Wet-type dust-removal fan

A wet dust removal and fan technology, which is applied in the directions of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of low air volume handling capacity and dust removal efficiency, easy to burn out fan motor maintenance work, and large resistance of dust removal system, etc. No need for frequent maintenance, significant energy-saving effect, and the effect of ensuring operational safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

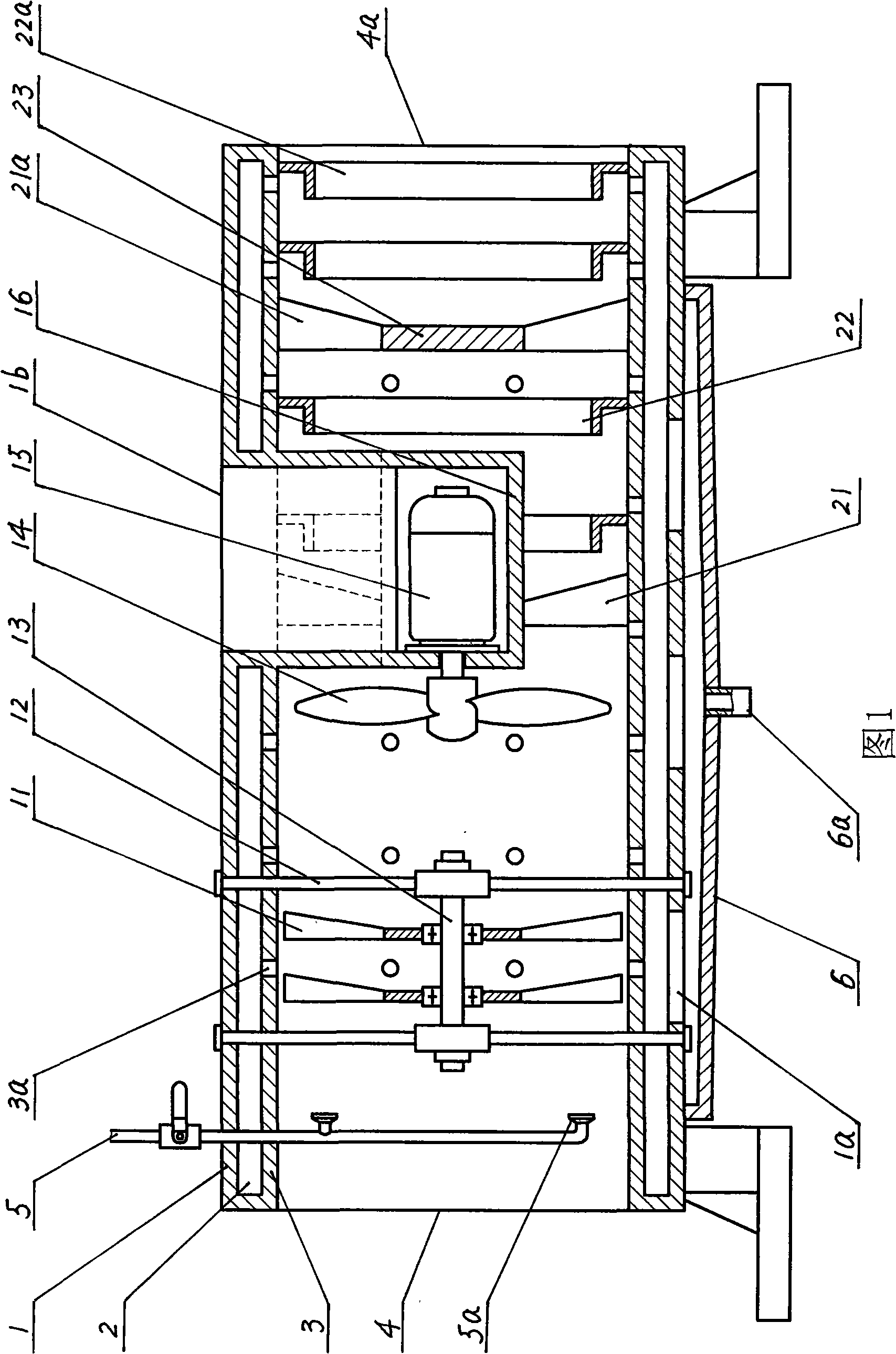

[0016] The front position in the air duct of the present invention is installed with water spray nozzle 5a, and the middle position is installed with the motor 15 of fan impeller 14; Open port 1b is offered on the air duct, and the protective shell 16 that is provided with heat dissipation port is arranged in the air duct, And it is connected with the blower, the port 1b communicates with the cooling port of the protective case 16 correspondingly, and the motor 15 is installed in the protective case 16 . The air cylinder is composed of an outer cylinder wall 1 and an inner cylinder wall 3 with several through holes 3a. There is a sandwich cavity 2 between the outer cylinder wall 1 and the inner cylinder wall 3; the bottom of the outer cylinder wall 1 is provided with a water outlet. 1a, the water storage box 6 is connected to the lower part of the outer cylinder wall 1, and corresponds to the water outlet 1a, and the bottom of the water storage box 6 is provided with a drainage...

Embodiment 2

[0019] On the basis of Embodiment 1, a plurality of water collection rings are respectively arranged at the rear positions of the two separated impellers 11 in the air cylinder, and there are intervals between them, and the plurality of water collection rings are respectively connected to the inner wall of the inner cylinder wall 3. It can make the dusty water flow on the inner wall of the inner cylinder wall 3 pass through the collection of the water collection ring, and then flow into the water storage box 6 regularly and be discharged. The water collecting ring can reduce the moisture content in the air, so as to avoid excessive humidity of the air discharged from the air outlet 4a.

Embodiment 3

[0021]On the basis of Embodiment 1, in the interval between the protective shell 16 and the inner cylinder wall 3, a first deflector composed of several first-stage deflector vanes 21 arranged in a circle is arranged, each of which is The outer ends of the first-stage guide vanes 21 are respectively connected to the inner cylinder wall 3, and the inner ends are respectively connected to the protective shell 16; There are intervals between them. The swirling centrifugal force generated by the first deflector can throw the dust-laden liquid droplets onto the inner cylinder wall 3 provided with several through holes 3a again, and the dust-laden liquid droplets enter the interlayer cavity 2 through the through holes 3a and fall. After entering the water storage box 6, it is discharged through the drain port 6a; in addition, the dusty water flow on the inner wall surface of the inner cylinder wall 3 is collected by two first-stage water collection rings 22 arranged in sections and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com