Patents

Literature

508results about How to "High speed rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

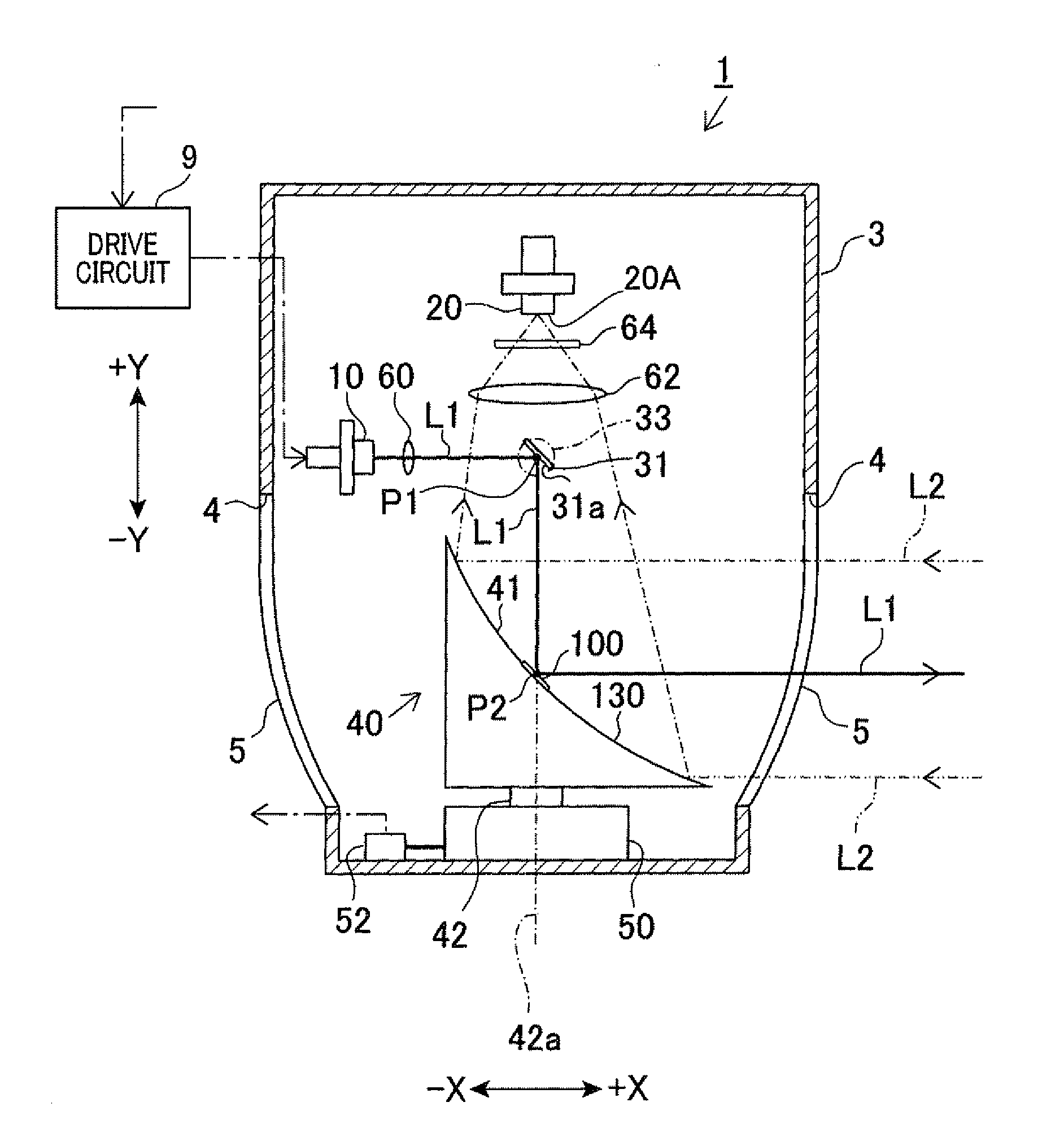

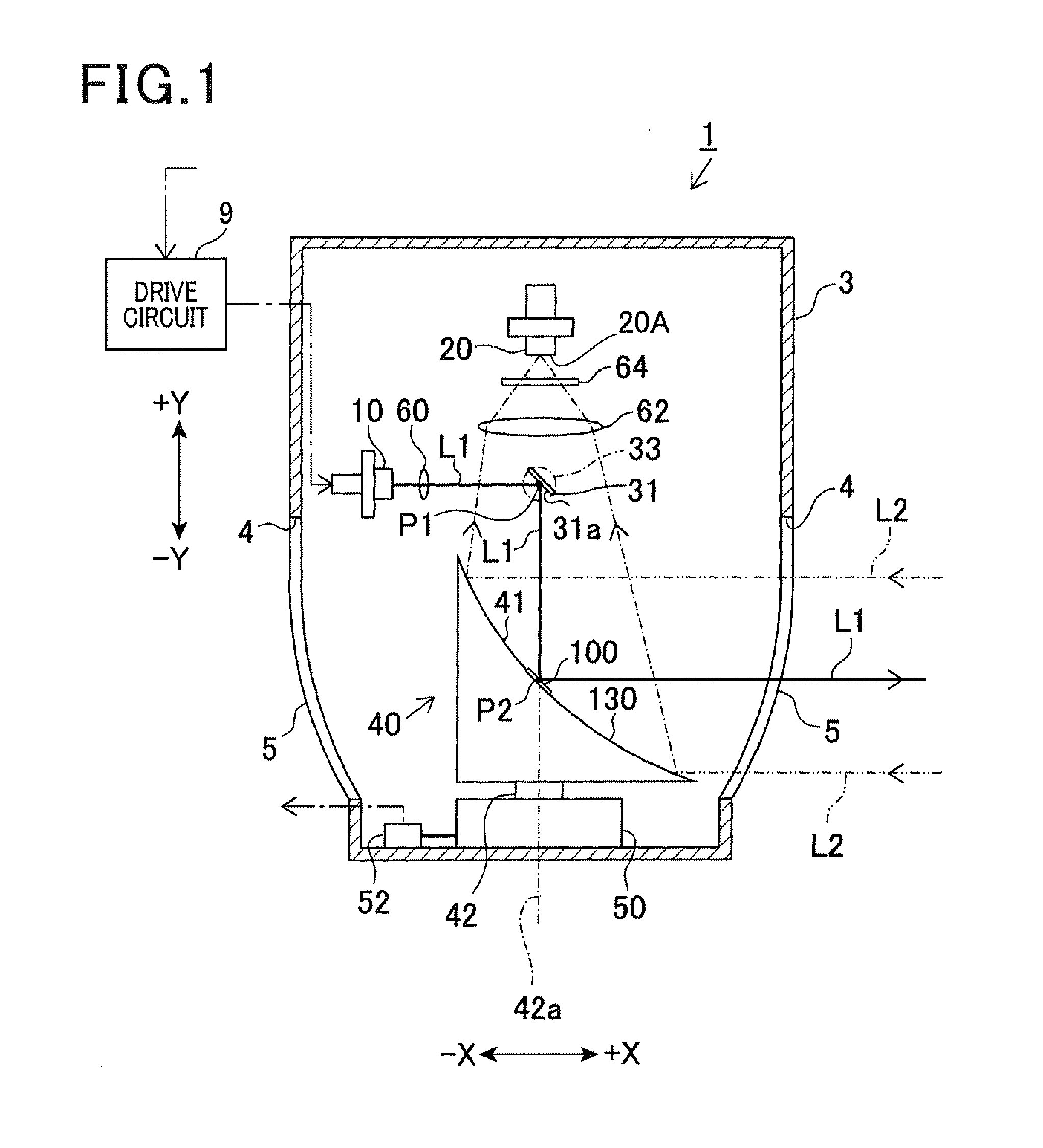

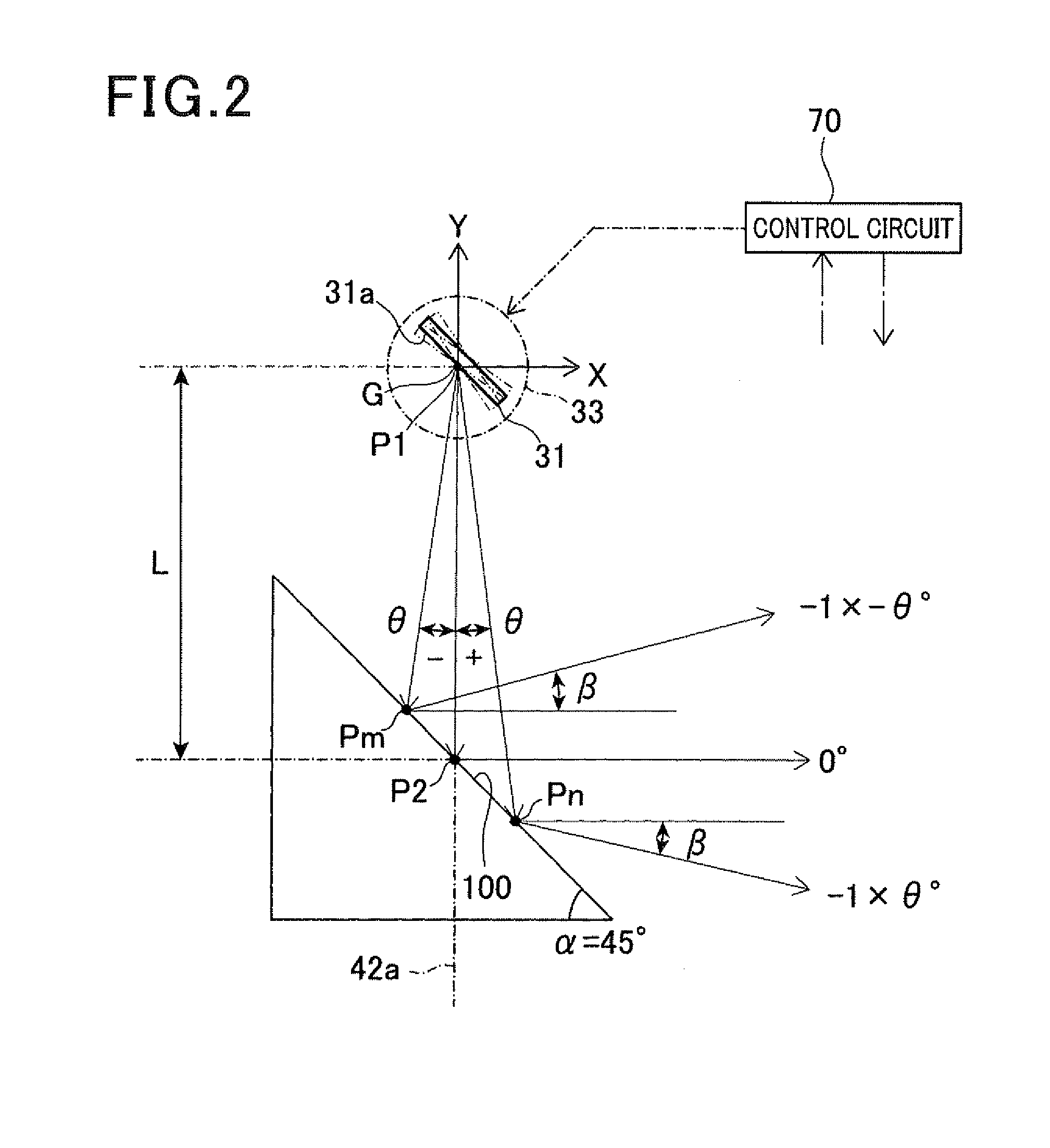

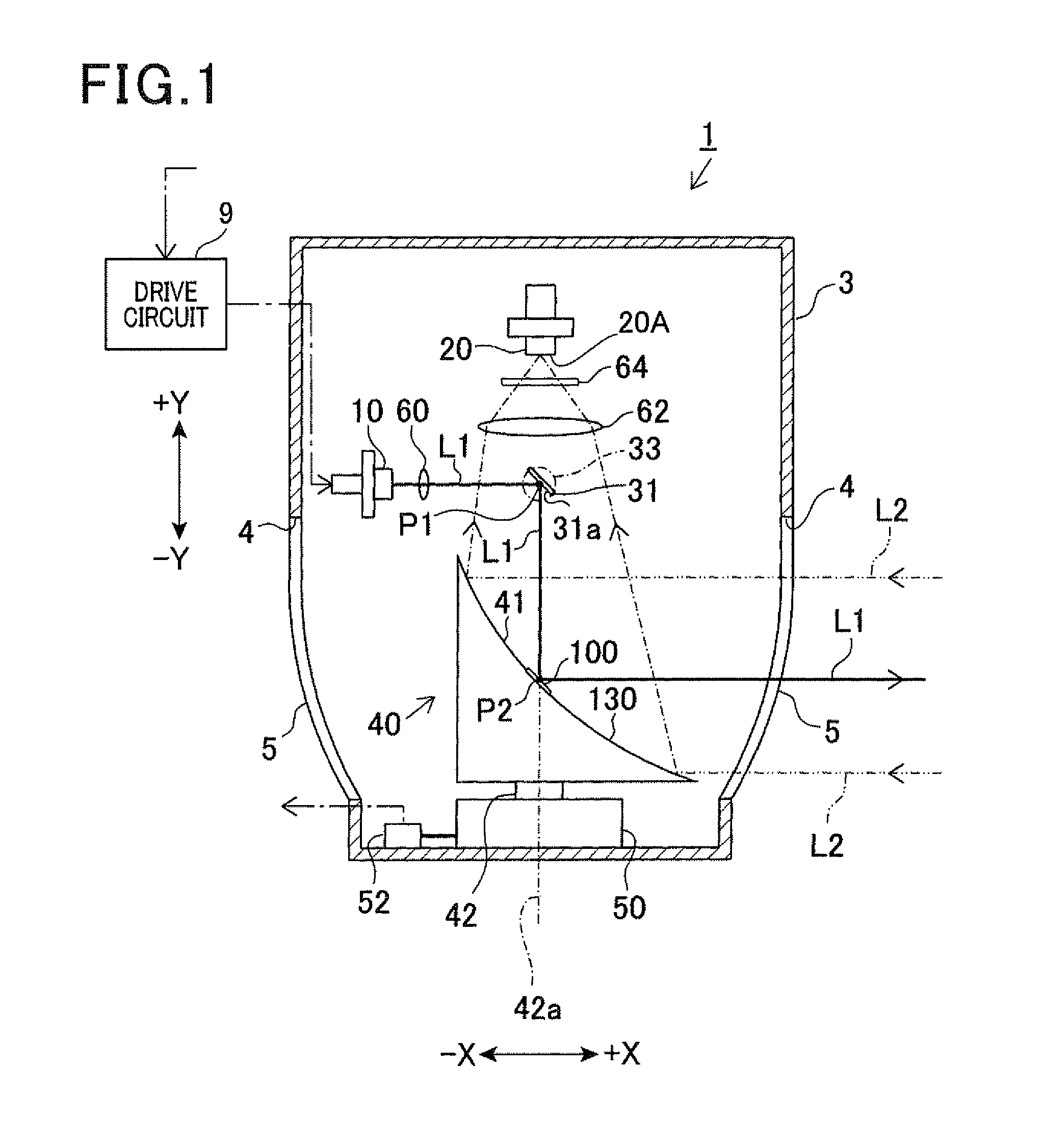

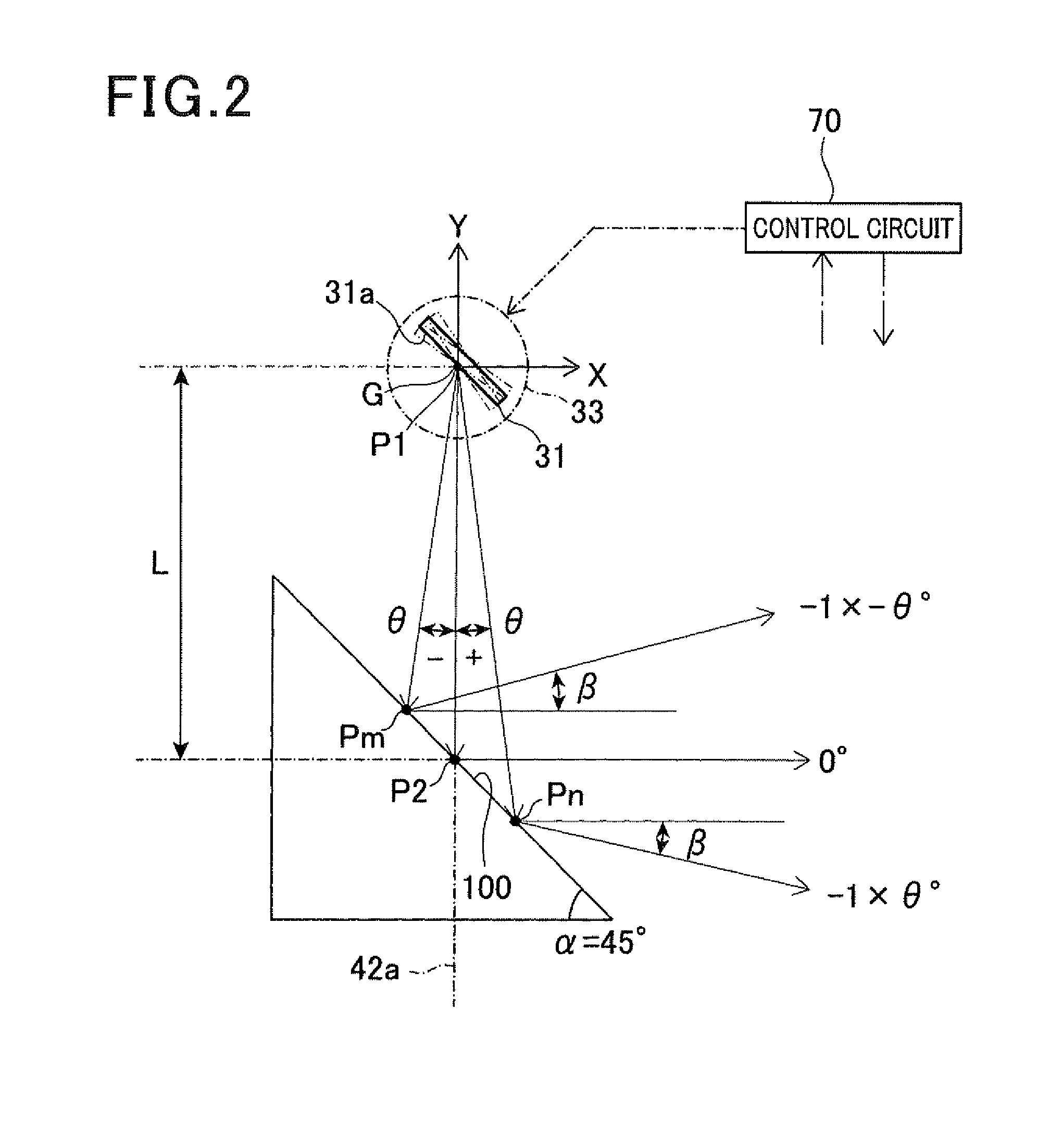

Laser radar for three-dimensional scanning

InactiveUS20120249996A1Applied load reductionReduce loadOptical rangefindersElectromagnetic wave reradiationBeam angleRadar

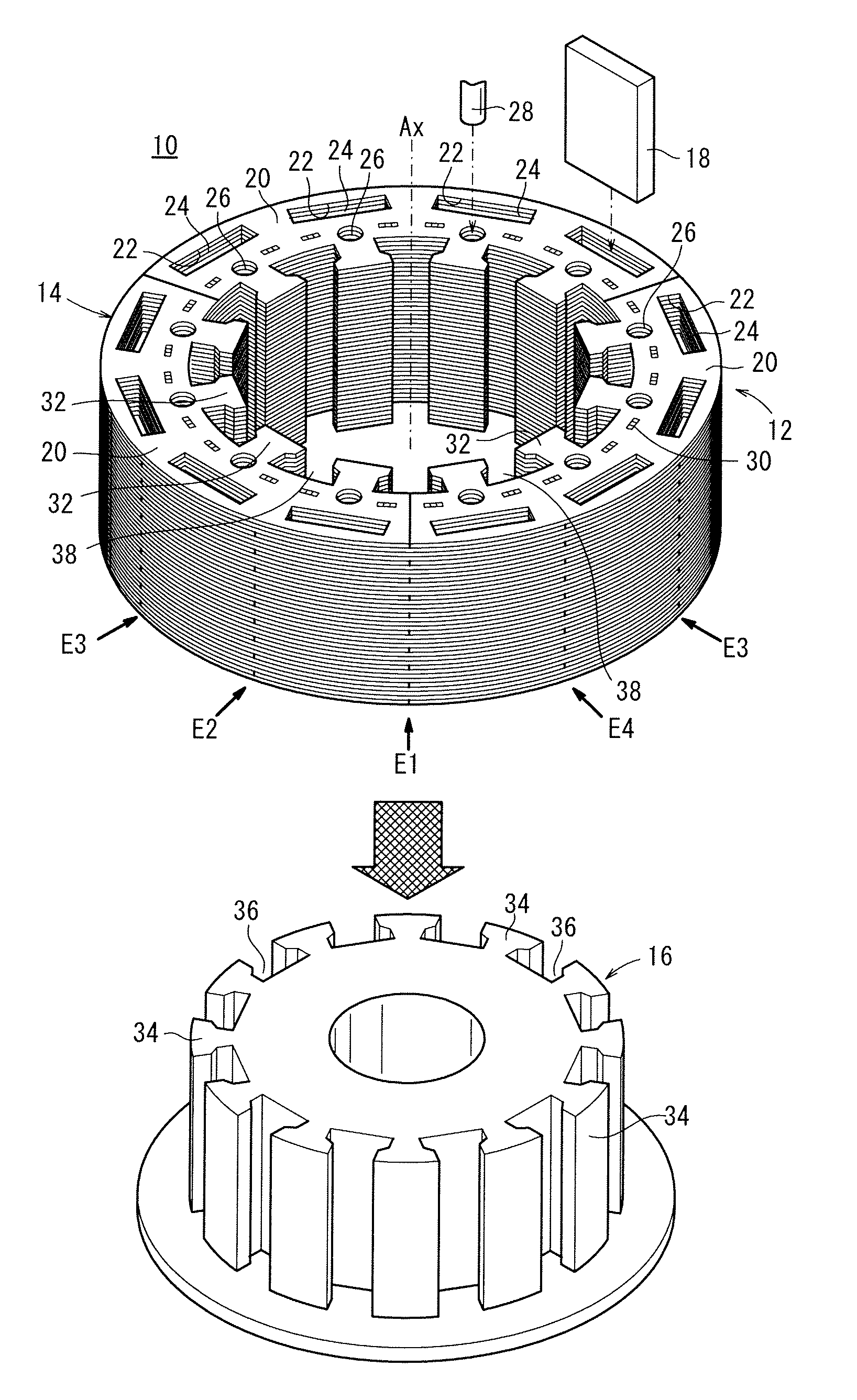

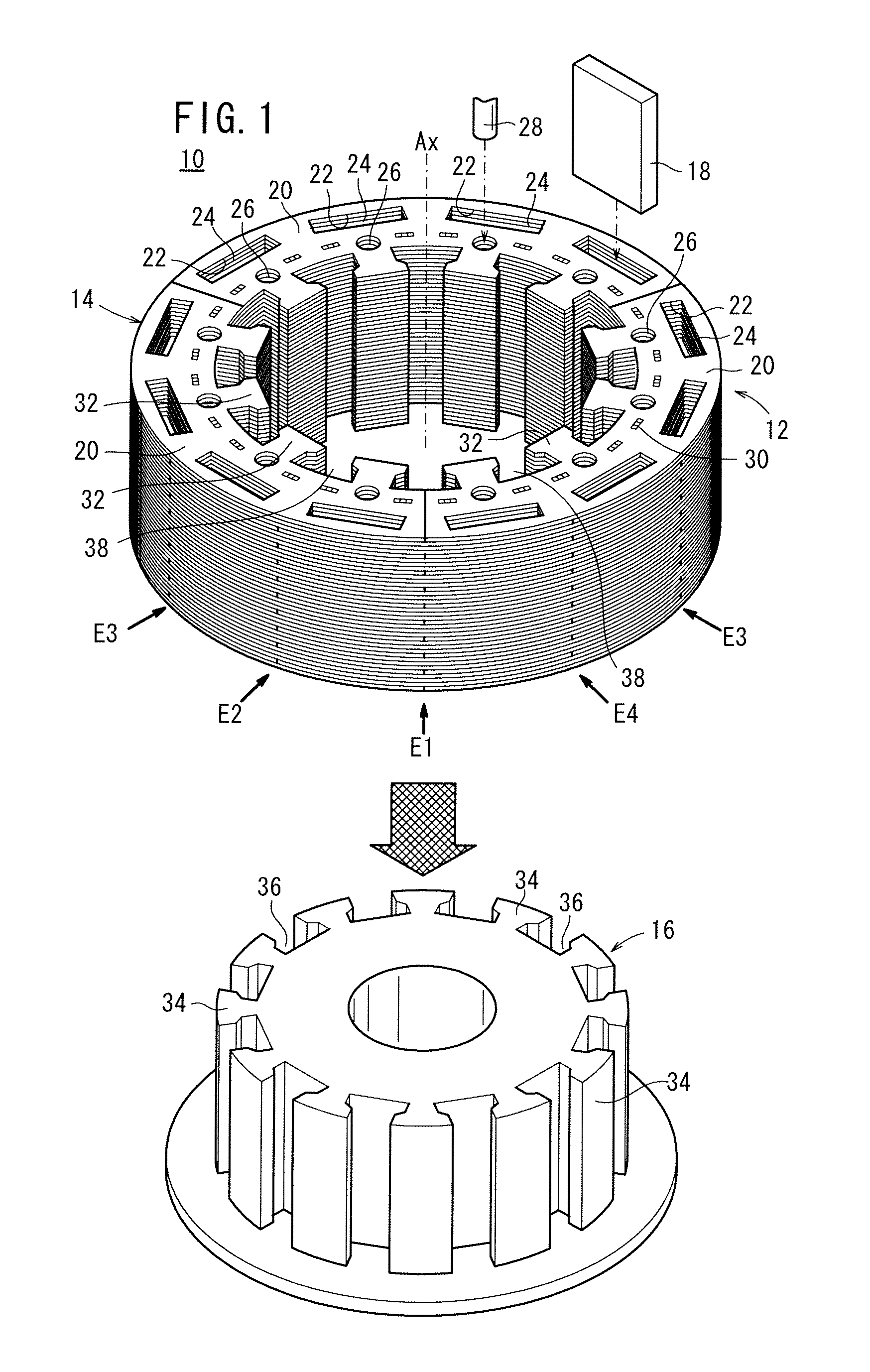

In a laser radar, a first scanning member scans a laser beam in a virtual plane passing through an axis. A control means controls displacements of the first scanning member to change a scan beam angle in the plane. A second scanning member deflects the scanned laser beam and again scans the deflected laser beam toward an external space. A light collecting means collects reflected light. A driving means rotates both the second scanning member and the light collecting means about the axis. The second scanning member has a deflecting surface to deflect the laser beam. The deflecting surface is formed around the axis and has a plurality of reflecting surfaces coaxially arranged centering on the axis. The reflecting surfaces have different inclinations with respect to a horizontal plane perpendicular to the axis.

Owner:DENSO WAVE INC

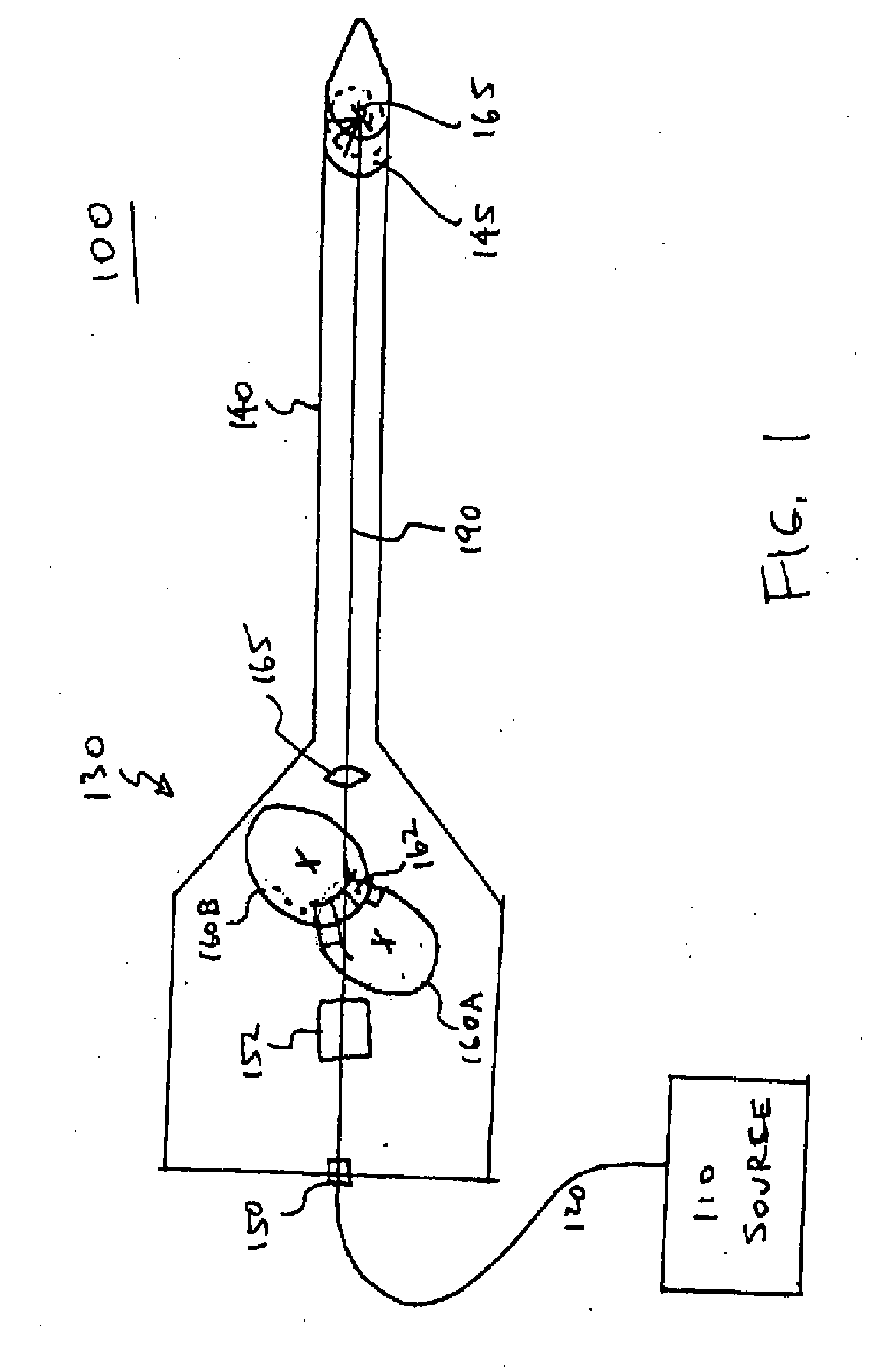

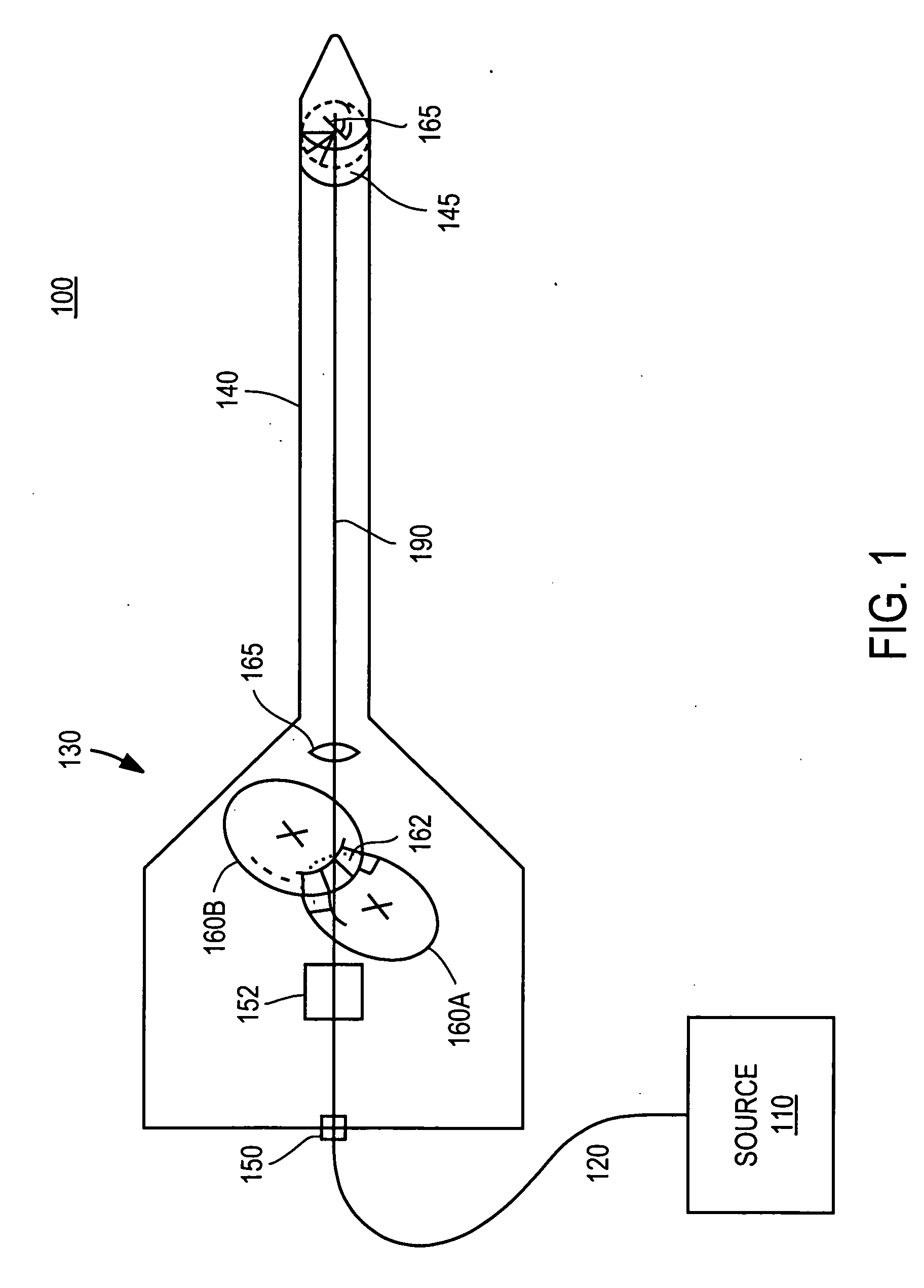

Method and Apparatus for Fractional Light-based Treatment of Obstructive Sleep Apnea

InactiveUS20070265606A1Faster treatment timeIncrease speedSurgical instrument detailsThroatLight delivery

An apparatus and method are described that uses fractional light based treatment to shrink soft tissue in the mouth or throat to reduce obstruction of the airways for patients suffering from obstructive sleep apnea. A light delivery probe with scanning optics can be used to deliver treatment. Cooling systems can be added to reduce damage to epithelial layers of tissue. Light based treatment can be nonablative or ablative and is preferably performed with a laser.

Owner:RELIANT TECH INC

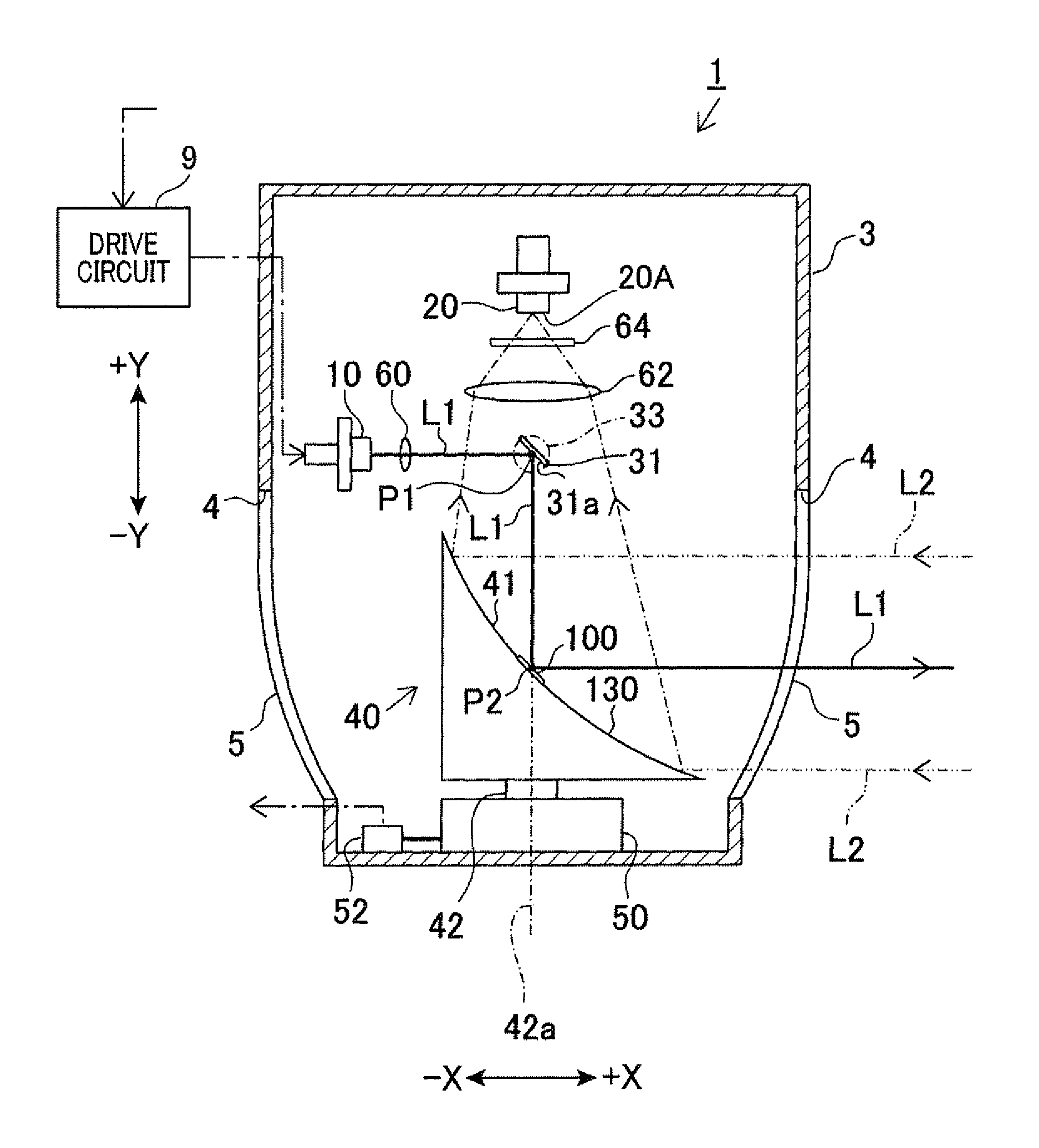

Laser radar for three-dimensional scanning

InactiveUS8681319B2Reduce weight and sizeReduce MechanismsOptical rangefindersHeight/levelling measurementBeam angleRadar

In a laser radar, a first scanning member scans a laser beam in a virtual plane passing through an axis. A control means controls displacements of the first scanning member to change a scan beam angle in the plane. A second scanning member deflects the scanned laser beam and again scans the deflected laser beam toward an external space. A light collecting means collects reflected light. A driving means rotates both the second scanning member and the light collecting means about the axis. The second scanning member has a deflecting surface to deflect the laser beam. The deflecting surface is formed around the axis and has a plurality of reflecting surfaces coaxially arranged centering on the axis. The reflecting surfaces have different inclinations with respect to a horizontal plane perpendicular to the axis.

