Moving-magnet type transverse flux linear oscillatory motor for direct-drive compressor

A technology of transverse magnetic flux and linear vibration, applied in the direction of machines/engines, electromechanical devices, electrical components, etc., can solve the problems of difficult processing, reduced motor efficiency, and difficult stacking, and achieve high-thrust, large-amplitude, high-frequency reciprocation The effect of smooth movement, output force, and small magnetic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

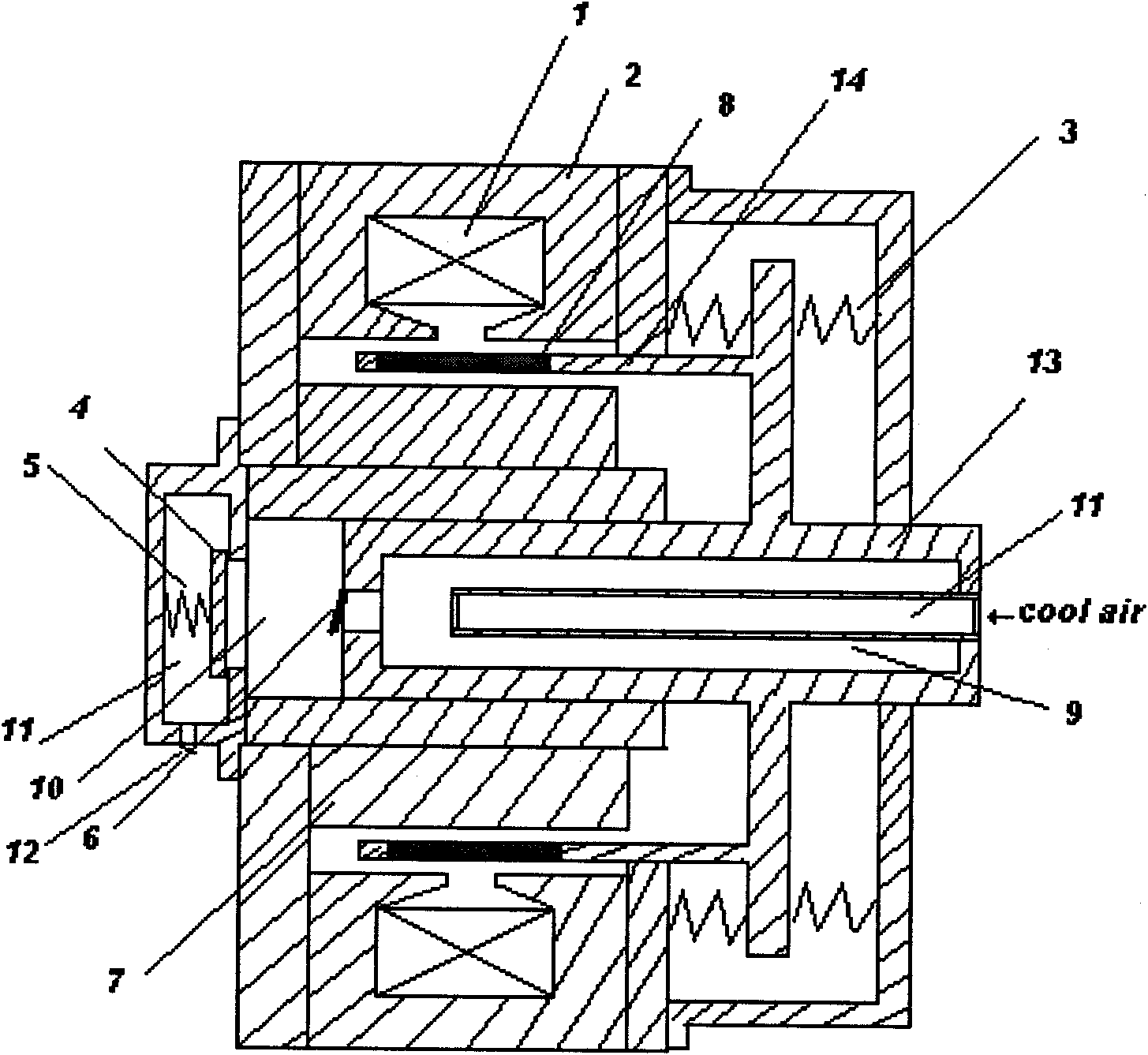

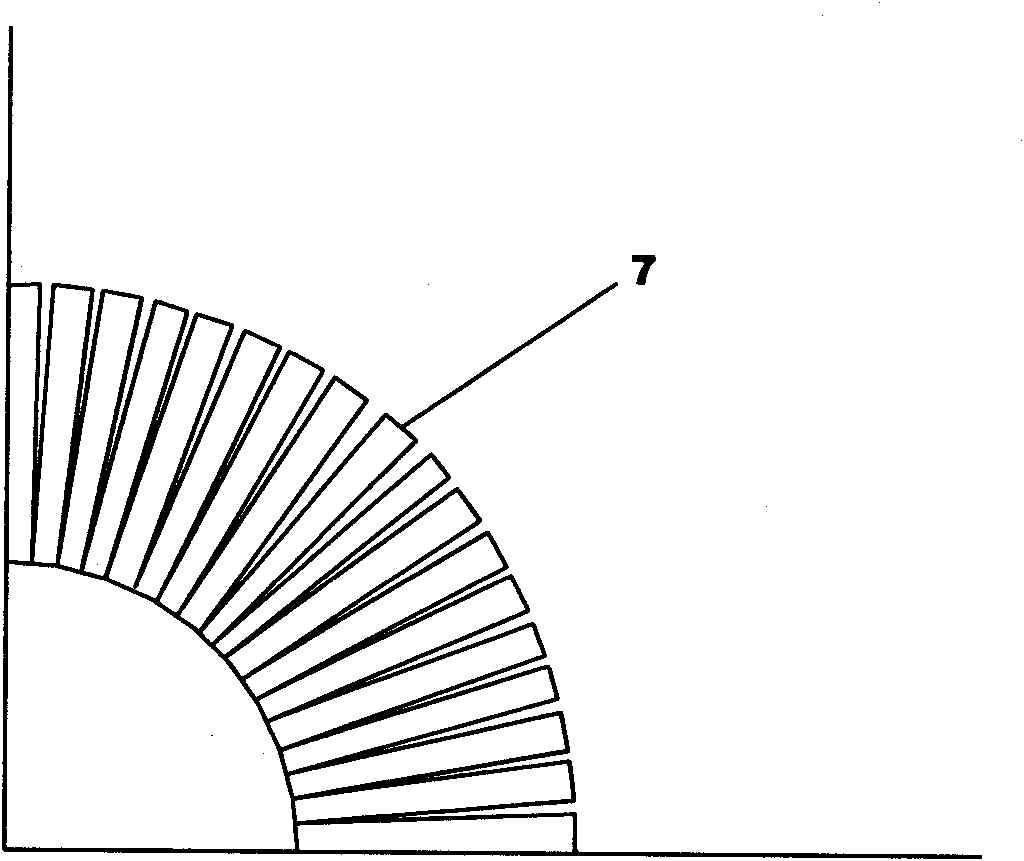

[0020] figure 1 It is a longitudinal section view of a linear vibration motor applied to a compressor in the prior art. As shown in the figure, the linear vibration motor is mainly composed of the following structures: stator winding 1, outer stator core 2, spring 3, inner stator core 7, permanent magnet 8, piston 13, permanent magnet support 14. The winding is embedded in the outer stator core and is a cake winding. The outer stator core is assembled from many small stator core blocks, and the outer stator punching pieces that form the small core blocks are in the shape of "C" ( figure 1 The C-shaped iron core cannot be seen in the middle). The inner stator is a radial structure with tight inside and loose outside (such as figure 2 As shown), the motor mover is composed of permanent magnets and non-magnetic permanent magnet brackets.

