Patents

Literature

49results about How to "Extensive processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

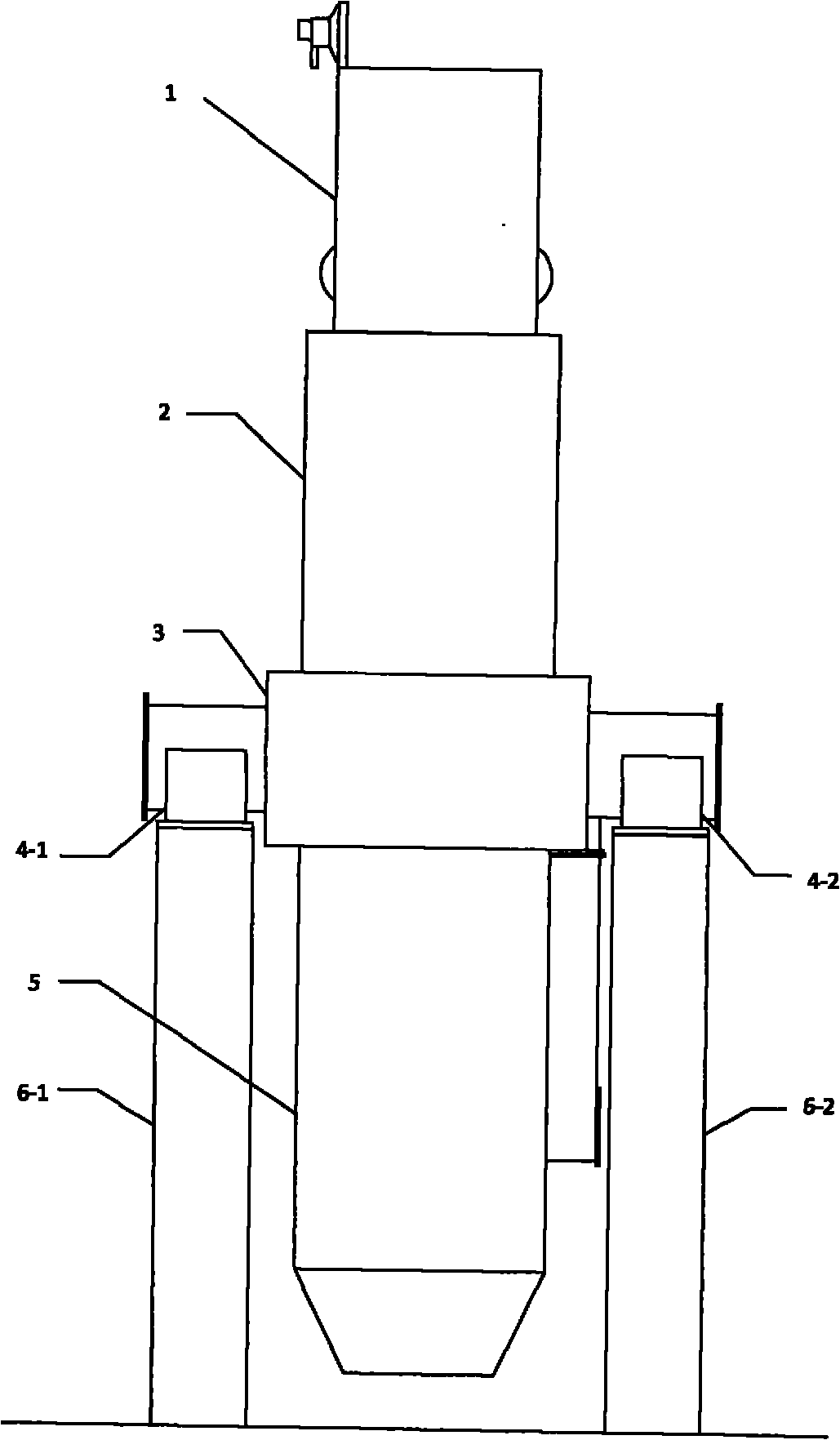

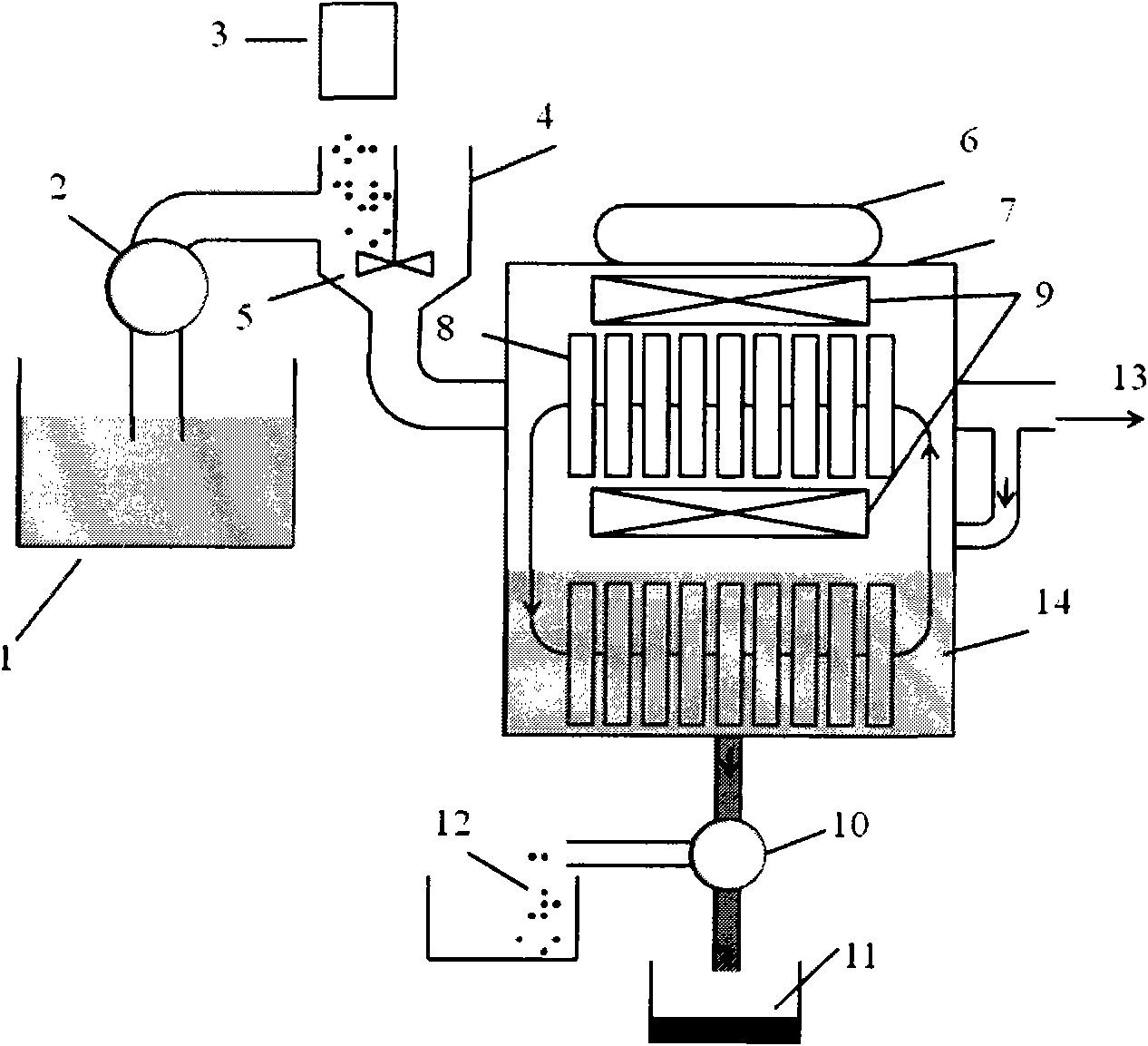

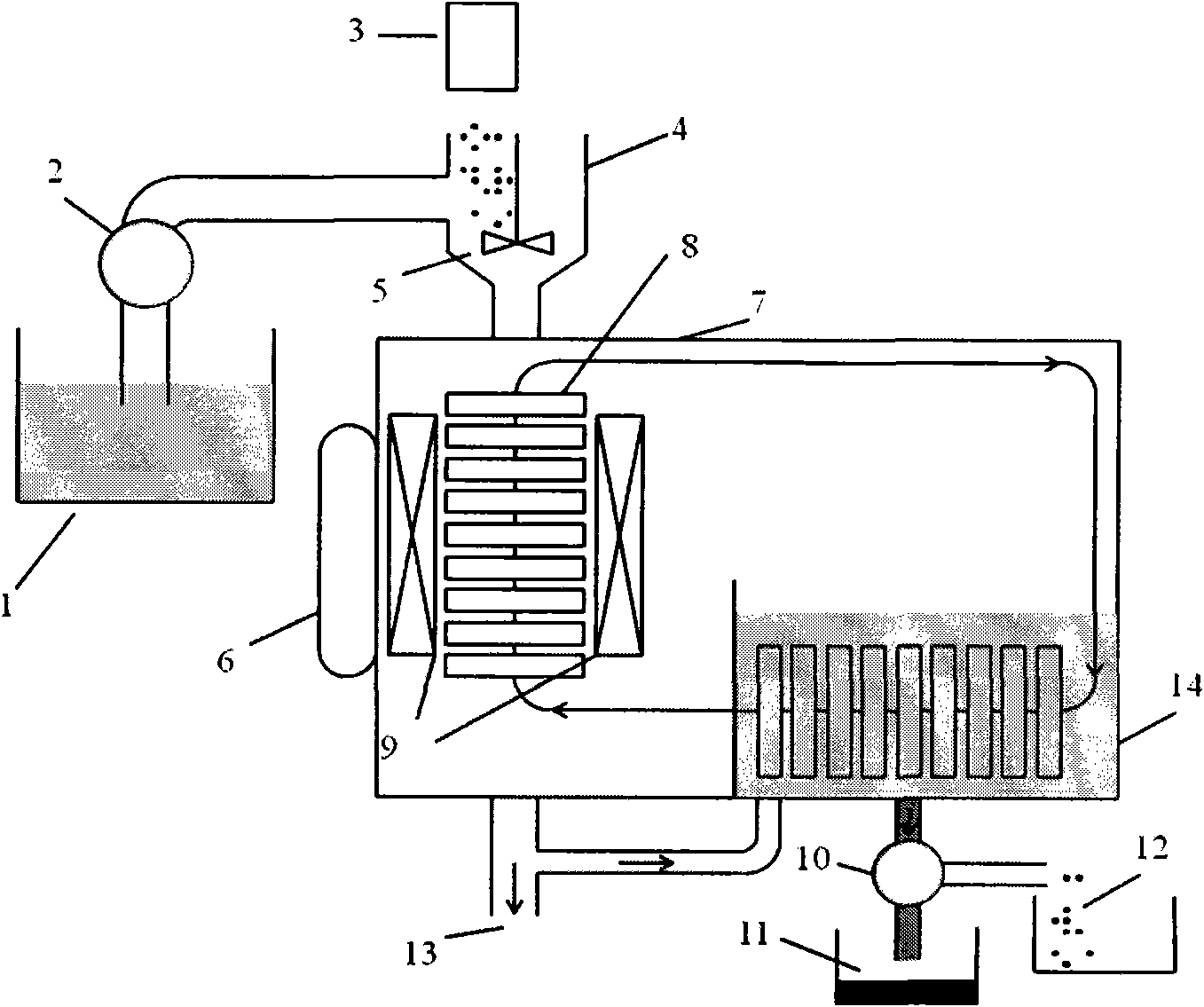

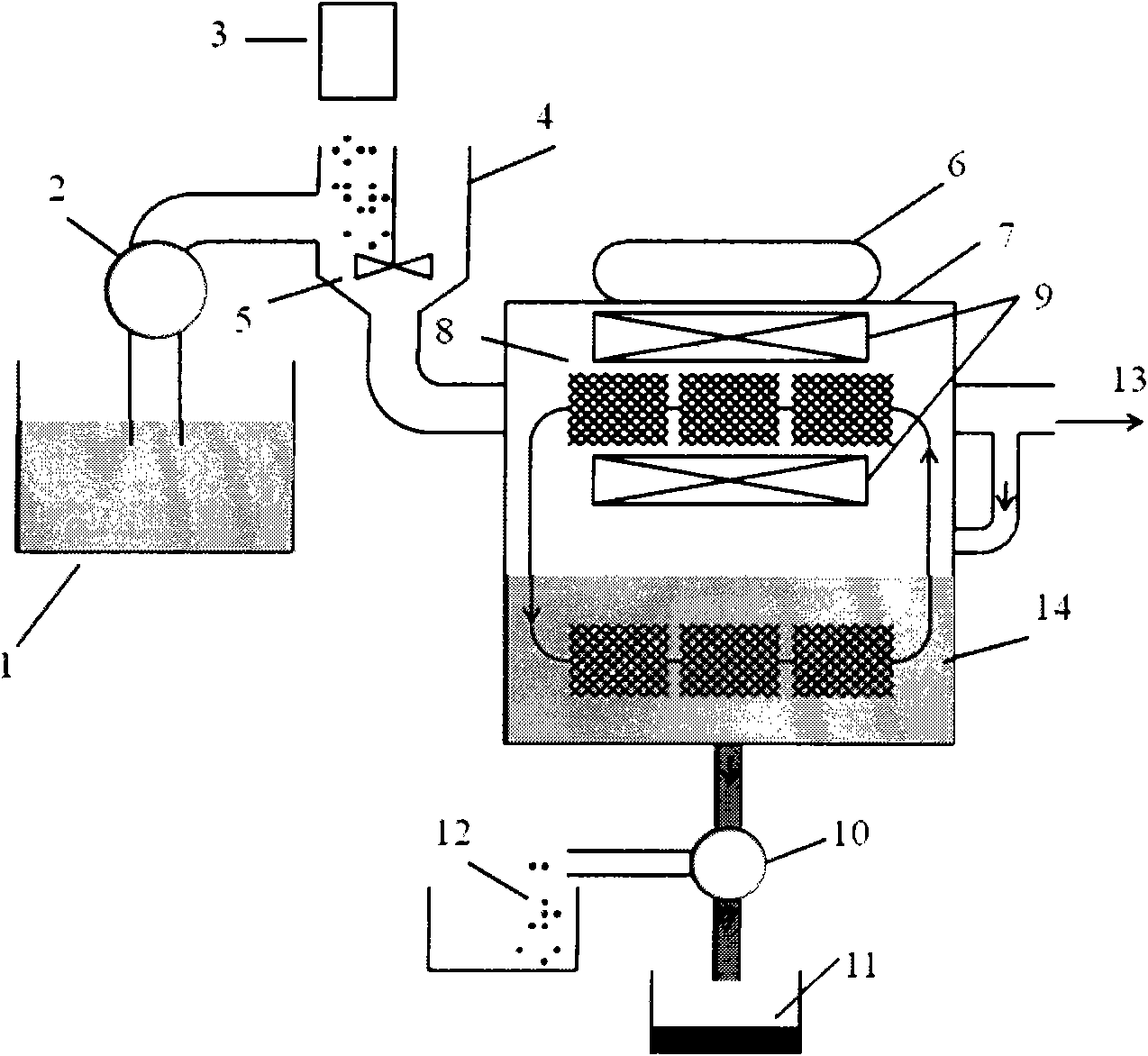

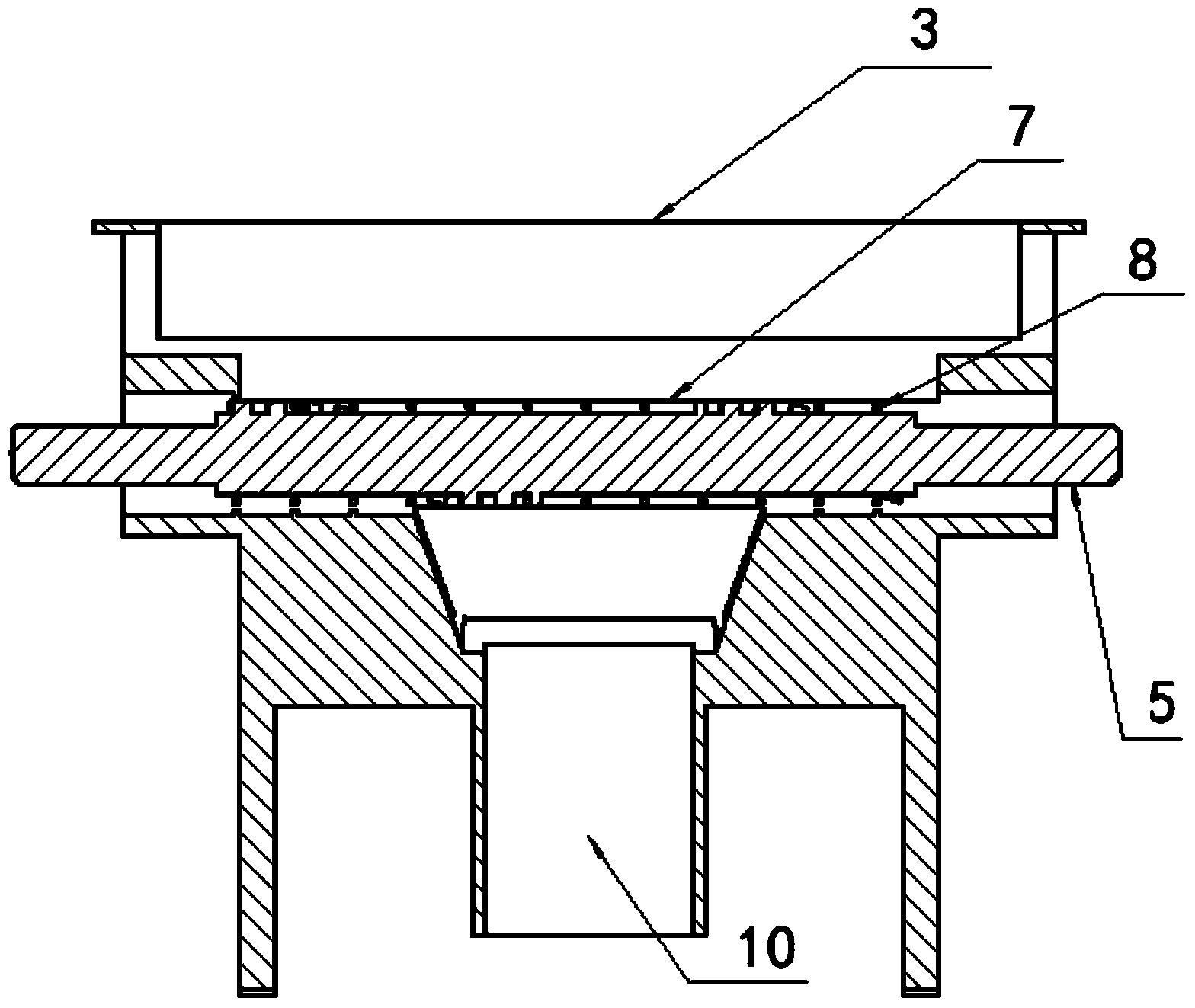

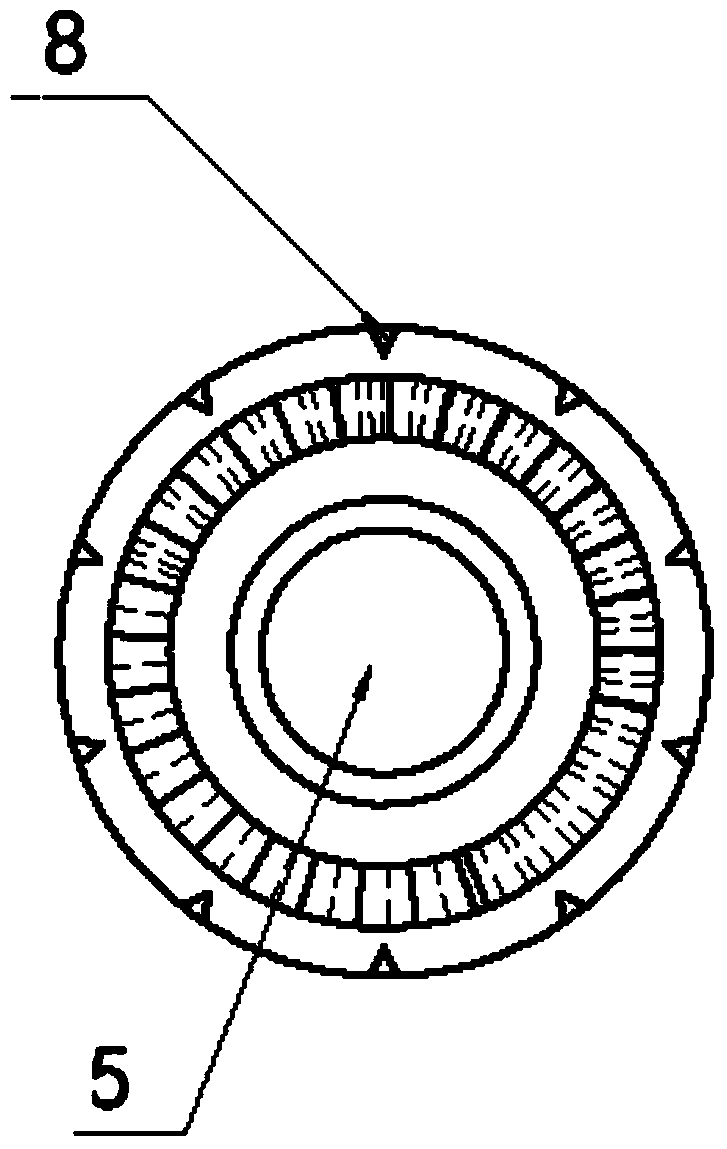

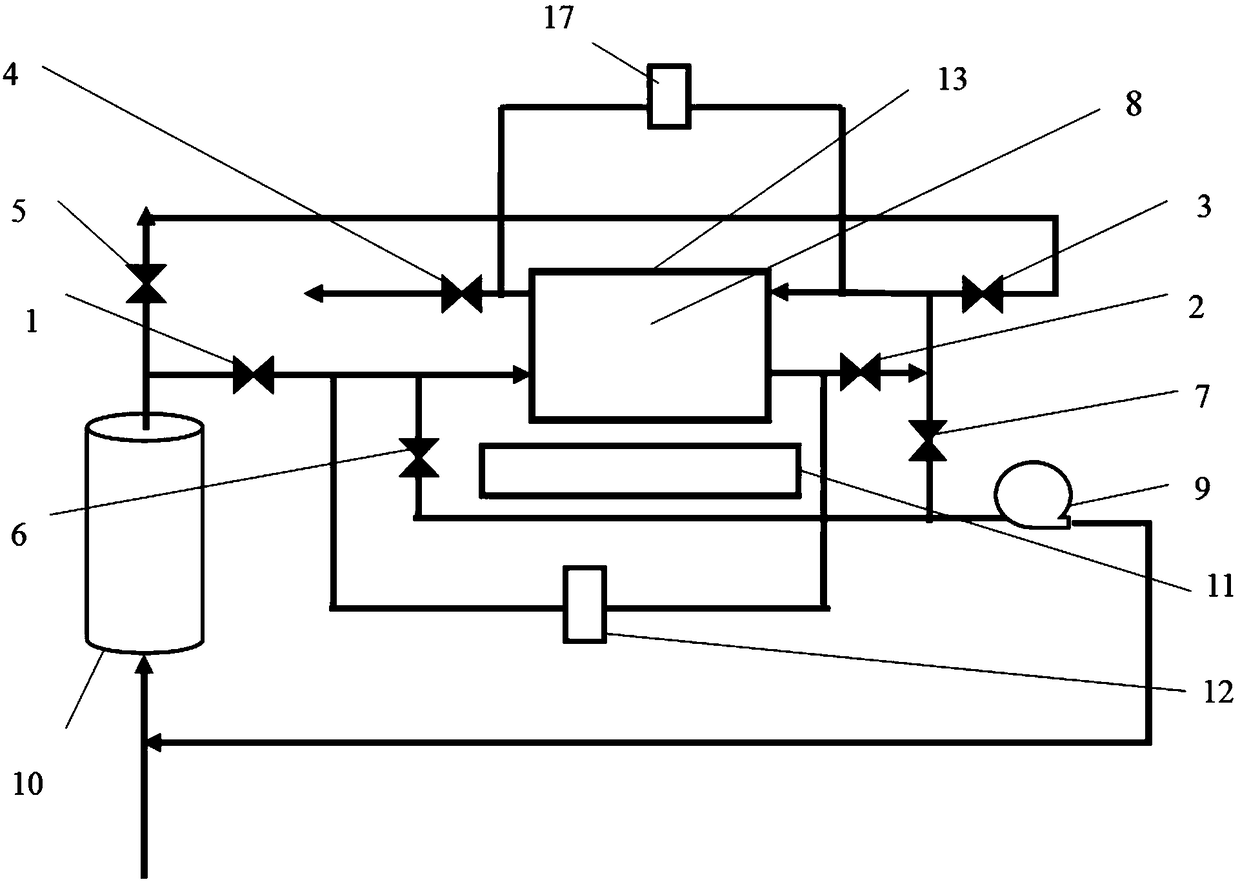

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

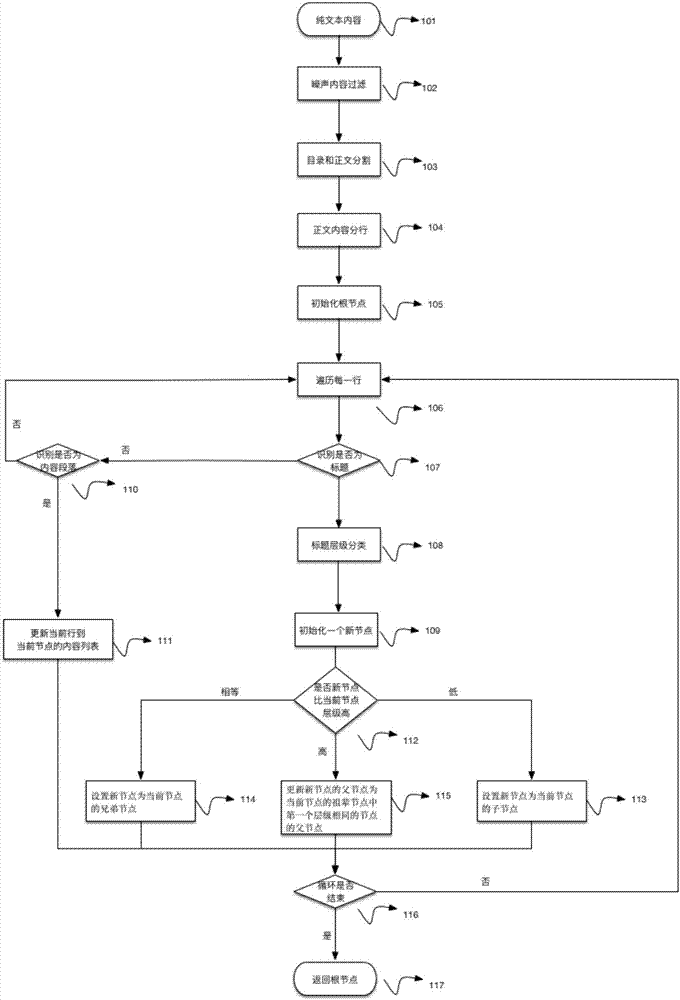

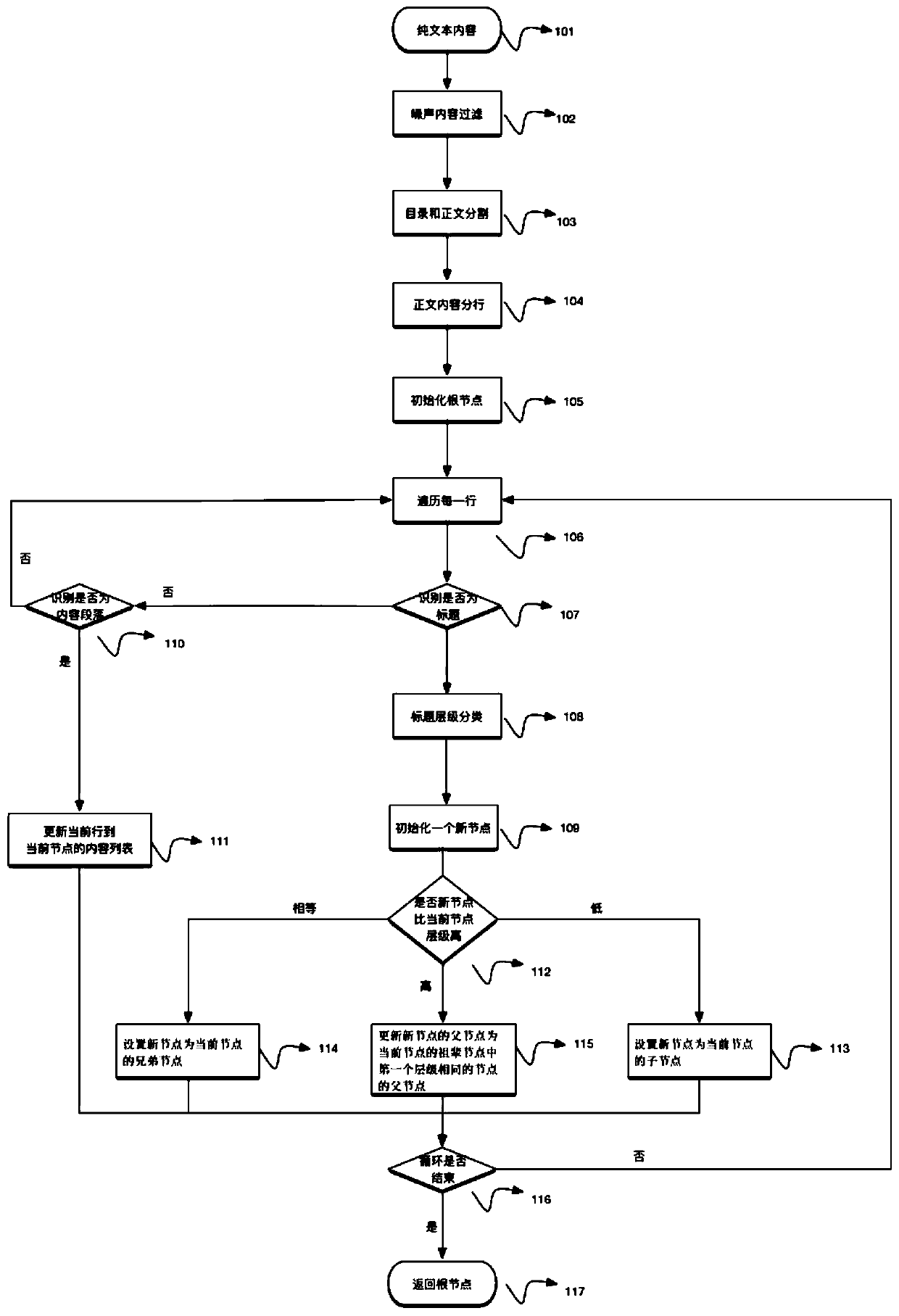

Text structure analysis method based on text semantics

ActiveCN107145479ACommon method frameworkWide range of applicationsSemantic analysisText processingContent extractionTheoretical computer science

The invention discloses a text structure analysis method based on text semantics. The text structure analysis method comprises the following steps: 1, acquiring data; 2, performing content extraction; 3, recognizing and extracting a title; and 4, establishing a hierarchical structure. By adopting the text structure analysis method, the technical problems that text structure information reduction is carried out for a pure text, a base is made for text mining tasks, and the like, are solved.

Owner:合肥图谱智能科技有限公司

Processing equipment for separating waste water by superconducting magnet

InactiveCN101781003AExtensive processingLow costWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFiltrationHazardous substance

The invention provides processing equipment for separating waste water by superconducting magnet, comprising a magnetic seed and flocculating agent feeding machine, a mixer and a superconducting magnetic coolant separator; wherein the magnetic seed and flocculating agent feeding machine is used for feeding magnetic seeds and flocculating agent to the mixer; the mixer is connected with a water pipe and used for fully mixing the magnetic seeds and flocculating agent with the waste water; one end of the superconducting magnetic coolant separator is connected with the mixer by a pipeline and the other end thereof is connected with a water outlet pipe, the superconducting magnetic coolant separator is provided with a filtration device made from ferrite stainless steel material. In the