Linear motor

A linear motor, magnetic pole tooth technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as slow moving speed, and achieve the effect of reducing magnetic resistance and eliminating high harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0170] Hereinafter, the specific configuration of the linear motor produced by the present inventors and the characteristics of the produced linear motor will be described.

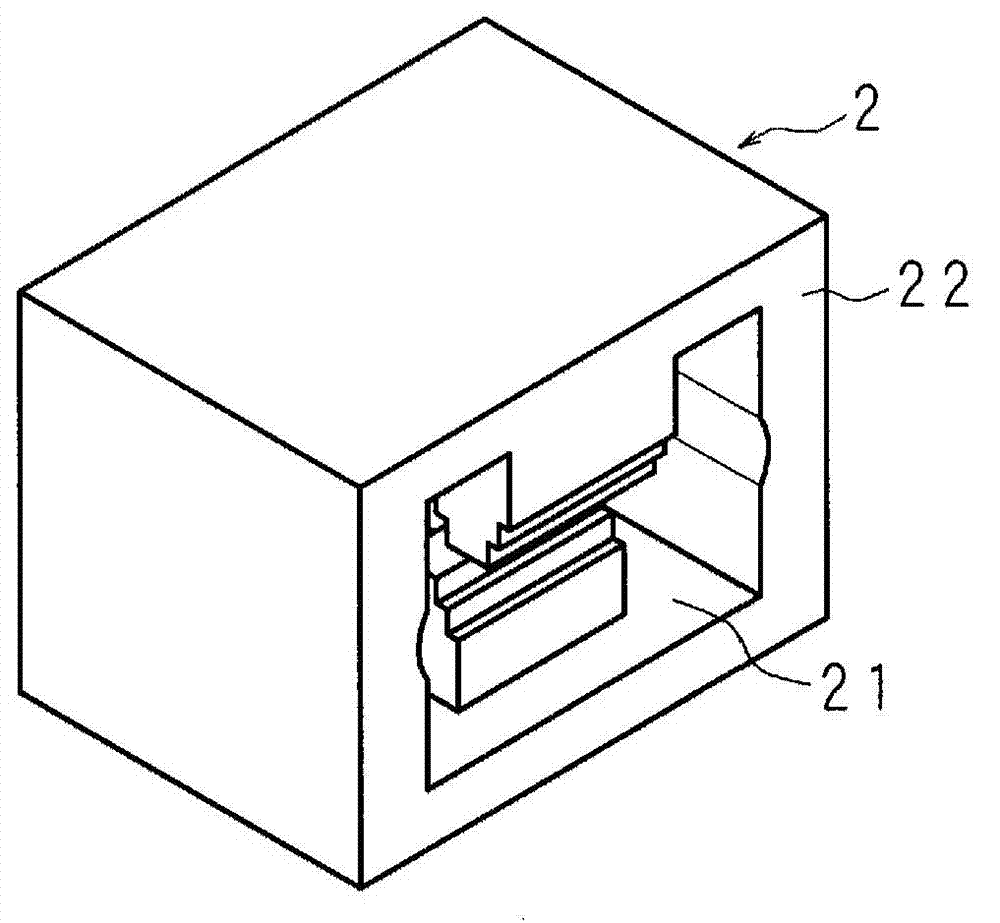

[0171] Figure 15A , 15B It is a plan view and a side view of the embodiment of the single-phase linear motor 3 of the present invention. The mover 1 penetrates the hollow portion 21 of the stator 2 to constitute the linear motor 3, wherein, in the stator 2, a plurality of magnetic pole teeth 23a and magnetic pole teeth 23b are respectively arranged in a row, and the plurality of magnetic pole teeth 23a The formed magnetic pole tooth group and the magnetic pole tooth group composed of a plurality of magnetic pole teeth 23b are respectively wound with drive coils 25a and drive coils 25b. In the mover 1, permanent magnets 11a, yokes 12, Permanent magnet 11b, yoke 12 . . . .

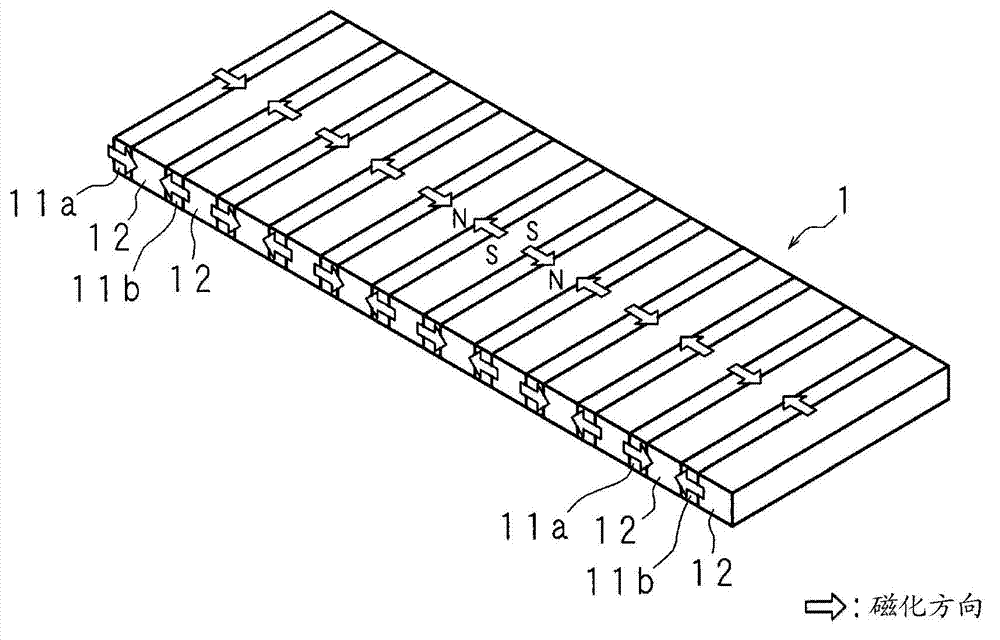

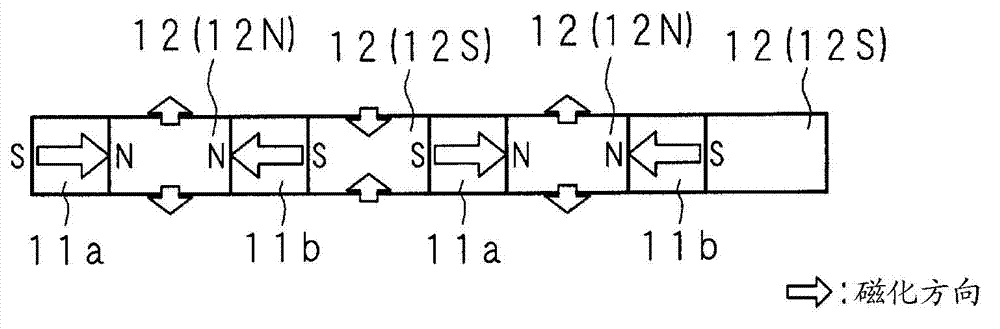

[0172] First, as the flat mover 1 used in the linear motor 3, a Figure 1A , 1B The mover 1 is shown in the shape of permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com