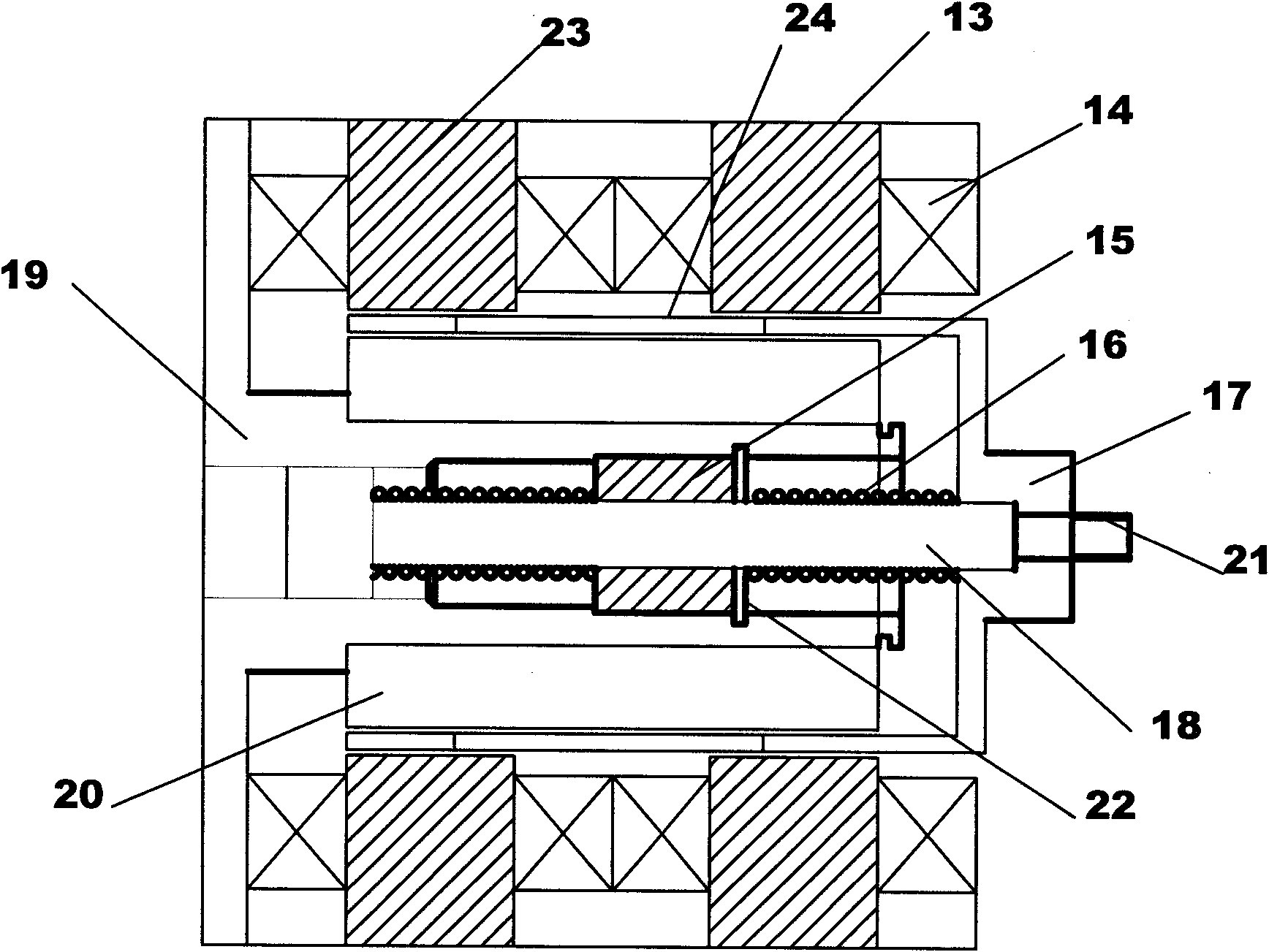

[0021] Different from the prior art, the present invention provides a moving magnet transverse magnetic flux linear vibration motor with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com