Owner:DENSO WAVE INC

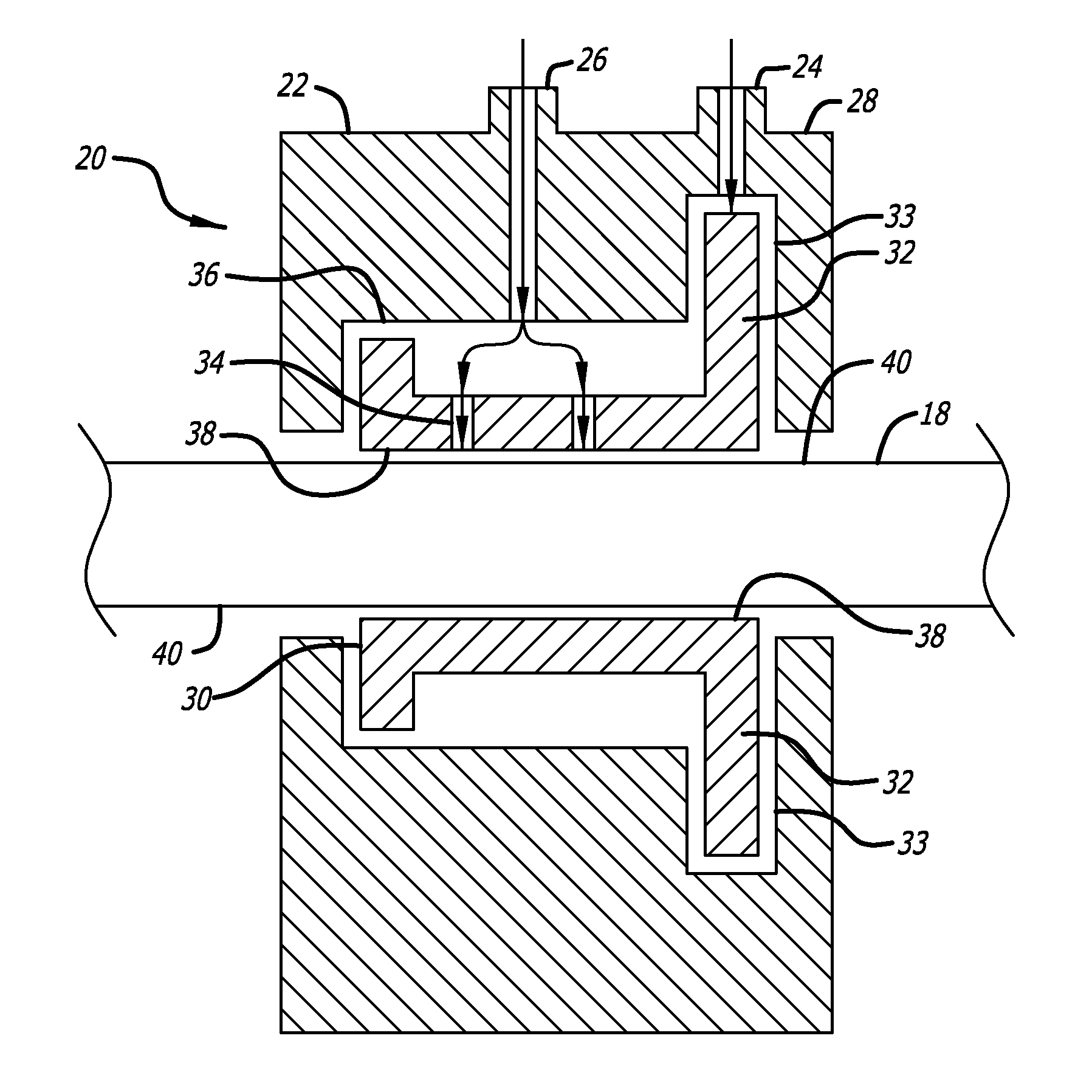

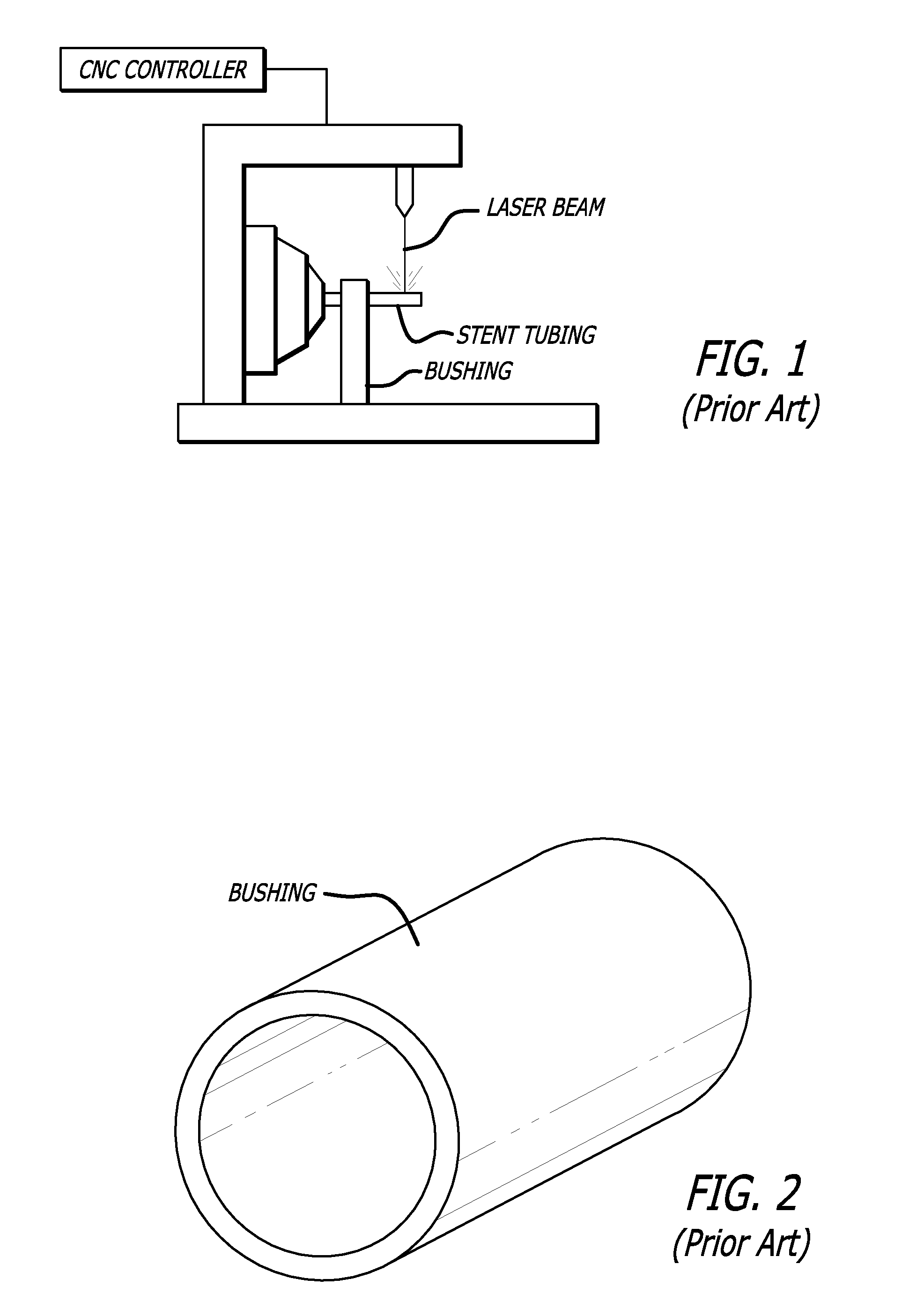

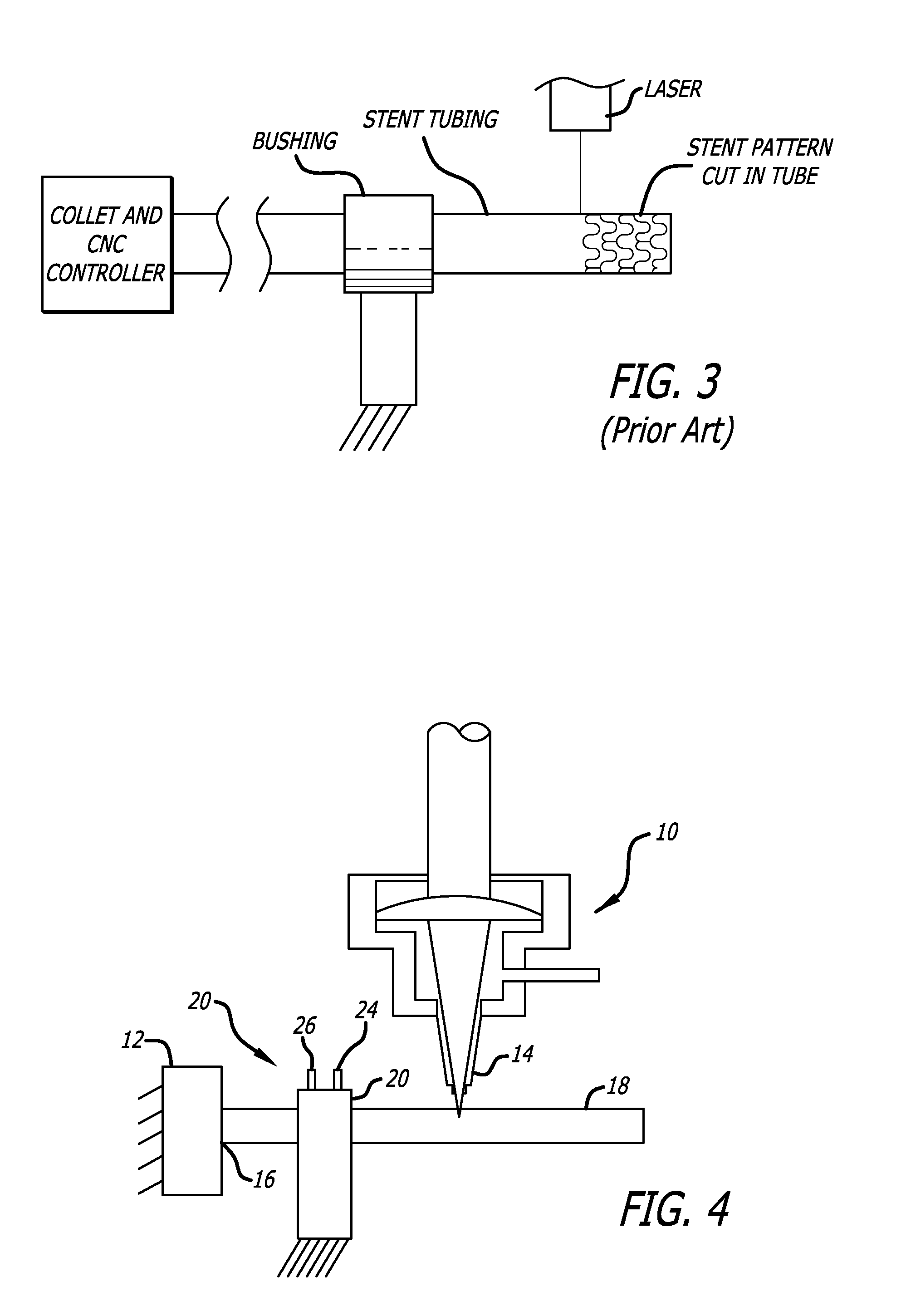

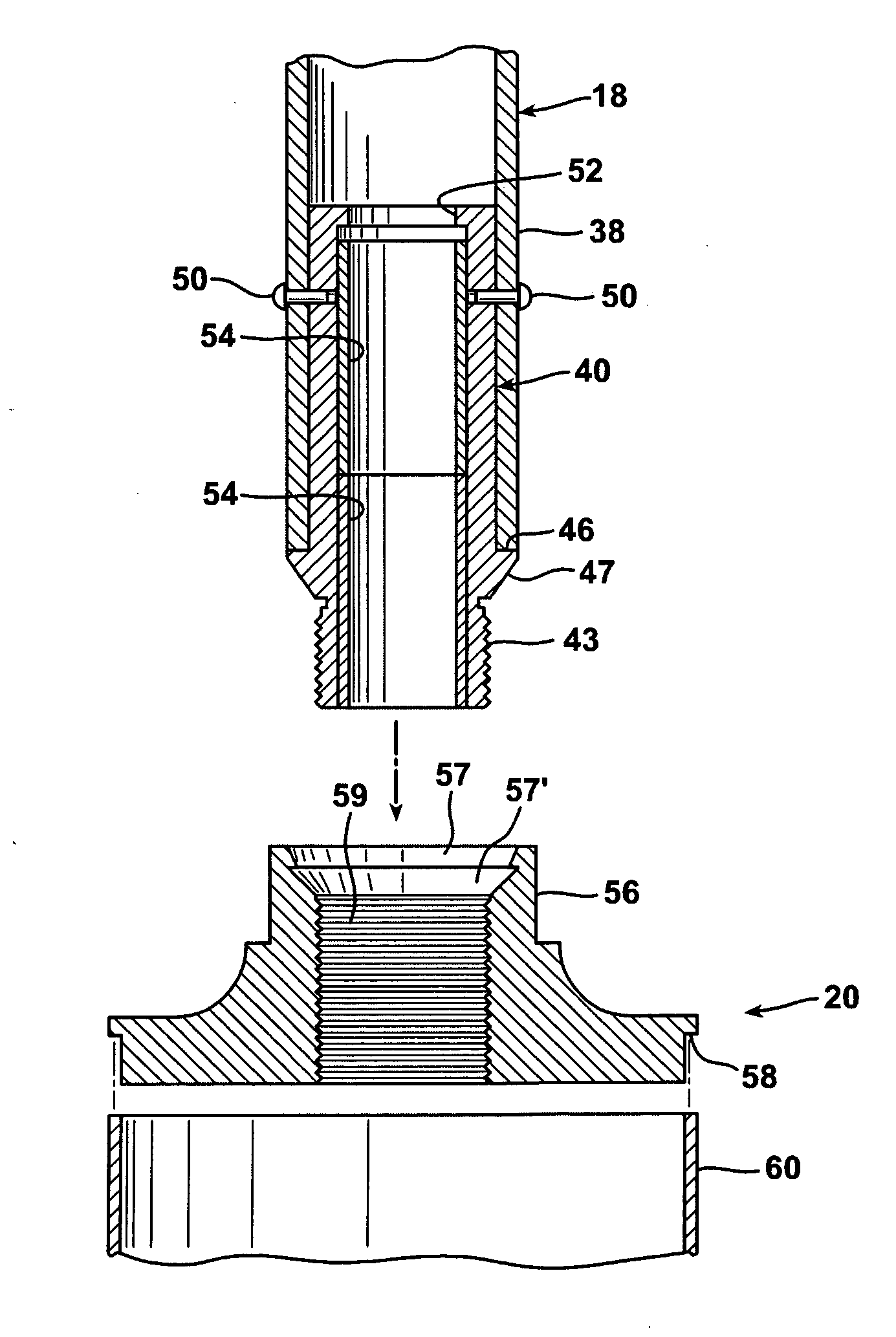

Fluid bearing to support stent tubing during laser cutting

ActiveUS20120057813A1Great precision , reliability , structural integrity and overall qualityImprove integrityStentsShaftsLaser cuttingStent

A fluid bearing assembly provides support to stent tubing while the stent tubing is undergoing laser cutting to form a stent pattern. The fluid bearing assembly supports the stent tubing and provides a fluid barrier between the bearing and the stent tubing thereby providing nearly frictionless movement between the support bearing and the stent tubing.

Owner:ABBOTT CARDIOVASCULAR

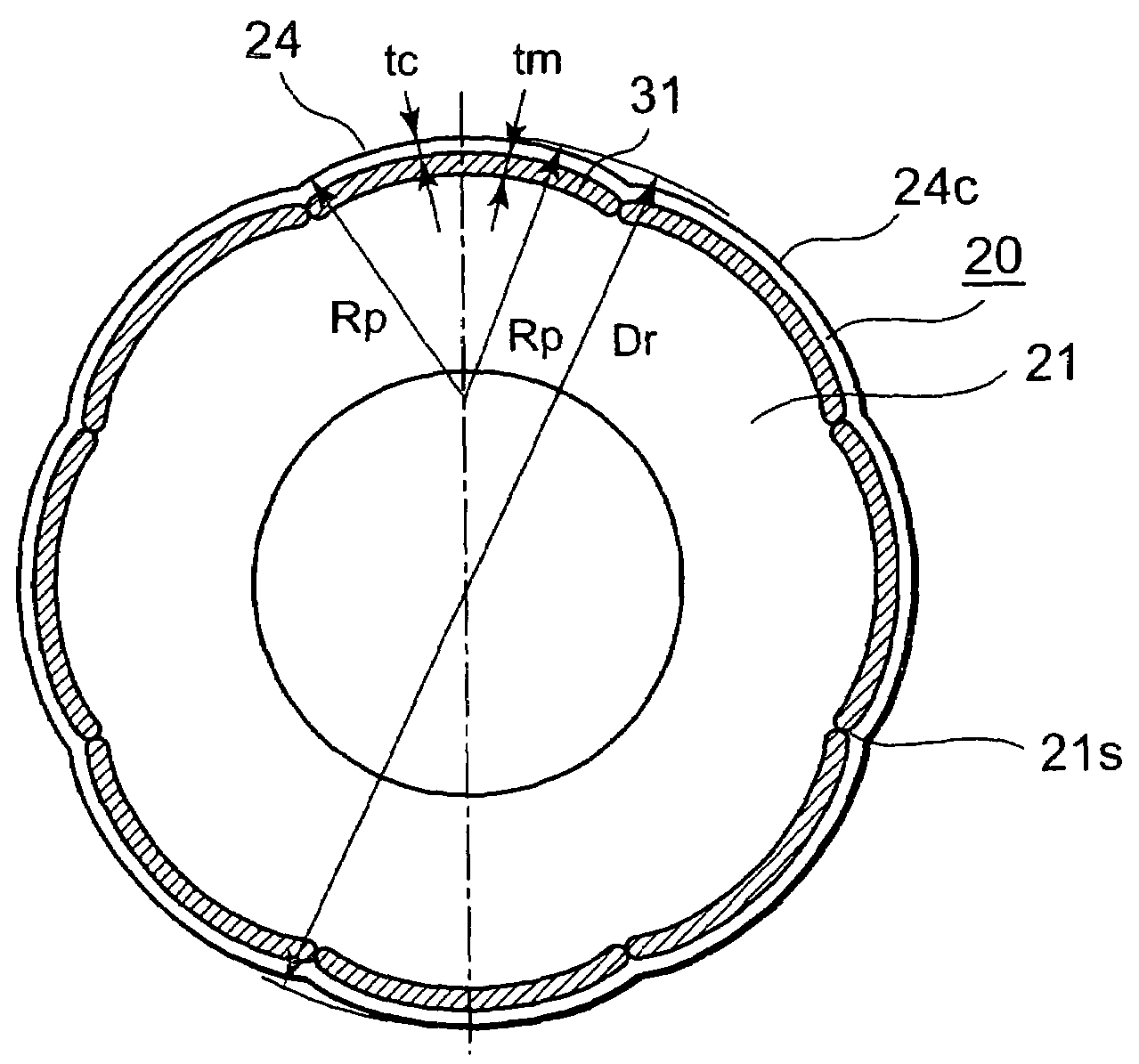

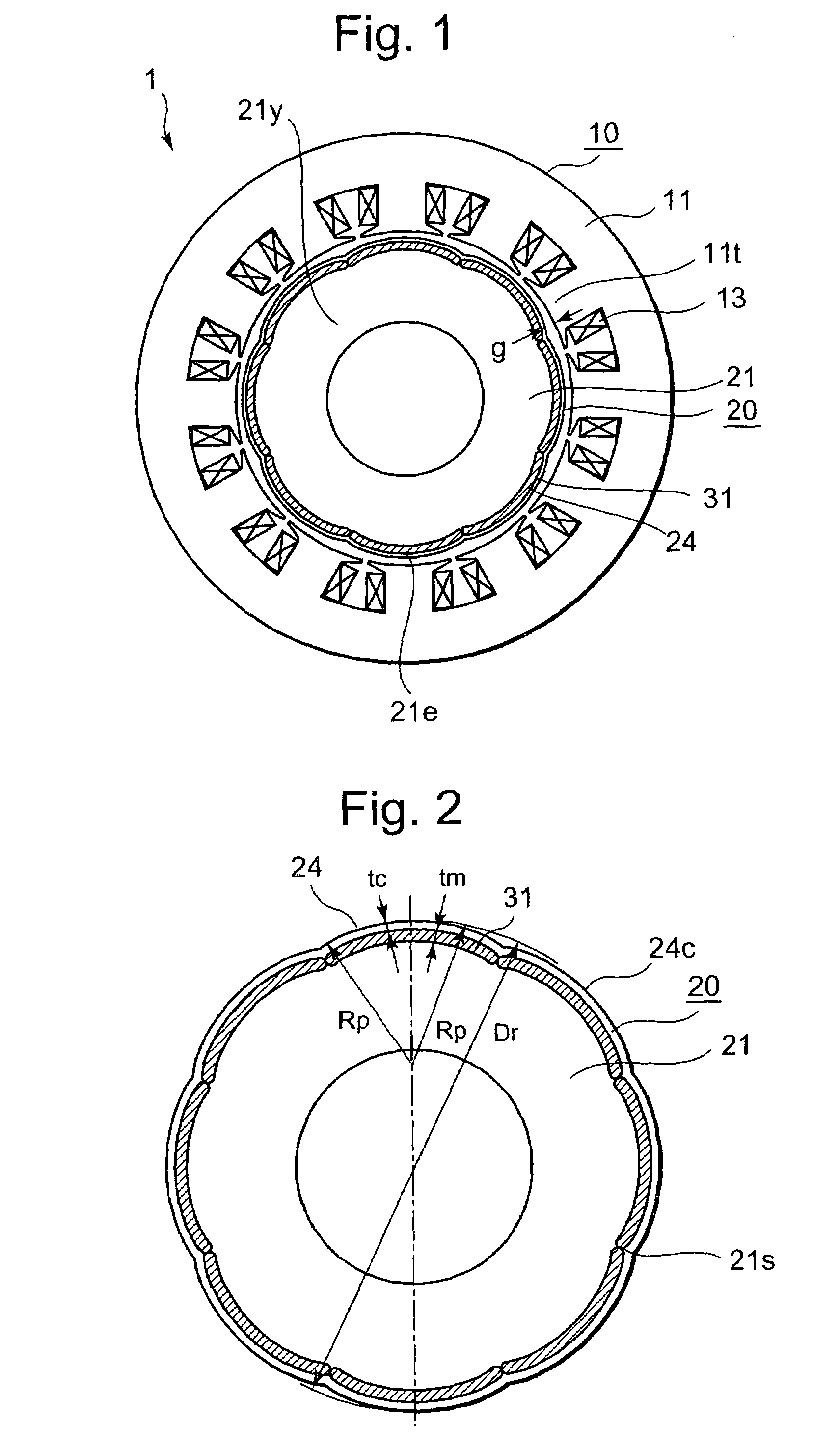

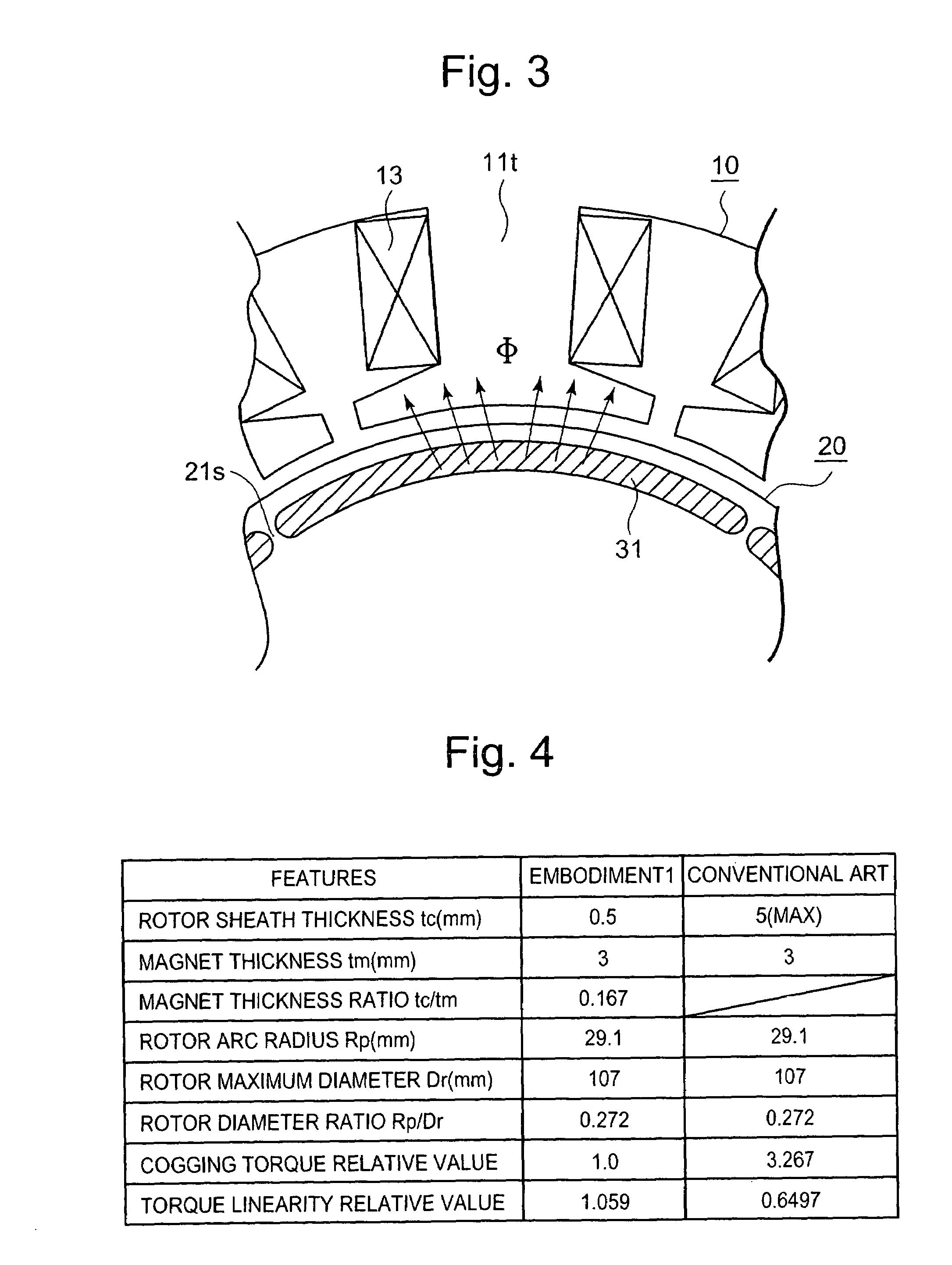

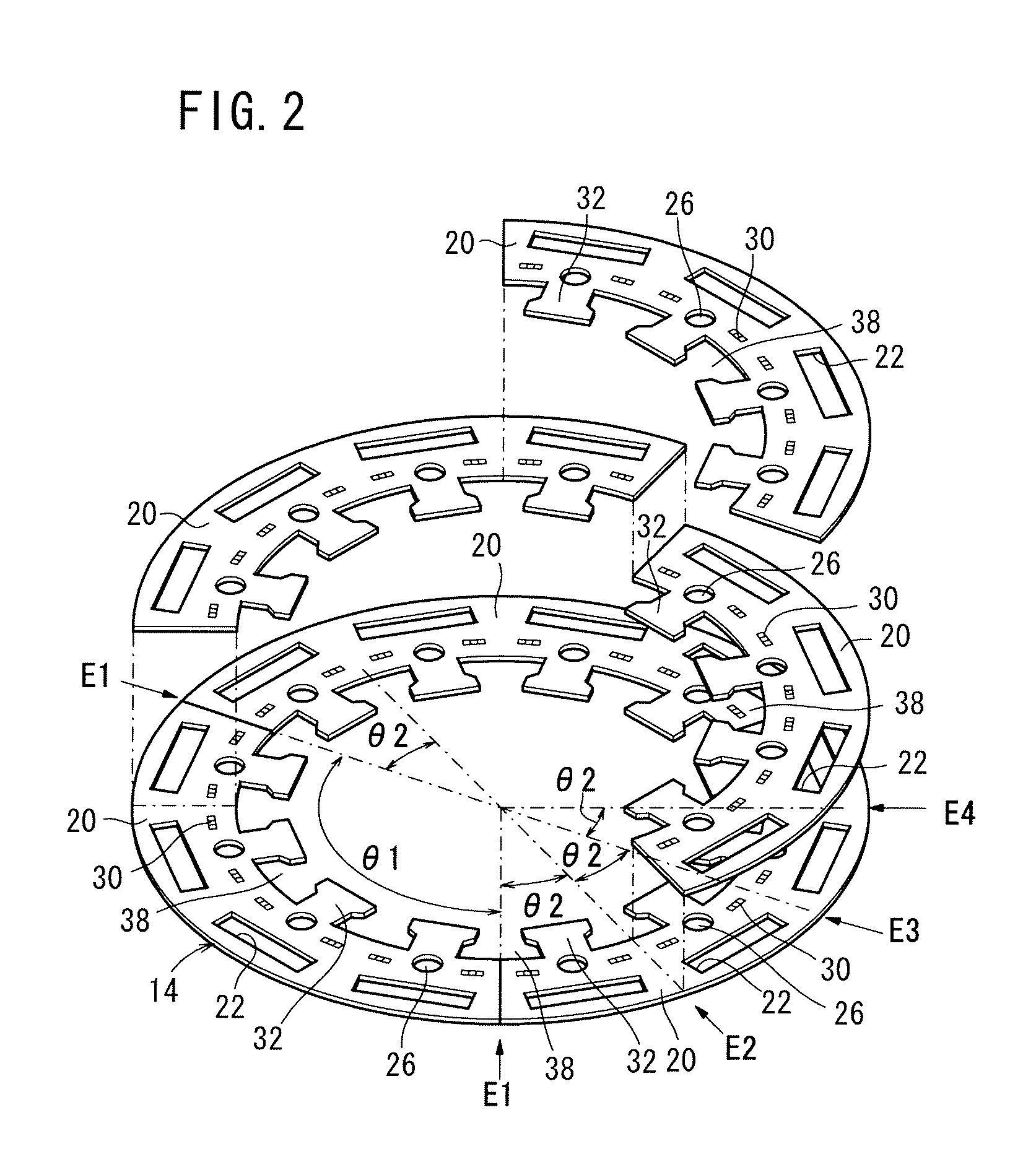

Permanent magnet type motor

InactiveUS20060131976A1Reducing cogging torqueCogging torque is smallMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPermanent magnet motor

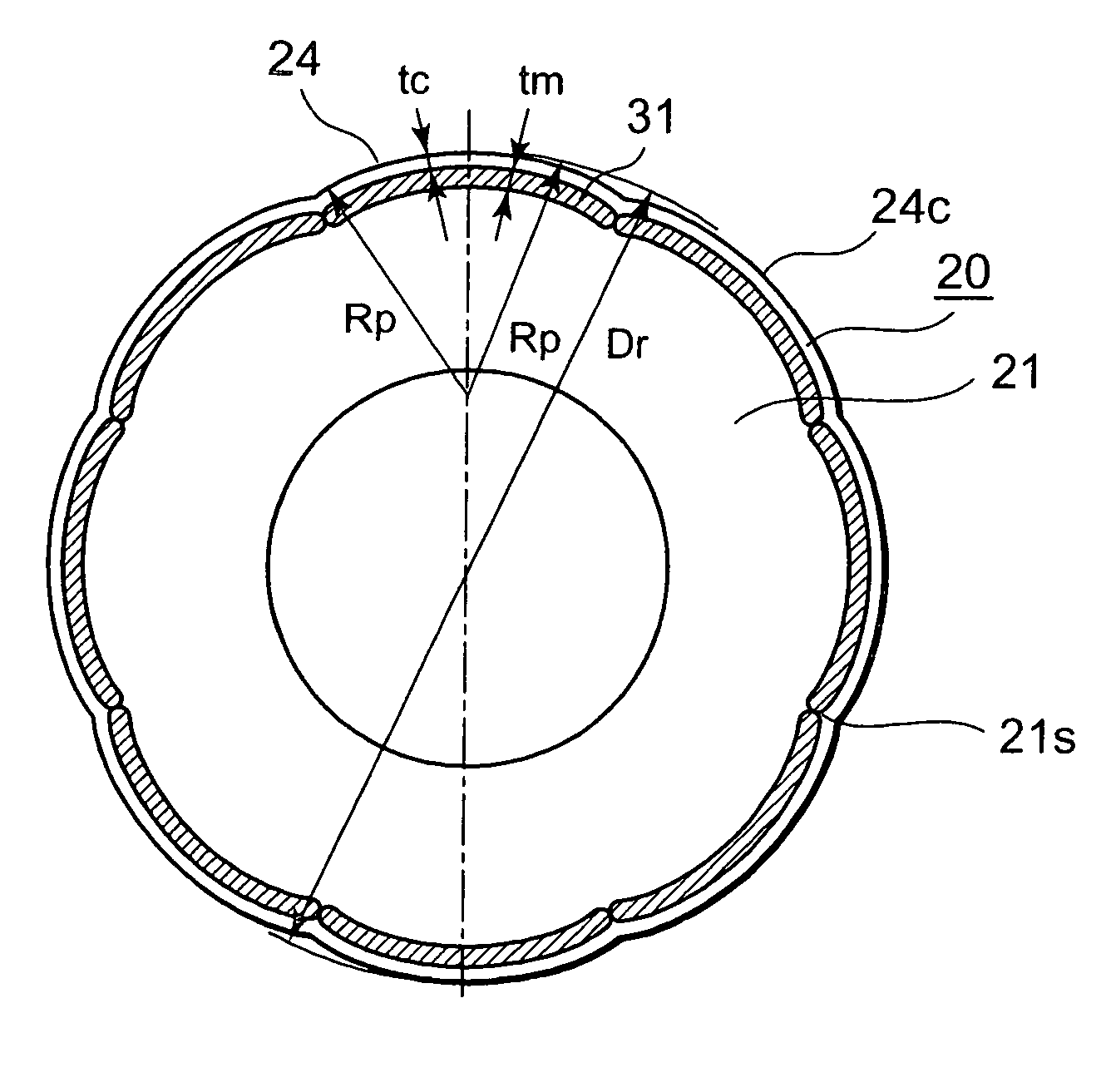

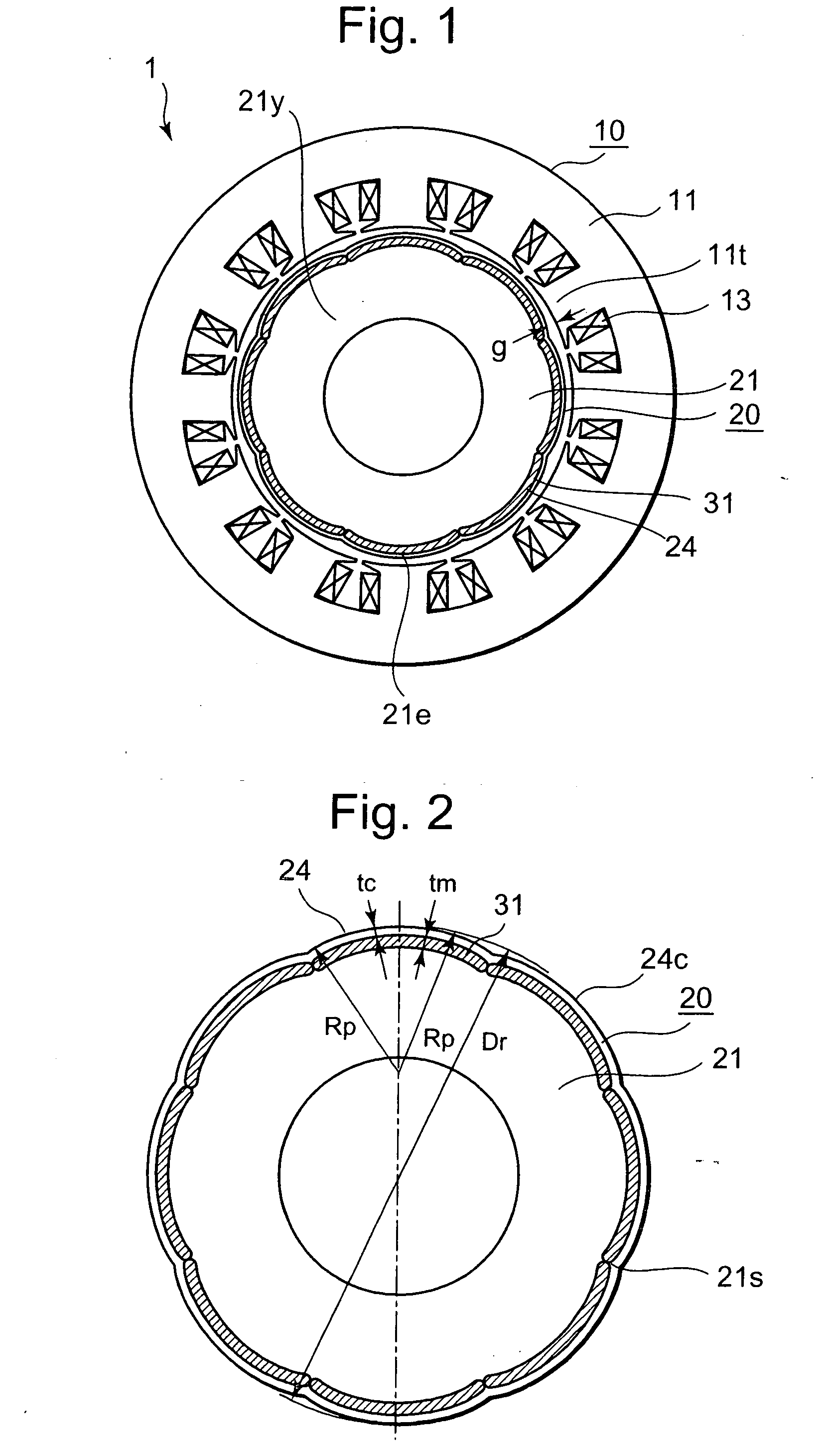

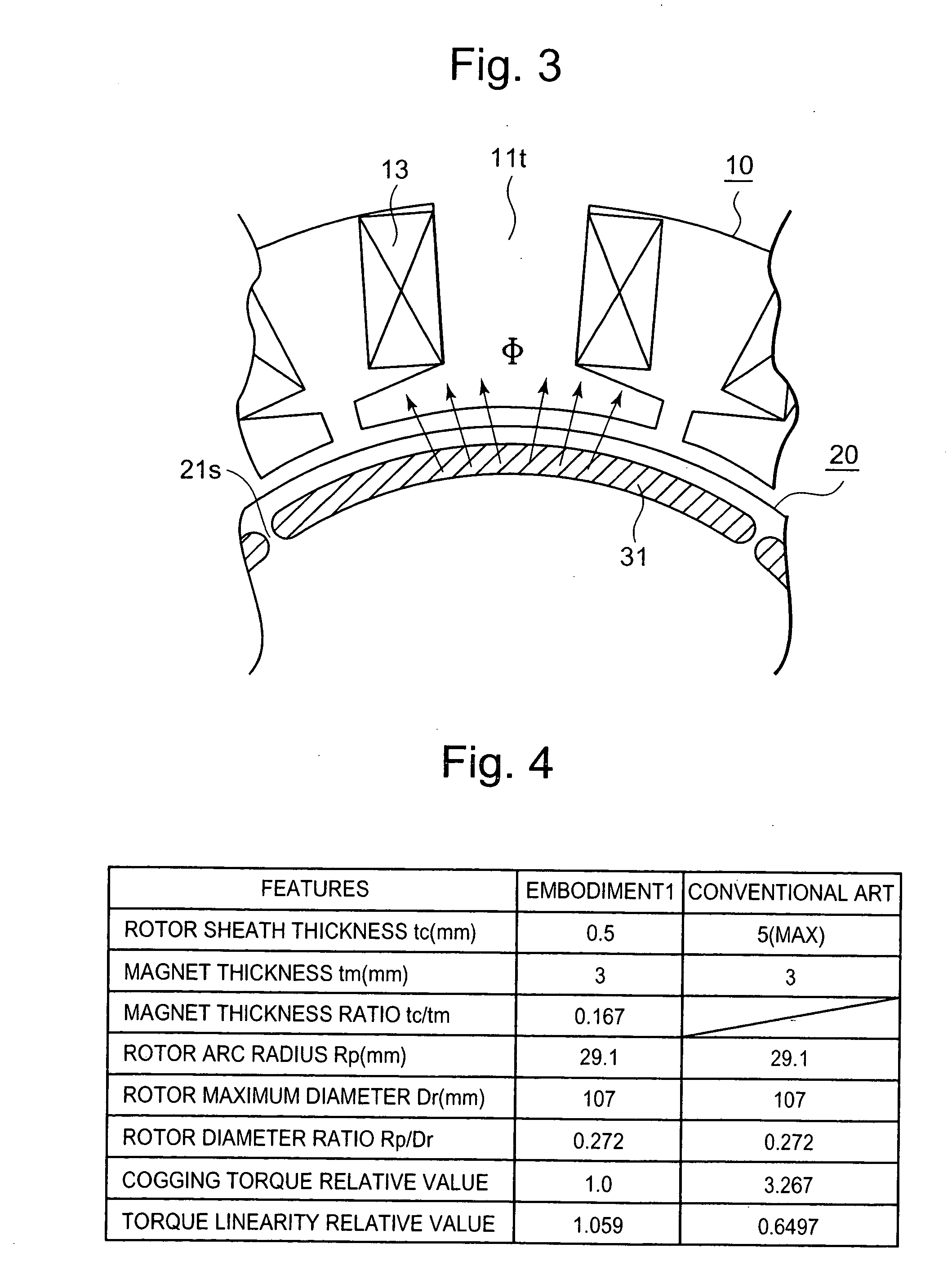

A permanent magnet motor 1 includes a rotor in which permanent magnets 31 are fixed. In the rotor 20, the outer peripheral shape of rotor magnetic-pole portions 24 is formed so that, in the circumferentially central portion, the distance from the center of the rotor iron core 21 is longest, and, at the inter-polar space, the distance from the center of the rotor iron core is shortest, and so that the outermost surface of the rotor magnetic-pole portions 24 forms an arc, and given that sheath thickness tc formed by the outer-side surface of each permanent magnet 31 and the outermost surface of each rotor magnetic-pole portion 24 is practically constant, and letting the thickness of the permanent magnets be the magnet thickness tm, then the relation tc / tm≦0.25 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

