Linear motor

A technology of linear motors and armatures, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of large pressure loss of cooling medium, difficult magnetic field to reach permanent magnets, increase of manufacturing costs, etc., to achieve efficient cooling and increase the maximum Thrust and pressure loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] [Construction of linear motor]

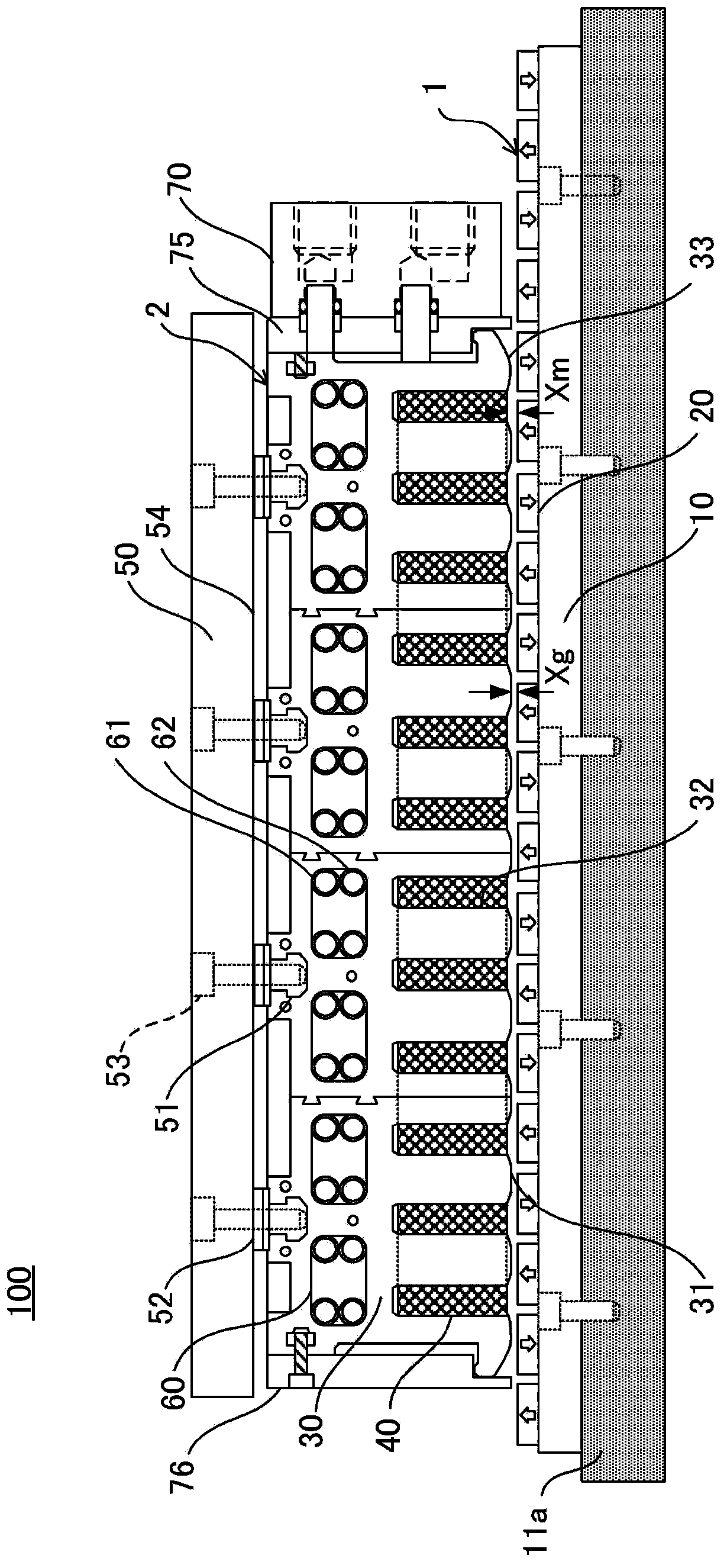

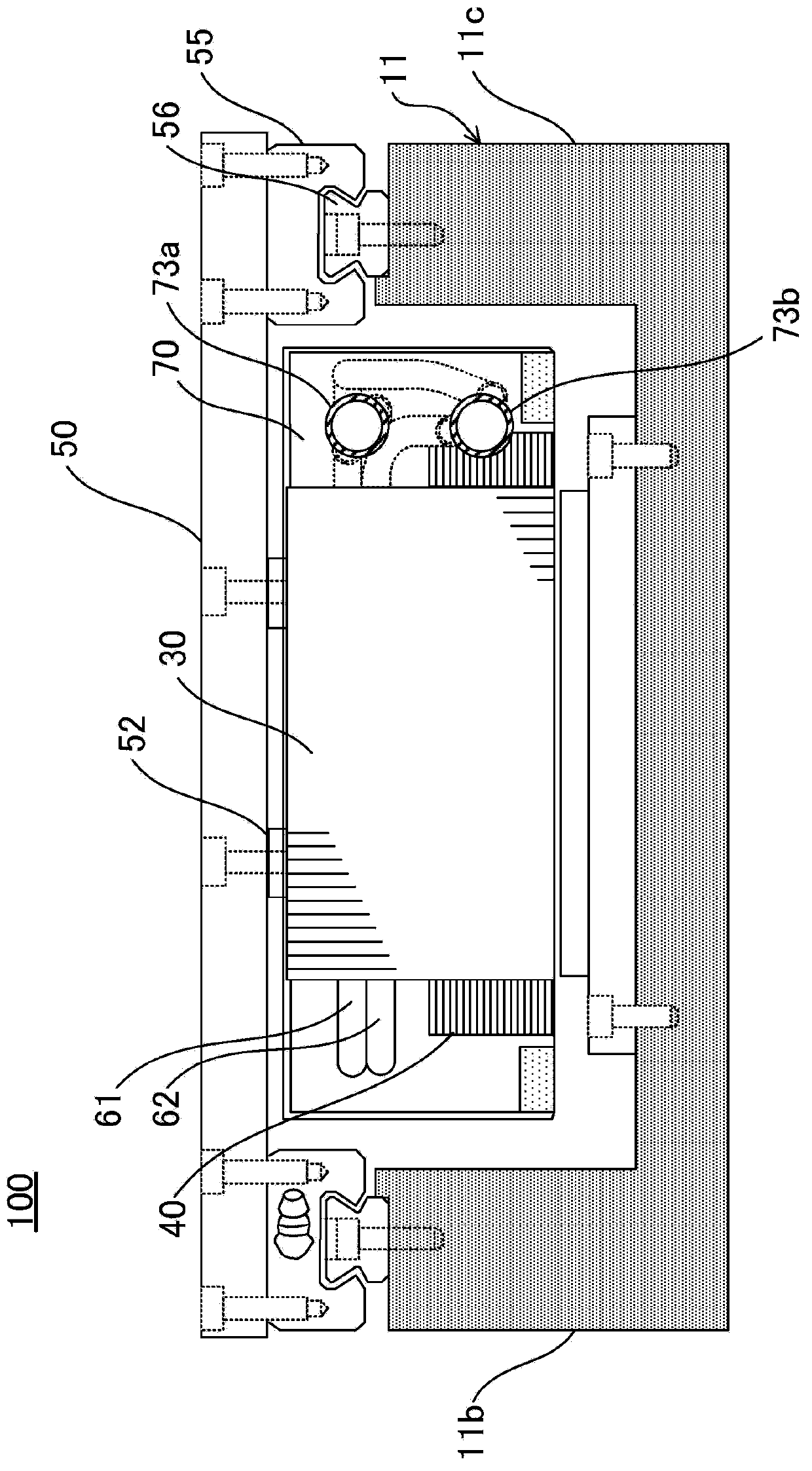

[0060] First, refer to figure 1 and figure 2 , and the configuration of the linear motor according to Embodiment 1 will be described. figure 1 It is a sectional view along the longitudinal direction of the linear motor of Embodiment 1. figure 2 It is the right side view of the linear motor of Embodiment 1.

[0061] Such as figure 1 and figure 2 As shown, the linear motor 100 according to Embodiment 1 is composed of a magnetic field generating unit 1 and an armature 2 .

[0062] The magnetic field generator 1 has a yoke 10 and a permanent magnet 20 .

[0063] The yoke 10 is a plate-shaped magnetic metal member. The yoke 10 is fixed on the bottom 11a of the assembly seat 11 having a concave cross section. The magnetic field generator 1 functions as a stator.

[0064] The yoke 10 has a function of closing the magnetic field lines from the magnetic field generator 1 to the assembly base 11 to maximize the electromagnetic inductio...

