Abrasive Belt Grinder for Pressure Vessel Intersecting Line Welds

A pressure vessel and abrasive belt grinder technology, which is applied in abrasive belt grinders, grinders, grinding/polishing equipment, etc., can solve the problems that carbon arc gouging cannot be adopted, the overall level of pressure vessel manufacturing is restricted, and the processing efficiency is low. High-efficiency grinding solution, reliable yaw motion of the grinding head, and stable support of the grinding head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

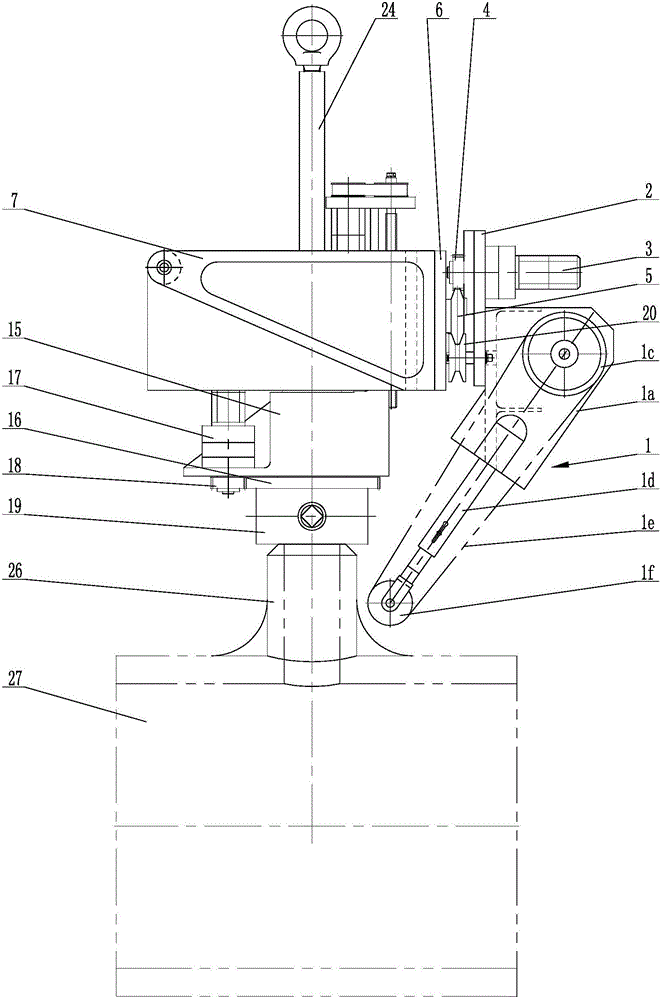

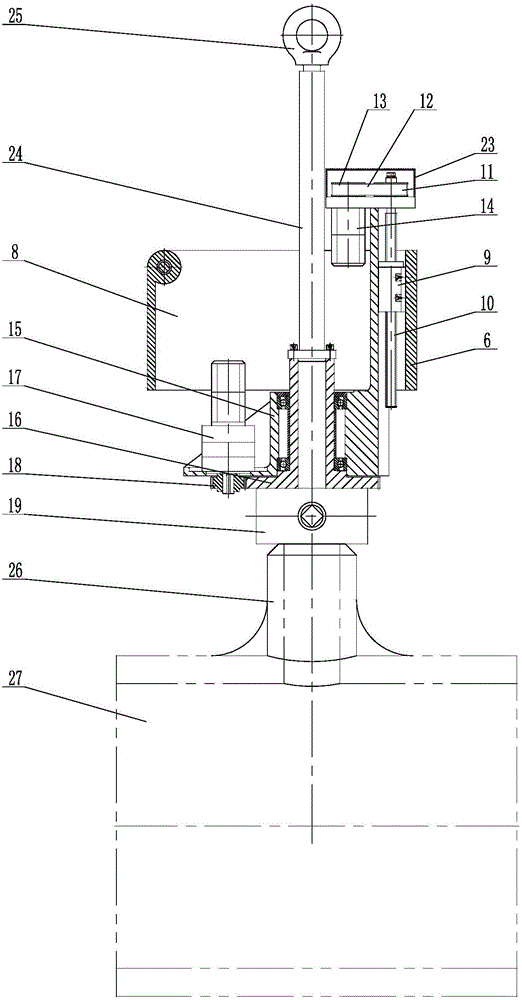

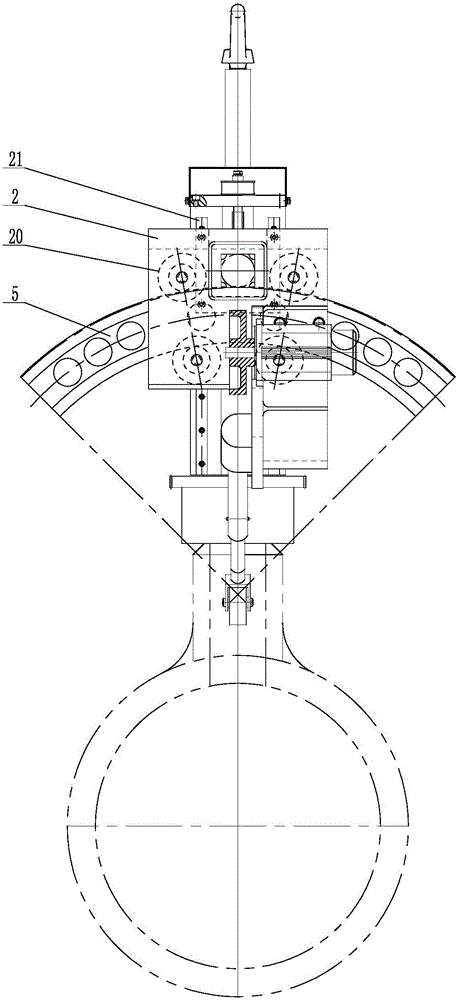

[0026] Such as figure 1 , figure 2 , image 3 Shown, the lower end of support seat 15 is a hollow sleeve structure, and two bearings up and down are embedded in the hole of support seat 15 lower ends, and the lower end of support seat 15 is supported on the axle of bull gear 16 by these two bearings. The bull gear 16 is an integral hollow structure with its shaft, the bull gear 16 is positioned at the lower end of its shaft, and the bull gear 16 is below the support seat 15 . A self-centering chuck 19 is installed at the bottom of the bull gear 16. This self-centering chuck 19 is preferably a three-jaw type self-centering chuck. The structure of the self-centering chuck 19 is a prior art, and will not be repeated here. . A rotary motor 17 is arranged next to the bull gear 16, the rotary motor 17 is installed on the support base 15, the output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com