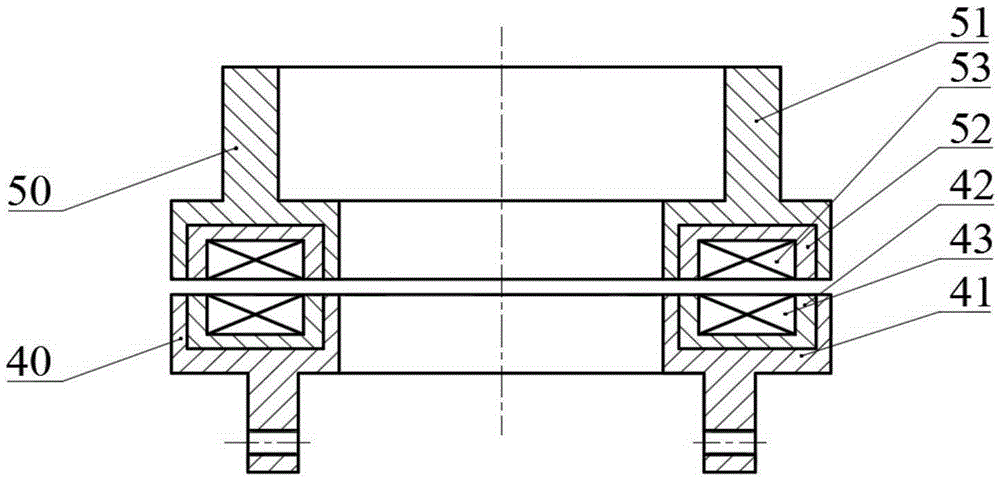

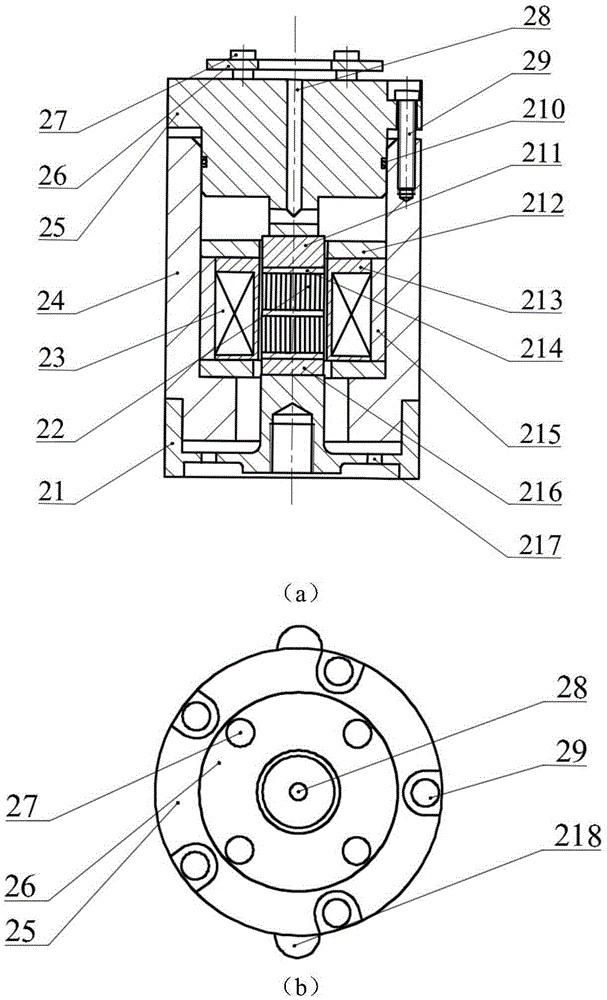

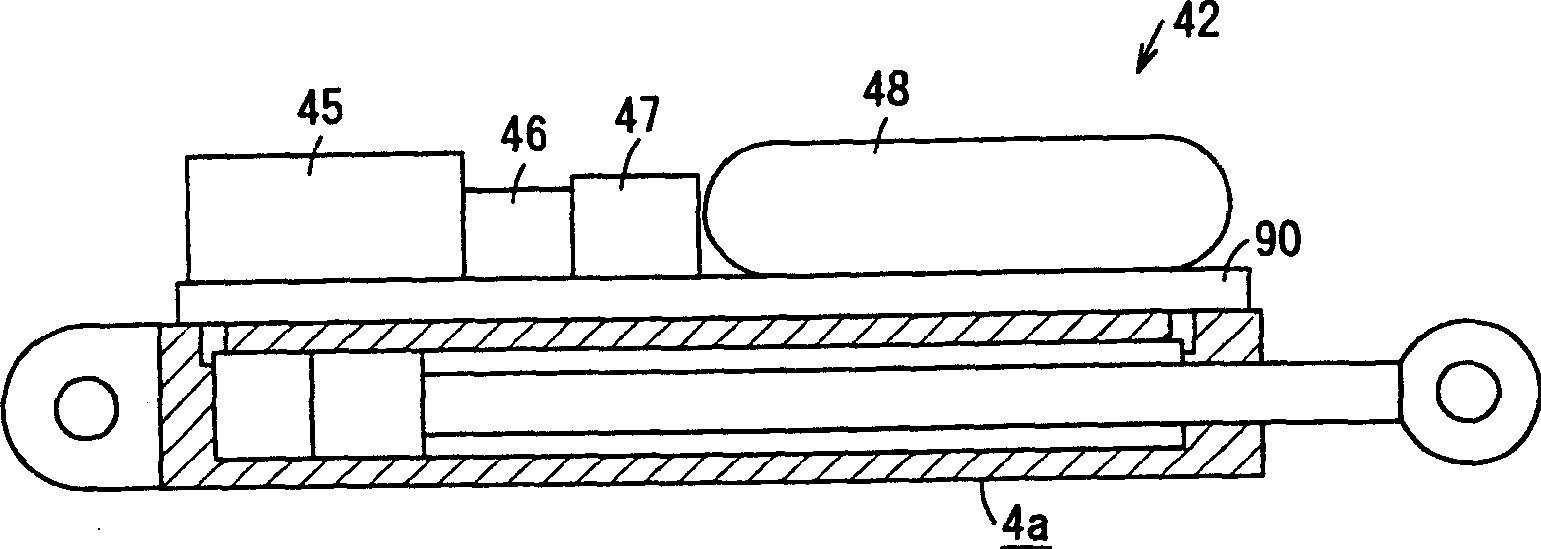

Giant magnetostrictive rotary ultrasonic vibration knife handle

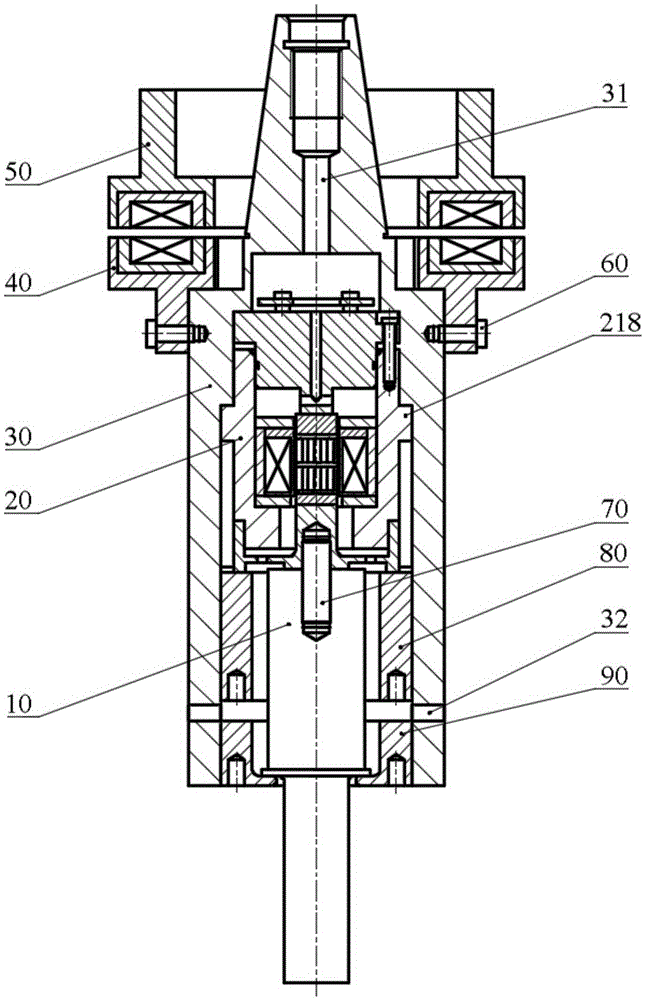

ActiveCN105397920AHigh magnetostriction coefficientIncrease output powerMechanical vibrations separationStone-like material working toolsTransducerAir cooling system

The invention relates to a giant magnetostrictive rotary ultrasonic vibration knife handle and belongs to the technical field of ultrasonic precise special machining. The knife handle comprises an amplitude-change pole, a giant magnetostrictive ultrasonic transducer, a hollow knife handle body, an auxiliary side component, a primary side component and a threaded pressing block, wherein the giant magnetostrictive ultrasonic transducer is connected with the amplitude-change pole through a threaded rod and installed in a cavity in the lower portion of the knife handle body; an ultrasonic vibrator formed by connecting the giant magnetostrictive ultrasonic transducer with the amplitude-change pole makes contact with the inner wall of the knife handle body, the lower end of the giant magnetostrictive ultrasonic transducer is tightly pressed onto the knife handle body through the threaded pressing block, and the threaded pressing block is connected with the knife handle body through threads; the lower end of the amplitude-change pole is tightly pressed through the threaded pressing block, and the threaded pressing block is connected with the knife handle body; the lower end of the auxiliary side component is fixed to the knife handle body through a screw, and the primary side component is fixed to the end face of a machine tool spindle. According to the giant magnetostrictive rotary ultrasonic vibration knife handle, the problem of heating of the transducer is effectively solved by means of a giant magnetostrictive material of a slice structure and an air cooling system. By the adoption of the knife handle, the machining efficiency can be improved. In addition, the knife handle can be suitable for any knife handle connection standards.

Owner:TSINGHUA UNIV

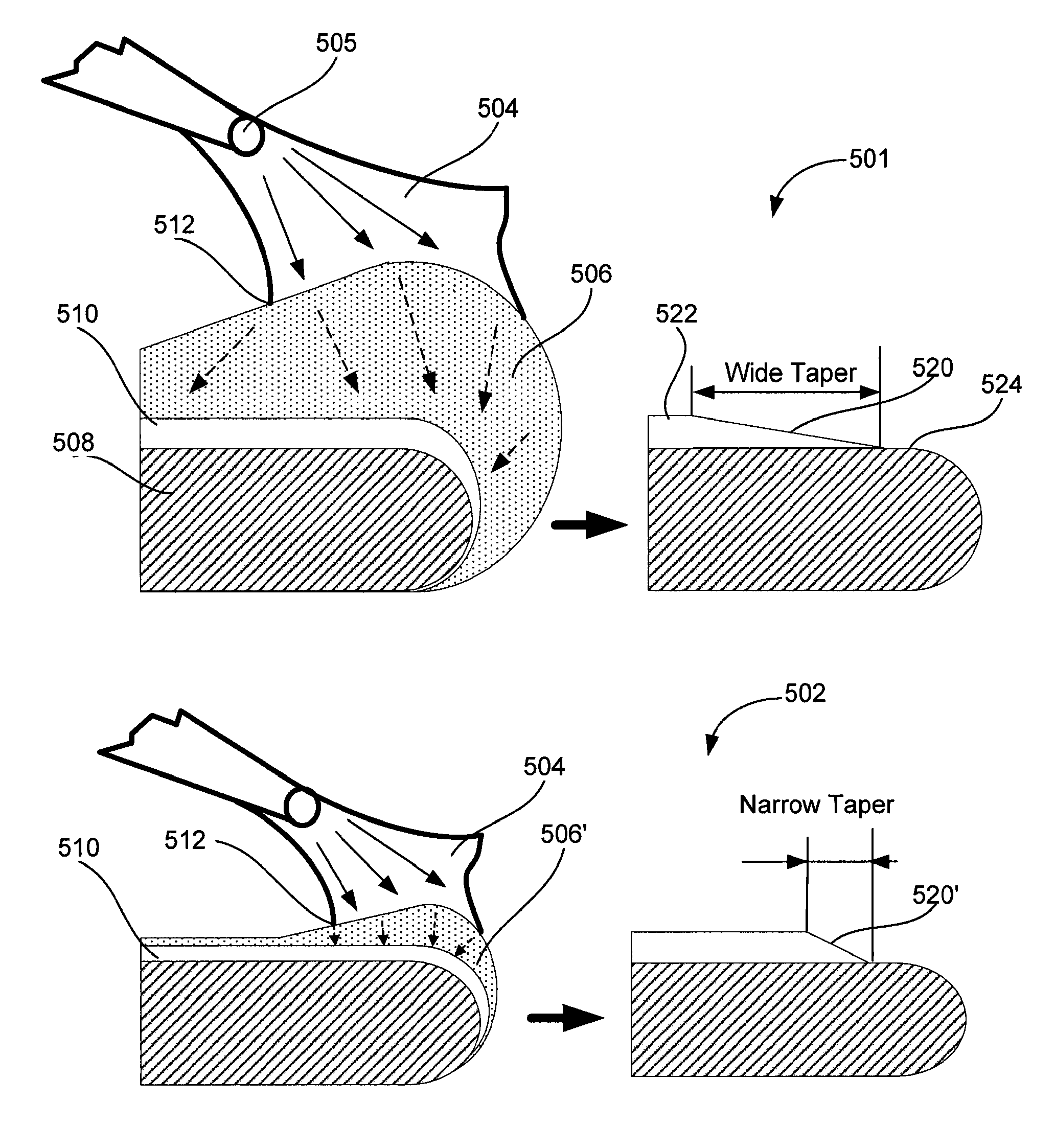

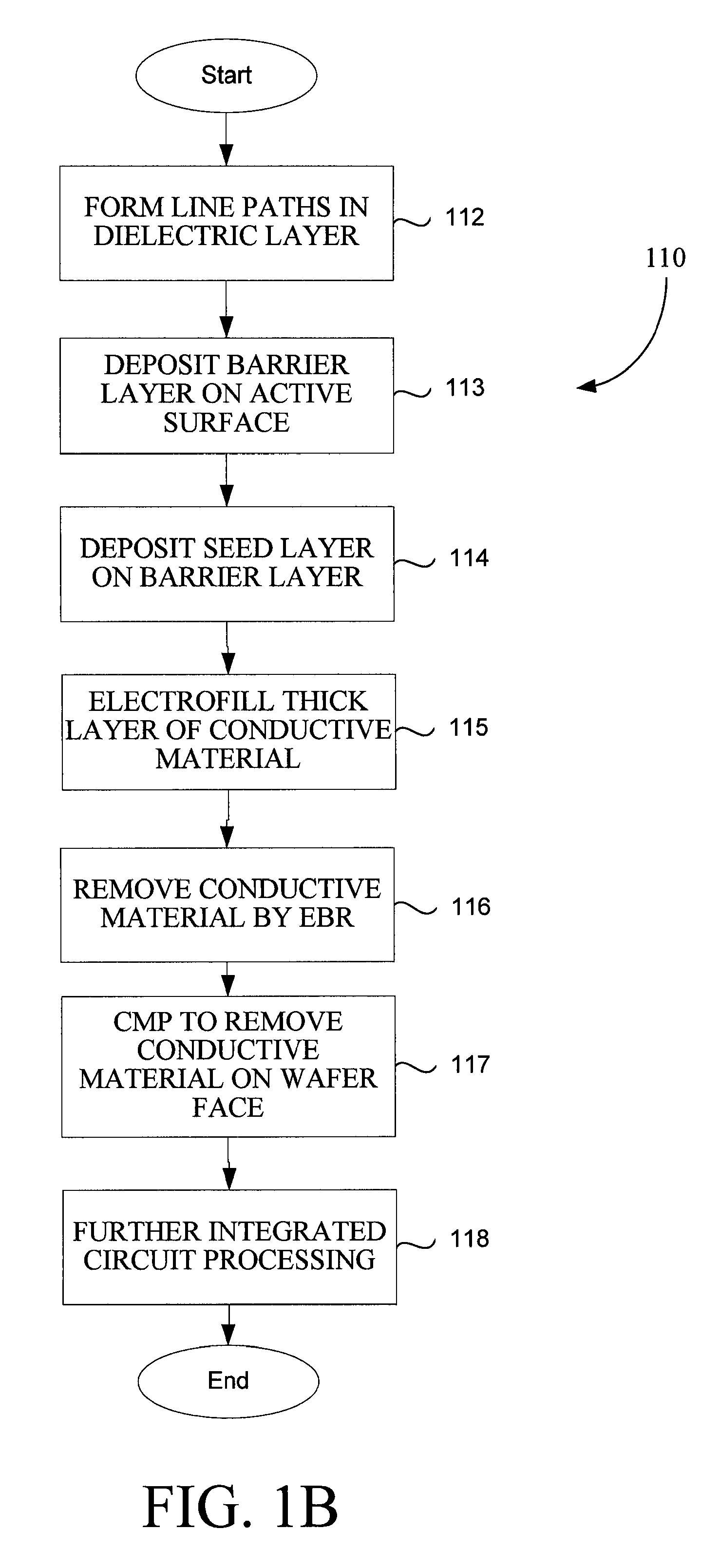

Apparatus and method for edge bevel removal of copper from silicon wafers

ActiveUS20100055924A1Facilitated DiffusionIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingLiquid layerThin layer

Chemical etching methods and associated modules for performing the removal of metal from the edge bevel region of a semiconductor wafer are described. The methods and systems provide the thin layer of pre-rinsing liquid before applying etchant at the edge bevel region of the wafer. The etchant is less diluted and diffuses faster through a thinned layer of rinsing liquid. An edge bevel removal embodiment involving that is particularly effective at reducing process time, narrowing the metal taper and allowing for subsequent chemical mechanical polishing, is disclosed.

Owner:NOVELLUS SYSTEMS

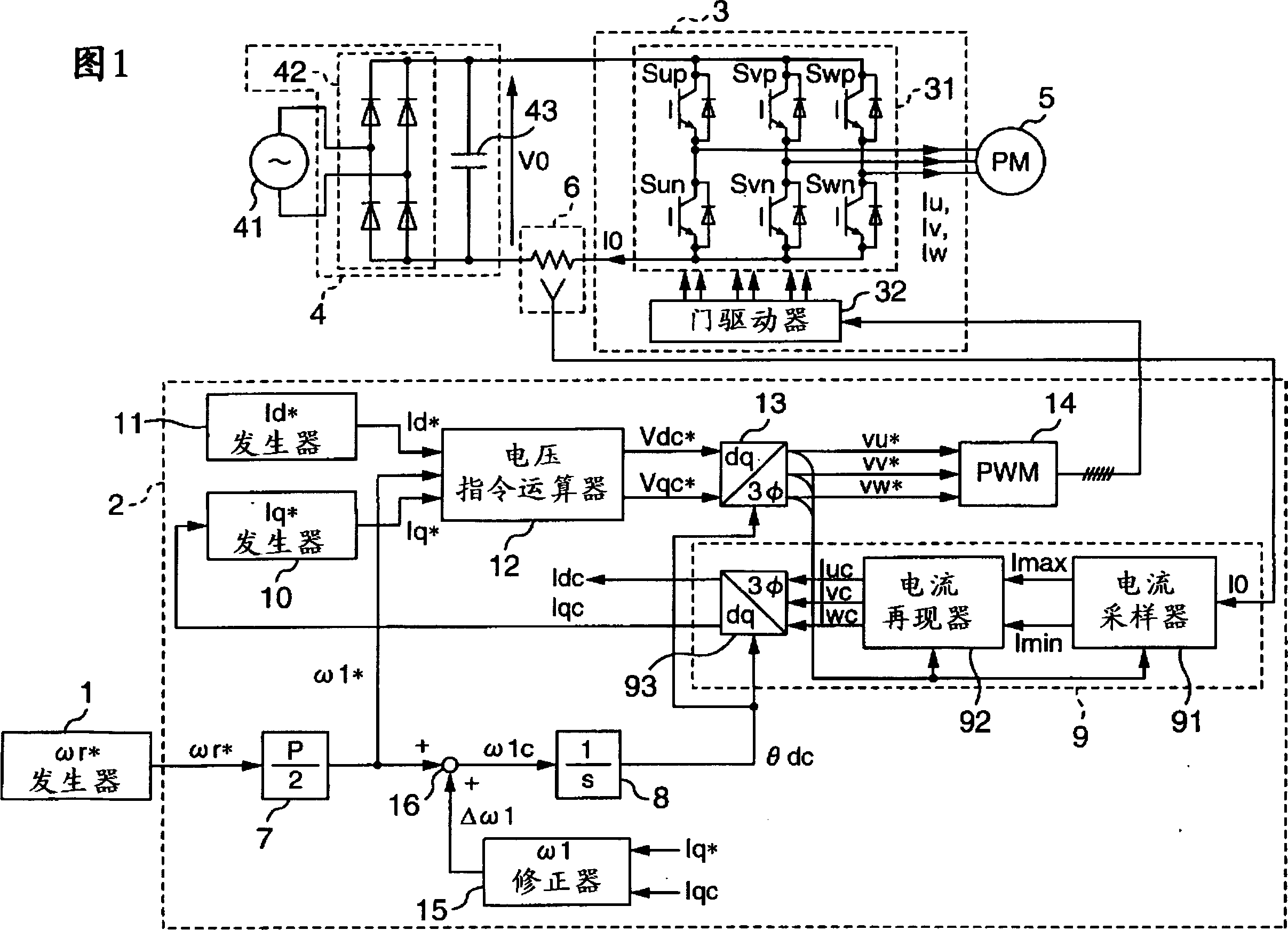

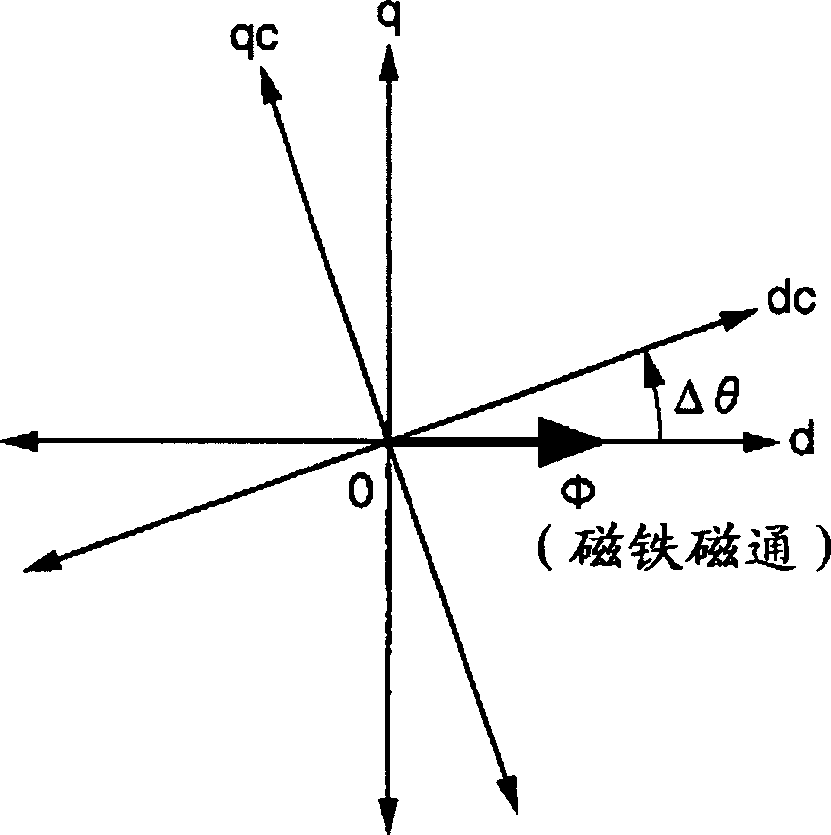

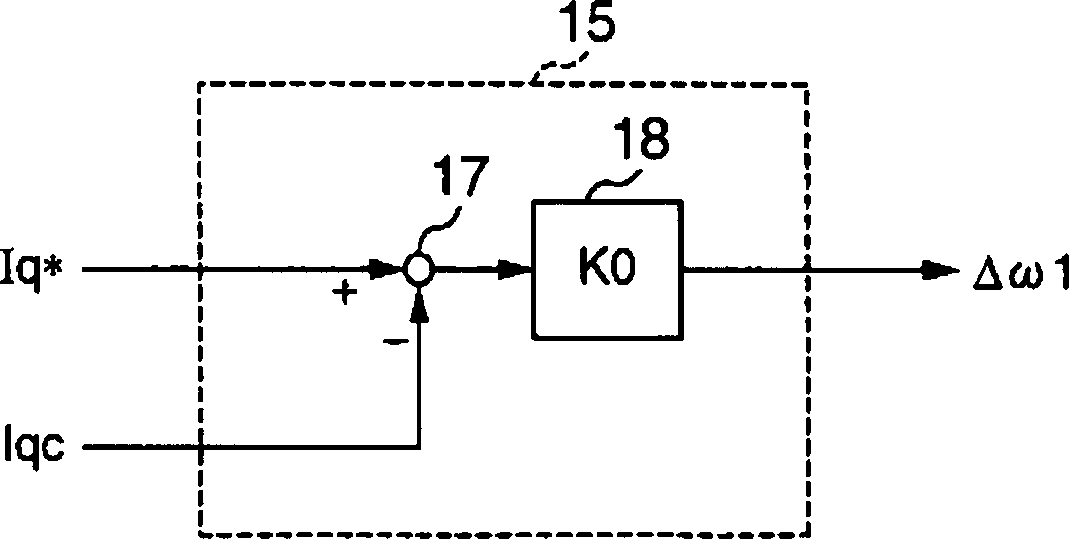

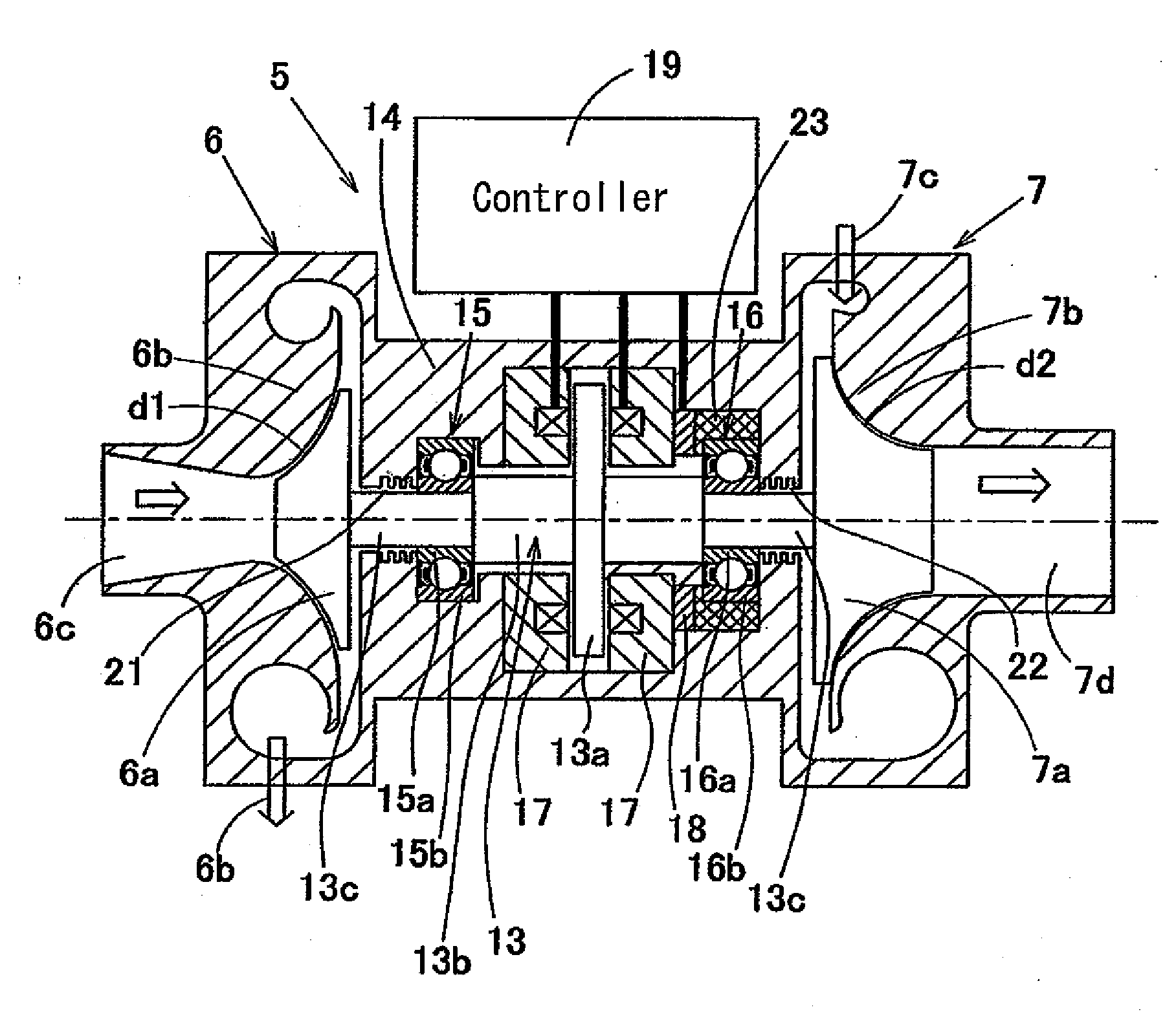

Speed controller for synchronous machine

ActiveCN1469542AStable and high-speed rotationSmooth rotationVector control systemsSingle motor speed/torque controlIntegratorPID controller

In order to rotate a motor stably at a high speed without using a magnetic pole position sensor and a current sensor, an electrical angle frequency command omega1* is calculated from a rotational number command omegar* and a correction value Deltaomega1 is calculated from a difference between Iq* and Iqc. omega1* and Deltaomega1 are added to calculate omega1c and omega1c is integrated by an integrator 8 to calculate an AC phase thetadc. A current I0 detected by a current detector 6 is sampled by a current sampler 91 and AC currents are reproduced by a current reproduction unit 3. The reproduced currents are coordinate-converted by a dq-coordinate conversion unit 93 on the basis of the AC phase thetadc to calculate Iqc, and Iq* is obtained by the Iq* generator 10 from Iqc. Applied voltage commands Vdc* and Vqc* are calculated by a voltage command calculator 12 on the basis of the Id*, Iq* and omega1 and three-phase AC voltage-commands vu* to vw* are obtained by a dq-reverse conversion unit 13 on the basis of the applied voltages. PWM signals are generated by a PWM generator 14 on the basis of the three-phase AC voltage commands to control the inverter 3 by the PWM signals.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

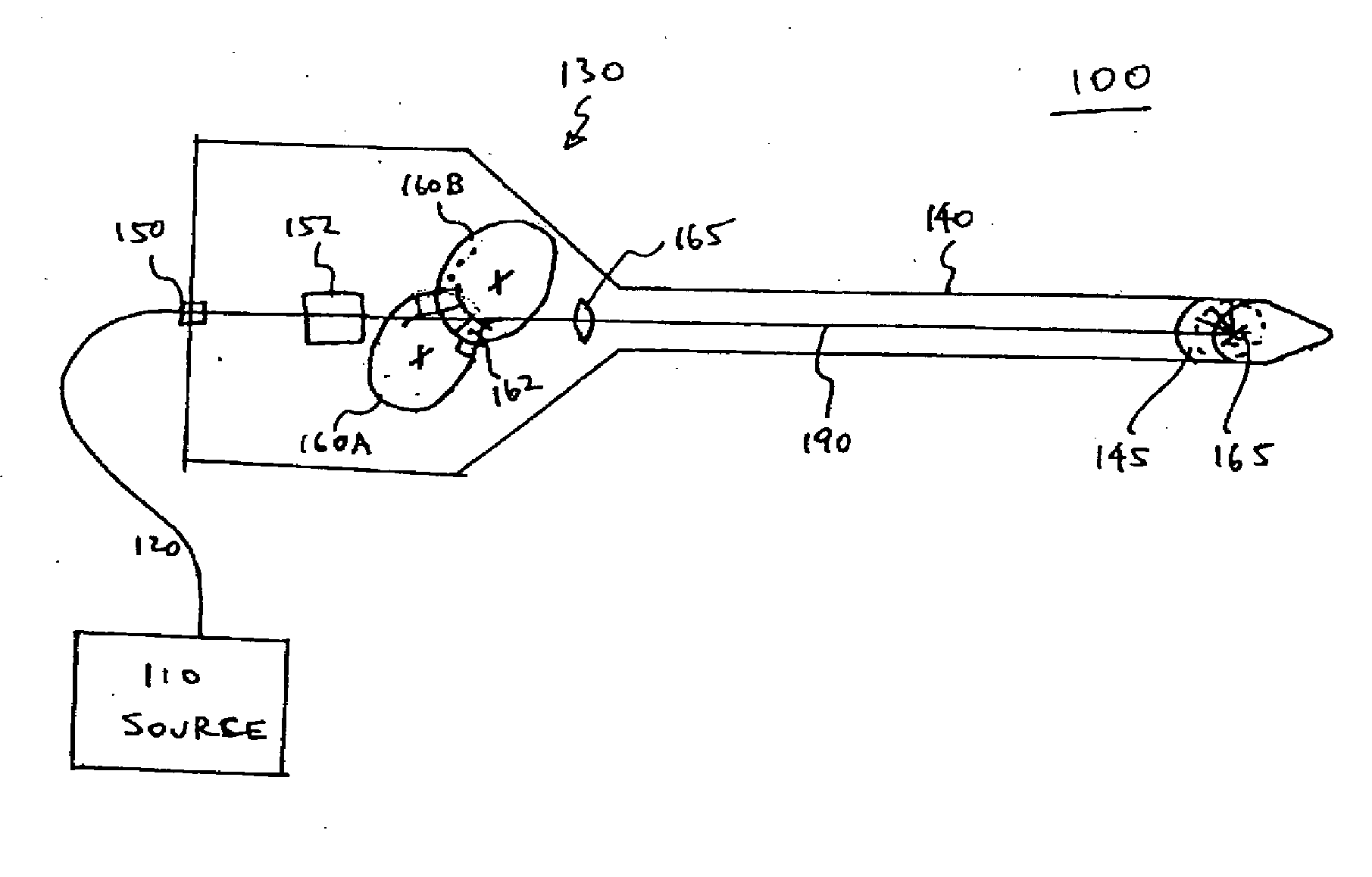

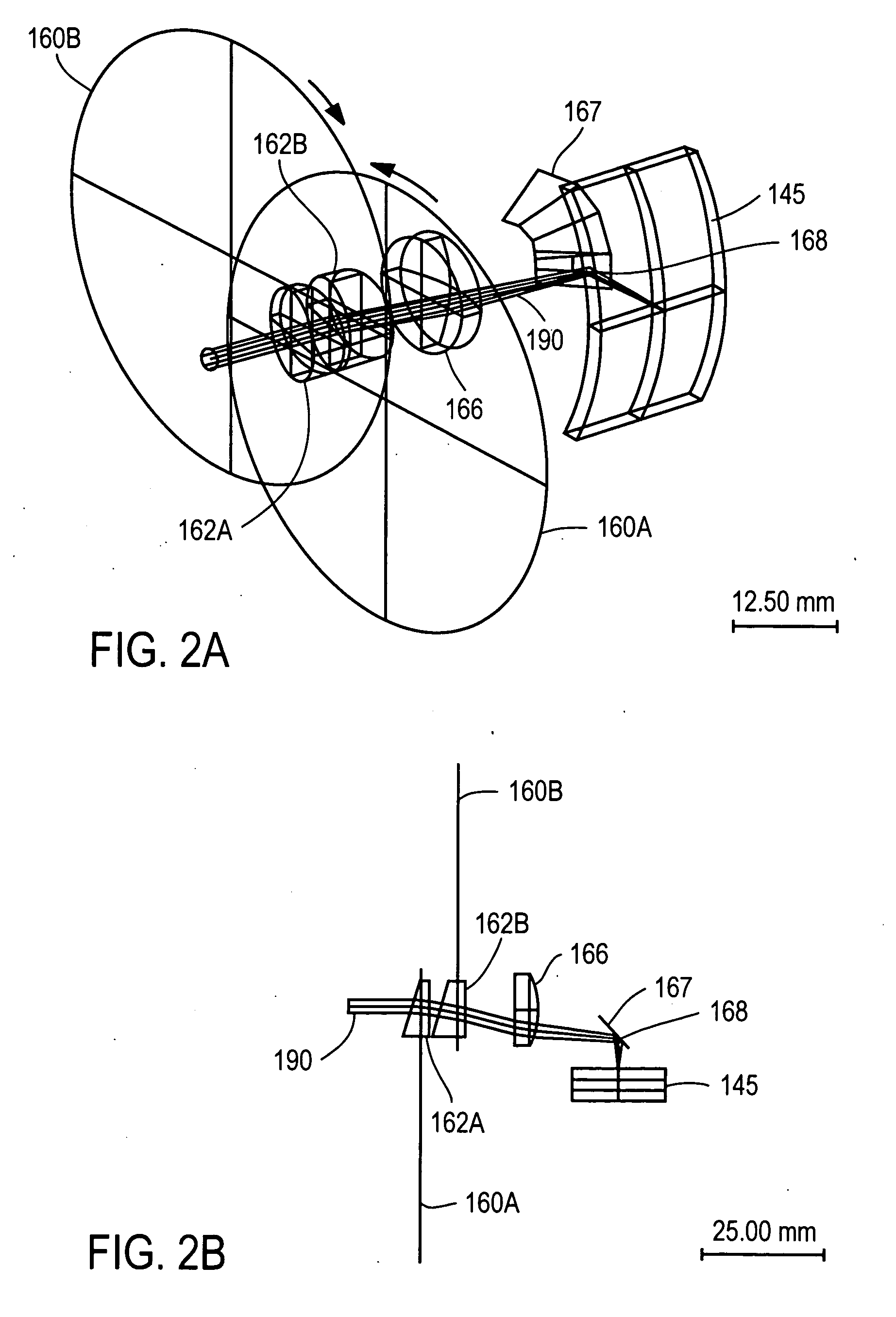

Optically-induced treatment of internal tissue

InactiveUS20060217695A1Increase speedFaster treatment timeMirrorsSurgical instrument detailsIrradiationTarget tissue

An optical beam is delivered to internal target tissue, for example via two counter-rotating disks or via a single rotatable component. In one approach, two counter-rotating disks deflect an incident optical beam in a manner that generates an irradiation pattern at the target tissue. In another approach, a rotatable component includes a plurality of deflection sectors arranged around a rotation axis, and each sector deflects an incident optical beam as the sector rotates through the beam to generate an irradiation pattern at the target tissue. A probe maintains an optical channel within the human body so that the deflected optical beam can be delivered to the target tissue.

