Radial magnetic field-based online abrasive grain monitoring sensor and monitoring method

A technology for monitoring sensors and radial magnetic fields, applied in instruments, material magnetic variables, analyzing materials, etc., can solve problems such as interference, fluctuation of monitoring results, inability to meet early fault prediction, etc., to reduce magnetic resistance, increase magnetic flux, The effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The online wear particle monitoring sensor and its monitoring method of the present invention will be described in detail below with reference to the accompanying drawings.

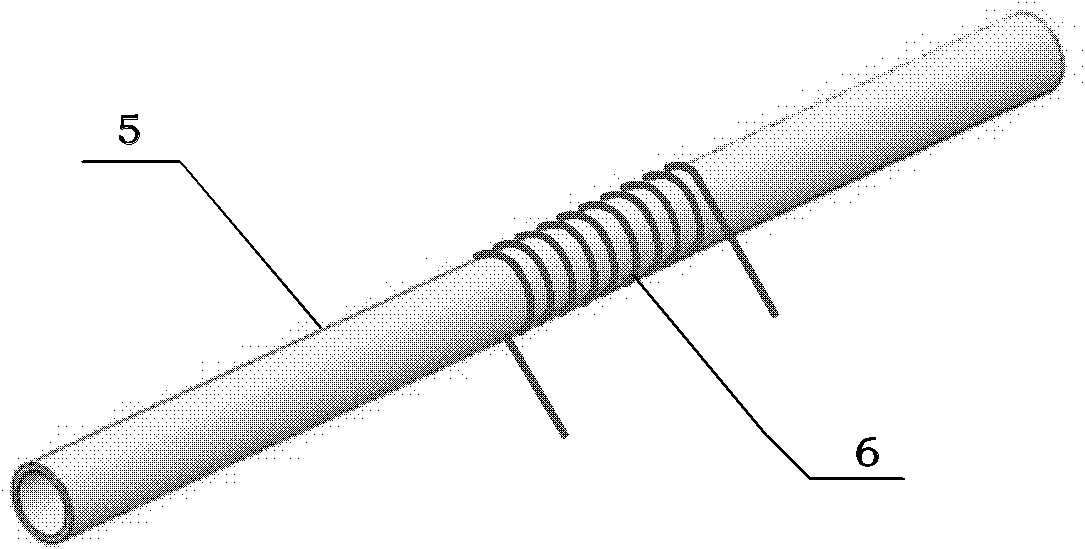

[0032] like figure 1 As shown, a traditional electromagnetic sensor is detecting abrasive particles. The coil 6 is directly wound on the oil pipe to form a magnetic field excitation source, and an axial magnetic field is applied to the oil pipe 5 . When the abrasive grains enter the sensor, the inductance of the coil 6 changes, and by detecting the inductance change, the material and size of the abrasive grains can be detected to a certain extent.

