Processing method for high-precision thin step shaft and grinding chuck for processing method

A processing method and technology for stepped shafts, which are applied in the field of shaft parts processing, can solve the problems of step end face grinding of difficult and thin stepped shafts, inability to realize centerless grinding, and poor outer diameter, so as to achieve stable processing quality and save raw materials and processing time. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention is further described below in conjunction with the accompanying drawings of the embodiments, but the scope of protection is not limited to the description.

[0038] A processing method of a high-precision thin stepped shaft according to the present invention mainly includes the following method steps:

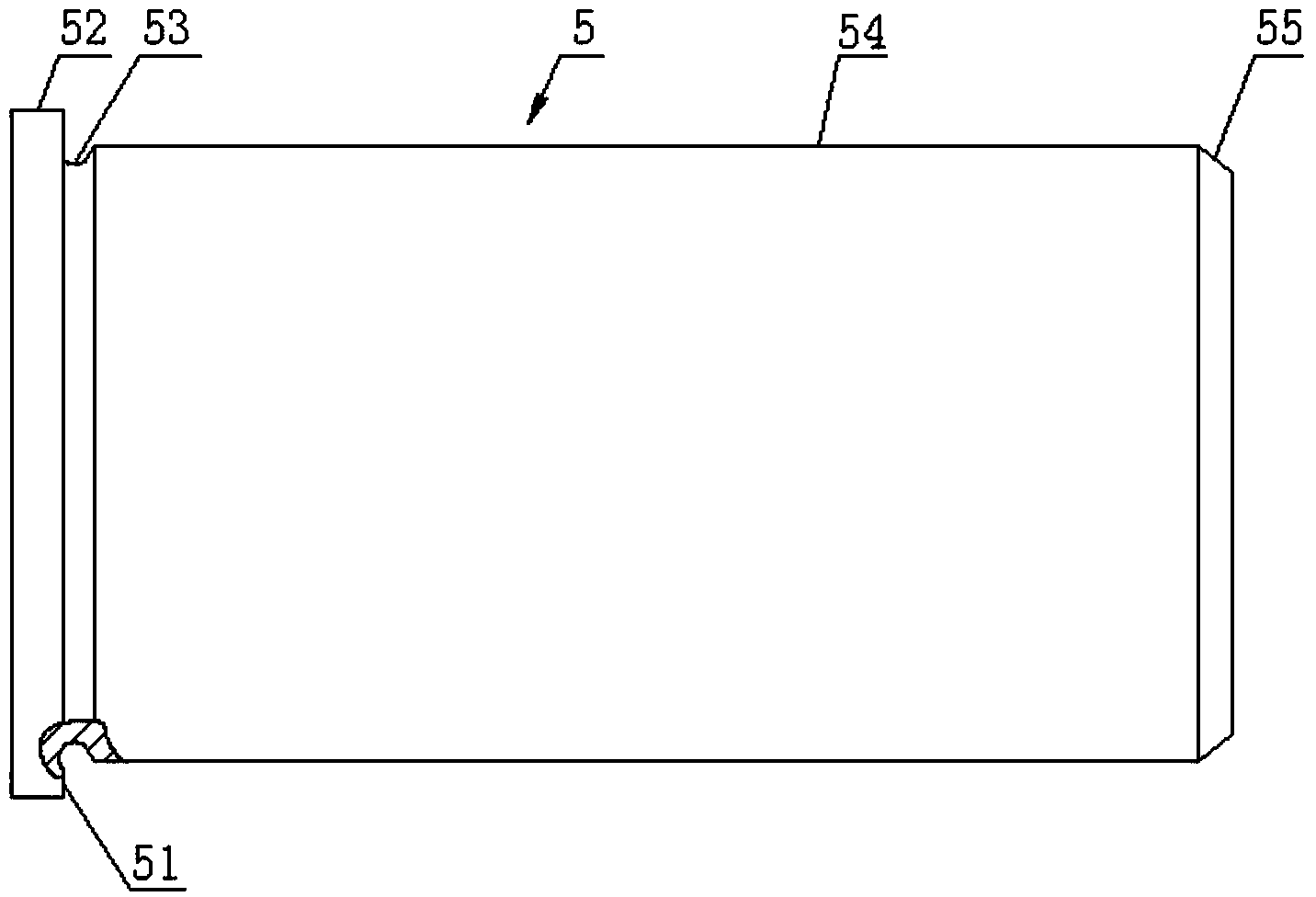

[0039] (1) Material preparation: such as figure 1 As shown, the blanking of the round bar is carried out according to the length of the step outer circle 52 and the length of the step axis outer circle 54, and the material is 20CrMnTi;

[0040] (2) Heat treatment: normalize the round bar or forging prepared in step (1) at a temperature of 950°C to 970°C, air cooling, and a hardness of HBS170 to 210;

[0041] (3) Car processing: the steps of the car processing method are as follows:

[0042] a. Clamp the outer circle of the bar, turn one end of the bar, and drill the center hole;

[0043] b. Clamp one end of the bar, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com