Motor rotor assembly and motor

A technology for motor rotors and components, applied in electric components, electrical components, synchronous machine parts, etc., can solve the problems of large size of the yoke, low structural strength, poor stability, etc., and achieve high structural strength, high power density, and stability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

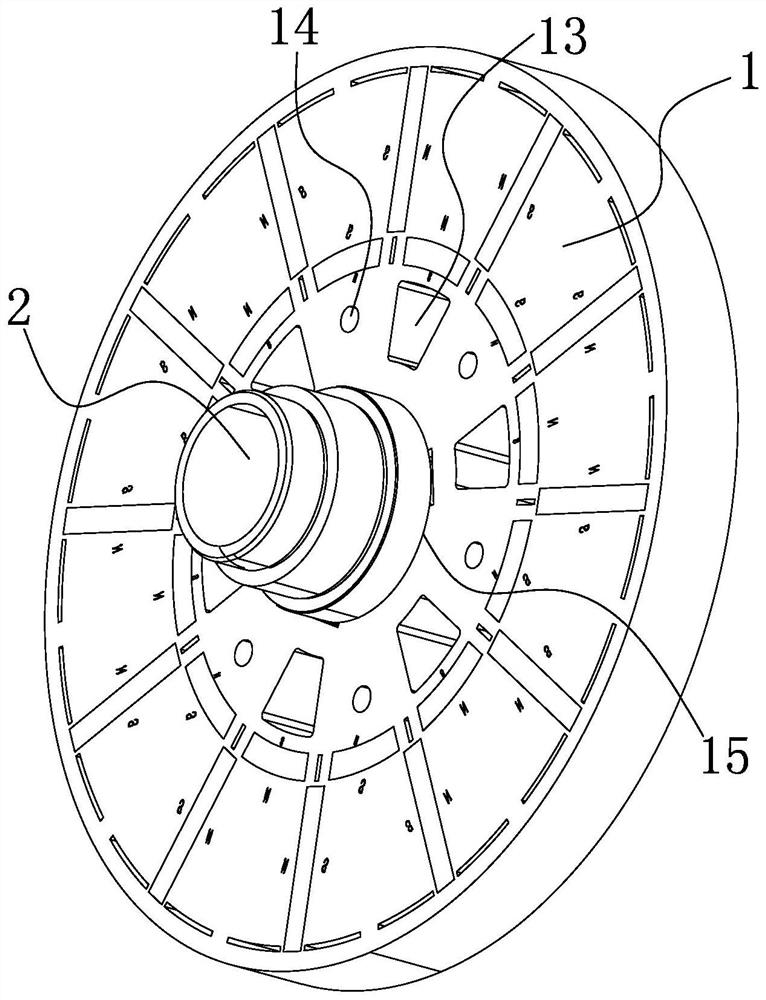

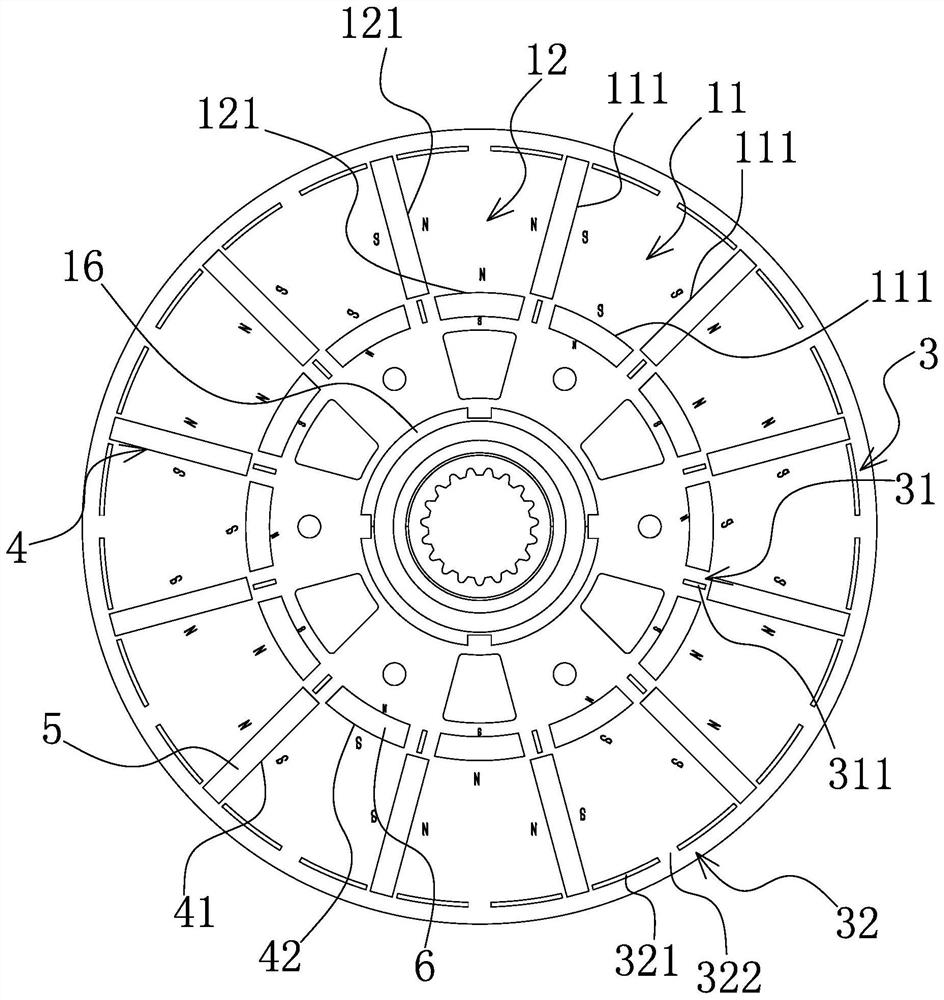

[0028] Such as Figure 1-2 As shown, the motor rotor assembly includes a rotor body 1 with a motor shaft 2 in the center. The rotor body 1 is a silicon steel sheet in the shape of a disc, and at least one end surface of the rotor body 1 has several S magnetic pole regions 11 and N magnetic poles in sequence in the circumferential direction. region 12 , and the S magnetic pole region 11 and the N magnetic pole region 12 are evenly staggered and adjacently distributed. Preferably, both end surfaces of the rotor body 1 here have S magnetic pole regions 11 and N magnetic pole regions 12, the S magnetic pole regions 11 on the two end surfaces of the rotor body 1 are arranged in one-to-one correspondence, and the N magnetic pole regions on the two end surfaces of the rotor body 1 12 one-to-one correspondence settings. At the same time, the size and shape of the S magnetic pole area 11 and the N magnetic pole area 12 here are the same, and the number of the S magnetic pole area 11 o...

Embodiment 2

[0039] The structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the outer magnetic isolation assembly 32 in this embodiment is a magnetic isolation coating covering the circumferential outer side of the rotor body 1; or, as Figure 5 As shown, the outer magnetic isolation assembly 32 includes arc-shaped recesses 323 uniformly formed on the outer peripheral edge of the rotor body 1 and recessed inward, and the arc-shaped recesses 323 are respectively located at two adjacent first permanent magnets 5 away from the rotor. There is a magnetic isolation layer 324 between one end of the center of the body 1 and outside the arc-shaped concave portion 323 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com