Marine quaternary formation drilling fluid

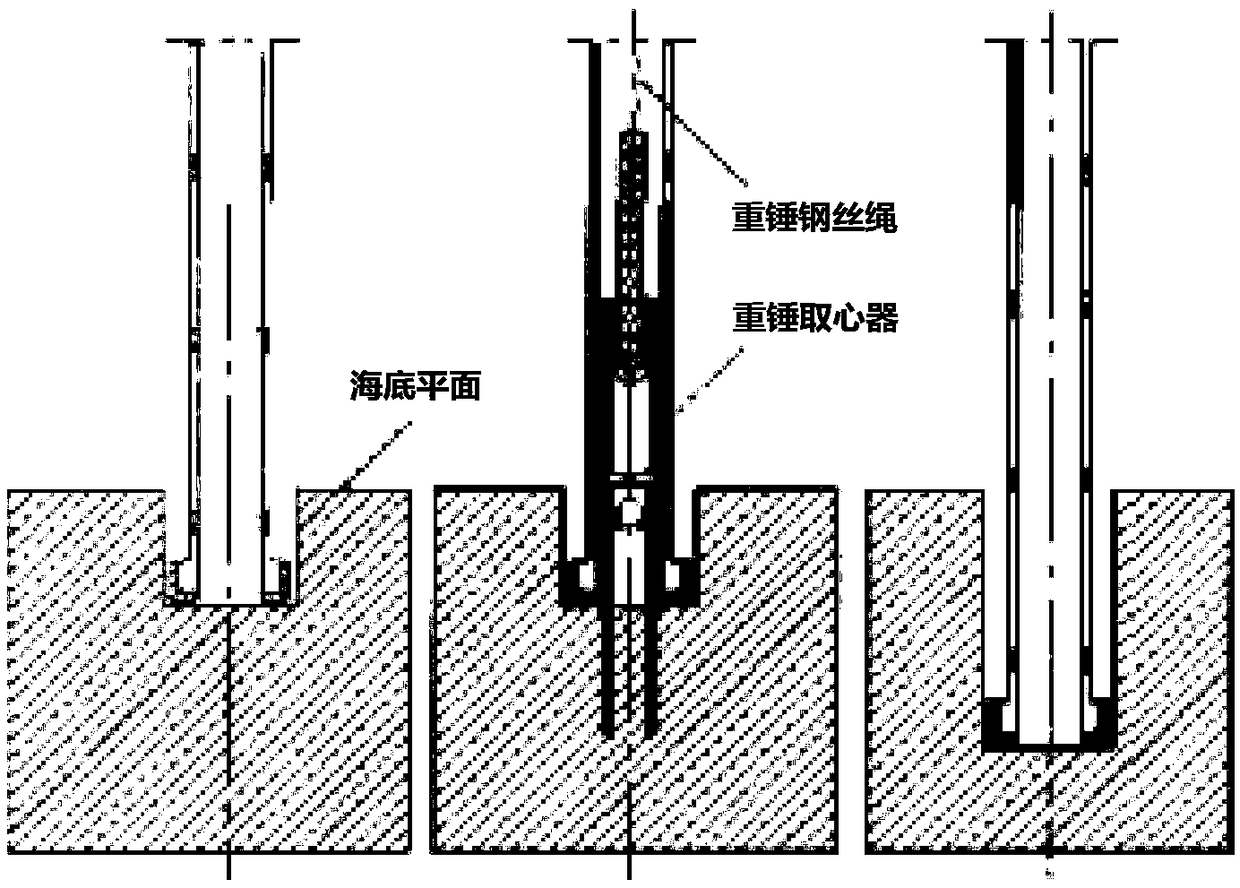

A drilling fluid and formation technology, applied in the field of drilling, can solve problems such as lack of retaining wall performance and unclean hole bottom, and achieve the effect of improving production efficiency and excellent retaining wall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