invention, the magnetic seeds are added in advance, so that nonmagnetic harmful substances can be fully combined with the magnetic seeds, thus realizing separation and purification of the waste water by superconducting magnet and being widely applied to process industrial and domestic waste water. Meanwhile, the invention has the advantages of low cost, high efficiency, small power consumption and unattended automatic operation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Nano coagulant for swimming pool

InactiveCN1626452ALarge specific surface areaHuge surface energyWater/sewage treatment by flocculation/precipitationAluminium sulfateSuspended matter

Owner:曾智勇 +1

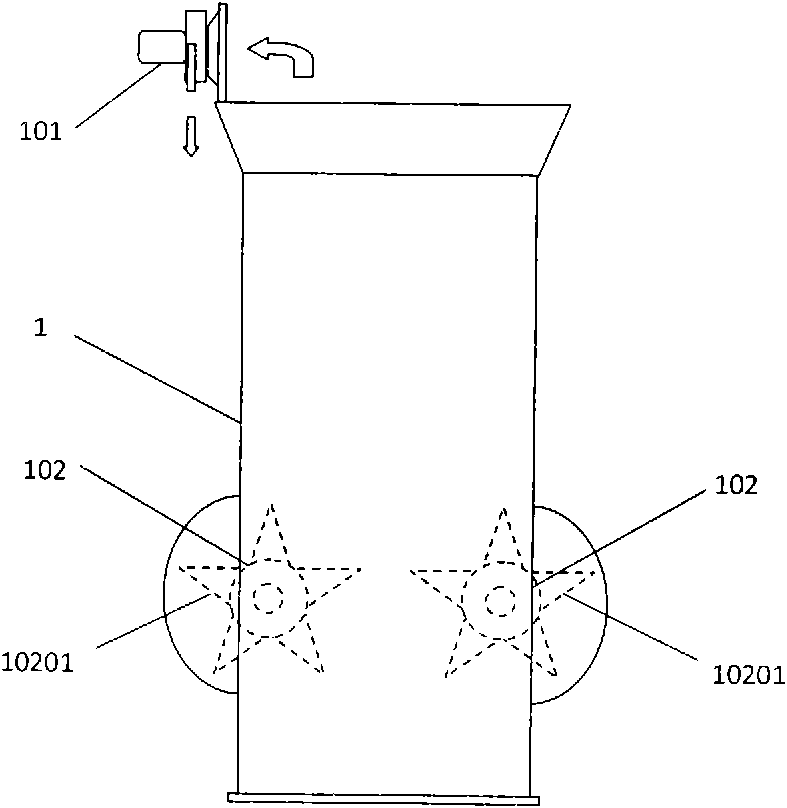

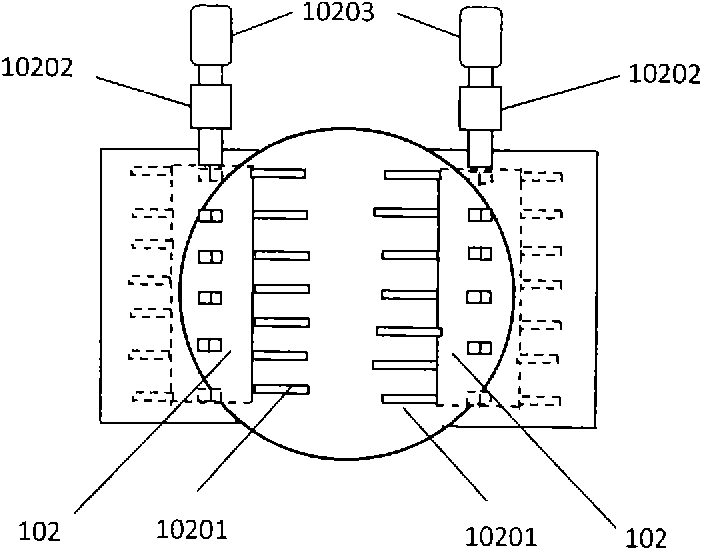

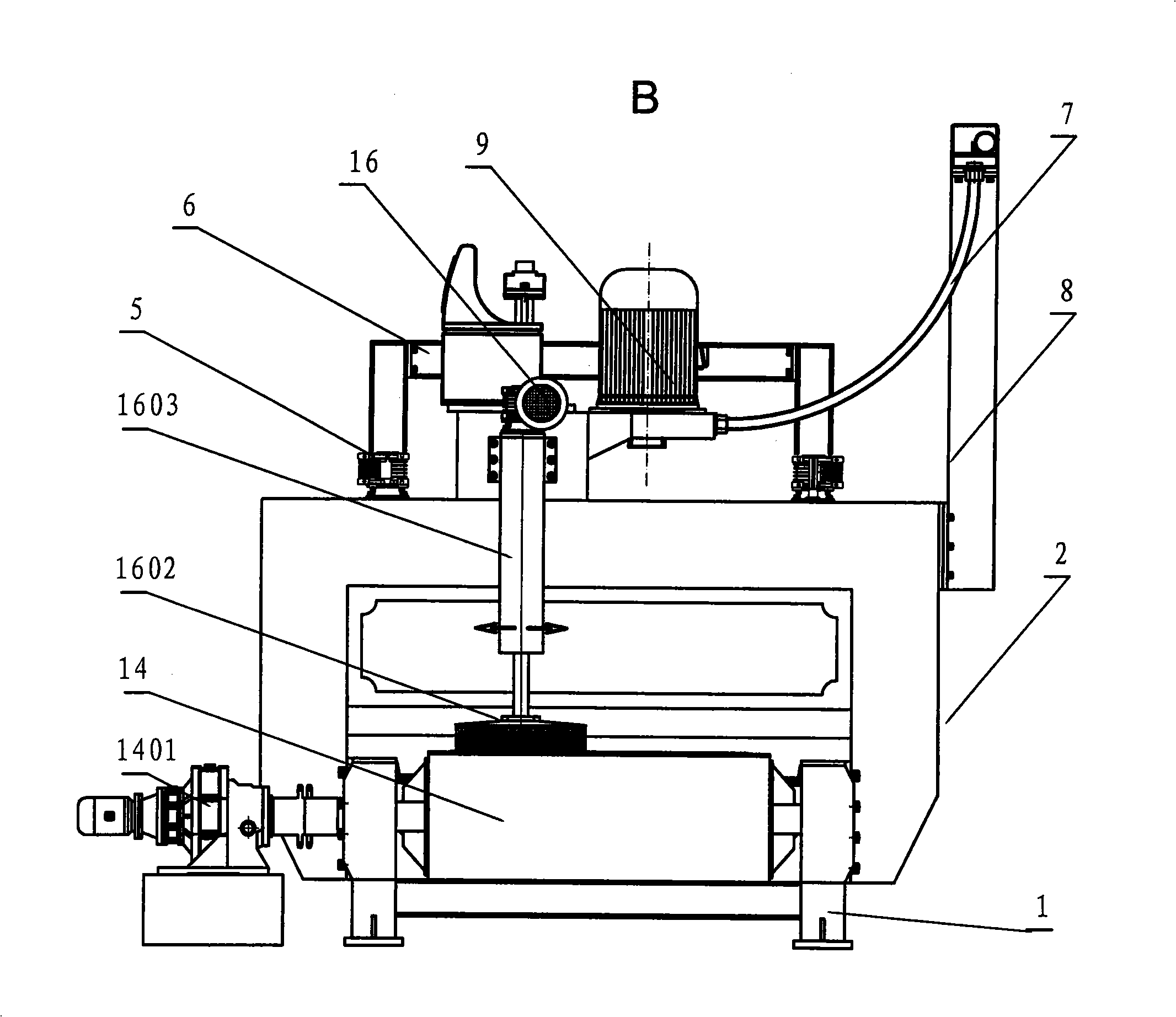

Slag cake crusher capable of dynamically adjusting speed and control method thereof

The invention provides a slag cake crusher capable of dynamically adjusting speed and a control method thereof. The slag cake crusher comprises a driving motor, a crushing chamber and a control system, wherein a feeding hole is formed at the upper end of the crushing chamber; a discharging hole is formed at the lower end of the crushing chamber; a crushing roller shaft is arranged inside the crushing chamber; the crushing roller shaft is connected with the driving motor through a coupler; spiral cutter teeth are welded on the surface of the crushing roller shaft; convex teeth are arranged on the inner wall of the crushing chamber; gaps are formed between the convex teeth and spiral cutter teeth; the control system comprises a power supply, a PLC (Programmable Logic Controller) controller, a man-machine interaction device, a frequency changer, a coder mounted on a shaft of the driving motor and a temperature senor mounted on the crushing roller shaft; the PLC controller comprises a speed controller and a temperature correction rotation speed controller. By improving the structure of the slag cake crusher and using a double closed-loop dynamic control adjustment method, the automatic control of crushing process and speed is achieved, the dynamic change of slag cake crushing load is automatically adapted, and the crushing force and crushing efficiency are maximized.

