Patents

Literature

64results about How to "Reduce the complexity of the manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

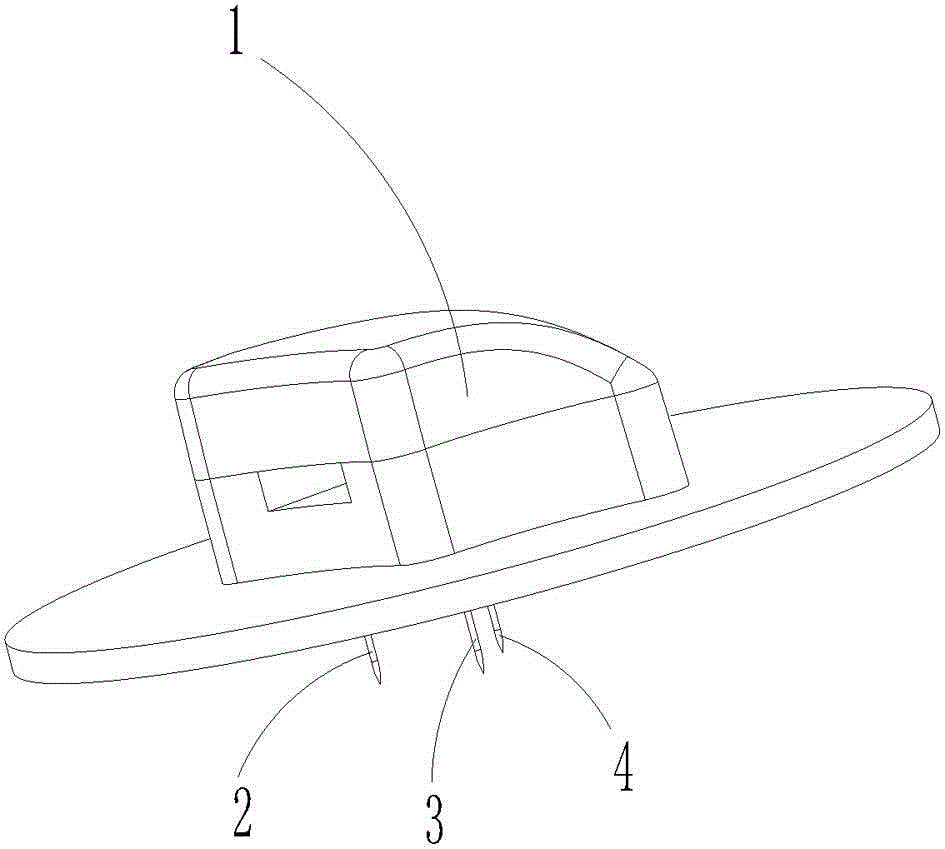

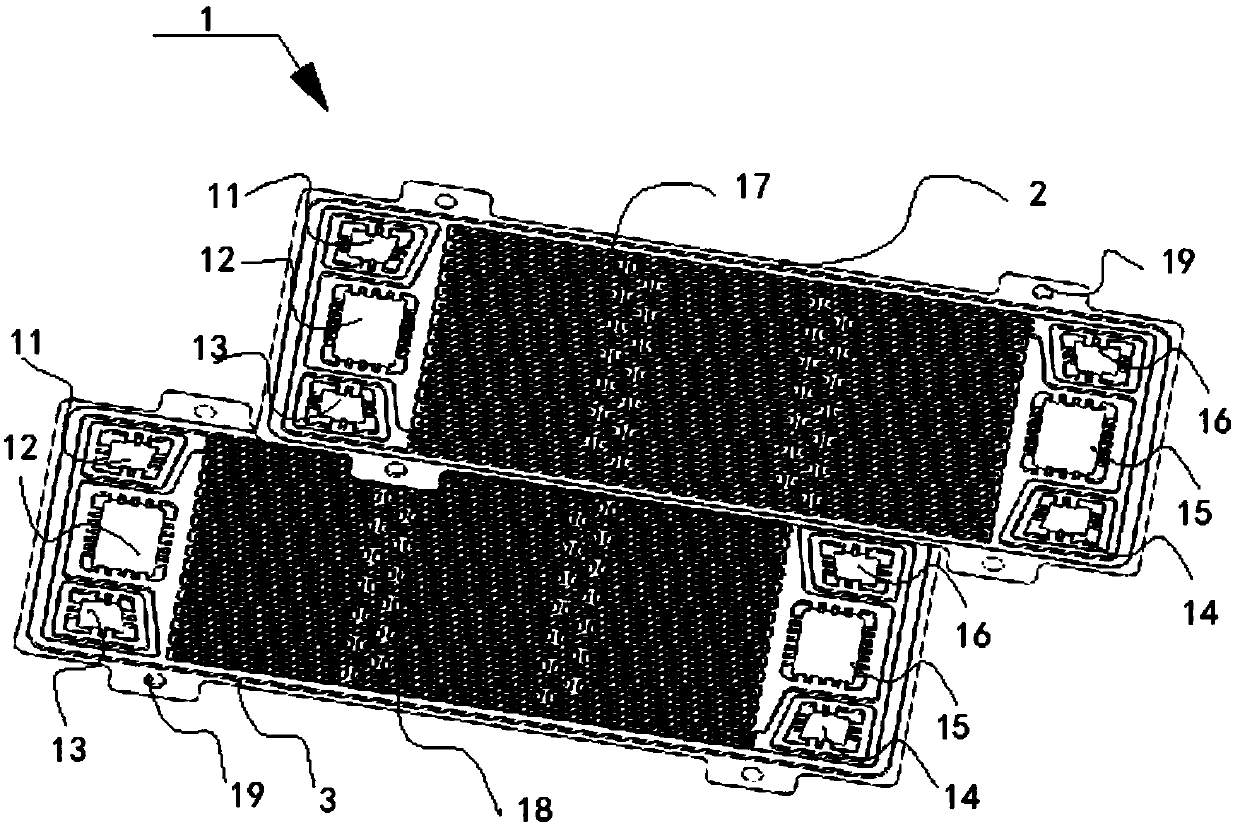

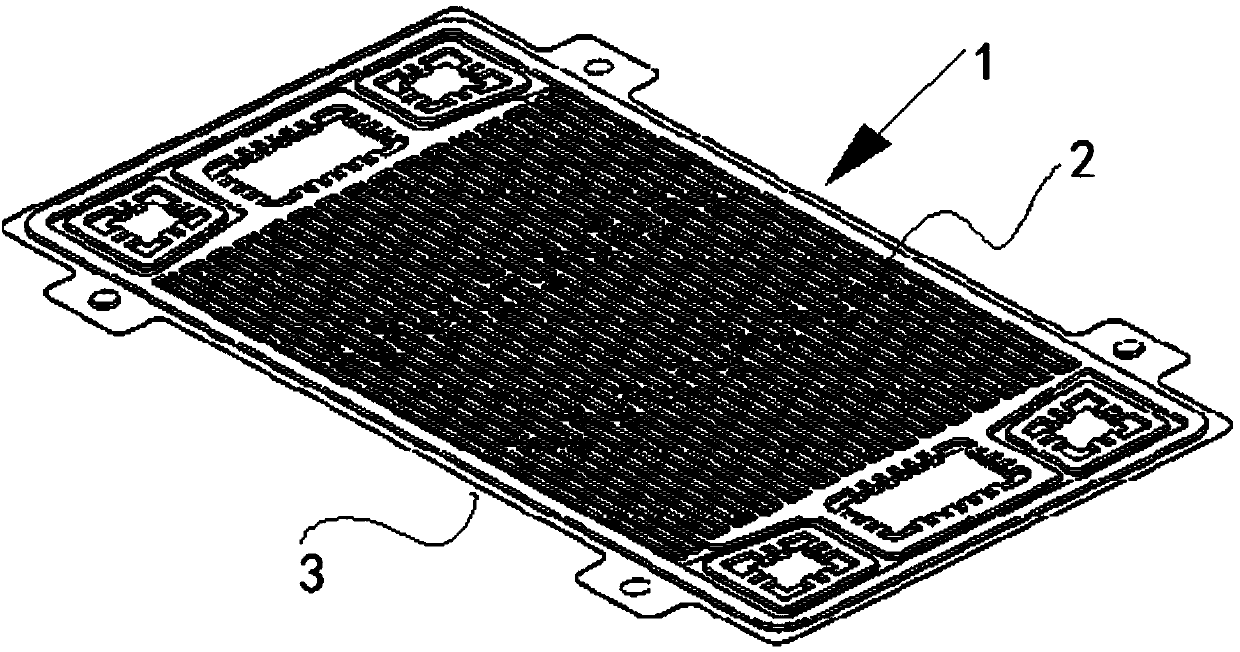

Large-area metal bipolar plate for automobile fuel cell

The invention relates to a large-area metal bipolar plate for an automobile fuel cell. The bipolar plate is formed by connecting two pieces of single-pole plates which are completely the same as each other; the two single-pole plates are respectively provided with a fuel inlet / outlet, an oxidant inlet / outlet, a cooling liquid inlet / outlet and a flow field; the flow field arranged on the single-pole plate on one side is connected with the fuel inlet / outlet so as to be taken as a fuel flow field, and the flow field arranged on the single-pole plate on the other side is connected with the oxidant inlet / outlet so as to be taken as an oxidant flow field; a cooling liquid flow field connected with the cooling liquid inlet / outlet is formed by an interlayer between the two single-pole plates which are clamped together; and therefore, a three-inlet and three-outlet structure can be formed, and the function of two plates with three fields can be realized. Compared with the prior art, the large-area metal bipolar plate can be prepared only by a mould, so that the mould development expenses and the forming technology complexity are reduced; due to the structure of the two single-pole plates, the area of flow field region is large, reaction efficiency is high and the demands of high power and high energy rate density of the automobile fuel cell are met; and the large-area metal bipolar plate is suitable for large-scale manufacturing methods such as stamping forming, soft film forming and hydro-bulging, thus being low in manufacturing cost.

Owner:SHANGHAI JIAO TONG UNIV +1

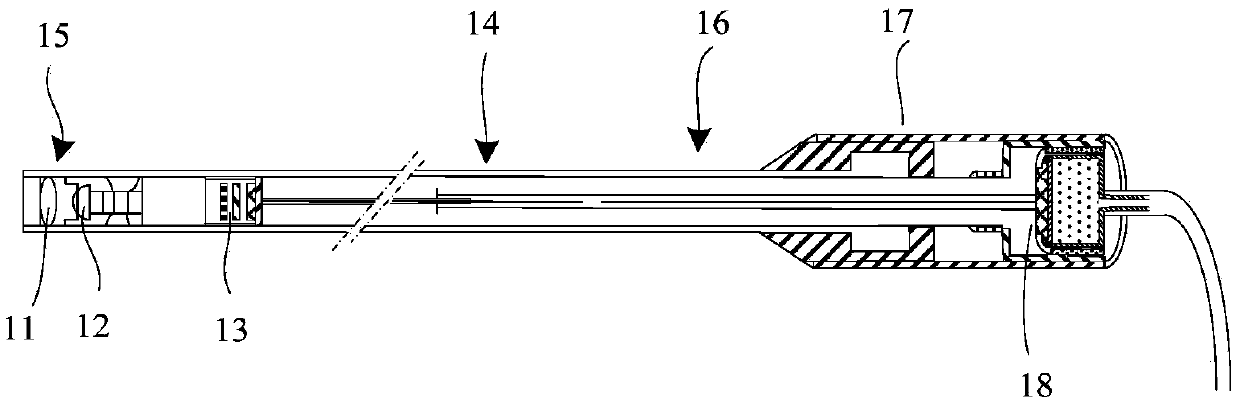

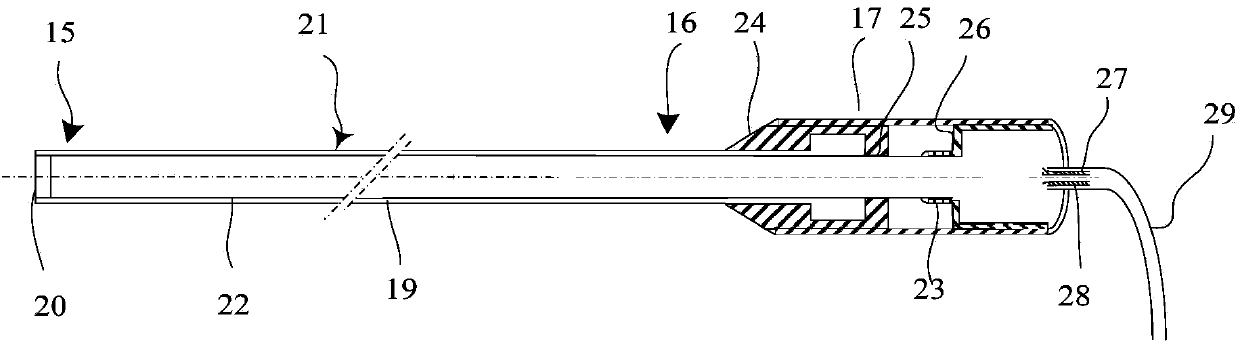

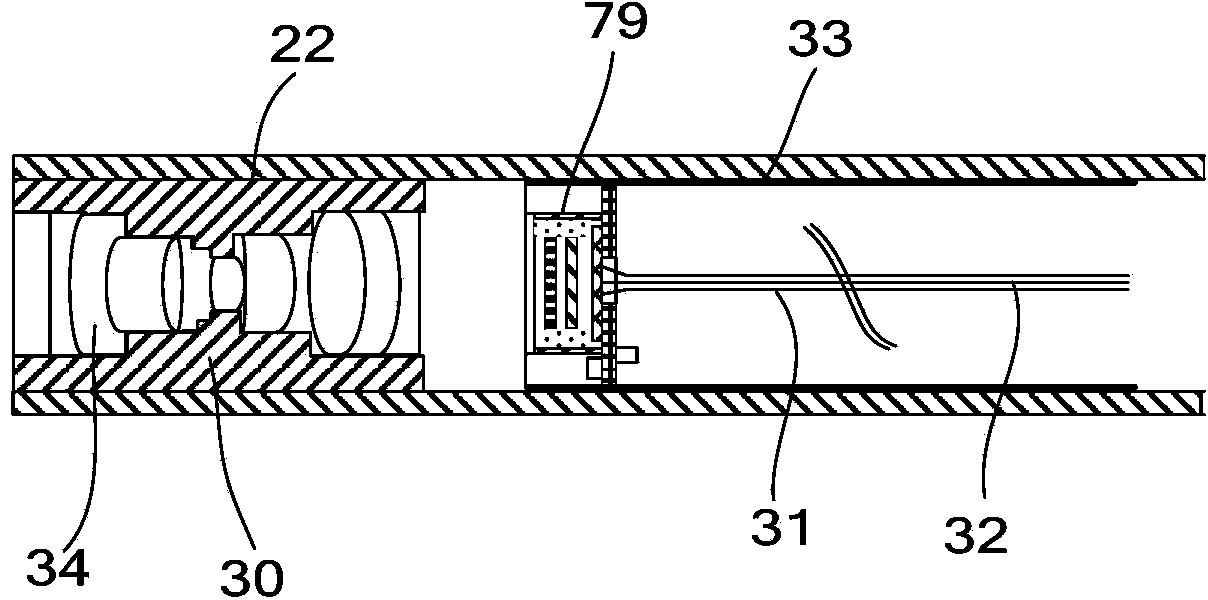

Integrated medical endoscope system

The invention belongs to the technical field of medical instruments, and discloses an integrated medical endoscope system which comprises an endoscope catheter of a step type sleeve tube structure, a crescent LED illuminating system, an optical system, a CMOS system and an image processing unit. The crescent LED illuminating system, the optical system, the CMOS image pick-up system and the image processing unit are arranged at the tail end of the endoscope catheter in sequence. The crescent LED illuminating system embedded in the tail end of the endoscope catheter is composed of a copper substrate and SMD LEDs arranged on the copper substrate. The integrated medical endoscope system overcomes the defects that original equipment is large in size and poor in imaging quality and is provided with many wires, wireless emission and receiving are adopted, the structure is simple, the operation is convenient and fast, a digital image processing system is adopted, full-high-definition 1080P output is supported, the image definition is high, and the higher dynamic range and better depth information can be obtained.

