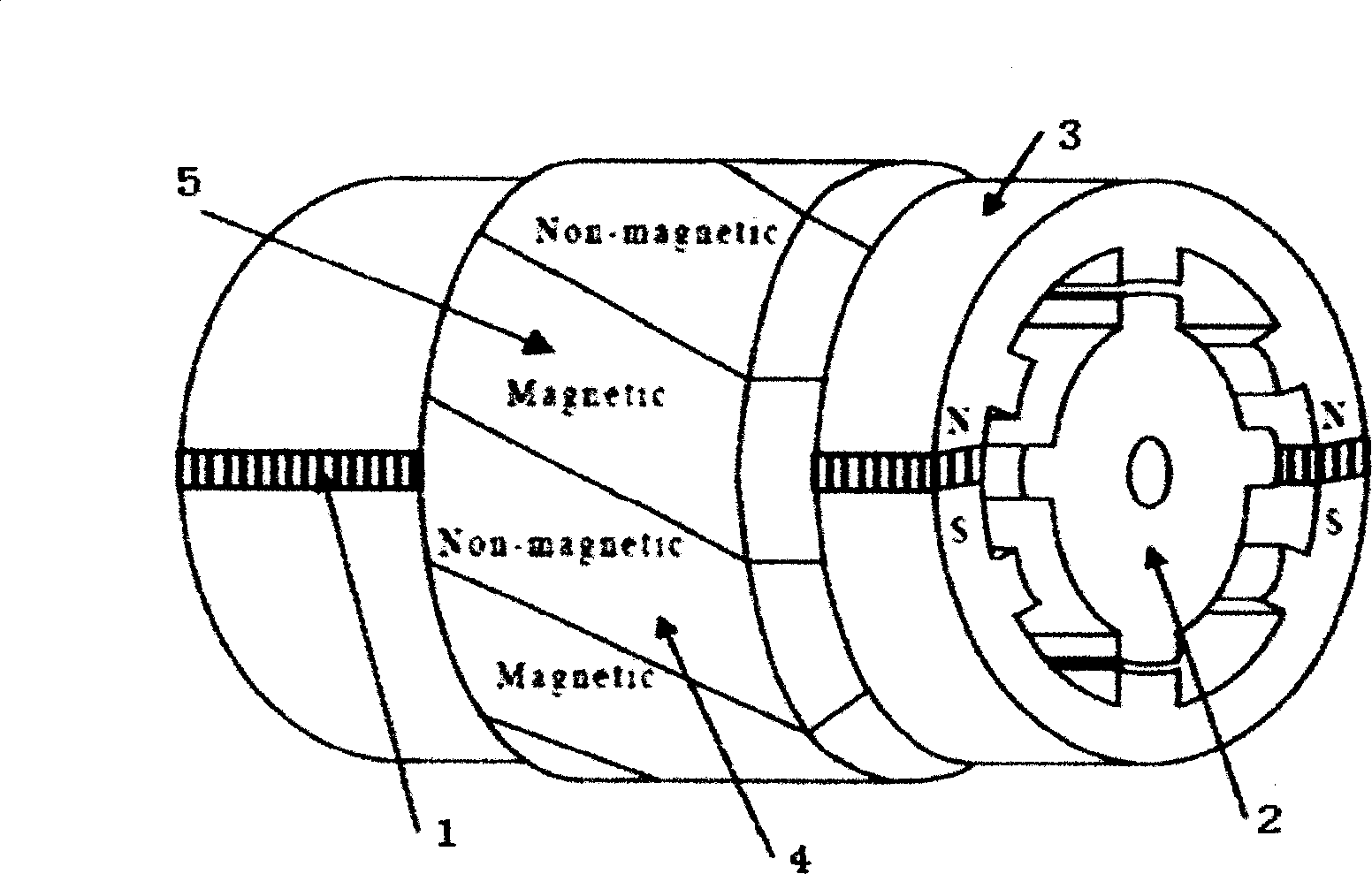

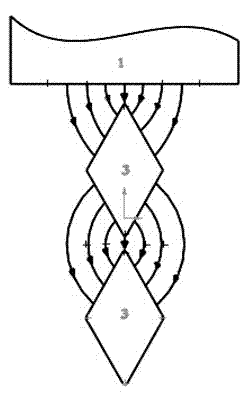

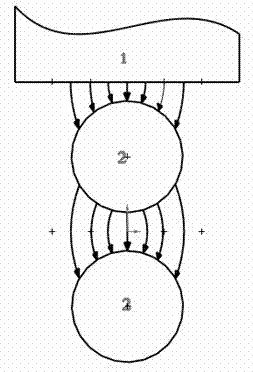

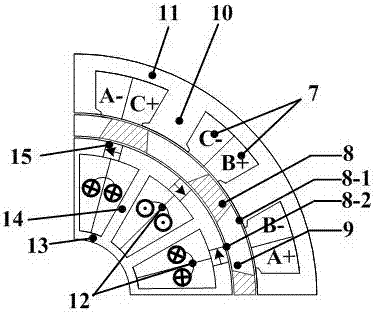

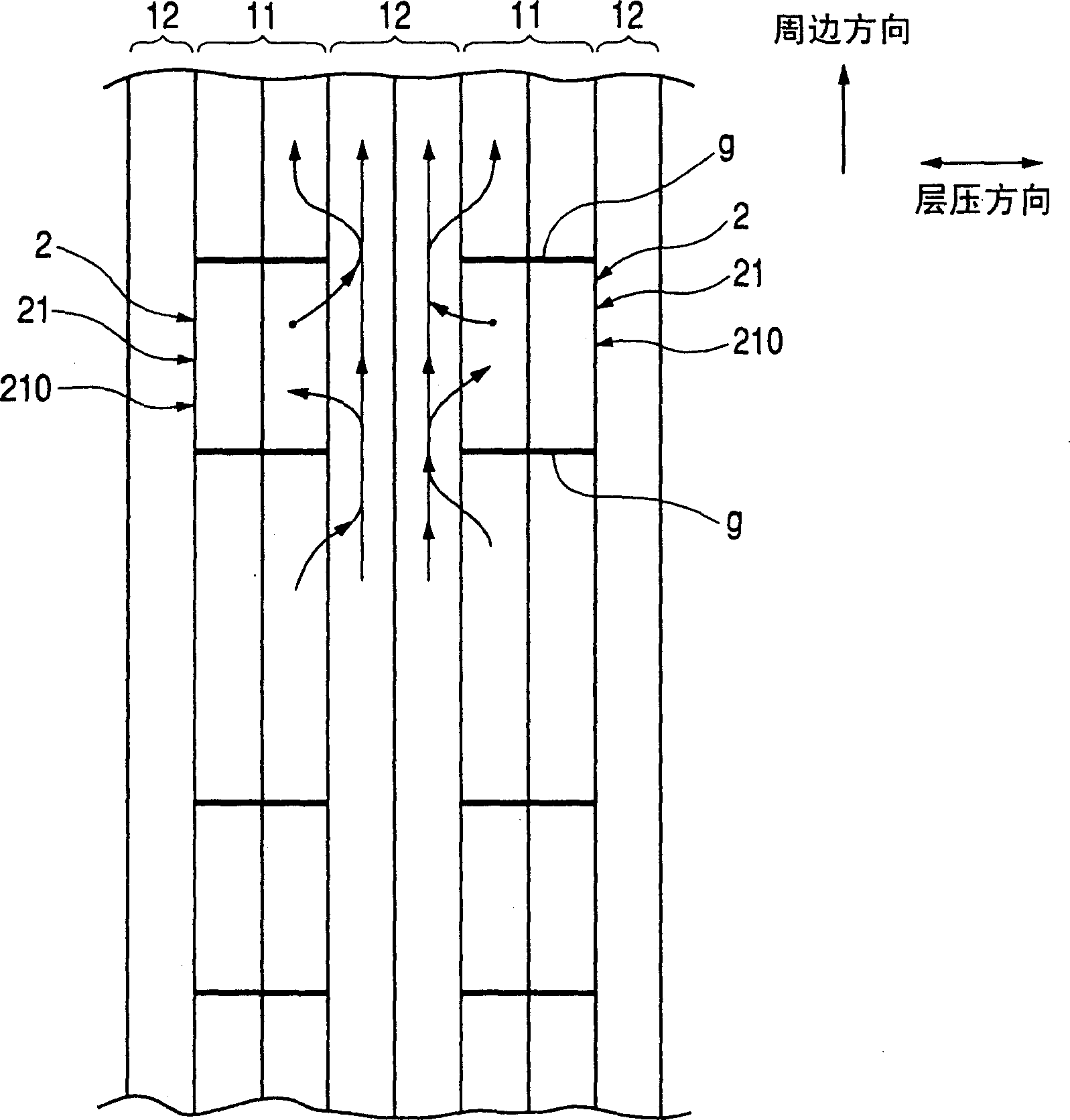

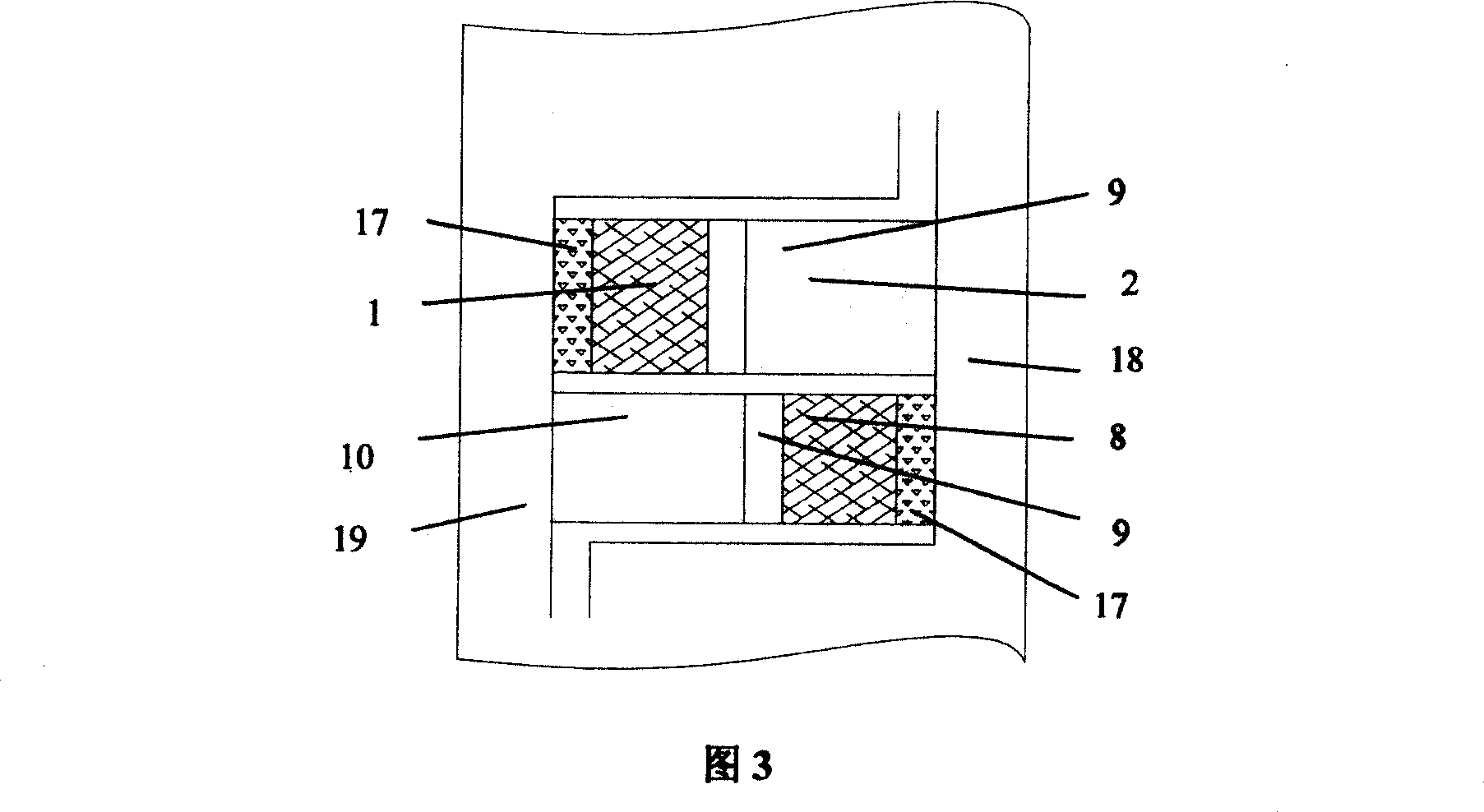