Owner:JIANGSU UNIV

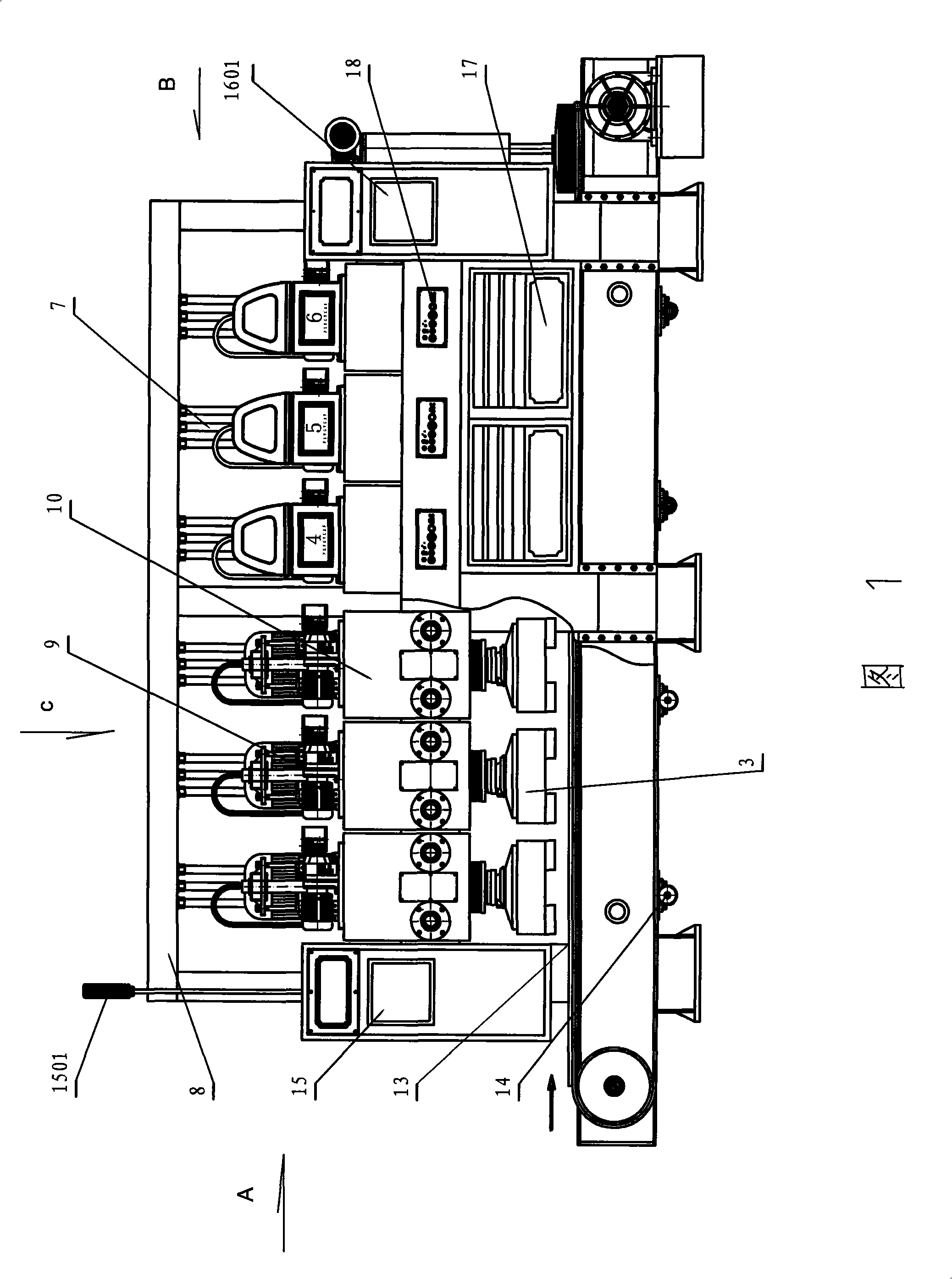

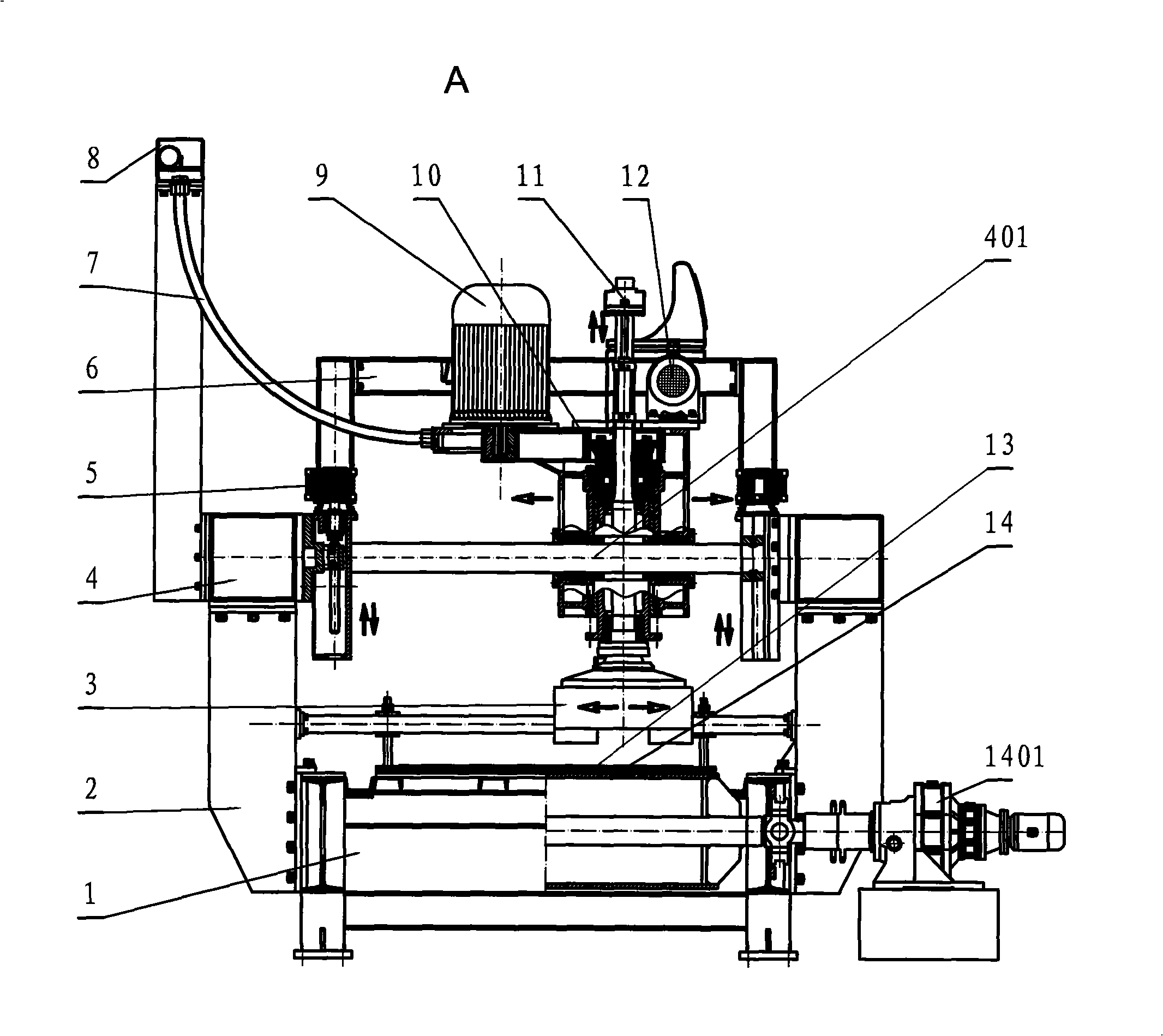

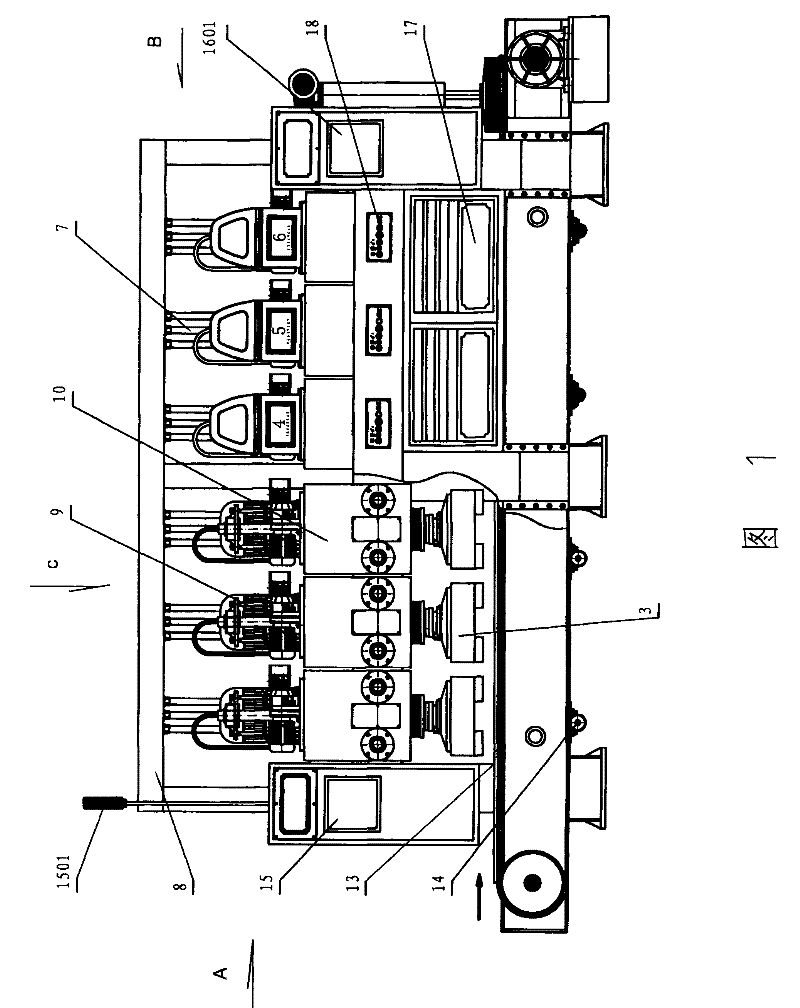

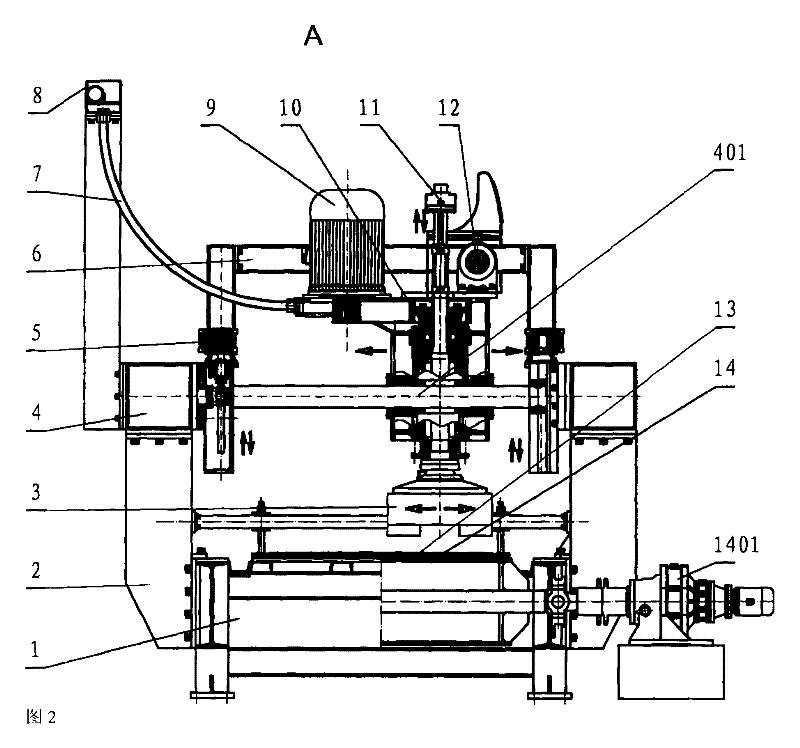

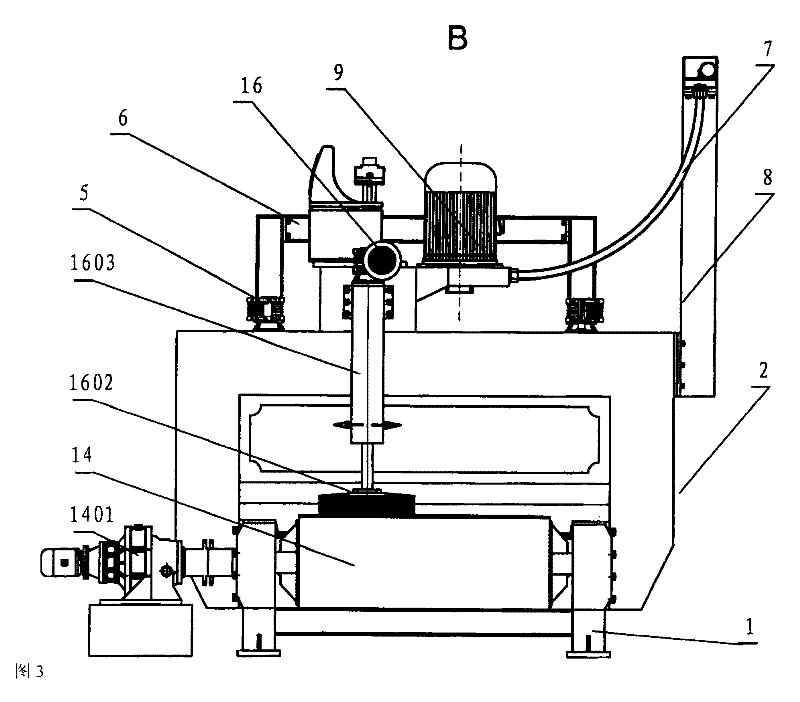

Full-automatic multi-grinding head polishing machine moving independently

ActiveCN101407037ASolving Grinding DifficultiesCompact and reasonable structureGrinding drivesGrinding machinesMotor driveEngineering

The invention relates to a full-automatic multi-grinding head independently moving polishing machine, which comprises a controller, a main motor, a cleaning device and a conveyer belt. A grinding head and a stand are fixedly connected with an upright post respectively, the top of the upright post is fixedly connected with an upper beam, and the grinding head is connected with a main shaft of a main shaft box. The polishing machine is characterized in that the main motor drives the main shaft of the main shaft box through a first-level conveyer belt, the main shaft is connected with the grinding head, the main shaft box is respectively connected with an independent left moving mechanism and an independent right moving mechanism as well as a lifting mechanism, and the lifting mechanism comprises a mechanical lifting mechanism and a pneumatic lifting mechanism. The polishing machine has a compact and reasonable structure, a single grinding head can swing solely, and the single grinding head can solely grind an irregular plate with an unfilled corner, so that the polishing machine radically solves a fundamental problem for stabilizing yield and quality. The polishing machine adopts pneumatic and mechanical double-level lifting so as to increase lifting stroke, and is widely applied for machining stones, so that the polishing machine not only can grind the prior stones, but also can grind various boulder strips with different heights and specifications. The polishing machine has the advantages of high working efficiency and long service life.

