Complementary modular hybrid excited linear motor

A hybrid excitation and linear motor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limited speed regulation range and difficulty in excitation regulation, and achieve increased magnetic flux density, saving permanent magnet materials, and large speed regulation. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

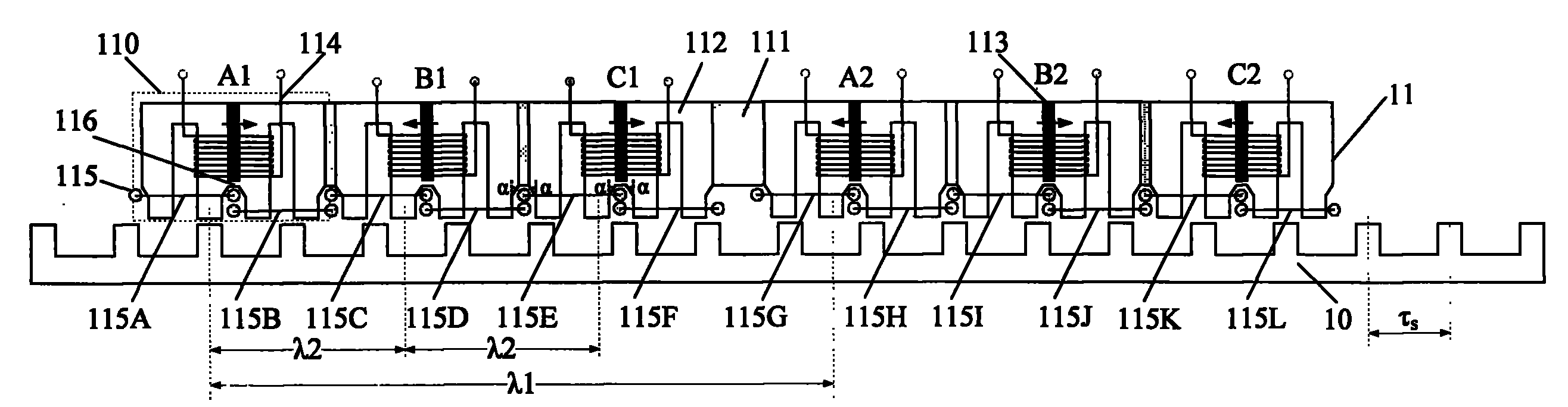

[0018] Such as figure 1 As shown, the complementary modular hybrid excitation linear motor provided by the present invention is composed of a stator 10 and a mover 11 with an air gap between them. As shown in the figure, both the stator 10 and the mover 11 adopt a salient pole structure. Wherein, there is neither permanent magnet nor winding on the stator 10, but only magnetically permeable material.