Owner:RELIANT TECH INC

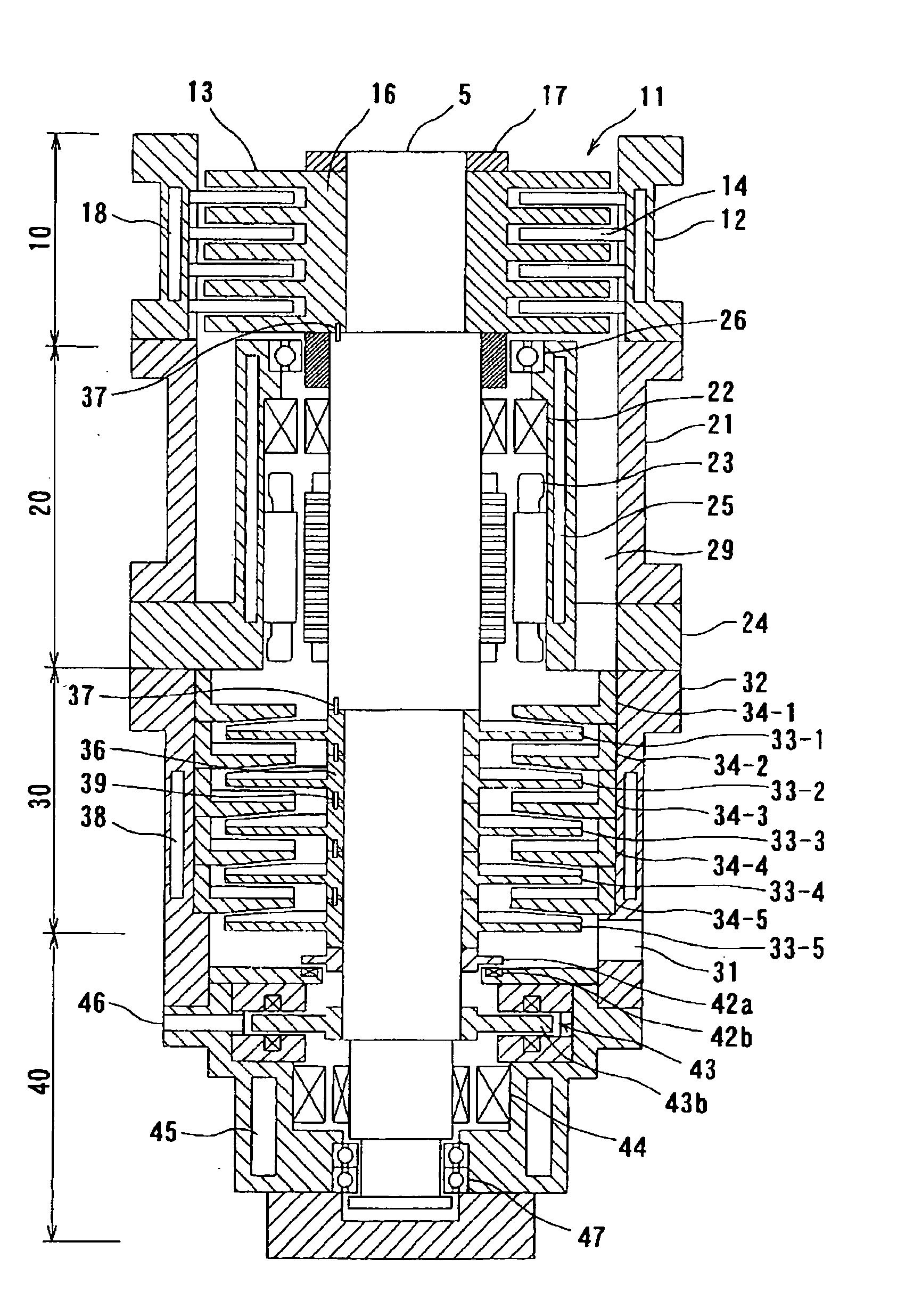

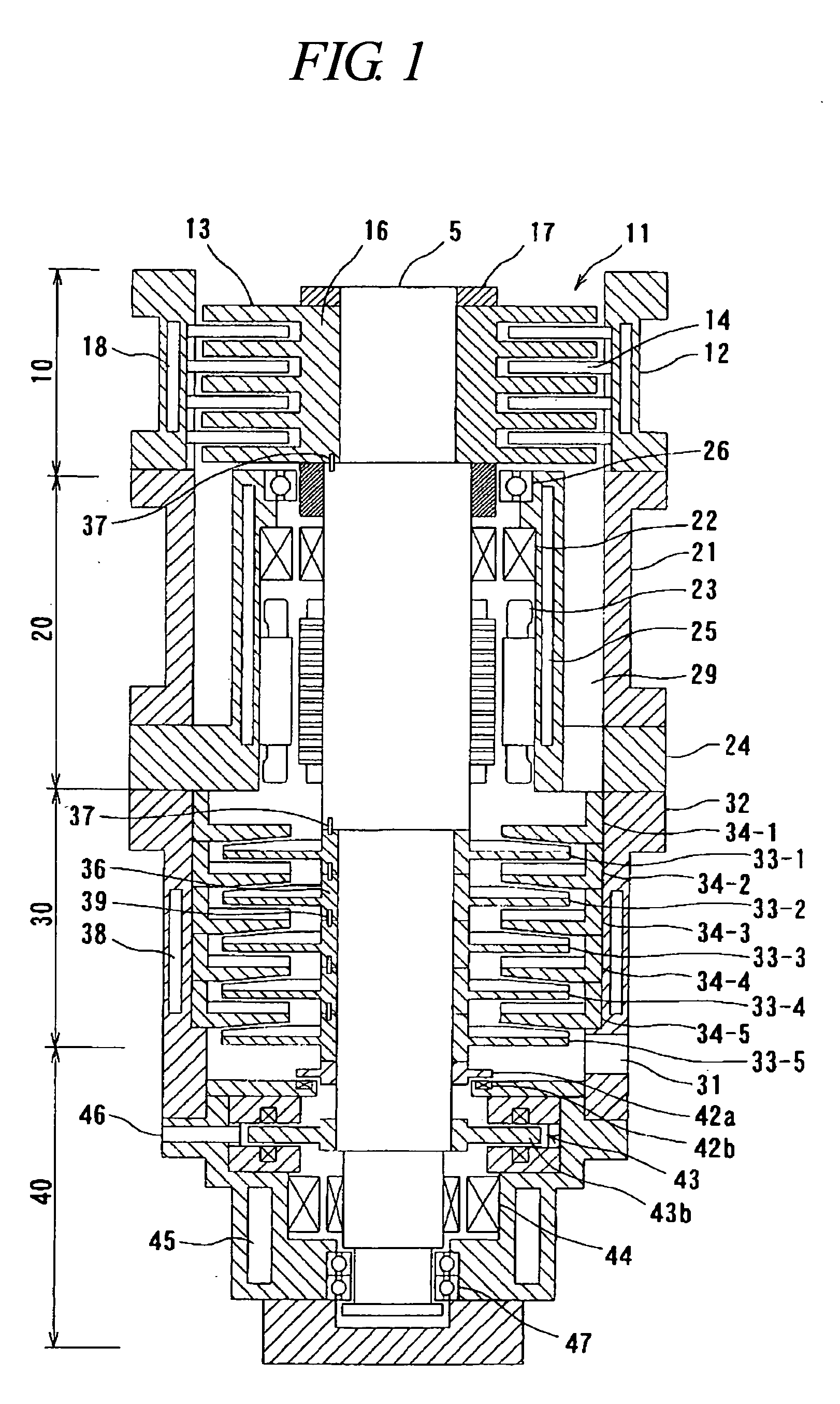

Vacuum pump and semiconductor manufacturing apparatus

InactiveUS20050025640A1Improve the exhaust effectIncreased durabilityPump componentsRotary non-positive displacement pumpsOil freeAtmospheric pressure

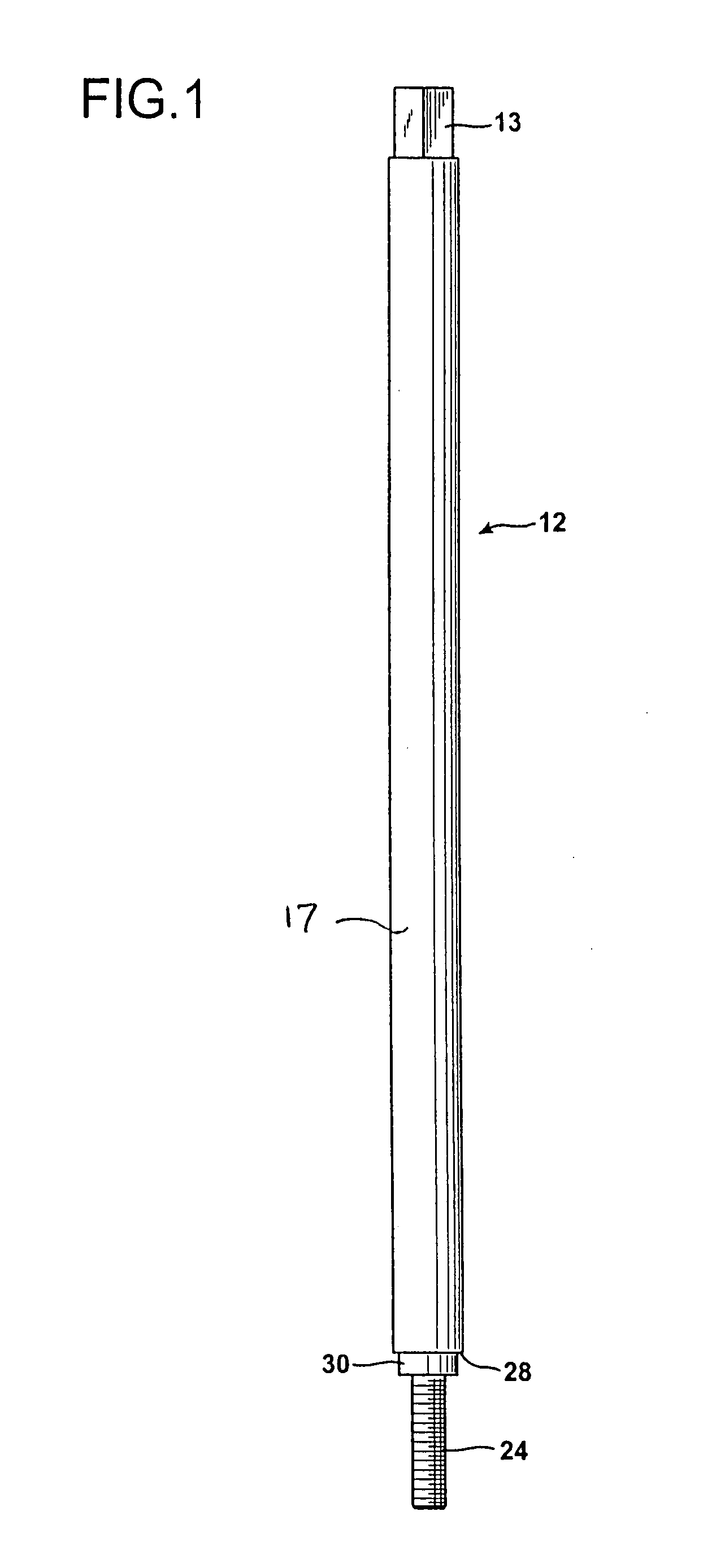

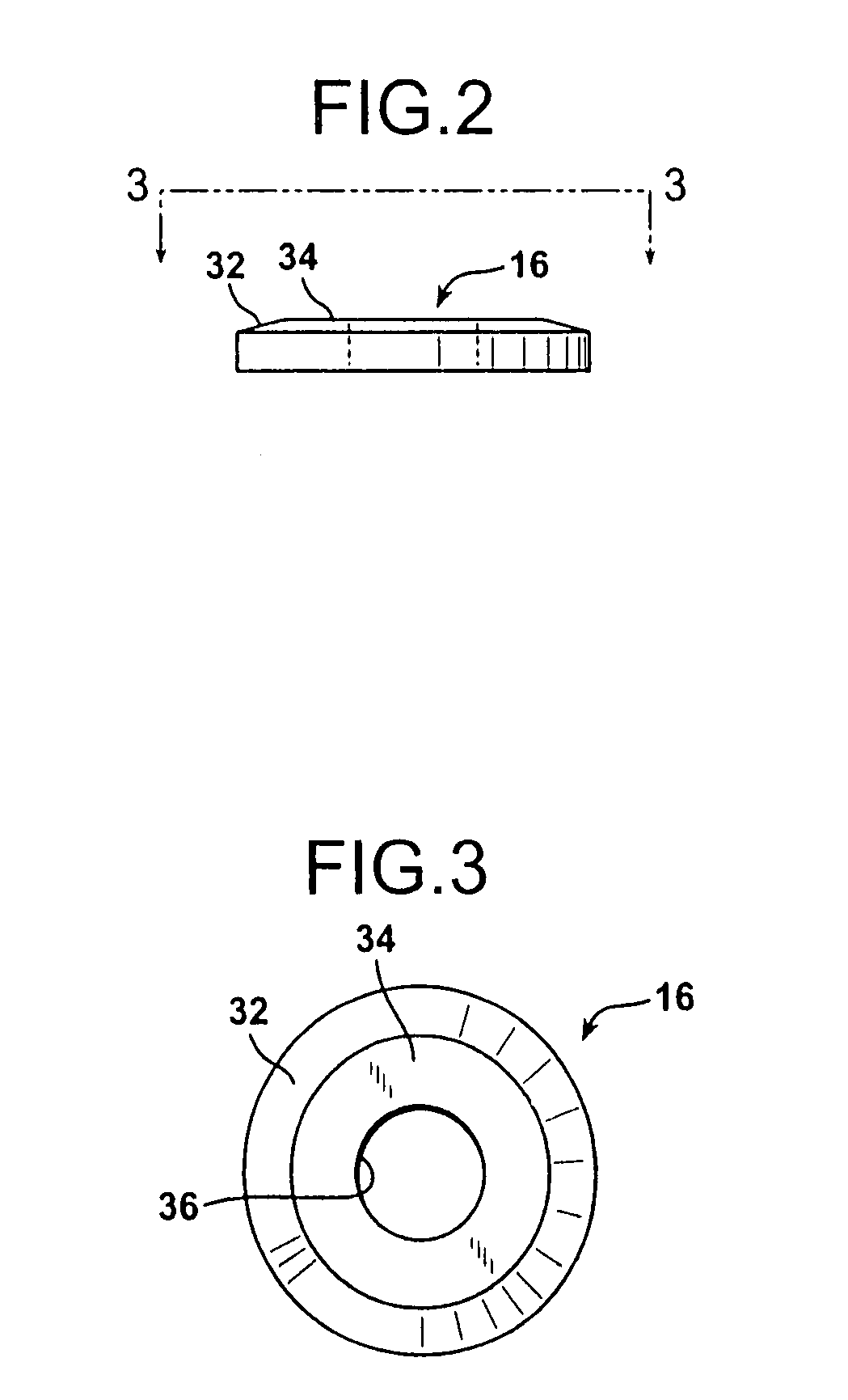

To provide a vacuum pump capable of evacuating in pressure ranges from an atmospheric pressure to a high vacuum, capable of rotating at a high speed to be downsized and improved in pumping performance, and capable of producing a completely oil-free vacuum. A vacuum pump for exhausting a gas comprises: a main shaft 5 rotatably supported by a bearing 22; a motor 23 for driving the main shaft 5 for rotation; a first exhaust section 10 having a first rotary vane 13 attached to the main shaft 5, a first fixed vane 14 fixed in a first casing 12, and an intake port 11; and a second exhaust section 30 having a second rotary vane 33 attached to the main shaft 5, a second fixed vane 34 fixed in a second casing 32, and an exhaust port 31. The intake port 11 is located in the vicinity of an end of the main shaft 5, and the first exhaust section 10, the bearing 22 and the second exhaust section 30 are arranged in this order axially along the main shaft 5.

Owner:EBARA CORP

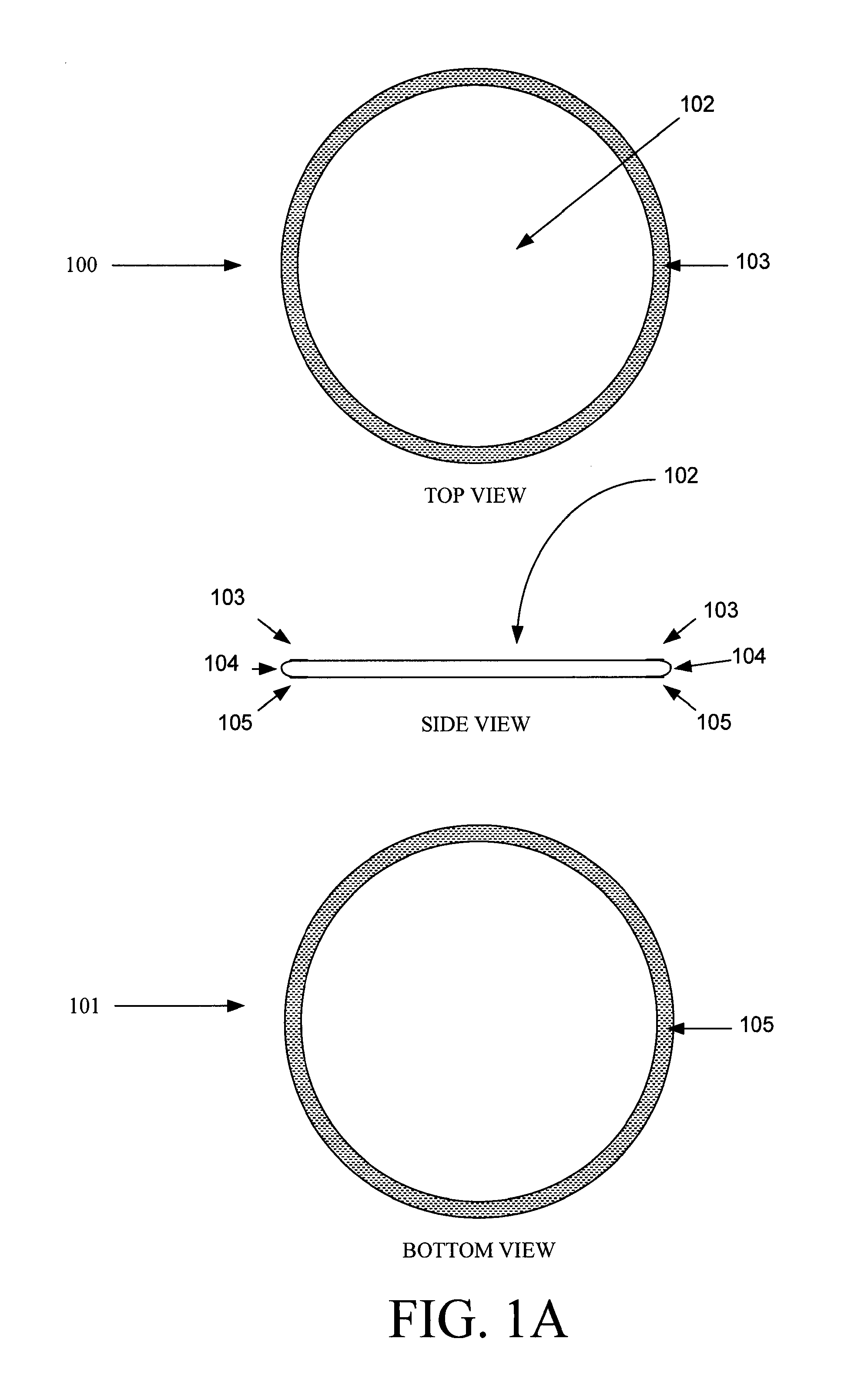

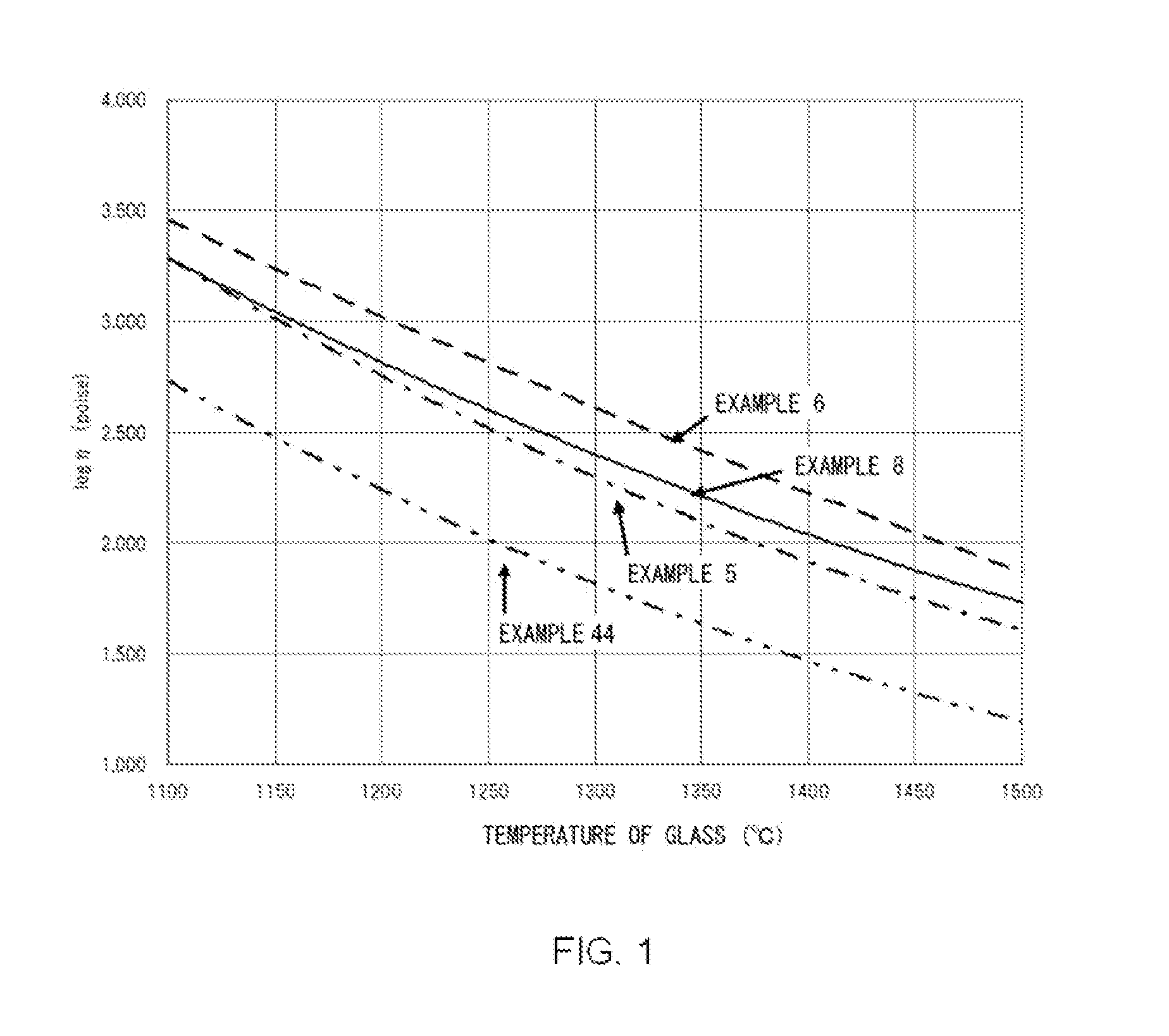

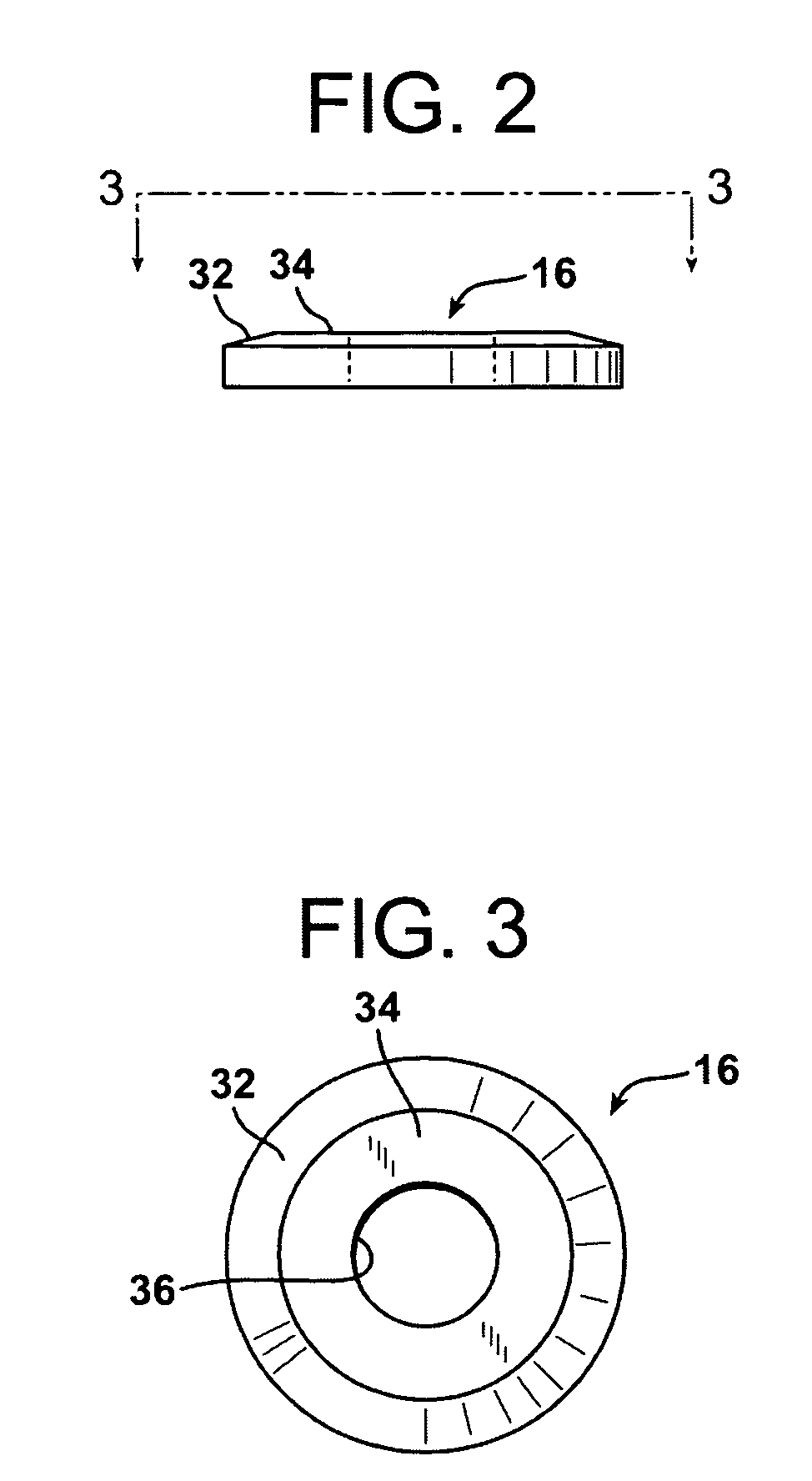

Glass substrate for information recording medium and method for producing the same

InactiveUS20100215993A1Improve balanceHighly smooth surface propertyMagnetic materials for record carriersBase layers for recording layersDrop impactYoung's modulus

There is provided a glass substrate which has the properties required in the use as a substrate for an information recording medium of the next generation such as a perpendicular magnetic recording system, and can be applied as a substrate for an information recording medium of the next generation particularly on the premise of using the glass substrate in a dynamic environment. More particularly, there is provided a glass substrate for an information recording medium which has sufficiently high surface hardness, has a good balance between specific gravity and mechanical strength, and has high strength to withstand high speed rotation or drop impact, and which can be produced with a high productivity adequate for a direct press method, without the occurrence of bubbles in the glass blank or reboil upon pressing even if arsenic components or antimony components are not substantially used. A glass substrate for an information recording medium, includes, as expressed in terms of percent by mass on the oxide basis: 52 to 67% of SiO2, 3 to 15% of Al2O3, and 0.2 to 8% of P2O5, the glass substrate having a Young's modulus of 85 GPa or greater, a specific gravity of 2.60 or less, and a ratio of Young's modulus to specific gravity (Young's modulus / specific gravity) of 33.0 or greater.

Owner:OHARA

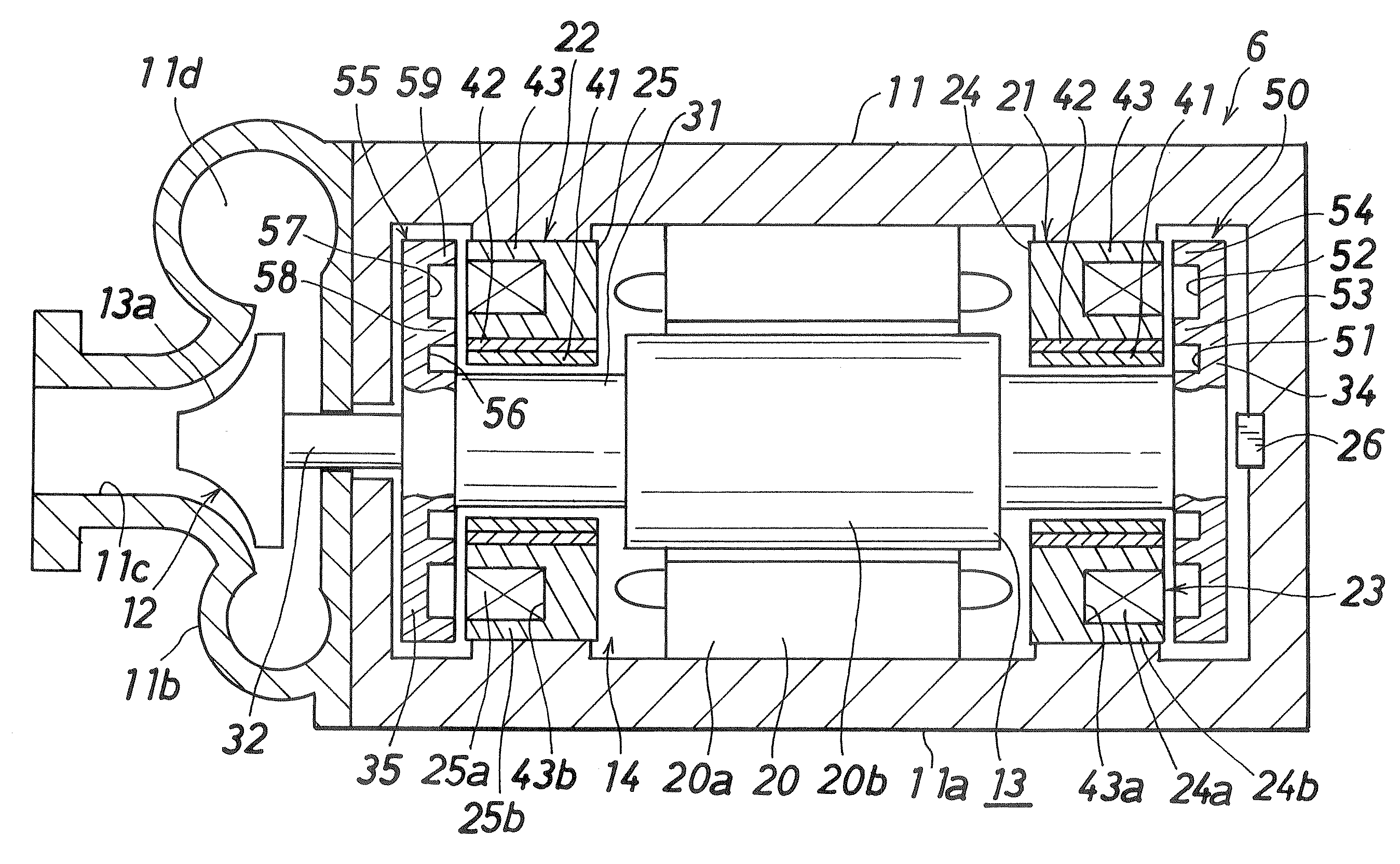

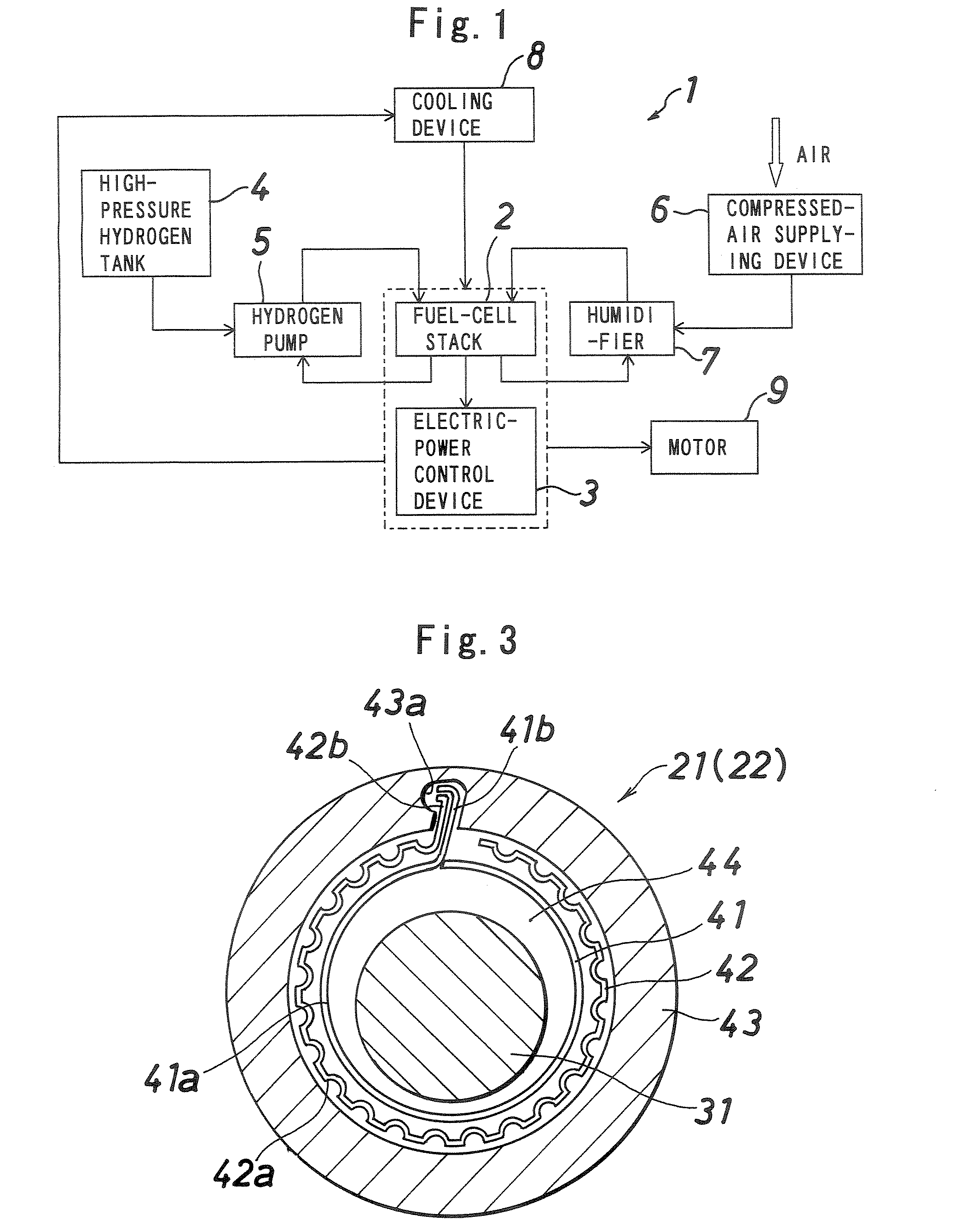

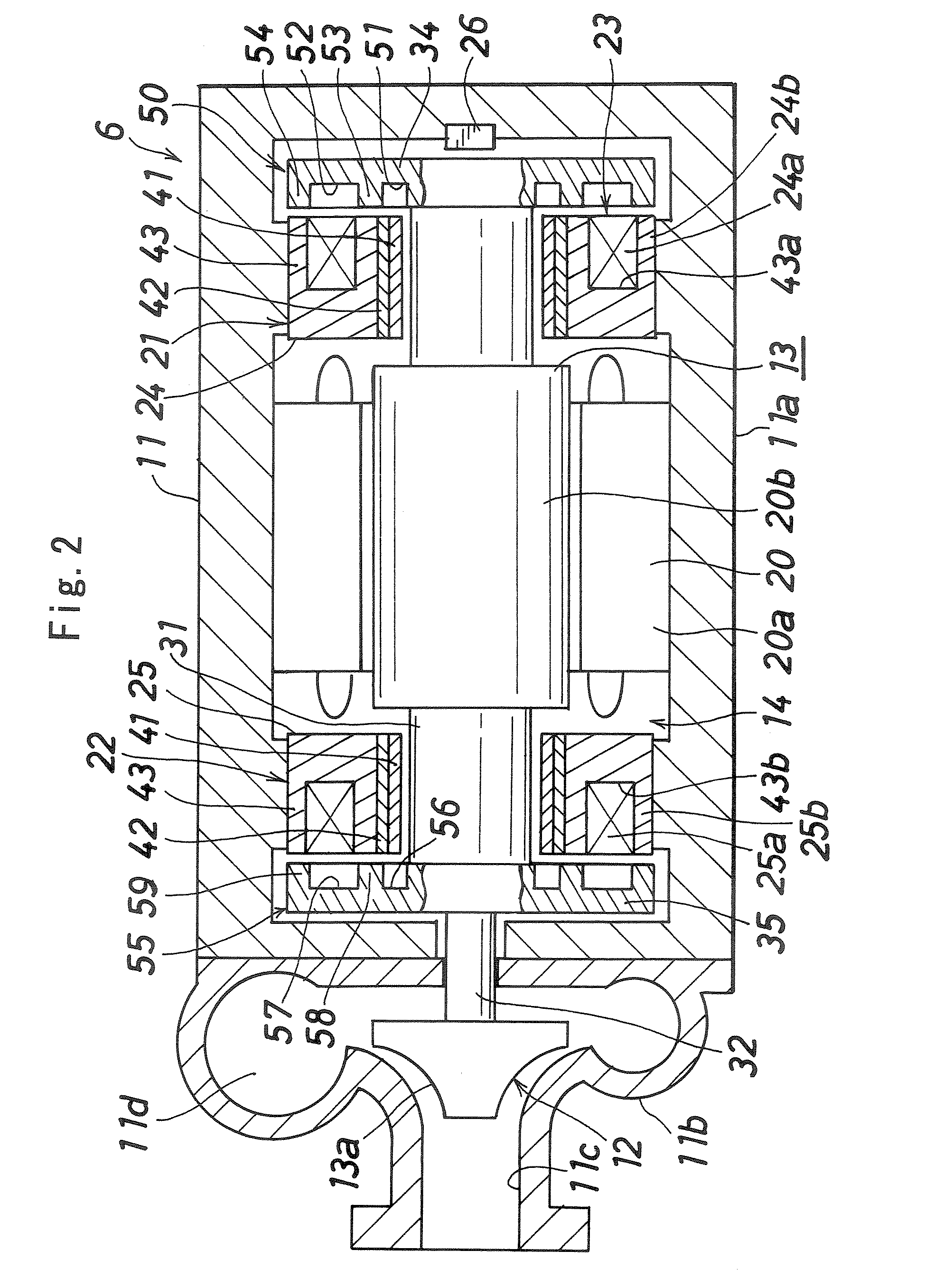

Fuel-cell compressed-air supplying device

A fuel-cell compressed-air supplying device 6 includes a centrifugal compressor 12 provided in a casing 11, and a bearing device 14 for supporting a rotation shaft 13 of the compressor 12. The bearing device 14 includes a pair of radial foil bearings 21 and 22 provided coaxially with the rotation shaft 13 for supporting the rotation shaft 13 in the radial direction, and an axial magnetic bearing 23 facing to the rotation shaft 13 in the axial direction for supporting the rotation shaft 13 in the axial direction. Axial electromagnets 24 and 25 of the axial magnetic bearing 23 are integrated with the radial foil bearings 21 and 22, respectively.

