Vibration isolator with active vibration absorbing ability

A vibration-absorbing capacity and vibration isolator technology, applied in the direction of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of wasting a lot of space, limited space, occupation, etc., to improve the level of lightweight, reduce transmission, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

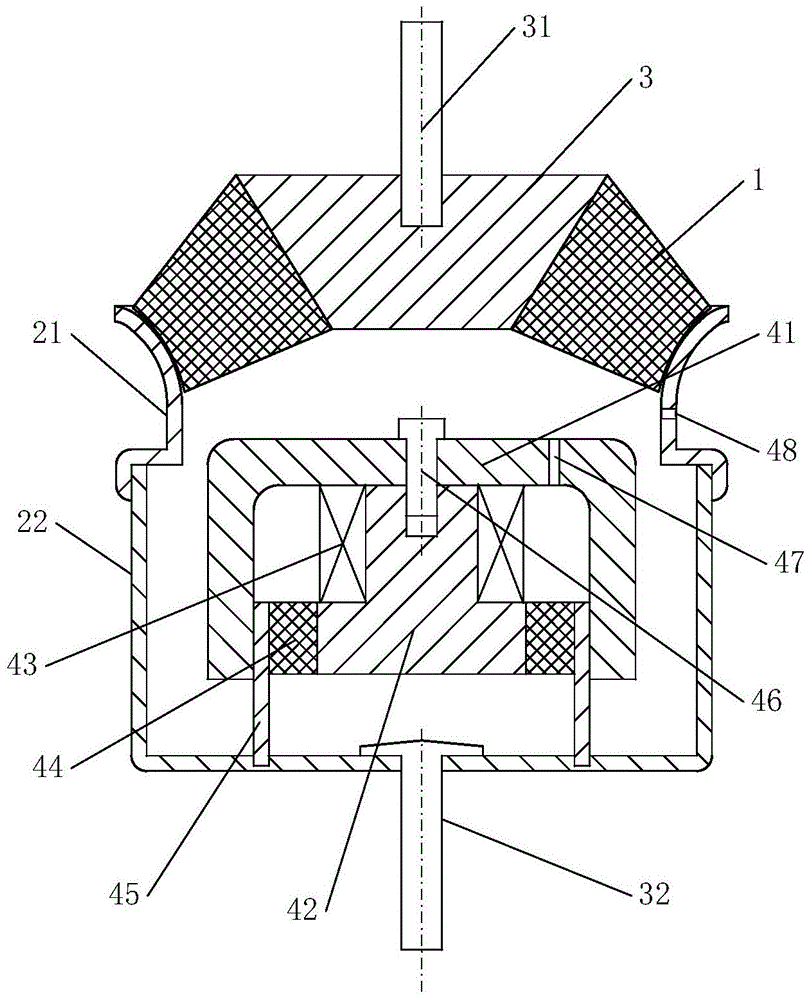

[0028] see figure 1 , Figure 2a , Figure 2b , Figure 3a , Figure 3b , Figure 4a and Figure 4b , the structural form of the vibration isolator with active vibration absorption capacity in this embodiment is:

[0029] A cylindrical upper casing 21 is provided, the rubber main spring 1 is blocked in the top opening of the upper casing 21, the main spring skeleton 3 runs through the rubber main spring 1, and a connecting stud 31 is arranged on the top of the main spring skeleton 3, The upper end of the connecting stud 31 is used to connect with the base body, and plays the role of connecting the rotating machine with the base body. The connecting stud 31 can also be processed as a whole with the main spring frame 3 .

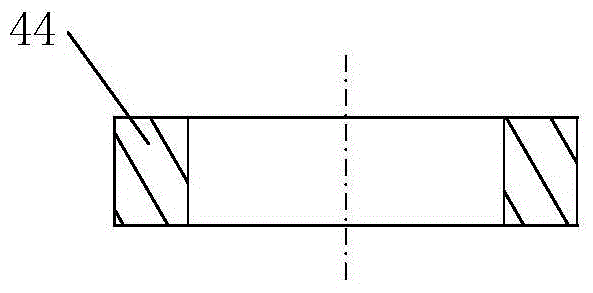

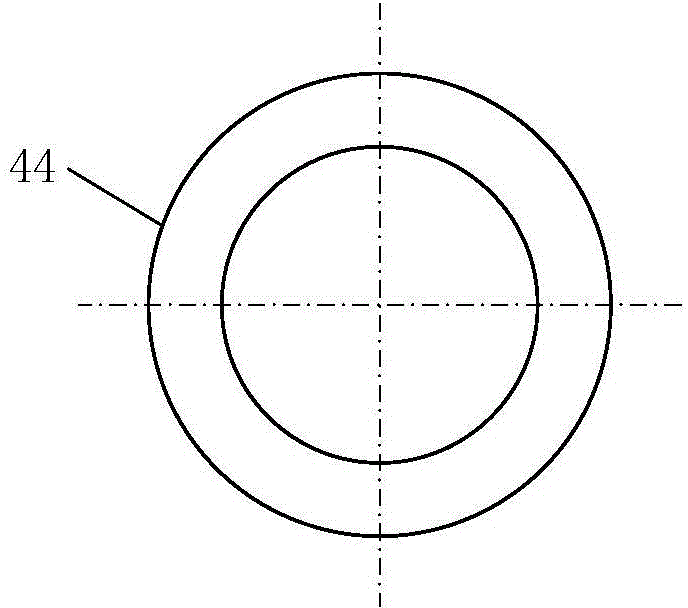

[0030] A lower housing 22 connected to the upper housing 21 is provided, and the lower housing 22 is used as an active vibration absorber housing cavity. In the lower housing 22, a shearing sleeve 45 is fixedly arranged on the bottom plate of the lower h...

Embodiment 2

[0035] see Figure 5 , the structural form of the vibration isolator with active vibration absorption capacity in this embodiment is:

[0036] A "T"-shaped main spring frame 3 is formed by a horizontal top plate and vertical struts, and the rubber main spring 1 is fixedly arranged on the upper surface of the horizontal top plate, and the rubber main spring 1 is connected with the base.

[0037] The lower housing 22 and the cover-shaped upper housing 21 form the active vibration absorber housing cavity, and the vertical struts in the main spring frame 3 penetrate through the active vibration absorber housing cavity, and the vertical struts passing through the active vibration absorber housing cavity The other end of the strut is connected with the main vibrating object by a connecting bolt 32;

[0038] In the lower housing 22, the columnar iron core 42 wound with the excitation coil 43 is supported on the vertical strut of the main spring frame 3 by the magnetorheological elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com