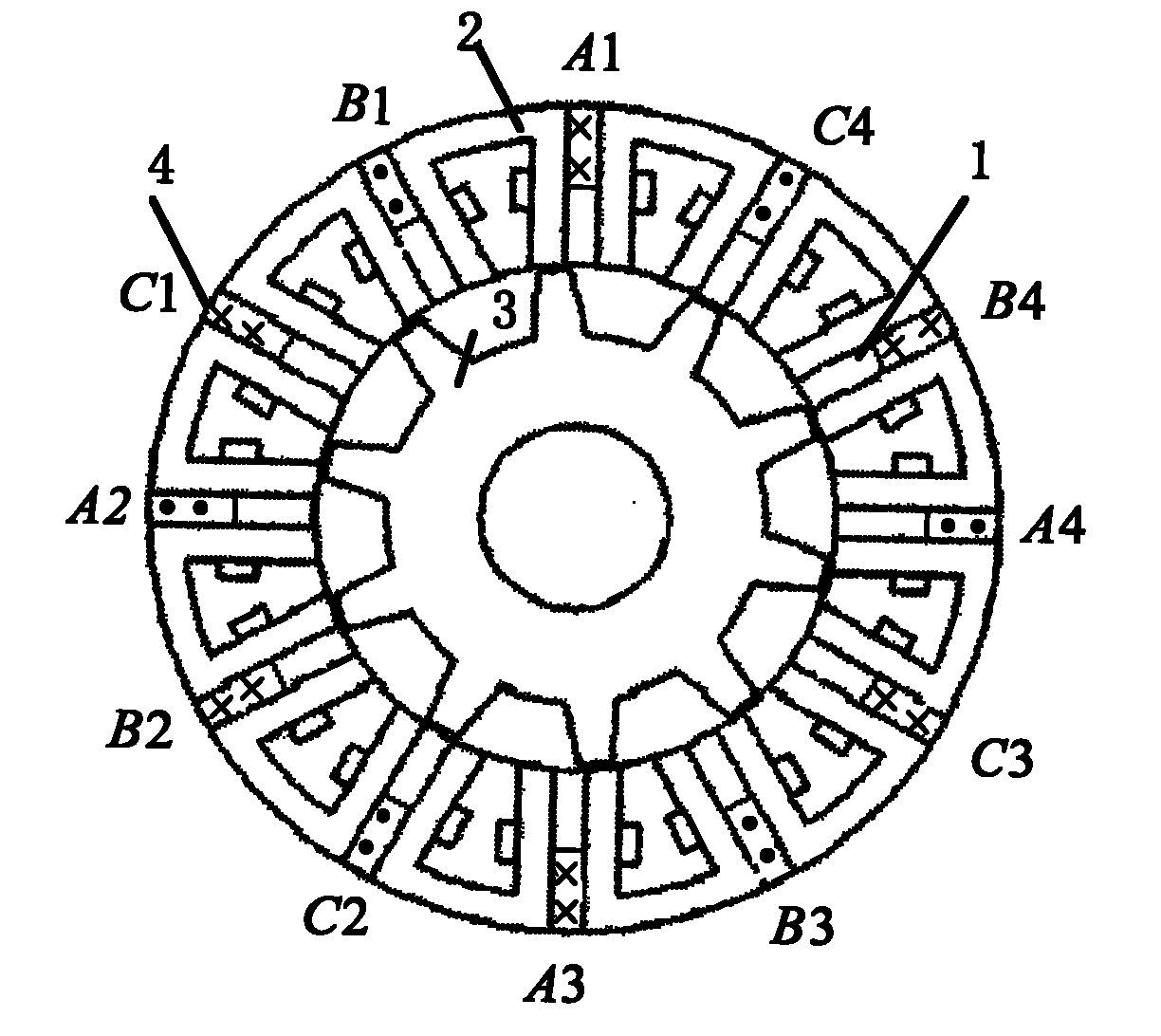

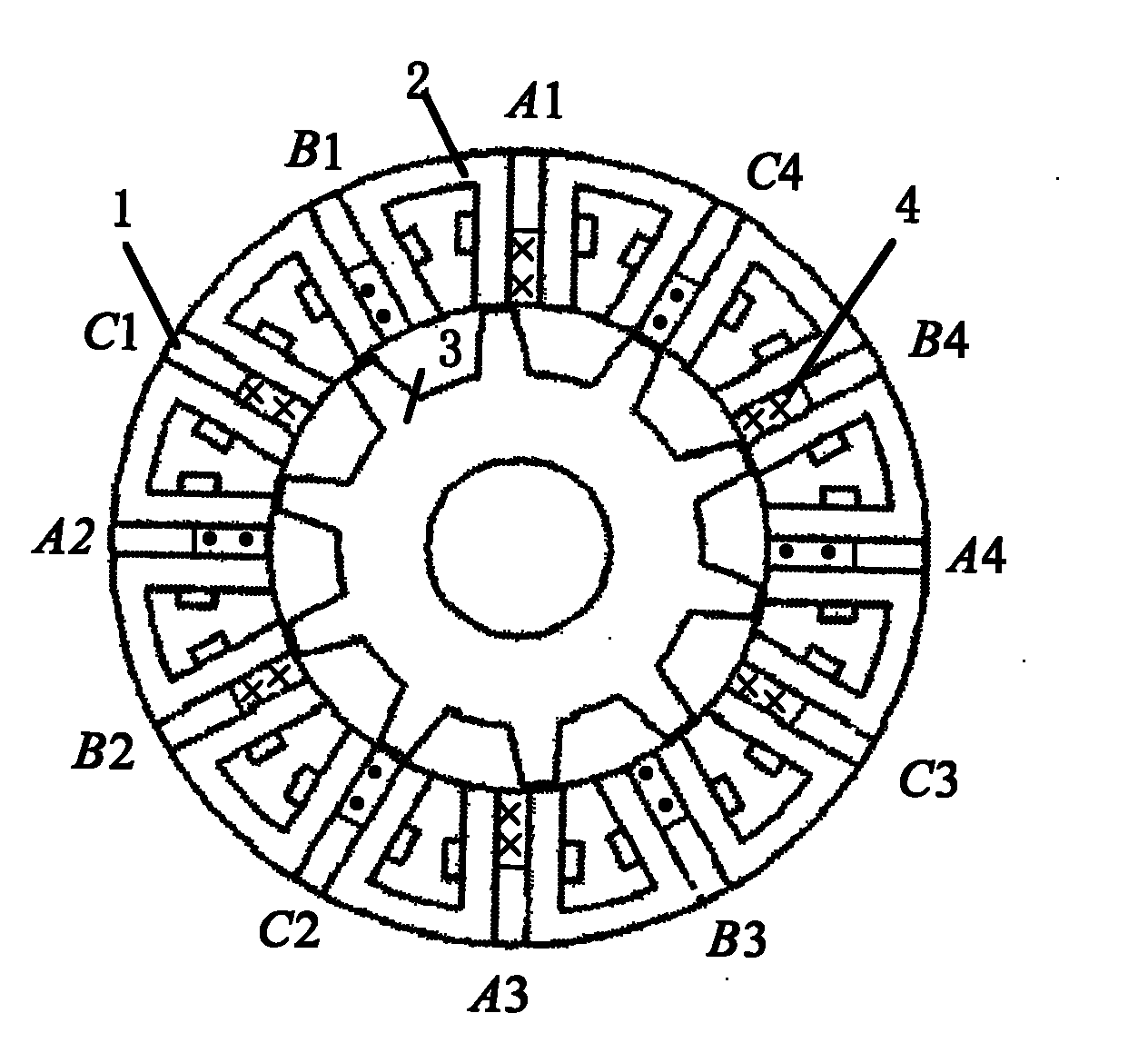

Non symmetrical interleaving mixed exciting synchronization motor

InactiveCN101056027AReduce resistance lossMany turnsMagnetic circuit rotating partsSynchronous motorsLow speedSynchronous motor

