Electromagnetic induction heating roller

An electromagnetic induction heating and compensation heating technology, which is applied in induction heating, induction heating devices, coil devices, etc., can solve the problems of power consumption and easy damage, and achieve reasonable distribution, enhanced magnetic induction intensity, improved working environment and safe production. conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

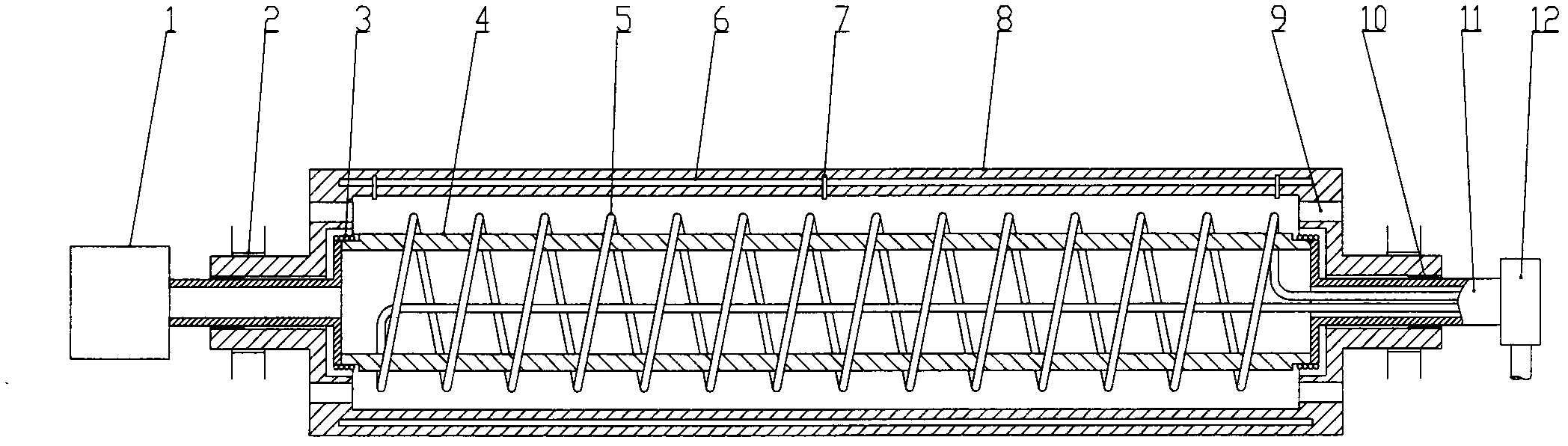

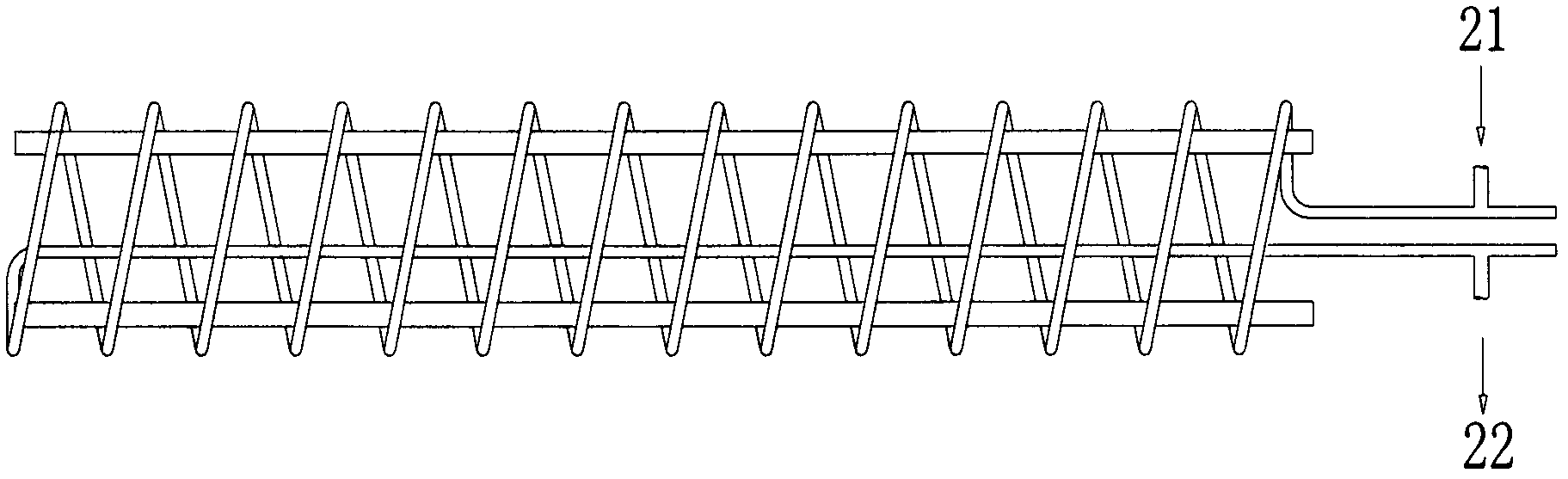

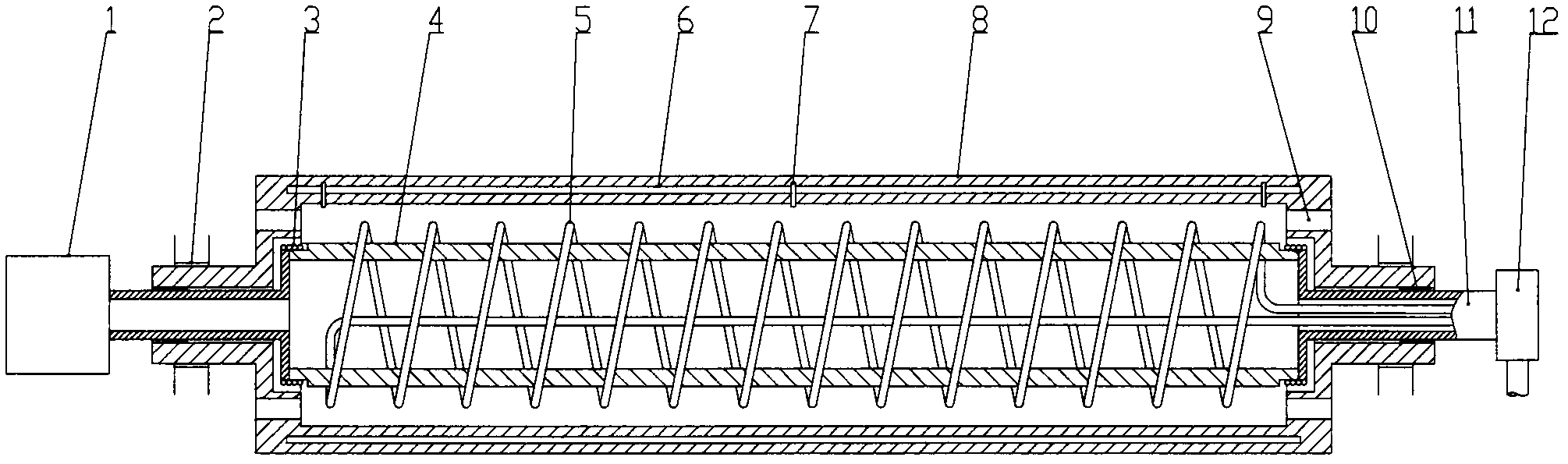

[0026] Such as figure 1 Shown in the figure is the optimal embodiment of the present invention, wherein the main part of the heating roller is a hollow, and the two ends are provided with the roller body 8 of the connecting shaft with the bearing 2, and the roller body 8 can be made of rigid . The roller body 8 is built with a magnetically conductive core 4 , and both ends of the magnetically conductive core 4 are provided with hollow half shafts 11 with high temperature resistant sleeve bearings 10 . One end is connected to the cable connector 12 through the half shaft 11 . A heating coil 5 wound around a conductive core 4 is guided from the cable connector 12 into the roller body 8 . And from the cable connector 12 to the inside of the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com