Owner:蔡崇友

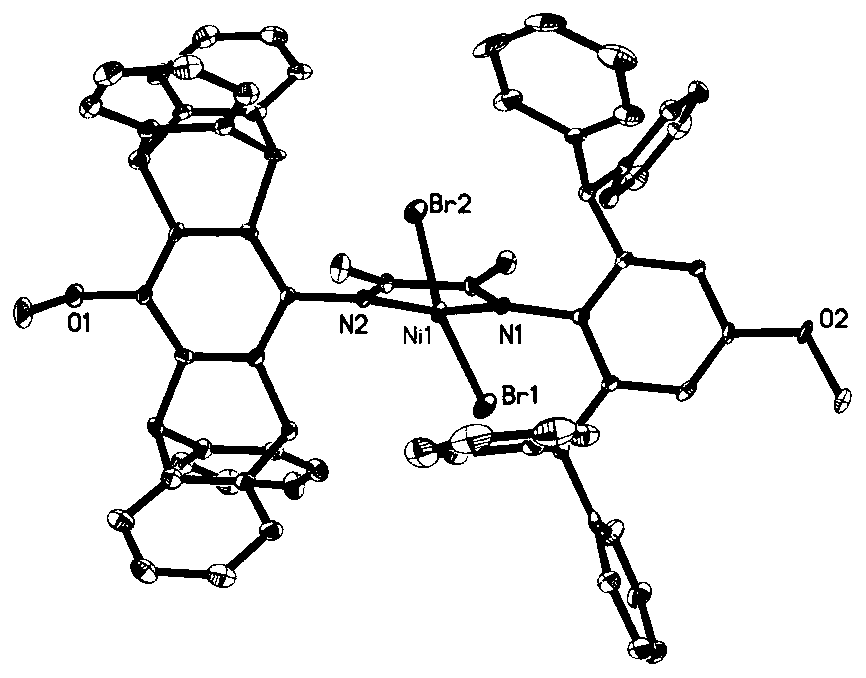

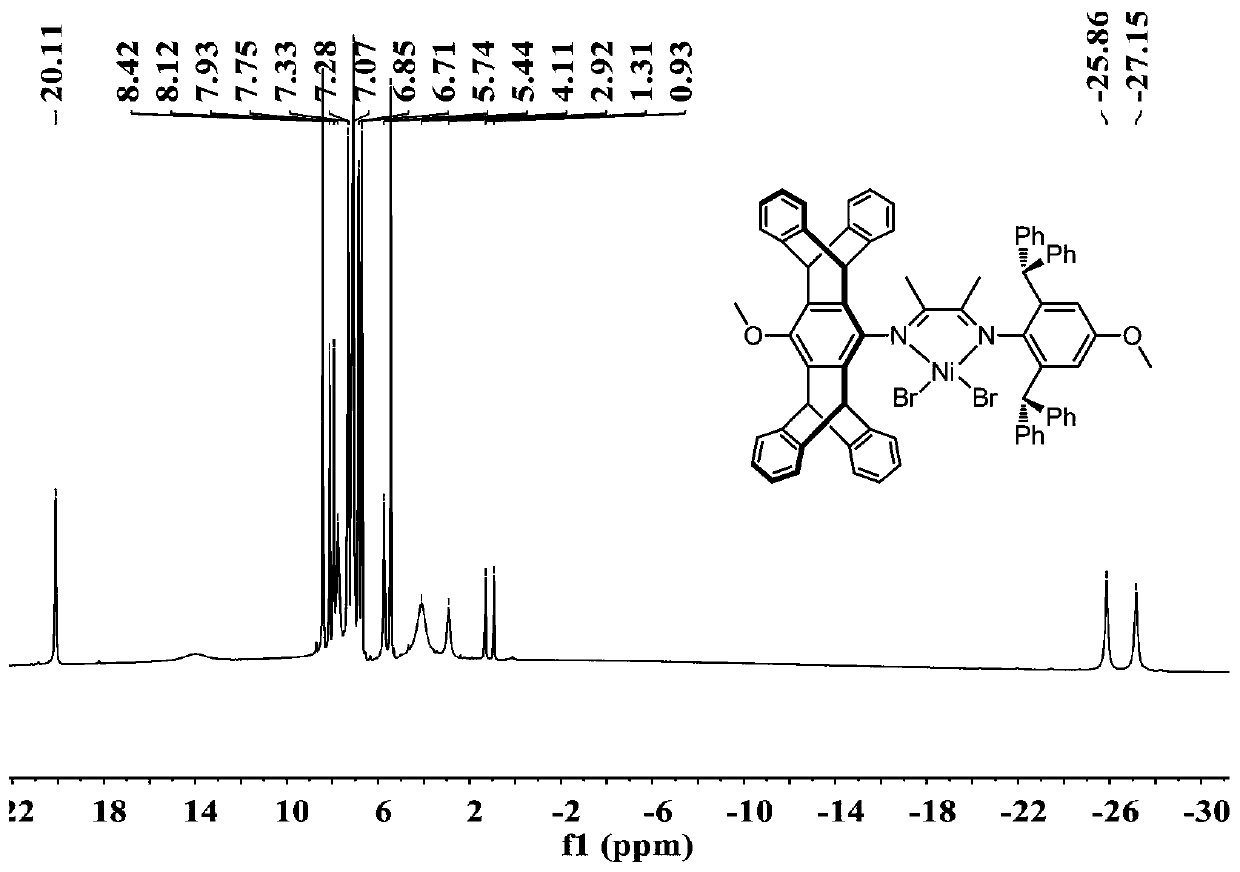

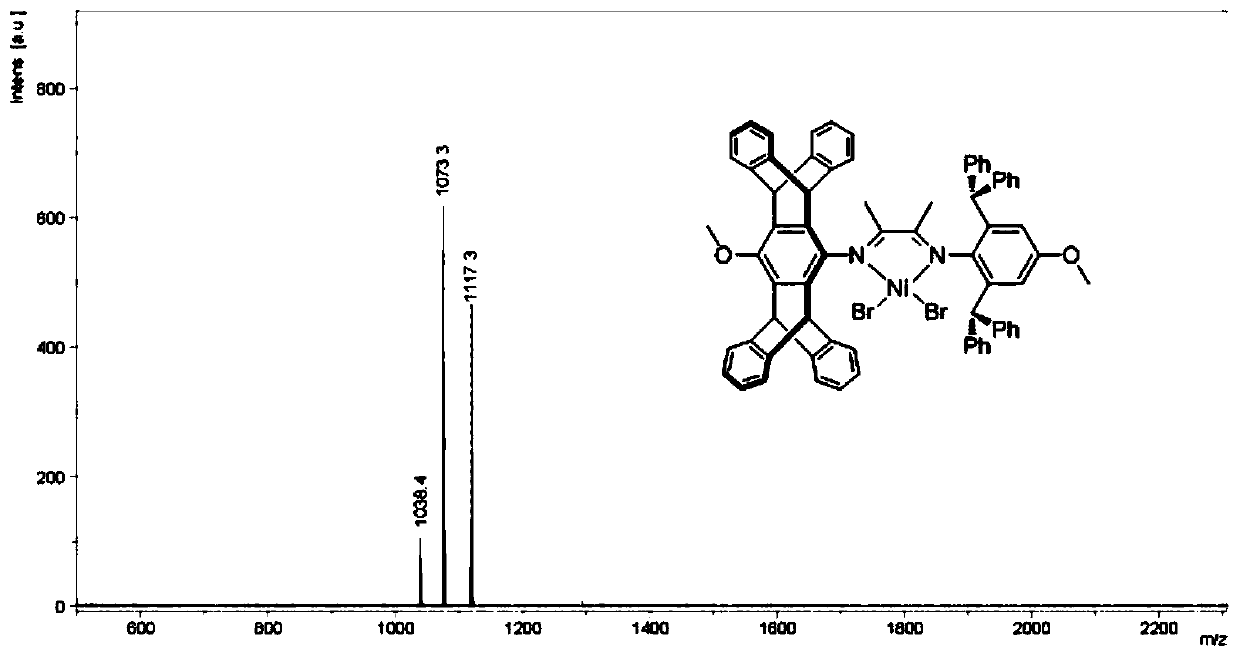

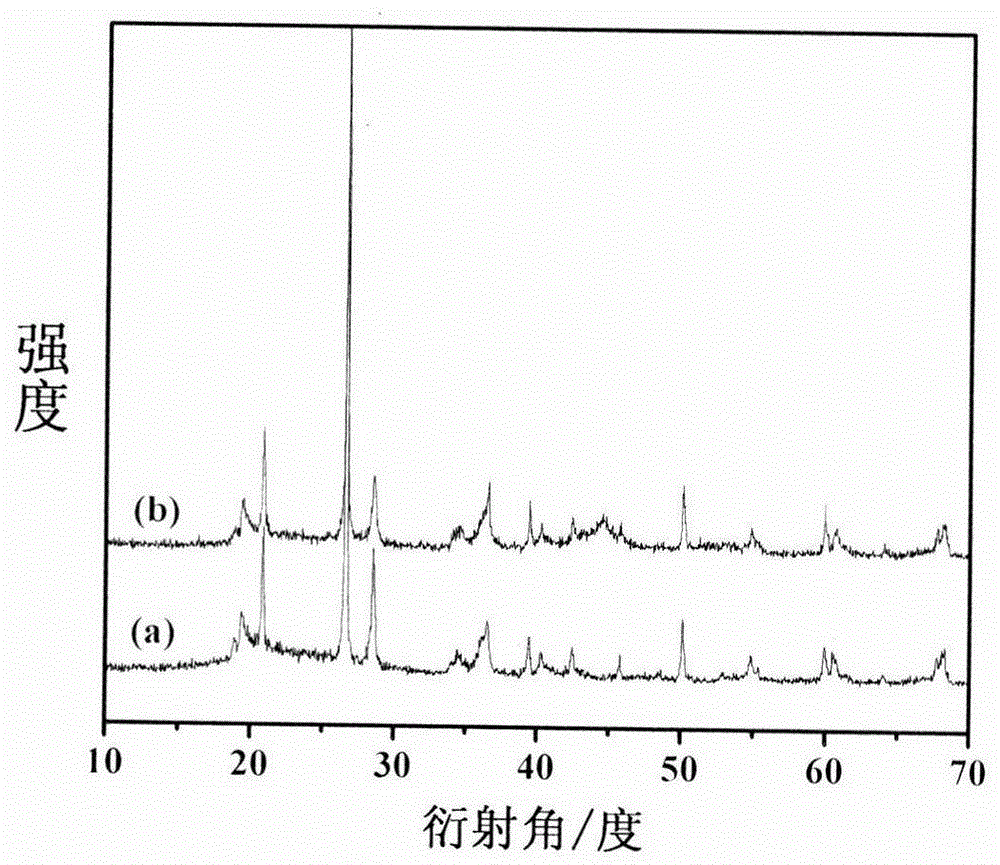

Asymmetric alpha-diimine nickel catalysts as well as preparation method and application thereof

The invention relates to asymmetric alpha-diimine nickel catalysts as well as a preparation method and application thereof, and belongs to the technical field of catalysts. On the basis of ensuring the thermal stability of the catalysts and the catalytic performance of the catalysts capable of obtaining a polymer with a high molecular weight through catslysis, the catalysts solve the technical problem of a low degree of branching of a polymer obtained by catalyst-catalyzed ethylene polymerization in the prior art. The asymmetric alpha-diimine nickel catalysts have a structural formula represented by a formula (I) shown in the specification, on one hand, the catalysts adopt large steric hindrance skeletons of 2,6-bis(diphenylmethyl)phenyl and derivatives of the 2,6-bis(diphenylmethyl)phenylwhich can rotate freely, the electronic and steric effects of the large steric hindrance are changed, on the other hand, the catalysts adopt skeletons of pentiptycene and derivatives of the pentiptycene which can limit geometric rotation, and the electronic and steric effects of the pentiptycene are changed, so that the target that the polymer with the high molecular weight and a branching degreecapable of being regulated and controlled in a large scale is obtained at high temperature can be realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Environmental-friendly biological stuffing and method of producing same

InactiveCN101665282ALow priceExtensive sources of raw materialsBiological water/sewage treatmentSpecific gravityPollutant

Owner:湖南清和环保技术有限公司

Method for preparing composite coagulant by comprehensively using pickling waste acid and waste residues on surfaces of aluminum and iron

InactiveCN105217754AWide variety of sourcesRich sourcesWater/sewage treatment by flocculation/precipitationSpent acidFerric

The invention relates to a method for preparing a composite coagulant by comprehensively using pickling waste acid and waste residues on surfaces of aluminum and iron. The method includes the steps that waste residues containing aluminum are dissolved in acid; heavy metal is removed; aluminum-containing liquid is prepared; an inorganic composite coagulant is prepared; the inorganic and organic composite coagulant is prepared. The method has the advantages that raw material resources are wide, production cost is low, product quality is excellent, and the production process is environmentally friendly.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

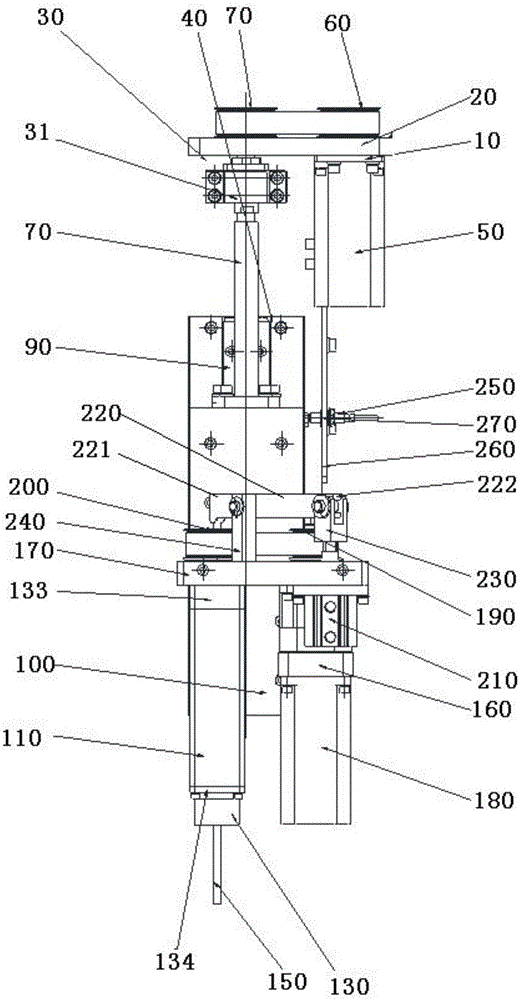

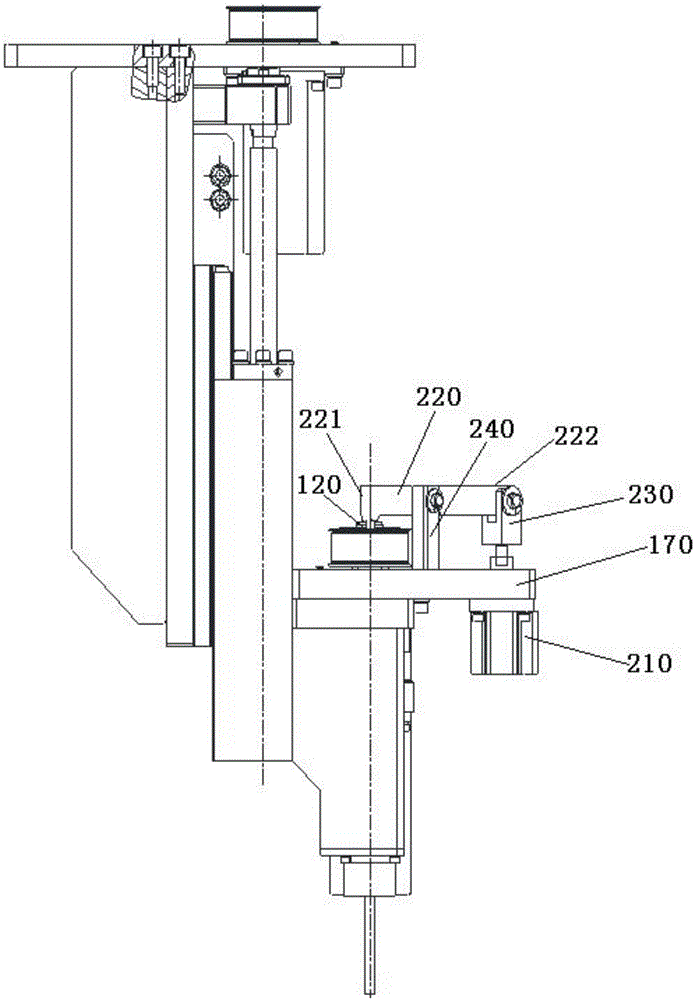

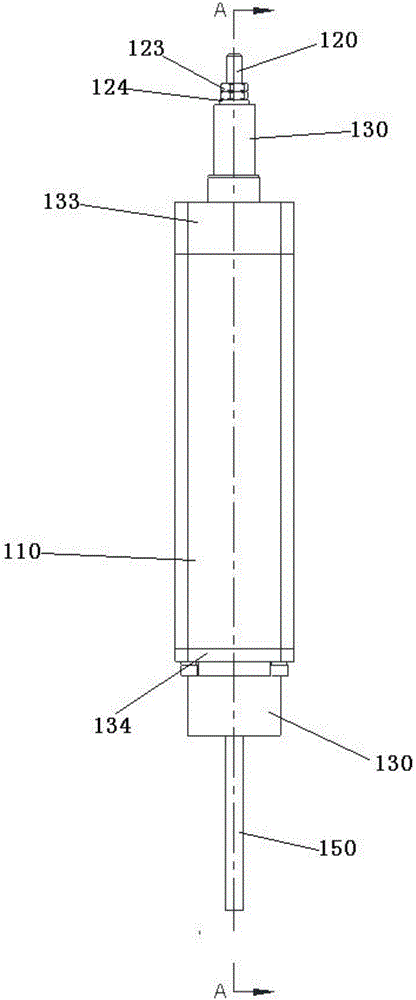

Full-automatic drill bit replacing type perforating machine

ActiveCN106624059ARealize vertical reciprocating movementRealize punchingFeeding apparatusDriving apparatusBall screwPaperboard

The invention discloses a full-automatic drill bit replacing type perforating machine. The machine comprises a perforating head, a rotating mechanism for driving the perforating head to rotate to perforate, a dismounting mechanism for automatically dismounting a drill bit on the perforating head, and a mounting mechanism for automatically mounting the drill bit on the perforating head, wherein a first servo motor can drive a first synchronous belt wheel and a second synchronous belt wheel during working, and a ball screw can rotate through the transmission of the synchronous belt wheels, and thus the drill bit is driven to lengthways reciprocate; a second servo motor can drive a third synchronous belt wheel and a fourth synchronous belt wheel, and the drill bit is driven to rotate through the transmission of the synchronous belt, thus realizing perforating; a cylinder runs to enable simple, quick and accurate automatic replacing of the drill bit after perforating. The machine is proper in size, simple to assemble, high in assembling performance, and high in transmission torque; the machine is applicable to processing of commonly-used paperboards, plastic, steel plates, workpieces, etc., and the applicable scope is wide; the service life of a cutter can be prolonged; and the production quality and efficiency can be improved.

Owner:西安绿港科技发展有限公司

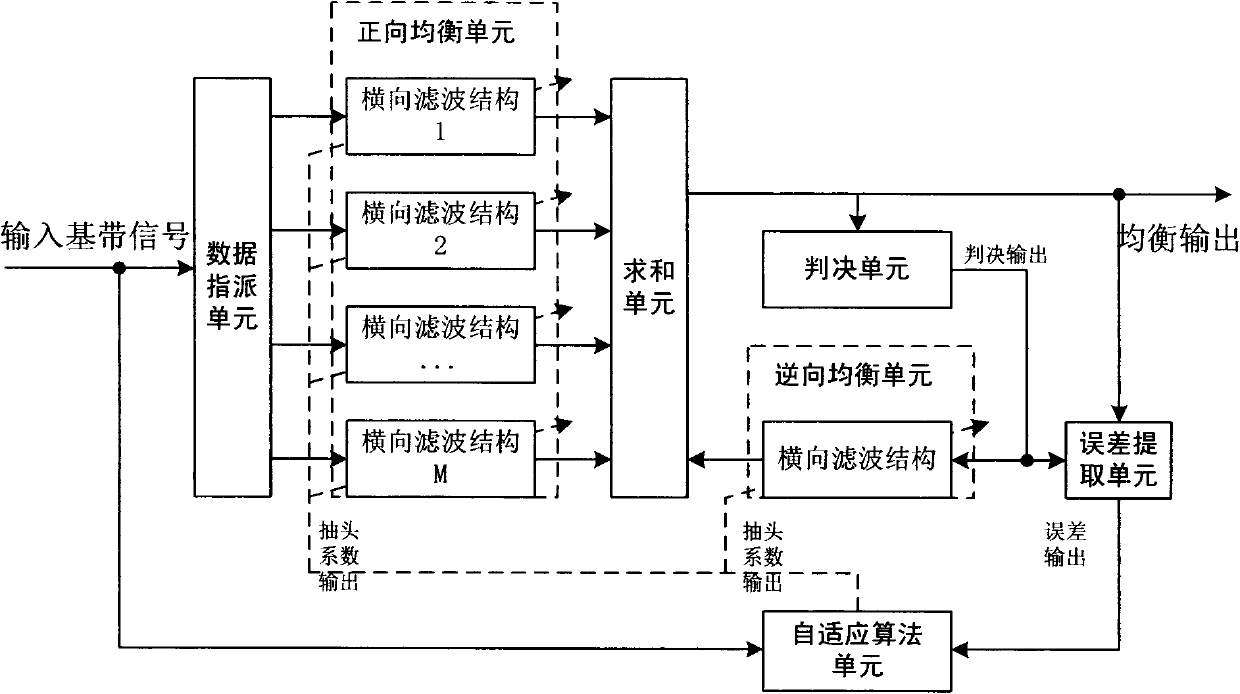

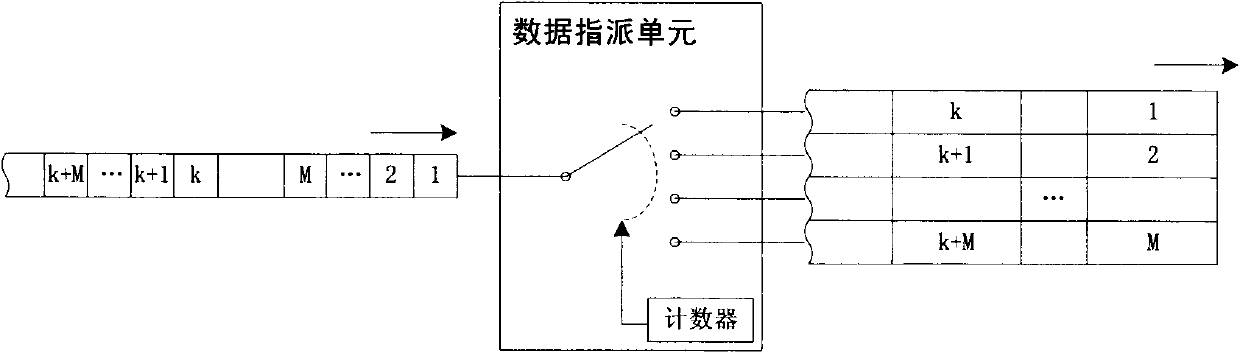

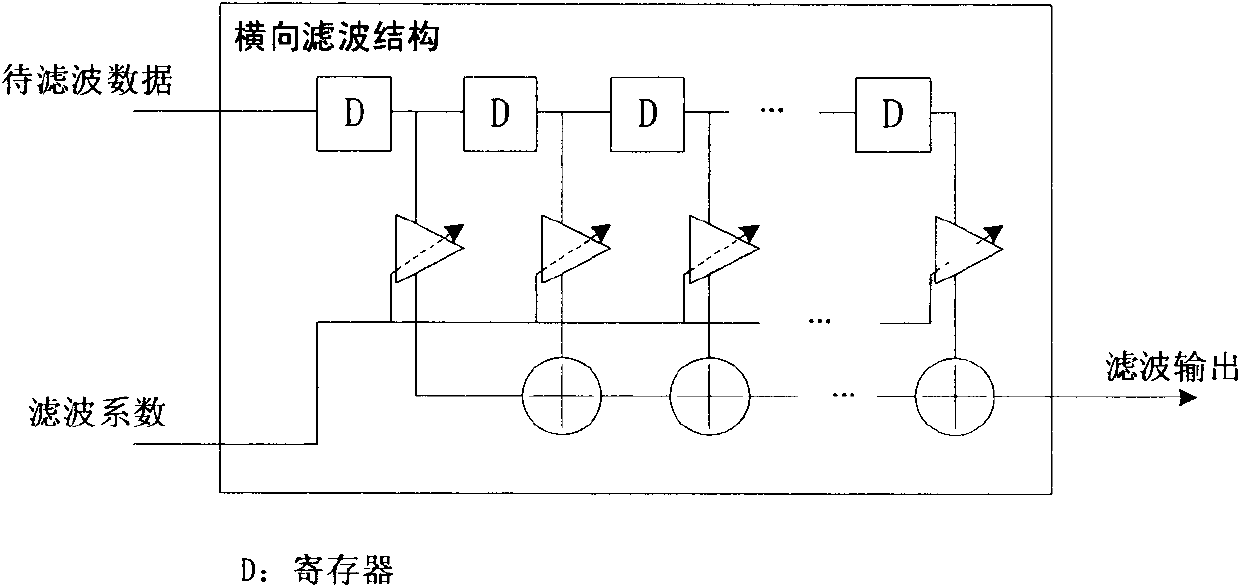

Method for carrying out equalization on 100M magnitude broadband reception signal

InactiveCN102594374AImprove adaptabilityHigh speedEnergy efficient ICTTransmitter/receiver shaping networksBlind equalizationTime domain equalization

The invention provides a method for carrying out equalization on a 100M magnitude broadband reception signal, and is aimed at providing a method for using a simple time domain parallel structure to carry out time domain equalization on the broadband signal with small resource consumption, a fast operation speed, and no need of changing a transmission system. The method is realized through the following technical scheme: (1) employing a fraction interval adaptive blind equalization digital logic circuit with decision feedback, and receiving over-sampling baseband signal to be equalized in parallel; (2) carrying out addition of output of all transverse filtering structures as equalization output, and sending the baseband signal to be equalized into the transverse filtering structures in a forward direction equalization unit according to a corresponding phase relationship; (3) judging an equalization output result with a decision unit, and solving an error signal e(n) of the output result and a decision result; after e(n) is adjusted through an error convergence factor, carrying out gradient estimation and equalization coefficient updating, and sending an updated equalization coefficient to each transverse filtering structure to carry out an equalization operation. According to the method, contradiction between generating the equalization results and carrying out the equalization coefficient updating simultaneously in a code element is solved.