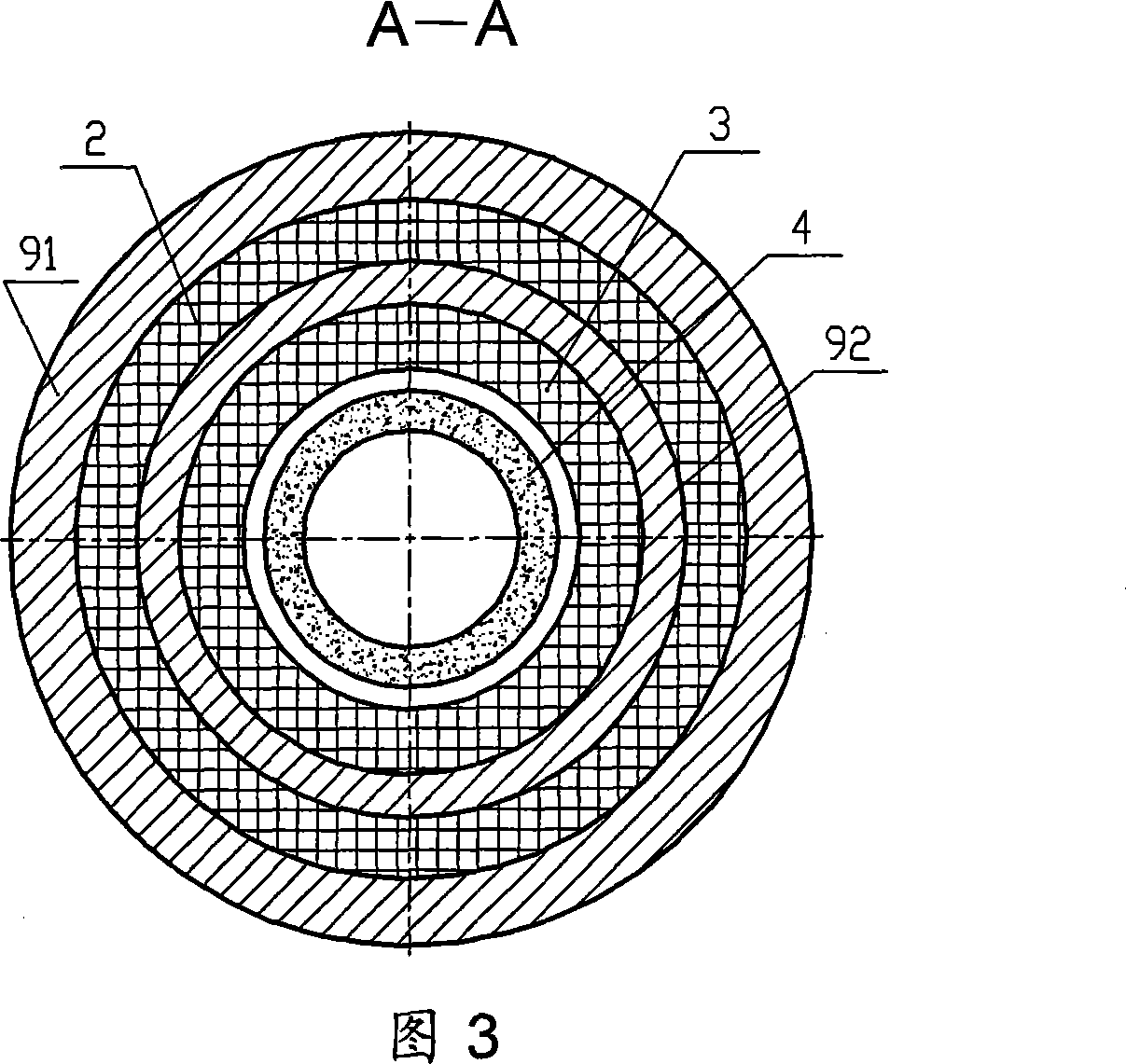

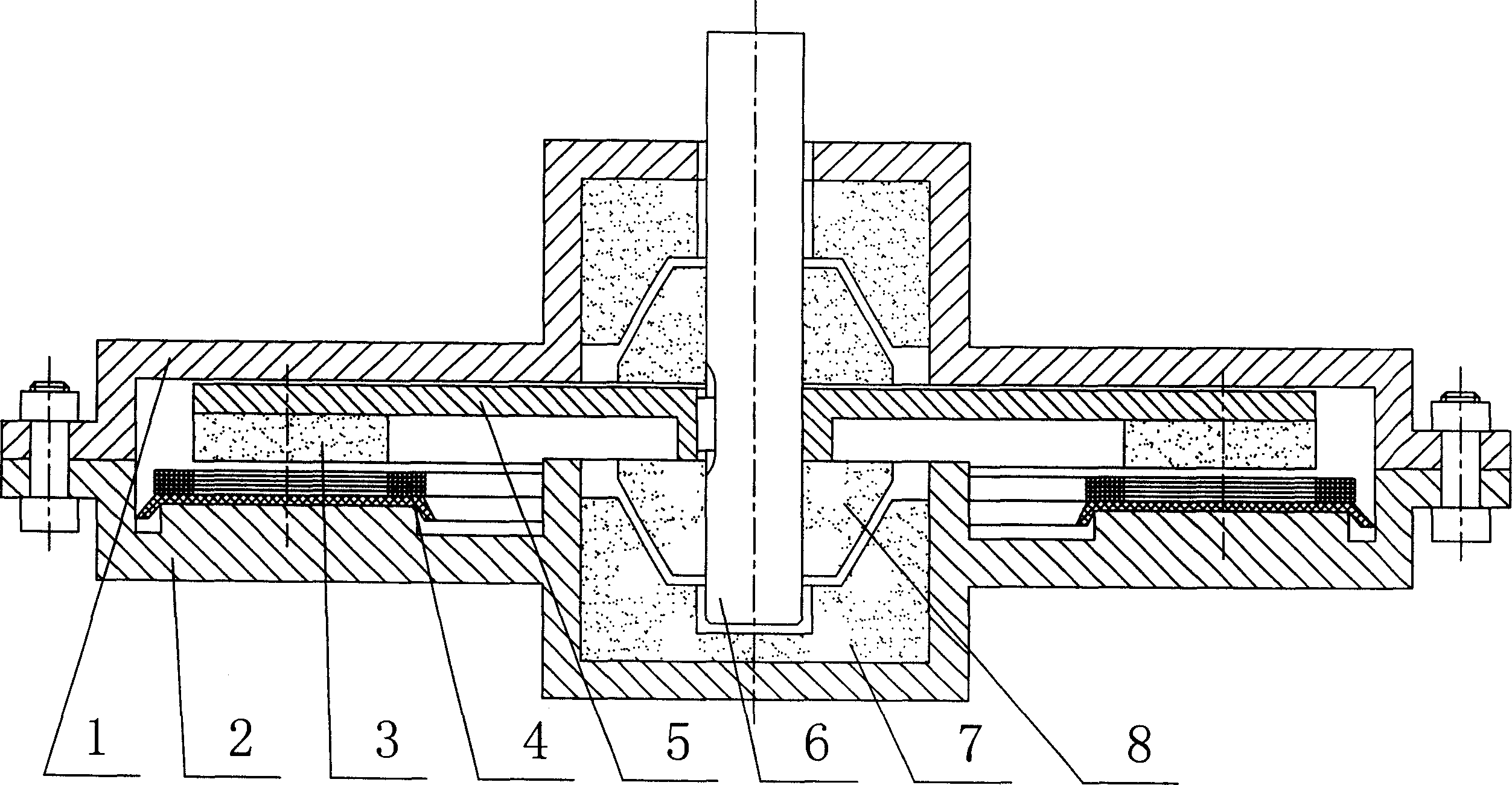

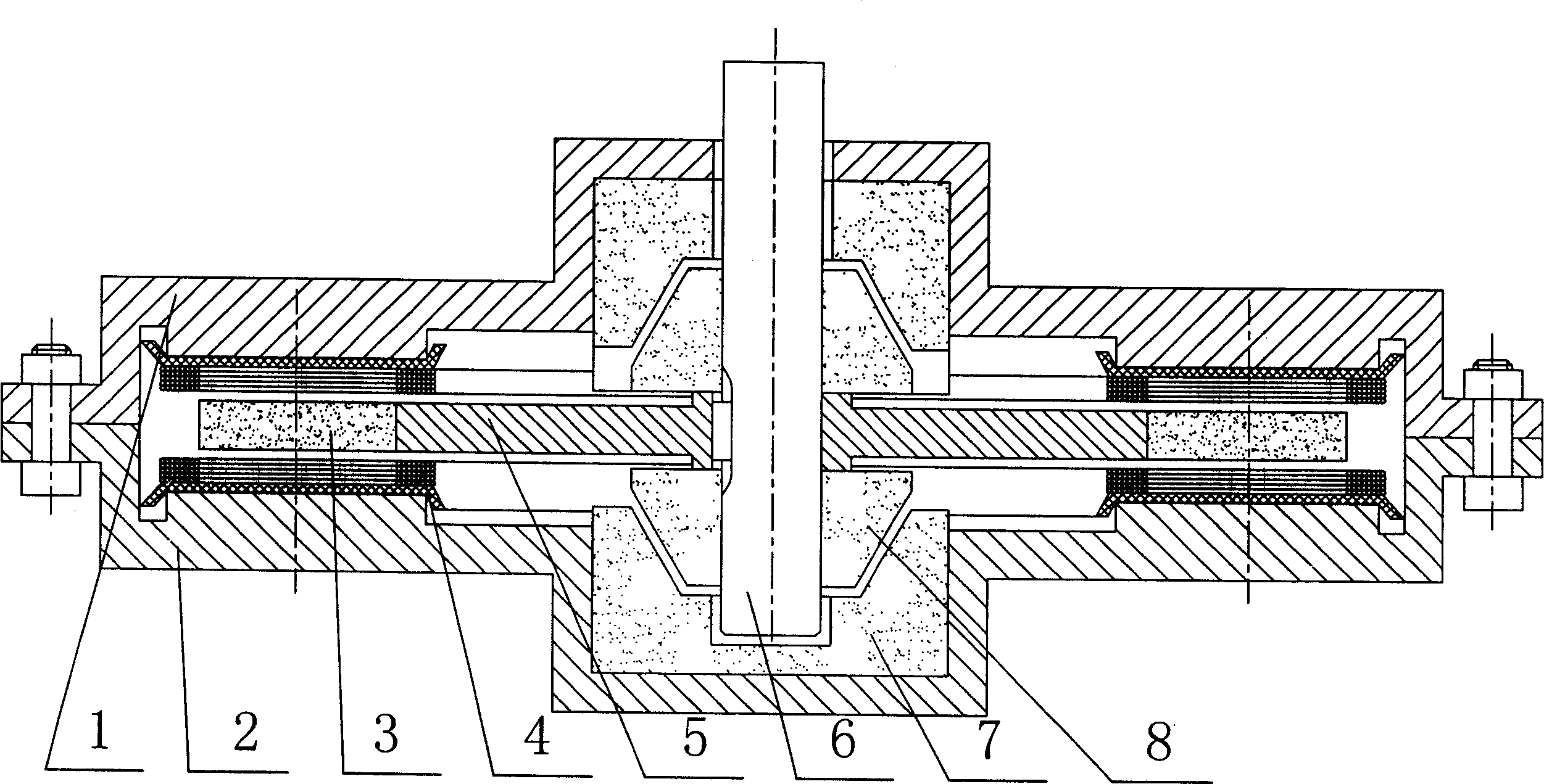

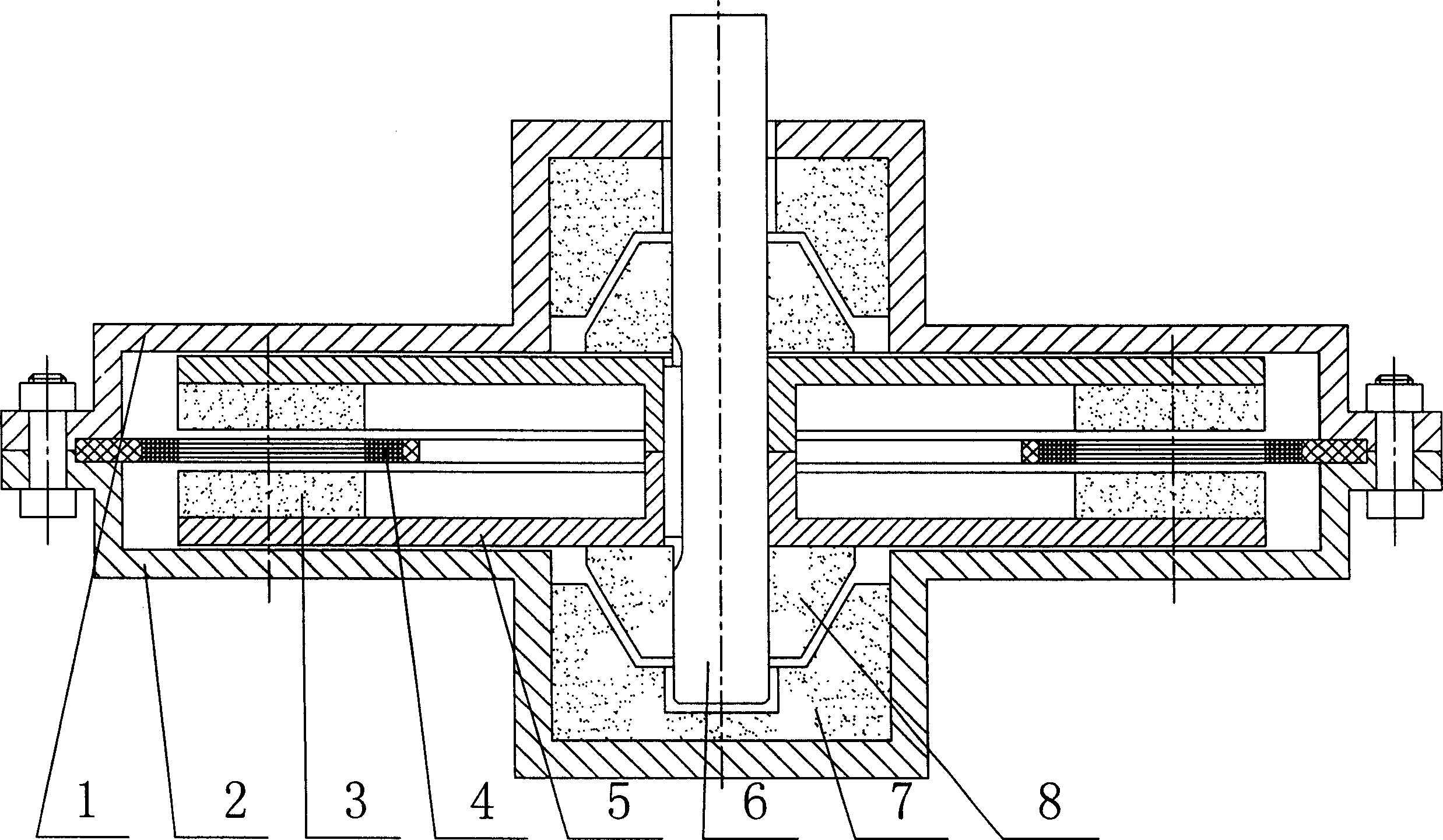

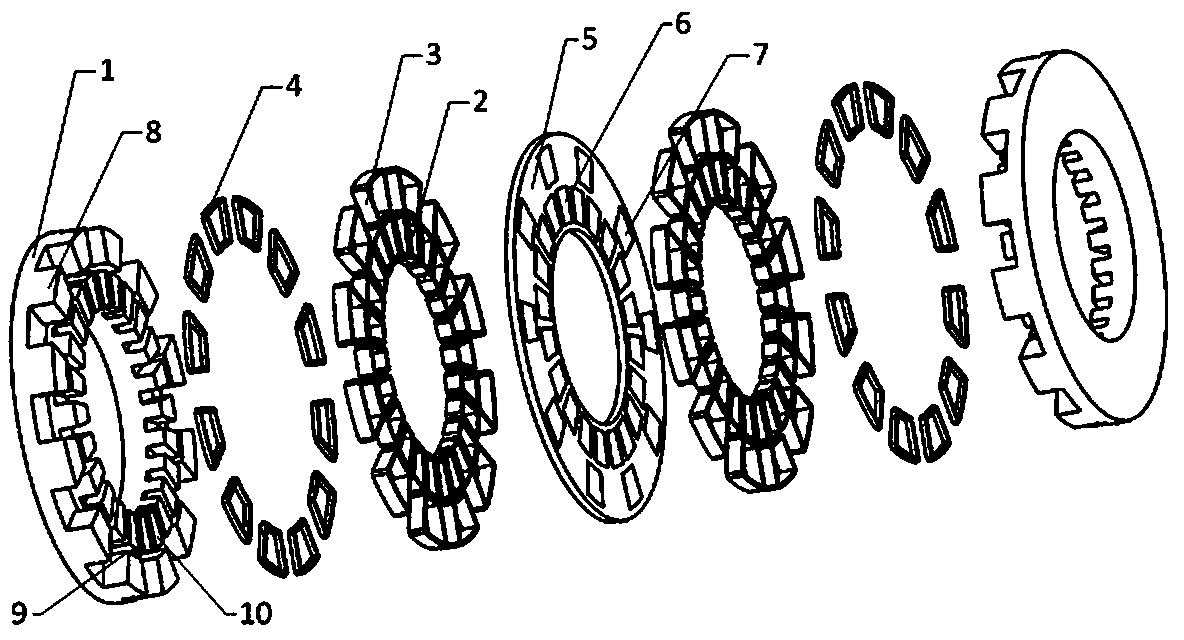

The present invention provides an unsymmetrical, crossly mixed excitation synchronous motor pertaining to the technology field of electric motor for variable-speed driving. The technology problem to be solved is: a new type mixed excitation synchronous motor which has been improved to have a higher efficiency, a bigger low-speed starting torque and a wider timing range. The motor in the present invention adopts a structure with an internal stator and an external stator. A stator back yoke (15) for magnetic guiding in the axes direction of a stator is provided out of a stator, adopting a unique tile shaped structure which is easy to process. The external stator is identical to the traditional stator of the electric motor, and the ring shaped field copper (7) is fixed on the end cover (14) of the electric motor to form an internal stator through a field yoke bracket (12). The thickness of the Claw-Pole (5) of the N pole is identical to that of the Claw-Pole (11) of the S pole, and the permanent-magnet pole (1) and the magnet core pole (2) of the N pole are adhered on the surface of the Claw-Pole of the N pole, and are separated by an air gap (9) for separating the magnet; the permanent-magnet pole (8) and the magnet core pole (10) of the S pole are adhered on the surface of the Claw-Pole of the S pole, and are separated by an air gap (9) for separating the magnet.

