Electric motor/generator

An electromagnetic coil and stator technology, applied in generator control parts, electronic commutation motor control, electric components, etc., can solve the problems of large size, complexity and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1A1

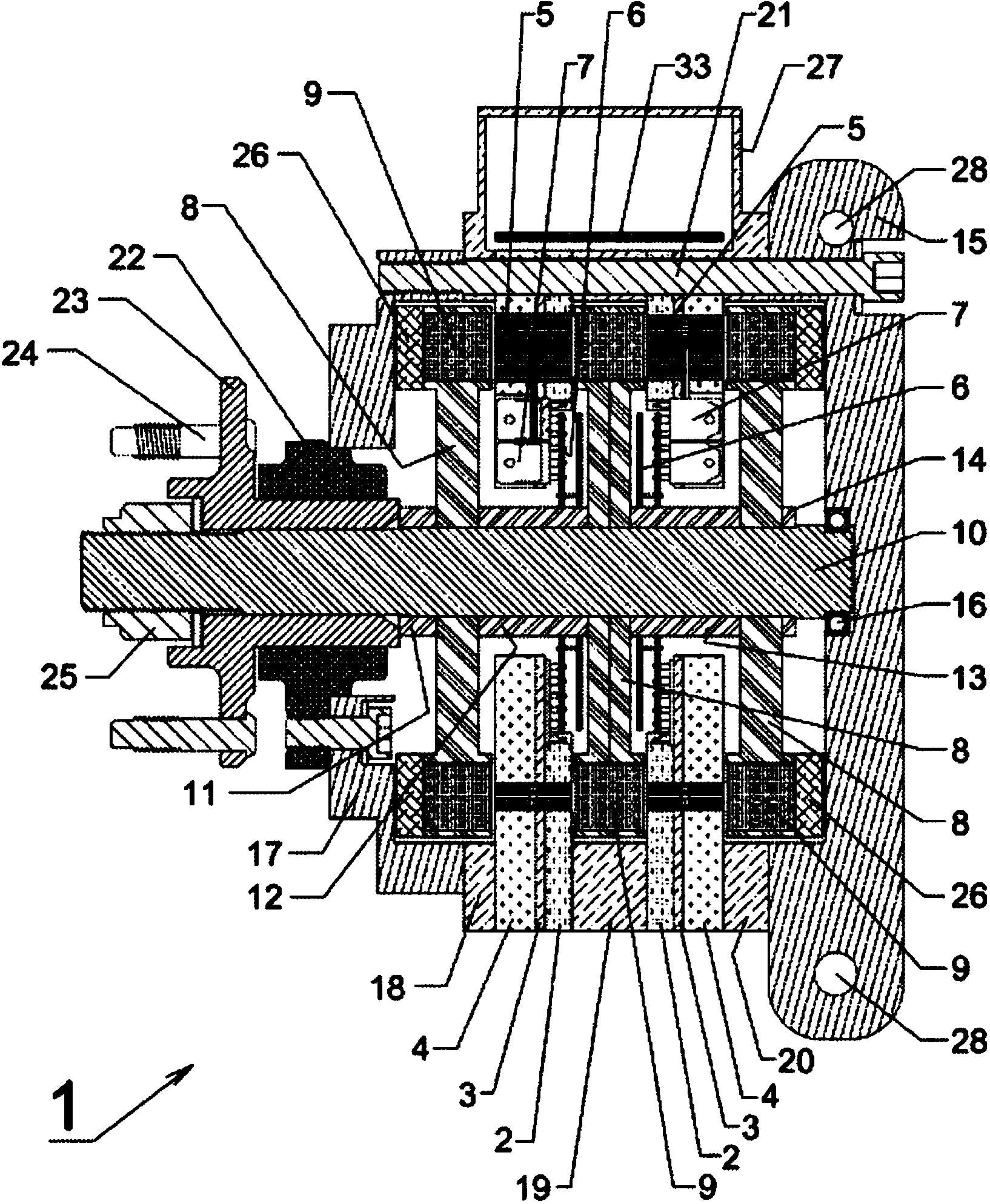

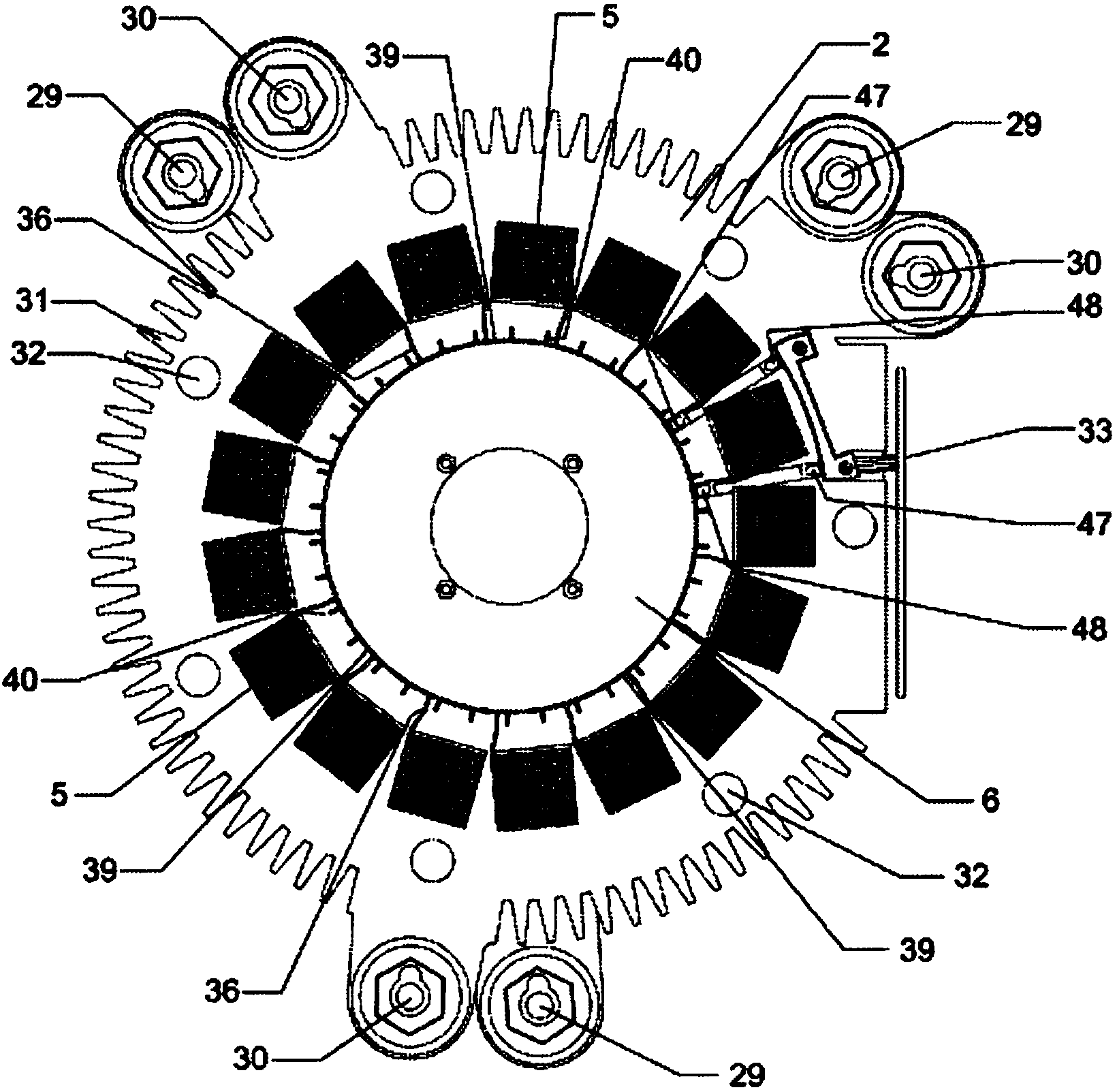

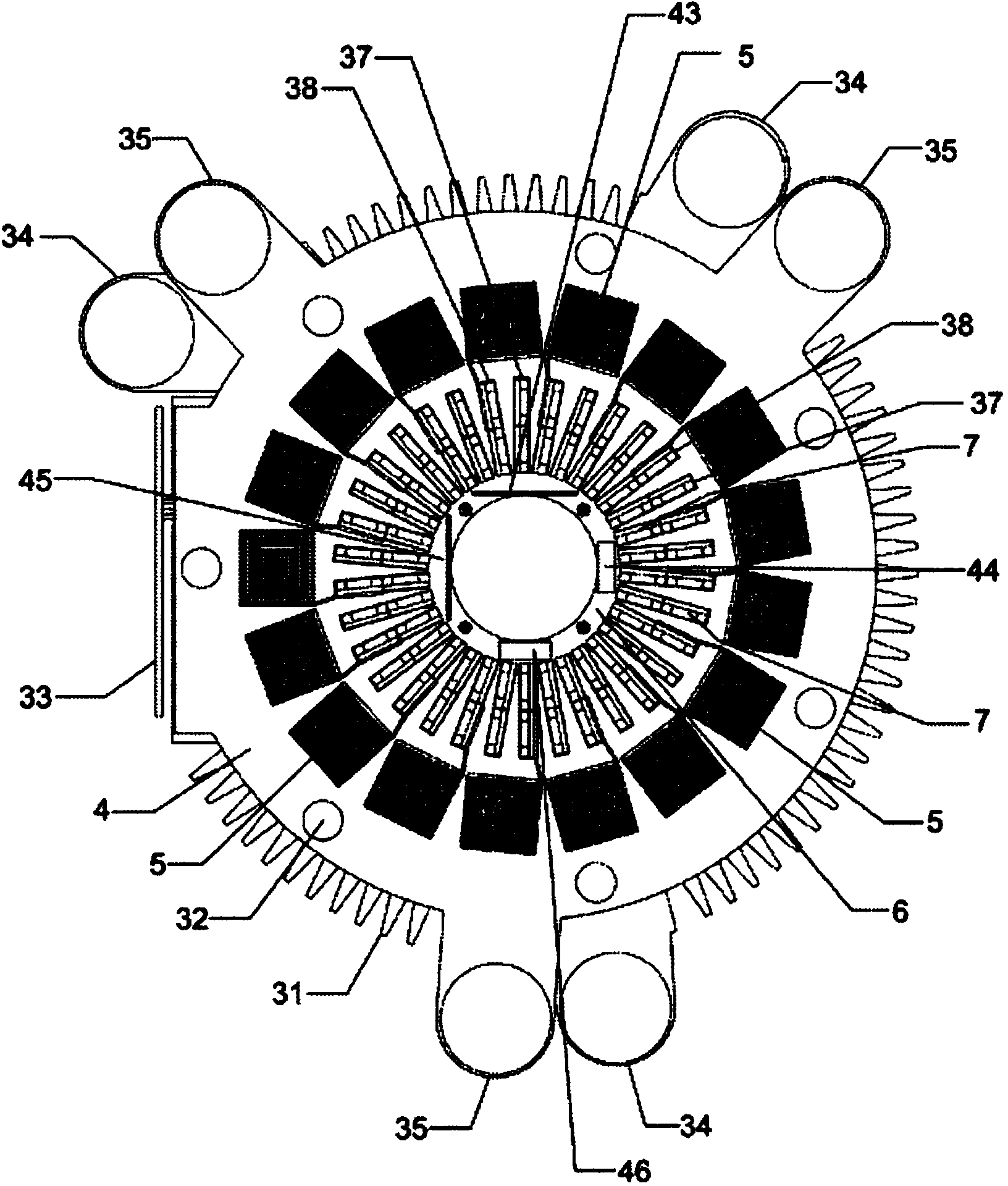

[0237] Example 1A.1 An electric machine comprising: at least one stator; at least one module, at least one module including at least one electromagnetic coil and at least one switch, at least one module attached to the at least one stator; at least one rotor with a motor attached to the at least one rotor a plurality of magnets, wherein at least one module is in spaced relationship to the plurality of magnets; and at least one rotor is in rotational relationship to at least one stator, wherein the number and configuration of at least one module in the electric machine is determined in part based on one or more operating parameters; at least one of the modules is individually controllable; and