Owner:10TH RES INST OF CETC

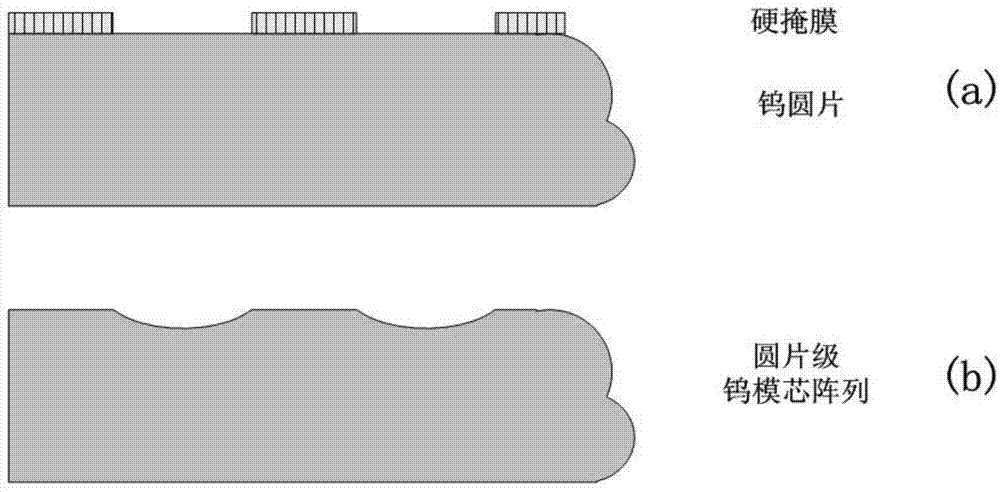

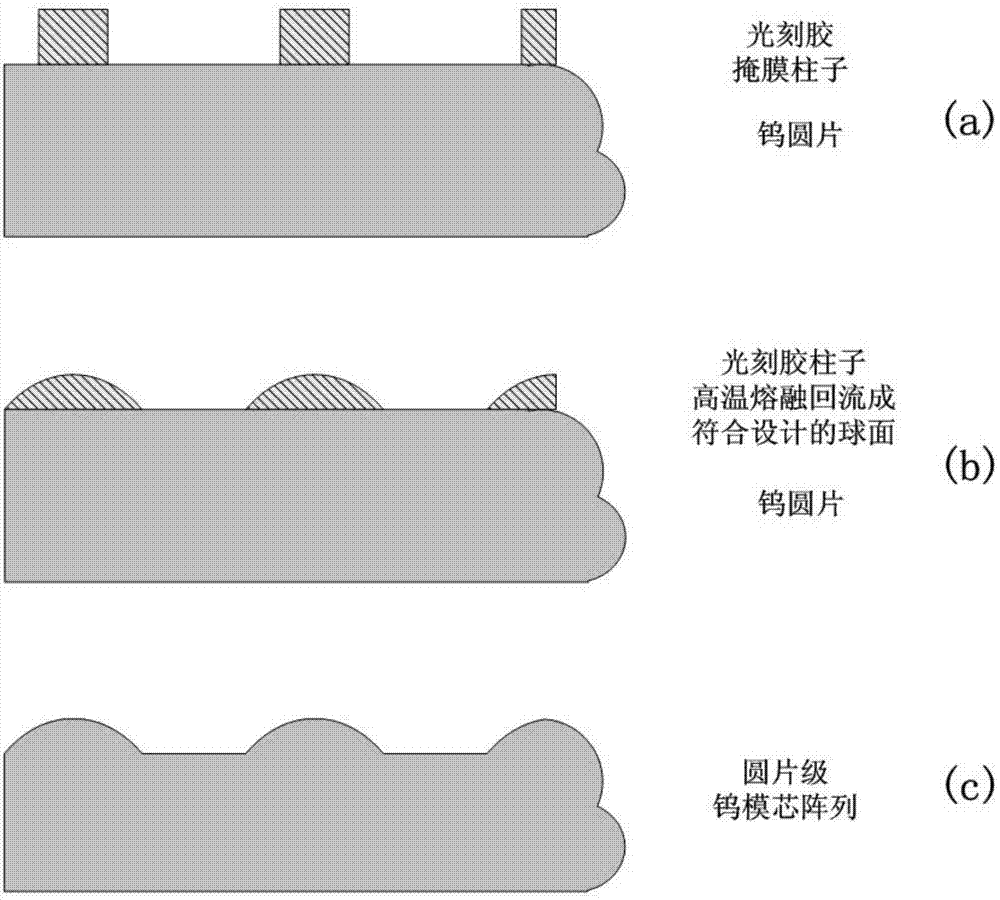

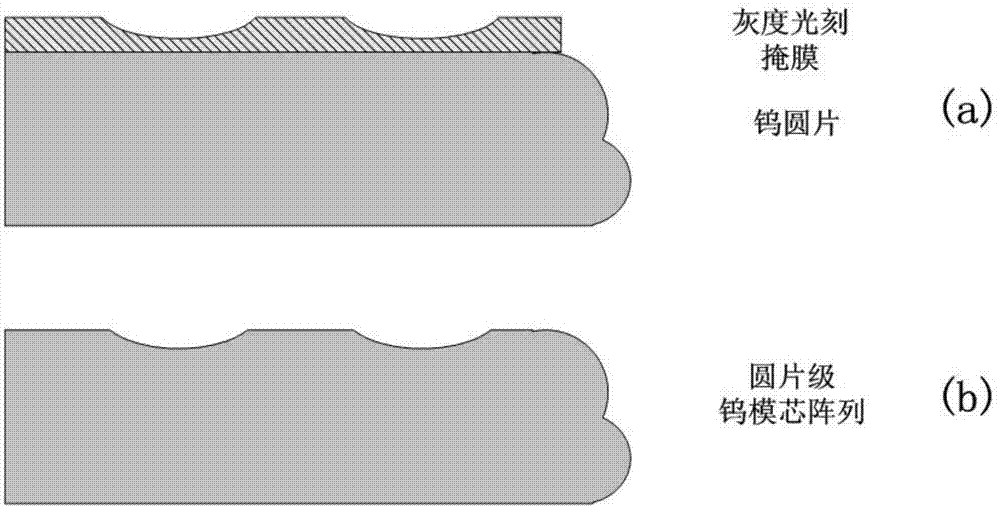

Novel mold core for optical lens processing and preparation method therefor

ActiveCN104843972AExtensive processingHigh melting pointGlass pressing apparatusCamera lensOptical glass

The invention relates to a novel mold core for optical lens processing and a preparation method therefor. The mold core is made of metallic tungsten, and is a single component level tungsten mold core or a wafer level tungsten mold core. The wafer level tungsten mold core adopts a photoetching and etching method, combines with a subsequent wafer level bonding and cutting technology, and meets the requirement of a wafer level optical lens; and the single component level tungsten mold core is formed by cutting the wafer level tungsten mold core. After the tungsten mold core is machined into a required shape, a single optical lens component or wafer level microlens array is prepared by utilizing the tungsten mold core in combination with a method such as injection molding and mould pressing. According to the invention, metallic tungsten is adopted as a mold core material for optical lens processing, and optical lens of a spherical surface or any curved surface of various materials (including organic materials, plastic, various high-quality optical glass materials with high melting points, and the like) can be processed and manufactured.

Owner:苏州含光微纳科技有限公司

Polymeric aluminum chloride flocculant preparation method using phthalocyanine green waste water

InactiveCN1544348AAchieve the purpose of useReduce pollutionWater/sewage treatment by ion-exchangeIron halidesAluminium chlorideLiquid product

A process for preparing polymerized aluminium chloride flocculating agent from phthalocyanine green waste water comprising, placing the type 335 weak alkaline anion exchange resin into adsorbing column, flowing dilute hydrochloric acid through the adsorbing column, rinsing the resin column with water or deionized water, processing the resin column by weak alkaline liquor, finally rinsing the adsorbing column with water or deionized water until water exhibits weak alkalinity, adjusting the pH of phthalocyanine green waste water, making it pass through the pretreated and transformed type 335 weak alkaline anion exchange resin column from normal temperature to 50 deg. C, and passing through another ion exchange resin adsorbing column, thus obtaining the phthalocyanine green waste water whose copper ion concentration meets second level standard. By concentrating the phthalocyanine green waste water treated by the resin under the condition of stirring and heating, adding in alkalinizing agents simultaneously for reaction, adjusting waste water till it exhibits weak acidity, continuously stirring and conducting heating reaction, the liquid product or solid end product can be obtained.

Owner:NANJING UNIV

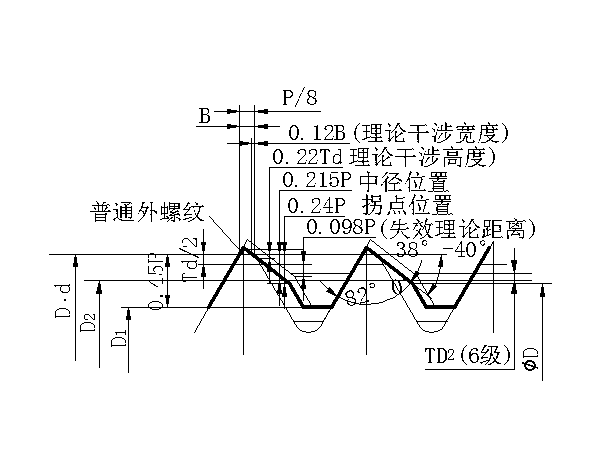

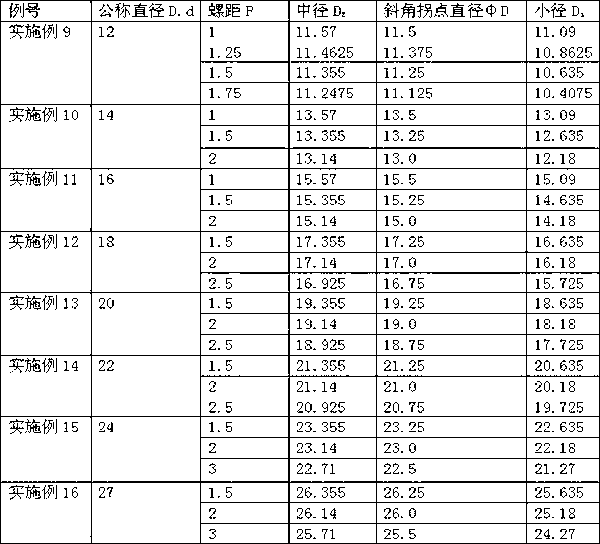

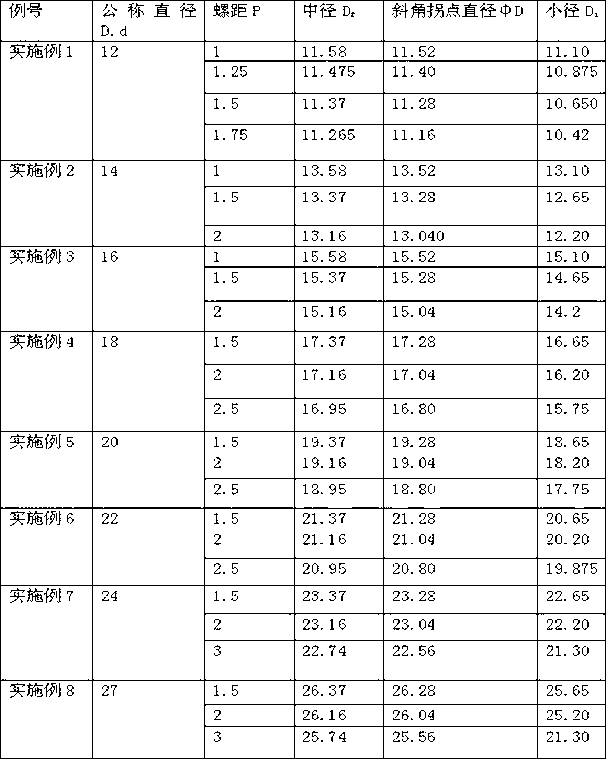

Anti-loose internally threaded fastener

InactiveCN103216513AImprove mechanical propertiesReduce contact stressNutsBoltsThreaded fastenerEngineering

The invention relates to an anti-loose internally threaded fastener, which comprises an internal thread substrate, and is characterized in that the shape of an internal thread arranged on the internal thread substrate is as follows: the oblique angle of an internal thread profile is 38 degrees to 40 degrees, the intermediate diameter D2 = D-(0. 42 to 0.43) P, the variable angle inflection point diameter phiD = D-(0.48 to 0.50)P, the minor diameter D1 = D-(0.90 to 0.91) P, the theoretical interference width is 0.12B, the theoretical interference height is 0.22Td, the failure theoretical distance is 0.098P, the intermediate diameter position is 0.215P, and the inflection point position is 0.24P. By improving the design parameters of the thread, and connecting the internal thread with six-level machining precision and an ordinary external thread with six-level machining precision, the mechanical properties of a thread pair are greatly improved, the contact stress of the thread pair is reduced, the plastic deformation of an external thread profile crest zone is reduced, the overloading assembly ability is strong, the anti-loose reliability is good, no interference occurs in a limit size state, the rotation following phenomenon is avoided, and the assembly quality and efficiency are high.

Owner:吉林市翔达电动车厂

Preparation method of mesoporous carbon/ graphene oxide compound

ActiveCN107640758ALarge specific surface areaImprove adsorption capacityGrapheneCarbon preparation/purificationCarbonizationSolvent

The invention discloses a preparation method of a mesoporous carbon / graphene oxide compound. The preparation method comprises the following steps: weighing asphalt and an additive, mixing the asphaltand the additive at a mass ratio of (1 to 10) to (10 to 1), then, adding solvent of 1-10 times of mass into a mixture, stirring, evenly mixing, distilling the solvent, then, putting in an oven to bedried, and then, preparing the mesoporous carbon / graphene oxide compound through a carbonization and oxidization technology. An in-situ growth method is adopted, graphene does not need to be preparedin advance, and the prepared mesoporous carbon / graphene oxide compound has a relatively high specific surface area, good adsorption performance on dye and heavy metal and high recyclable rate, wherein the specific surface area is 150-700m<2> / g, and a graphene degree is 30-50 percent. In addition, the preparation method has the advantages of rich raw material, low price, simpleness in operation and easiness in realizing industrial production.

Owner:FUZHOU UNIV

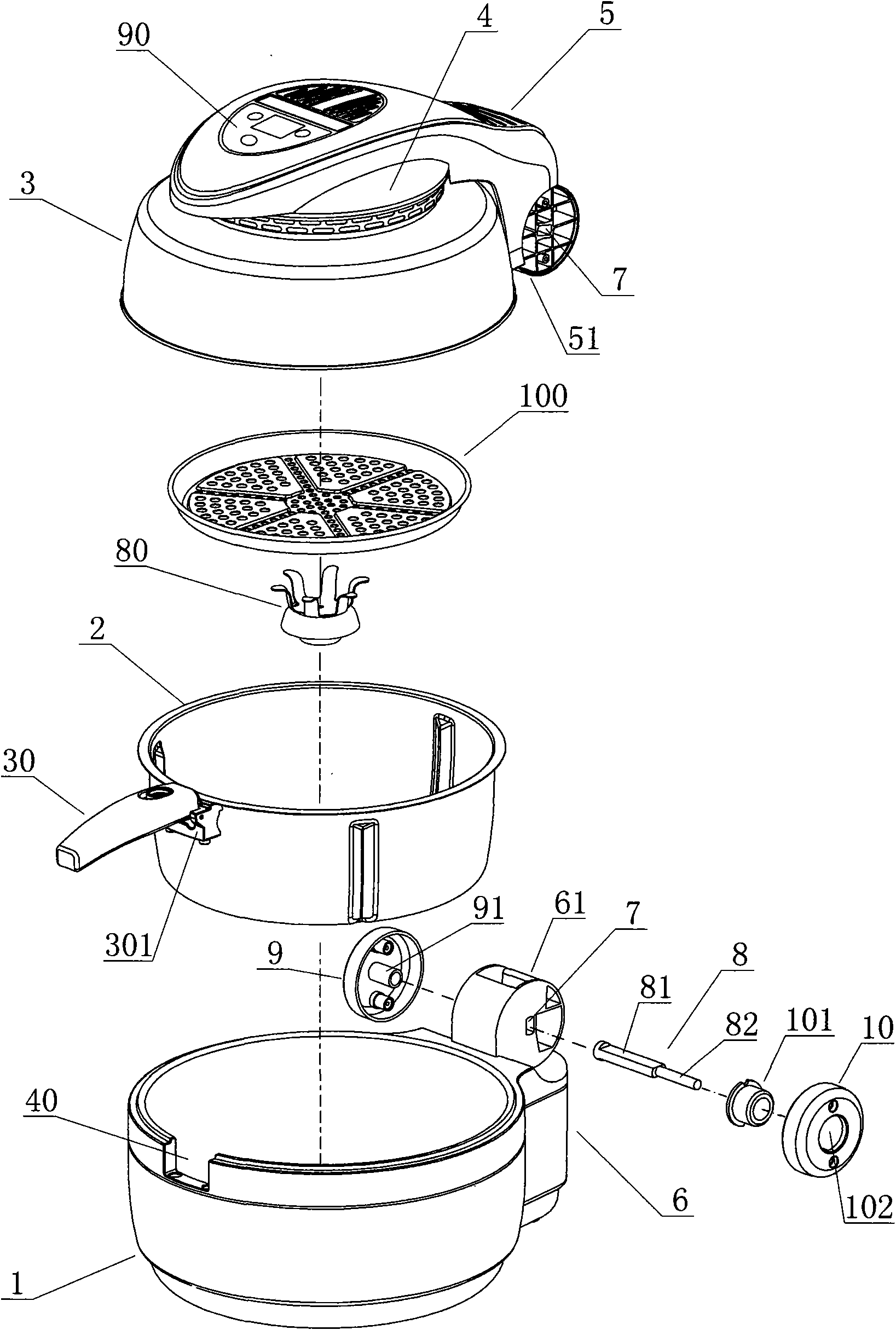

Full-automatic cooking processor

ActiveCN101669774AAvoid hitting the pot holderAvoid pinchingCooking vesselsKey pressingLocking mechanism

The invention relates to a full-automatic cooking processor, comprising a pot seat, a pot body and a pot cover body, wherein a heating device which can transfer heat to the inner cavity of the pot body is arranged on the pot cover body, and the pot body is sheathed in the pot seat; the full-automatic cooking processor is characterized in that: the pot cover body and the pot seat are respectively provided with a connecting arm and an arm-connecting base, the pot cover body can be arranged on the pot seat in an opening way by the articulating connection of the connecting arm and the arm-connecting base, and a locking mechanism for locking the pot cover body is arranged between the connecting arm and the arm-connecting base. The usage is simple and convenient, the pot cover body can be covered on the pot seat by pressing down a key of the locking mechanism after the pot cover body is opened, thereby effectively avoiding the phenomenon that the pot cover body is hit against on the pot seatsuddenly and violently, ensuring the pot cover body and the pot seat not to be damaged and ensuring the normal service life of the whole processor on one hand, on the other hand, the probability thathand is hurt is avoided and the using safety of the processor is greatly improved.

