High-gradient magnetic flux converging medium for high intensity magnetic separator

A magnetic concentrating medium and high gradient technology, applied in the mineral processing field of mining and metallurgy engineering, can solve the problems of medium magnetic short circuit, easy blockage, etc., and achieve the effect of saving energy consumption, not easy to block, and small magnetic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

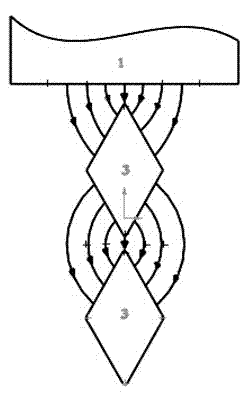

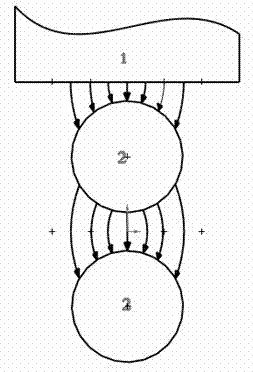

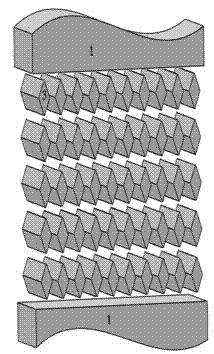

[0042] High gradient magnetic gathering medium of the present invention (see Figure 5 ) is used on XCSQ50×70 and double-ring magnetic separators, including non-magnetic metal plates 6 and magnetic medium rods 3, and the medium rods are riveted between two non-magnetic metal plates 6 to form a size suitable for the separation chamber of the magnetic separator. Sorting medium box, diamond-shaped magnetic-conductive medium rods are vertically riveted between two non-magnetic-conductive metal plates at a density of 50%, the length-to-width ratio of the two diagonals of the diamond-shaped cross-section is 2:1, and the lengths of the two diagonals of the rhombus-shaped cross-section are respectively 10mm and 5mm, the two top corners (acute corners) of the dielectric rod are rounded by R2mm.

[0043] Figure 5 Among them, the separation magnetic field space of the magnetic separator is the cross-sectional gap between the magnetic pole 1 (N) and the magnetic pole 1 (S) in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com