A single-waisted multi-leaf cylinder drill bit and a hole-forming construction method for bored piles

A technology of bored cast-in-place piles and construction methods, which are applied to drill bits, sheet pile walls, drilling equipment, etc., can solve problems such as difficulties in bored cast-in-place piles, and achieve the effects of good wall protection, good guidance, and reduced scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

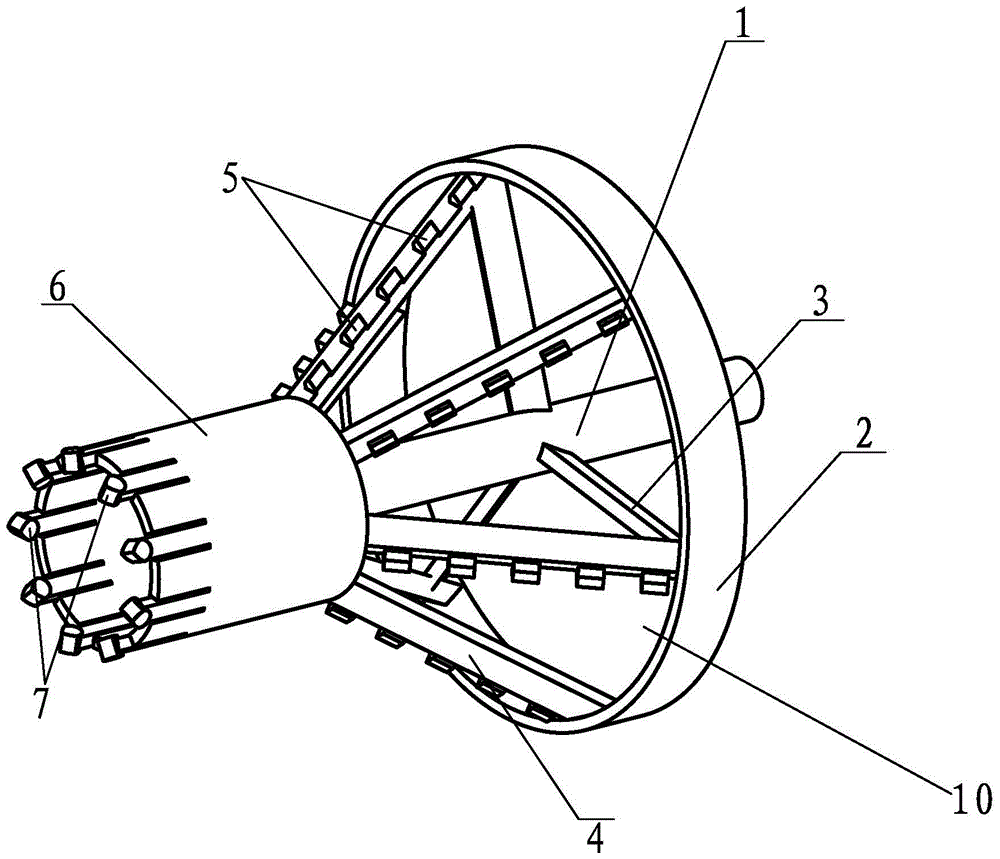

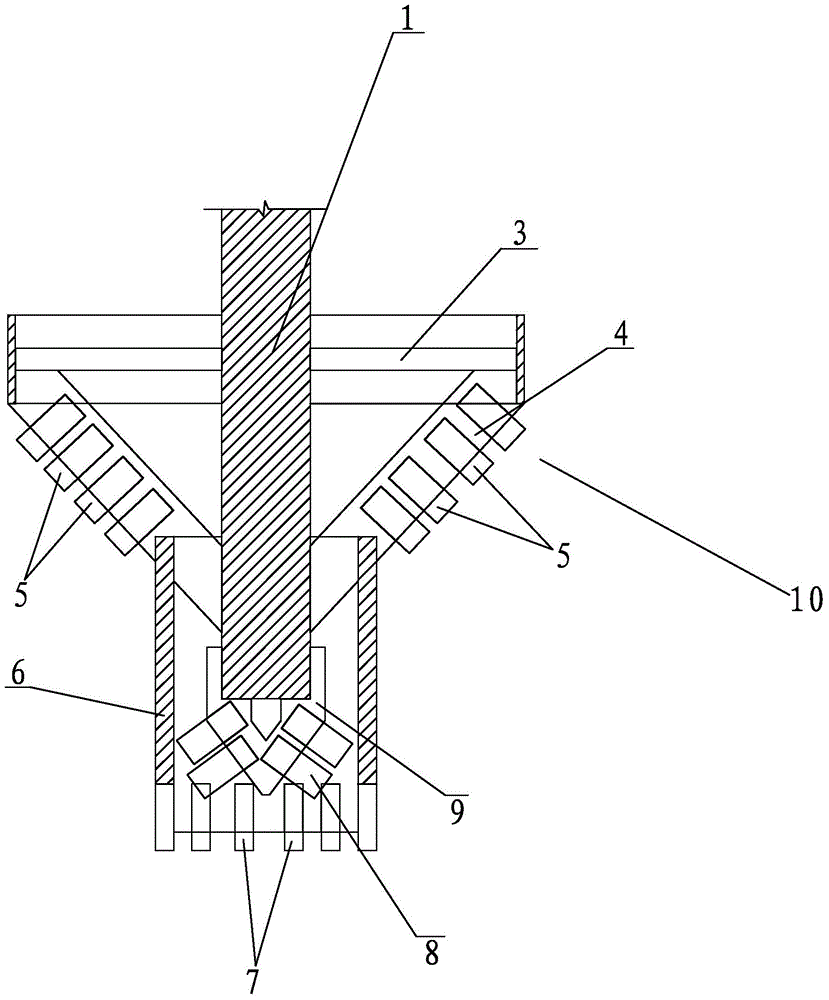

[0025] Such as figure 1 , 2 As shown, the present invention discloses a single-waist multi-lobe cylindrical drill bit for bored piles, including a single-waist multi-lobe tapered drill bit 10, and a positioning guide cylinder 6 is fixedly welded at the end of the single-waist multi-lobe tapered drill bit 10. A plurality of positioning and guiding cylinder tungsten steel heads 7 are distributed on the circumference edge of one end of the positioning guiding cylinder 6 .

[0026] Further, the single waist multi-lobe tapered drill bit 10 includes a drill rod 1, and the outer peripheral surface of the drill rod 1 is fixedly welded with several horizontal leaves 3, and several horizontal leaves 3 are connected in series through the horizontal ring 2; the drill rod 1 and the horizontal ring 2 are connected by several oblique leaves 4, and the ends of the oblique leaves 4 of the drill pipe 1 are fixedly welded with a triangular drill bit 9, and the triangular drill bit 9 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com