Owner:王刚

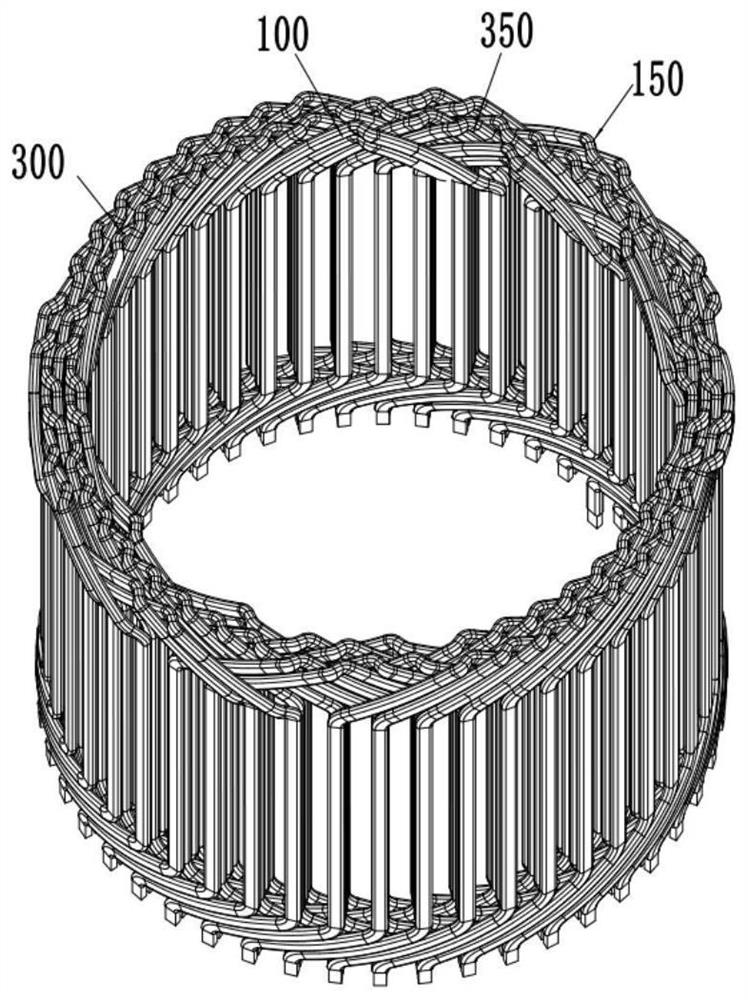

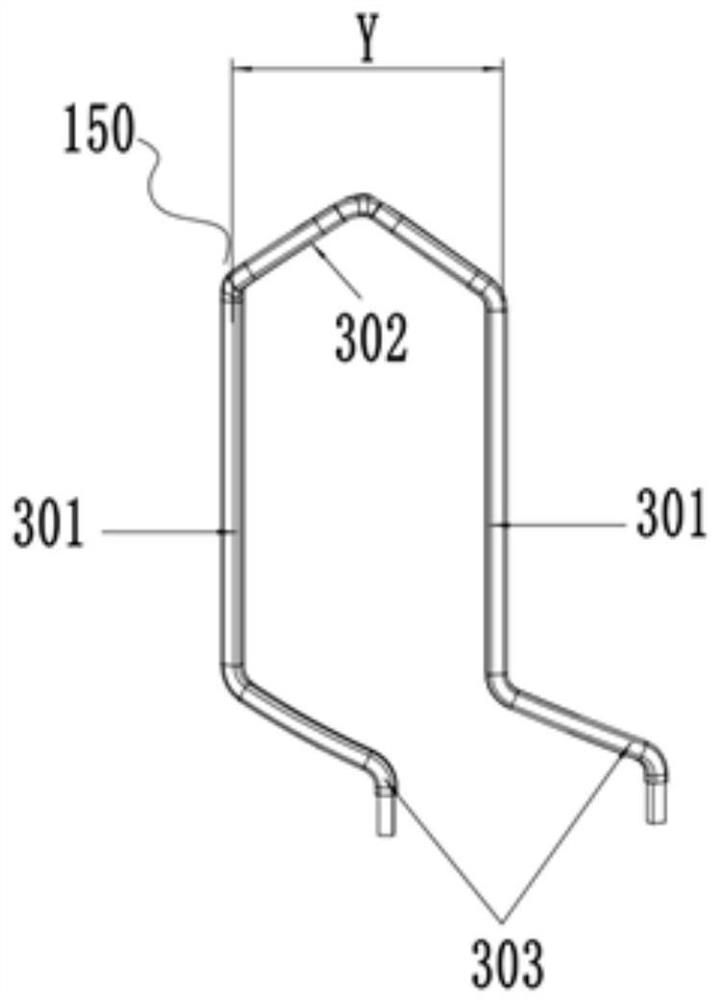

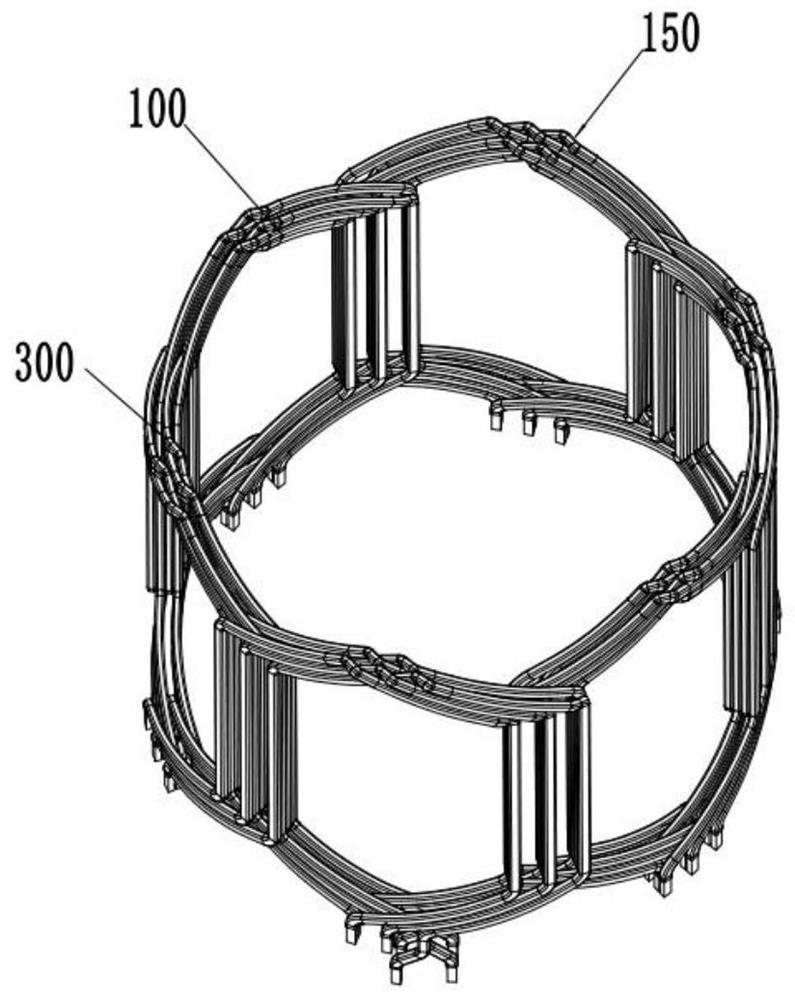

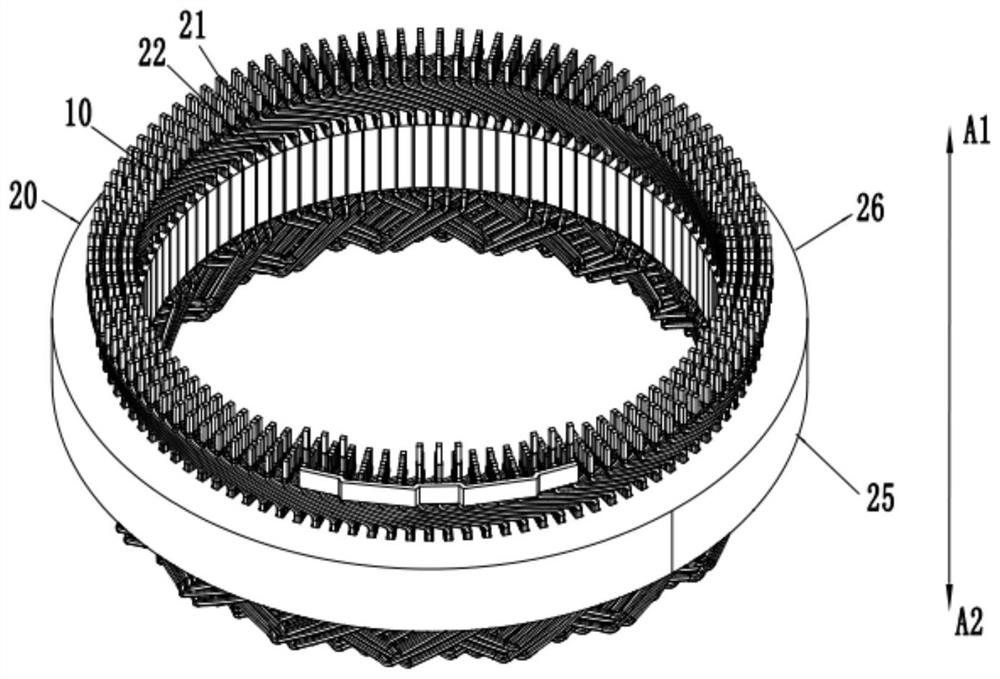

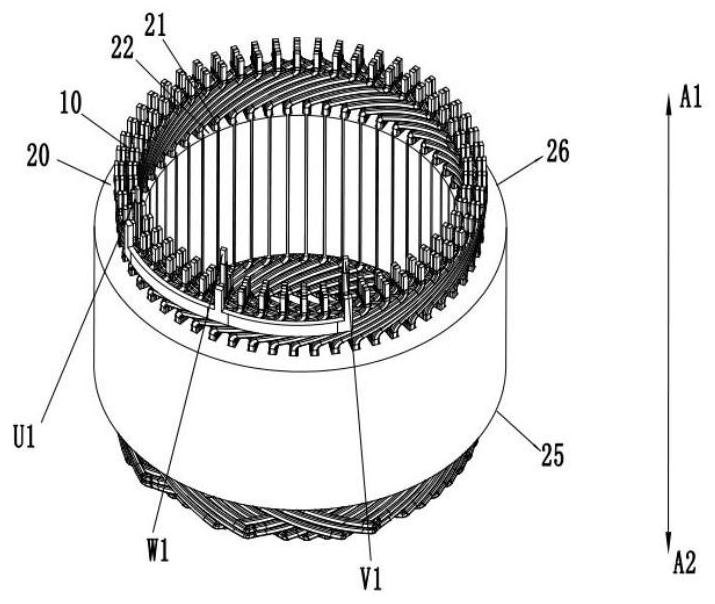

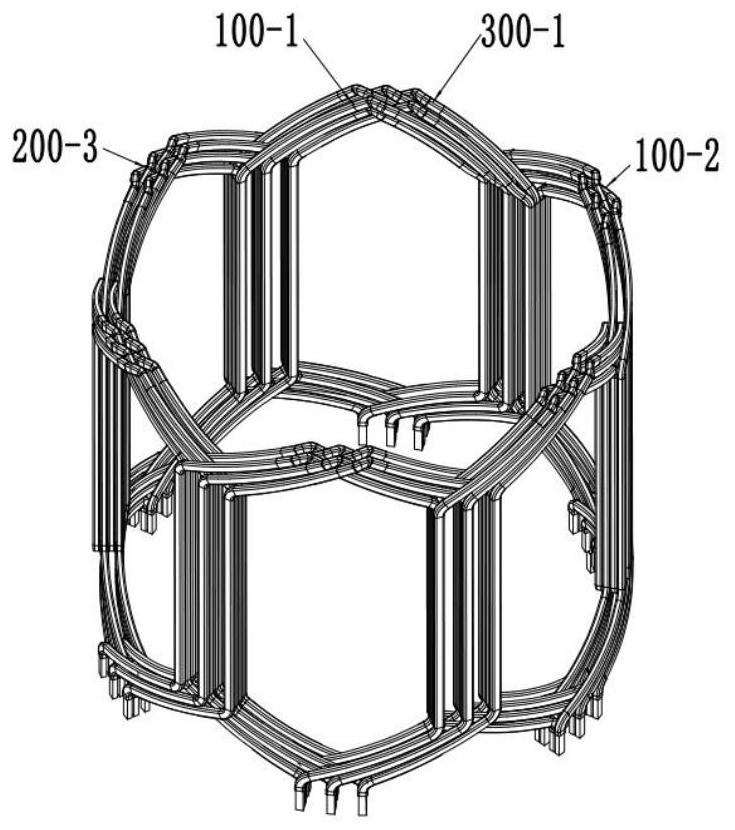

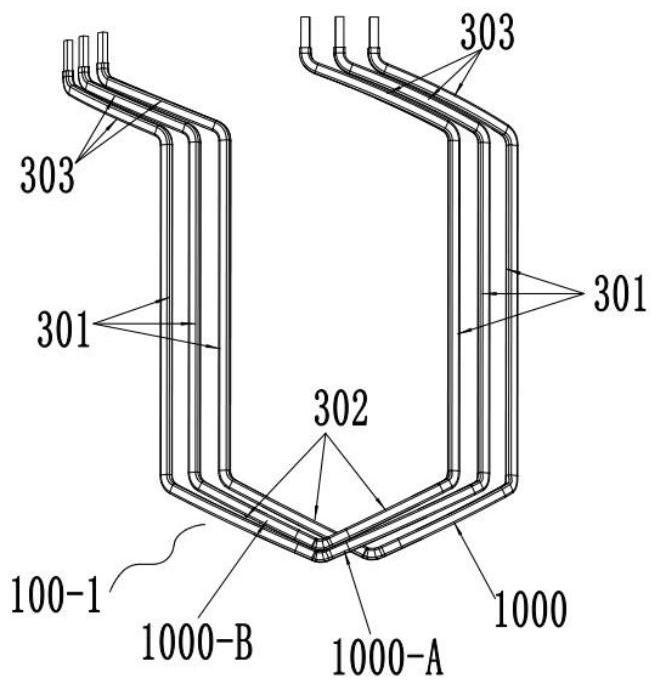

