Flow pattern regulator for synthesizing base drilling fluid, and preparation method thereof

A technology of flow pattern regulator and drilling fluid, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and drilling compositions, etc. The effect of strong, improving emulsion stability and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

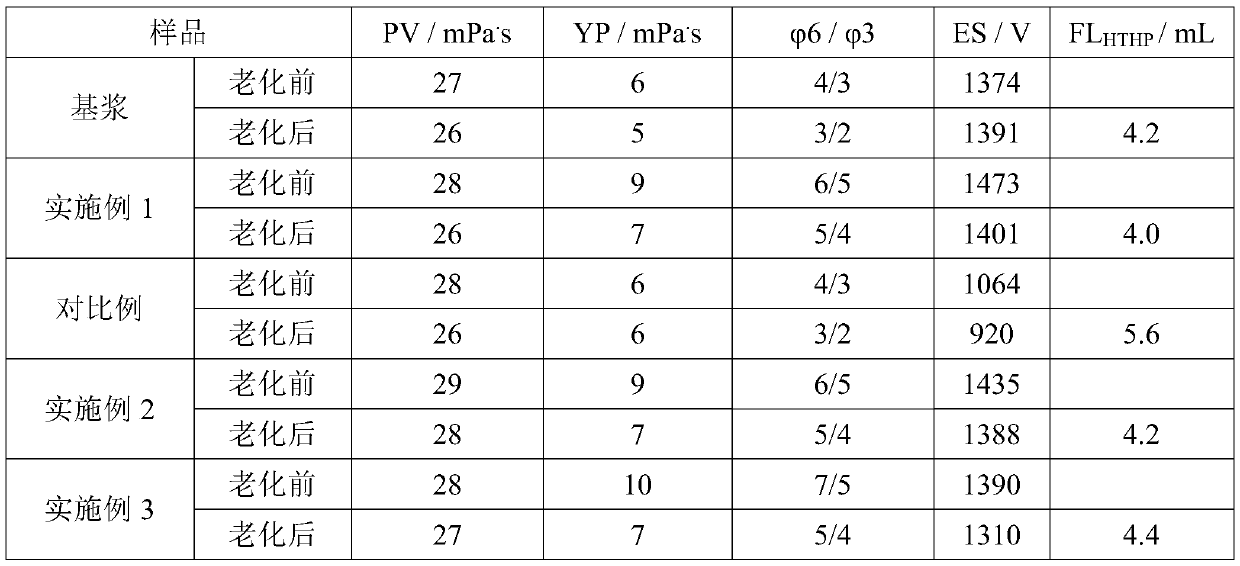

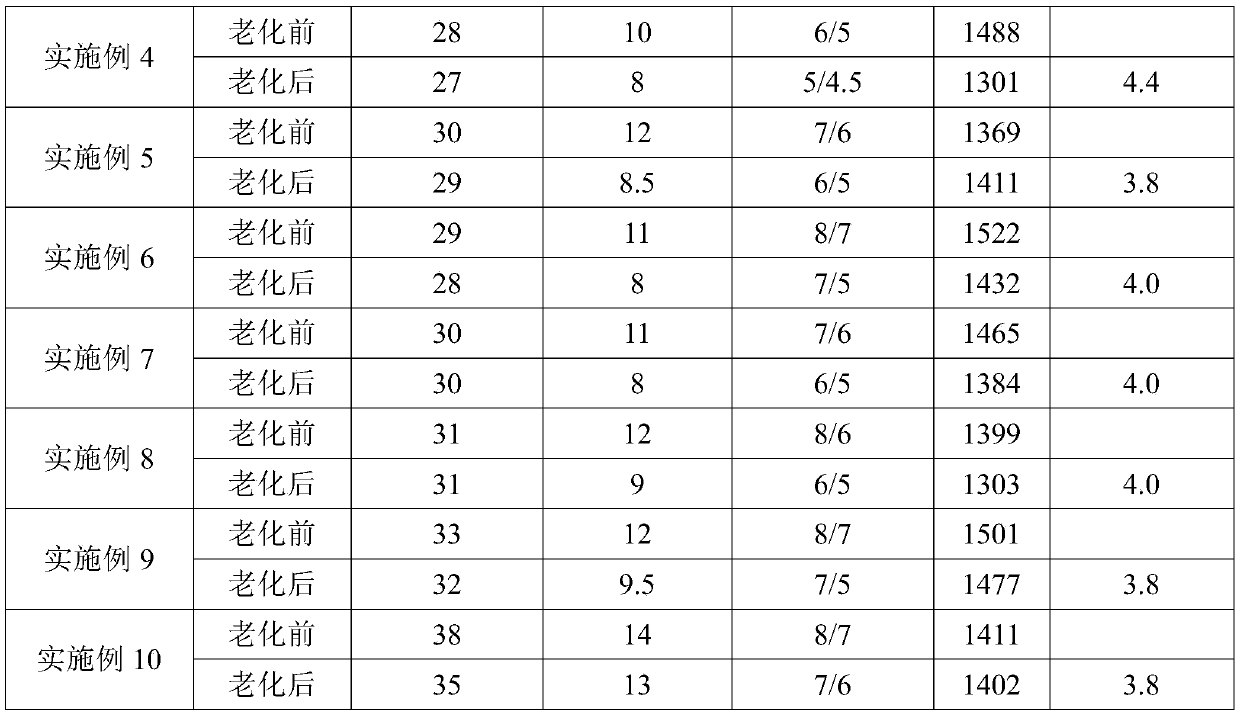

Examples

Embodiment 1

[0022] A flow pattern regulator for synthetic-based drilling fluid, its preparation method is as follows: add 53 parts of glucose methylamine, 24 parts of adipic acid and 190 parts of ethanol successively in a stainless steel reaction kettle equipped with a mechanical stirrer and a condenser, After mixing and stirring evenly, add 0.08 parts of sodium ethylate, heat the oil bath to 130°C, and reflux for 4 hours to obtain a viscous liquid; spin evaporate the viscous liquid to remove ethanol, and then cool to obtain a waxy solid; After the solid is dried and pulverized, the flow regulator can be obtained.

Embodiment 2

[0026] A synthetic-based drilling fluid flow regulator, its preparation method is as follows: sequentially add 43 parts of glucose methylamine, 25 parts of suberic acid and 200 parts of propanol in a stainless steel reaction kettle equipped with a mechanical stirrer and a condenser After mixing and stirring evenly, add 0.14 parts of sodium ethylate, heat the oil bath to 130°C, and reflux for 5 hours to obtain a viscous liquid; spin evaporate the viscous liquid to remove propanol, and then cool to obtain a waxy solid; After drying and pulverizing the waxy solid, the flow regulator can be obtained.

Embodiment 3

[0028] A flow regulator for synthetic-based drilling fluids, the preparation method of which is as follows: add 43 parts of glucose methylamine, 33 parts of dimethyl sebacate and 150 parts of Parts of ethanol, mix and stir evenly, add 0.15 parts of sodium ethylate, heat in an oil bath to 130°C, reflux for 5 hours to obtain a viscous liquid; spin evaporate the viscous liquid to remove ethanol, then cool to obtain a waxy solid ; After drying and pulverizing the waxy solid, the flow regulator can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com