Slag cake crusher capable of dynamically adjusting speed and control method thereof

A crusher and slag cake technology, applied in the field of electromechanical, can solve the problems of difficult feeding, low productivity and high energy consumption of the crusher, and achieve the effect of eliminating the problem of over-crushing, fast feeding and good feeding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

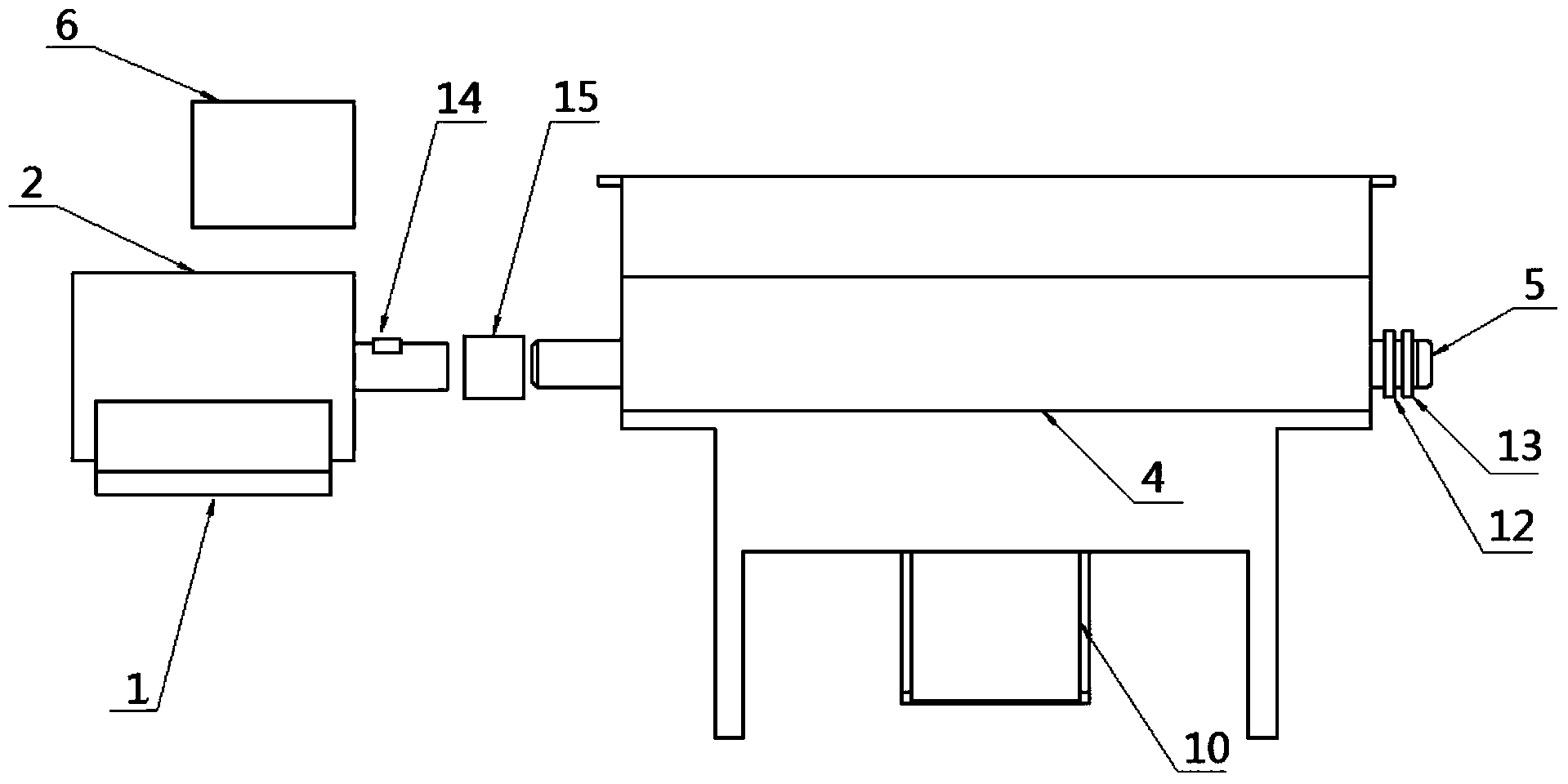