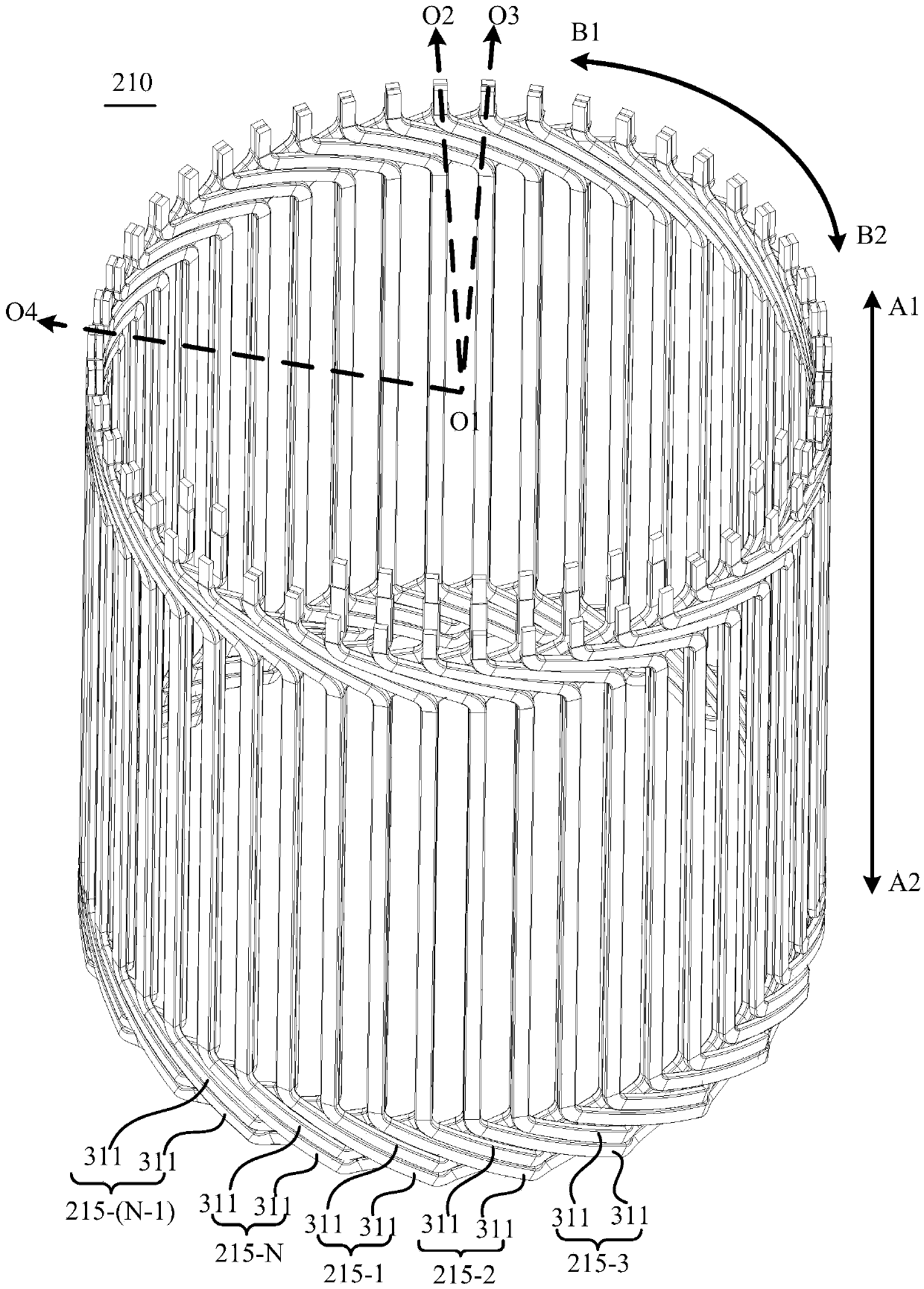

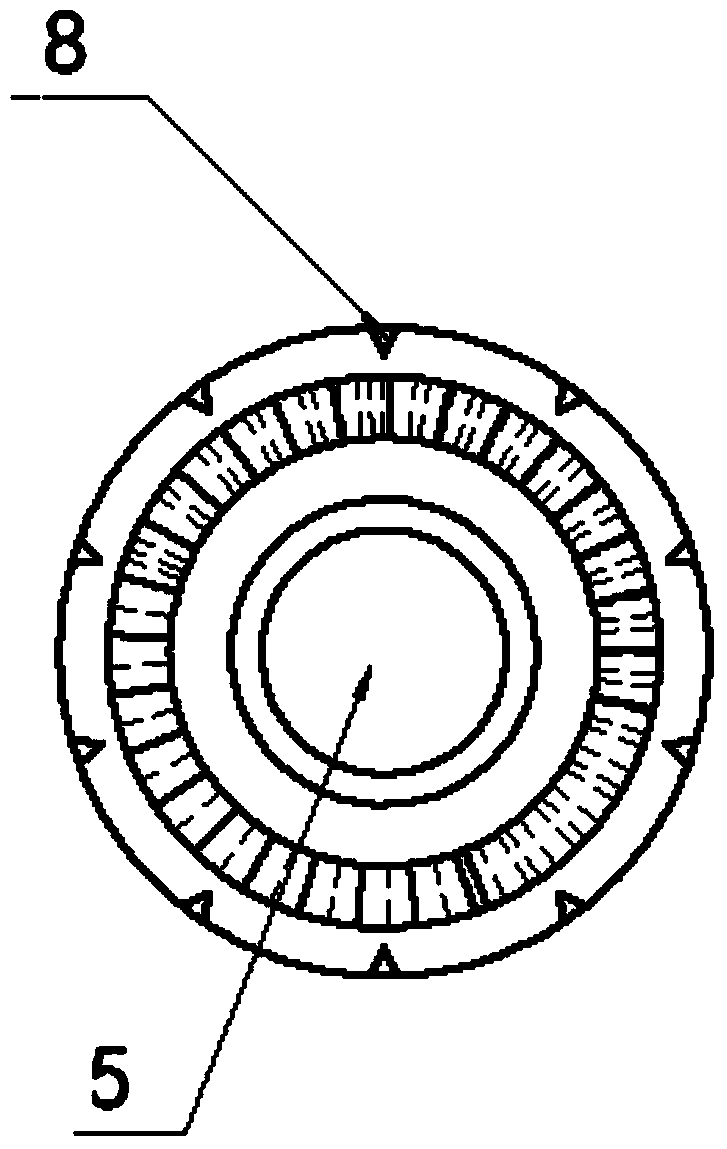

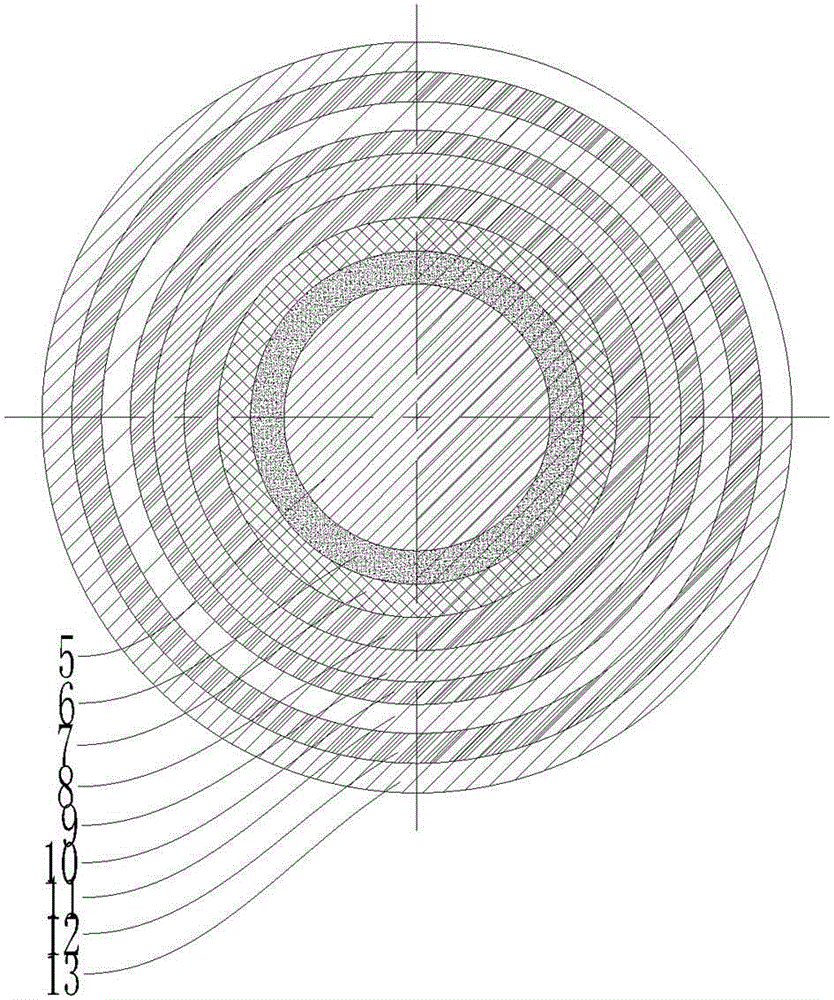

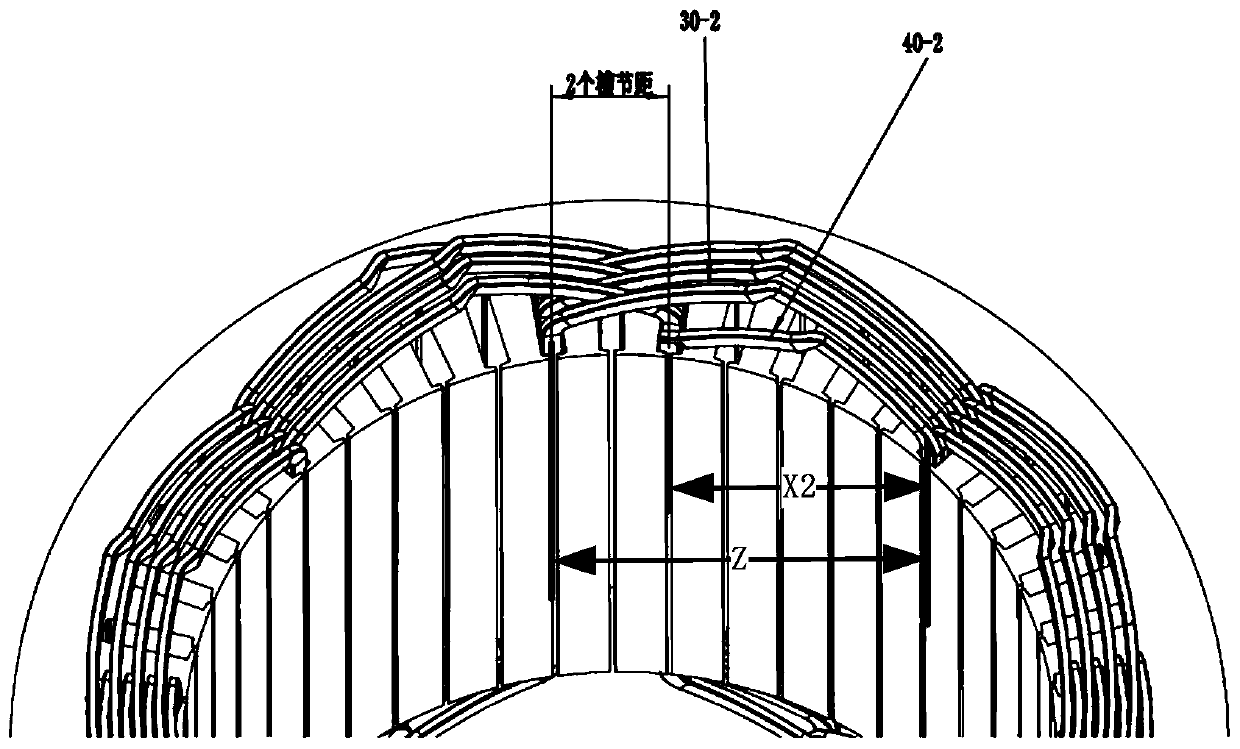

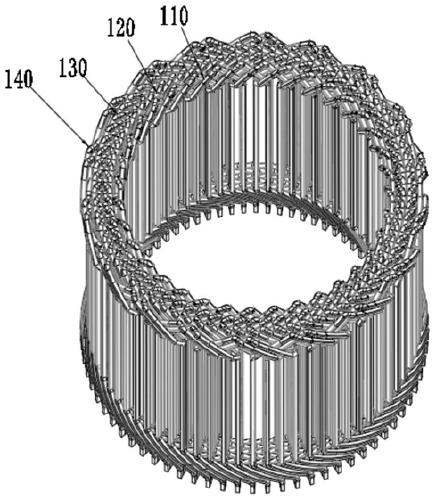

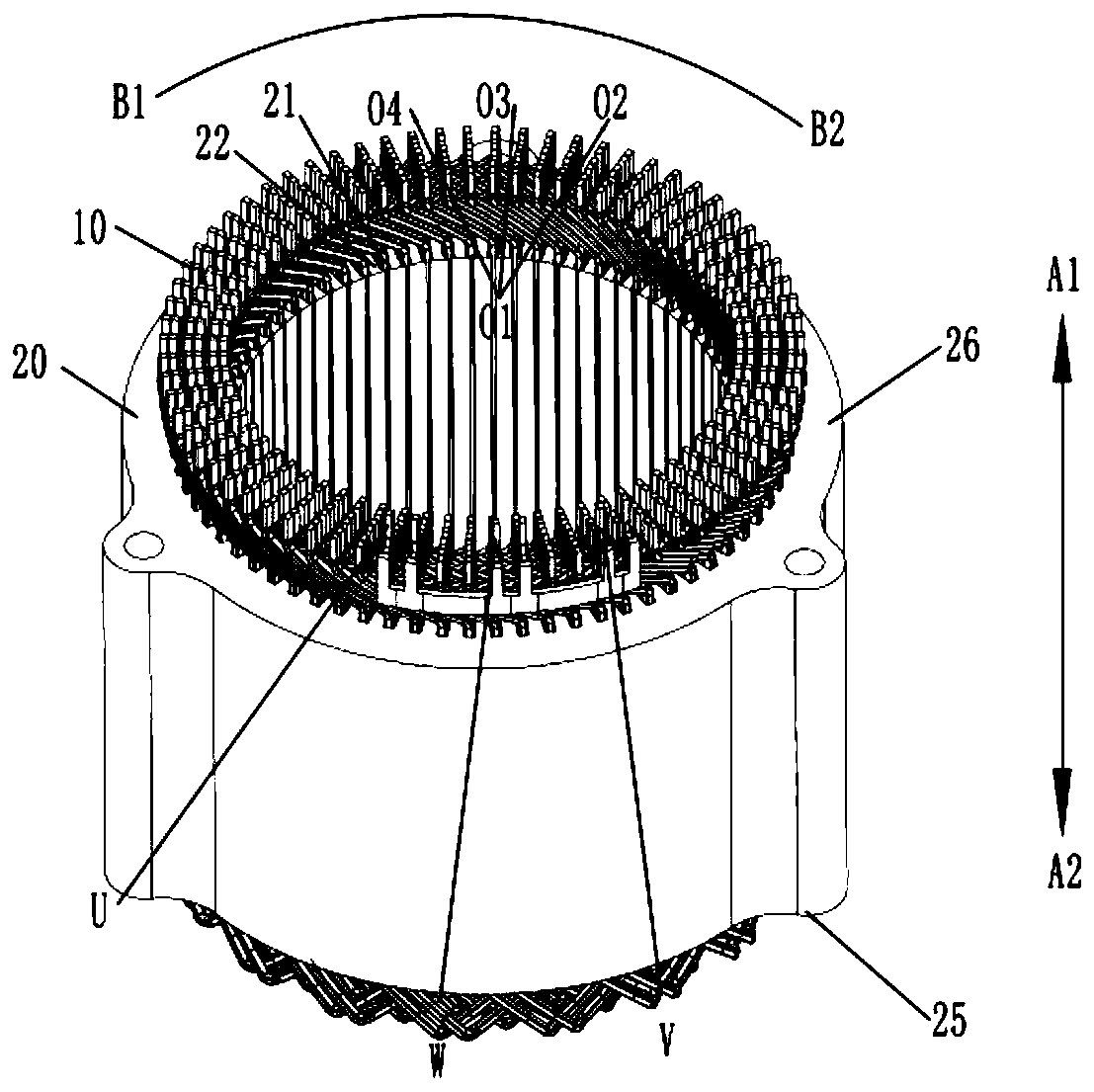

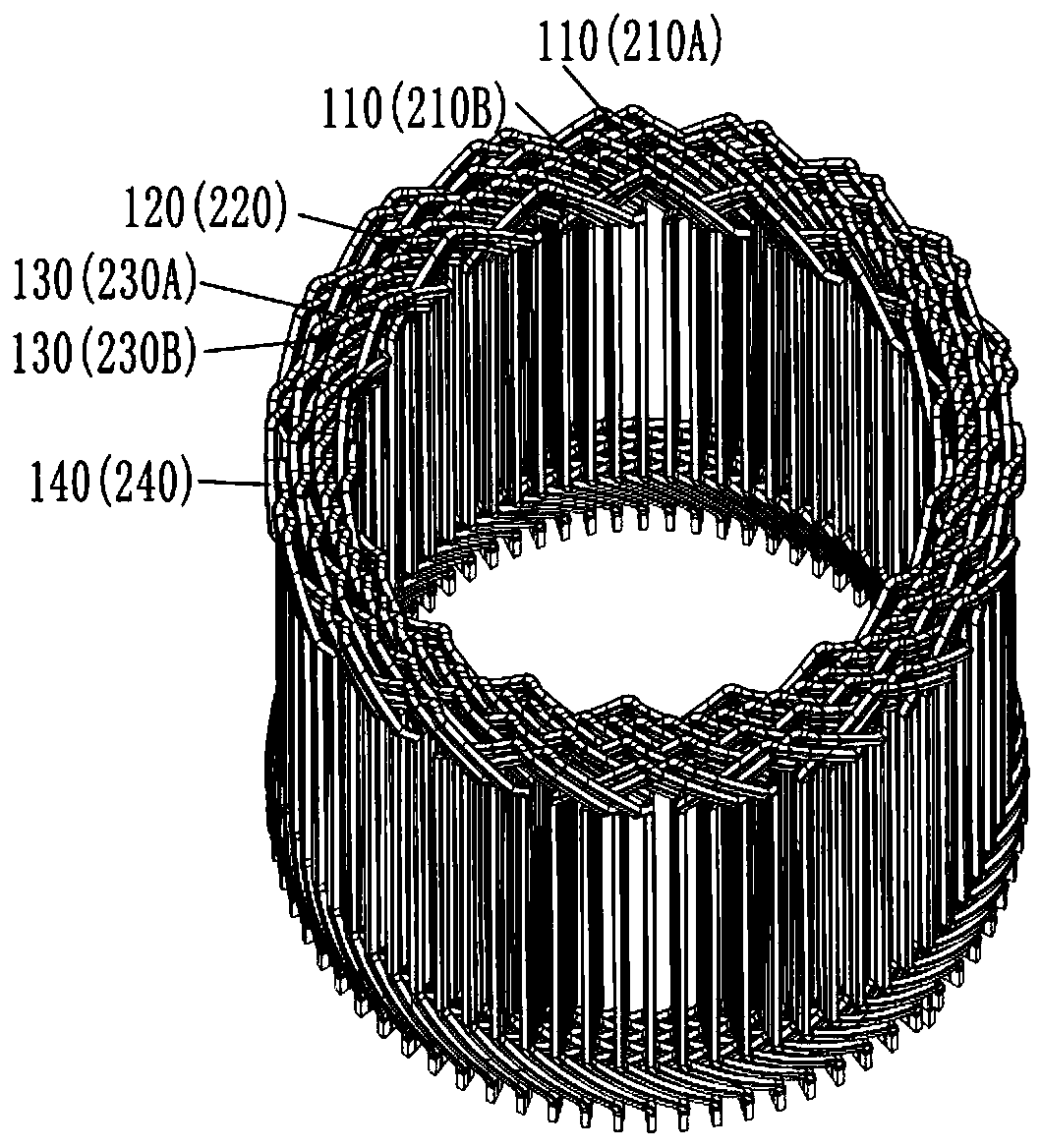