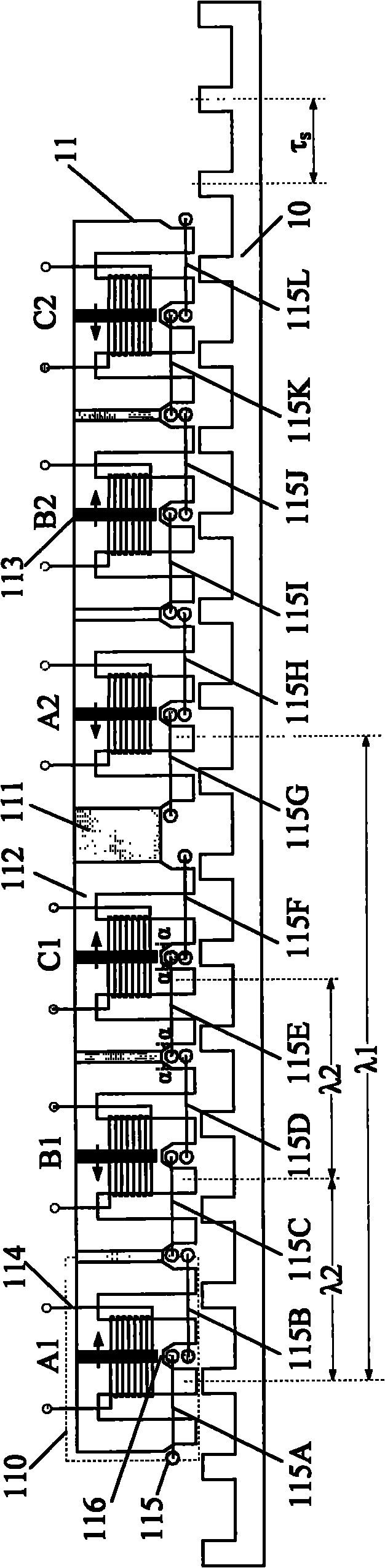

[0019] The mover 11 is composed of 2m E-shaped modules 110, and a non-magnetic material 111 is filled between two adjacent E-shaped modules. As shown in the figure, the relative displacement between two E-type modules in the same phase (such as A1 phase and A2 phase) is λ 1 =(n±1 / 2)τ s , the relative displacement between two out-of-phase E-type modules (such as phase A1 and phase B1 or phase B1 and phase C1) is λ 2 =(j±1 / m)τ s , τ s is the stator pole pitch, n and j are both positive integers. In this embodiment, m=3, that is, the motor has three phases A, B and C shown i...

Embodiment 2

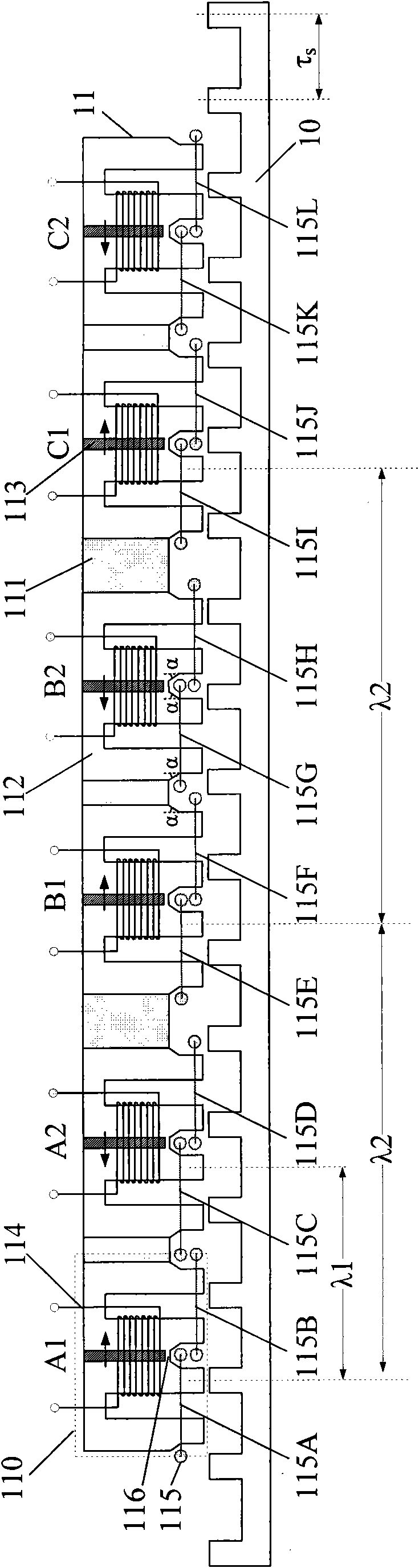

[0028] Such as figure 2 As shown, the difference between the complementary modular hybrid excitation linear motor in this embodiment and that in Embodiment 1 lies in the two E-type Adjacent placement of modules. The displacement of the two E-type modules relative to the stator is also λ 1 =(n±1 / 2)τ s , forming a complementary symmetric structure. Phase B and Phase C have the same structure as phase A. The displacement of the E-type module where the A, B, and C three-phase windings are located relative to the stator is λ 2 =(j±1 / m)τ s , where τ s is the stator pole pitch, n and j are both positive integers. Other structures and characteristics are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com