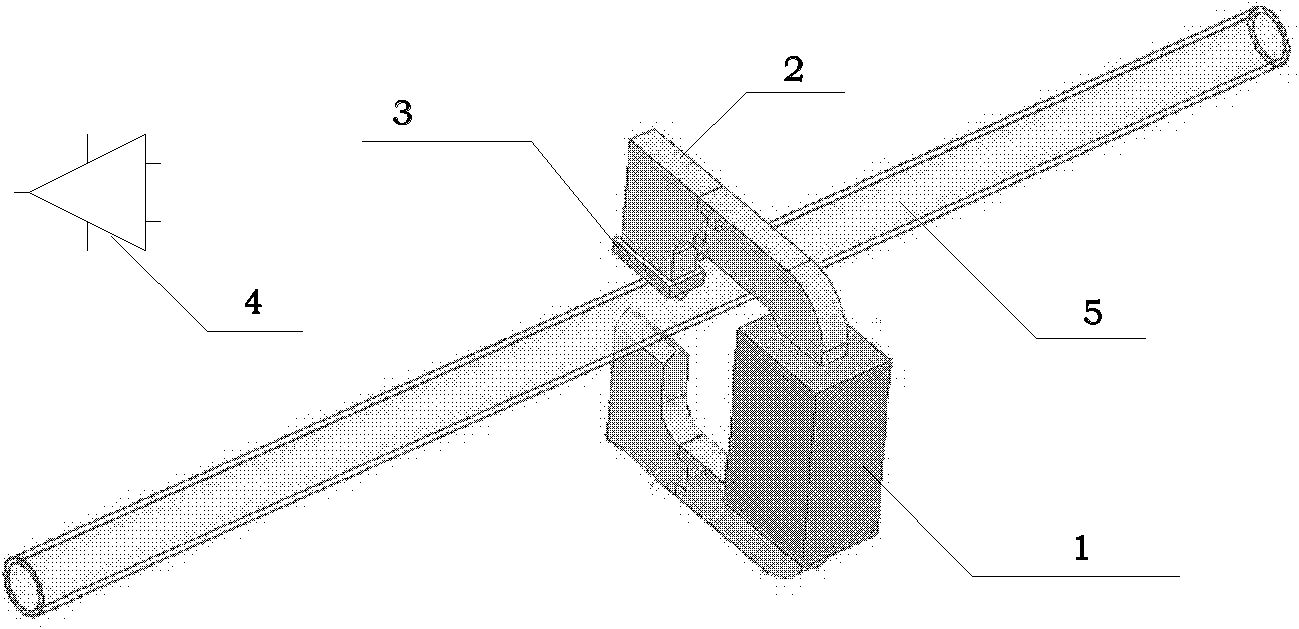

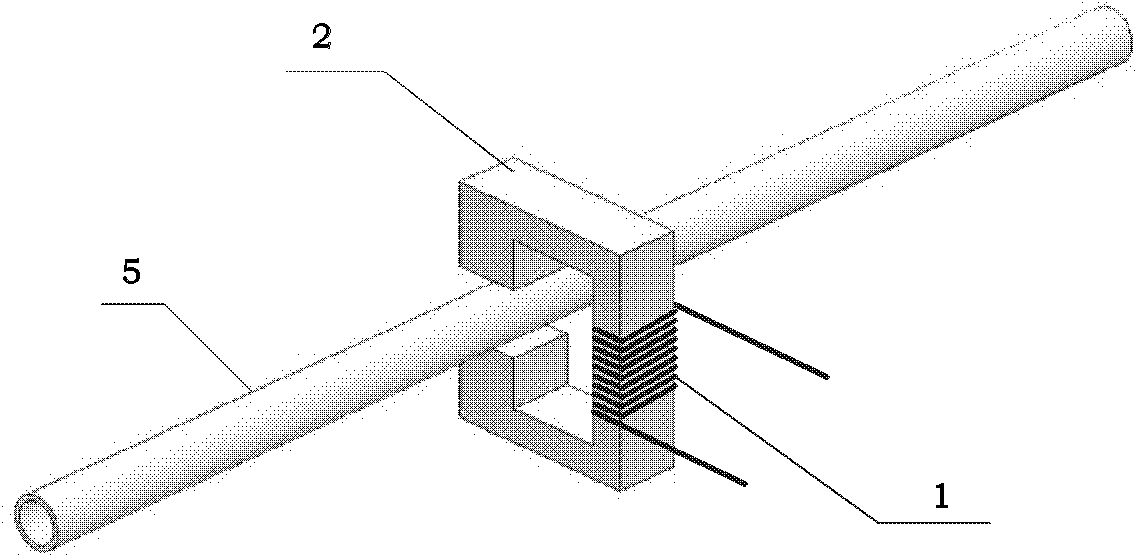

[0033] like figure 2 As shown, the online wear particle monitoring sensor of the present invention mainly includes a magnetic field excitation source 1 , an iron core 2 , a detection coil 3 and an amplifying circuit 4 . The magnetic field excitation source 1 generates a stable magnetic potential, and a stable magnetic field is obtained through the ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com