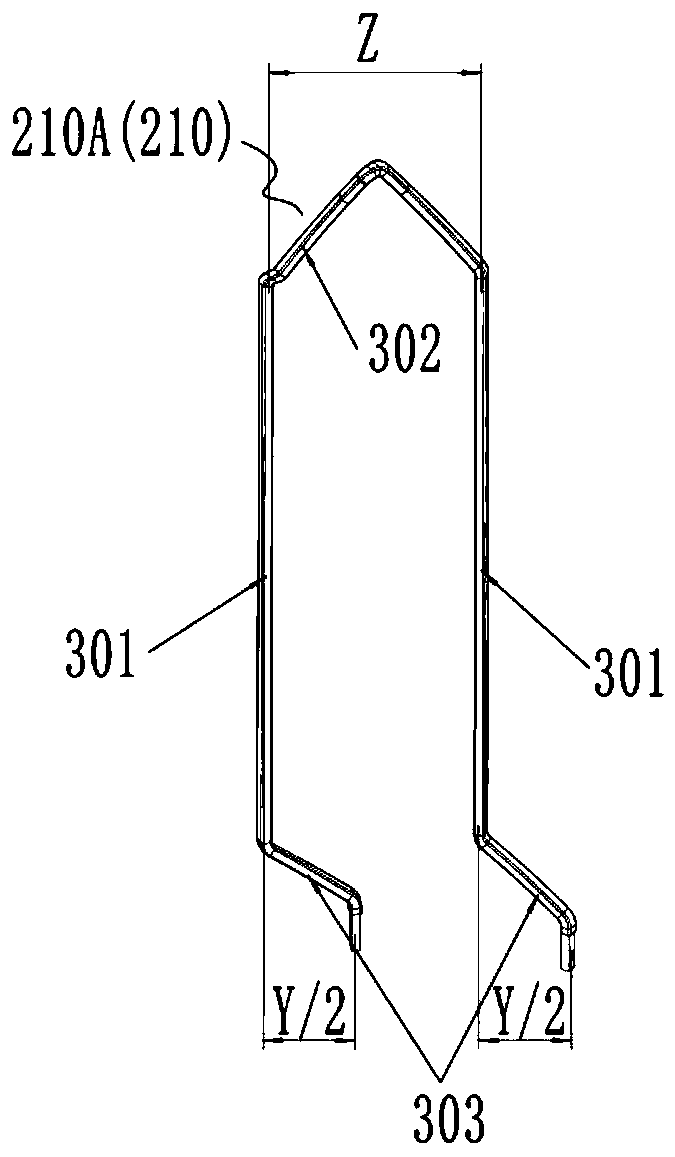

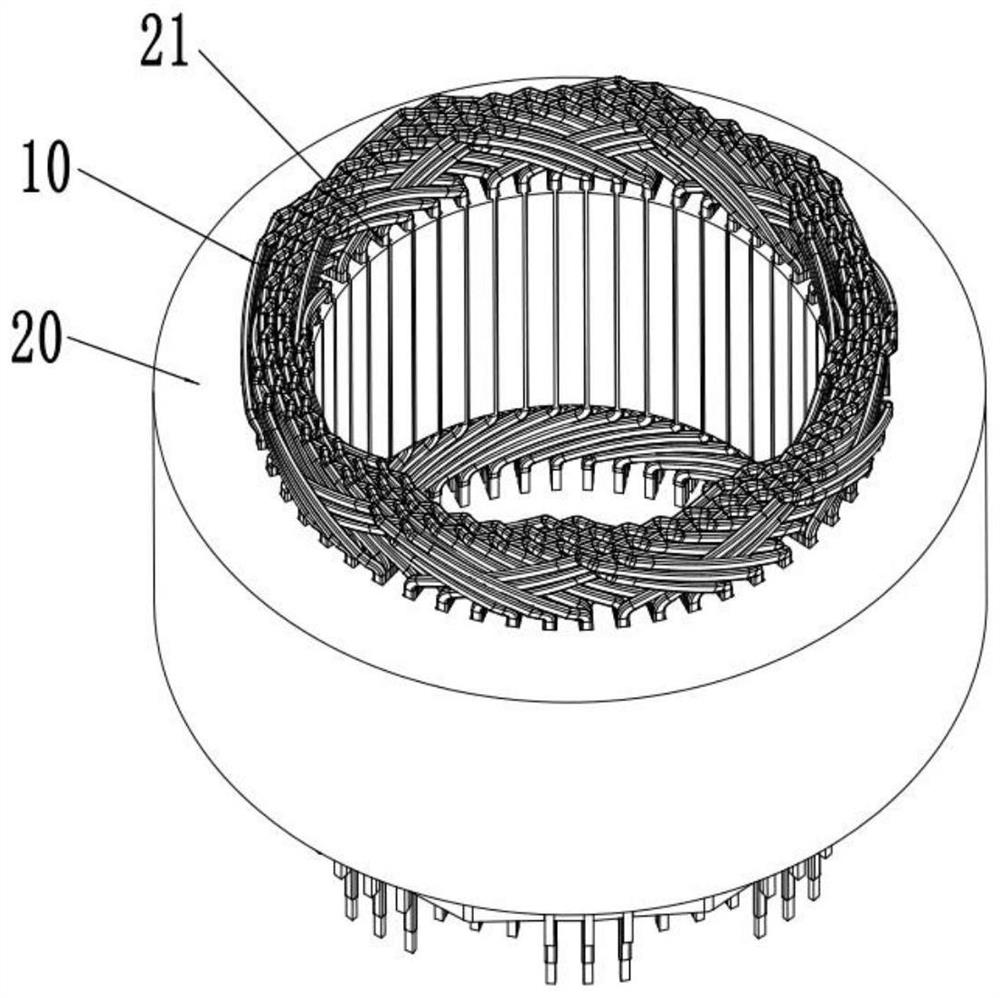

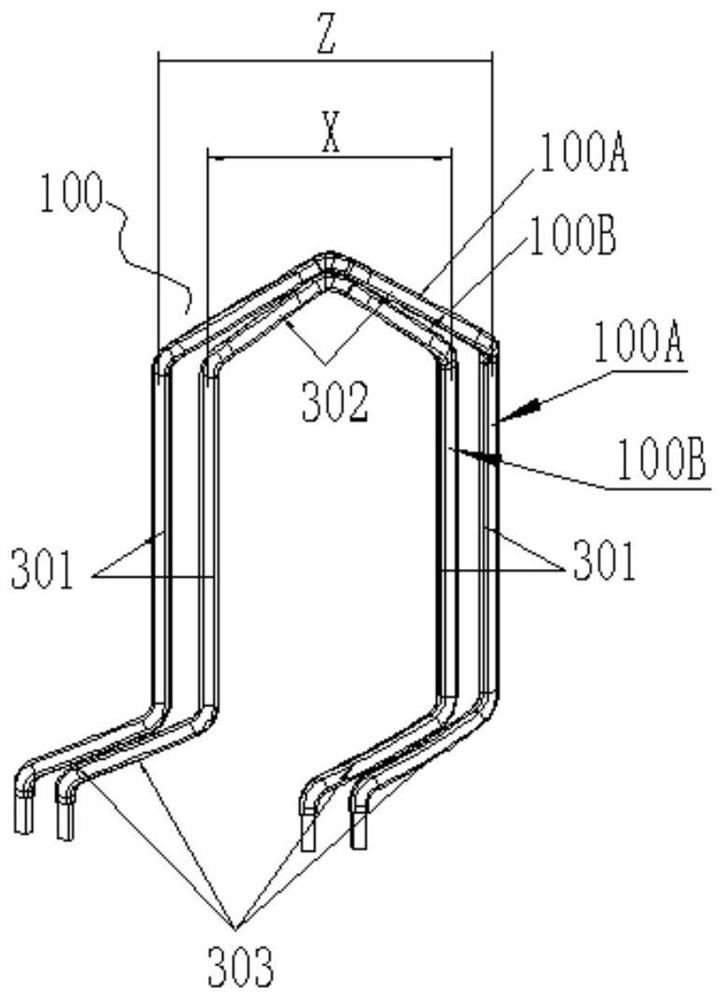

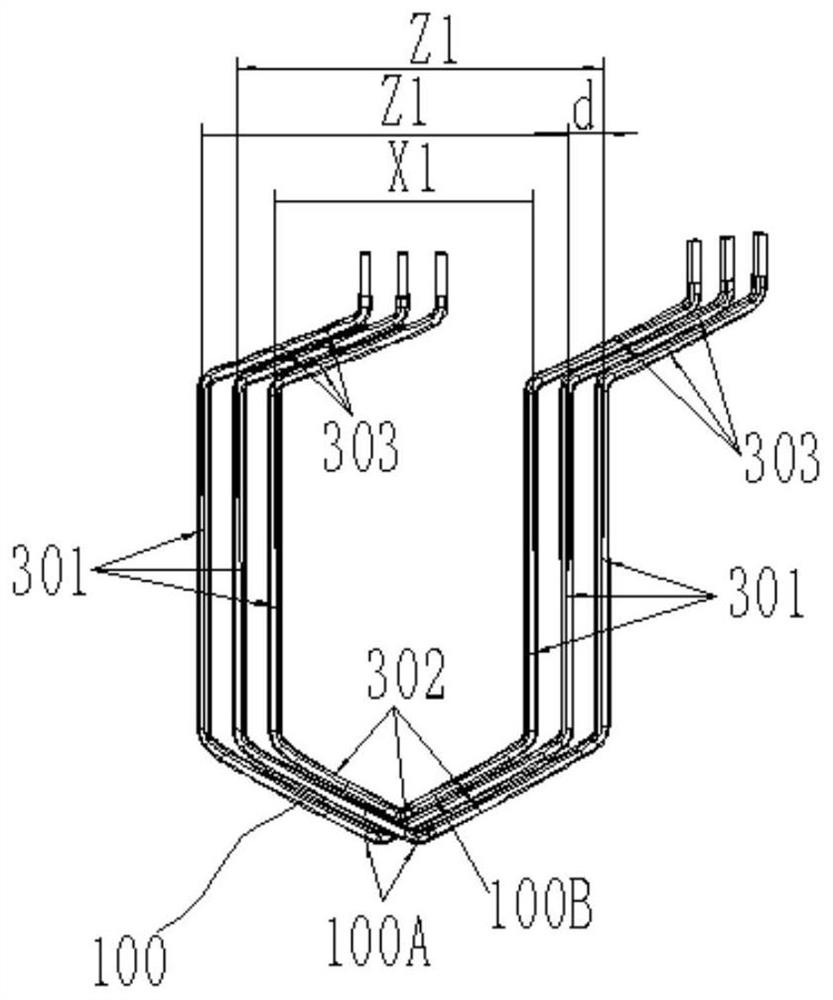

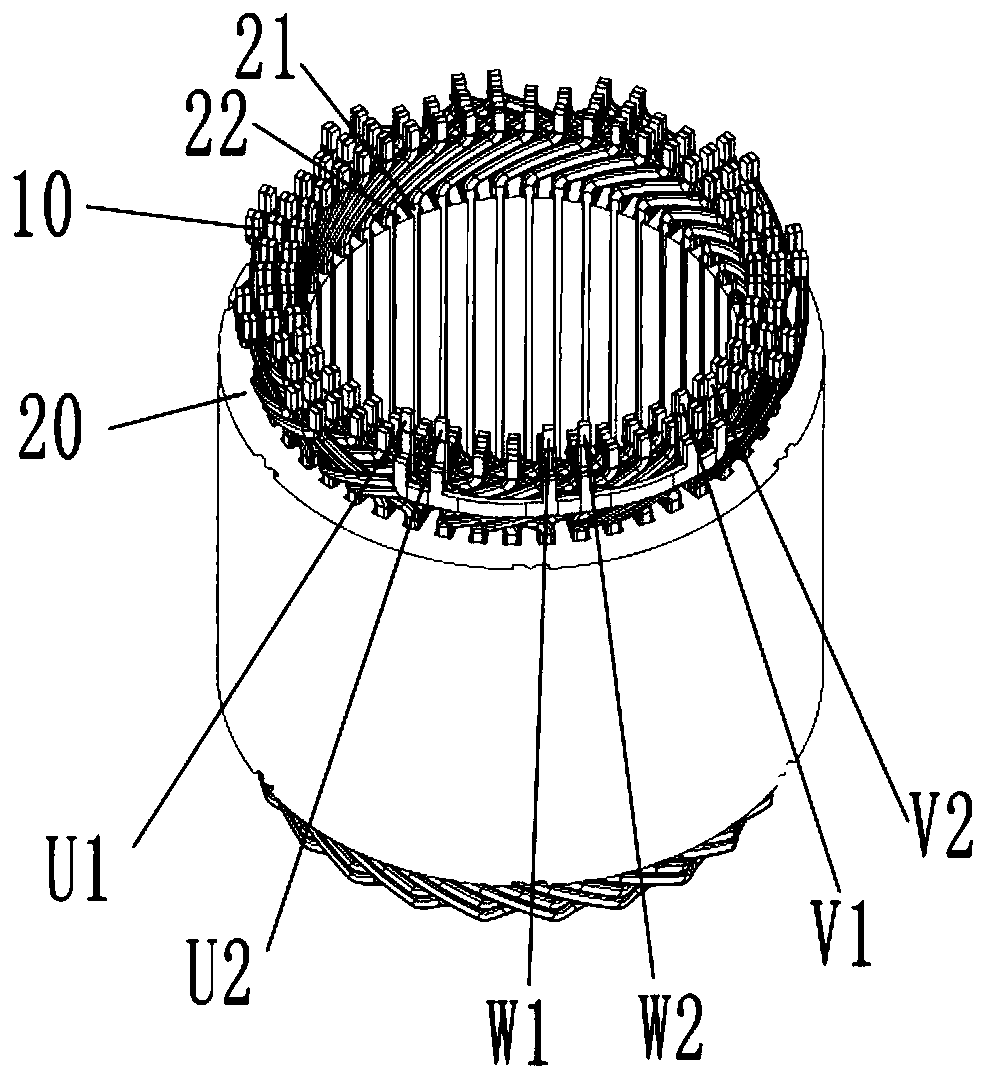

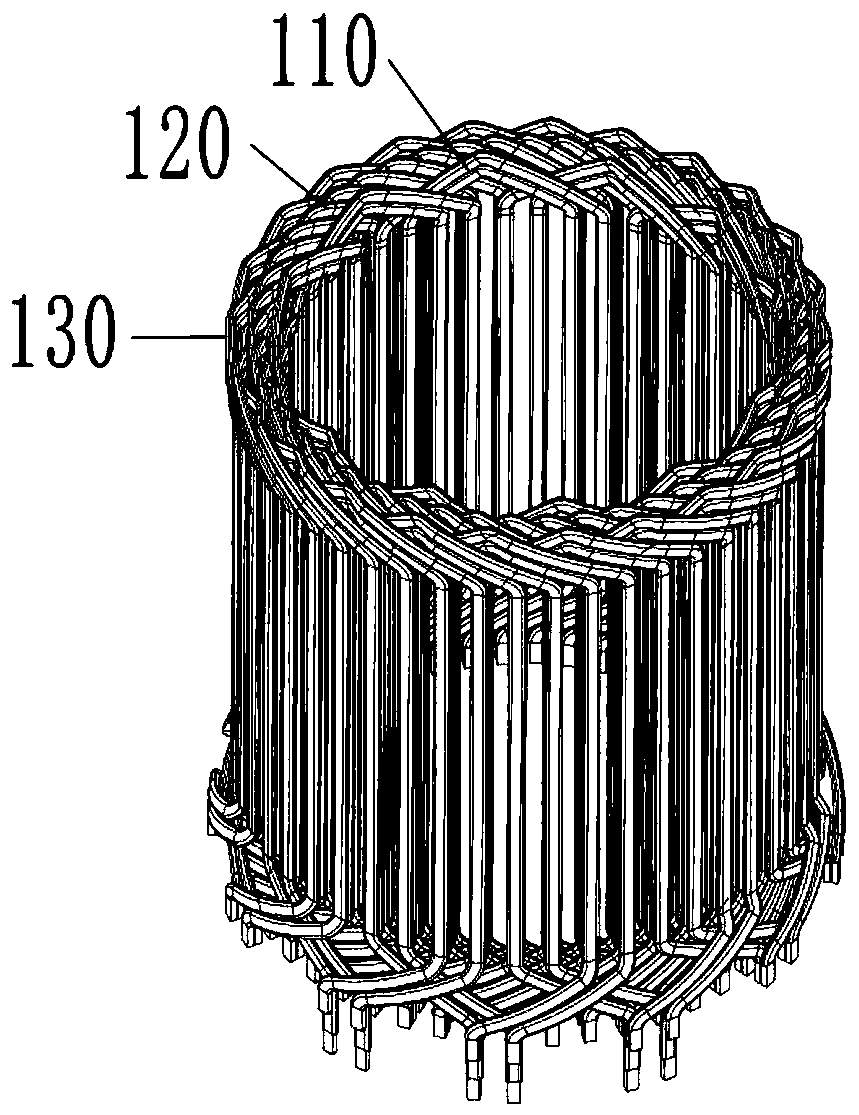

Motor winding and motor stator