Owner:SOUTHEAST UNIV

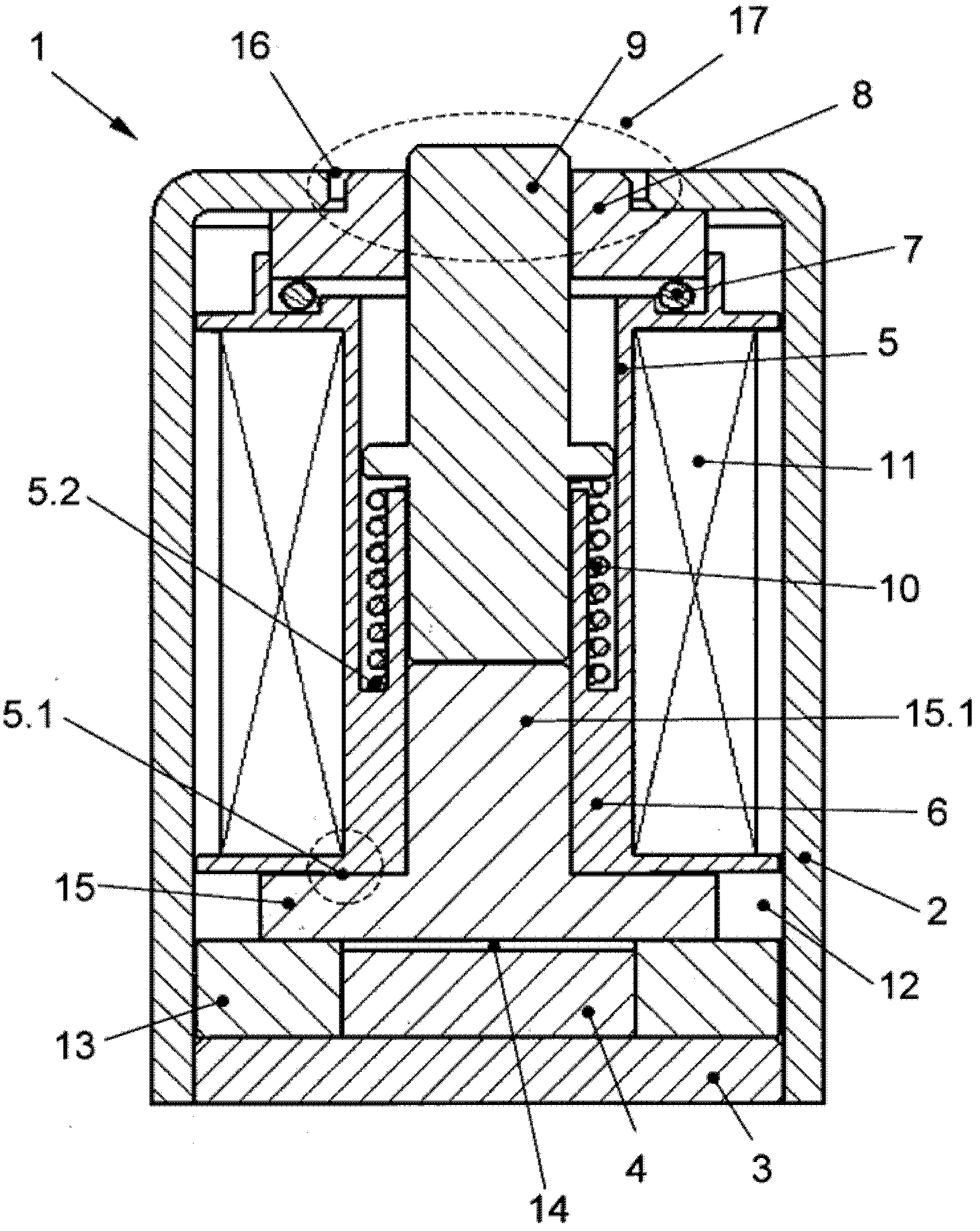

Magnetic trigger mechanism

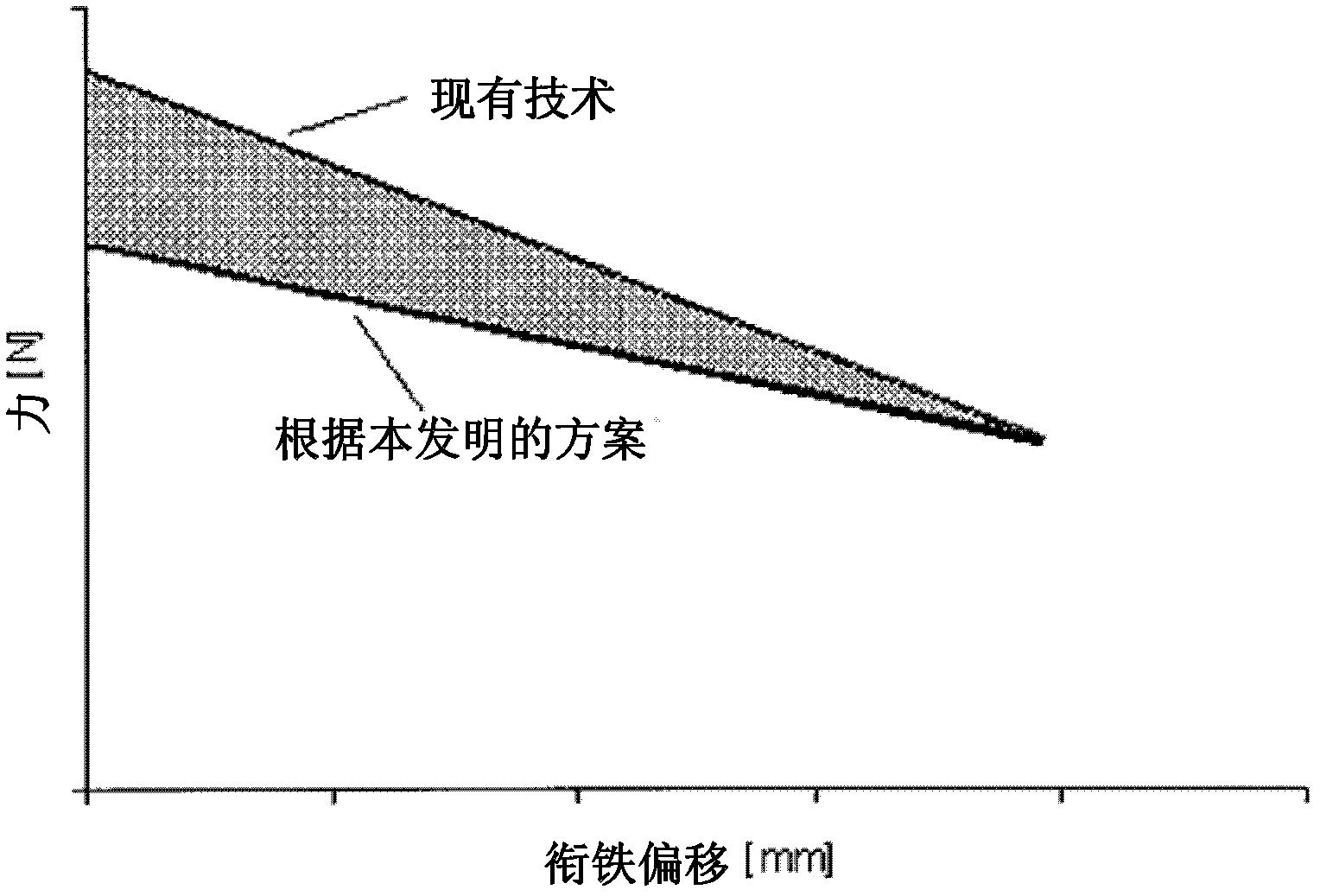

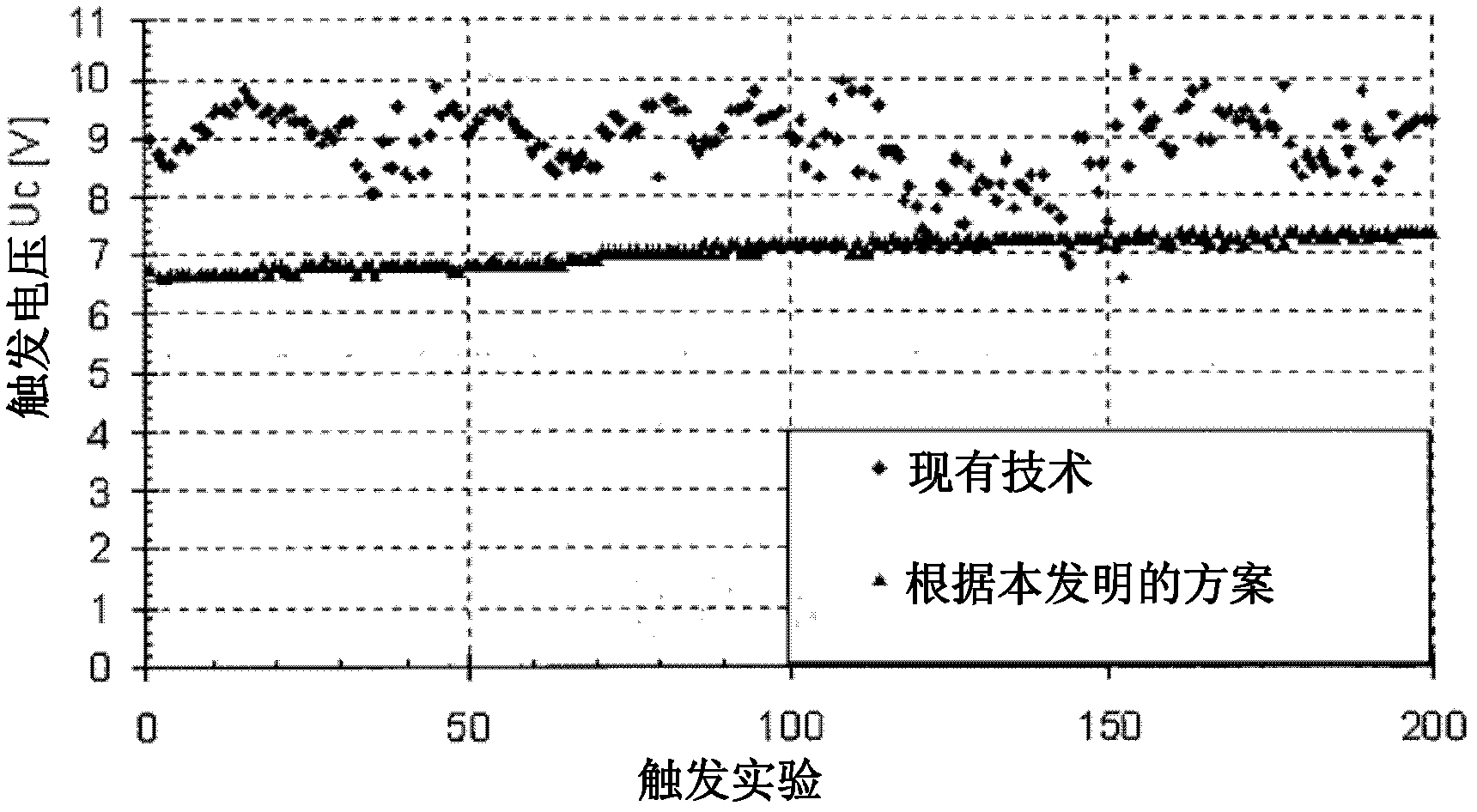

ActiveCN102549683AAttenuation of magnetic holding forceArmature AccelerationProtective switch operating/release mechanismsElectromagnets with armaturesSpring forceMagnetic flux

The invention relates to a magnetic trigger mechanism at least comprising a yoke having an armature opening, in which yoke an armature is placed, which armature is coaxially surrounded by at least one section of the coil body having at least one excitation coil and which is acted on by the force of a preloaded spring element and which remains in a first end position due to the magnetic retaining force of a permanent magnet when current is not flowing through the excitation coil, the permanent magnet being arranged in the area of the first end of the armature together with a base extending between the armature and the permanent magnet, and the second end position of the armature being achieved by means of a brief flow of current through the excitation coil together with the accompanying lowering of the magnetic retaining force and the spring force, which is effective then. The invention is characterized in that the first end of the armature, which first end faces away from the armature opening, is guided in the coil body in a centered manner, and the second of the armature, which second end faces the armature opening, is likewise guided in a centered manner by means of a centering ring centered in the coil body, the highly permeable centering ring lies against the yoke at the armature opening and can move radially relative to the yoke, the base is centered in the coil body, the centering ring together with the coil body ensuring that the armature lies flat in the area of the first end without tipping and always guaranteeing maximum retaining forces due to the armature lying flat, the spring element having a larger diameter than the armature, and the magnetic flux commutating upon triggering from a series connection to a parallel connection.

Owner:JOHNSON ELECTRIC DRESDEN

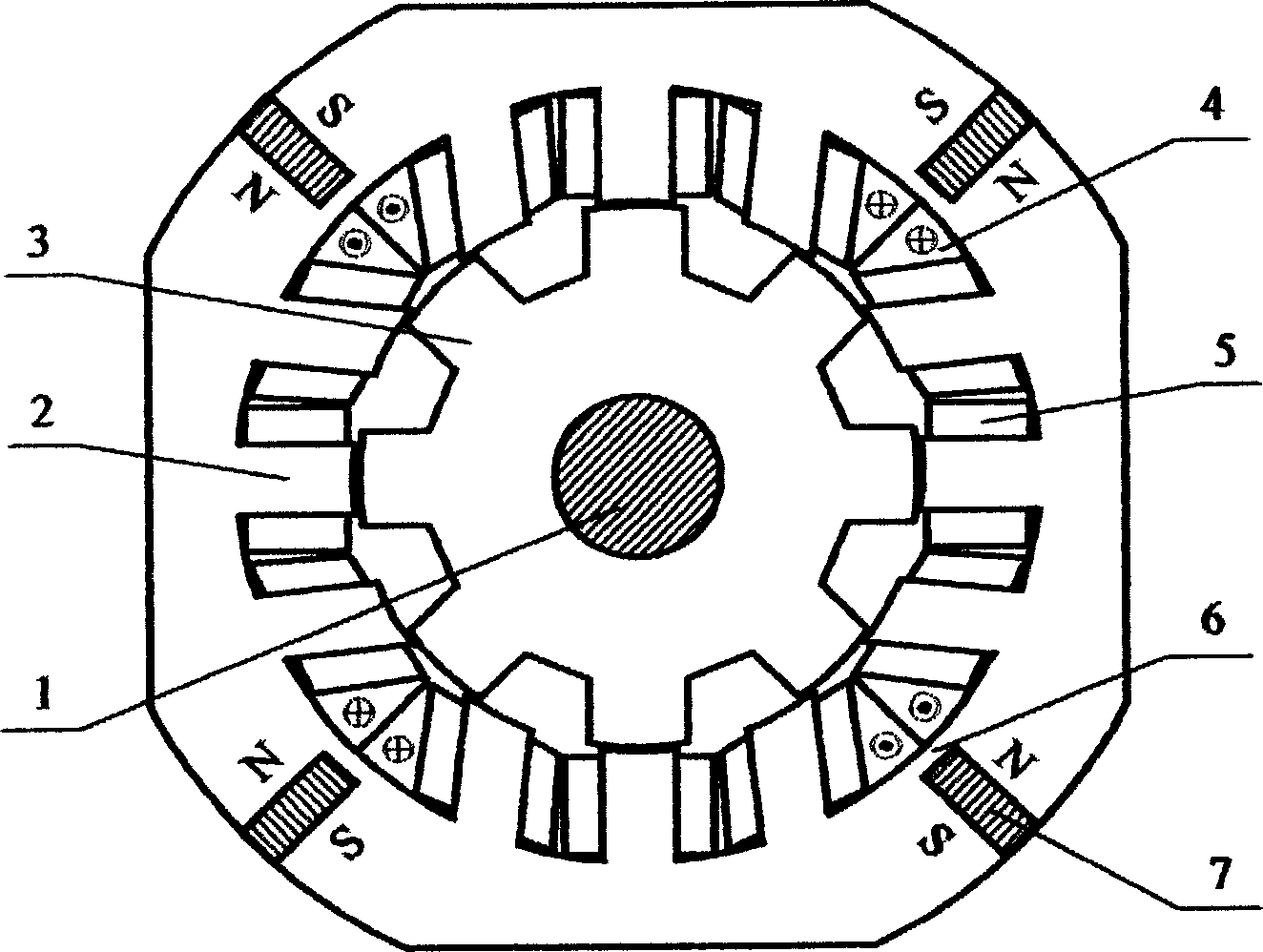

Mixed excitation servo motor

InactiveCN107070014AImprove reliabilityHigh speed rotationMagnetic circuit stationary partsWindings conductor shape/form/constructionConductor CoilStator poles

The invention discloses a mixed excitation servo motor. The mixed excitation servo motor comprises a stator iron core, a rotor iron core, excitation windings, armature windings, a permanent magnet and a shaft, belonging to the special motor technology field. The rotor iron core is fixed on the shaft; ten convex rotor poles are uniformly distributed on the rotor iron core; the stator iron core has twelve convex stator poles; the twelve stator poles consists of six pairs of parallel stator poles; an armature groove is arranged between the two stator poles in each pair of parallel stator poles; an excitation groove is formed between two adjacent pairs of parallel stator poles; an excitation winding is wound on each pair of parallel stator poles; the winding directions of adjacent excitation windings are reverse; the excitation winding is arranged on the bottom of the excitation groove; a concentrated armature winding is wound on each stator pole; the armature winding is arranged at the notches of the excitation groove and the armature groove; tangential magnetizing permanent magnets are embedded in the yoke parts of the two stator poles in each pair of parallel stator poles; and the magnetizing direction of the adjacent permanent magnets are opposite. The mixed excitation servo motor has advantages of the mixed excitation motor; the excitation windings are isolated from the armature windings; the rotor has no permanent magnet and no excitation winding, so that the mutual-interference does not exist and the reliability is high.