[0238] At least one of the modules is reconfigurable based at least in part on one or more of: at least one operating parameter during operation, at least one performance parameter during operation, or a combination thereof.

example 1A2

[0239] Example 1A.2 The electric machine comprises: at least one stator; at least one module, at least one module including at least one electromagnetic coil and at least one switch, at least one module attached to the at least one stator; at least one slider with a a plurality of magnets of a block, wherein at least one module is in a spaced relationship to the plurality of magnets; and at least one slider is in a linear relationship to at least one stator, wherein the number and configuration of at least one module in the electric machine is based in part on one or more operating parameters wherein at least one module is individually controllable; and at least one module is reconfigurable based at least in part on one or more of: at least one operating parameter during operation, at least one performance parameter during operation, or a combination thereof.

example 1A3

[0240] Example 1A.3 The motor comprises: at least one stator; at least one module, at least one module including at least one electromagnetic coil and at least one switch, at least one module attached to the at least one stator; at least one slider with a A plurality of magnets of a block, wherein at least one module is in spaced relationship with the plurality of magnets; and at least one rotor is in linear, substantially linear, circular, substantially circular, arcuate, substantially arcuate, or combinations thereof with at least one stator wherein the number and configuration of at least one module in the electric machine is determined in part based on one or more operating parameters; wherein at least one module is individually controllable; and at least one module is reconfigurable based at least in part on one or more of the following : at least one operational parameter during operation, at least one performance parameter during operation, or a combination thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com