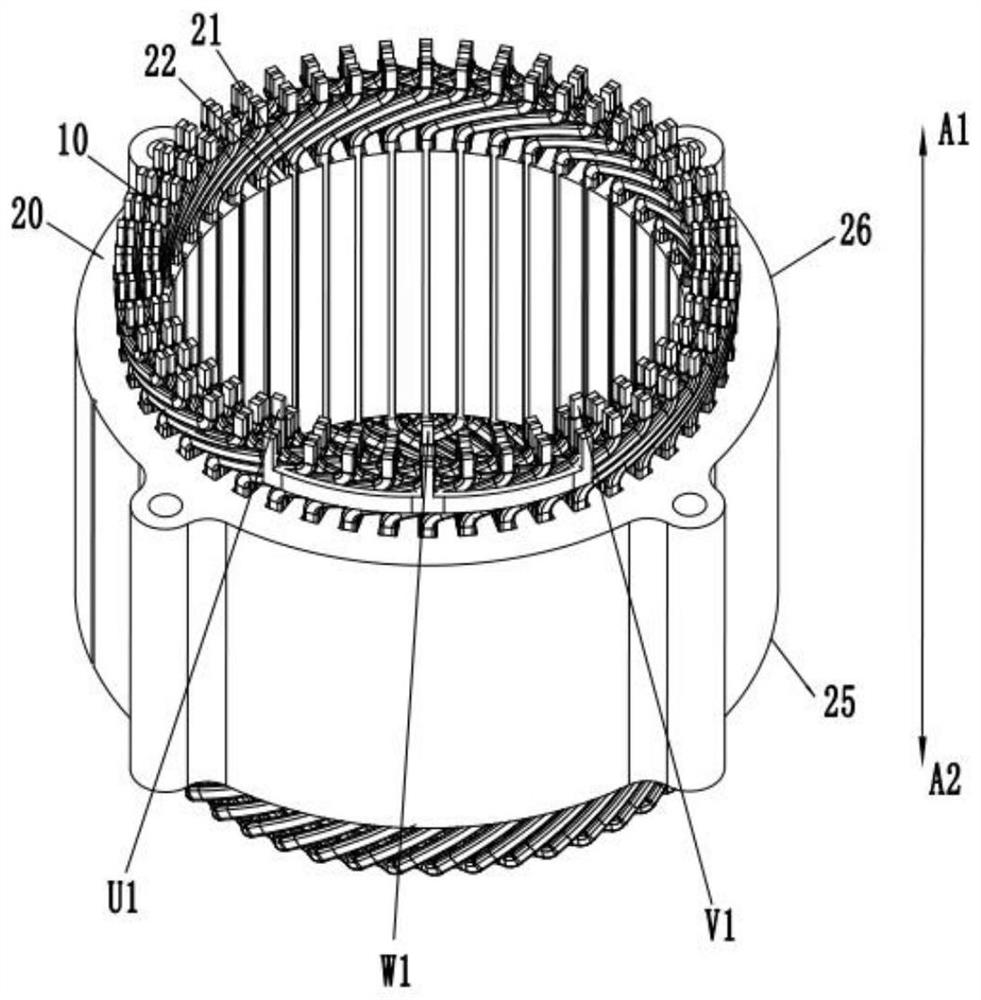

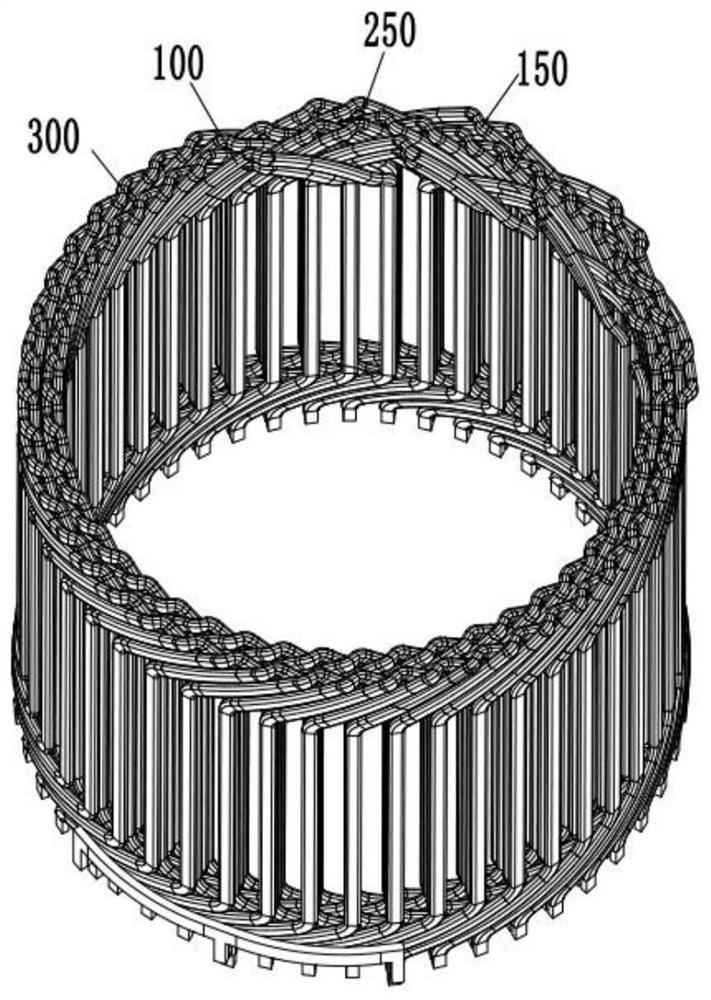

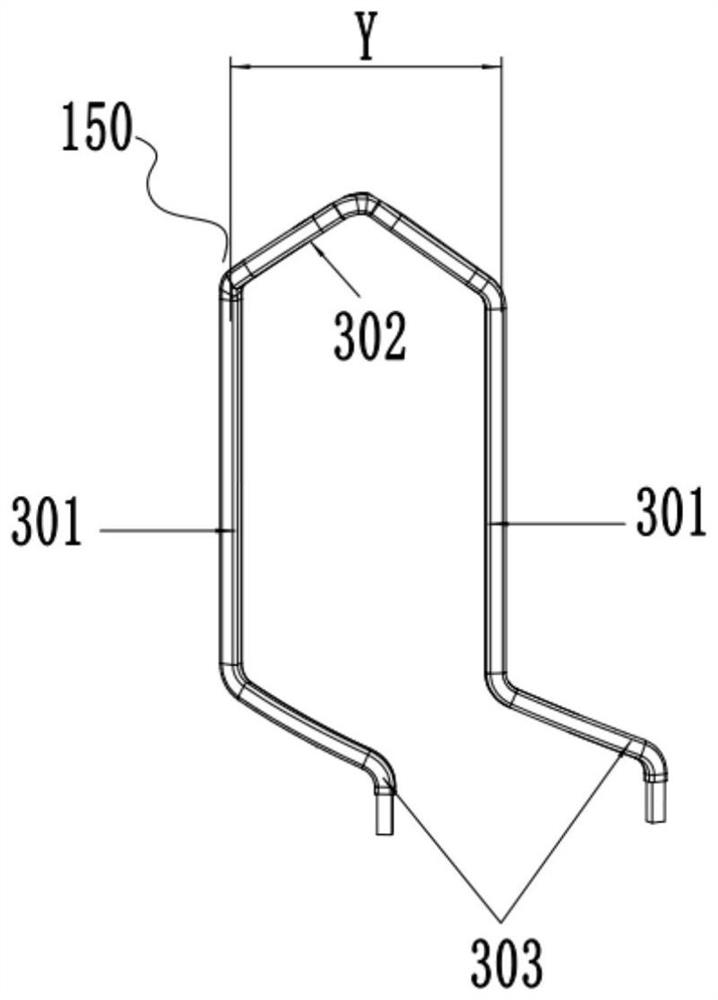

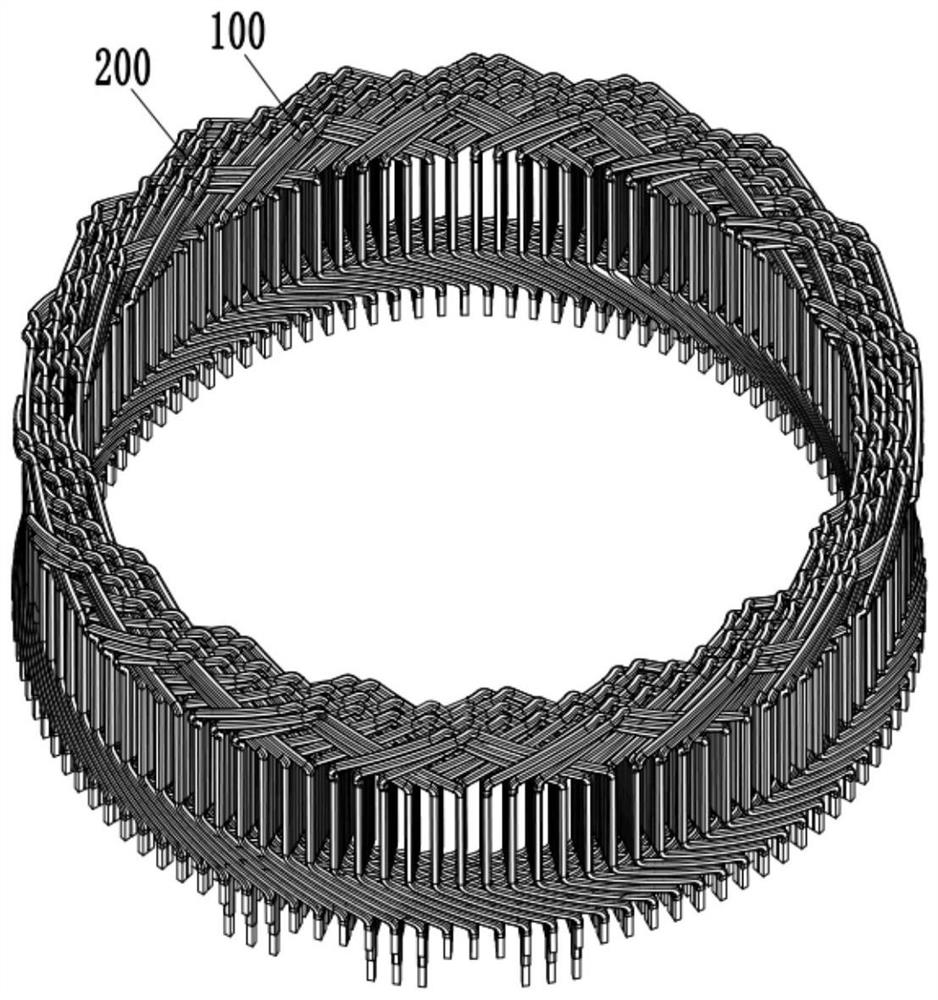

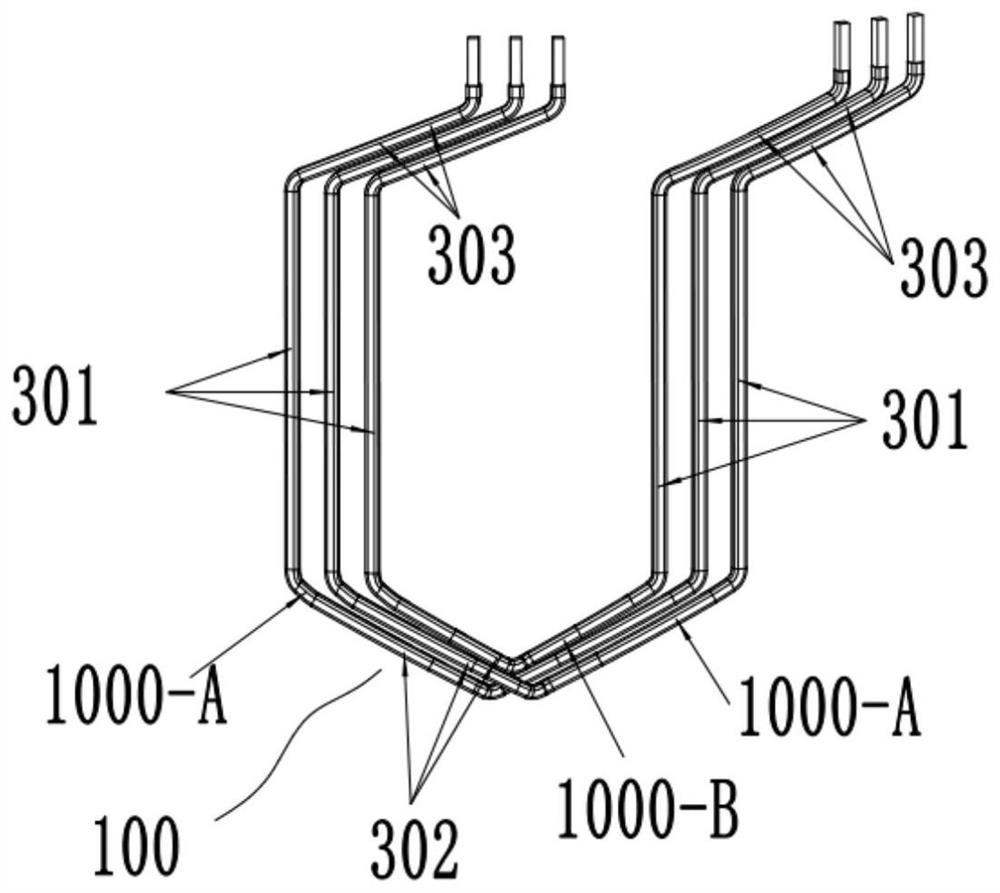

PendingCN109546779AReduce typesSimple arrangementWindings conductor shape/form/constructionStatorEngineering