Owner:胡启康

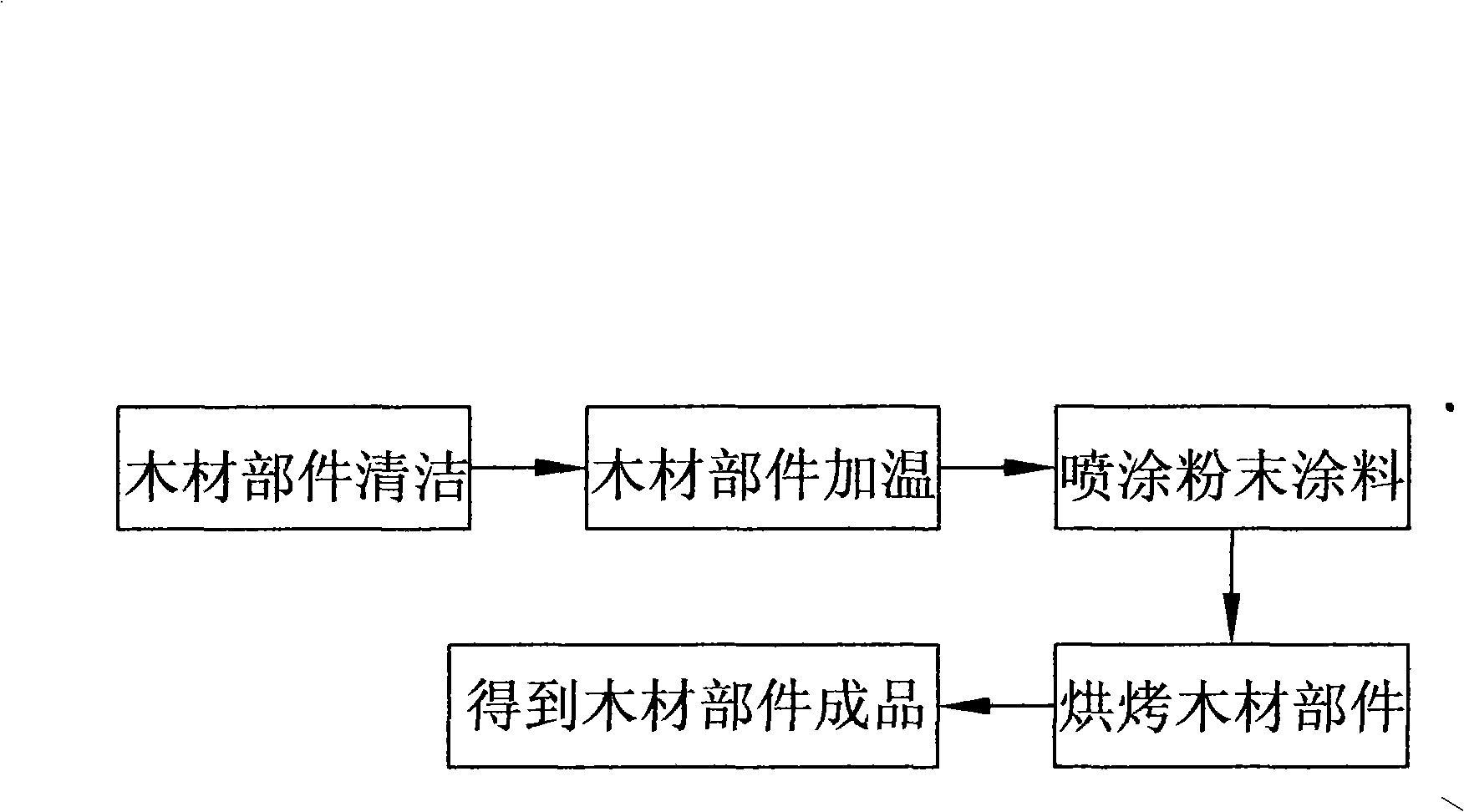

Method for solidifying powder paint on lumber component surface

The invention relates to a method for solidifying powder coatings on the surfaces of wooden components, mainly including wooden-component cleaning, wooden-component heating, spraying powder coating, baking wooden-component, etc. The invention can settle the problem of the existing methods that wooden-components decorated by the combination of paint and tianna water have the disadvantages of residue of formaldehyde, toluene and other toxic and harmful substances on the wooden-components which can not meet the green, safe and environment-friendly requirements; the wooden-components processed by the method is green, safe, environment-friendly and free of peculiar smell and the residue of formaldehyde, toluene and other toxic and harmful substances; besides, the products processed by such method is not easy to fade and scale off, and the service life is long. The production process of the invention is simple, and is applicable to processing the wooden-components made of batten, flitch, plank or composite wooden panel.

Owner:何镜添

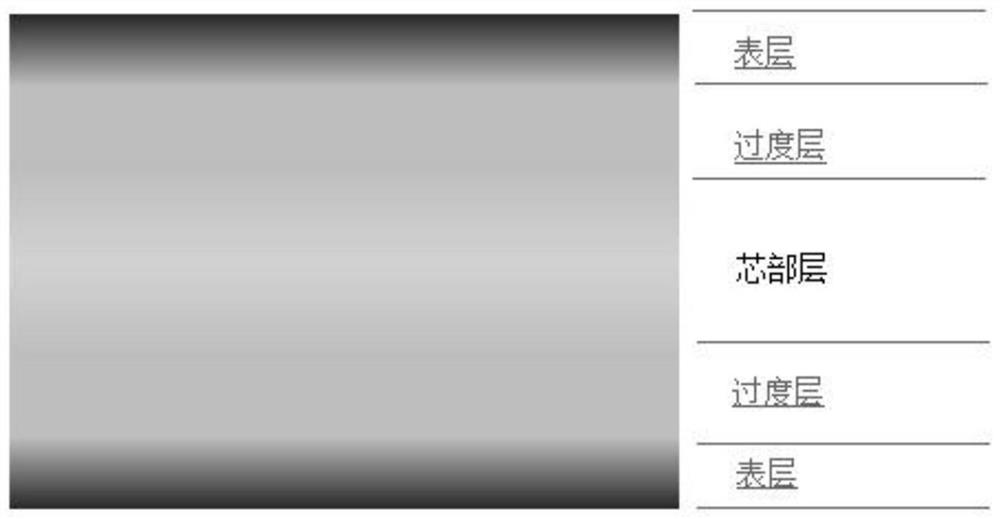

Boron carbide-tungsten carbide composite ceramic gradient material for tool as well as preparation method and application of boron carbide-tungsten carbide composite ceramic gradient material

ActiveCN111646801AExtend your lifeAvoid peeling fractureNuclear energy generationComposite ceramicHigh surface

The invention belongs to the technical field of cutting tools, and discloses a boron carbide-tungsten carbide composite ceramic gradient material for a tool and a preparation method and application ofthe boron carbide-tungsten carbide composite ceramic gradient material. The surface layer of the ceramic gradient material comprises 70-100 vol% of B4C and 0-5 vol% of Co, wherein the core part of the ceramic gradient material contains 50-95 vol% of WC and 5-20 vol% of Co; the relative density of the material is higher than 97%, the hardness of the surface layer is 20-35 GPa, and the fracture toughness of the surface layer is 3-10 MPa.m < 1 / 2 >. The hardness of the core part is 14-22 GPa, and the fracture toughness of the core part is 8-20 MPa.m < 1 / 2 >. By controlling the contents of boron carbide, tungsten carbide and metal cobalt on the surface and the core, the hard-surface tough-core high-performance boron carbide-tungsten carbide composite ceramic gradient material is prepared by hot pressed sintering. The composite ceramic gradient material has very high surface hardness, wear resistance and good tipping fracture resistance.

Owner:GUANGDONG UNIV OF TECH

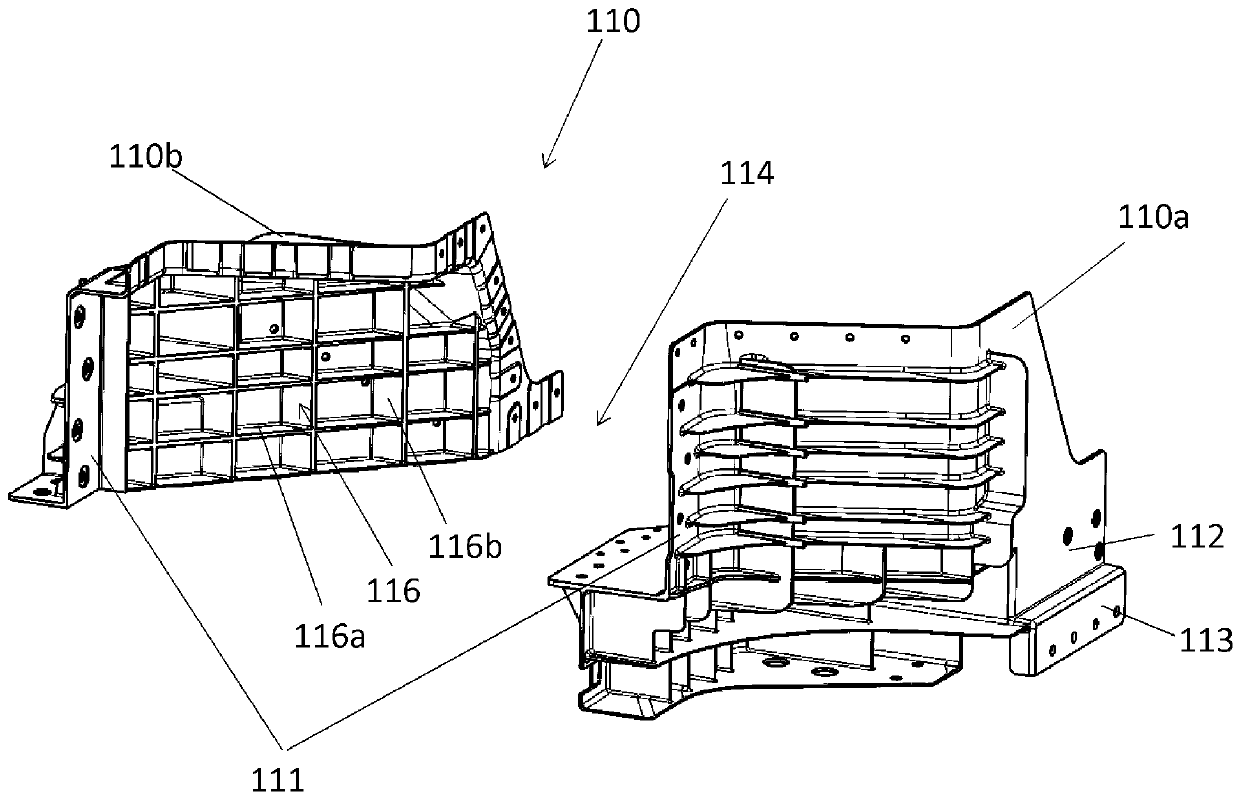

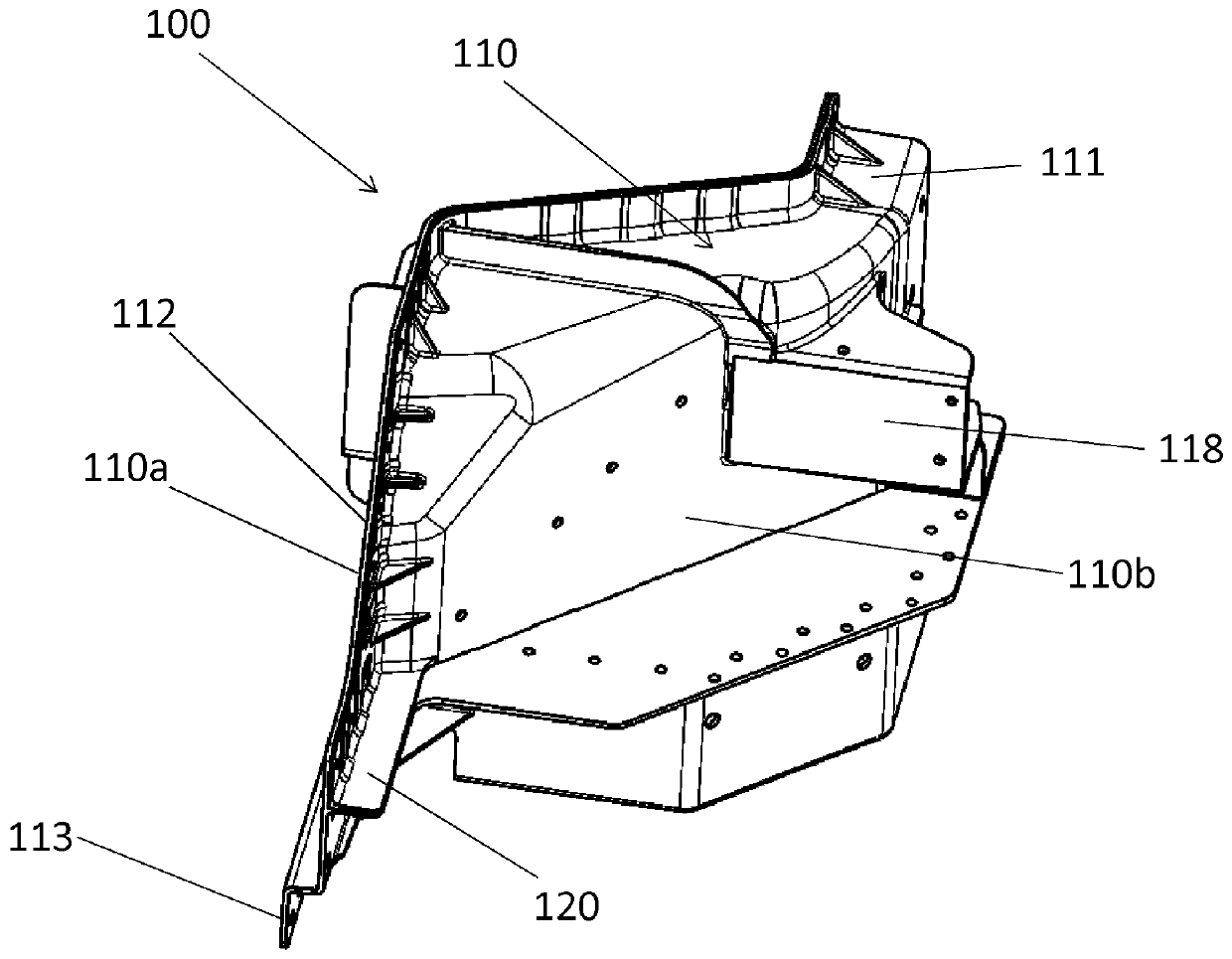

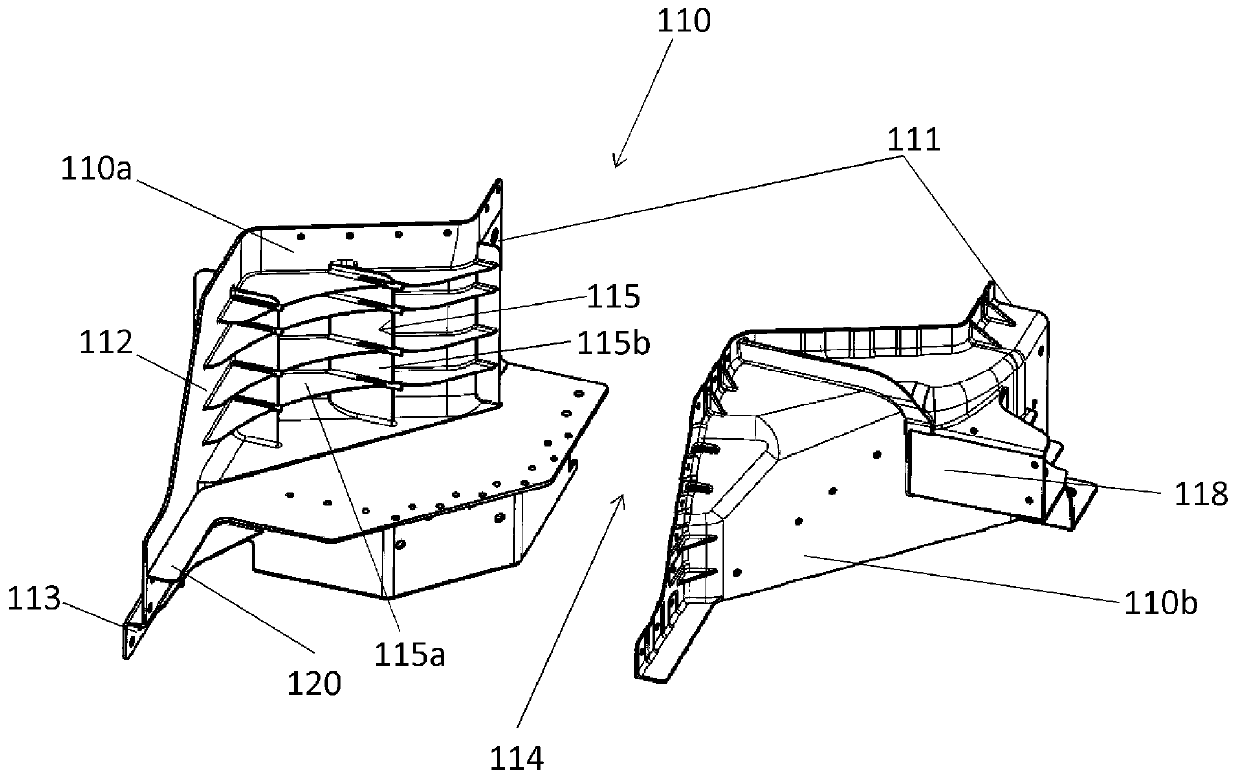

Car frame connecting piece for electric car, car frame assembly and electric car

PendingCN110304146AReduce casting difficultyEasy processing and wide applicationUnderstructuresVehicular energy storageVehicle frameElectric cars

The invention discloses a connecting piece for a car frame, a car frame assembly and an electric car. The car frame connecting piece comprises a connecting piece base. The connecting piece base is atleast provided with a front longitudinal beam connecting part, an A column lower inner plate connecting part and a threshold longitudinal beam connecting part; when orienteering is performed along thecar frame, the front longitudinal beam connecting part is located in the front of the connecting piece base 110, the A column lower inner plate connecting part is located at the outer side of the connecting piece base 110, and the threshold longitudinal beam connecting part is located at the rear part of the connecting piece base 110; the connecting piece base comprises an outer side connecting piece and an inner side connecting piece with transverse orienteering along the car frame. The car frame connecting piece has the low casting difficulty by designing the split structure of the inner side and outer side mode, and the car frame connecting piece is suitable for being widely applied; the connecting strength of a car frame and a key joint is enhanced, and the collision safety performance is improved.