Owner:史立伟

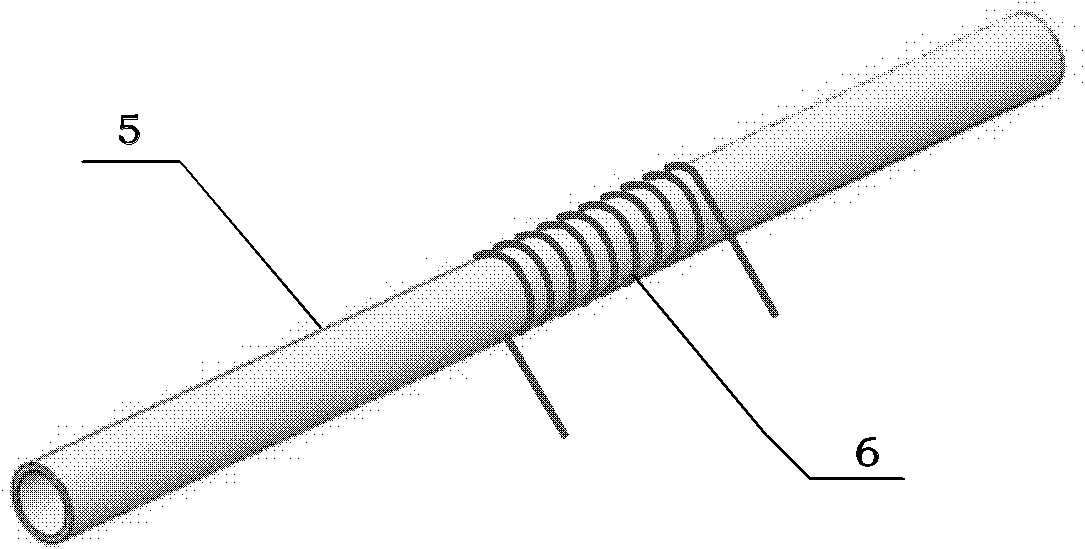

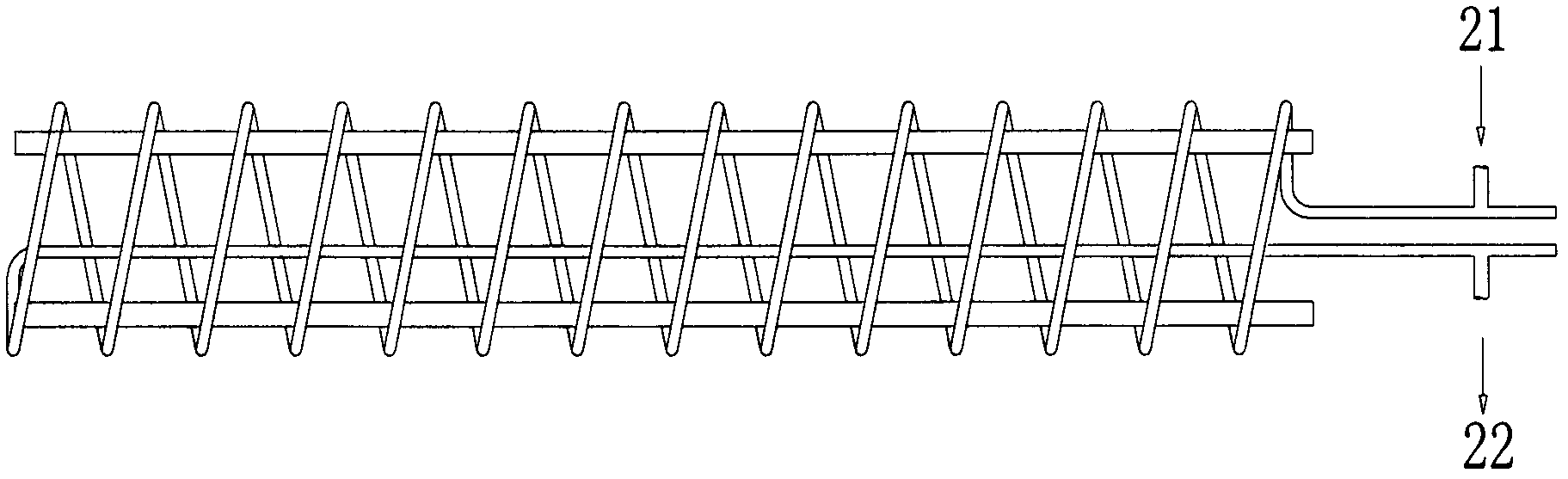

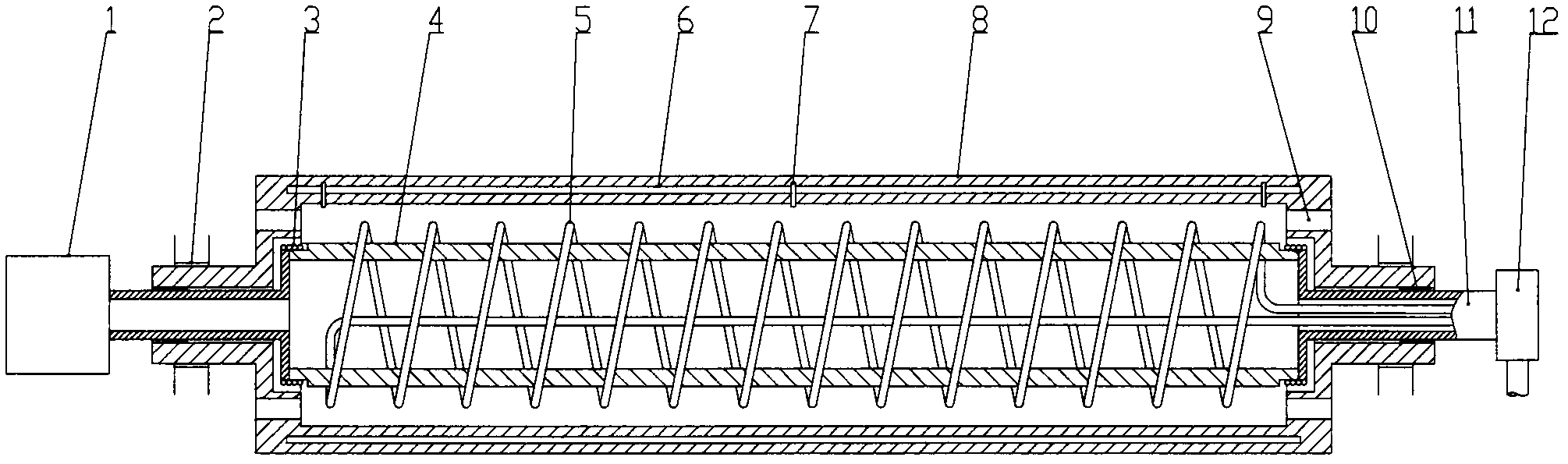

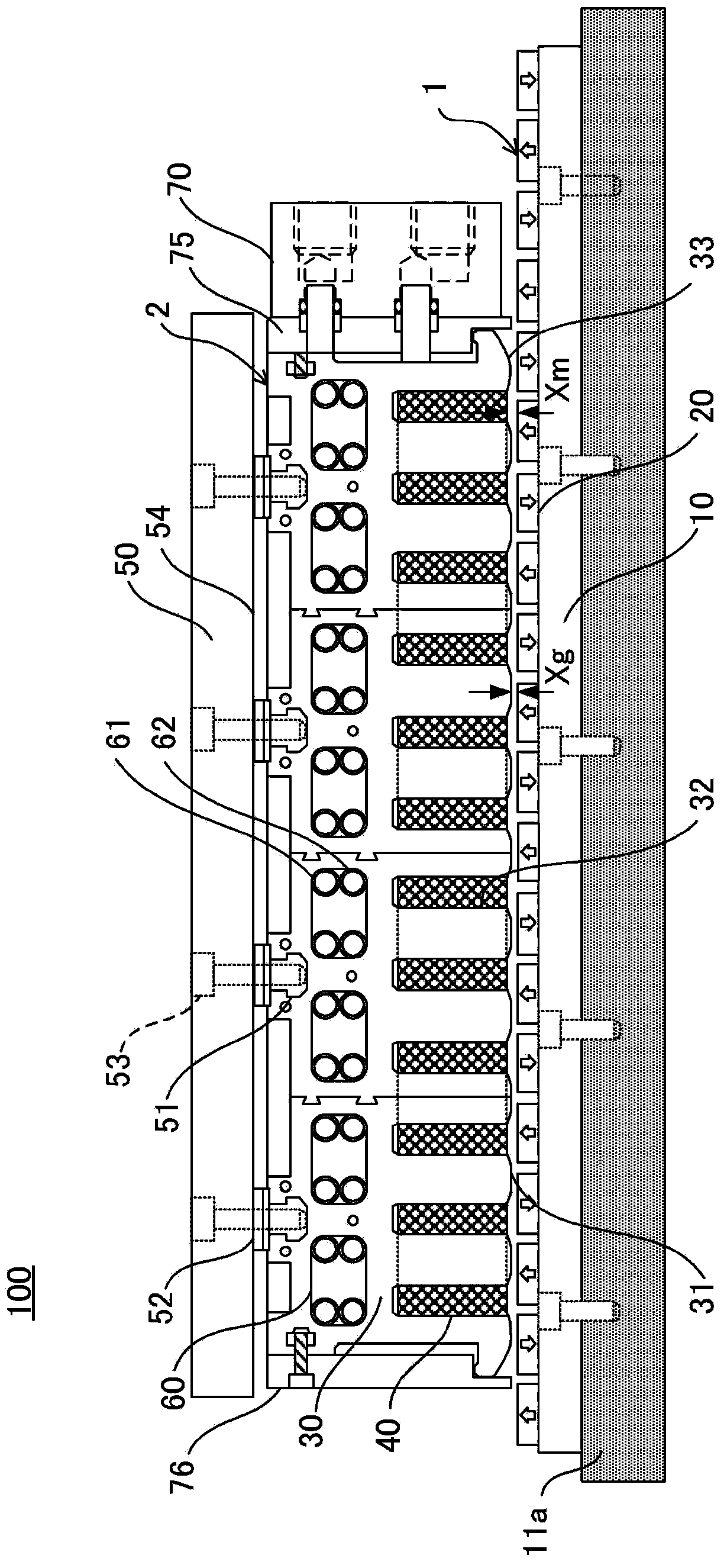

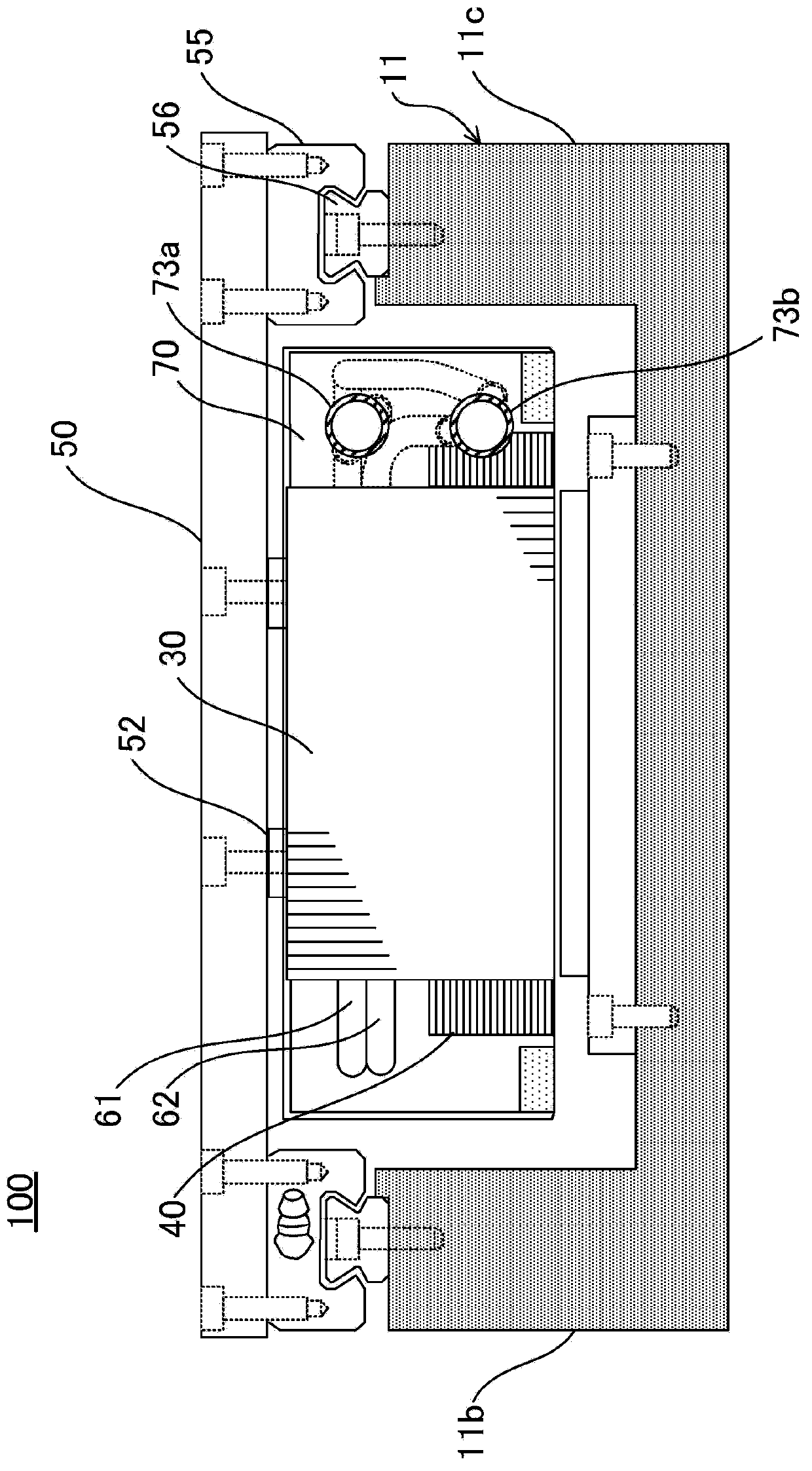

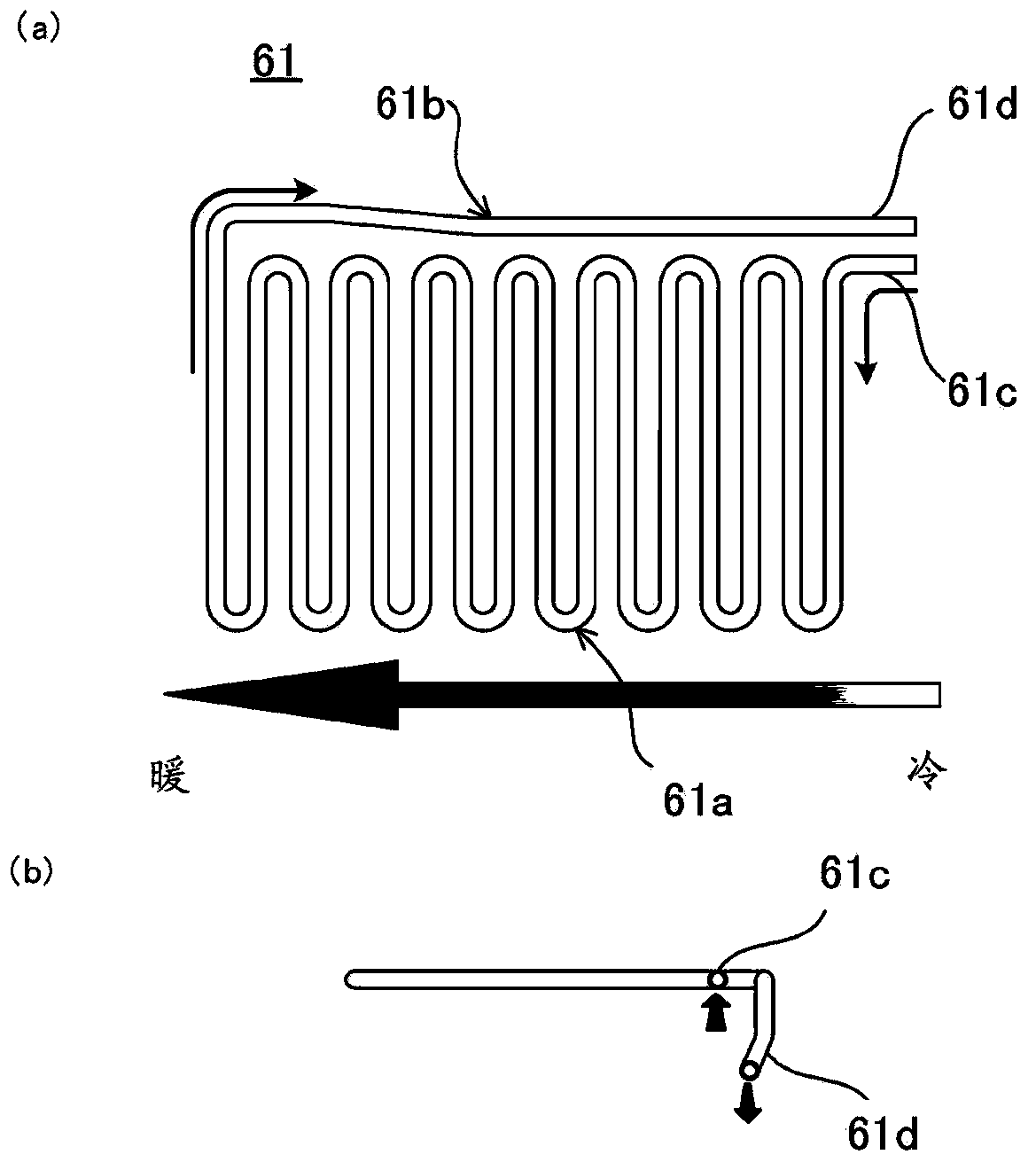

Linear motor

InactiveCN103633811AIncrease the cross-sectional areaSmall pressure lossMagnetic circuit rotating partsMagnetic circuit stationary partsLinear motorRefrigerant

The invention relates to a linear motor capable of realizing pressure loss of the cooling medium, enabling the uniform temperature distribution, and carrying out the high efficiency cooling. An armature(2) of a linear motor (100) includes a plurality of cooling pipe storage holes(60) formed along a longitudinal direction of a core(30), and a plurality of cooling pipes(61,62) stored vertically in the cooling pipe storage holes and having a meander shape. The cooling pipes (61,62)vertically adjacent to each other are arranged such that inlets(61c,62c) and outlets(61d,62d) of the cooling pipes are alternately connected in parallel to a refrigerant inlet(73a) and a refrigerant outlet (73b)in order to allow a refrigerant to flow in the reverse direction.

Owner:SANYO DENKI CO LTD

Double-stator/double-rotor motor and direct actuator for washer using same

ActiveCN102948049AImprove efficiencyShorten the pathMagnetic circuitMechanical energy handlingEngineeringActuator

The present invention relates to a double-stator / double-rotor motor and a direct actuator for a washer using same, and aims to provide a double-stator / double-rotor motor and a direct actuator for a washer using same, which can promote increased efficiency by disposing a double rotor, having magnets coupled to the inner circumferential surface and the outer circumferential surface of a back yoke, between an inner stator and an outer stator so as to face same. To this end, the double-stator / double-rotor motor of the present invention comprises: a rotor provided with