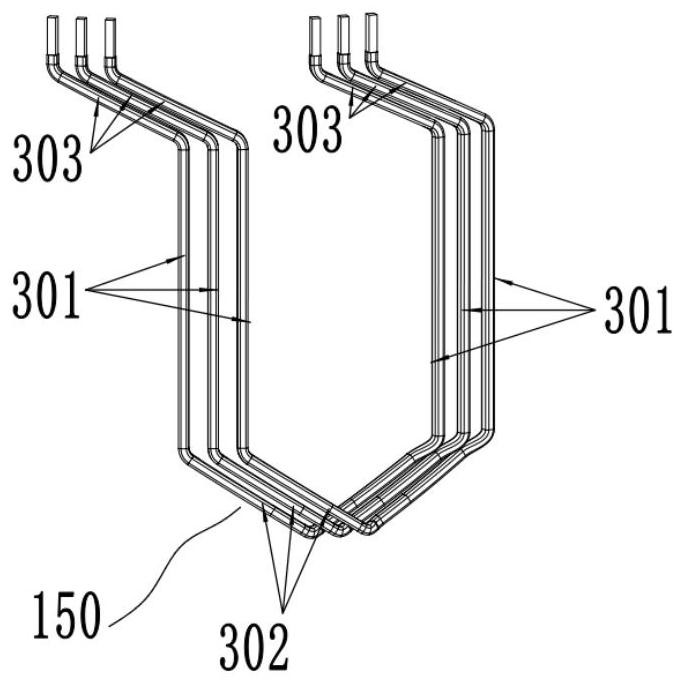

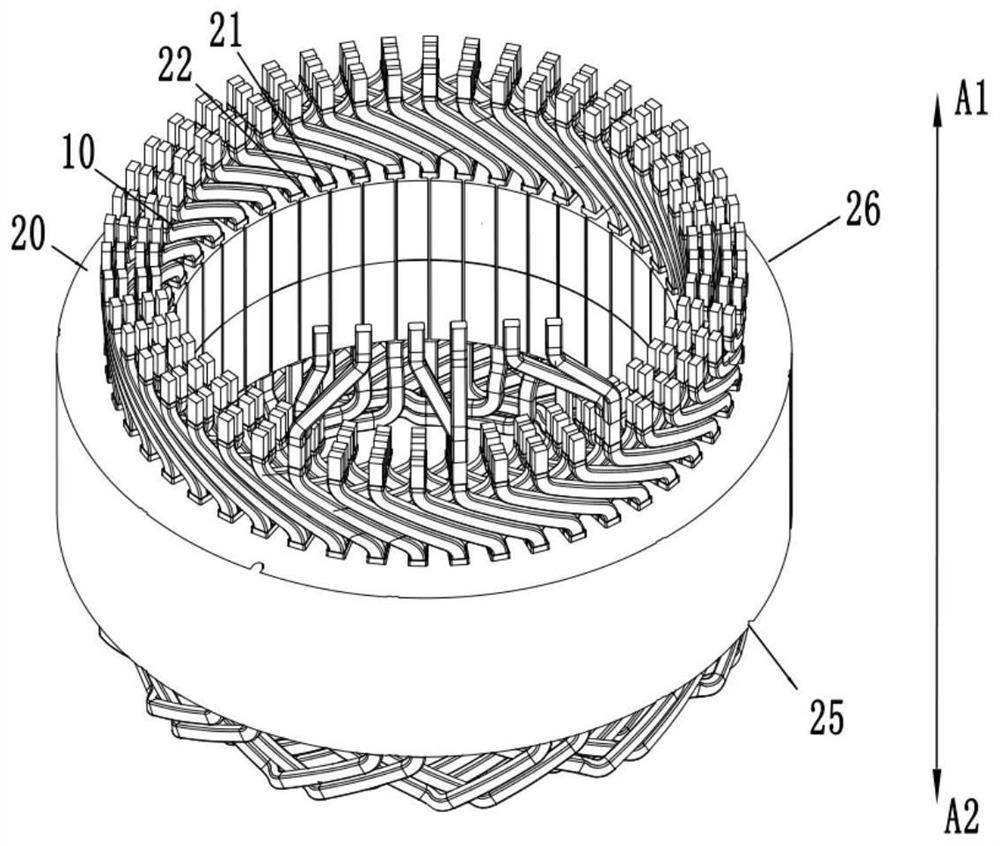

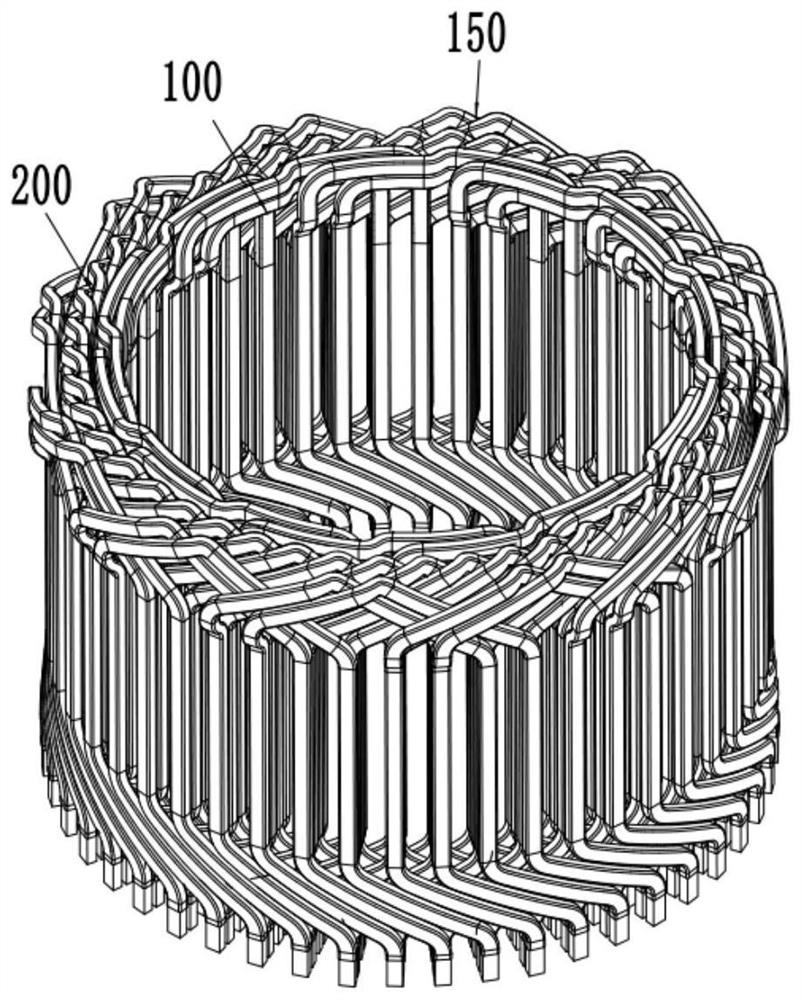

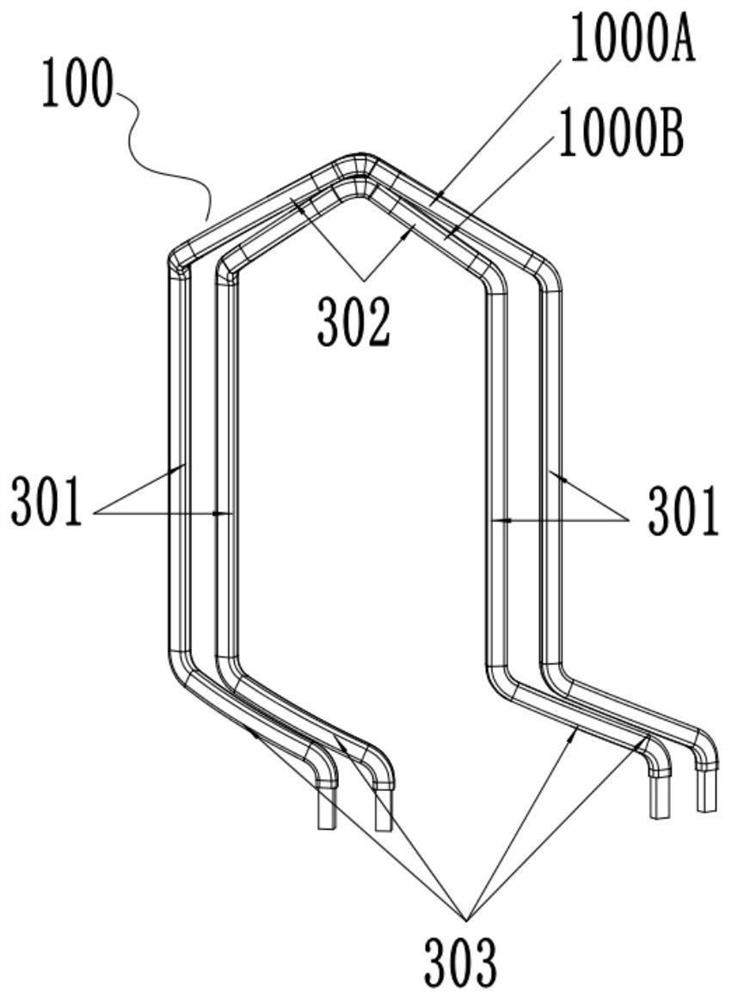

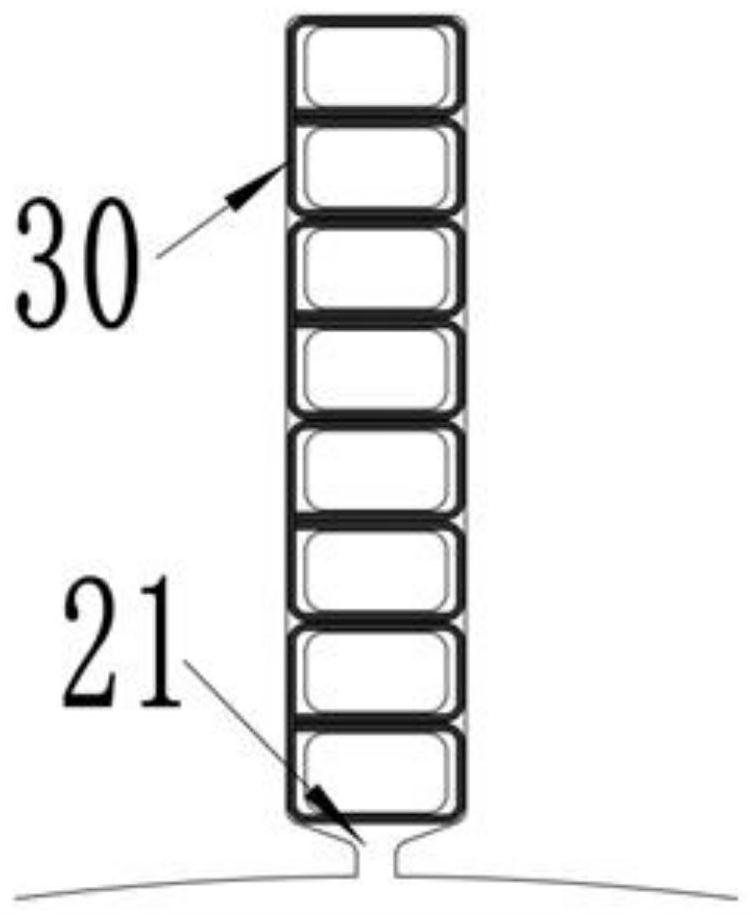

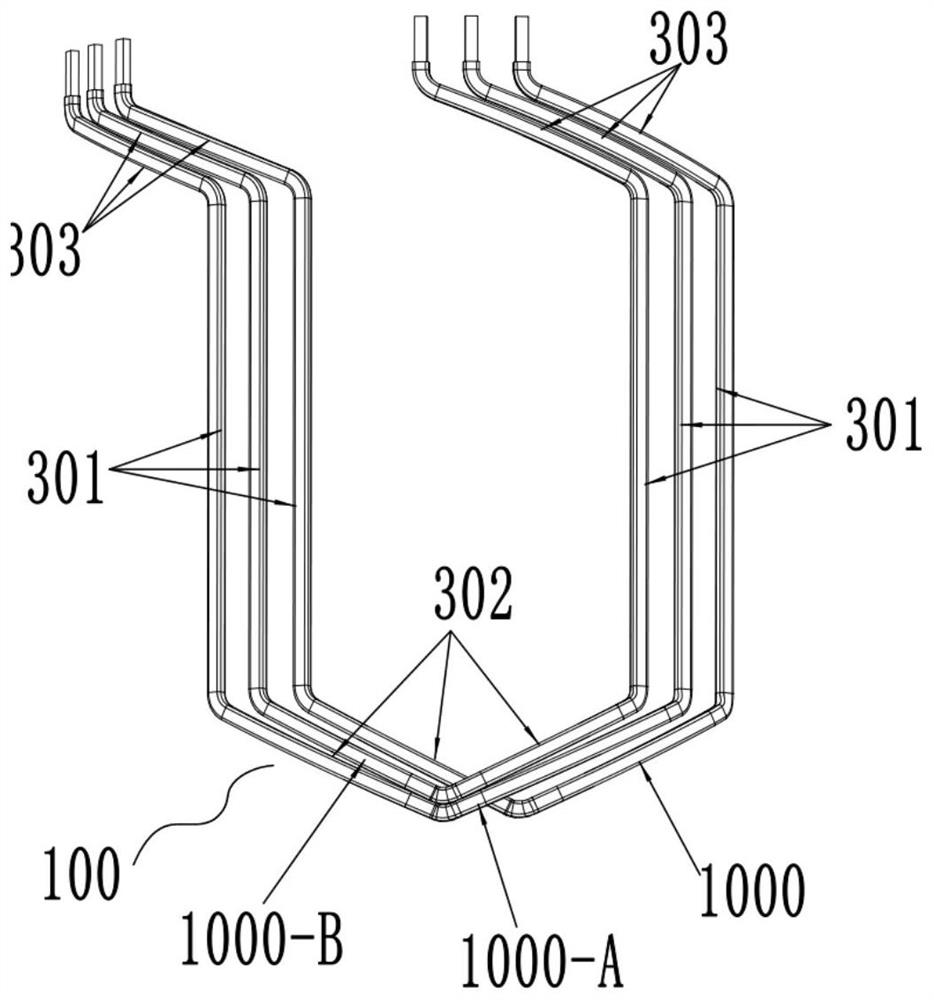

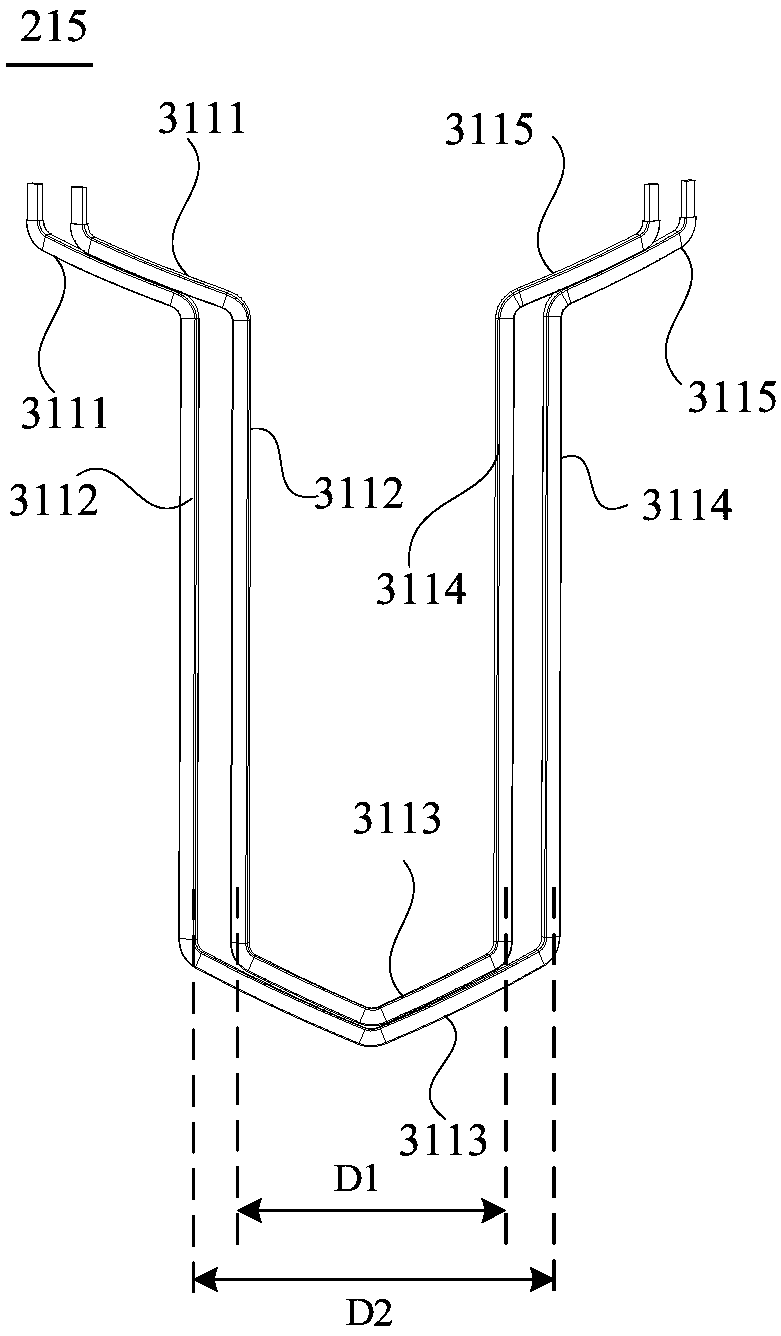

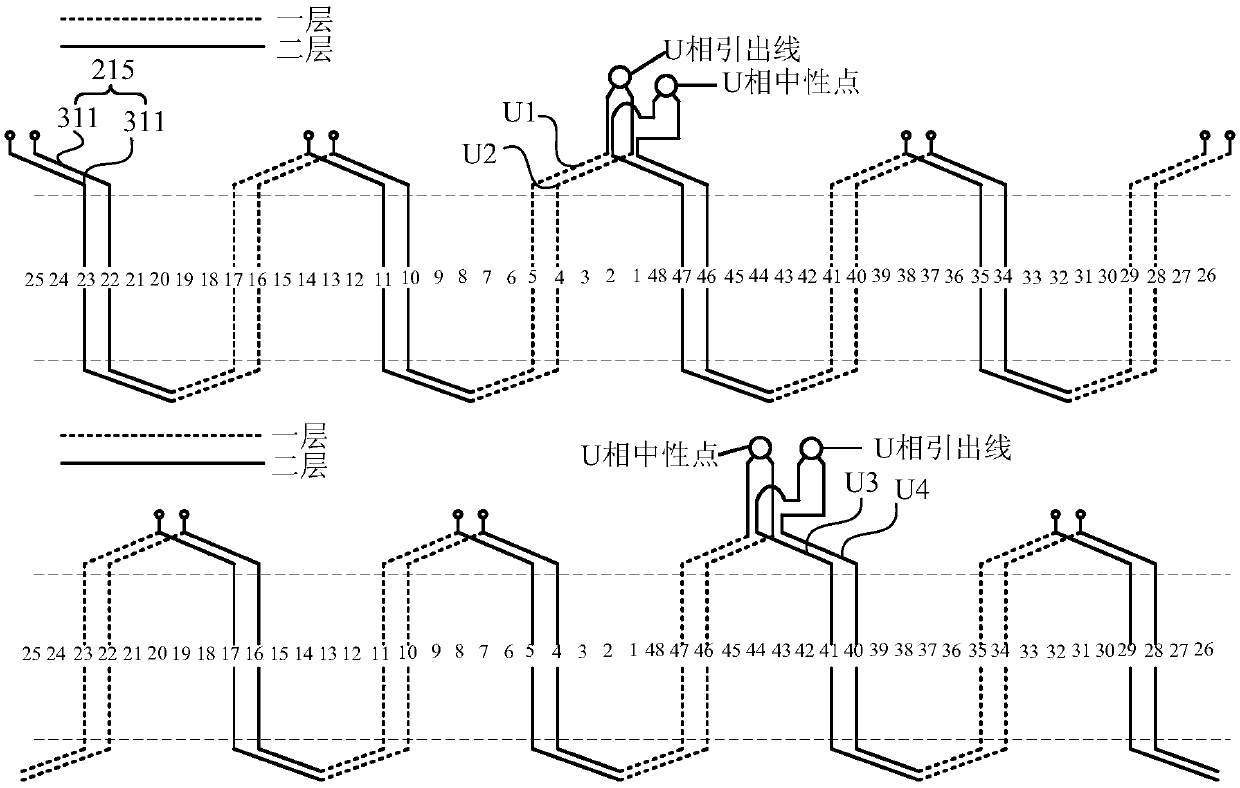

Embodiments of the invention disclose a motor winding and a motor stator. The motor winding includes at least one first segmented coil assembly; Each of the first segmented coil assemblies includes Nfirst segmented coil units, and any of the first segmented coil units includes M first hairpin coils having different groove pitches; any of the first hairpin coils includes a first groove outer end portion, a first groove inner portion, a first groove outer turning portion, a second groove inner portion, and a second groove outer end portion which are sequentially connected, the first groove outer end portion and the second groove outer end portion oppositely extend in the circumferential direction, and the M first hairpin coils are arranged concentrically; and the N first segmented coil units of each of the first segmented coil assemblies are sequentially arranged in the circumferential direction, and portions in N*M grooves are distributed in two layers in the radial direction. According to the technical scheme of the embodiments of the invention, the complexity degree of a production process can be reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

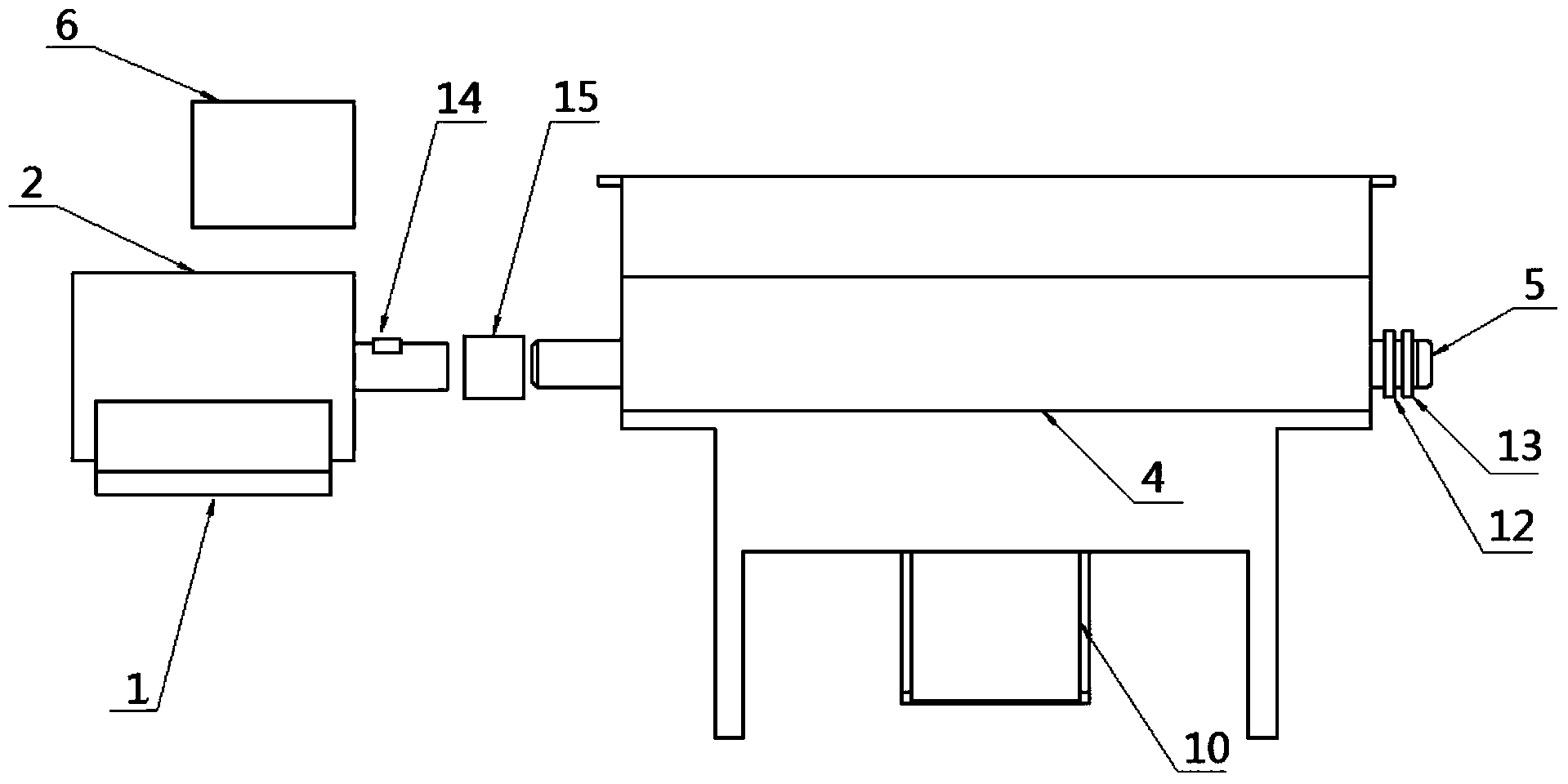

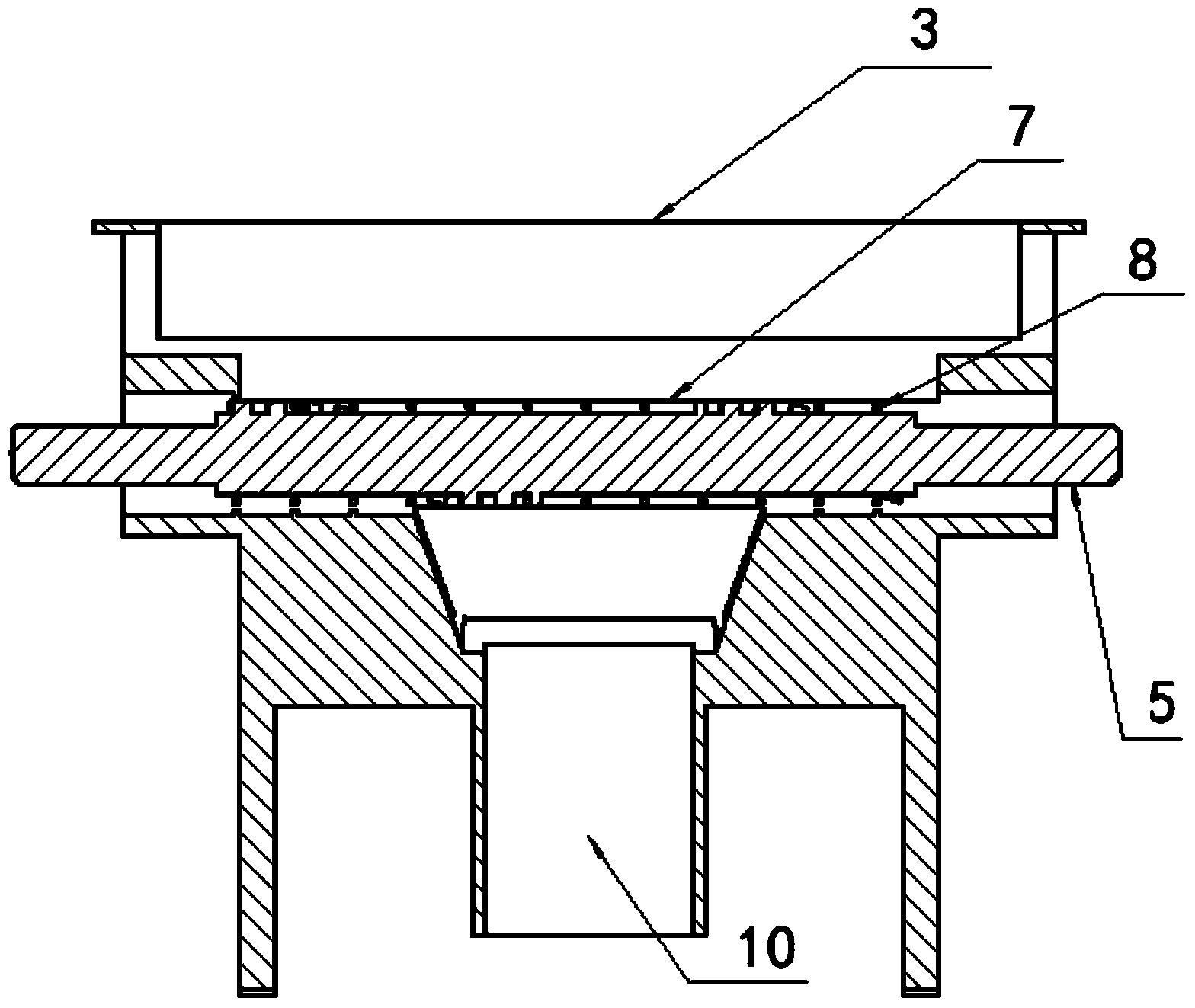

Slag cake crusher capable of dynamically adjusting speed and control method thereof