Owner:NIO ANHUI HLDG CO LTD

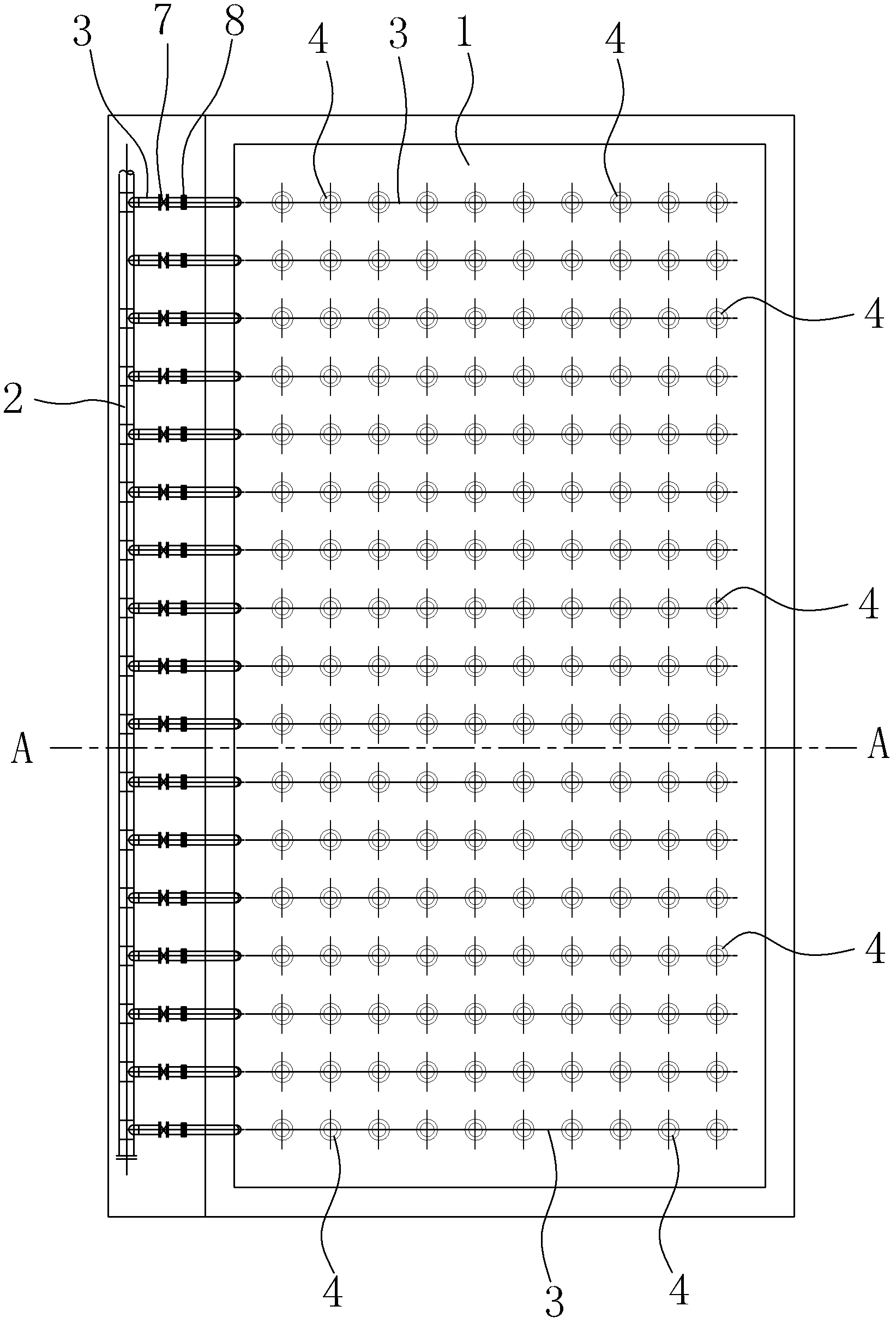

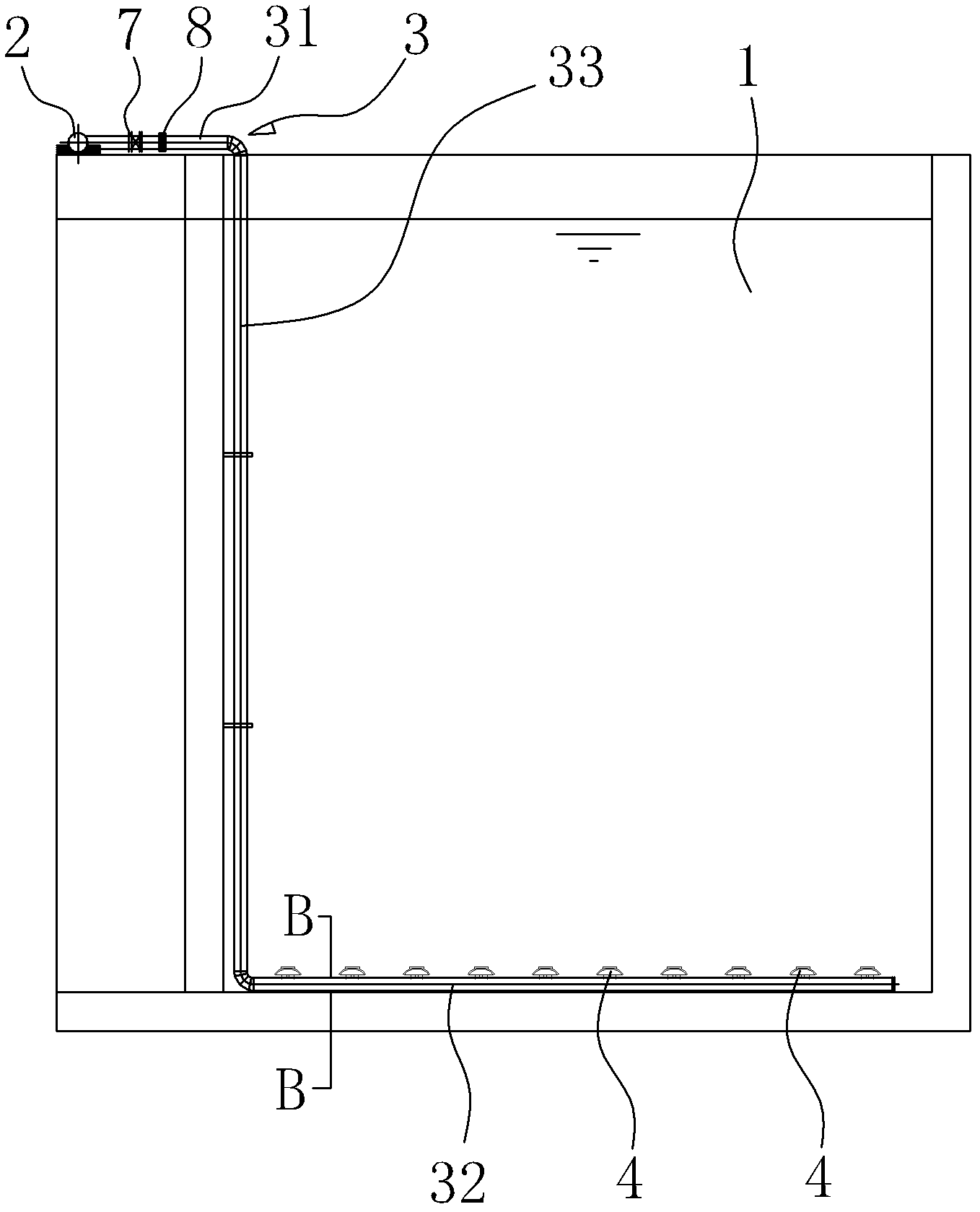

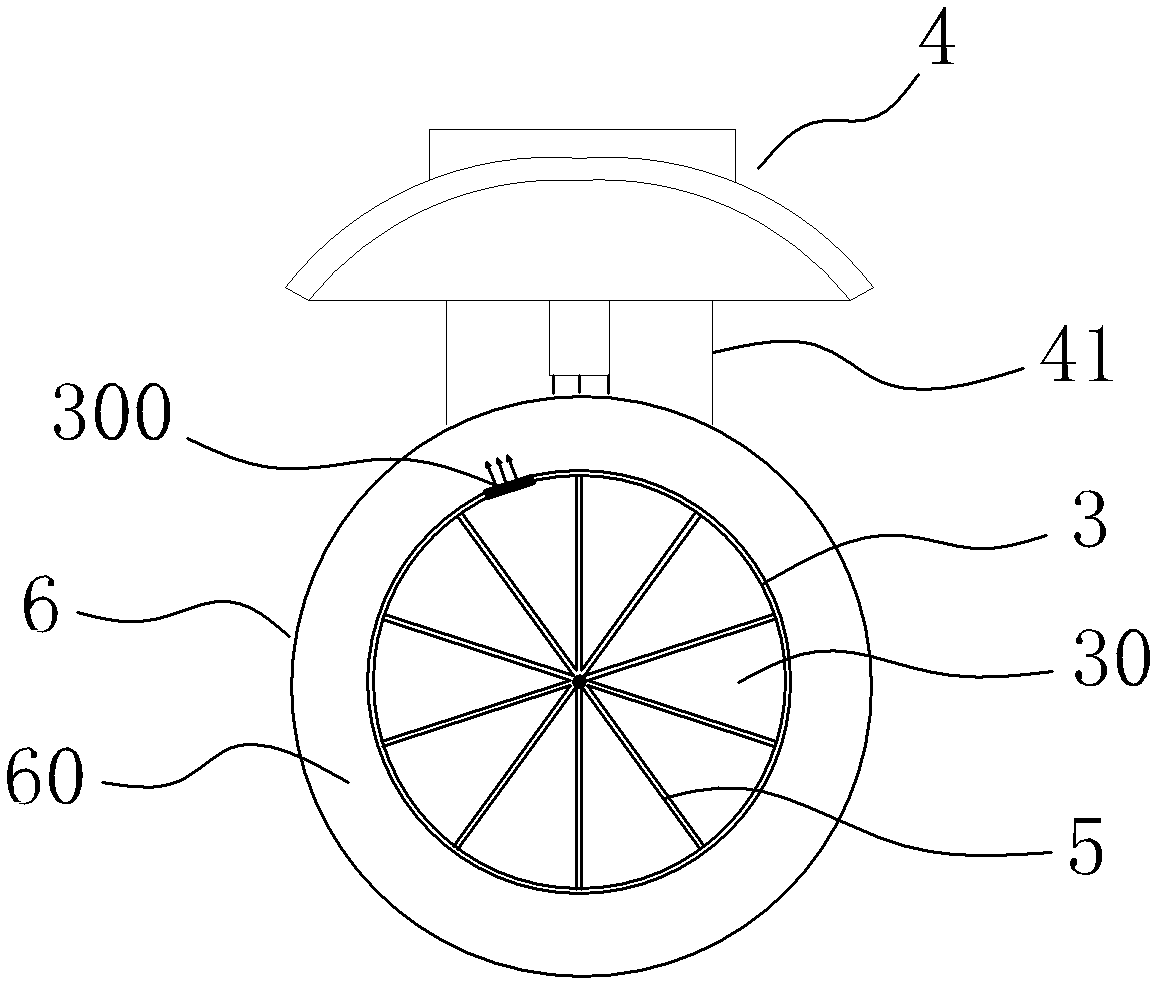

Orange segment type micro-porous aeration system

ActiveCN102649601AEasy to useIncrease independenceSustainable biological treatmentBiological water/sewage treatmentAeration systemControl valves

The invention discloses an orange segment type micro-porous aeration system, which comprises a reaction tank, an aeration main pipe, a plurality of aeration branch pipes and a plurality of aeration discs, wherein the aeration main pipe is fixedly arranged on the reaction tank; the aeration branch pipes are uniformly arranged on the aeration main pipe; the aeration discs are arranged on each aeration branch pipe; the pipe cavity of each aeration branch pipe is uniformly divided into a plurality of cavities by a partition plate to form a plurality of orange segment pipes of which the sectional shapes are similar to orange segments; and each aeration disc and the orange segment pipe are provided with corresponding serial numbers. According to the orange segment type micro-porous aeration system, the aeration discs can independently work without affecting mutually, and high reliability is guaranteed. As long as no more than three aeration discs on a single branch pipe are damaged, the entire system can normally operate and is maintenance-free; and the aeration of the aeration system is also extremely uniform and the aeration stability is extremely excellent. Each aeration disc and the orange segment pipe in the corresponding aeration branch pipe have corresponding serial numbers; and if one of the aeration discs is damaged, only one tailor-made air blockage sheet is required to be closely embedded in a corresponding through hole of a control valve without affecting the use of other aeration discs.

Owner:GUANGDONG KAIYUAN ENVIRONMENT TECH

Polymeric aluminum chloride ferric flocculant preparation method using phthalocyanine green waste water

InactiveCN1544349AReduce pollutionImprove protectionWater/sewage treatmentIron halidesAluminium chlorideLiquid product

A process for preparing polymerized aluminium chloride flocculating agent from phthalocyanine green waste water comprising, (1) subjecting the phthalocyanine green waste water to micro electrolyzation with ferrum, so as to replace the copper ions in the phthalocyanine green waste water, (2) filtering the phthalocyanine green waste water after micro electrolyzation for concentration, the concentration ratio being 10%-80%, (3) stirring the concentrated phthalocyanine green waste water and charging in alkalinizing agents for heating reaction, adjusting waste water till it exhibits weak acidity, continuously stirring and conducting heating reaction for 1h-10h, thus the liquid product according to the invention can be obtained, and its solid product can also be prepared by further drying the liquid product.

Owner:NANJING UNIV

Preparation method of polypropylene fiber-glass fiber thermoplastic composite material

InactiveCN105908362AHigh strengthImprove impact resistanceNon-woven fabricsMonocomponent polyolefin artificial filamentGlass fiberPolymer science

The invention discloses a preparation method of a polypropylene fiber-glass fiber thermoplastic composite material. The preparation method comprises the following preparation steps of 1 preparing of polypropylene fibers; 2 preparing of glass fibers; 3 mixing of the polypropylene fibers and the glass fibers, wherein the polypropylene fibers and the glass fibers are mixed through a fiber self-weighing mixing system, the humidity of a mixing environment is controlled to be 33% to 43%, and the temperature of the mixing environment is controlled to be 20 DEG C to 30 DEG C; 4 fiber needling felt forming, wherein the precisely-mixed polypropylene fibers and glass fibers are carded with a carding machine and lapped through a clamping type lapping machine to obtain a fiber net, then fiber needling felt forming is conducted through pre-needling equipment and main needling equipment, and lastly cutting and rolling are conducted to obtain the polypropylene fiber-glass fiber thermoplastic composite material. According to the preparation method, the process steps are simple, the production process is continuous, the production efficiency is high, the equipment is simple, and the technology is convenient to master; the polypropylene fiber-glass fiber thermoplastic composite material has the advantages that on one hand, the good heat-conducting property is achieved, on the other hand, the mechanical property of a heat-conducting material is enhanced, and processing is convenient.

Owner:ZHEJIANG HENGZE ENVIRONMENT TECH CO LTD

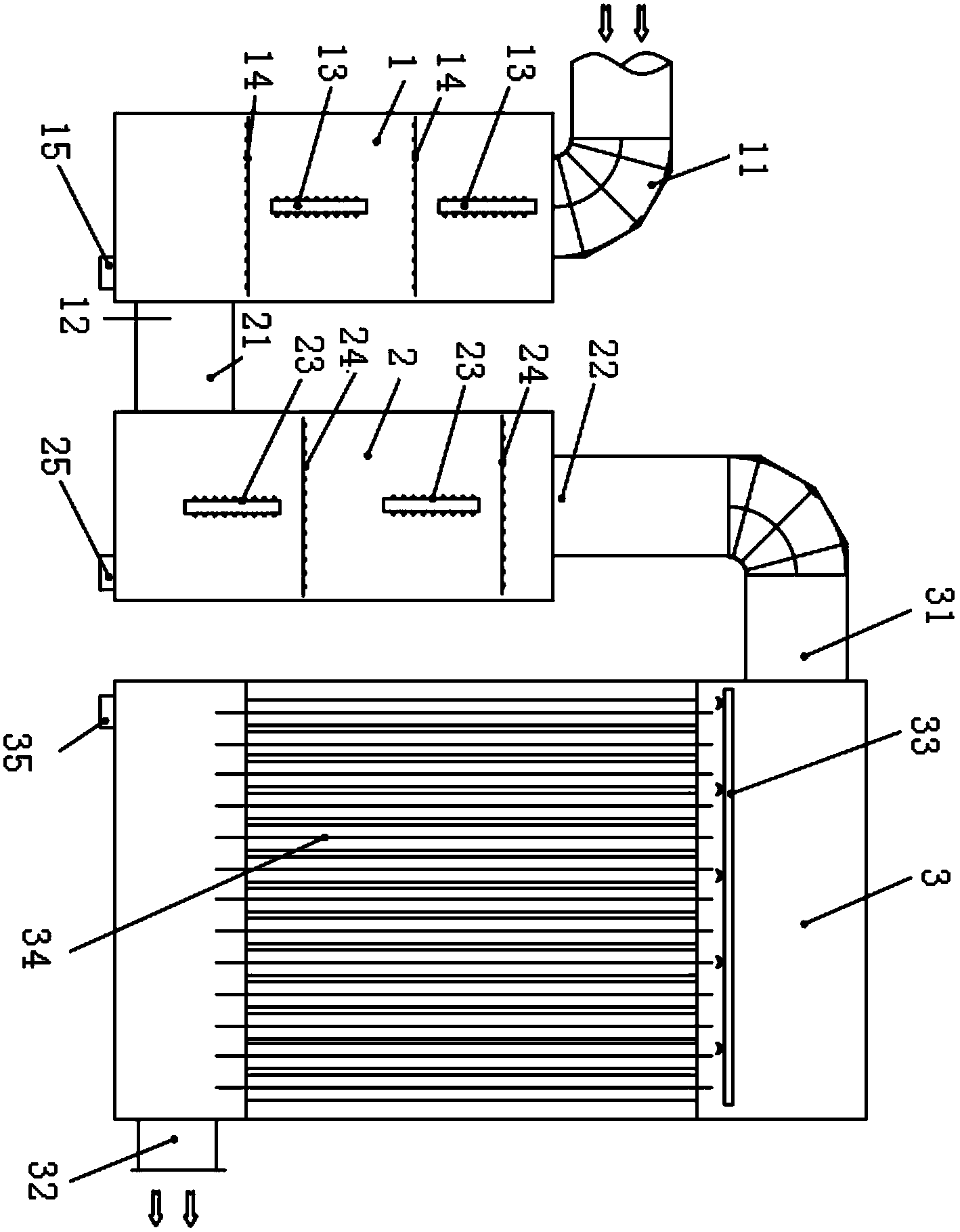

Two-stage spraying high-voltage electrostatic waste gas treatment device of printing and dyeing setting machine

InactiveCN104226059AImprove dust collection efficiencyReduce manufacturing costCombination devicesHigh pressureElectric control

The invention discloses a two-stage spraying high-voltage electrostatic waste gas treatment device of a printing and dyeing setting machine. The two-stage spraying high-voltage electrostatic waste gas treatment device comprises a purification chamber, wherein the purification chamber comprises a first-stage atomizing purification device, a second-stage water spraying purification device and a high-voltage electrostatic dust removal device which are connected in sequence, wherein the first-stage atomizing purification device, the second-stage water spraying purification device and the high-voltage electrostatic dust removal device are all controlled by an electric control system; an upper high-density atomizing water column layer and a lower high-density atomizing water column layer are arranged in the first-stage atomizing purification device; a first air guide plate is arranged below each atomizing water column layer; an upper large-particle-size water spraying column layer and a lower large-particle-size water spraying column layer are arranged in the second-stage water spraying purification device; a second air guide plate is arranged above each water spraying column layer; a washing region and a high-voltage electrostatic field region are arranged in the high-voltage electrostatic dust removal device in sequence from top to bottom. By the adoption of two waste gas humidification purification mechanisms with different effects and due to final high-voltage electrostatic adsorption purification, the dust collection efficiency is improved, and the production cost is lowered; the two-stage spraying high-voltage electrostatic waste gas treatment device can be widely used in waste gas treatment of the printing and dyeing setting machine.

