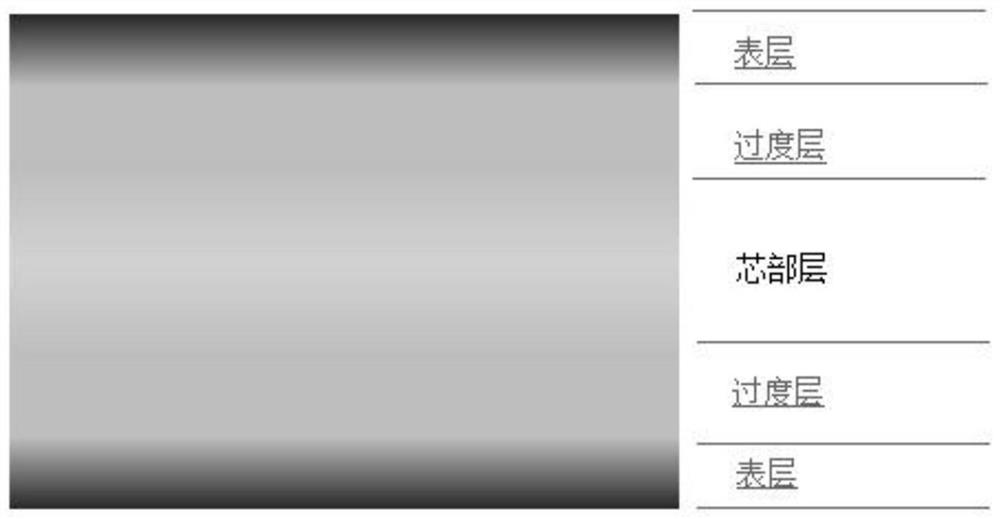

Boron carbide-tungsten carbide composite ceramic gradient material for tool as well as preparation method and application of boron carbide-tungsten carbide composite ceramic gradient material

A gradient material and composite ceramic technology, applied in the direction of reducing greenhouse gases, nuclear power generation, and climate sustainability, can solve problems such as poor high-temperature performance and difficult-to-process materials, so as to improve tool life, enhance interlayer bonding, and alleviate Effect of Gradient Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation: (1) boron carbide (B 4 C) powder and tungsten carbide (WC) powder according to the volume fraction ratio is 90%: 10% carry out batching, with ethanol as solvent, YG6 (WC-6wt% Co) hard alloy ball is ball milling medium in roller ball mill with 150r / min mixing for 8 hours, after mixing, ultrasonic dispersion and drying, B 4 C-WC micron composite powder, marked as BCWC1; boron carbide (B 4 C) powder and tungsten carbide (WC) powder are mixed according to the volume fraction ratio of 20%:80%, with ethanol as solvent and YG6 cemented carbide balls as ball milling medium in a roller ball mill at 150r / min for 8h, after mixing , ultrasonic dispersion, and drying, to obtain B 4 C-WC micron composite powder, marked as BCWC2;

[0034] (2) The surface layer of the ceramic gradient material uses BCWC1 as the raw material and Co (cobalt) powder as the binder; according to the volume fraction ratio of BCWC1: Co of 98%: 3%, the mixed powder obtained after mixing a...

Embodiment 2

[0040] 1. Preparation: (1) boron carbide (B 4 C) Powder and tungsten carbide (WC) powder are mixed according to the volume fraction ratio of 100:0, with ethanol as the solvent and YG6 cemented carbide balls as the ball milling medium in a roller ball mill at 150r / min for 8h, after mixing material, ultrasonic dispersion, and drying, to obtain B 4 C-WC micron composite powder, marked as BCWC1; boron carbide (B 4 C) powder and tungsten carbide (WC) powder are mixed according to the volume fraction ratio of 30%: 70%, with ethanol as solvent and YG6 cemented carbide ball as ball milling medium in a roller ball mill at 150r / min for 8h, After mixing, ultrasonic dispersion and drying, B 4 C-WC micron composite powder, marked as BCWC2;

[0041] (2) The surface layer of the ceramic gradient material uses BCWC1 as a raw material and Co (cobalt) powder as a binder; according to the ratio of BCWC1: Co volume fraction of 100%: 0%, after mixing and drying, the obtained Mixed powder, m...

Embodiment 3

[0047] 1. Preparation: (1) boron carbide (B 4 C) Powder and tungsten carbide (WC) powder are mixed according to the volume ratio of 70%: 30%, with ethanol as solvent and YG6 cemented carbide ball as ball milling medium in a roller ball mill at 150r / min for 8h, After mixing, ultrasonic dispersion and drying, B 4 C-WC micron composite powder, marked as BCWC1; boron carbide (B 4 C) Powder and tungsten carbide (WC) powder are mixed according to the volume fraction ratio of 5%: 95%, with ethanol as solvent and YG6 cemented carbide ball as ball milling medium in a roller ball mill at 150r / min for 8h, After mixing, ultrasonic dispersion and drying, B 4 C-WC micron composite powder, marked as BCWC2;

[0048] (2) The surface layer of the gradient tool material uses BCWC1 as a raw material and Co (cobalt) powder as a binder; according to the ratio of BCWC1: Co volume fraction of 95%: 5%, after mixing and drying, a mixed Powder, marked as BCWC1-Co, the mixing step is the same as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com