The invention provides a slag cake crusher capable of dynamically adjusting speed and a control method thereof. The slag cake crusher comprises a driving motor, a crushing chamber and a control system, wherein a feeding hole is formed at the upper end of the crushing chamber; a discharging hole is formed at the lower end of the crushing chamber; a crushing roller shaft is arranged inside the crushing chamber; the crushing roller shaft is connected with the driving motor through a coupler; spiral cutter teeth are welded on the surface of the crushing roller shaft; convex teeth are arranged on the inner wall of the crushing chamber; gaps are formed between the convex teeth and spiral cutter teeth; the control system comprises a power supply, a PLC (Programmable Logic Controller) controller, a man-machine interaction device, a frequency changer, a coder mounted on a shaft of the driving motor and a temperature senor mounted on the crushing roller shaft; the PLC controller comprises a speed controller and a temperature correction rotation speed controller. By improving the structure of the slag cake crusher and using a double closed-loop dynamic control adjustment method, the automatic control of crushing process and speed is achieved, the dynamic change of slag cake crushing load is automatically adapted, and the crushing force and crushing efficiency are maximized.

Owner:JIANGSU UNIV

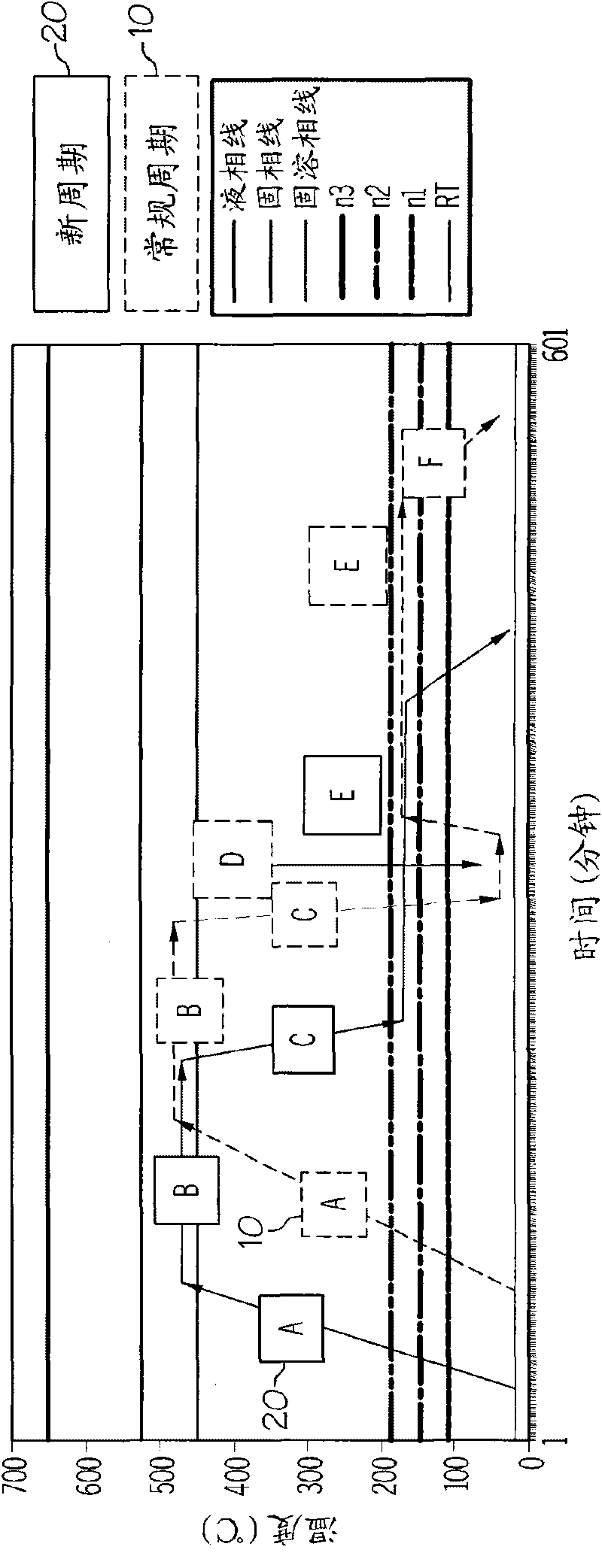

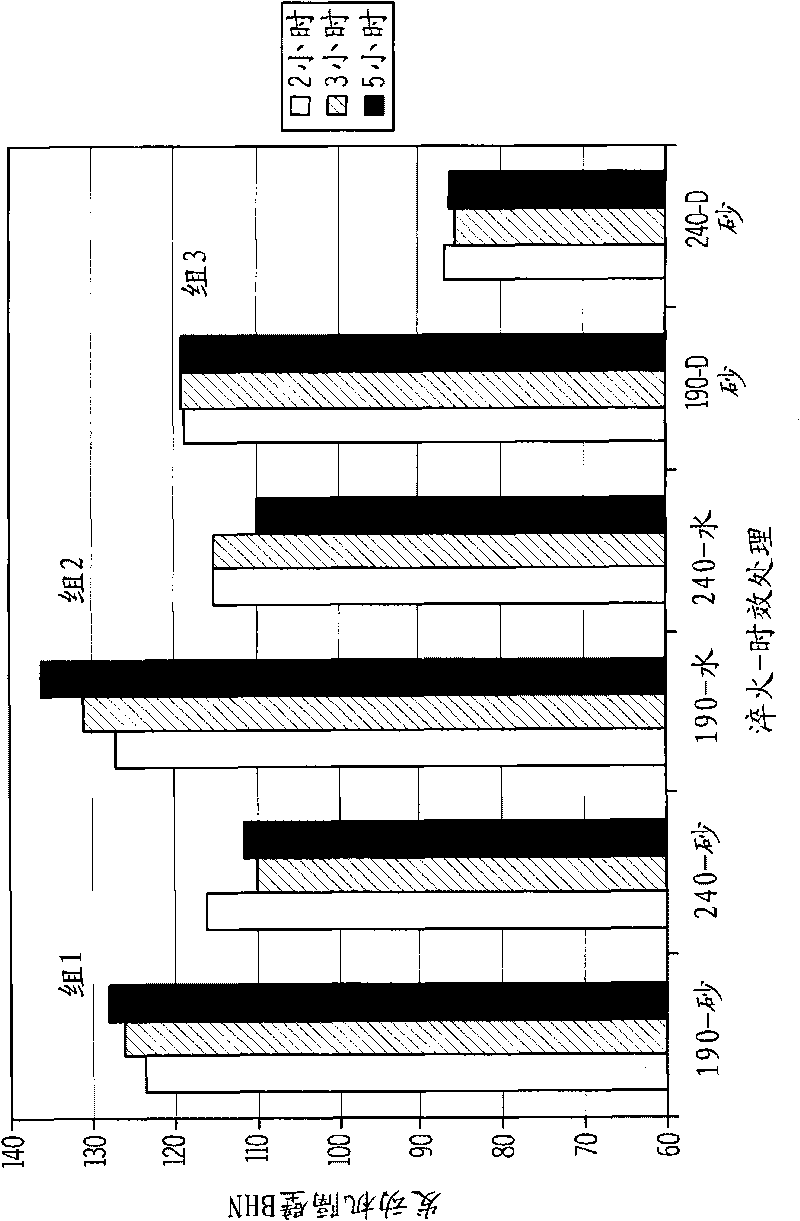

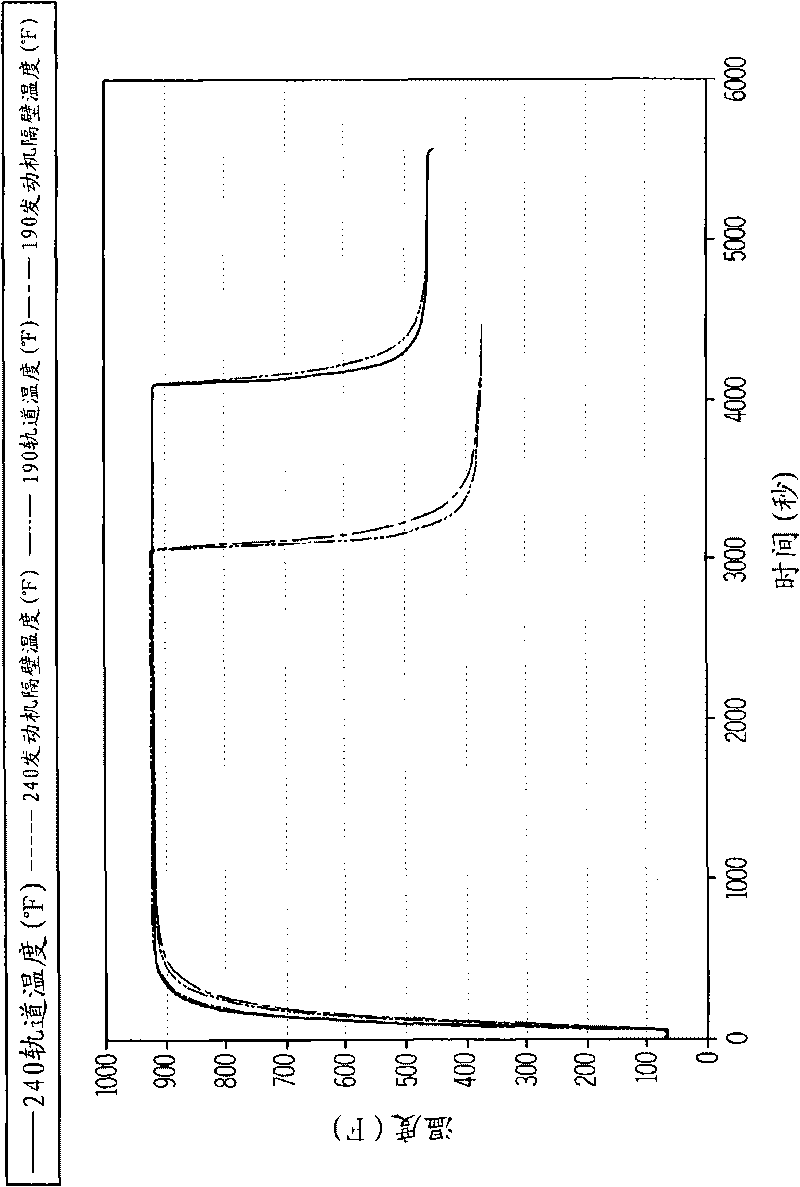

Direct quench heat treatment for aluminum alloy castings

InactiveCN101724796AAchieve mechanical propertiesLow costHeat treatment process controlSoluble phaseRoom temperature

A heat treatment method for the direct quench of aluminum alloy castings is presented. An aluminum alloy casting can be heated to the solutionizing temperature. The temperature can be maintained for a period of time sufficient to dissolve the hardening elements into the aluminum solid solution and affect any morphological changes to non-soluble phases, such as speriodization of the eutectic silicon phase. After solutionizing, the aluminum alloy casting can be quenched. The aluminum alloy casting can be rapidly cooled from the solutionizing temperature directly to the aging temperature, eliminating the room temperature hold of a conventional process. Thereby, the process can reduce process steps and equipment, can improve throughput, and can eliminate some waste heat. Further, the process can reduce residual stress and can provide a potential to form new precipitates. Direct quench can also be used with the sequential aging of aluminum casting alloys.

Owner:GM GLOBAL TECH OPERATIONS LLC

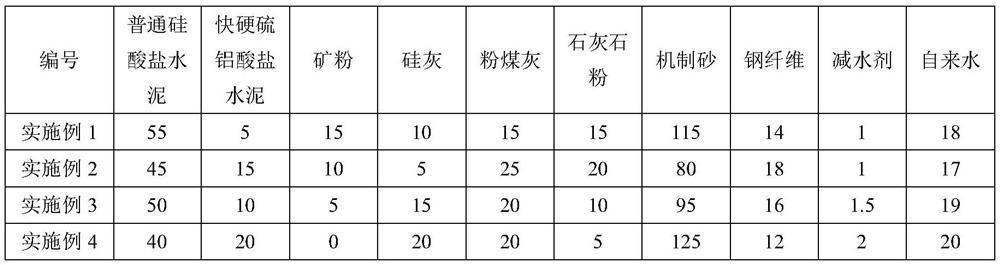

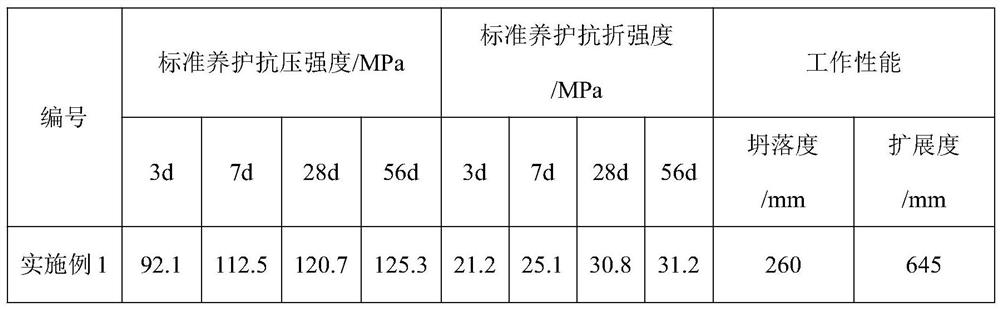

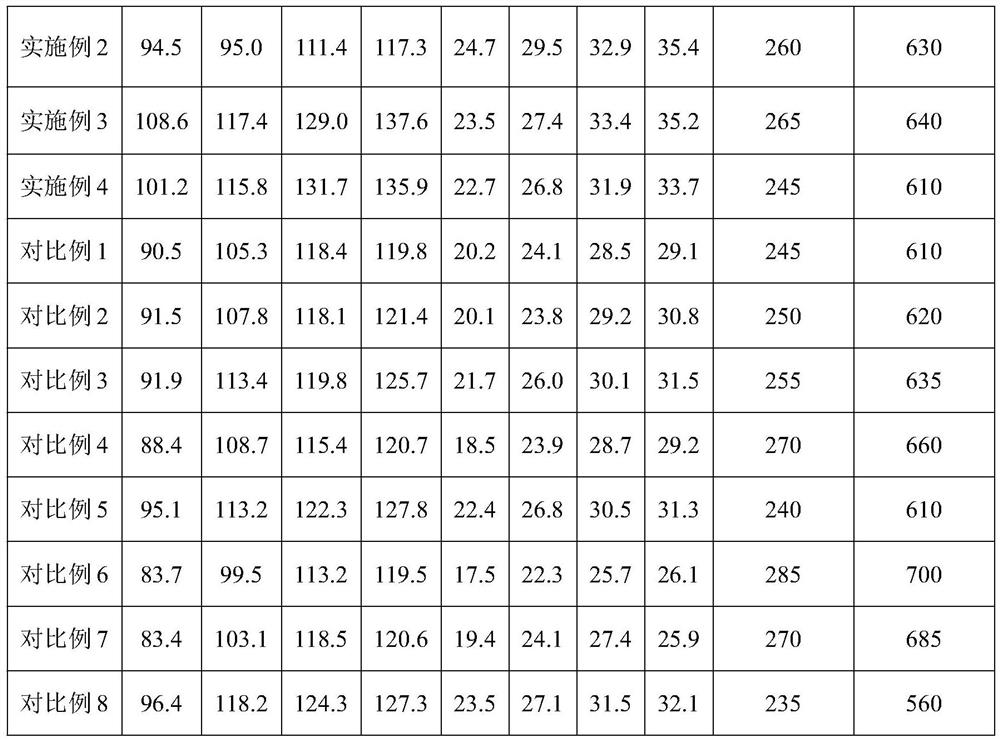

Steam-curing-free low-cost ultra-high performance concrete and preparation method thereof

PendingCN114409347AReduced mechanical propertiesReduced durabilitySolid waste managementCeramic shaping apparatusAluminateProcess engineering

The invention discloses steam-curing-free low-cost ultra-high performance concrete and a preparation method thereof, relates to the technical field of building materials, and solves the problems of high cost and cumbersome curing of ultra-high performance concrete in the prior art. The steam-curing-free low-cost ultra-high performance concrete is prepared from the following raw materials in parts by weight: 40-55 parts of ordinary Portland cement; 5 to 20 parts of rapid hardening sulphoaluminate cement; 0-15 parts of mineral powder; 5 to 20 parts of silica fume; 15 to 25 parts of fly ash; 5-20 parts of limestone powder; 80 to 125 parts of machine-made sand; 12-18 parts of waste steel fiber; 1-2 parts of a water reducing agent; and 17-20 parts of water. The preparation method of the steam-curing-free low-cost ultra-high performance concrete comprises the following steps: weighing the raw materials in parts by weight; after the raw materials are uniformly mixed, the steam-curing-free low-cost ultra-high performance concrete is obtained. The steam-curing-free low-cost ultra-high performance concrete is low in cost, simple and convenient to produce and excellent in various properties.