Owner:JTEKT CORP

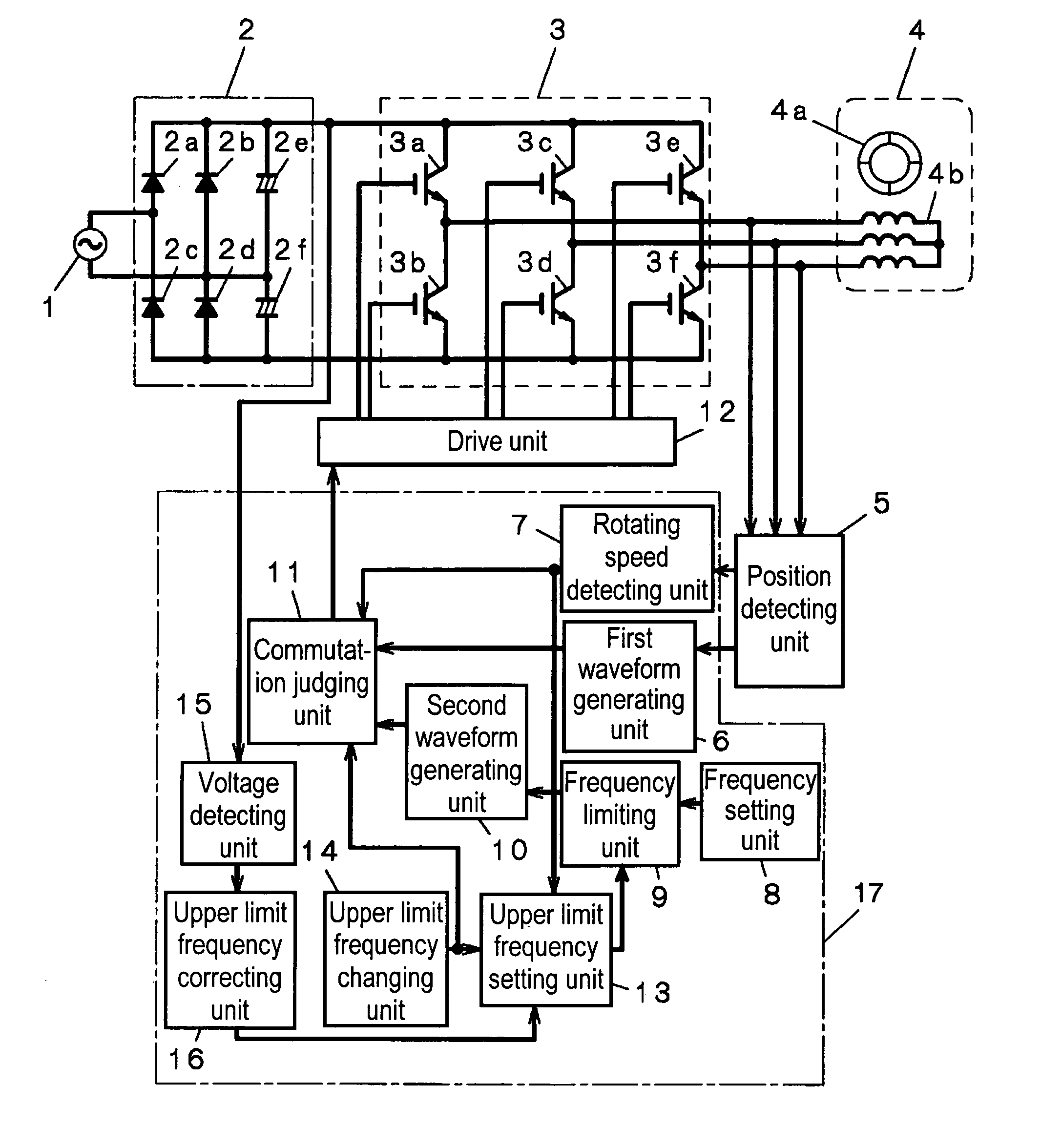

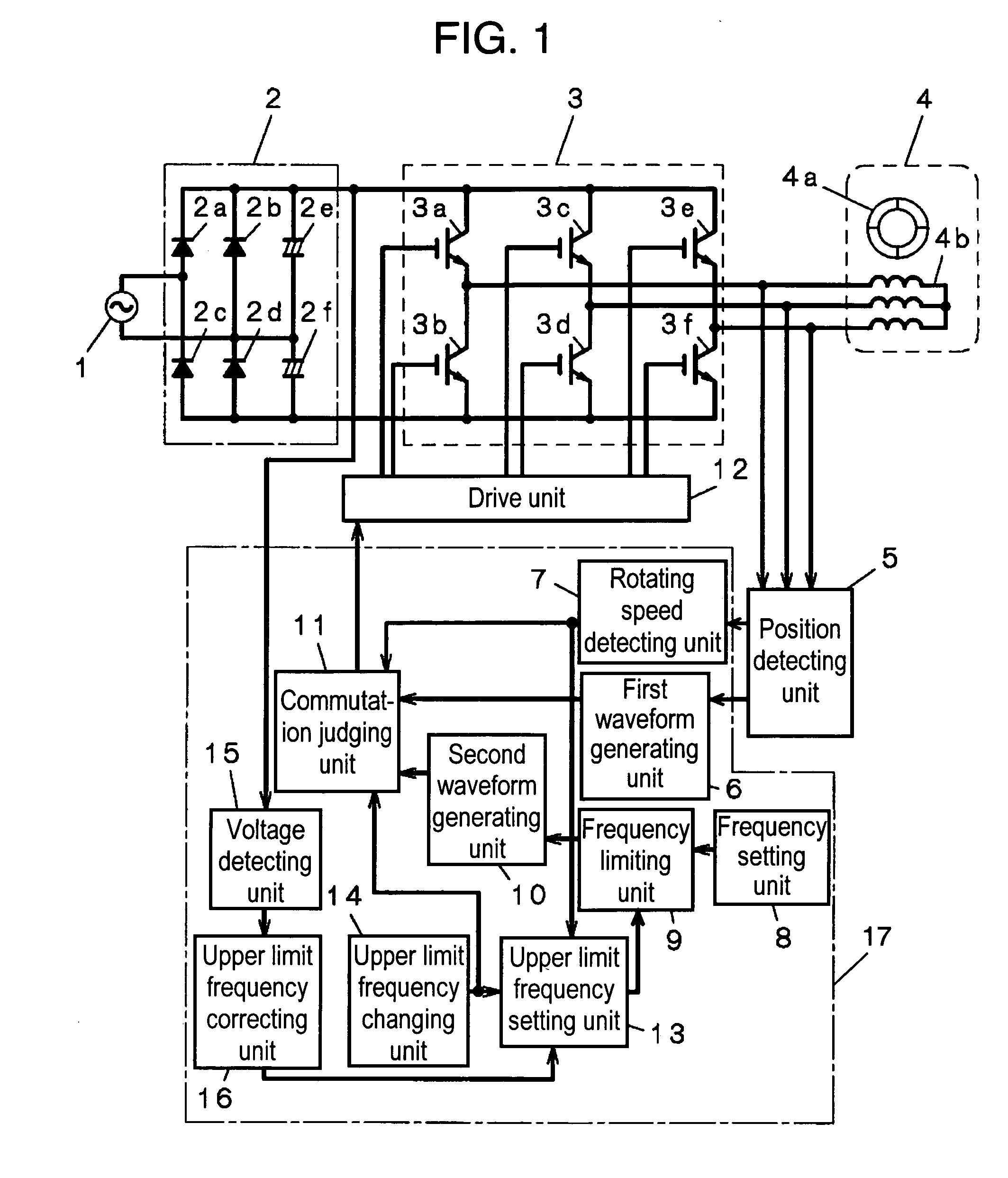

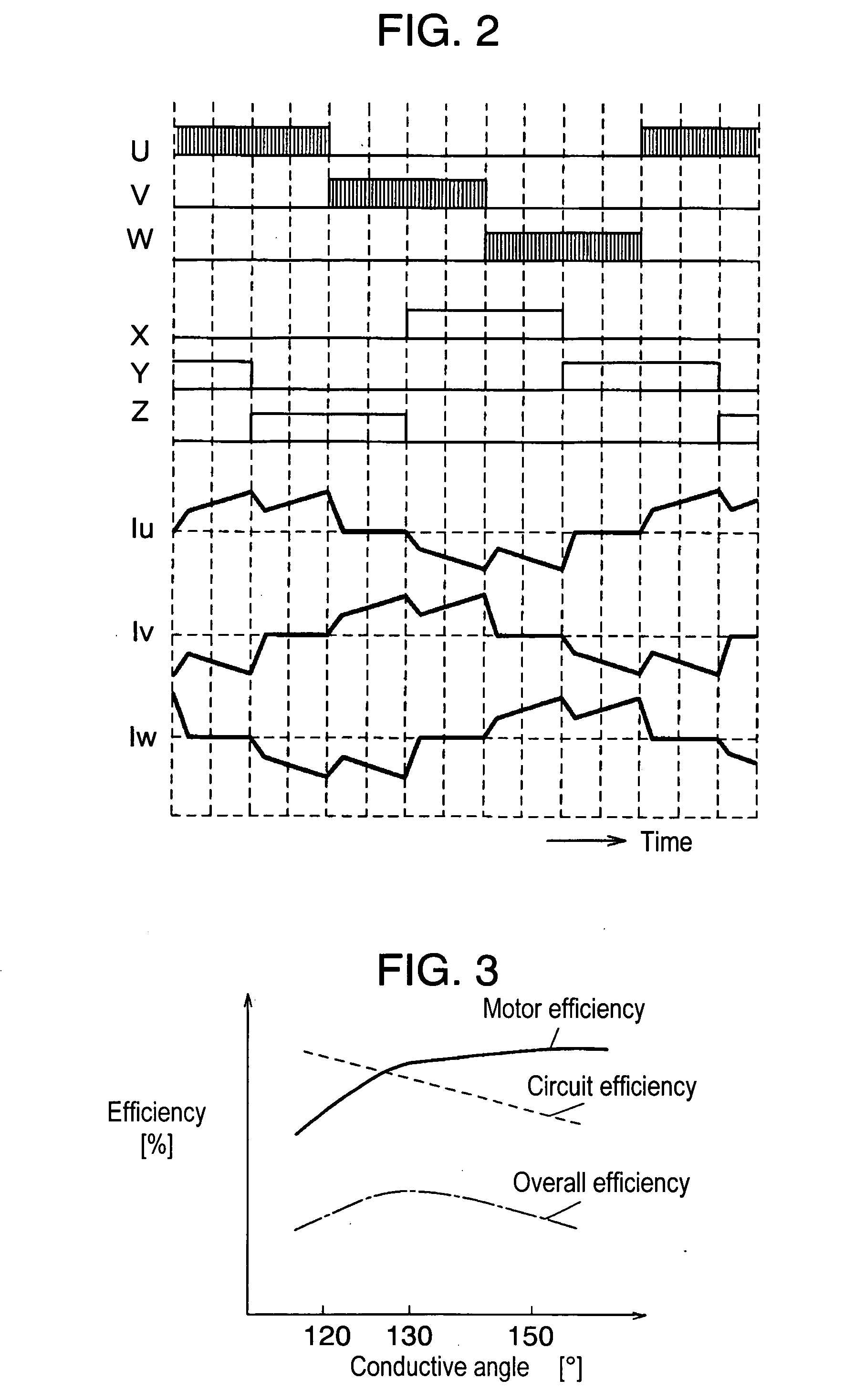

Brushless DC motor driving method and apparatus for it

ActiveUS20060082339A1Improve motor efficiencyHigh speed rotationTorque ripple controlSynchronous motors startersLow noiseLow speed

A rectangular wave or a waveform similar to the rectangular wave is output with an conductive angle no less than 120° but no more than 150° during low-speed operation, but output a rectangular wave, a sine wave or a waveform similar to them with an conductive angle no less than 130° but under 180° by changing the frequency only while maintaining the PWM duty constant at high-speed operation, making it possible to realize high-efficiency and low-noise operation at low-speed operation, secure stable high speed, and prevent peak current of effective current because the current waveform also comes closer to sine wave.

Owner:PANASONIC CORP

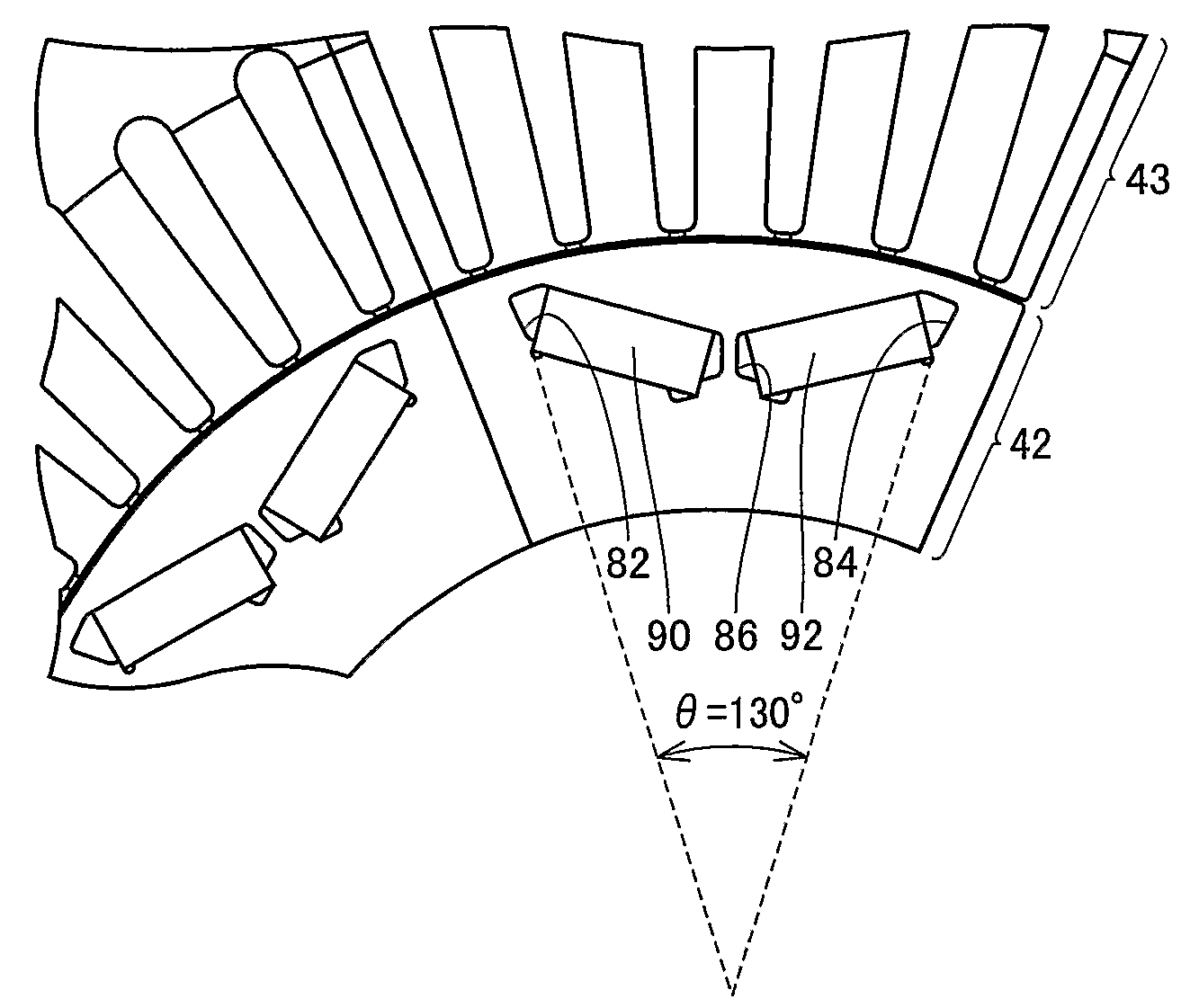

Rotor of Rotating Electric Machine, Rotating Electric Machine and Vehicle Drive Apparatus

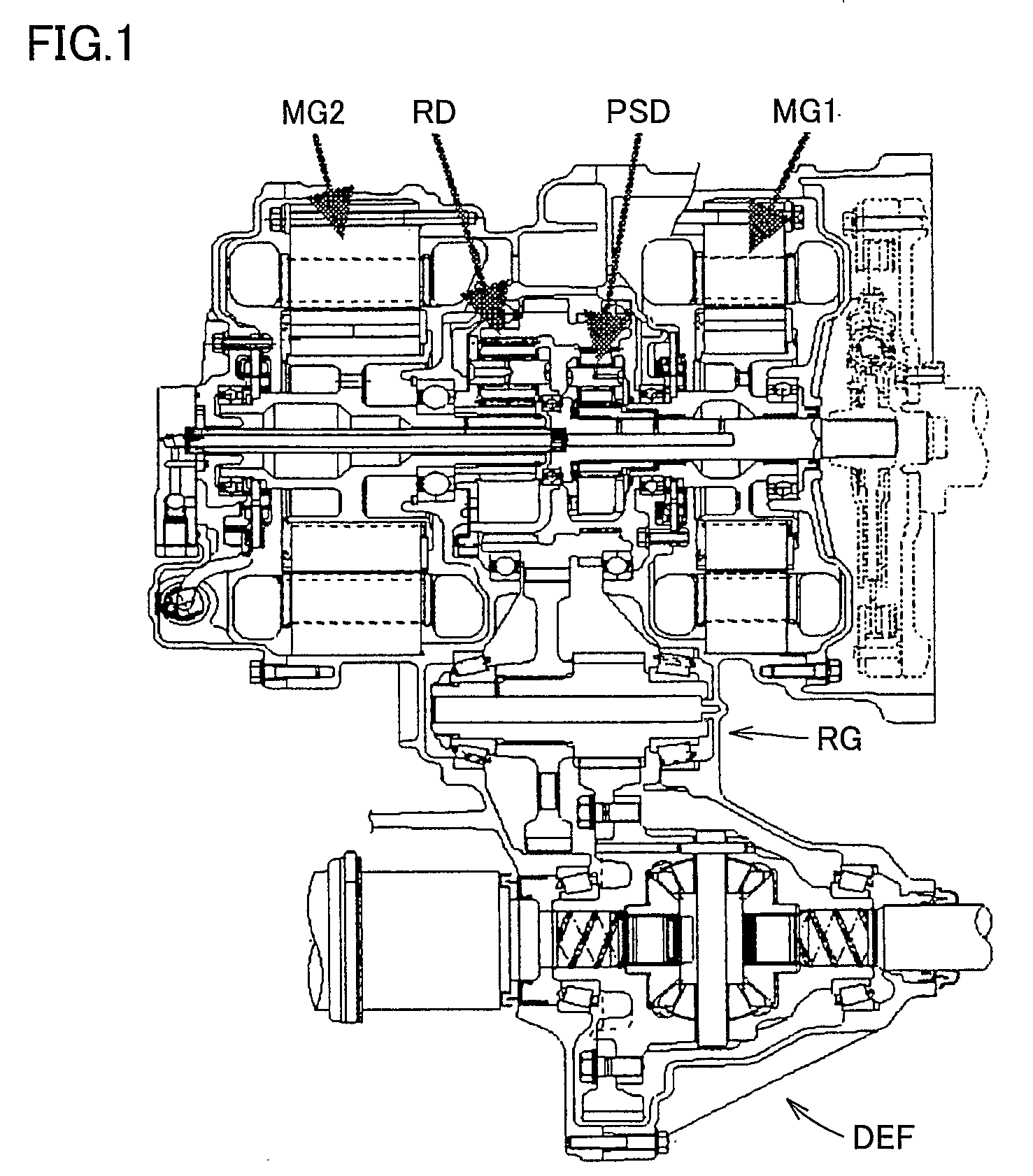

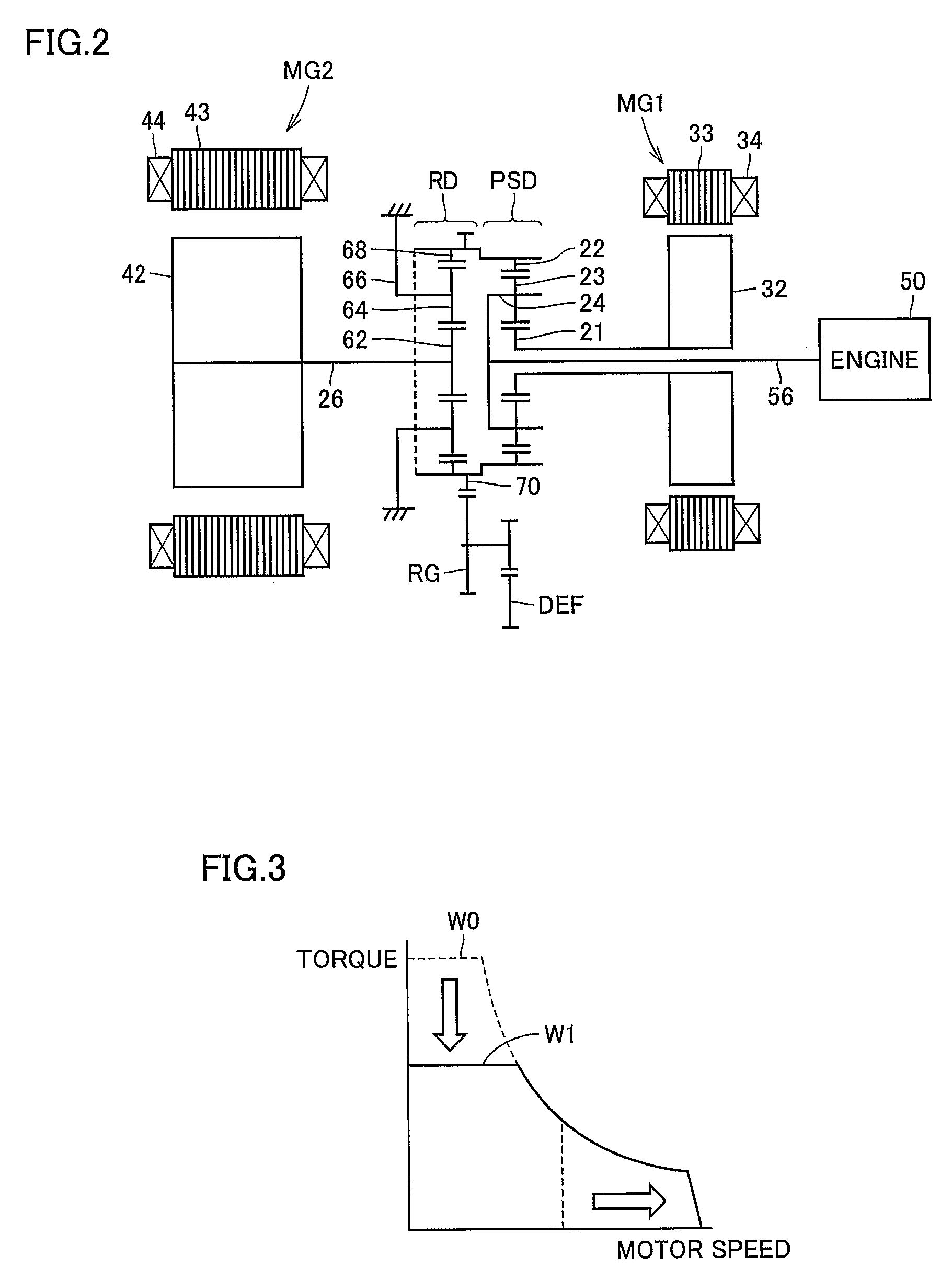

InactiveUS20080258573A1Improve energy efficiencyHigh speed rotationHybrid vehiclesMagnetic circuitElectric machineCentre of rotation

There are provided a rotor of a rotating electric machine that can implement high-speed rotations with improved energy efficiency, as well as the rotating electric machine and a vehicle drive apparatus. The rotor of the rotating electric machine includes two magnets arranged within an electrical angle in the range of 127° to 140°, the electrical angle having its center at the center of rotations of the rotor, and the magnets being arranged along a V-shape with its acute end facing toward the center of rotations. The rotor further includes a rotor body having two openings housing the two magnets respectively. The rotor body has a support portion placed at the acute end of the V-shape and serving as a partition between the two openings.

Owner:TOYOTA JIDOSHA KK

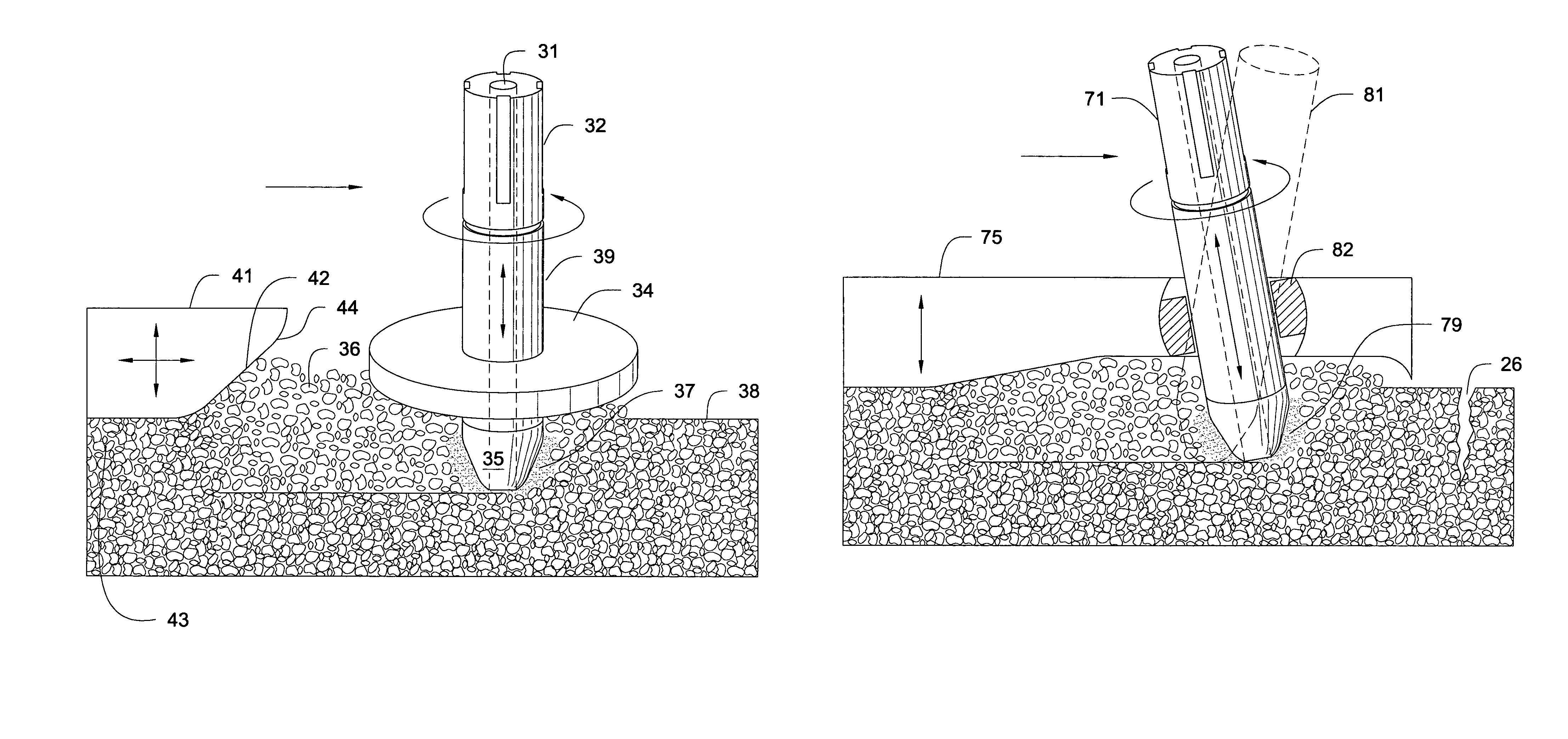

Hole coring system with lever arm

A hole coring system is provided that greatly stabilizes a tubular core drill bit for drilling into concrete or other materials enabling large diameter holes to be drilled with a handheld tool. The drill bit is guided by a mandrel which is attached to the concrete. The mandrel serves as a central guidepost that ensures that a relatively large diameter, tubular core drill bit remains precisely centered relative to the guide mandrel. This enables the operator to use a commonly available tool to rotate the drill and apply drill pressure only. The motor may rotate the drill bit via a gear box. The gear box may have a lever arm which may be used to resist any torquing action of the gear box due to the friction between the drill bit and the concrete. Additionally, in the event the motor's housing is not fixed to the gearbox and allowed to rotate, a brace may be attached to the lever arm which may be used to resist any torquing action of the motor's housing due to the friction between the drill bit and the concrete.

Owner:DUNCAN

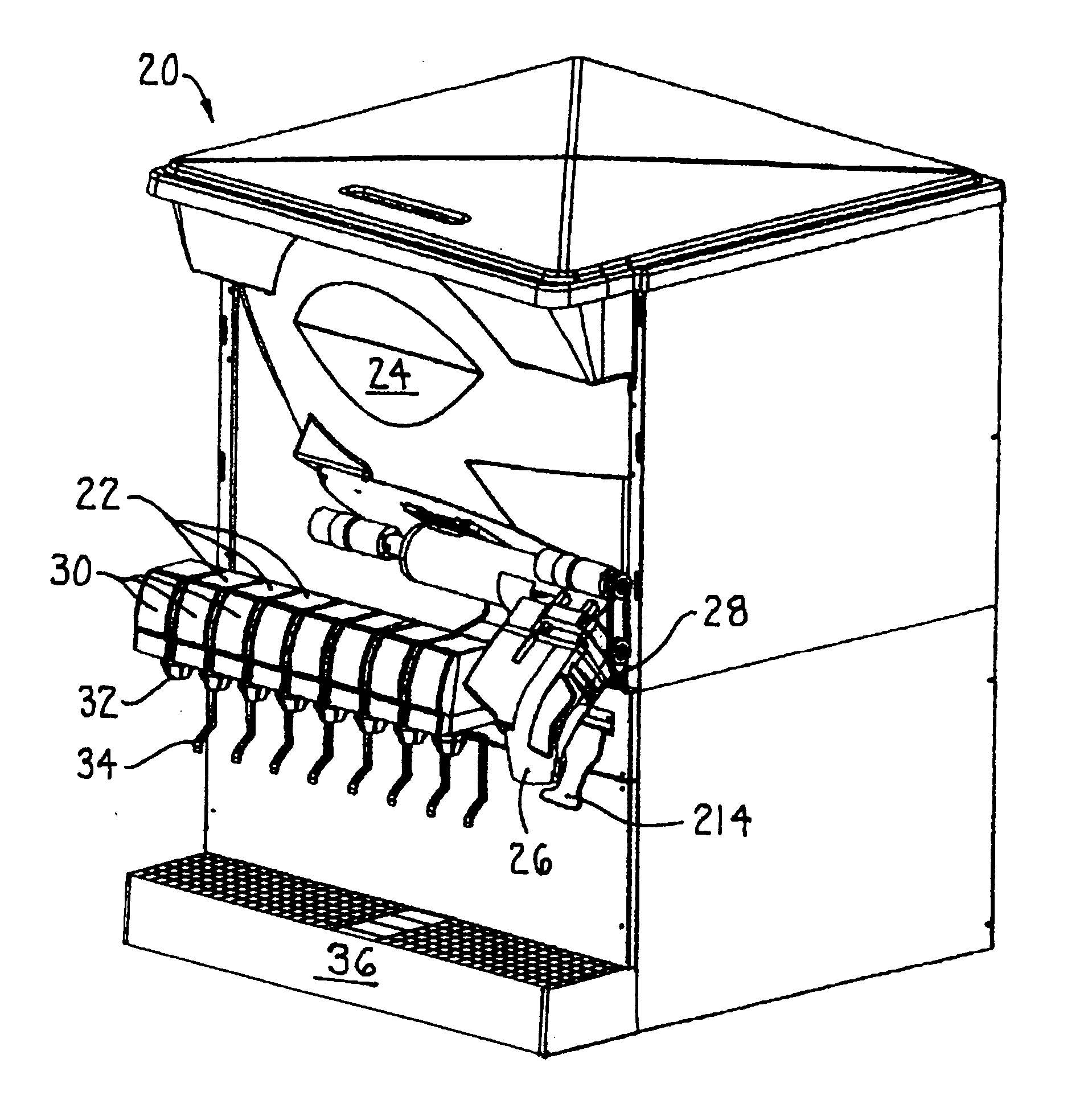

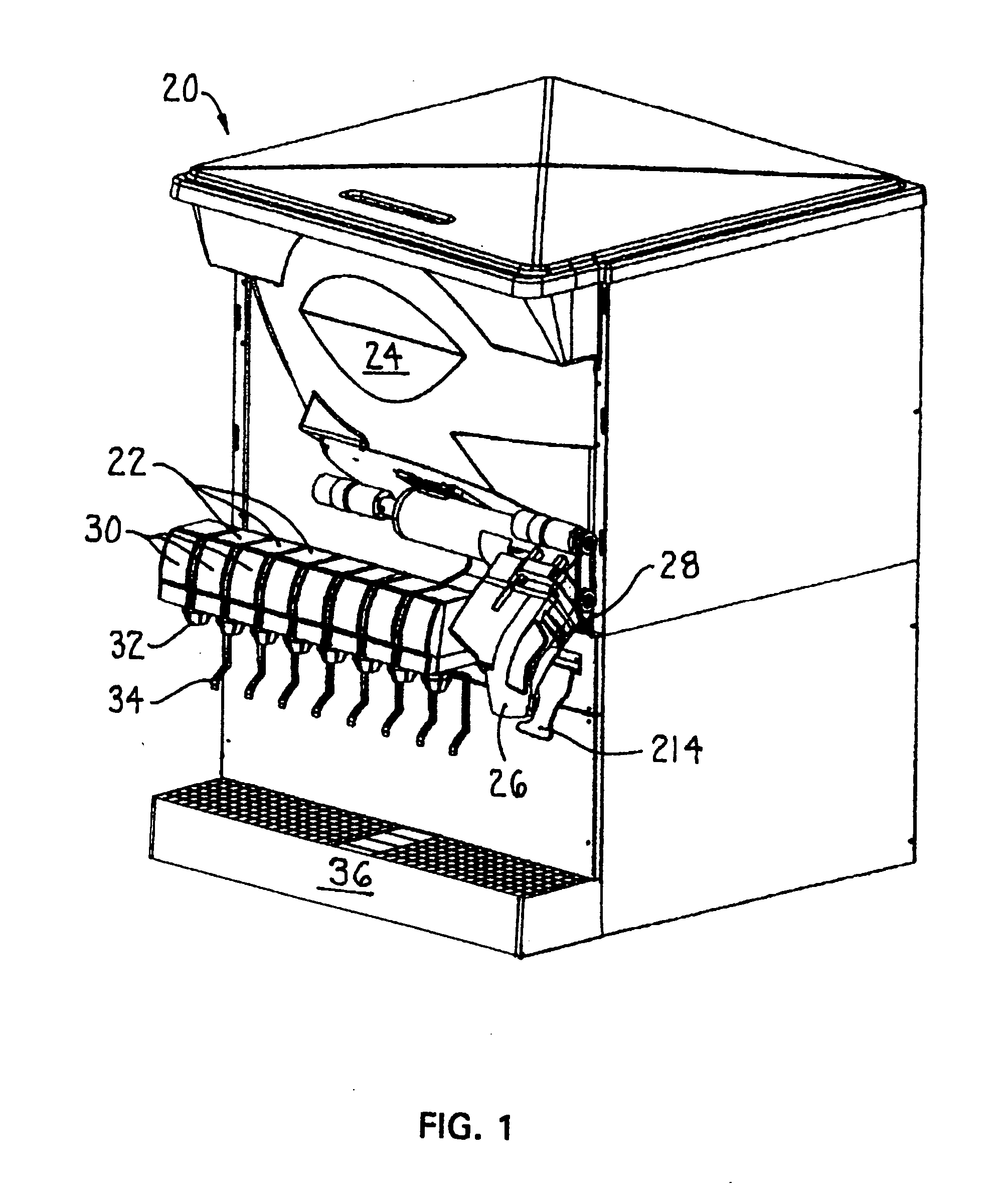

Beverage and ice dispenser capable of selectively dispensing cubed or crushed ice

ActiveUS20060169721A1Reduce latencyReduce complexityLighting and heating apparatusSolid waste disposalEngineeringCrusher

A beverage and ice dispenser that dispenses both beverages and cubed or crushed ice. Beverages are dispensed from dispensing heads. Cubed ice is stored in a bin. A duct leads from the bin. The duct has first and second outlet openings. A chute leads from the outlet openings. The chute has a single discharge opening from which ice from both duct outlet openings is discharged. An ice crusher is between a first outlet opening and the chute. A gate opens and blocks the flow path from the second opening into the chute. When cubed ice is desired, the gate is spaced from the second opening so that cubed ice is discharged from the duct and chute. When crushed ice is desired, the gate closes the second opening. Ice flows out of the first opening, is crushed by the ice crusher and discharged through the chute.