a first permanent magnet mounted on the inner circumferential surface of the back yoke and a second permanent magnet mounted on the outer circumferential surface of the back yoke; an inner stator facing the first permanent magnet and having a gap therebetween, which generates a magnetic field that rotates the rotor; and an outer stator facing the second permanent magnet and having a gap therebetween, which generates a magnetic field that rotates the rotor.

Owner:AMOTECH

Electro-magnetic flux switching motor

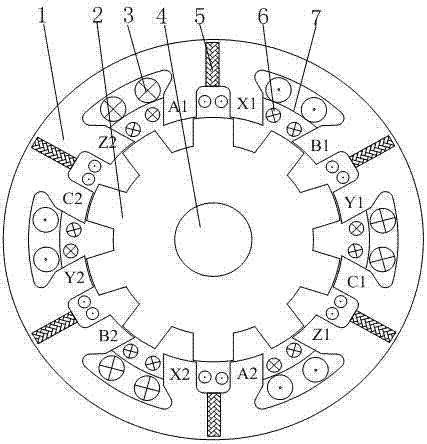

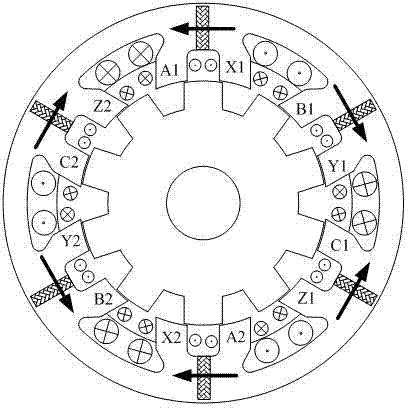

InactiveCN101789641ASmall magnetic resistanceImprove excitation current utilizationMagnetic circuit stationary partsWindings conductor shape/form/constructionPhysicsWave shape

The invention discloses an electro-magnetic flux switching motor belonging to the field of the electro-magnetic motors. The electro-magnetic flux switching motor comprises salient pole stators, excitation windings, armature windings and salient pole rotors, wherein the salient pole of each stator is a U-shaped iron stator block, a strip-shaped magnetizer is embedded in the space between every two U-shaped iron stator blocks, the length of the magnetizer phase is less than that of the U-shaped arm of the U-shaped iron stator block, the excitation windings are wound on the magnetizer along the radial direction of the motor, and the armature windings are wound on the two U-shaped arms connected with the magnetizer. Based on the maintenance of the high sine degree of the idle stator flux linkage and the ambipolar idle stator flux linkage waveform of the flux switching motor, the invention makes the idle air-gap field to be completely adjusted by the exciting current with a strong magnetic field adjustment capability, thereby overcoming the defect that the air-gap magnetic field of the permanent-magnetism flux switching motor is difficult to adjust.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

