Well cementation method for high-temperature oil-gas well

A technology for oil and gas wells and cementing, which is applied in wellbore/well components, drilling equipment and methods, chemical instruments and methods, etc., and can solve the problem that the cementing construction requirements of deep wells and ultra-deep wells cannot be met, and the suspended upper drilling cannot be achieved. It can improve the suspension ability, increase the internal friction and stabilize the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

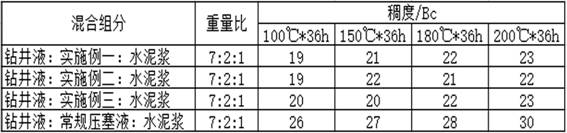

Embodiment 1

[0033] The preparation method of the plugging liquid in step (6) comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, fresh water: 100 parts, weighting agent barite: 30 parts, suspending agent: 3 parts, diluent: 1 Among them: the raw material components and weight content of the suspending agent are as follows, deionized water: 100 parts, drilling bentonite: 100 parts, 2-acrylamide-2-methylpropanesulfonic acid: 30 parts, xanthan gum: 8 parts , acrylamide: 23 parts and carboxymethyl cellulose: 15 parts; the raw material components and weight content of the diluent are as follows, deionized water: 100 parts, sodium lignosulfonate: 100 parts and sulfonated tannin: 18 parts ;

[0034] ⑵Put drilling bentonite into deionized water and mix evenly, then add 2-acrylamide-2-methylpropanesulfonic acid and mix evenly, then add xanthan gum and mix evenly, then add acrylamide and mix evenly, and finally add carboxylate M...

Embodiment 2

[0039] The preparation method of the tamponade in step (6) comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, fresh water: 100 parts, weighting agent: 70 parts, suspending agent: 6 parts, diluent: 3 parts; : The raw material components and weight content of the suspension are as follows, deionized water: 100 parts, drilling bentonite: 100 parts, 2-acrylamide-2-methylpropanesulfonic acid: 30 parts, xanthan gum: 8 parts, acrylamide : 23 parts and carboxymethyl cellulose: 15 parts; the raw material components and weight content of diluent are as follows, deionized water: 100 parts, sodium lignosulfonate: 100 parts and sulfonated tannin: 18 parts;

[0040] ⑵Put drilling bentonite into deionized water and mix evenly, then add 2-acrylamide-2-methylpropanesulfonic acid and mix evenly, then add xanthan gum and mix evenly, then add acrylamide and mix evenly, and finally add carboxylate Methyl cellulose and mix unif...

Embodiment 3

[0045] The preparation method of the tamponade in step (6) comprises the following steps in turn: (1) Prepare raw materials according to the following components and weight content, fresh water: 100 parts, weighting agent: 100 parts, suspending agent: 10 parts, diluent: 5 parts; : The raw material components and weight content of the suspension are as follows, deionized water: 100 parts, drilling bentonite: 100 parts, 2-acrylamide-2-methylpropanesulfonic acid: 30 parts, xanthan gum: 8 parts, acrylamide : 23 parts and carboxymethyl cellulose: 15 parts; the raw material components and weight content of diluent are as follows, deionized water: 100 parts, sodium lignosulfonate: 100 parts and sulfonated tannin: 18 parts;

[0046] ⑵Put drilling bentonite into deionized water and mix evenly, then add 2-acrylamide-2-methylpropanesulfonic acid and mix evenly, then add xanthan gum and mix evenly, then add acrylamide and mix evenly, and finally add carboxylate Methyl cellulose and mix un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com