Owner:PEPSICO INC

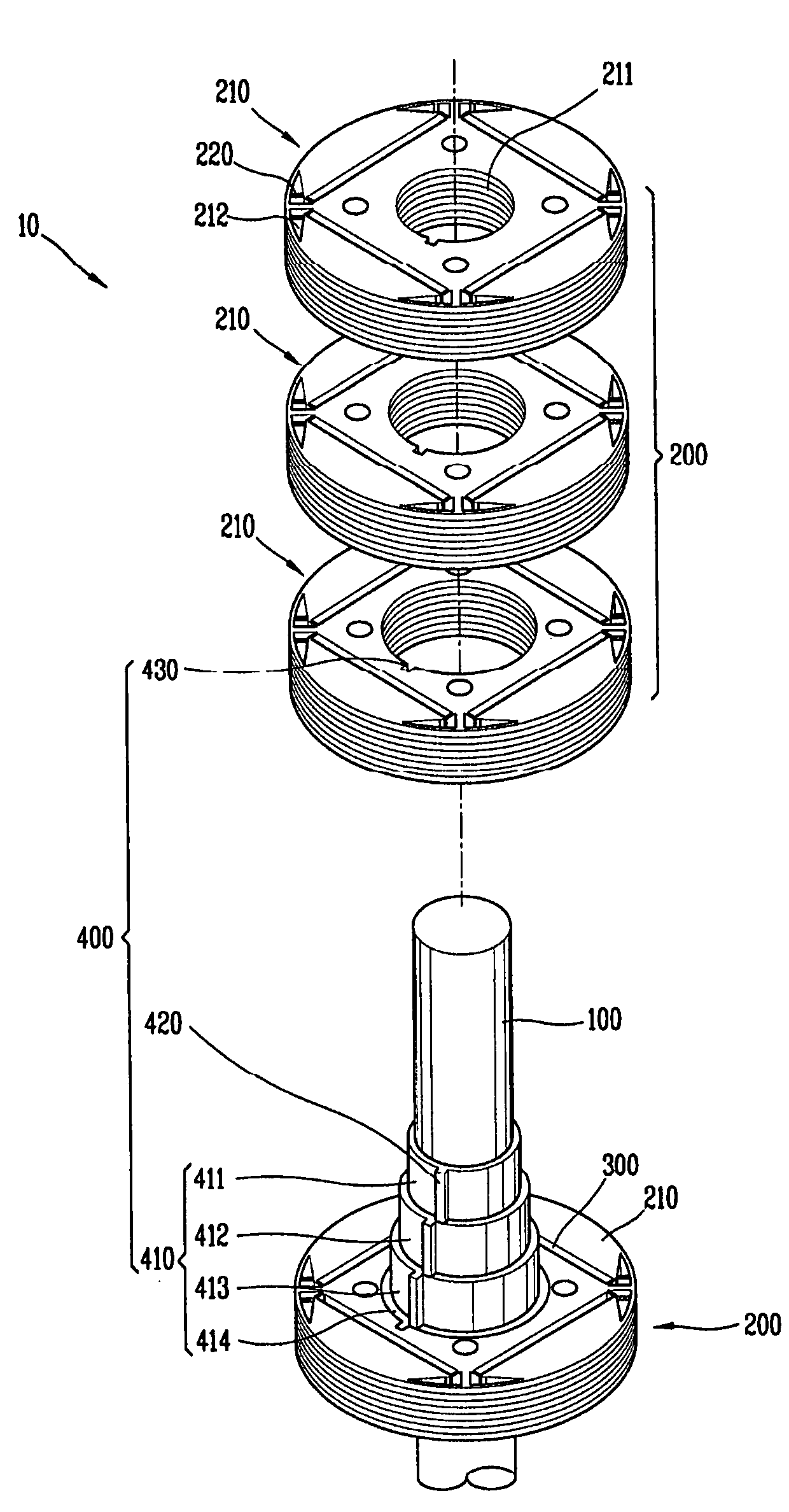

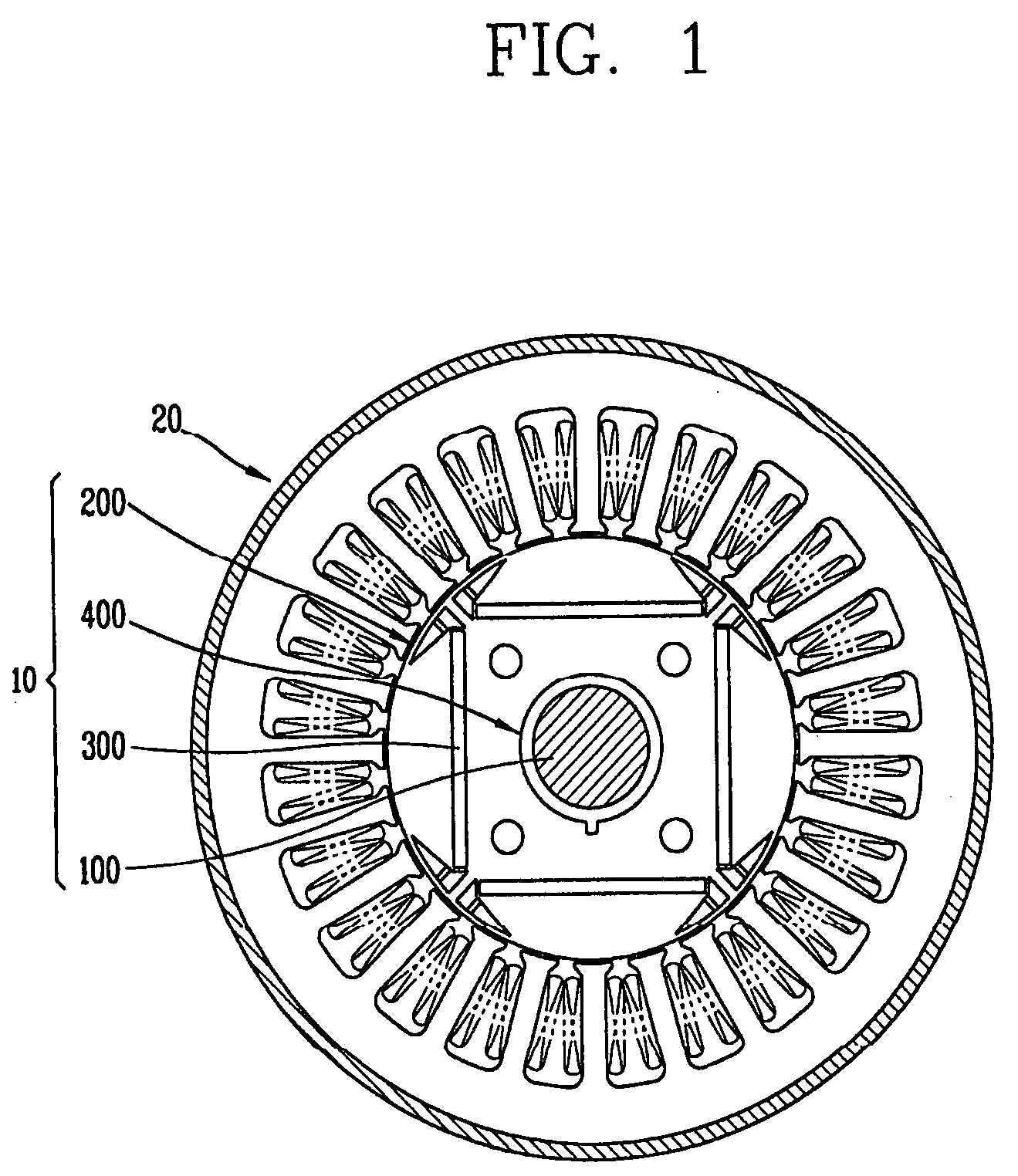

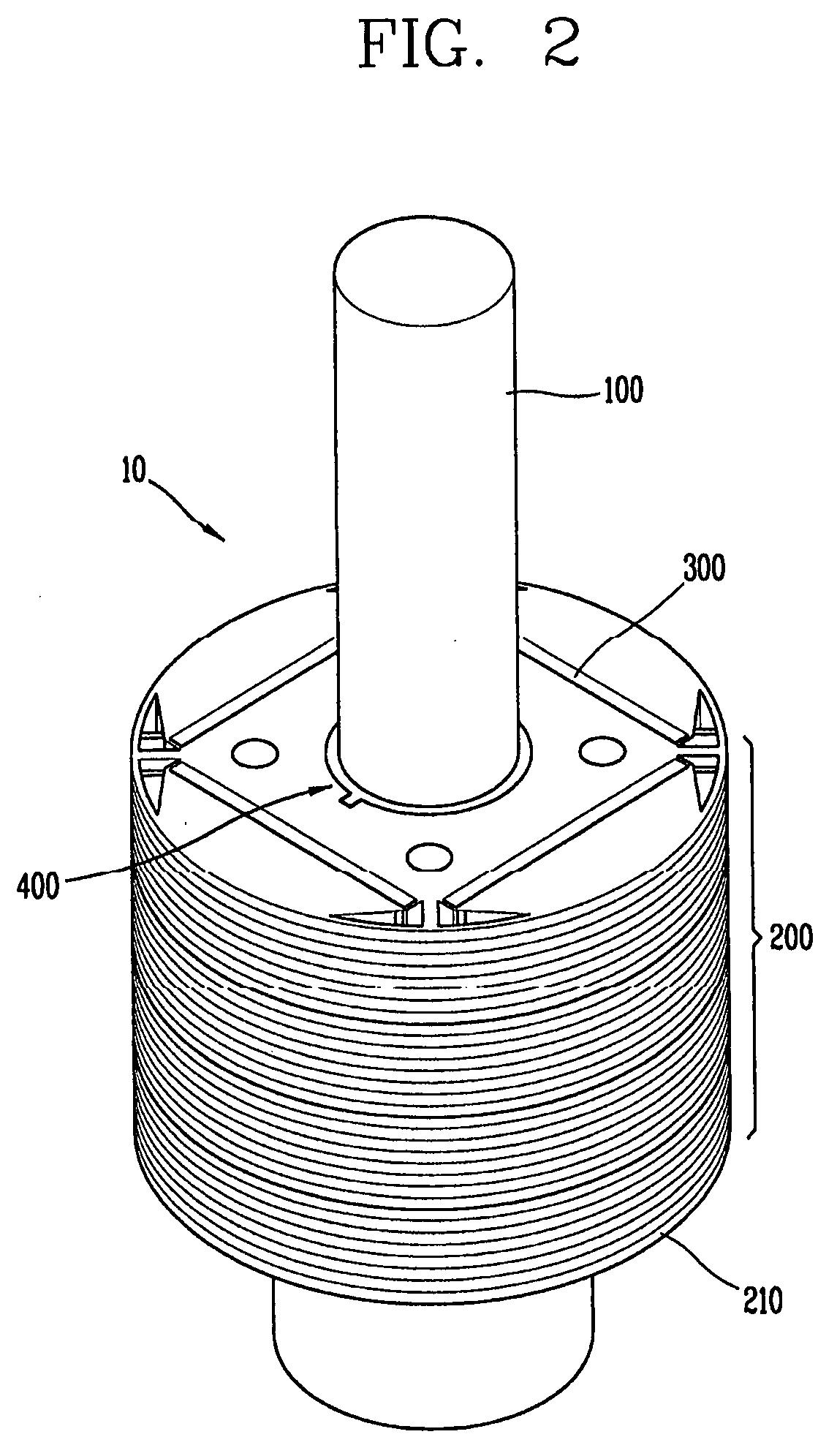

Motor

ActiveUS20080218022A1Reducing a cogging torqueIncrease speedMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEngineering

A motor that reduces a cogging torque and rotates at a high speed is presented. The motor comprises: a shaft, a plurality of core blocks coupled to the shaft, a plurality of permanent magnets inserted into each of the core blocks, and an aligning unit, coaxial with the shaft, and disposed between the shaft and the core blocks. The core block includes a plurality of core sheets each having at least a pair of flux barriers formed to be symmetrical to each other about a line of symmetry. A first rib lies along the line of symmetry and a separate anti-deformation rib is positioned within each of the pair of flux barriers. Accordingly, a skew process for a rotor is facilitated. An anti-deformation rib within the flux barrier provides structural integrity for the core block. Accordingly, when the rotor is rotated with a high speed, a bridge is prevented from being deformed.

Owner:LG ELECTRONICS INC

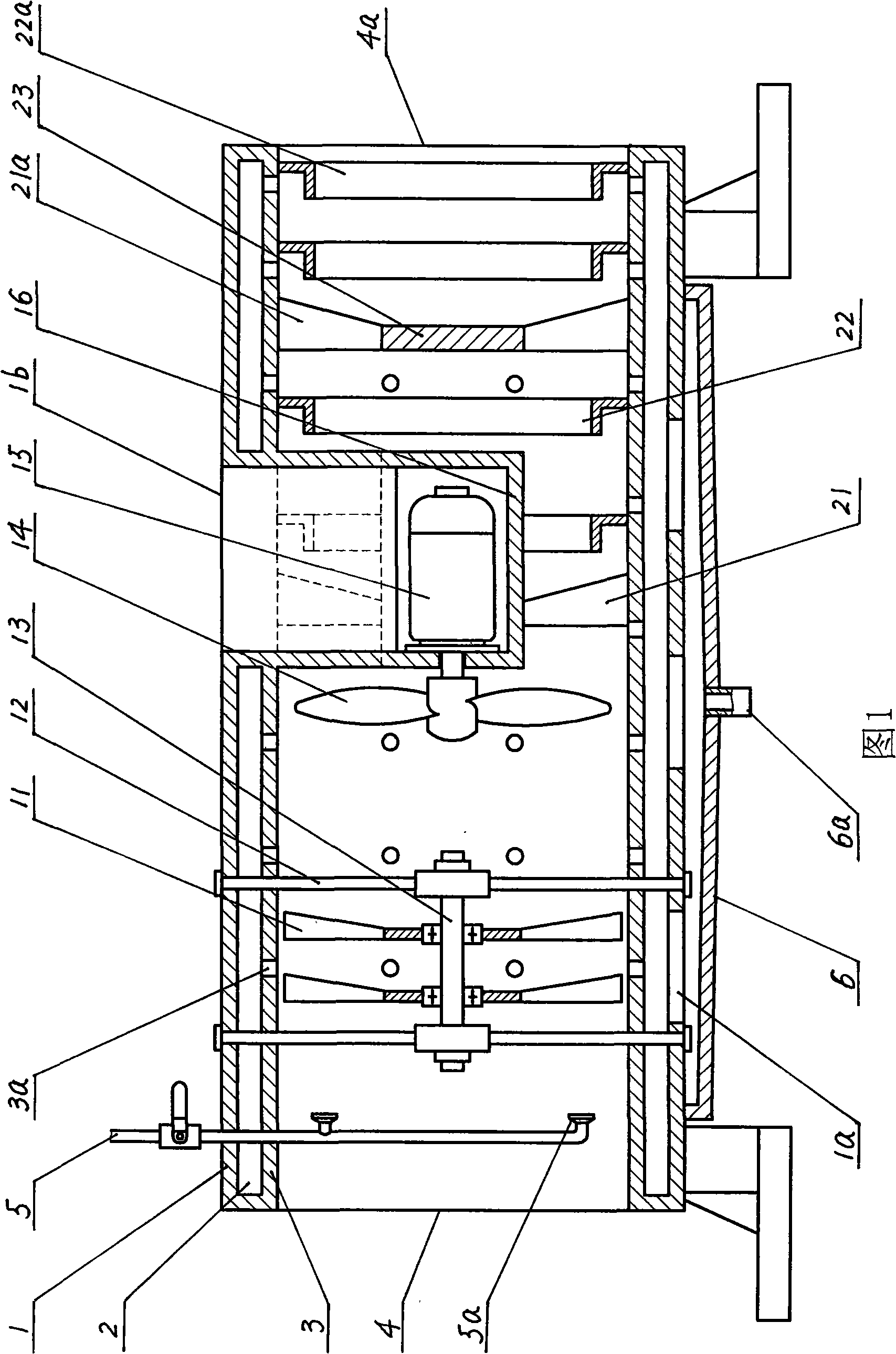

Wet-type dust-removal fan

ActiveCN101259355AHigh speed rotationIntensified conflictCombination devicesImpellerOperational costs

The invention discloses a wet dust removal fan, which comprises a wind-cone. The wind-cone consists of the wall of an outer cone and the wall of an inner cone which is provided with a plurality of through holes. A sandwich cavity is arranged between the wall of the outer cone and the wall of the inner cone; a flow port is opened at the bottom of the wall of the outer cone; a seeper box is connected with the lower part of the wall of the outer cone and is correspondent to the flow port; an outlet is arranged at the bottom of the seeper box; the inner wall of the inner cone is provided with a support which is equipped with an axle; the support is connected with the wind-cone and is arranged between a water injection nozzle and a fan wheel, and the axle is provided with at least a separating blade. The wet dust removal fan has the advantages of high purification efficiency in the practical application, low operational cost, notable energy saving effect and no frequent maintenance, which completely solves the problems that large resistance of the dust removing system exists owning to a filter screen, the handling ability of blast volume is bad, the increasing of the loading of a fan motor is directly affected by the dust capacity adsorbed of and the fan motor is burnt down easily owing to the phenomenon of blocking, thus ensuring the operation safety and work efficiency of the fan motor.

Owner:郭峰

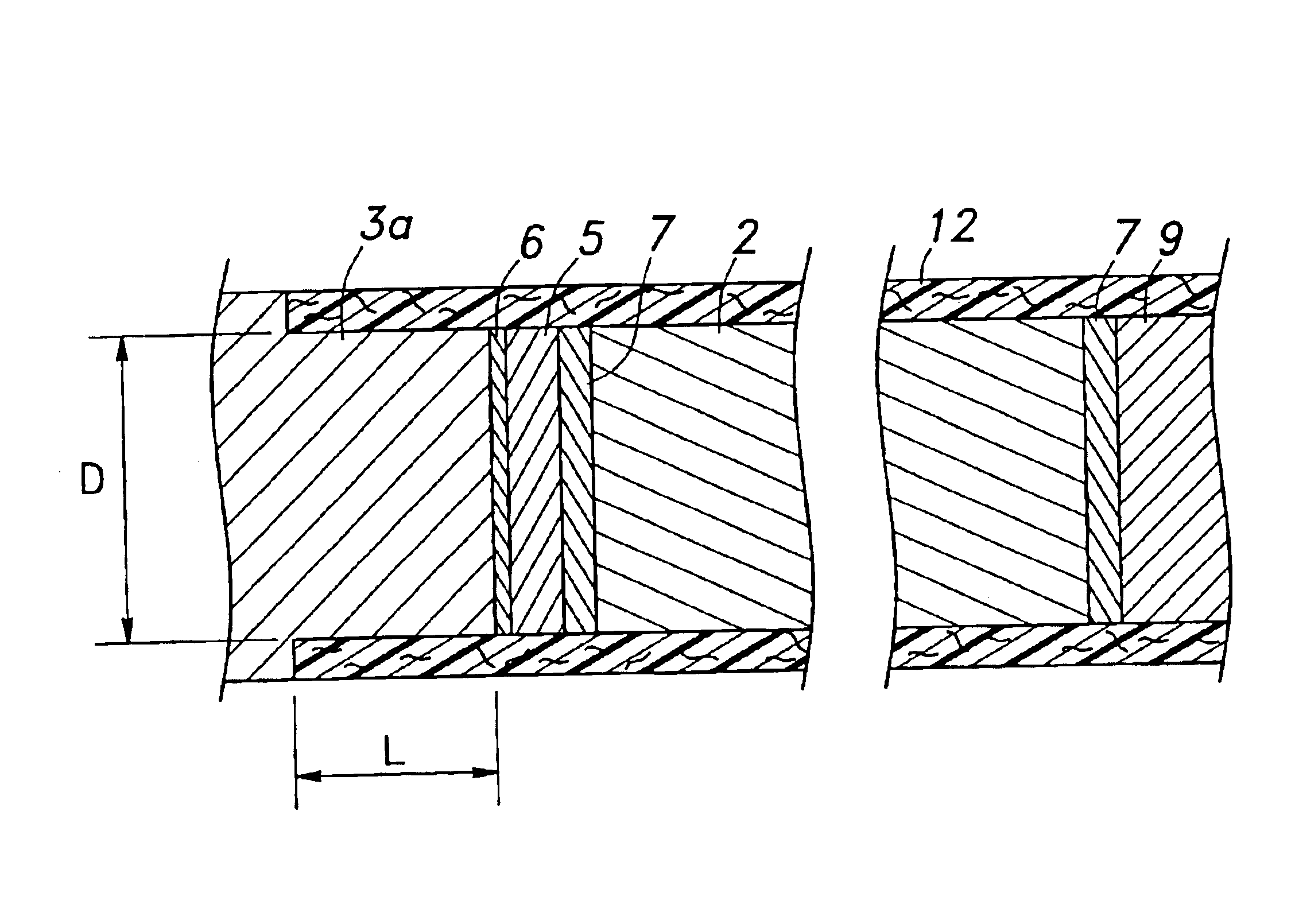

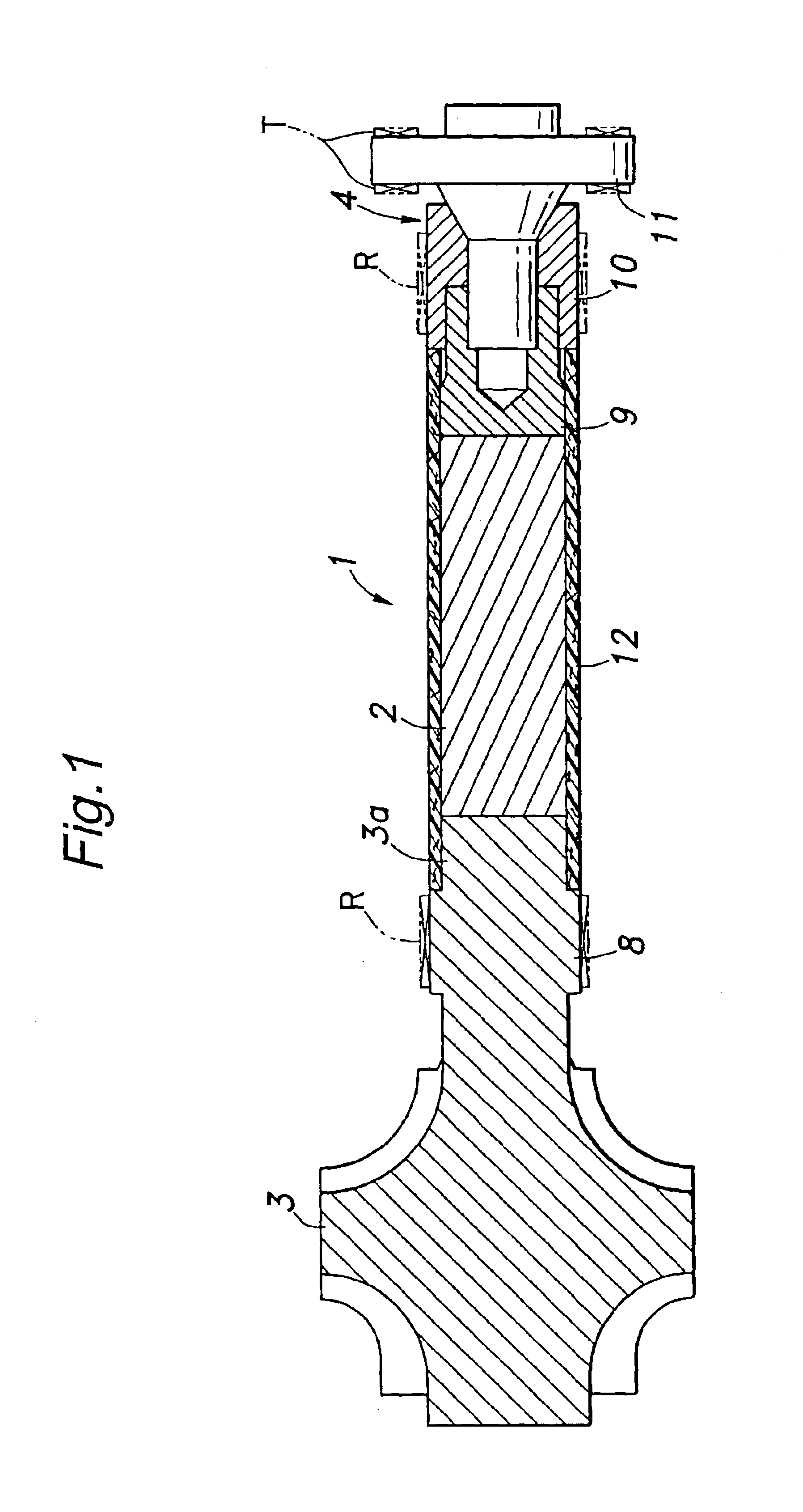

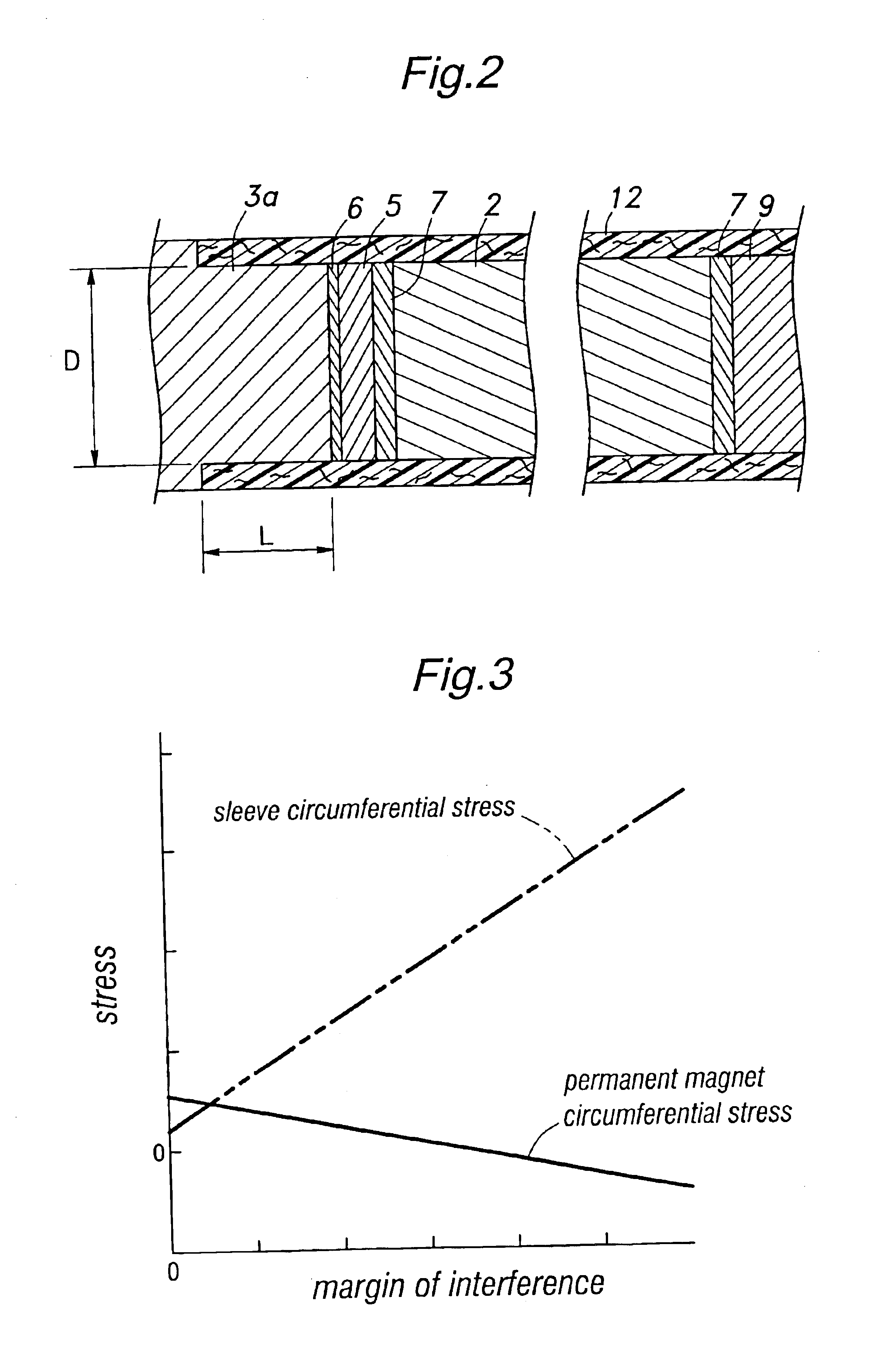

Permanent magnet rotor

InactiveUS6841912B2Increase axial dimensionReduction in cross sectional area can be avoidedMagnetic circuit rotating partsPump componentsPermanent magnet rotorEngineering

In a permanent magnet rotor, a power transmitting shaft is connected to an axial end of a solid cylindrical permanent magnet, and a reinforcement sleeve is fitted on the outer circumferential surface of the permanent magnet. Thus, the shaft is not required to be passed through the permanent magnet as was the case with the conventional permanent magnet rotor for the purpose of transmitting the rotational torque and increasing the overall rigidity, and the increase in the axial dimension of the rotor due to the reduction in the cross sectional area of the permanent magnet can be avoided. Also, because the sleeve surrounds the permanent magnet, the resistance to centrifugal stress resulting from a high speed rotation and repeated bending stress owing to vibrations can be improved.

Owner:HONDA MOTOR CO LTD

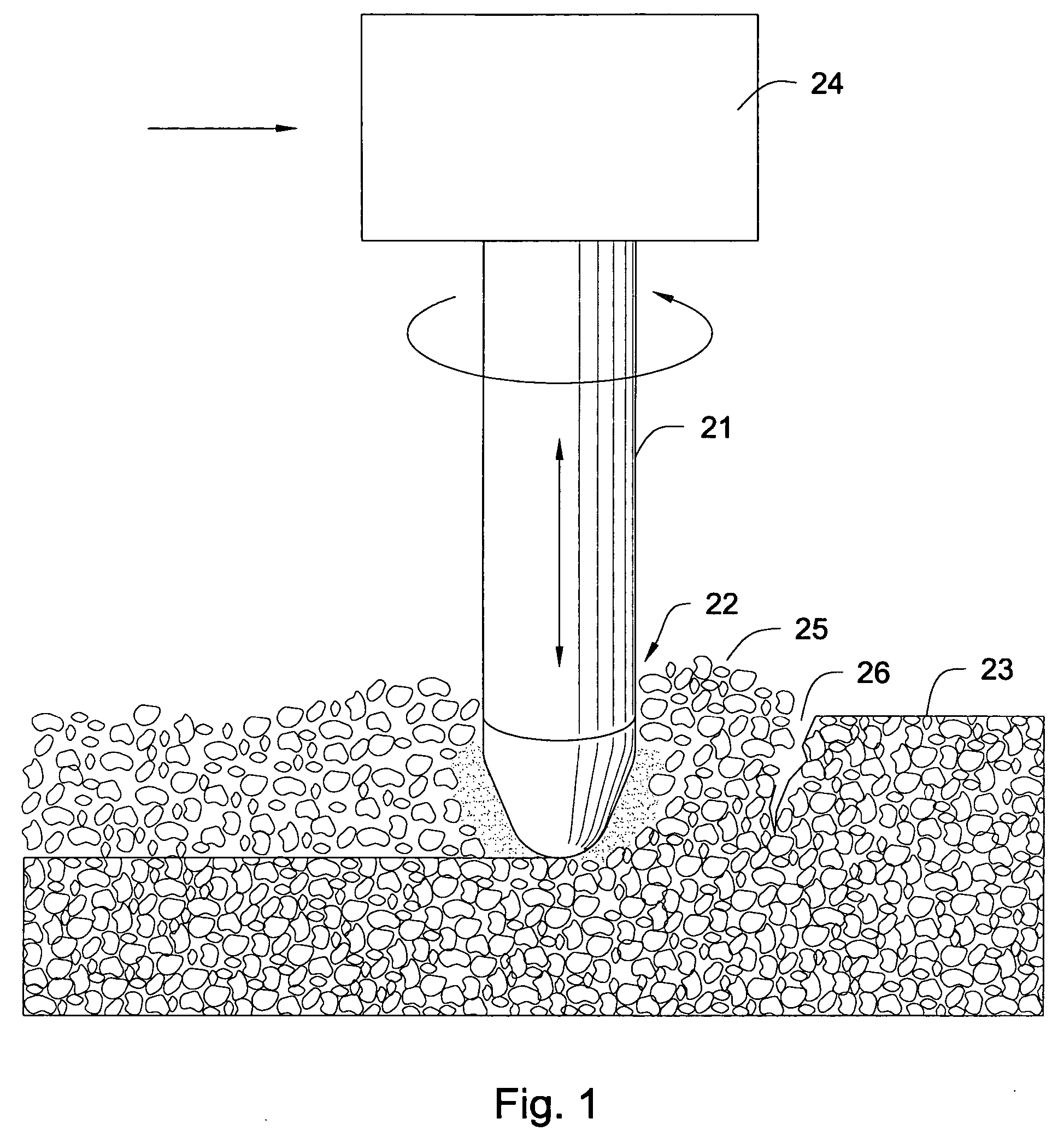

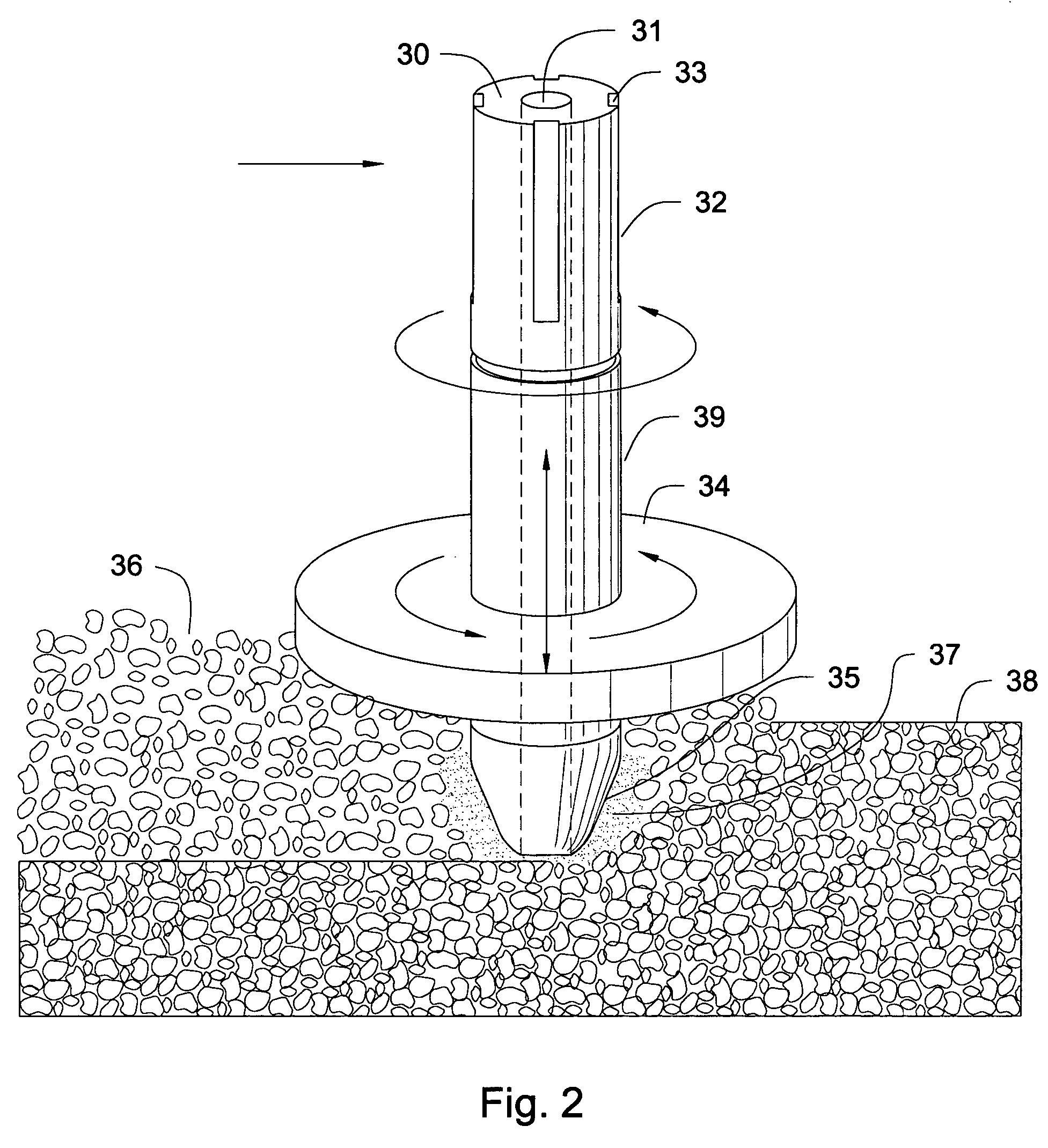

Apparatus and method for working asphalt pavement

InactiveUS7179018B2Reduce frictionEasy to wearDisloding machinesThermal drillingClosed loopPolycrystalline diamond

A method and apparatus for working asphalt pavement, comprising one or both of a mechanical, hydraulic, electric, or pneumatic means for providing high-speed rotation; a rotary tool comprising a first end comprising a working surface and a second end adapted for connection to the means for providing high-speed rotation; and a screed, cooperatively arranged with the rotary tool, and comprising a working surface adjacent the working surface of the rotary tool, wherein the rotary tool is spun at high speed and applied to the asphalt pavement, frictionally heating the asphalt pavement to a temperature sufficient to work the pavement locally adjacent rotary tool and the screed. The screed and rotary tool comprising abrasion resistant materials selected from the group consisting of high-strength steel, hardened alloys, cemented metal carbide, polycrystalline diamond, and cubic boron nitride. The rotary tool and the screed apparatus may comprise a closed loop control system.

Owner:NOVATEK IP

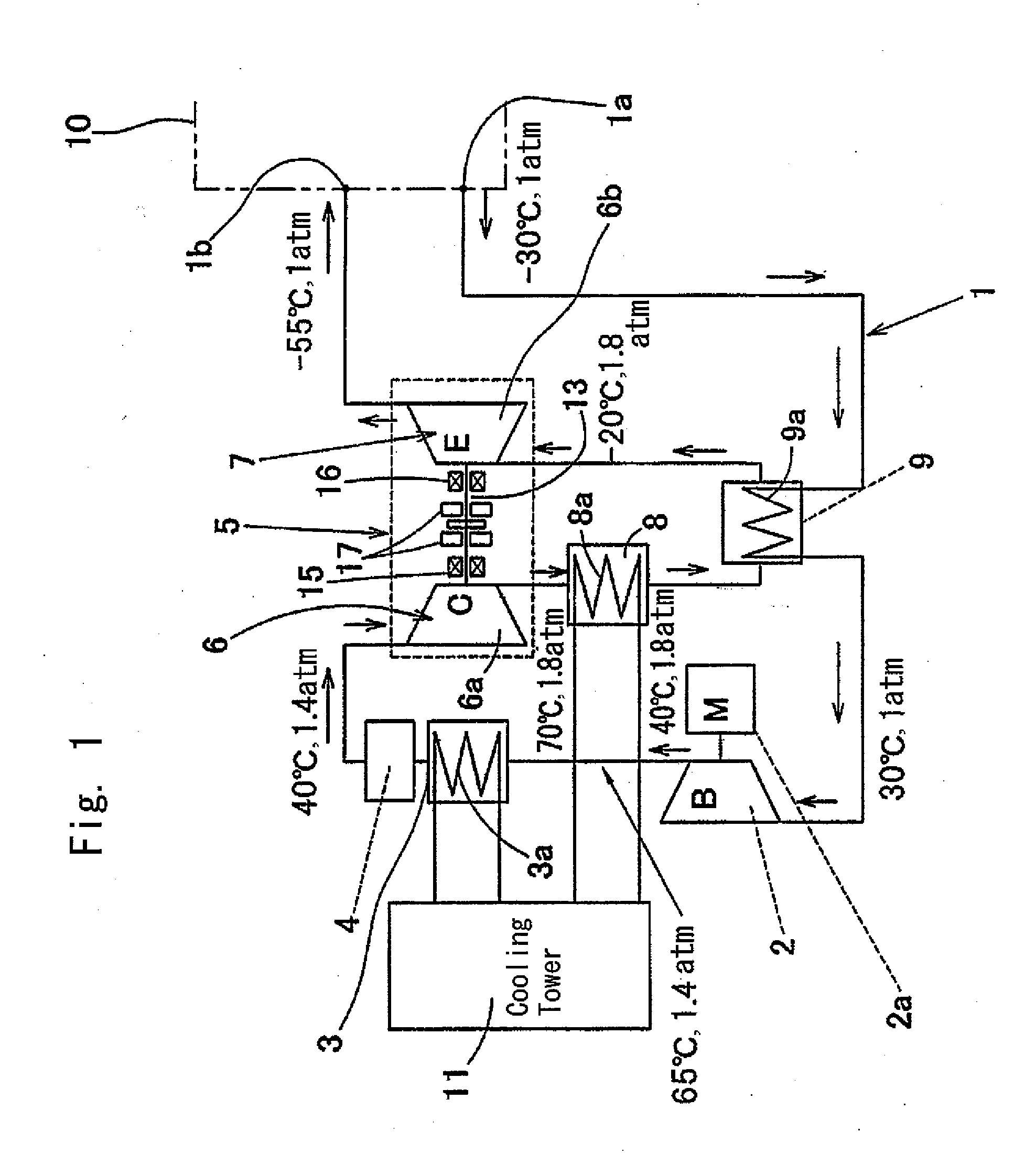

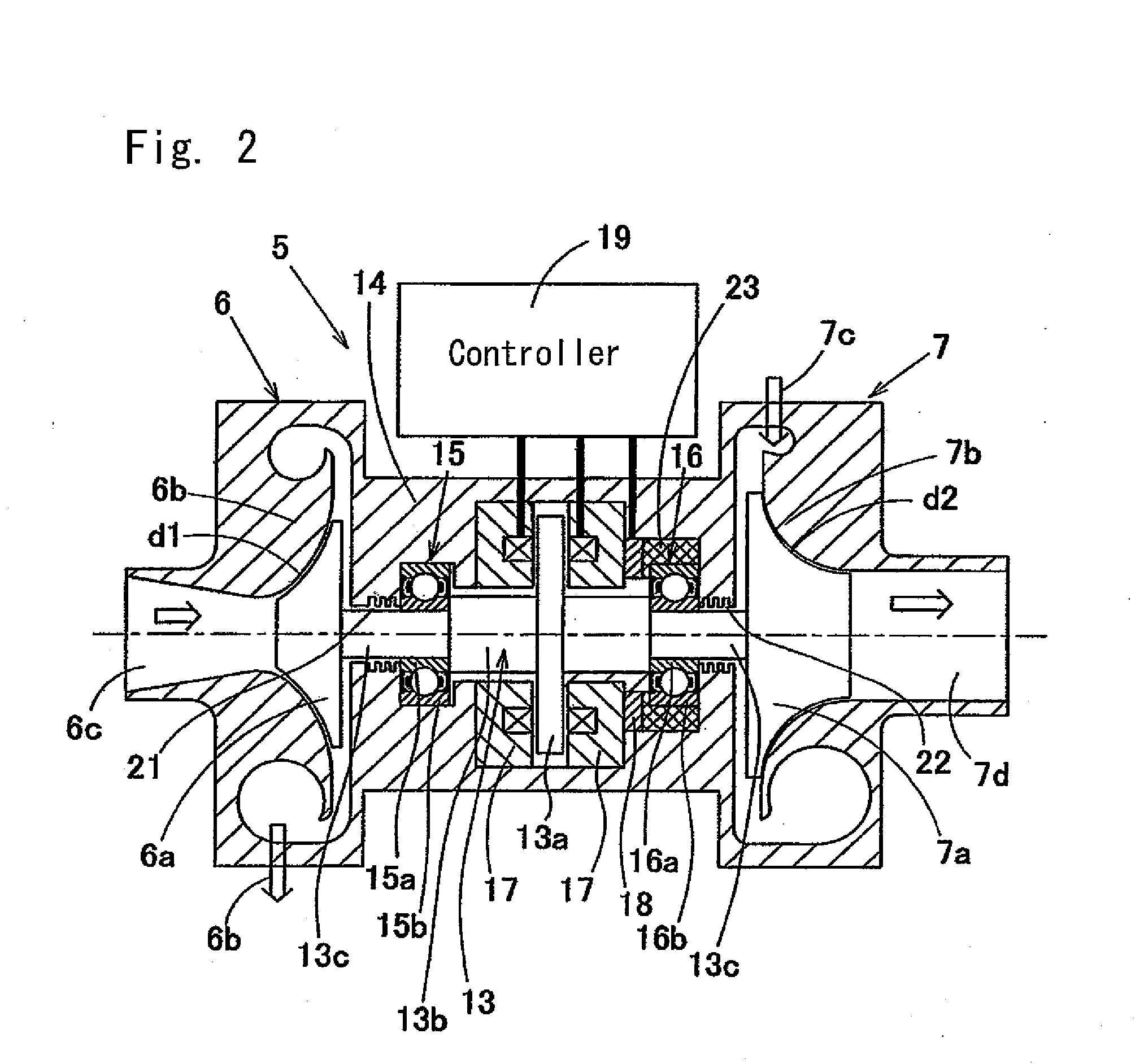

Air cycle refrigerating/cooling system and turbine unit used therefor

InactiveUS20090260388A1High speed rotationEfficient compressionPump componentsDomestic cooling apparatusAir cycleFree rotation

The air cycle refrigerating / cooling system compresses air that has flown in with a compressor (6) in a turbine unit (5) and adiabatically expands the air with an expansion turbine (7) in a turbine unit (5). In the turbine unit (5), a compressor rotor (6a) of the compressor (6) and a turbine rotor (7a) of the expansion turbine (7) are attached to the same main shaft (13), the main shaft (13) is supported by bearings (15) and (16) so as to be freely rotatable, and part or the entirety of the thrust force applied to this main shaft (13) is supported by an electromagnet (17).

