Working machine driving unit

A technology for driving devices and working machines, which is applied in the direction of fluid pressure actuating devices, mechanical equipment, and motor speed or torque control. The effect of eliminating pressure loss and throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

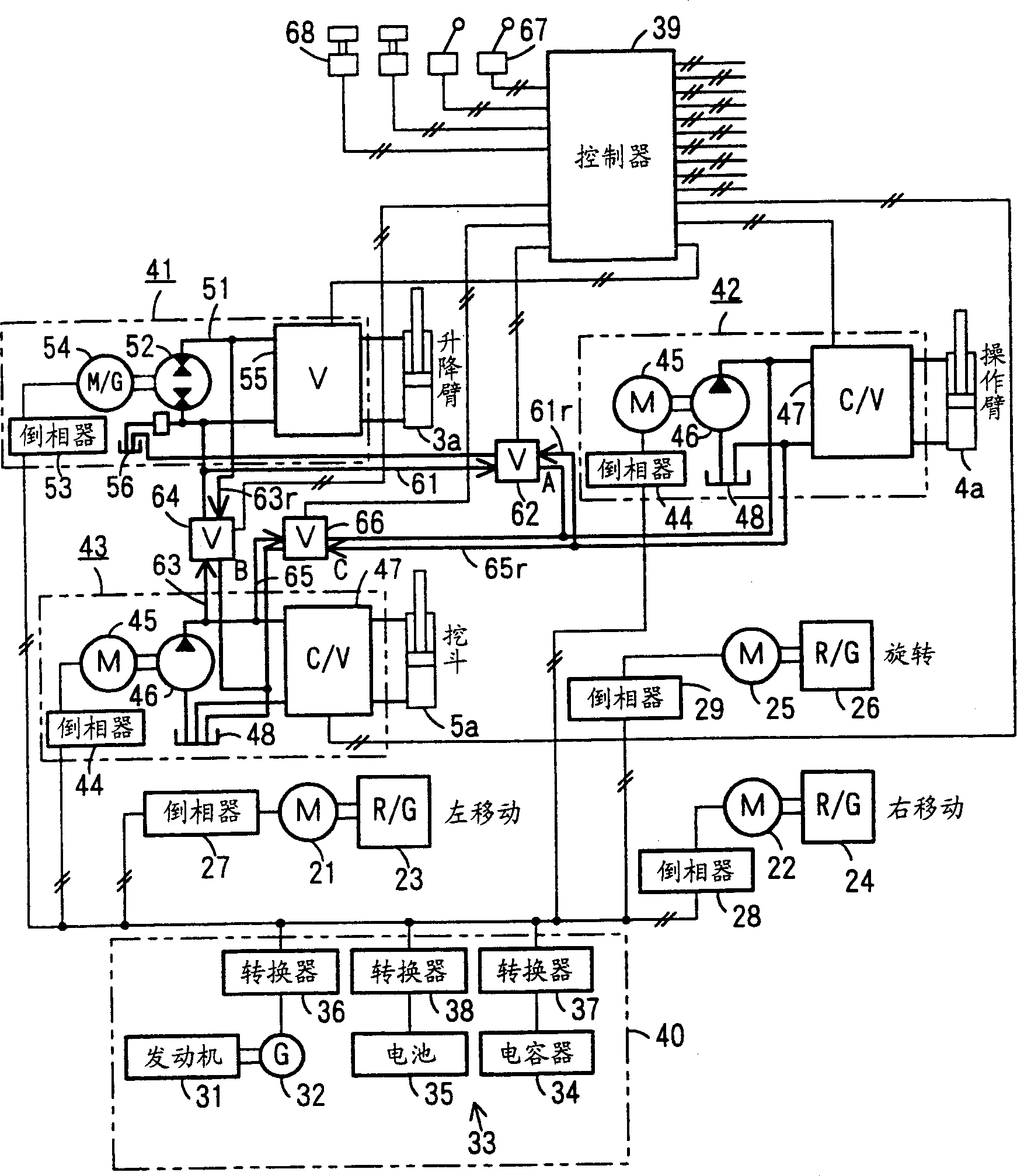

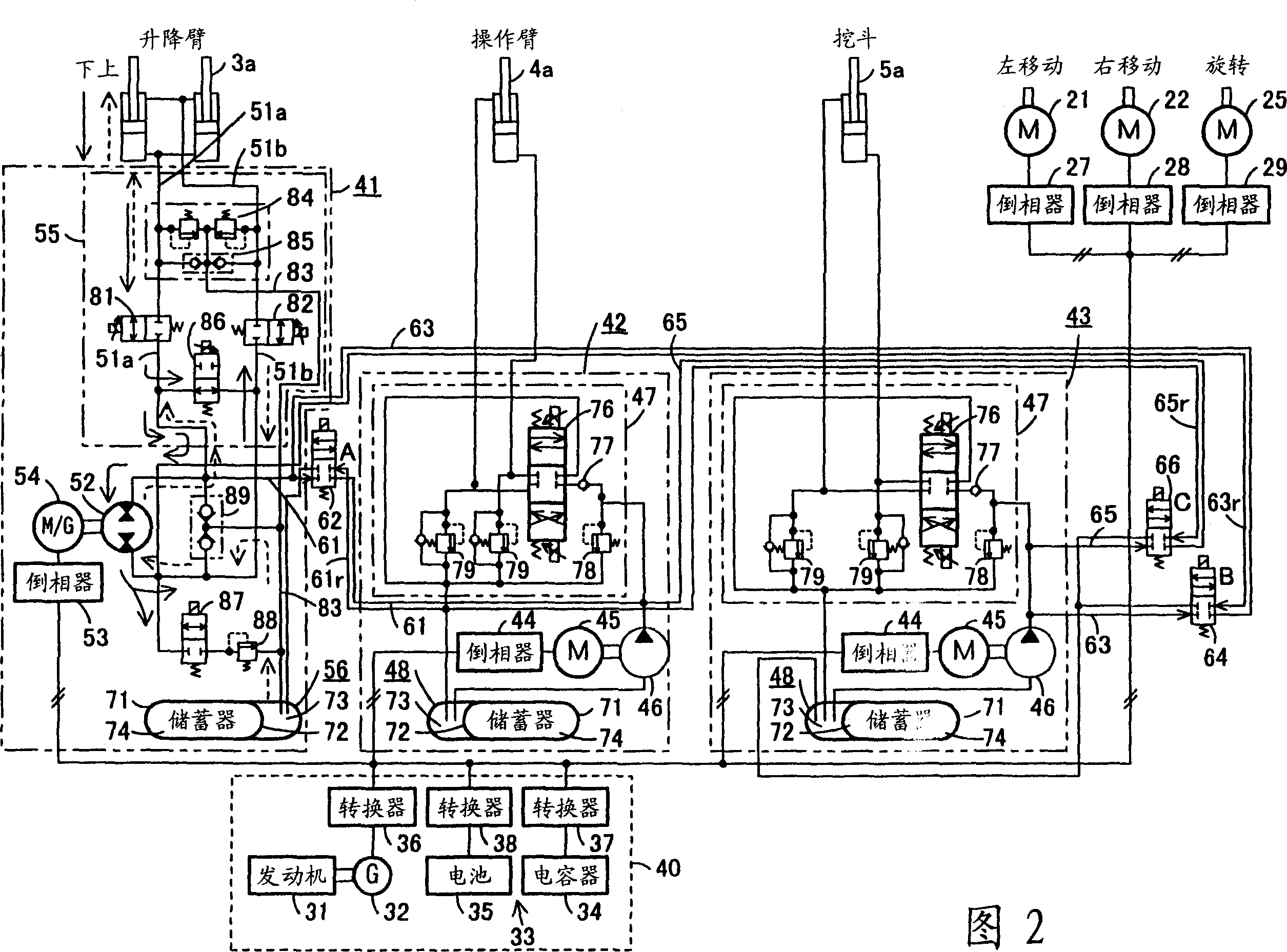

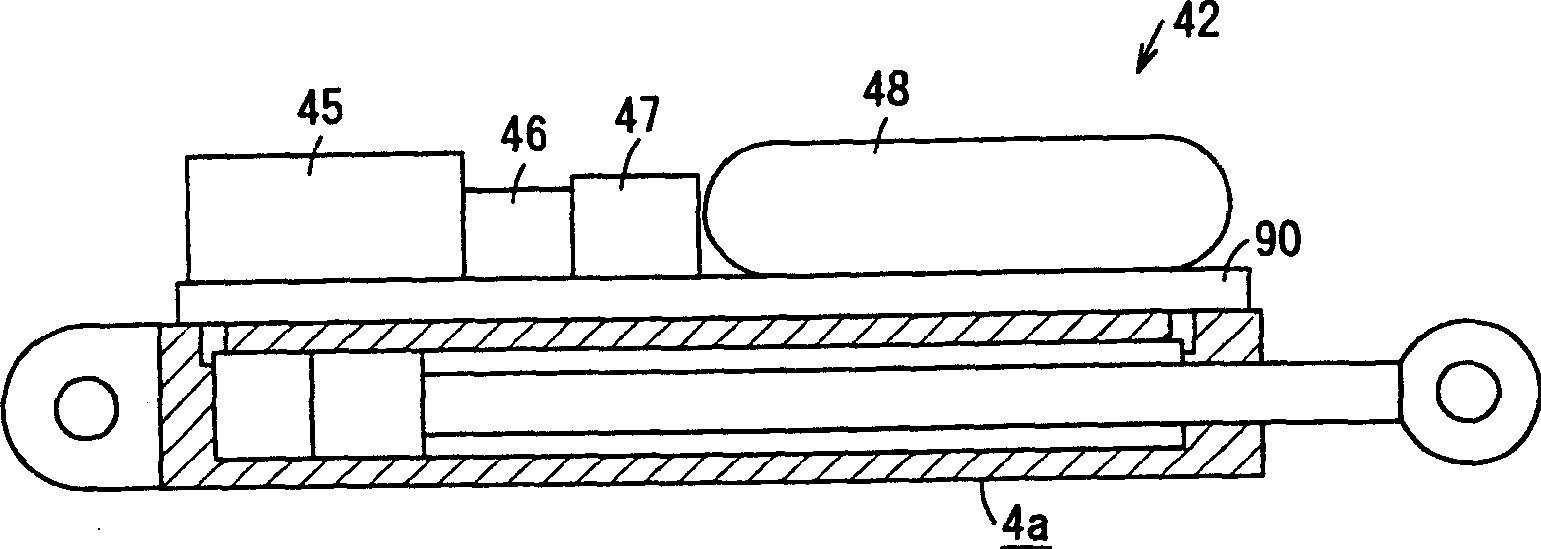

[0031] Below, combine Figure 1 to Figure 3 The first embodiment shown, Figure 4 The second embodiment shown, Figure 5 The third embodiment shown, Figure 6 and Figure 7 The fourth embodiment shown, and Figure 8 The shown fifth embodiment describes the present invention in detail. In addition, about Figure 9 The description of the shown hydraulic excavator is also used in the description of the present invention.

[0032] figure 1 Indicates the first embodiment of the driving device of the working machine, such as Figure 9 As shown, the working machine is a hydraulic excavator as a construction machine having a working device 6 that sequentially connects an elevating arm 3 , an operating arm 4 , and a bucket 5 . figure 1 Represent the circuit diagram of the composite driving device with the lifting arm-operating arm-digging bucket-compound circuit of the hydraulic excavator, and Fig. 2 shows the circuit diagram using figure 1 The circuit diagram shown is a more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com