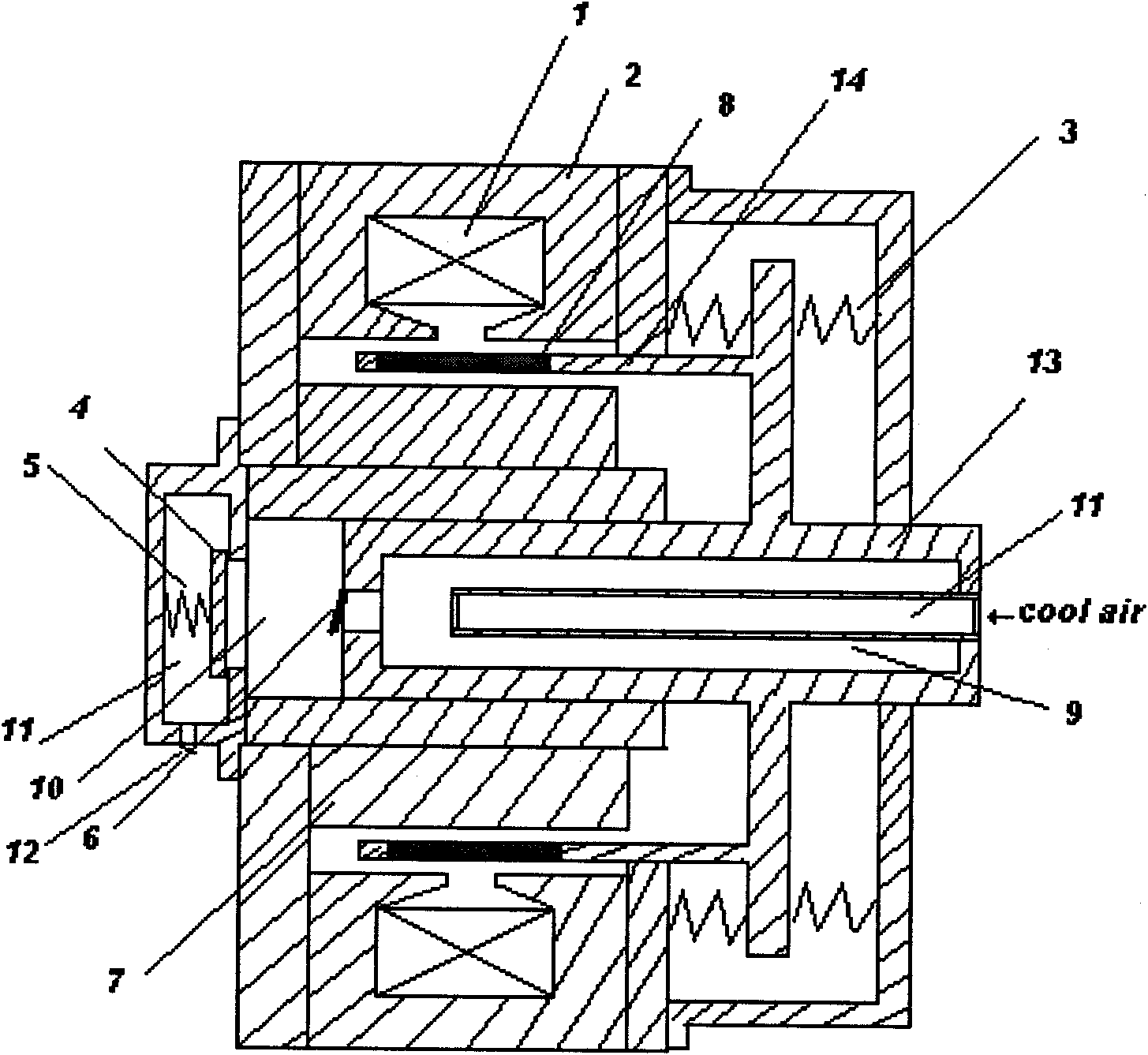

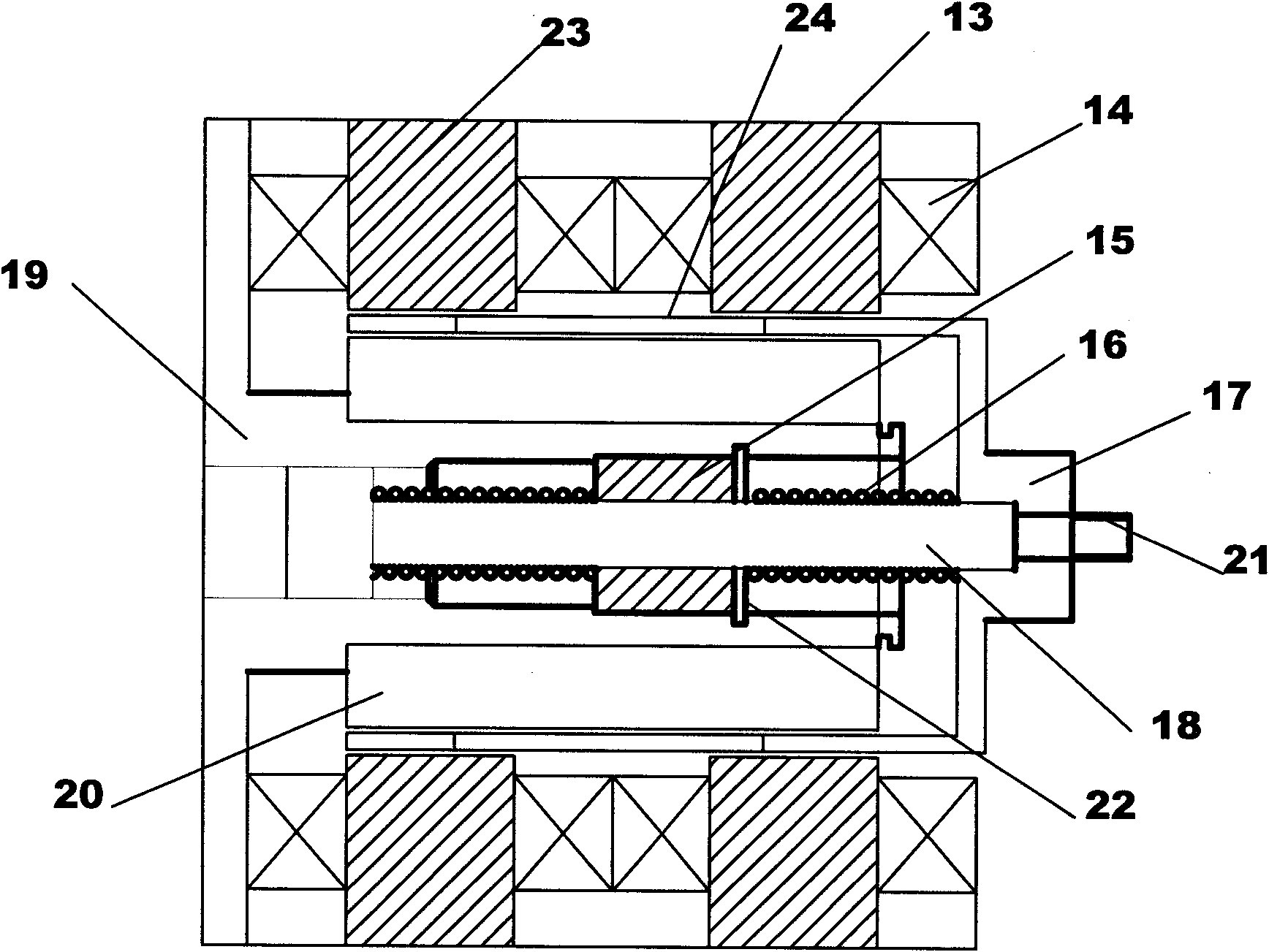

Moving-magnet type transverse flux linear oscillatory motor for direct-drive compressor

InactiveCN101834510ASmall magnetic resistanceSmooth output forcePiston pumpsDynamo-electric machinesTransverse fluxElectric machine

The invention discloses a moving-magnet type transverse flux linear oscillatory motor for a direct-drive compressor, which comprises a rotor component and stator components which are matched with each other. In the motor, a transverse magnetic circuit structure is adopted to ensure that the motion directions of a magnetic circuit and the motor are in a perpendicular relation, thus the internal and external stators of the motor can both adopt an internal and external stator structure of an ordinary electric rotating motor and are stacked up along an axial direction. The moving-magnet type transverse flux linear oscillatory motor has the advantages of convenient processing, higher efficiency, small magnetic resistance, smooth output force curve, and the like and is easy to realize high frequency reciprocating oscillation with high thrust and large amplitude.

Owner:ZHEJIANG UNIV +1

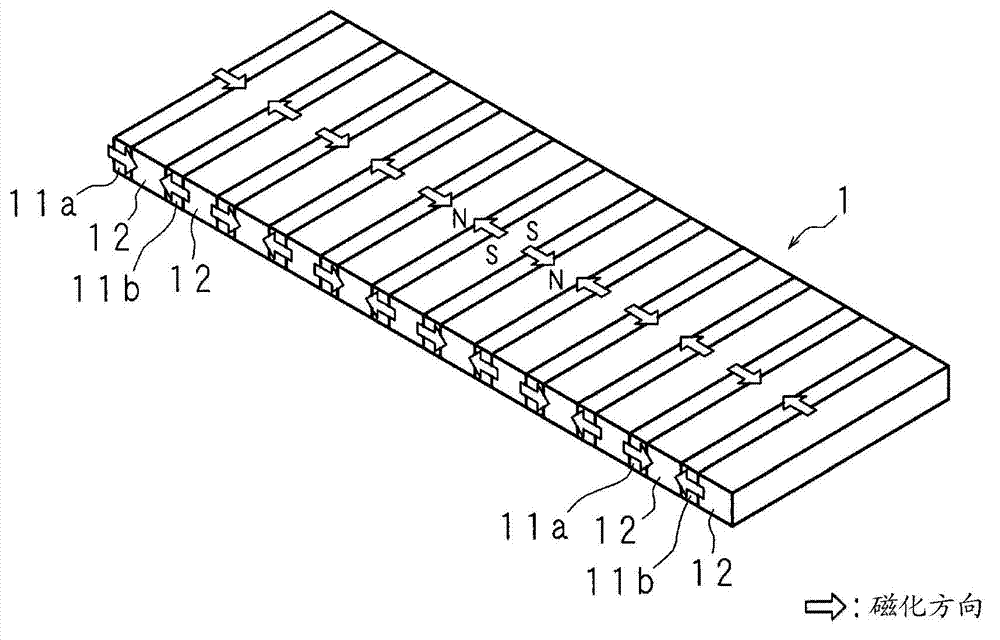

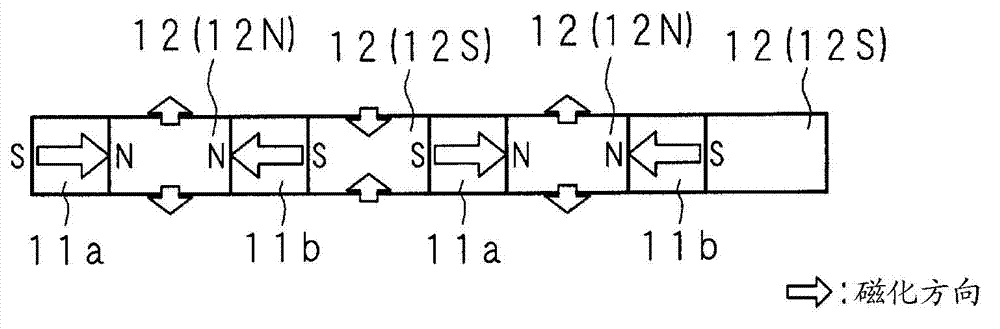

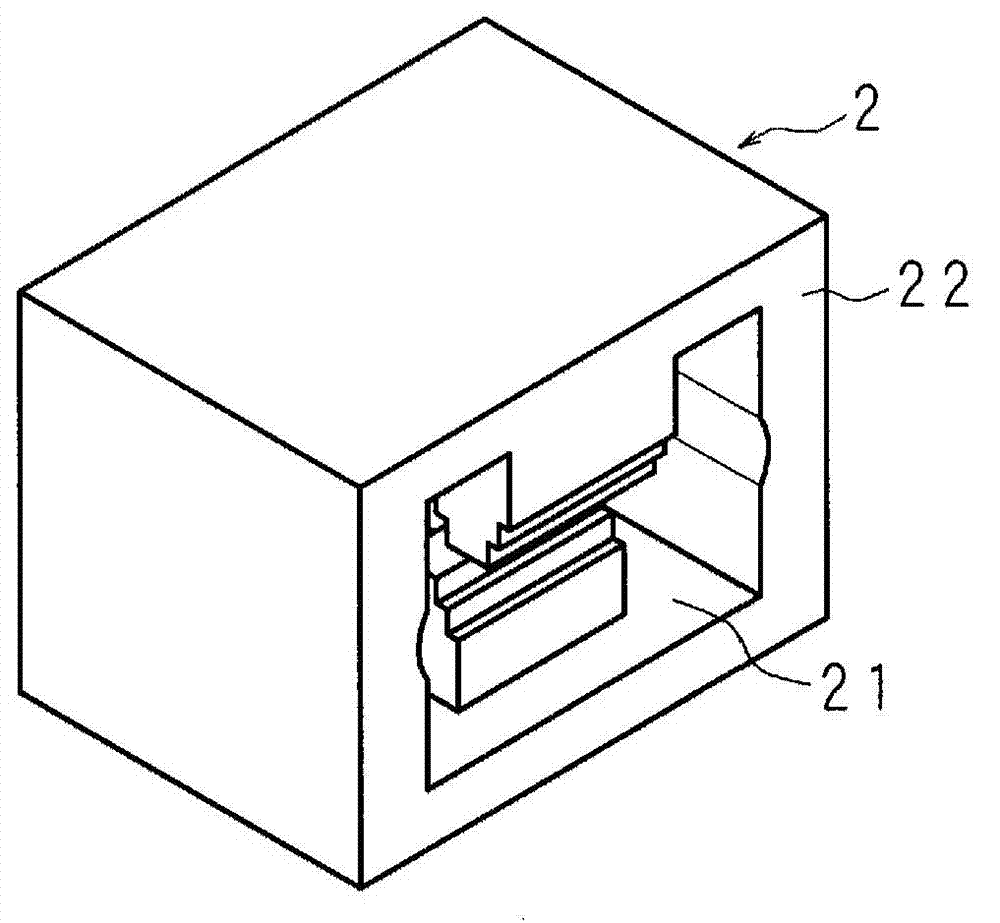

Linear motor

ActiveCN102792571AAvoid short circuitLess influence of demagnetizationPropulsion systemsMagnetomotive forceMagnetic poles

Disclosed is a linear motor which has a configuration not prone to generate magnetic flux causing short circuits between the poles of different polarity, as in monopolar drive systems, and, by means of using a bipolar drive, is capable of preventing the maximum thrust force from decreasing and has a high ratio of thrust force / magnetomotive force. A linear motor (3) is configured by a movable element (1) penetrating the hollow space of a stator (2). The movable element (1) has a permanent magnet magnetized in one of the movable directions, a soft magnetic yoke, a permanent magnet magnetized in the other of the movable directions, a soft magnetic yoke..., alternately arranged in that order. The stator (2) has multiple magnetic pole teeth arranged in a row on both sides thereof which face the movable element (1), and is formed by winding together with each drive coil (25a, 25b) the respective magnetic pole tooth group comprising multiple magnetic pole teeth.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com