Owner:NTN CORP

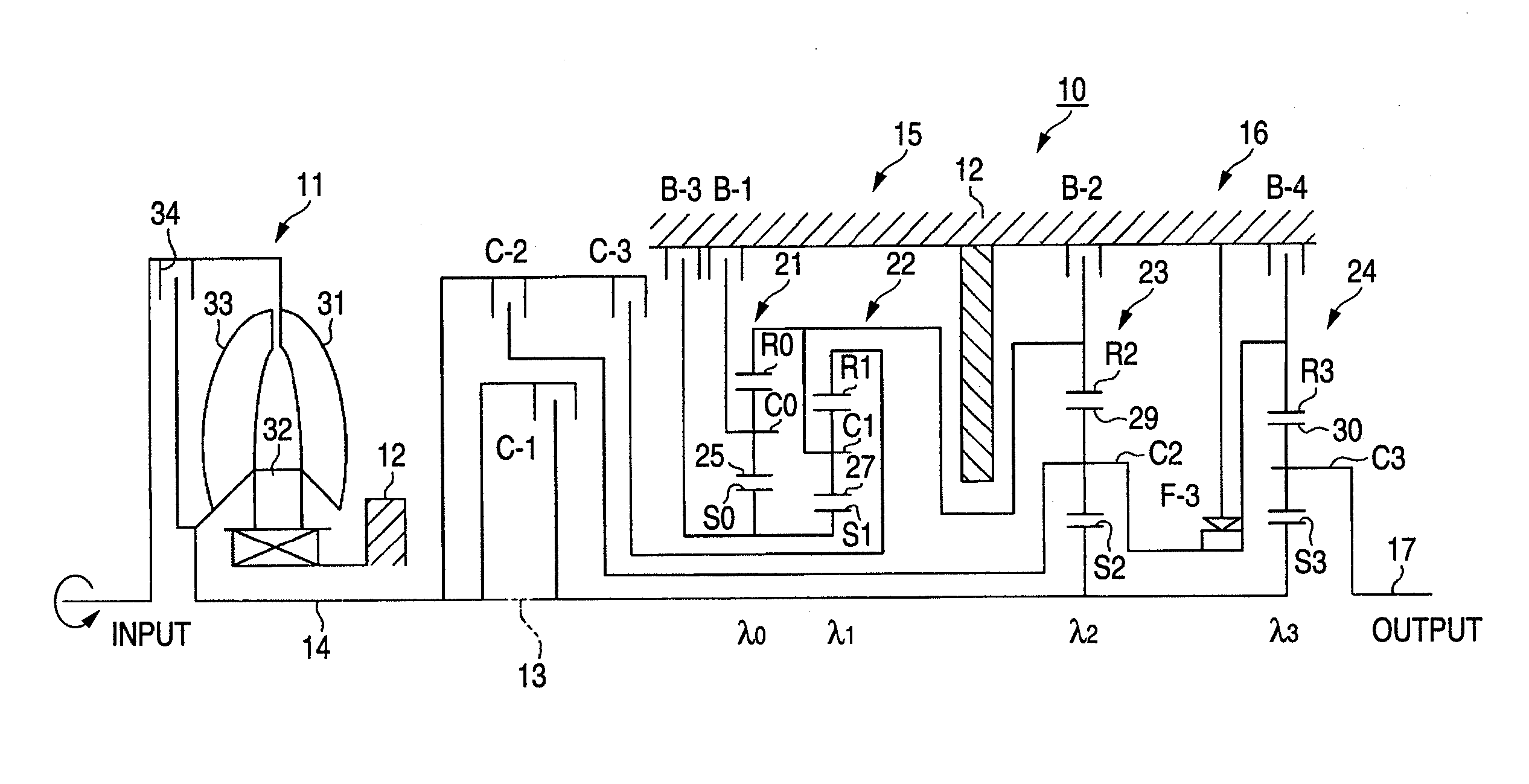

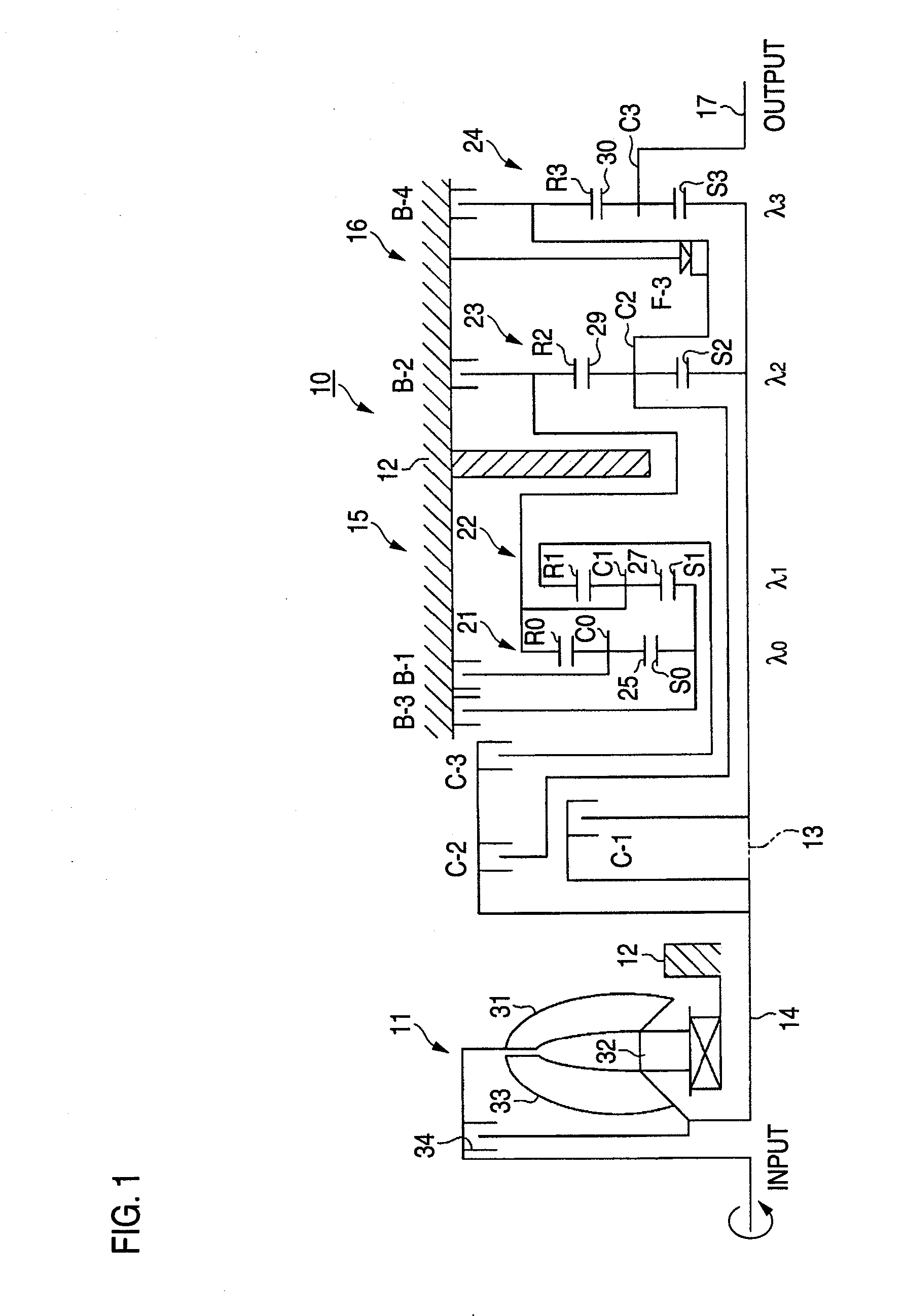

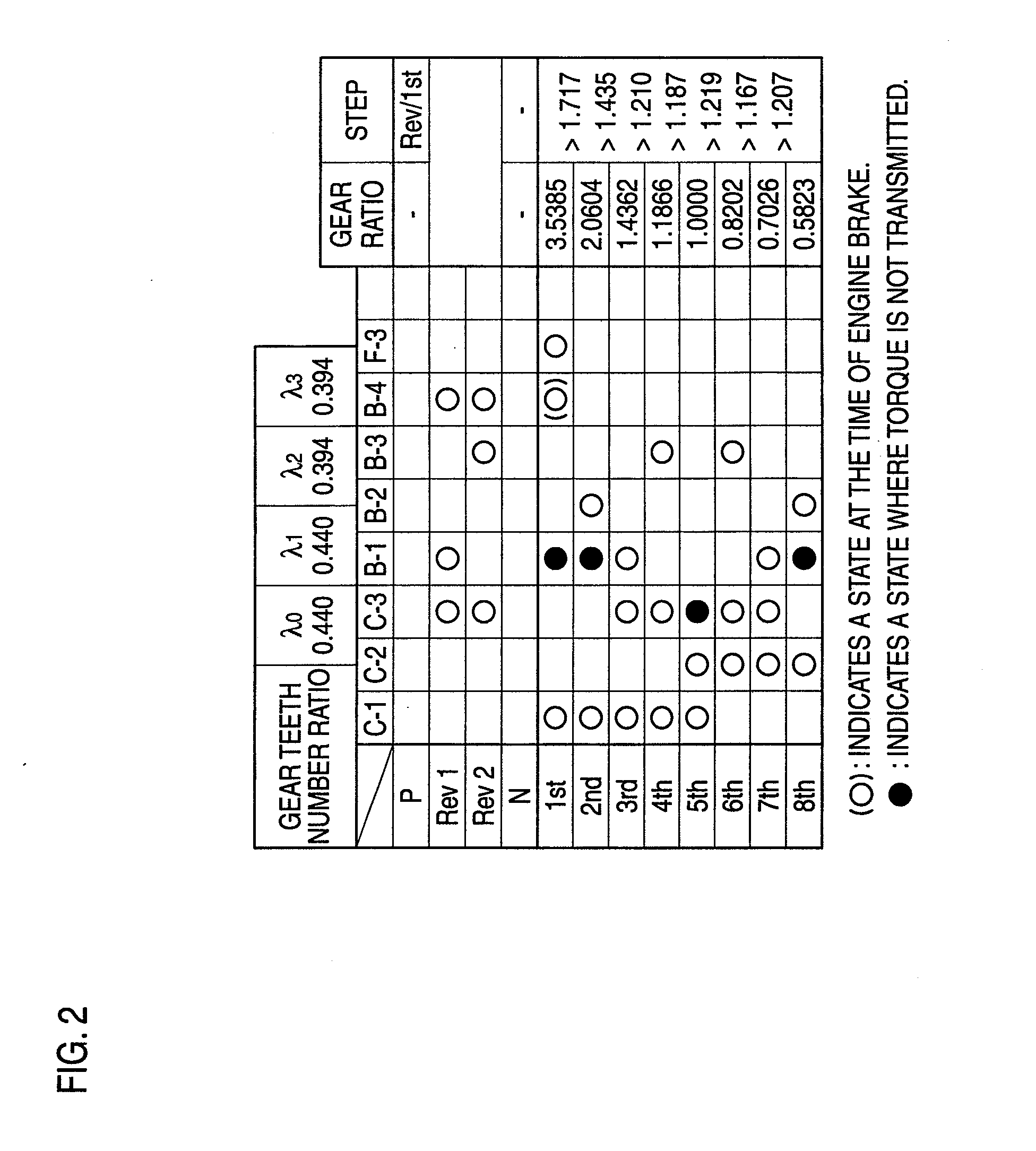

Automatic transmission

InactiveUS20080248913A1High speed rotationToothed gearingsTransmission elementsAutomatic transmissionTransmitted power

An automatic transmission having a second ring gear of planetary gear mechanisms and is connected to an input shaft so as to be able to transmit power thereto, and a first sun gear and a second sun gear, and a first carrier that are connected to each other are in turn connected to a third control brake and a first control brake, respectively. A third sun gear and a fourth sun gear of the planetary gear mechanisms are connected to each other, and are in turn detachably connected to the input shaft 14 by a first control clutch. A third ring gear R2 and a fourth ring gear R3 are connected to a second control brake and a fourth control brake, respectively. Furthermore, a third carriers is detachably connected to the input shaft by a second control clutch, and a fourth carrier is connected to an output shaft.

Owner:AISIN AW CO LTD

Industrial method for selectively recycling copper and nickel from copper-nickel mud

ActiveCN102994762ASimple operation processHigh recovery ratePhotography auxillary processesProcess efficiency improvementPower flowWaste material

The invention discloses an industrial method for selectively recycling copper and nickel from copper-nickel mud, belonging to the field of recycling non-ferrous metal resources. The industrial method comprises the following steps of: acid-leaching the copper-nickel mud; filtering leachate; punching the leachate to a sealed tubular slot from a circulating slot under the action of a circulating pump, rotating the solution in the slot at a high speed, and carrying out rotational flow electrolysis to remove the copper; returning electrodeposited solution to the leaching process for continuously carrying out leaching; and gathering the nickel in the copper-nickel mud for preparing nickel sulfate. According to the industrial method provided by the invention, an high-speed rotation electrolytic technology for a solution in an electrolytic cell is combined with other processes to recycle the metal in the solution for being continuously used for other industries, so that the waste material is changed into things of value for realizing recycling the resources; the current density and the current efficiency are high, the reagent consumption is low, the production cost is reduced, and performances of the enterprise are improved. Meanwhile, the solution is circulated in a closed-loop manner, so that no harmful gases are exhausted, and the existing circular economy and environmental protection theories are satisfied.

Owner:浙江科菲科技股份有限公司

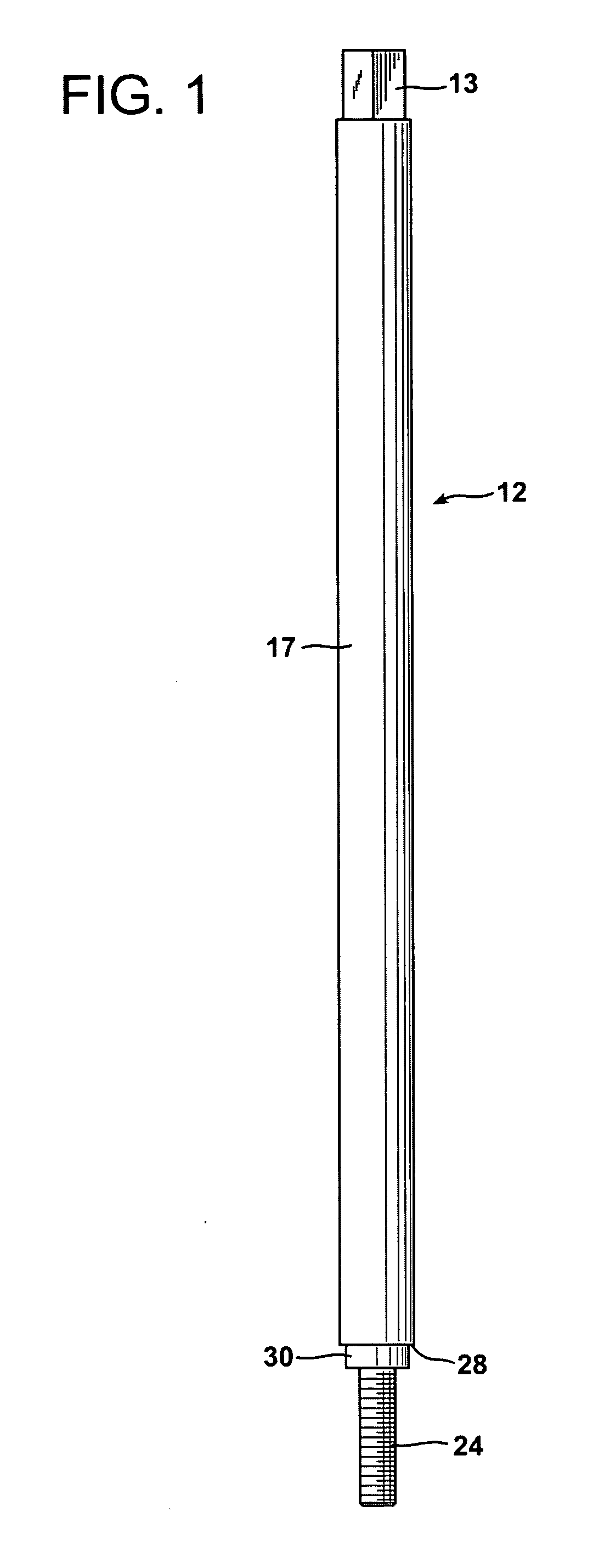

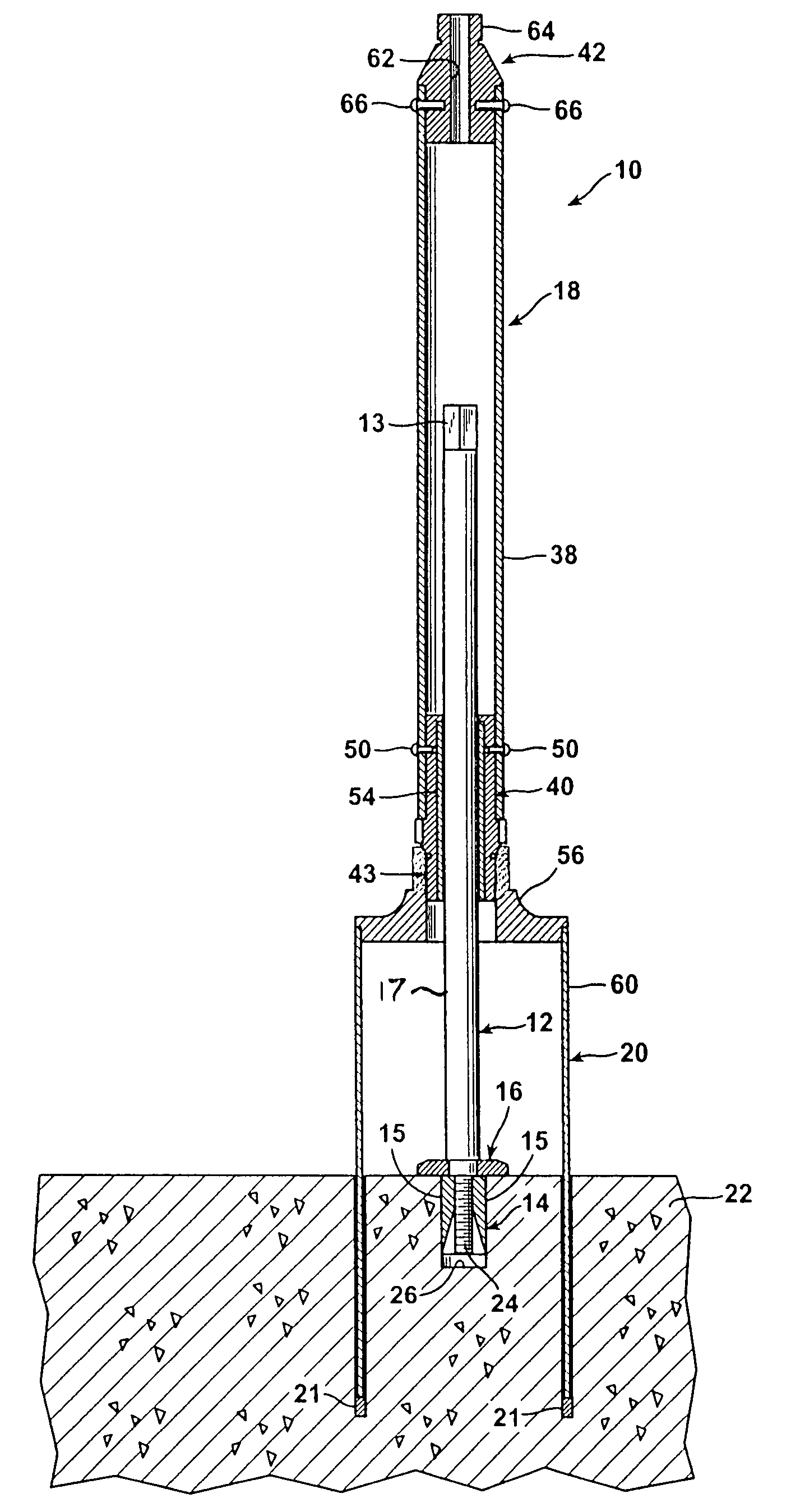

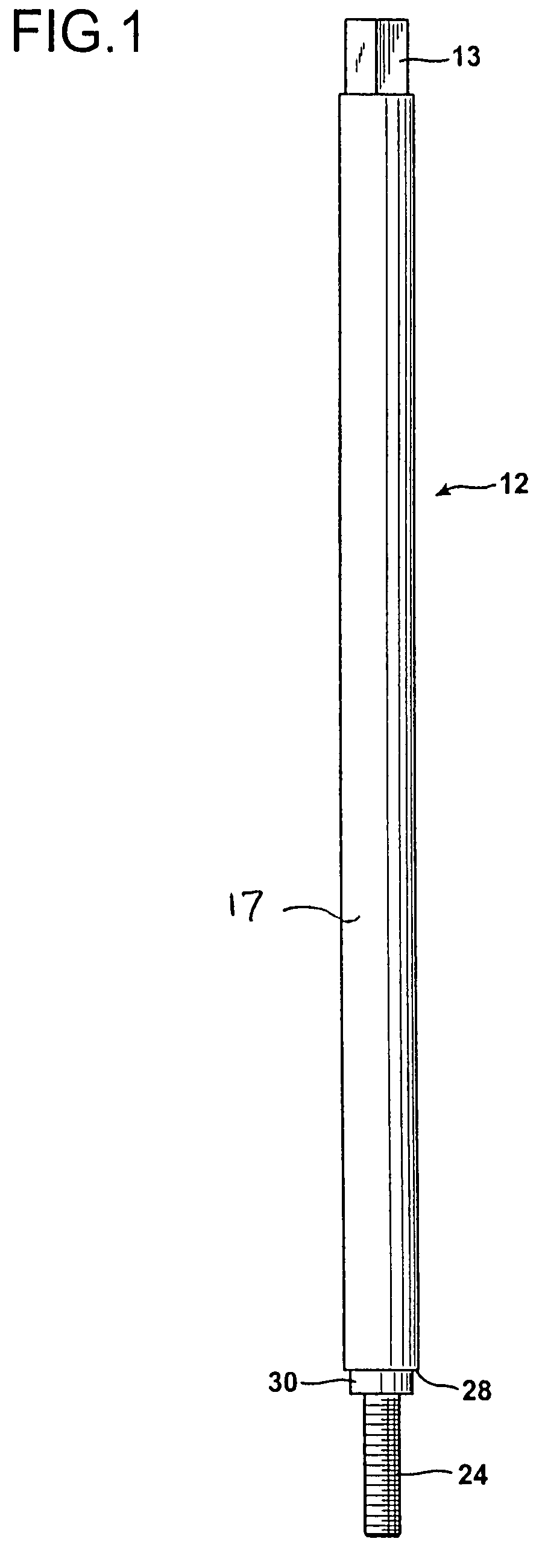

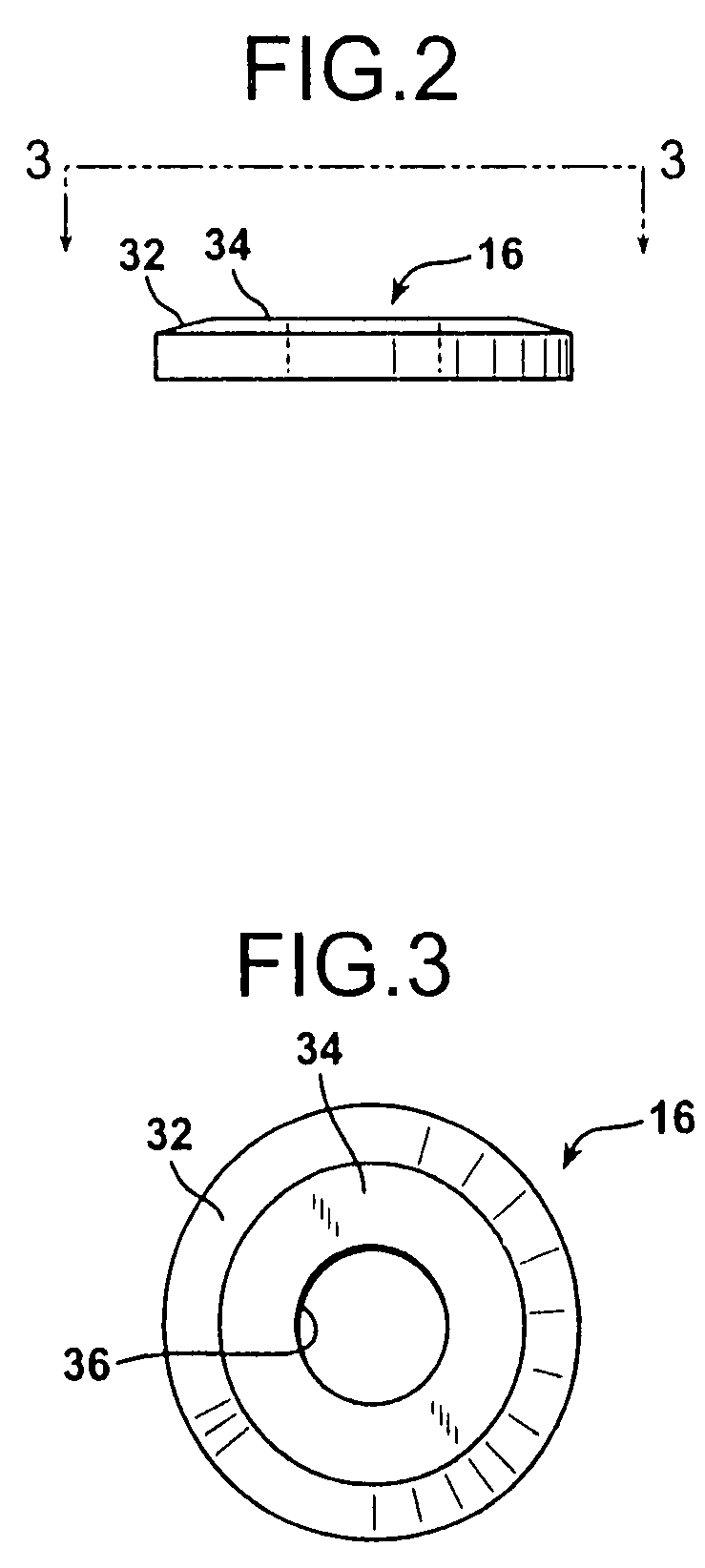

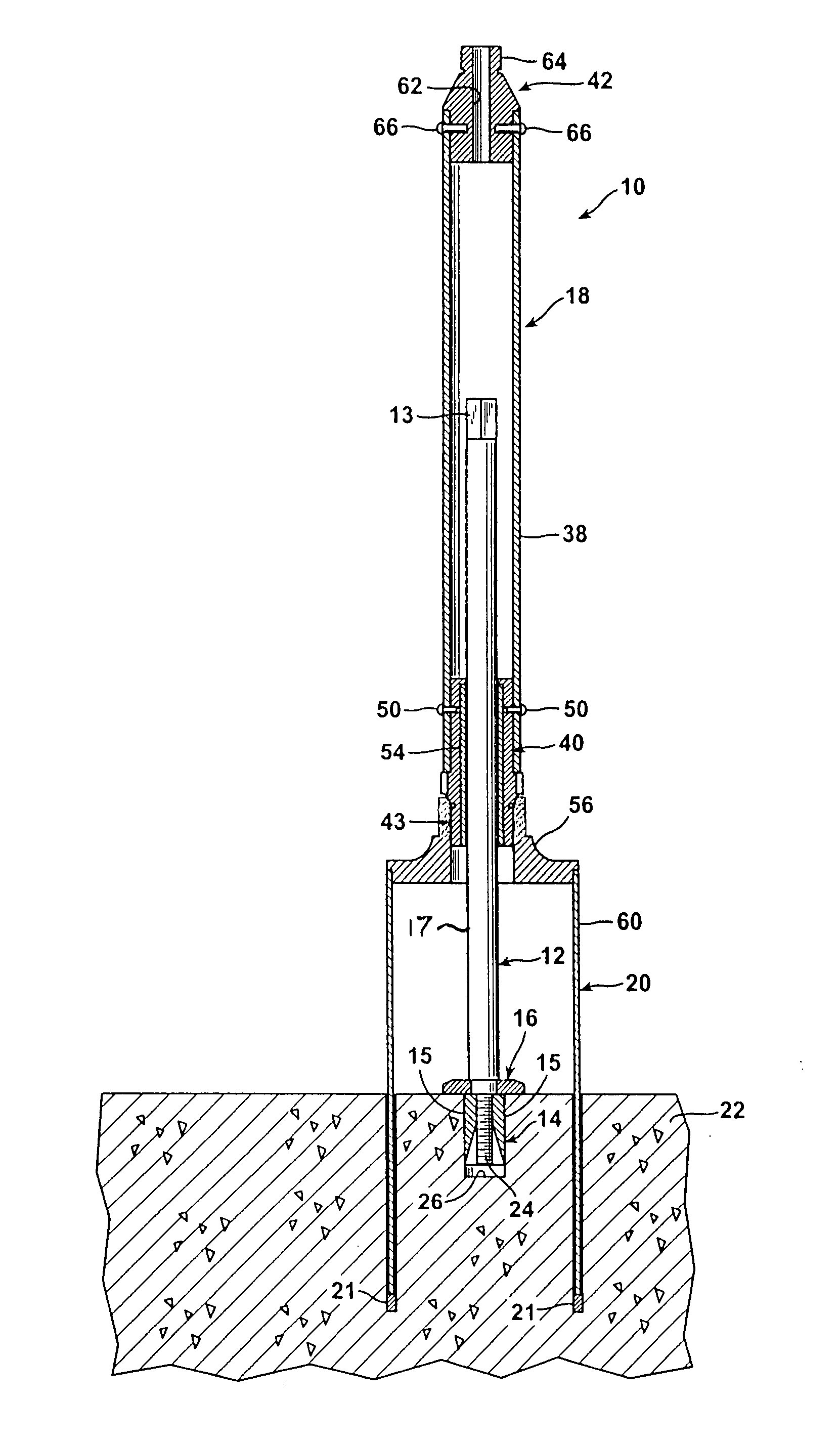

Hole coring system

An apparatus for drilling holes in a substrate wherein a mandrel is anchored to the substrate. A hollow drill bit rotates about the mandrel via a drive motor and is a guided along a length of the mandrel.