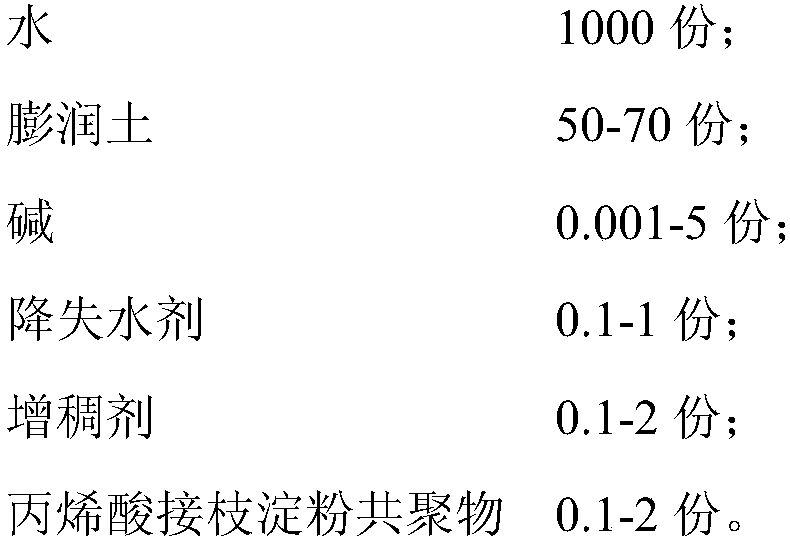

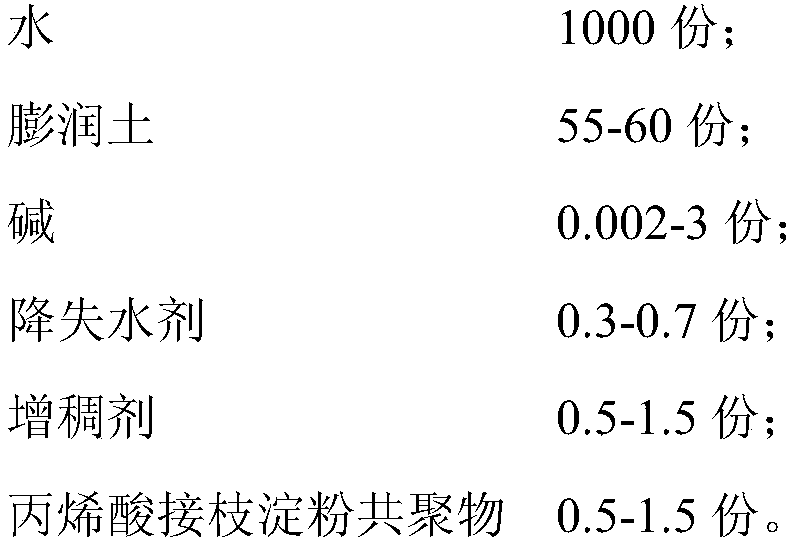

[0035] Weigh 1000g of fresh water, 58g of sodium bentonite, 2g of sodium carbonate, 0.5g of polyanionic cellulose, 1g of sodium carboxymethyl cellulose, and 1g of acrylic acid grafted starch copolymer, and mix them with BW-850 mud pump jet flow suction type Finally, the marine Quaternary formation drilling fluid sample 1# was prepared.

Embodiment 2

[0037] Weigh 1000g of fresh water, 55g of sodium bentonite, 0.004g of sodium hydroxide, 0.3g of polyanionic cellulose, 0.5g of sodium carboxymethyl cellulose, and 0.5g of acrylic acid grafted starch copolymer, and use a BW-850 mud pump jet to flush After suction stirring and mixing, the marine Quaternary formation drilling fluid sample 2# was prepared.

Embodiment 3

[0039] Weigh 1000g fresh water, 60g sodium-based bentonite, 3g sodium carbonate, 0.7g polyanionic cellulose, 1.5g sodium carboxymethyl cellulose, 1.5g acrylic acid grafted starch copolymer, and use BW-850 mud pump jet flushing type After stirring and mixing, the marine Quaternary formation drilling fluid sample 3# was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com