Full-automatic multi-grinding head polishing machine moving independently

A multi-grinding head, fully automatic technology, used in grinding machine parts, grinding/polishing equipment, grinding machines, etc., can solve the problems of grinding quality and output decline, achieve long service life, wide processing stone, work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

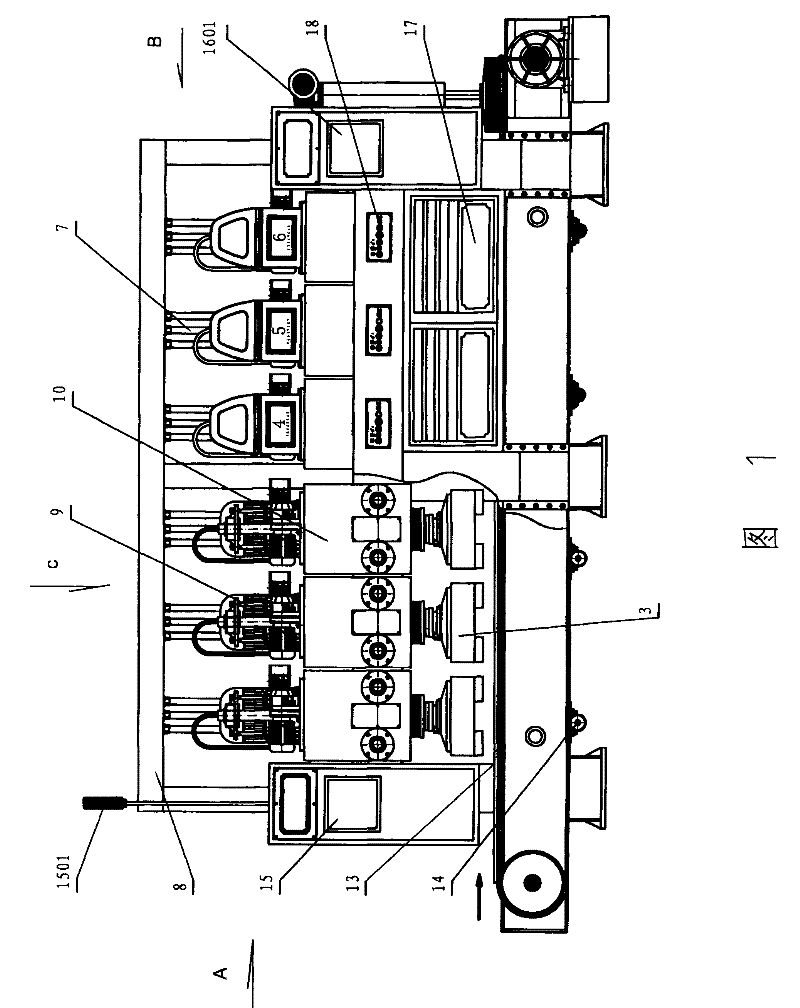

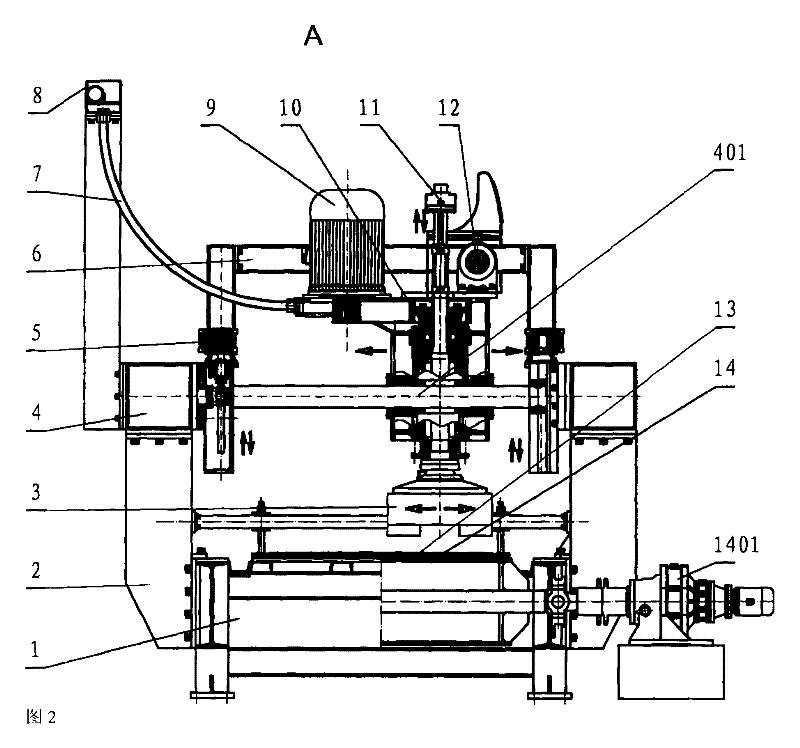

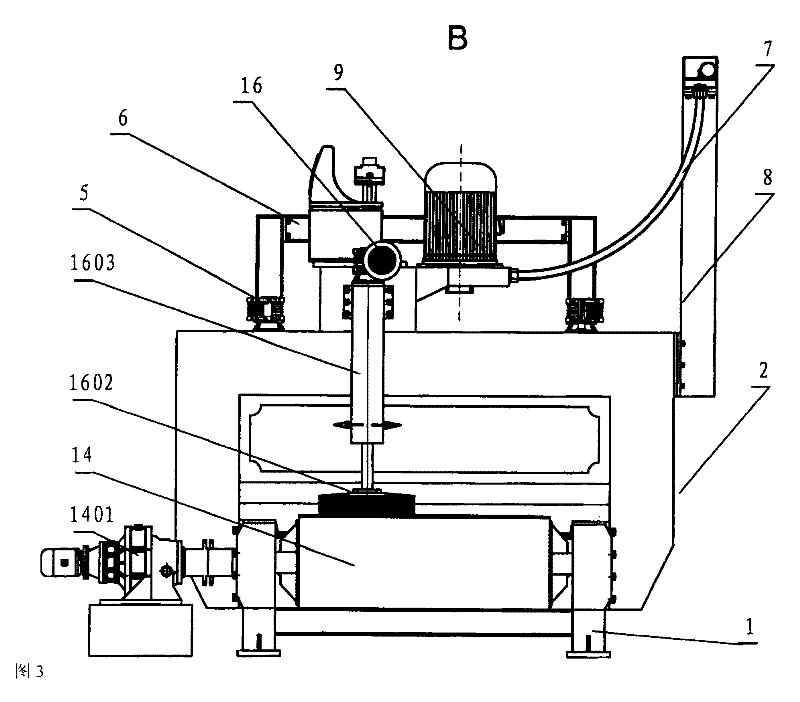

[0049] A fully automatic multi-grinding head independently mobile polishing machine, such as Figure 1-5 As shown, it includes: a controller, a main motor 9, a cleaning device 16, a conveyor belt 14, a grinding head 3 and a machine base 1, the machine base 1 is fixedly connected to the column 2, the top of the column 2 is fixedly connected to the upper beam 4, and the grinding head 3 It is connected with the main shaft 1001 of the headstock 10. Described spindle box 10 is made up of box body, main shaft sleeve 1003, main shaft 1001, main shaft sleeve 1003 is connected with main shaft 1001 by bearing 1002, casing is arranged on the outside of main shaft sleeve 1003, and protective cover 1004 is arranged outside main shaft sleeve 1003, in box body Two sliding sleeves 1005 perpendicular to the main shaft 1001 in the left and right directions are arranged on the top. Such as Figure 8 , 9 shown. Described main motor 9 drives the main shaft 1001 of headstock 10 through the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com