Embodiment approach 2

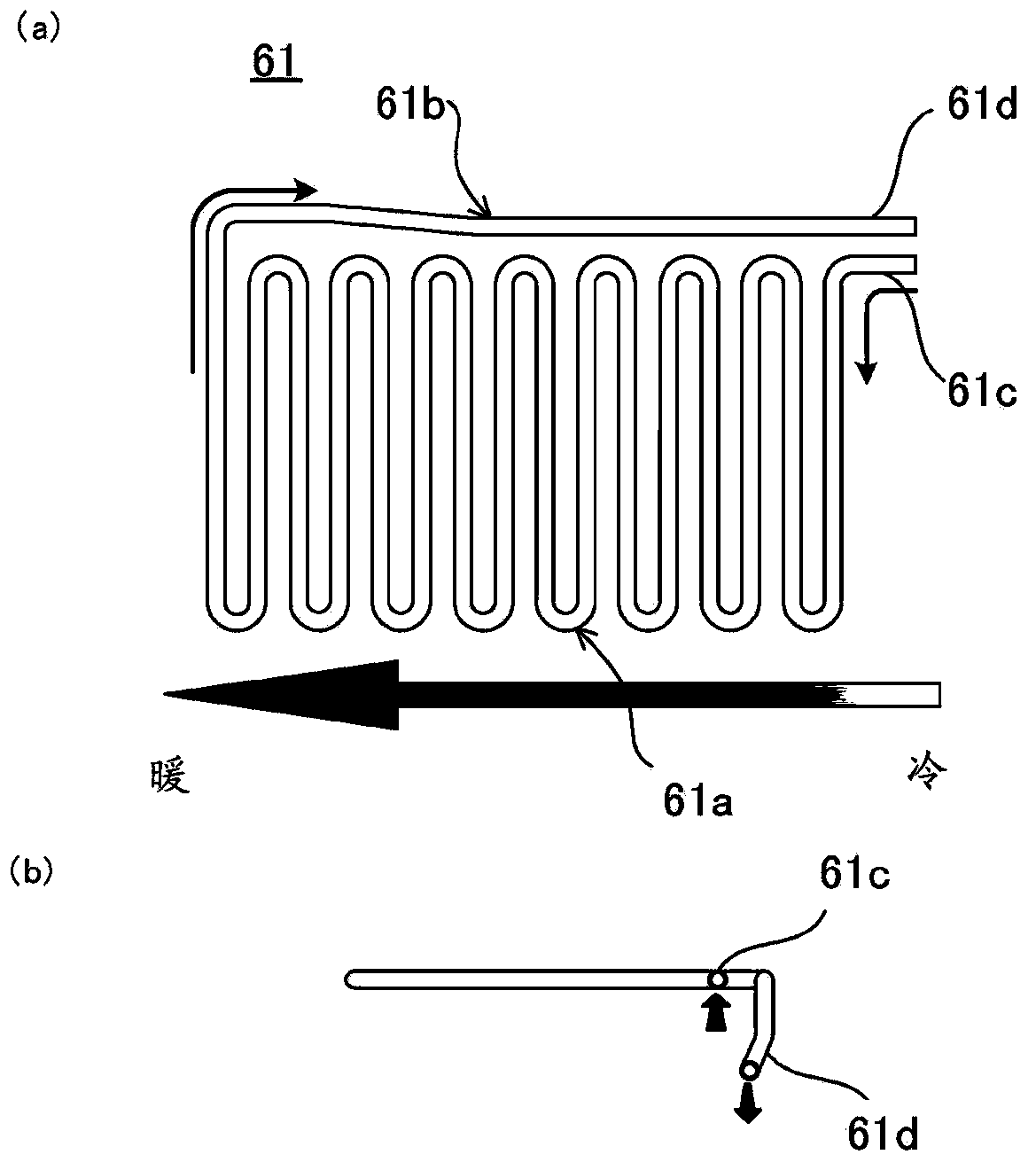

[0113] Then, refer to Figure 8 , Embodiment 2 will be described. Figure 8 It is a schematic cross-sectional view of an arrangement example of cooling pipes in Embodiment 1. FIG. In addition, the same code|symbol is attached|subjected to the same component as the linear motor 100 of Embodiment 1, and description is abbreviate|omitted.

[0114] Such as Figure 8 As shown, Embodiment 2 is different from Embodiment 1 in the arrangement example of cooling pipes 61 and 62 .

[0115] In the arrangement example of Embodiment 2, in the cooling pipe receiving hole 60, the upper layer side cooling pipe 61 and the lower layer side cooling pipe 62 are in contact, and the space between the cooling pipes 61, 62 is interposed with a high thermal conductivity heat transfer tube. Material 81. As a constituent material of the heat transfer material 81, for example, a material with high thermal conductivity such as copper, aluminum, or graphite is used.

[0116] Figure 8 The cross-sectio...

Embodiment approach 3

[0124] Then, refer to Figure 9 , Embodiment 3 will be described. Figure 9 It is a schematic cross-sectional view of an arrangement example of cooling pipes in Embodiment 3. FIG. In addition, the same code|symbol is attached|subjected to the same component as the linear motor 100 of Embodiment 1, and description is abbreviate|omitted.

[0125] Such as Figure 9 As shown, Embodiment 3 differs from Embodiment 1 in the arrangement example of cooling pipes 61 and 62 .

[0126] Such as Figure 7 As described in (b), when the upper and lower cooling pipes 61 and 62 are in contact, the cooling pipes 61 and 62 can easily transfer heat to the cooling medium, thereby enabling effective cooling. On the other hand, it is also easy to place the The heat is transferred to the movable table 50 side. Therefore, in order to prevent heat transfer to the movable table 50 side, in the arrangement example of the third embodiment, the upper cooling pipe 61 and the lower cooling pipe 62 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com