Owner:U S SAWS

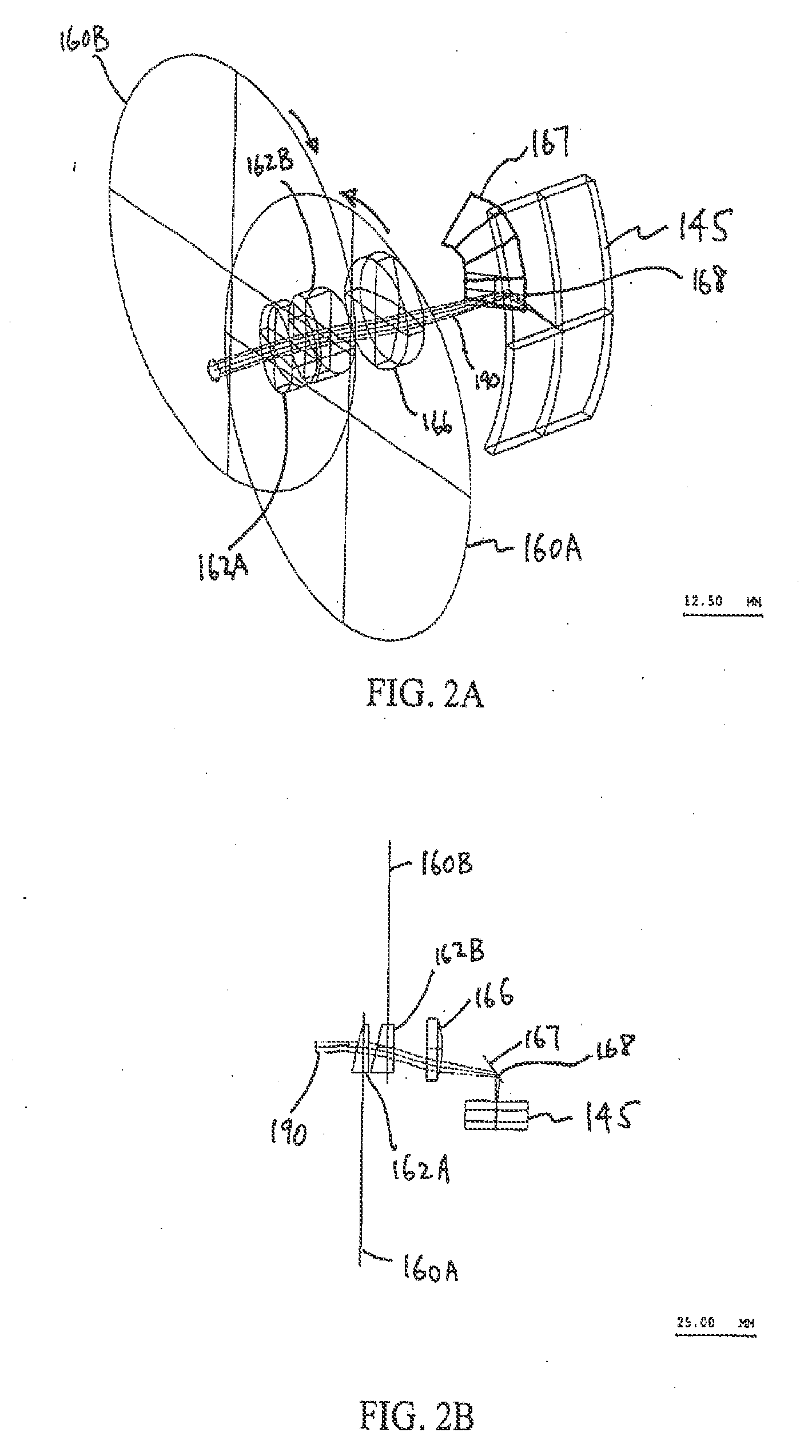

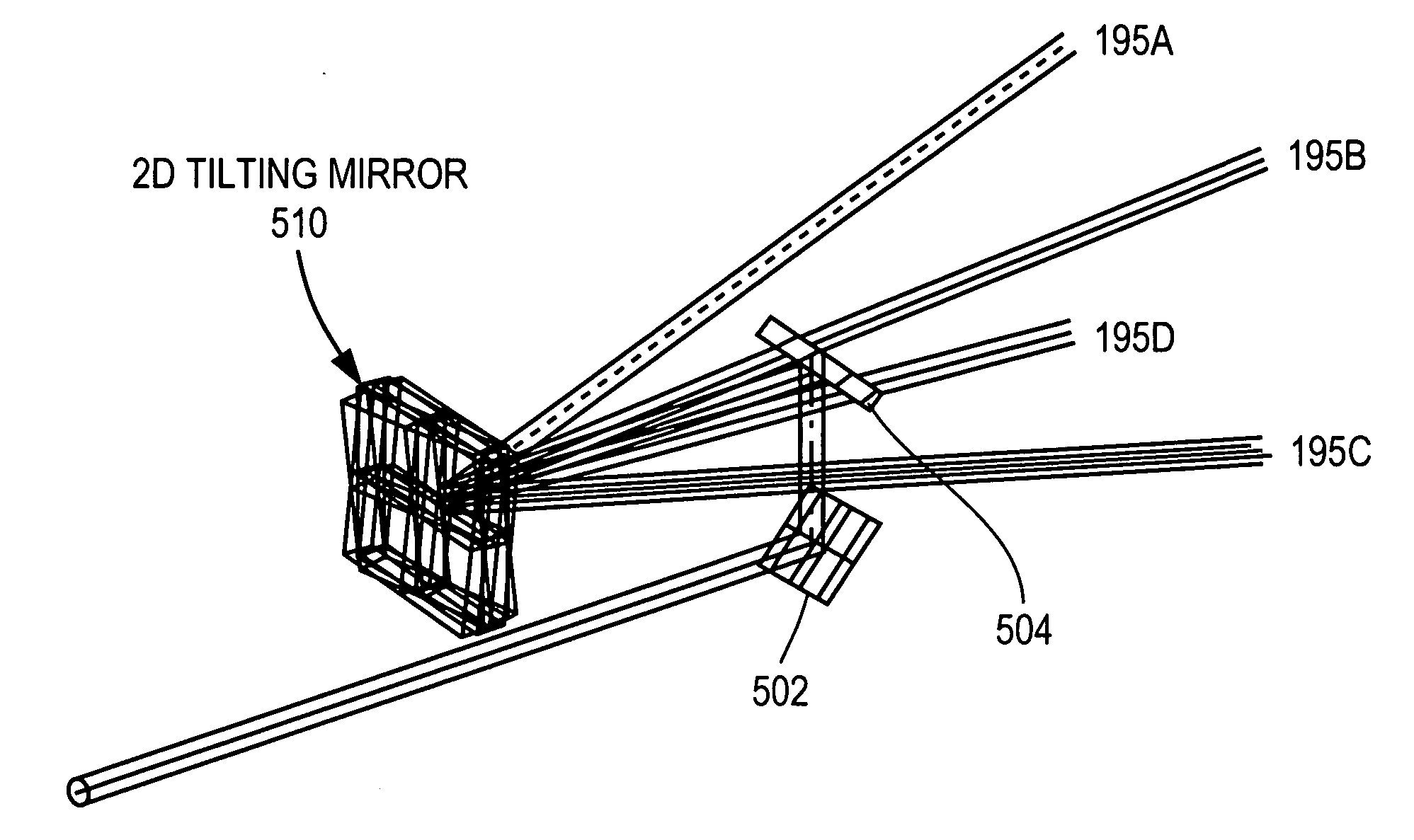

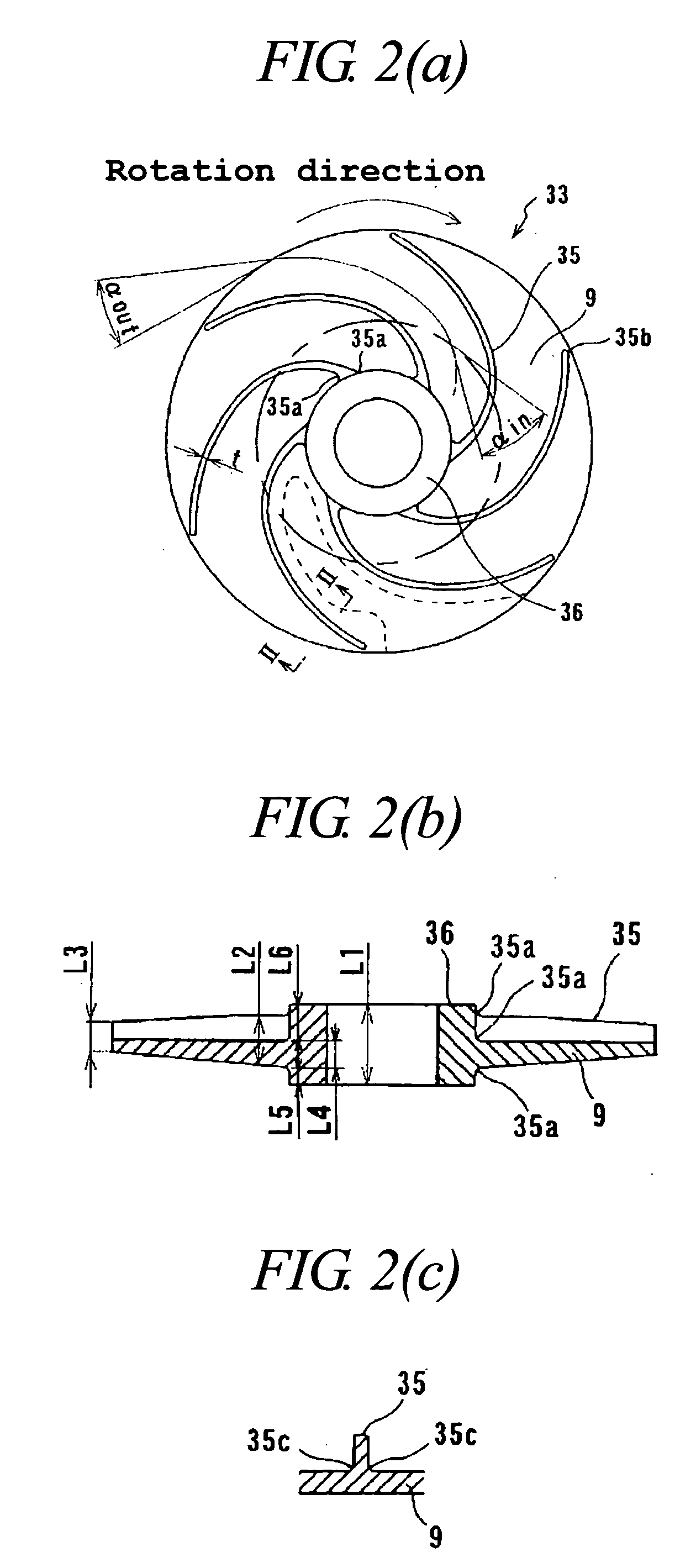

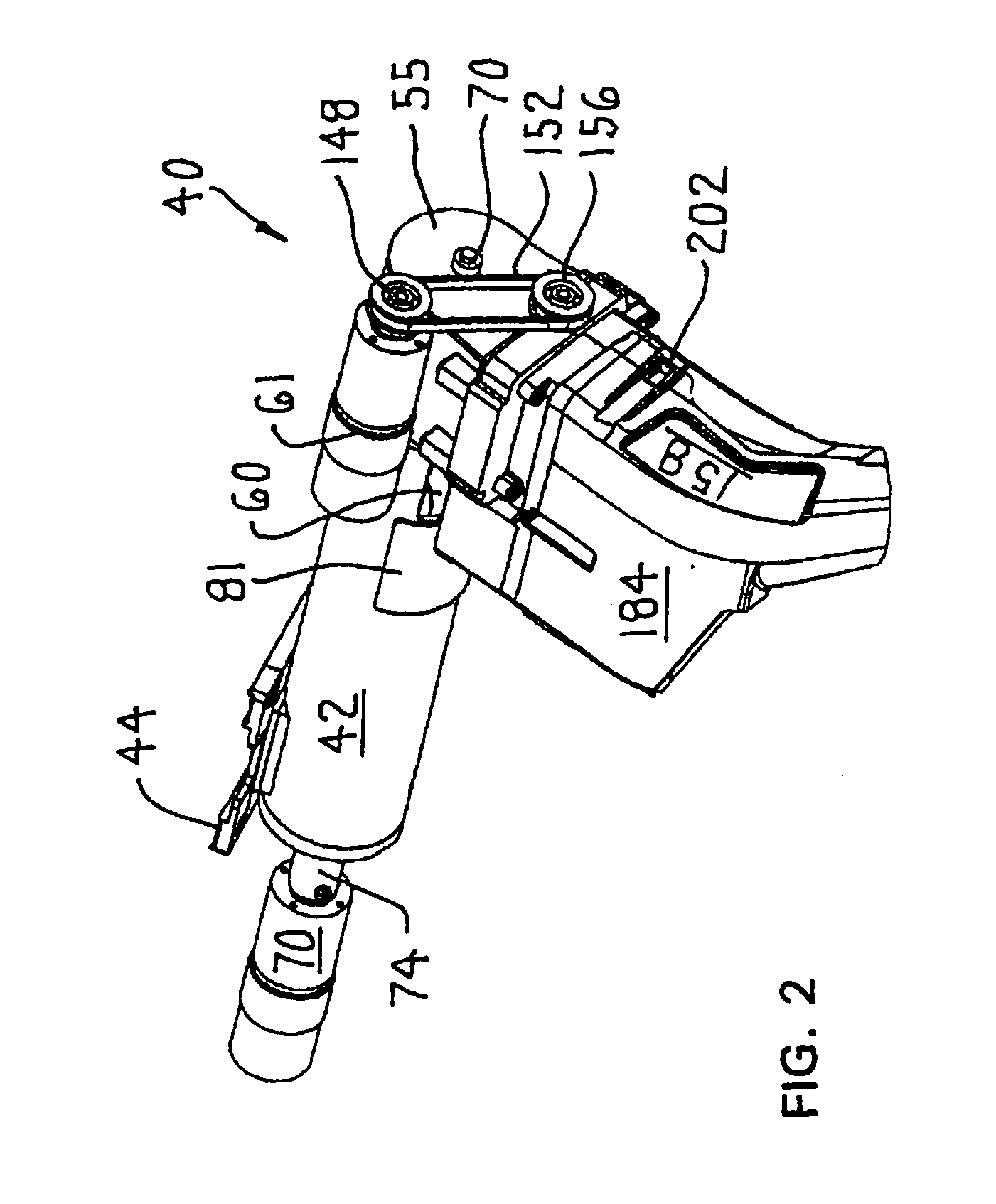

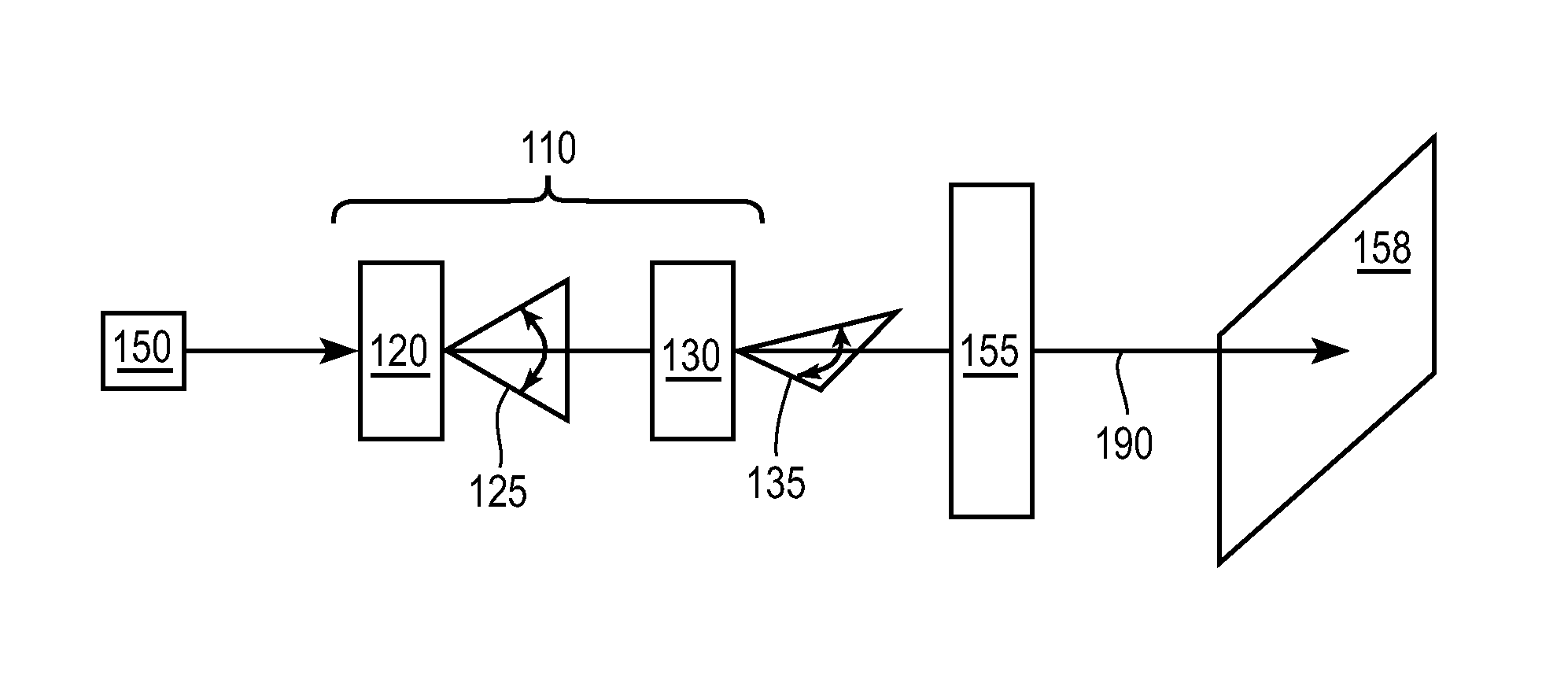

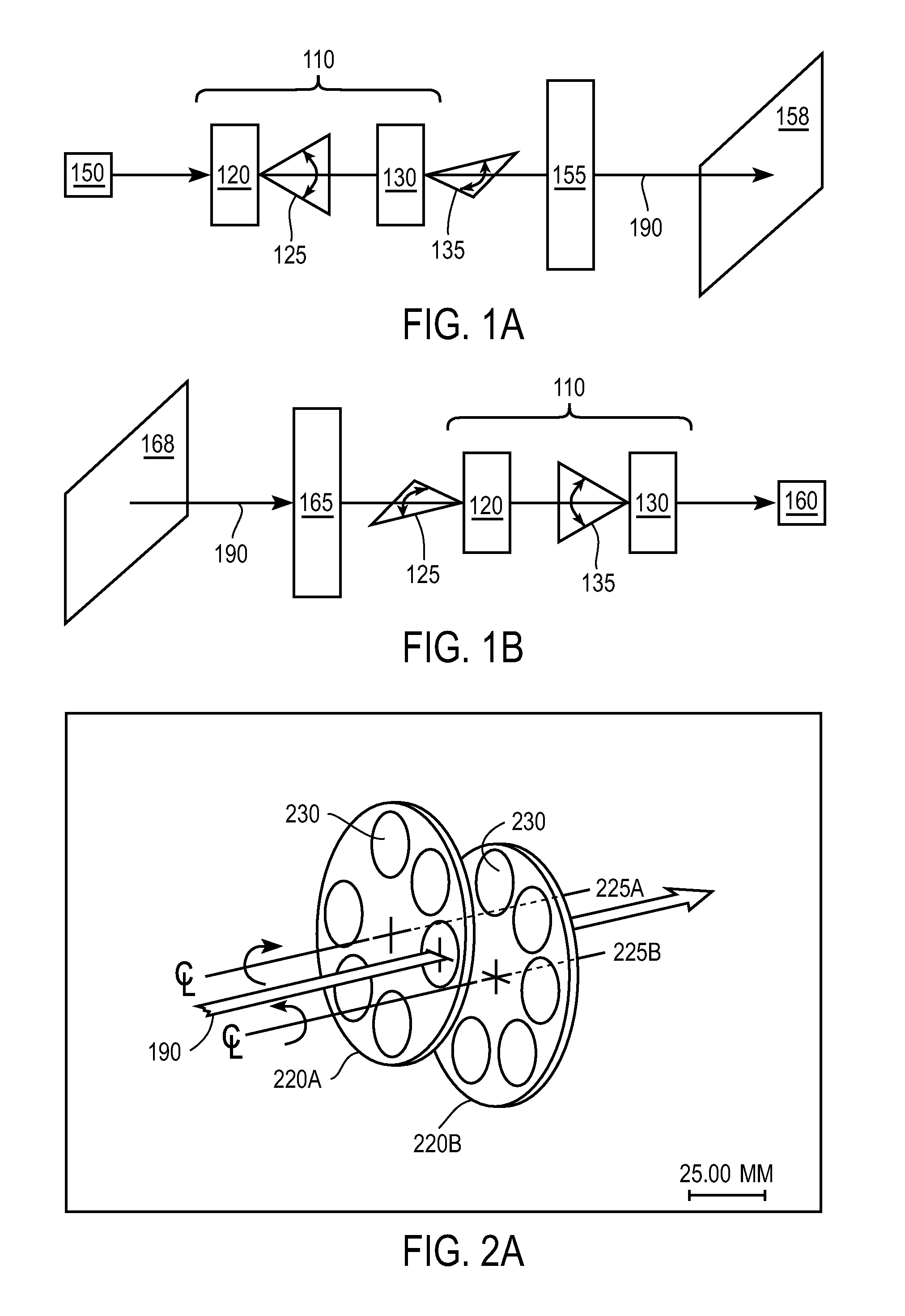

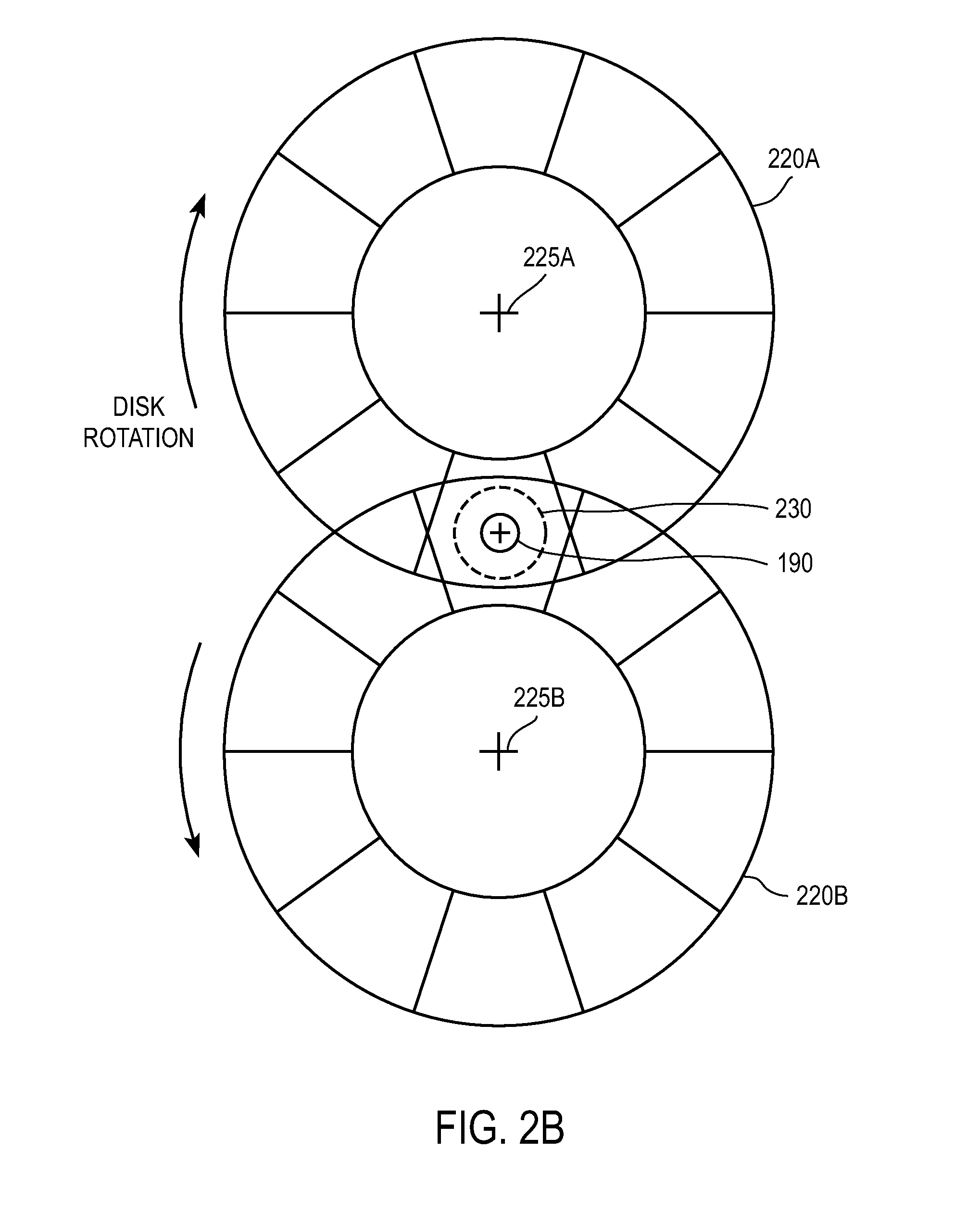

Two-dimensional optical scan system using a counter-rotating disk scanner

ActiveUS7196831B2Net bow is significantly reducedIncrease speedProjectorsOptical elementsOptical axisComputer science

A counter-rotating disk scanner together with another scan mechanism provides two-dimensional optical scanning. The counter-rotating disk scanner includes counter-rotating scan disks that implement the scanning action as they rotate through an optical axis of the system.

Owner:SOLTA MEDICAL

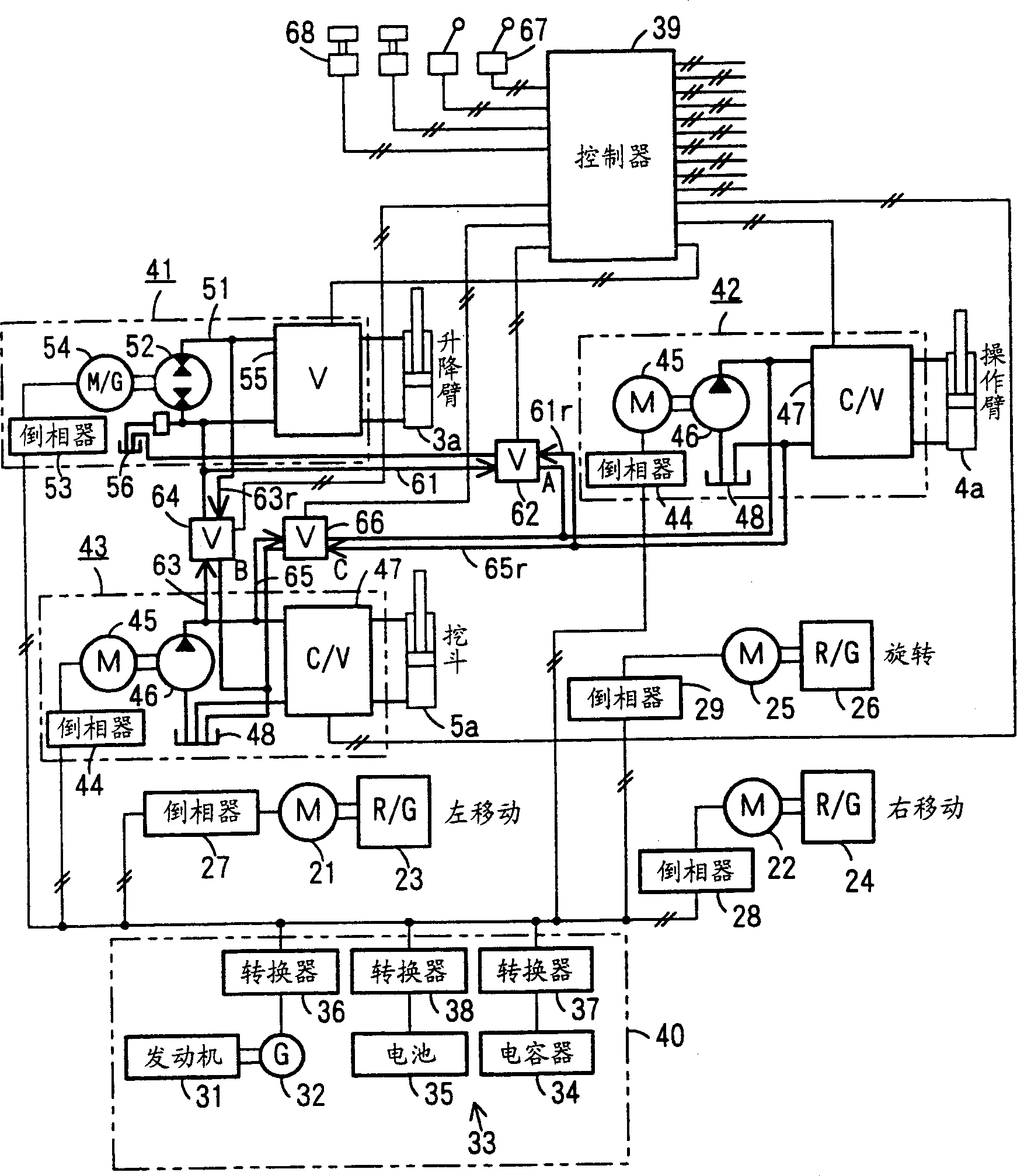

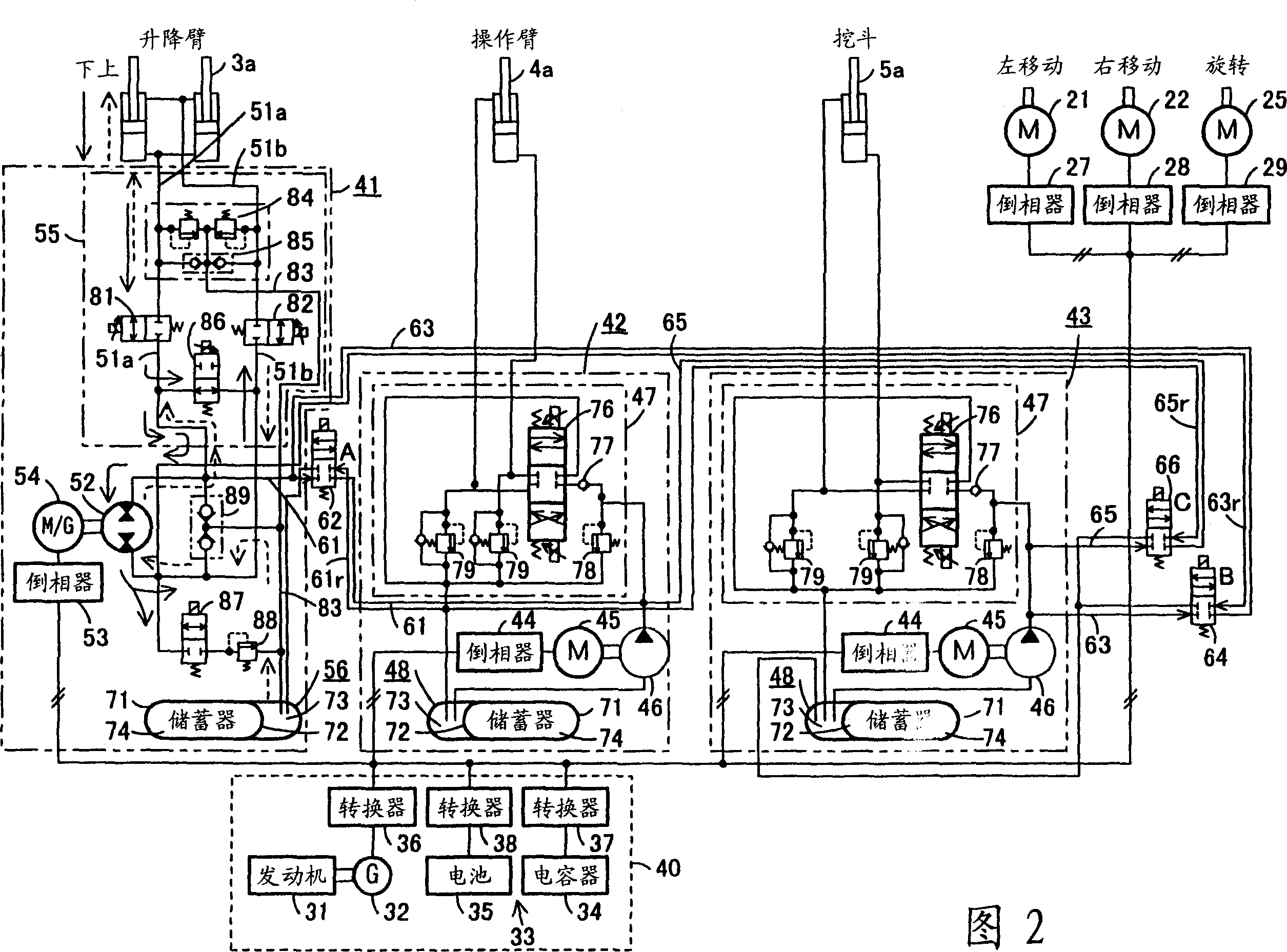

Working machine driving unit

InactiveCN1685161AReduce the numberLow costServomotorsServometer circuitsElectric power systemEngineering

A driving device of a work machine includes a power generator adapted to be driven by an engine, and a power storage device for storing the electric power generated by the power generator. Electric motors and a motor generator, both adapted to be operated by electric power supplied from either one or both of the power generator and the power storage device respectively drive pumps and a pump motor. Supporting circuits for feeding supporting hydraulic oil are provided between a plurality of driving circuits that drive a plurality of hydraulic actuators of a working unit by oil hydraulics generated by the pumps and the pump motor. By enabling the plurality of driving circuits to effectively share excess energy, the invention makes possible a compact construction of a driving device of a work machine.

Owner:CATEPILLAR SARL

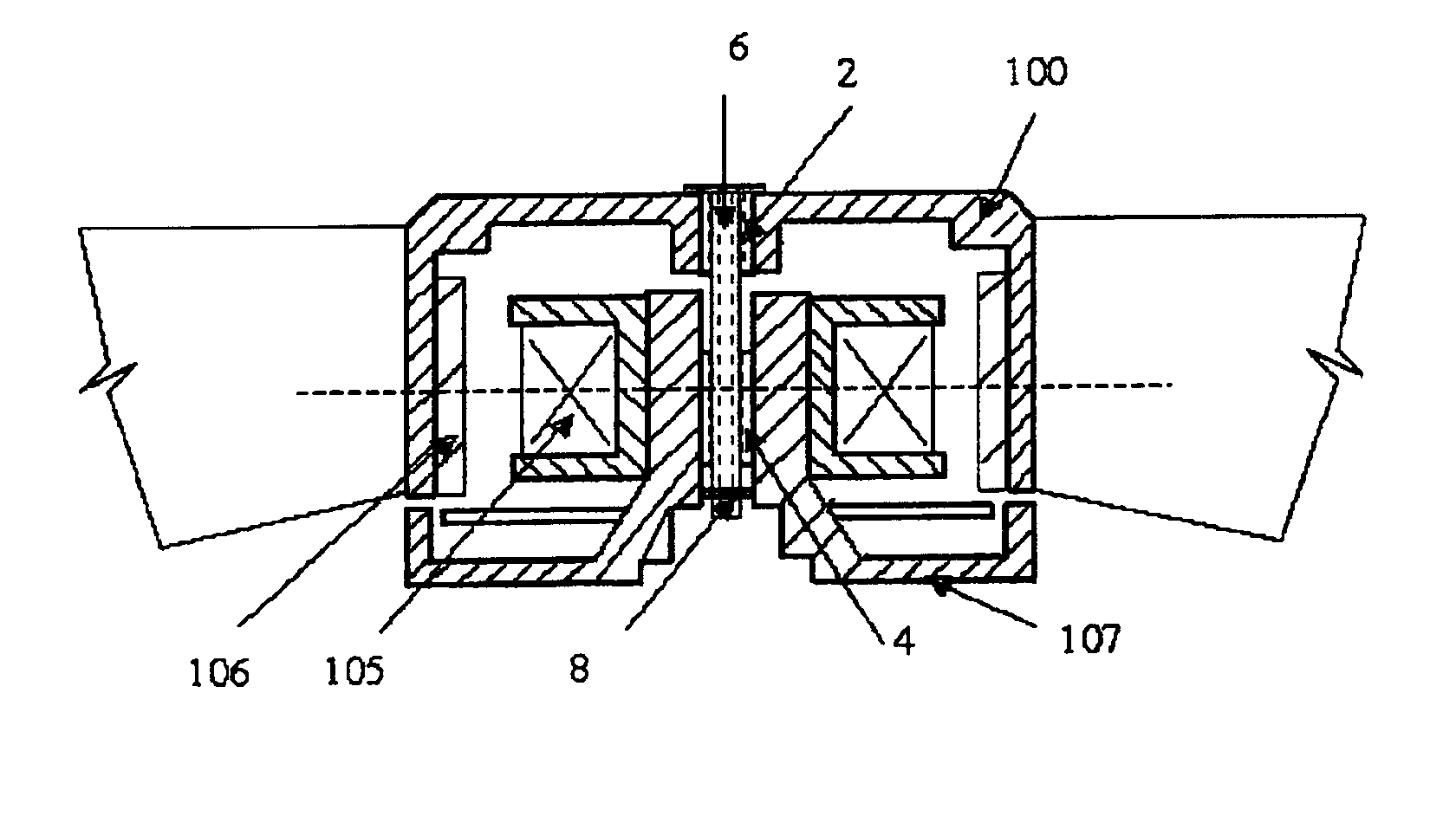

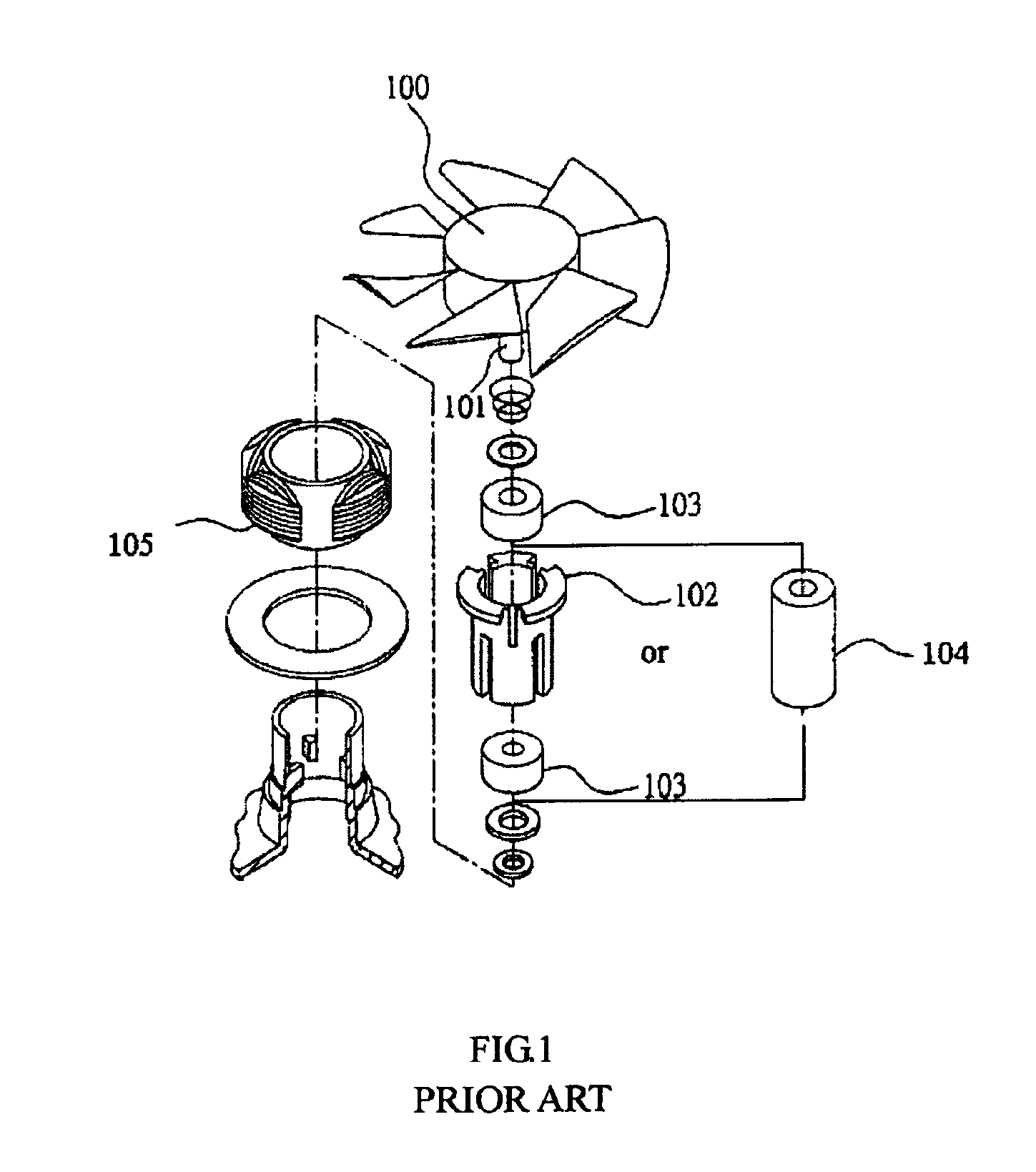

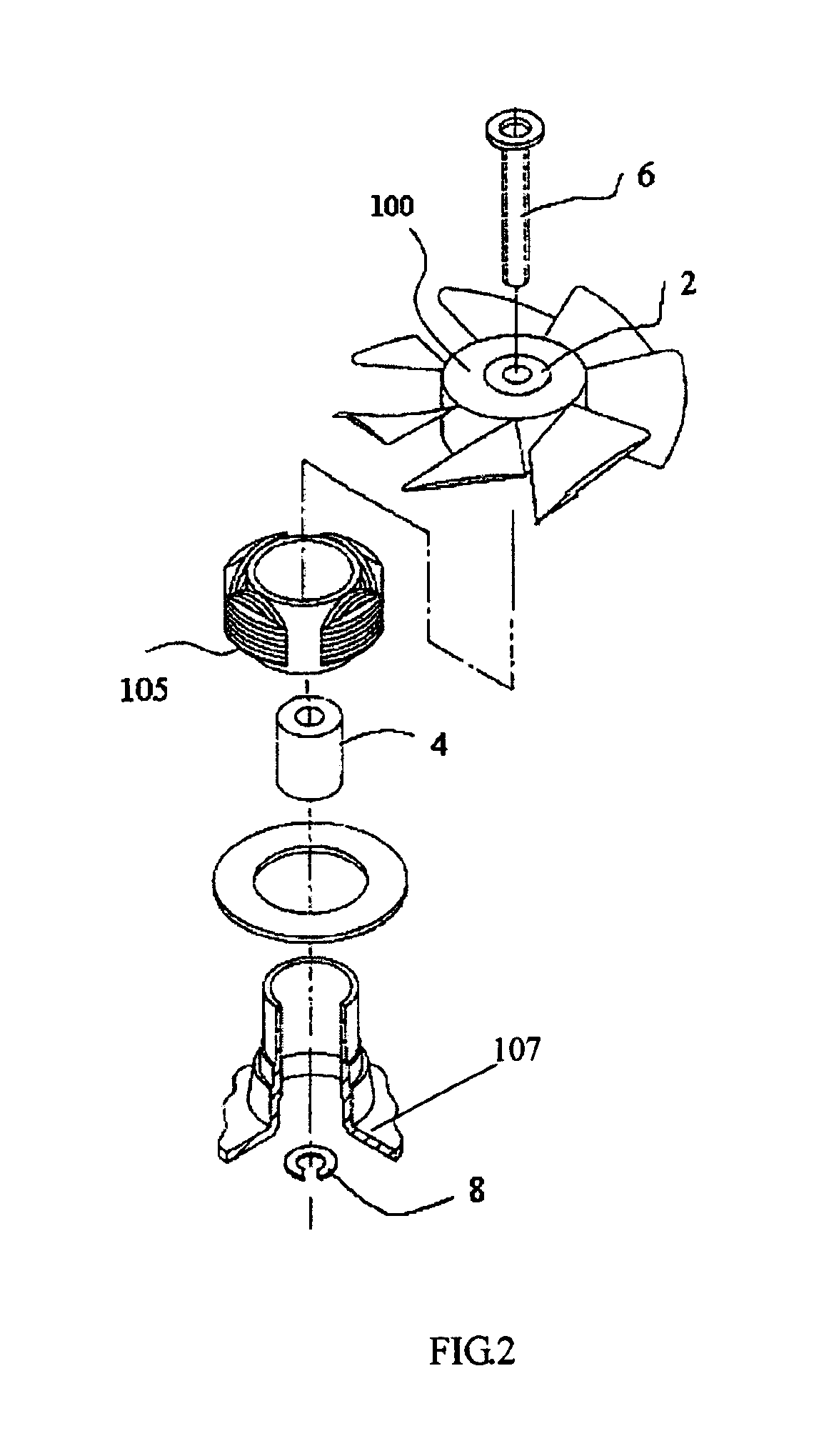

Rotation support of heat-dissipation fan

InactiveUS6893230B2Reduce frictionHigh speed rotationPropellersPump componentsFriction reductionFree rotation

An improved structure for rotational support for a heat-dissipation fan is disclosed, comprising a hollow ceramic bearing passing through and concentric with the fan rotor and rotating with said rotor, a hollow ceramic support bearing fixedly mounted to the base of the fan, and a hollow or solid ceramic axle tube passing through the inside of said bearing and rotating freely to reduce friction and allow high-speed rotation. The exterior surface of said bearing is ground or otherwise formed to provide better connection with the rotor, while the interior of the bearing and exterior of the axle tube are further processed to reduce contact area therebetween to reduce rotation friction. This improved structure has achieved reduced friction, reduced noise, reduced power consumption, longer life and higher rotational speed.

Owner:SUNG KUAN KUAN +1

Permanent magnet motor

InactiveUS7474027B2Cogging torque is smallImprove linearityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPermanent magnet motor

A permanent magnet motor 1 includes a rotor in which permanent magnets 31 are fixed. In the rotor 20, the outer peripheral shape of rotor magnetic-pole portions 24 is formed so that, in the circumferentially central portion, the distance from the center of the rotor iron core 21 is longest, and, at the inter-polar space, the distance from the center of the rotor iron core is shortest, and so that the outermost surface of the rotor magnetic-pole portions 24 forms an arc, and given that sheath thickness tc formed by the outer-side surface of each permanent magnet 31 and the outermost surface of each rotor magnetic-pole portion 24 is practically constant, and letting the thickness of the permanent magnets be the magnet thickness tm, then the relation tc / tm≦0.25 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

Hole coring system

A hole coring system is provided that greatly stabilizes a tubular core drill bit for drilling into concrete or other materials enabling large diameter holes to be drilled with a handheld tool. The hole coring assembly includes a hollow drive shaft assembly that fits over a stationary mandrel that is initially installed and anchored in a pilot hole in the concrete or other material. Once the mandrel has been firmly installed as a guidepost extending rigidly out from the concrete surface, the hollow drive shaft assembly is lowered onto the mandrel. The drive shaft assembly is stabilized relative to the mandrel by means of elongated, cylindrical bearing sleeves, which may be formed of self-lubricated or fluid lubricated bearing materials. The mandrel serves as a central guidepost that ensures that a relatively large diameter, tubular core drill bit remains precisely centered relative to the guide mandrel. This enables the operator to use a commonly available tool to rotate the drill and apply drill pressure only. Preferably a releaseable latch and catch mechanism is provided to releaseably couple the drive shaft assembly to said mandrel.

Owner:U S SAWS

Rotating electrical machine and method for manufacturing rotating electrical machine

InactiveUS20120007464A1Guaranteed normal transmissionAvoid contactMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

Provided are a rotating electrical machine and a method for manufacturing the rotating electrical machine, wherein the tapered surface of a plate-side tapered section and the tapered surface of a shaft-side tapered section are bonded with pressure by having forces operate between a plurality of plate-side protruding sections and a plurality of shaft-side protruding sections in the directions wherein the plate-side protruding sections and the shaft-side protruding sections are separated from each other. Thus, a ring core is fixed to a shaft.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com