Owner:FUJIAN GUANGMINGXING ENERGY ENVIRONMENT PROTECTION CO LTD +2

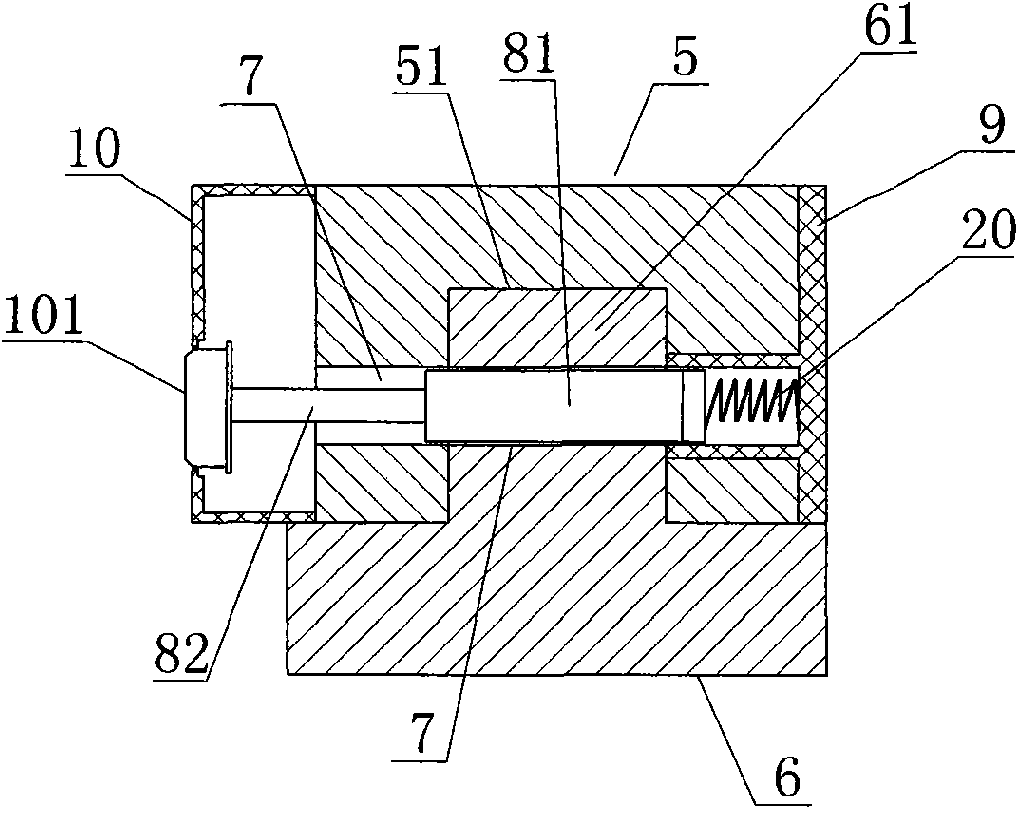

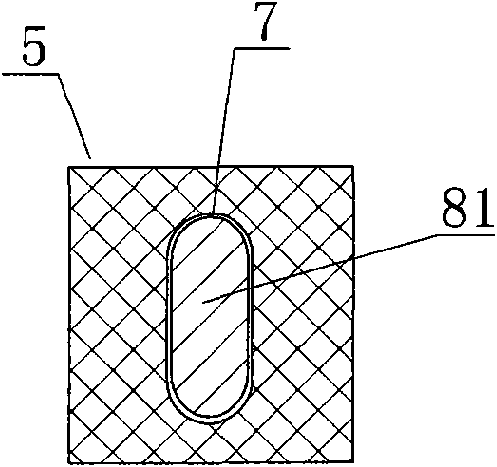

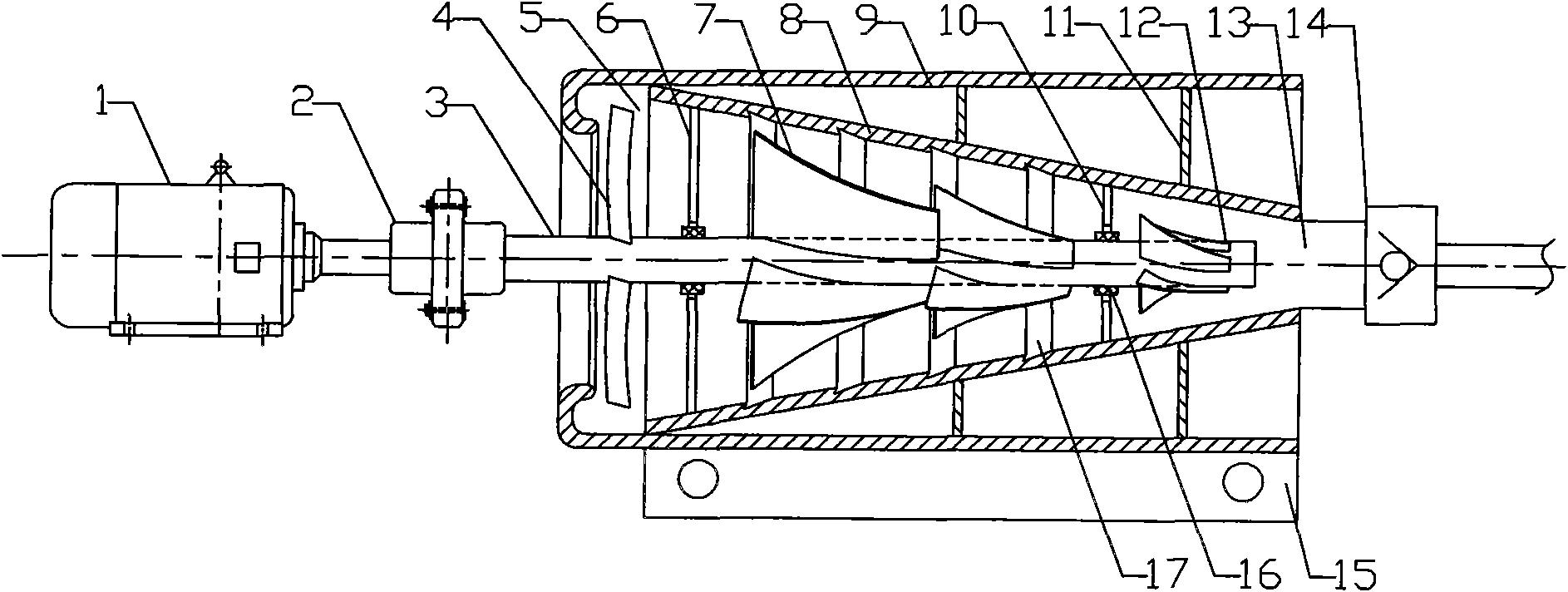

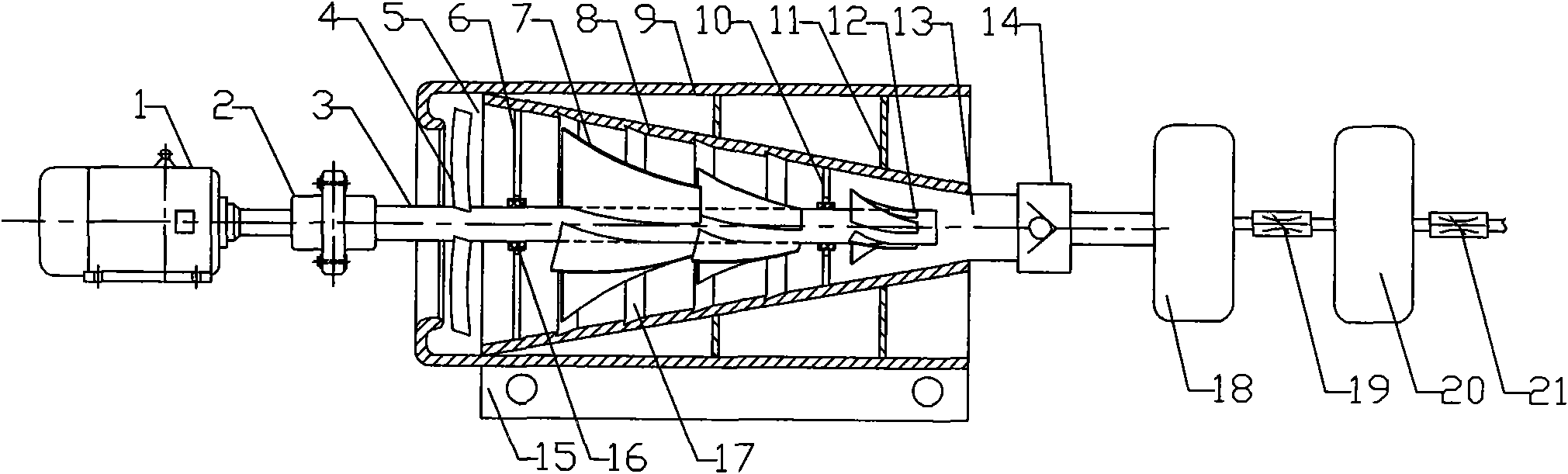

Gas supercharger

InactiveCN101963165AEasy to handleChange volumeFluid-pressure convertersChemical industryHybrid system

The invention discloses a gas supercharger, which belongs to the field of gas supercharging devices. The gas supercharger of the invention can widely be used in gas supercharging and industrial waste-gas treatments in chemical industry, and can be available for the fields such as generating systems, liquid-gas mixing systems, gas delivery system, vacuum systems and the like. The gas supercharger is characterized in that the inner wall of a tapered supercharging-chamber shell (8) is provided with a plurality of backflow slots (17), and the section of each backflow slot is v-shaped; the left end of a power transmission shaft (3) arranged in supercharging-chamber shell (8) is provided with a half-trapezoid blade device (7), and the right end of the power transmission shaft (3) is provided with a gas-lead out blade device (12); a gas-outlet transmission shaft bracket (10) is arranged between the half-trapezoid blade device (7) and the gas-derived blade device (12); the left part of the half-trapezoid blade device (7) is provided with a gas-inlet transmission shaft bracket (6) and a gas-lead out blade device (4); and a gas outlet (13) of the tapered supercharging-chamber shell (8) is provided with a one-way valve (14). The invention has the advantages of no reciprocation components, simple structure, high energy utilization, large discharge, and the like.

Owner:王强

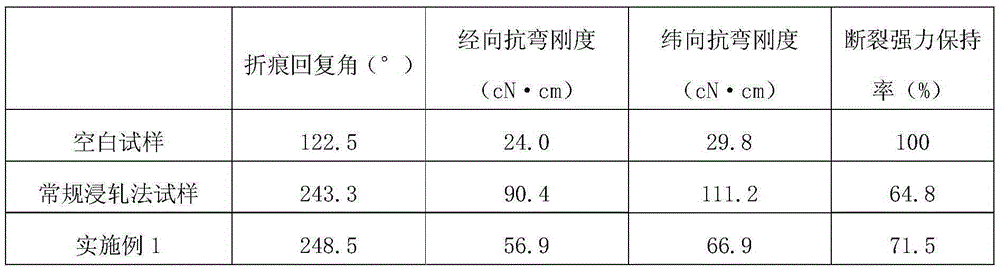

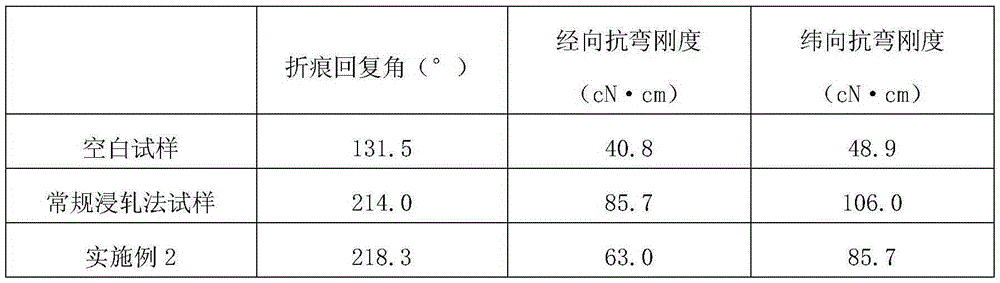

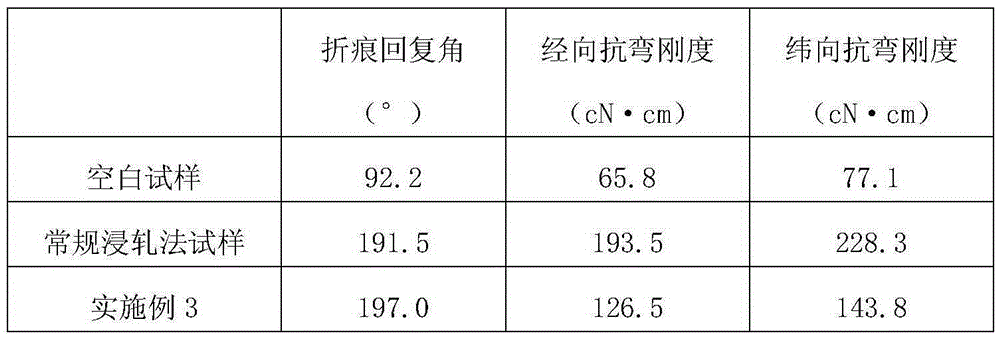

A fabric anti-wrinkle finishing method based on spray point crosslinking

InactiveCN104018339BImprove wrinkle resistanceDoes not affect strengthPhysical treatmentWrinkle skinFiber

The invention relates to a crease-resistant finishing method for point-like crosslinked fabric based on a spraying method. Precisely-controllable spraying equipment is utilized to uniformly spray a crease-resistant finishing agent on the fabric at a certain dimension and at a certain interval, uniform dense uncontinuous crosslinked points are formed in the fabric after thermal processing and / or electron-beam irradiation are / is performed, so that the point-like crosslinking structure is formed. The crosslinking points fix molecular chains, prevent large slippage of the molecular chains and provide crease resistance for the fabric. Certain relative movable capability is provided between the molecular chain segments among crosslinking points and fiber, so that the fabric is endowed with softness and high tensile-strength retention rate, and the tensile-strength reduction phenomenon easily caused by routine fabric crease-resistant finishing method is prevented. The provided method has the advantages of being simple in operation, high in processing efficiency, green and environment-friendly, and high in economic benefit. The prepared product is good in crease resistance, soft in handfeeling, free of obvious reduction on tensile strength and good in tensile-strength retention rate, and is applicable to clothes, bedding articles and the like.

Owner:JIHUA 3509 TEXTILE +1

Full-automatic multi-grinding head polishing machine moving independently

ActiveCN101407037BSolving Grinding DifficultiesCompact and reasonable structureGrinding drivesGrinding machinesMotor driveEngineering

Owner:蔡崇友

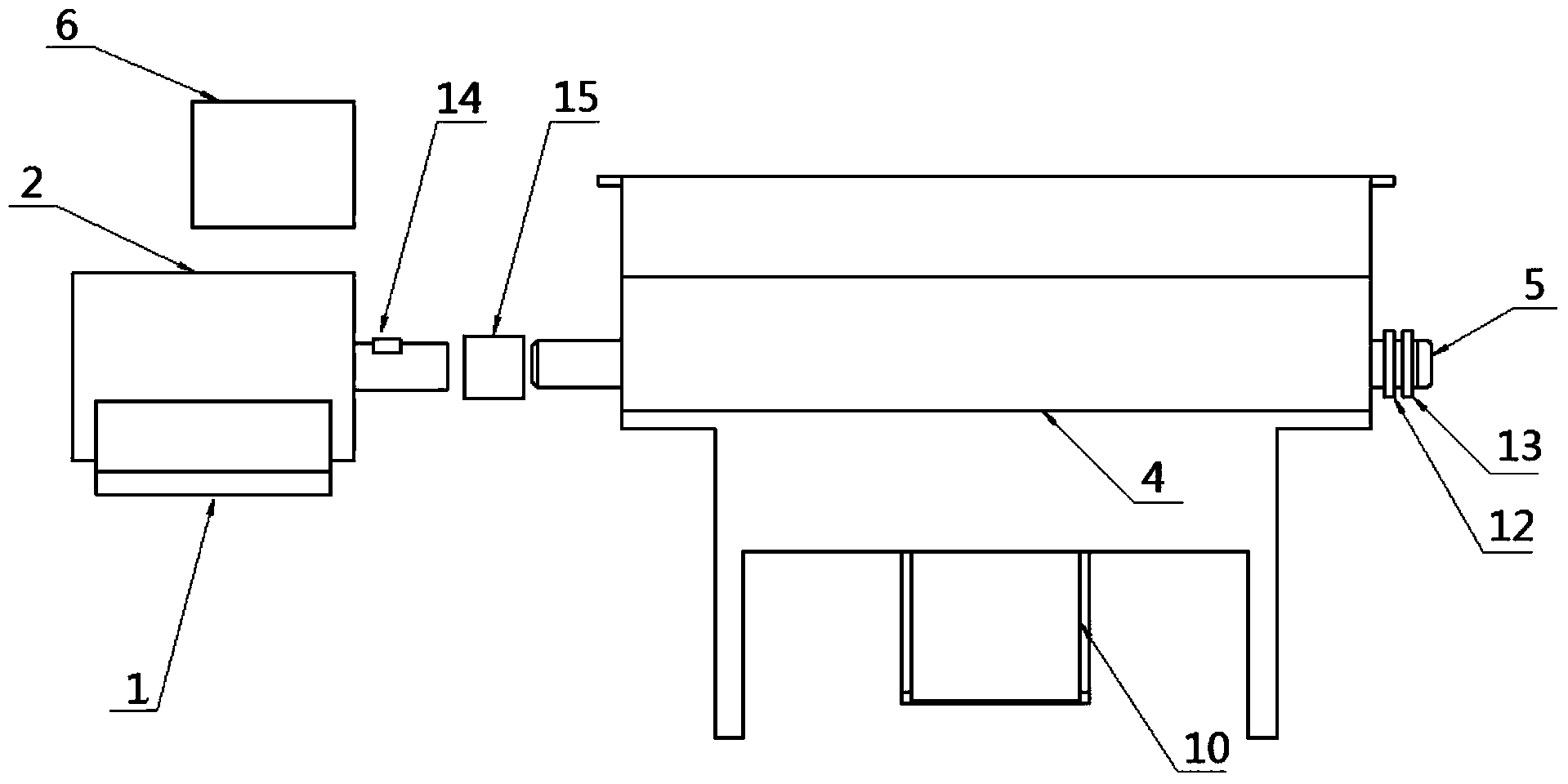

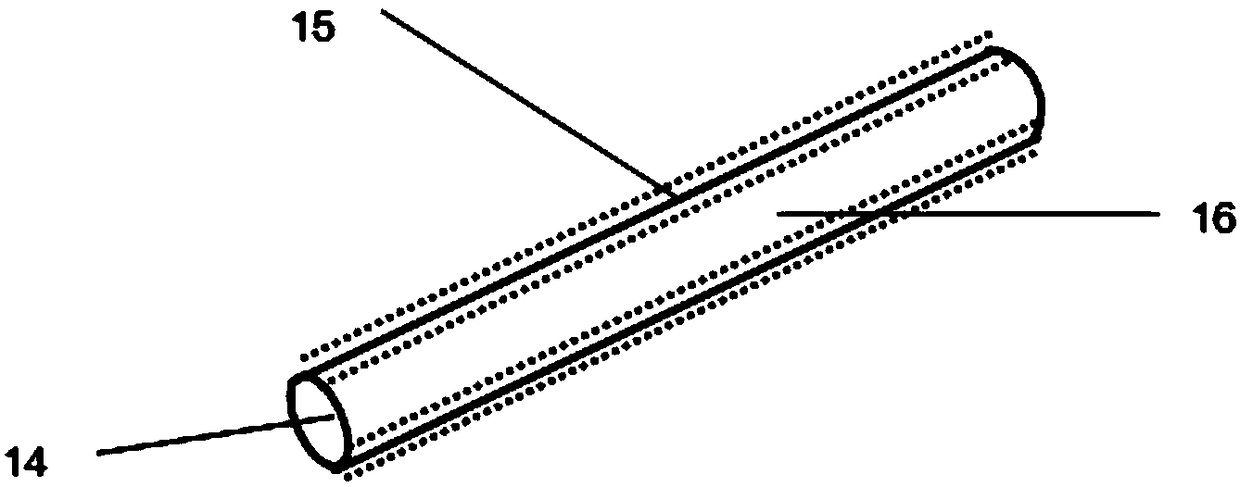

Gas phase organic substance catalytic combustion device and method based on two-dimensional zeolite catalyst

PendingCN109185902ALarge amount of processingTake advantage ofGas treatmentDispersed particle separationAtmospheric airGas phase

The invention discloses a gas phase organic substance catalytic combustion device and method based on an ultra-thin two-dimensional zeolite catalyst. A filter, a catalytic ceramic membrane module, a vacuum pump and two differential pressure controllers are included; the inner and outer walls of a tube pass of the catalytic ceramic membrane module are each coated with an ultra-thin two-dimensionalzeolite catalyst layer, an outlet of the filter is connected to a tube-pass inlet and a shell-pass inlet of the catalytic ceramic membrane module through pipes provided with valves, a tube-pass outletand a shell-pass outlet of the catalytic ceramic membrane module communicate with the atmosphere through pipes provided with valves, an inlet of the vacuum pump is connected to the tube-pass inlet and the shell-pass inlet of the catalytic ceramic membrane module through the valves, an outlet of the vacuum pump is connected to an inlet of the filter, and the two differential pressure controllers are used for detecting pressure differences between the tube-pass inlet and the tube-pass outlet of the catalytic ceramic membrane module and between the shell-pass inlet and the shell-pass outlet of the catalytic ceramic membrane module. The gas phase organic substance catalytic combustion device and method have the beneficial effects that the combustion efficiency is high, environmental protection is achieved, energy consumption is low, secondary pollution is avoided, repeated utilization can be achieved, and the catalytic combustion process of gas phase organic pollutants is achieved.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of magnetic clay nanocomposite material

InactiveCN103537258BSafe and easy processLow costOther chemical processesNanotechnologyMass ratioFilm material

Owner:HEFEI UNIV OF TECH

Textual Semantics-Based Text Structure Analysis Method

ActiveCN107145479BGreat restorationExtensive processingSemantic analysisText processingDocument structuringText mining

The invention discloses a text structure analysis method based on text semantics. The text structure analysis method comprises the following steps: 1, acquiring data; 2, performing content extraction; 3, recognizing and extracting a title; and 4, establishing a hierarchical structure. By adopting the text structure analysis method, the technical problems that text structure information reduction is carried out for a pure text, a base is made for text mining tasks, and the like, are solved.

Owner:合肥图谱智能科技有限公司

A kind of method of using enteromorpha to prepare seaweed polysaccharide oral liquid

ActiveCN107874173BReduce heavy metal contentExtensive processingFood ingredient functionsFood extractionBiotechnologyMicrobiology

The invention discloses a method for preparing seaweed polysaccharide oral liquid by using Enteromorpha, which comprises the following steps: (1) providing fresh Enteromorpha, drying it, cutting it into sections, and soaking it in soaking liquid; (2) using Enteromorpha Wash with clean water and spin dry, add clean water to heat and stir, then filter, wash with clean water and spin dry; (3) Add NaOH aqueous solution to Enteromorpha enteromorpha, and extract three times, combine the three extracts; (4) combine The final extract was concentrated, and 95% ethanol was added to collect the precipitate; (5) water was added to the precipitate obtained in step 4 to dissolve, then 95% ethanol was added to collect the precipitate, and the precipitate was dried under reduced pressure, and Add water to dissolve to obtain seaweed polysaccharide oral liquid. The method of the invention can prepare the seaweed polysaccharide oral liquid with lower heavy metal content. The method has reasonable steps and advanced technology, and can be widely used in processing enteromorpha.

Owner:荣成海锐芯生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com