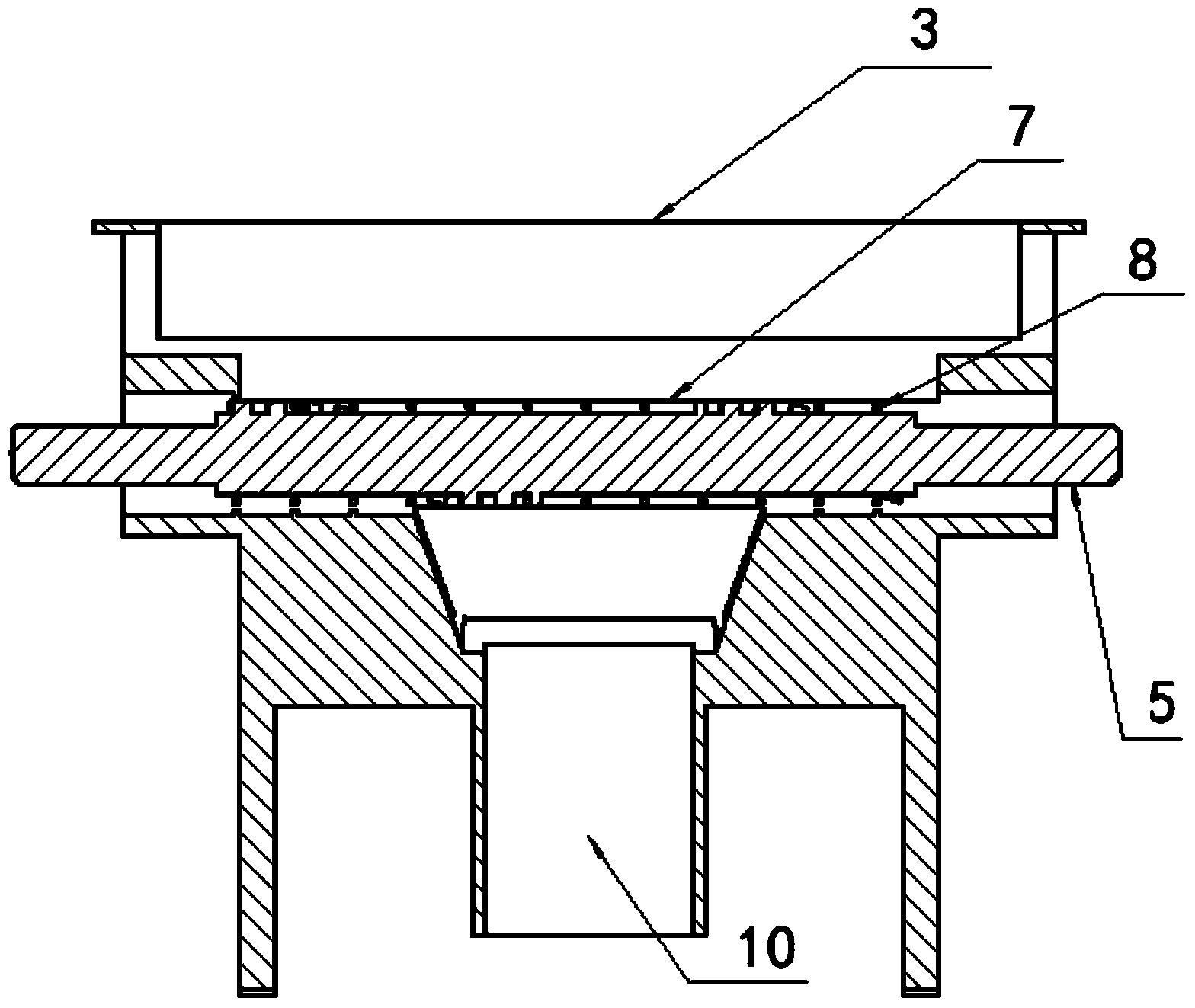

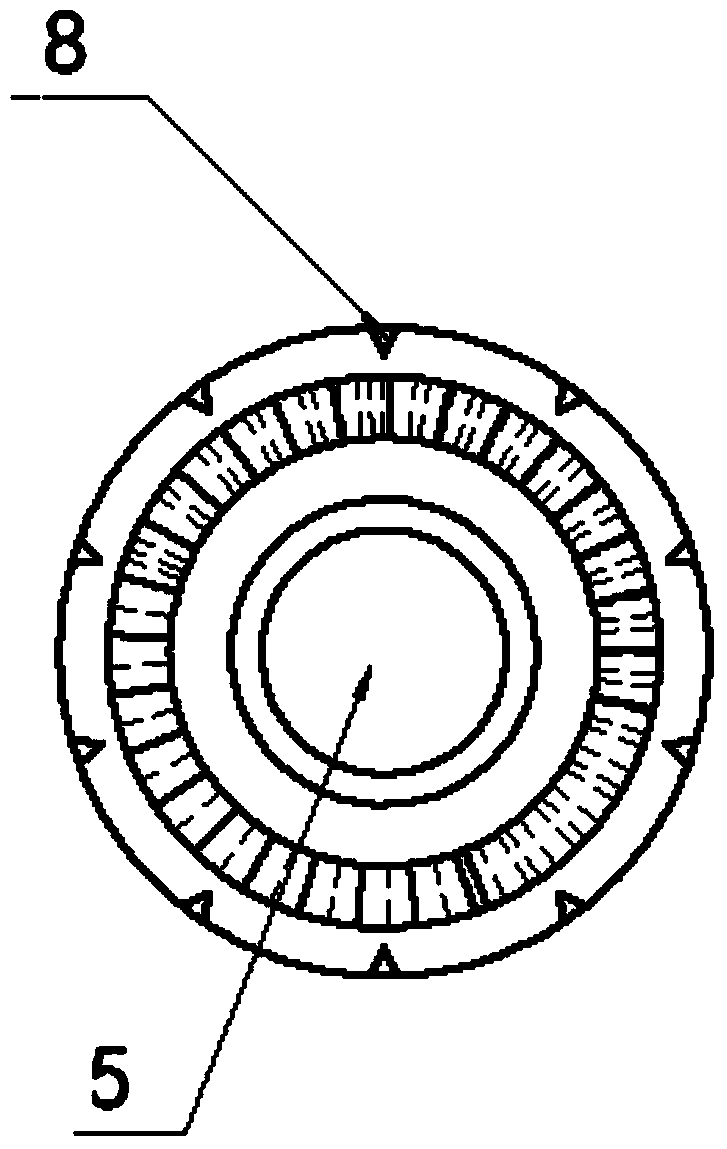

[0043] Such as figure 1 , figure 2 As shown, the dynamic speed-adjustable slag cake crusher of the present invention includes a drive motor 2 , a crushing chamber 4 and a control system 6 . The upper end of the crushing chamber 4 is provided with a rectangular feeding port 3, and the lower end is provided with a discharge port 10. Both the feeding port 3 and the discharge port 10 are made of high chromium cast iron to increase the service life. The crushing chamber 4 is provided with a crushing roller shaft 5 that runs through the crushing chamber 4, and the crushing roller shaft 5 is in sealing connection with the left and right side walls of the crushing chamber 4, and the two ends of the crushing roller shaft 5 extend to the outside of the crushing chamber 4, Suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com