Owner:JIAHUA SPECIAL CEMENT

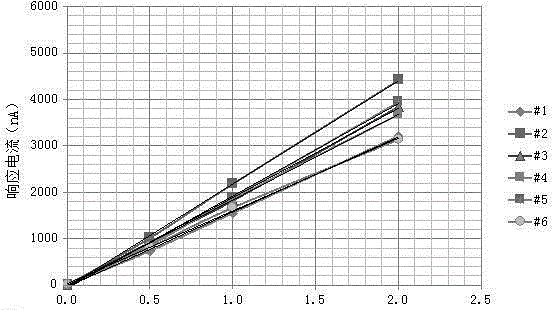

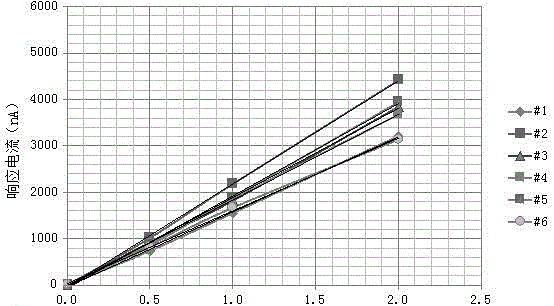

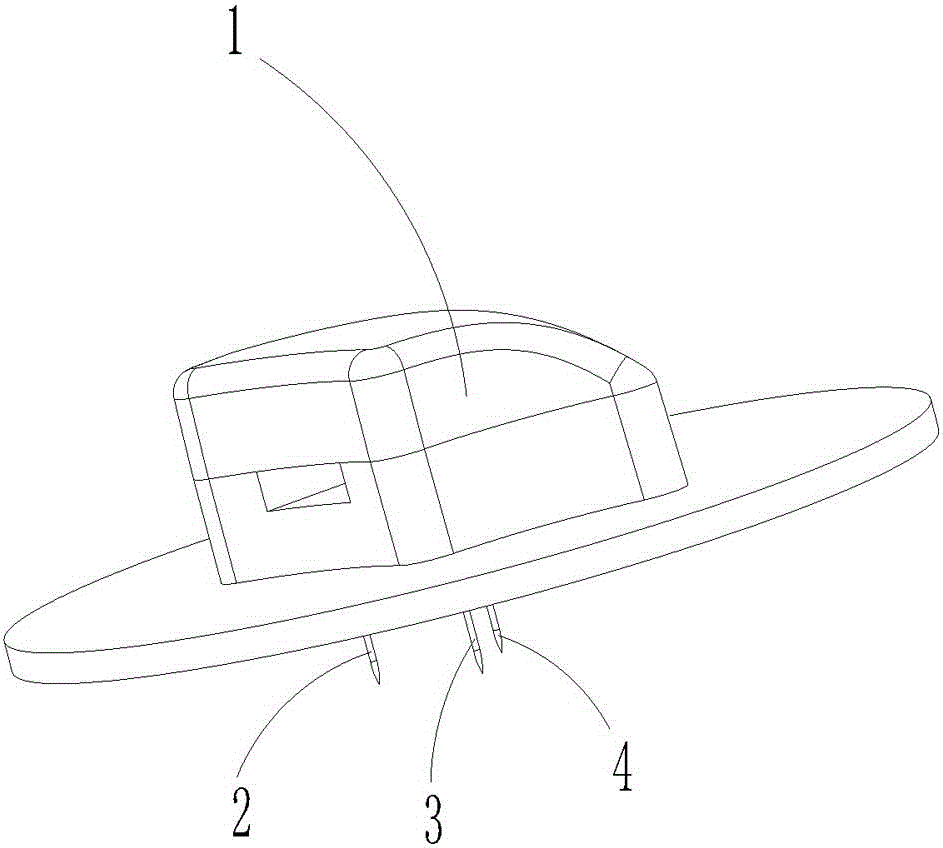

Subcutaneous tissue interventional type needle glucose sensor and its preparation method

ActiveCN105266826ASolve the conduction problemSignal acquisition is stableDiagnostic recording/measuringSensorsGlucose sensorsSubcutaneous tissue

The invention relates to a sensor, in particular to a subcutaneous tissue interventional type needle glucose sensor and its preparation method. The sensor comprises a base, the bottom of the base is provided with a working electrode, a counter electrode and a reference electrode, and the working electrode, the counter electrode and the reference electrode form a split needle three-electrode system. The subcutaneous tissue interventional type needle glucose sensor and its preparation method have the advantages that the structure is compact, operating performance is improved and the service life is prolonged.

Owner:杭州瀚科医疗科技有限公司

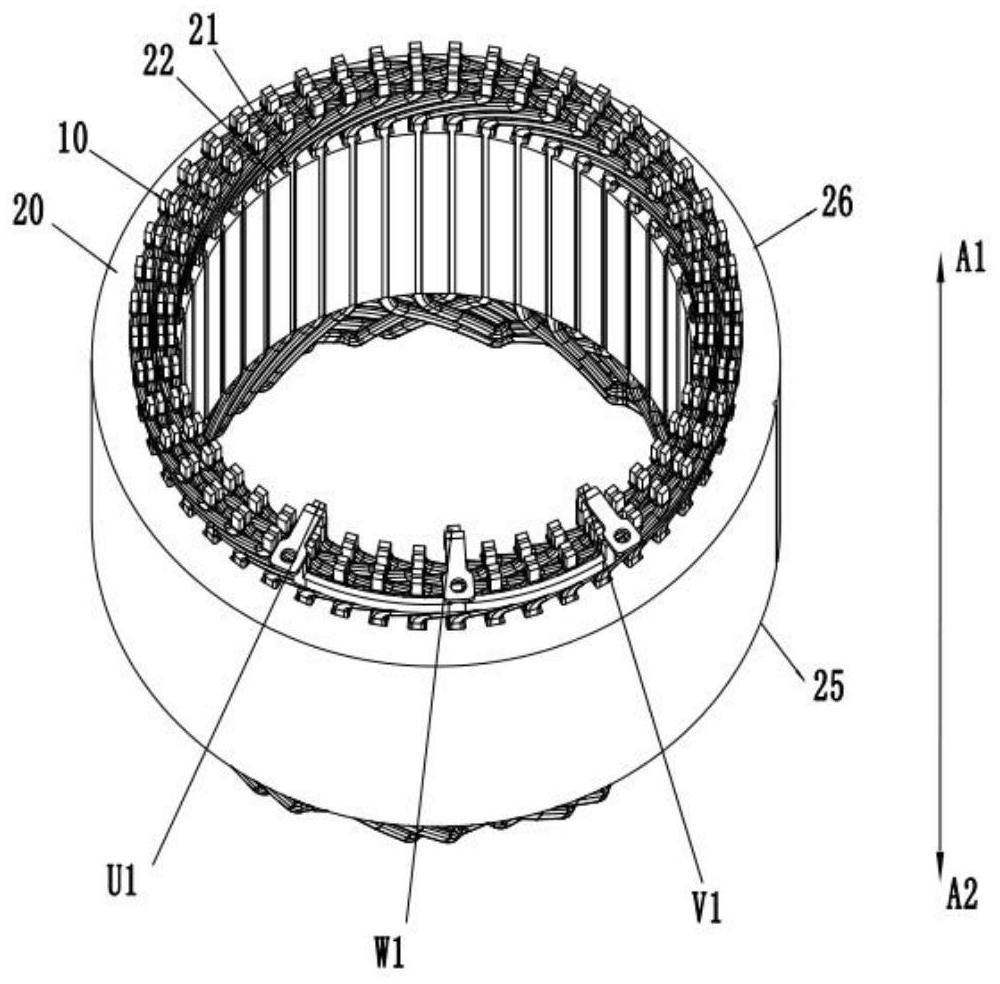

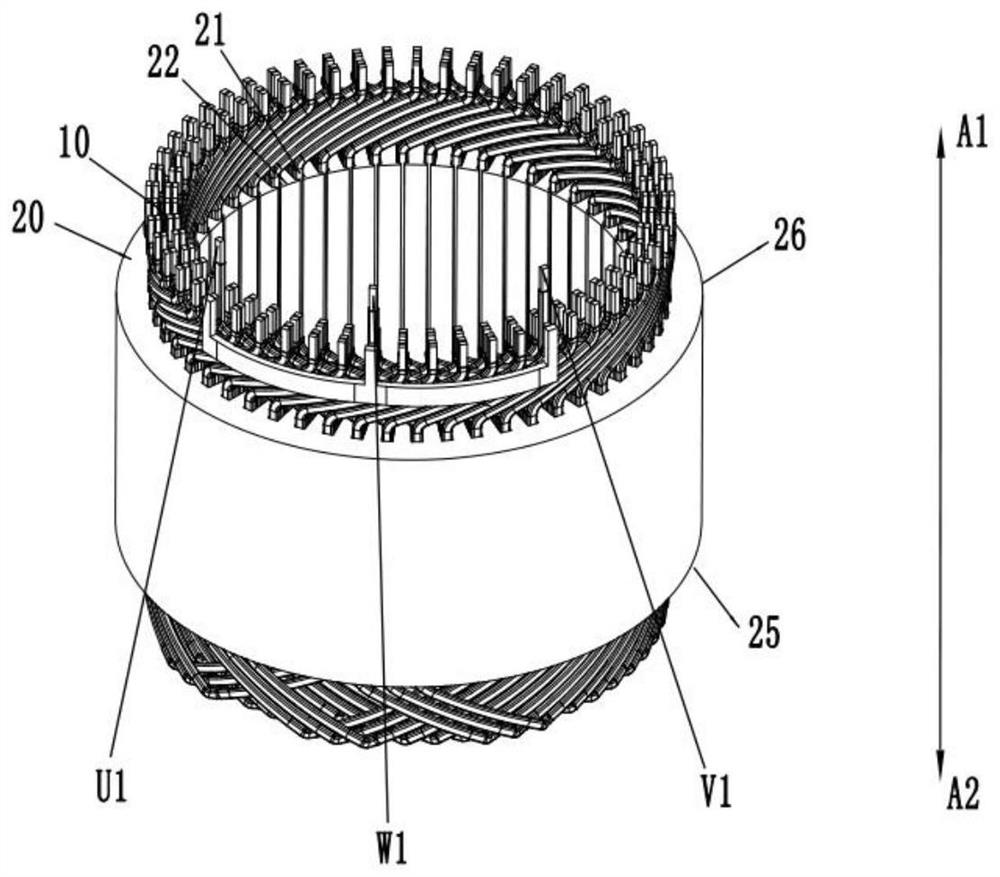

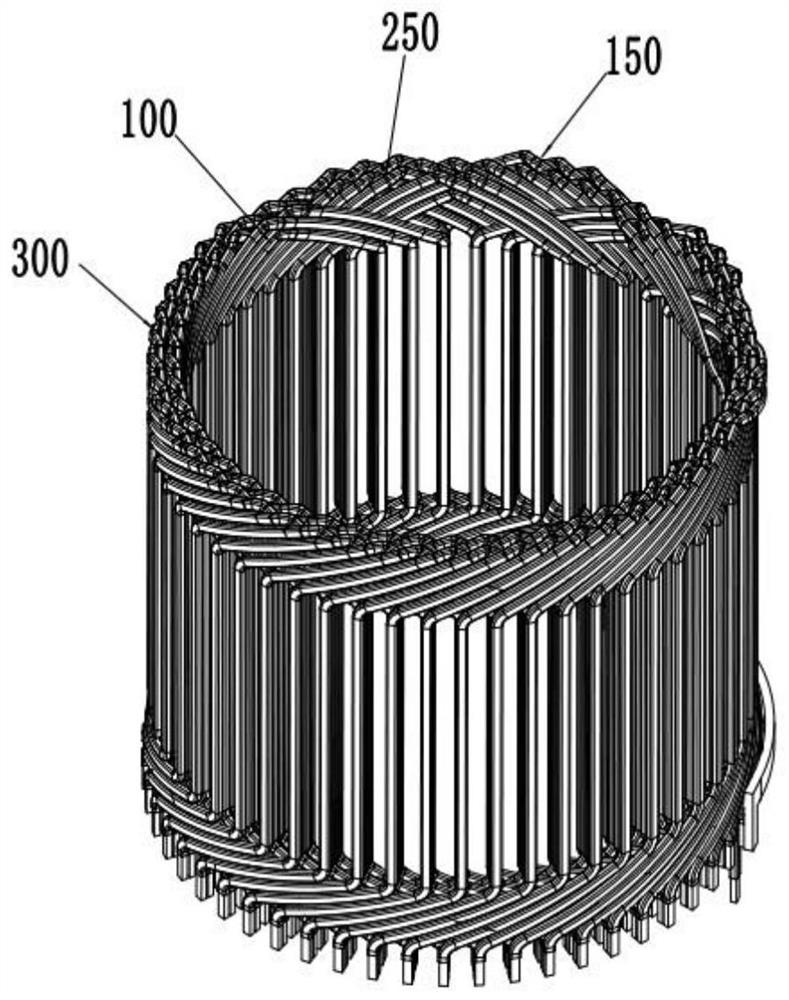

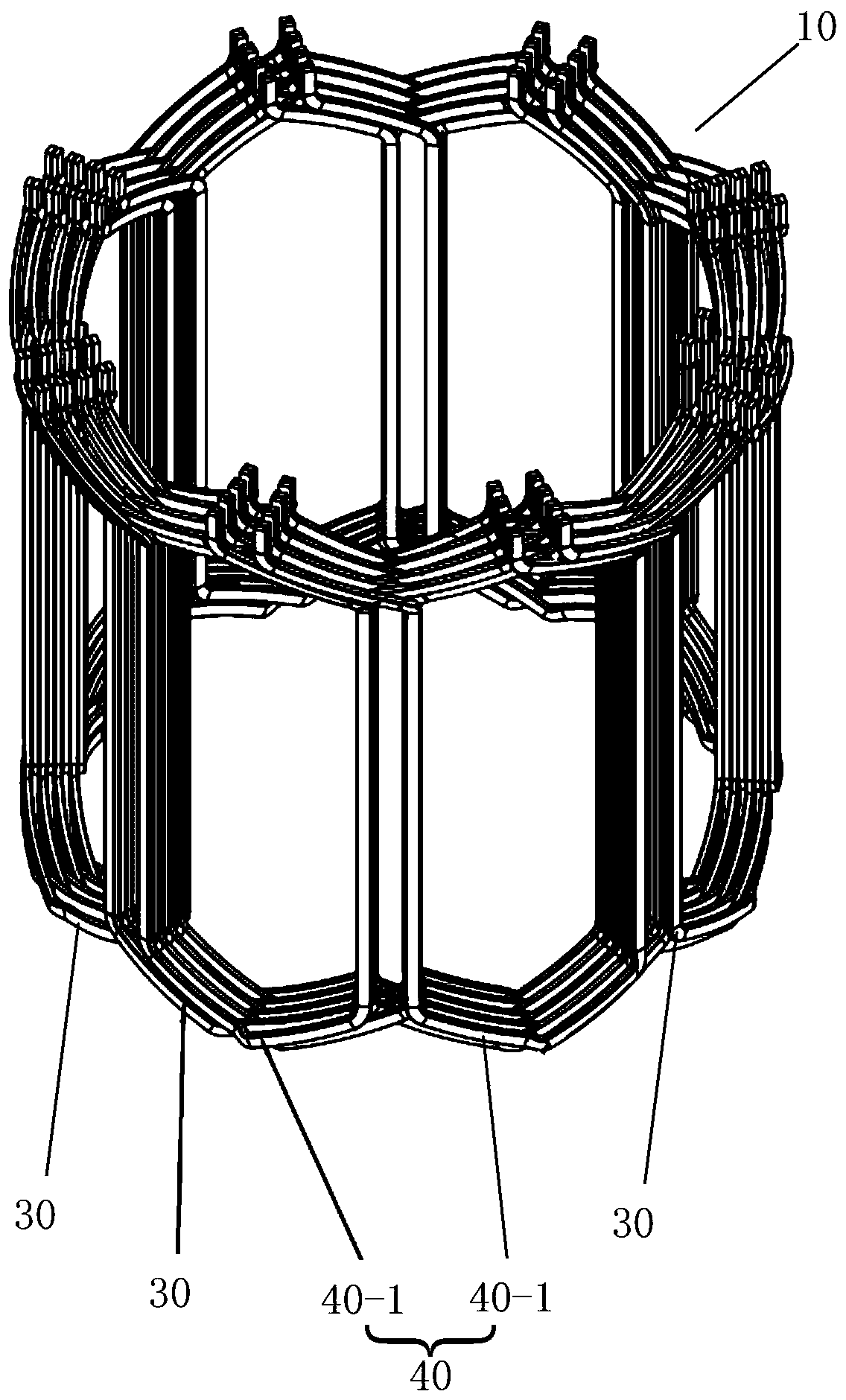

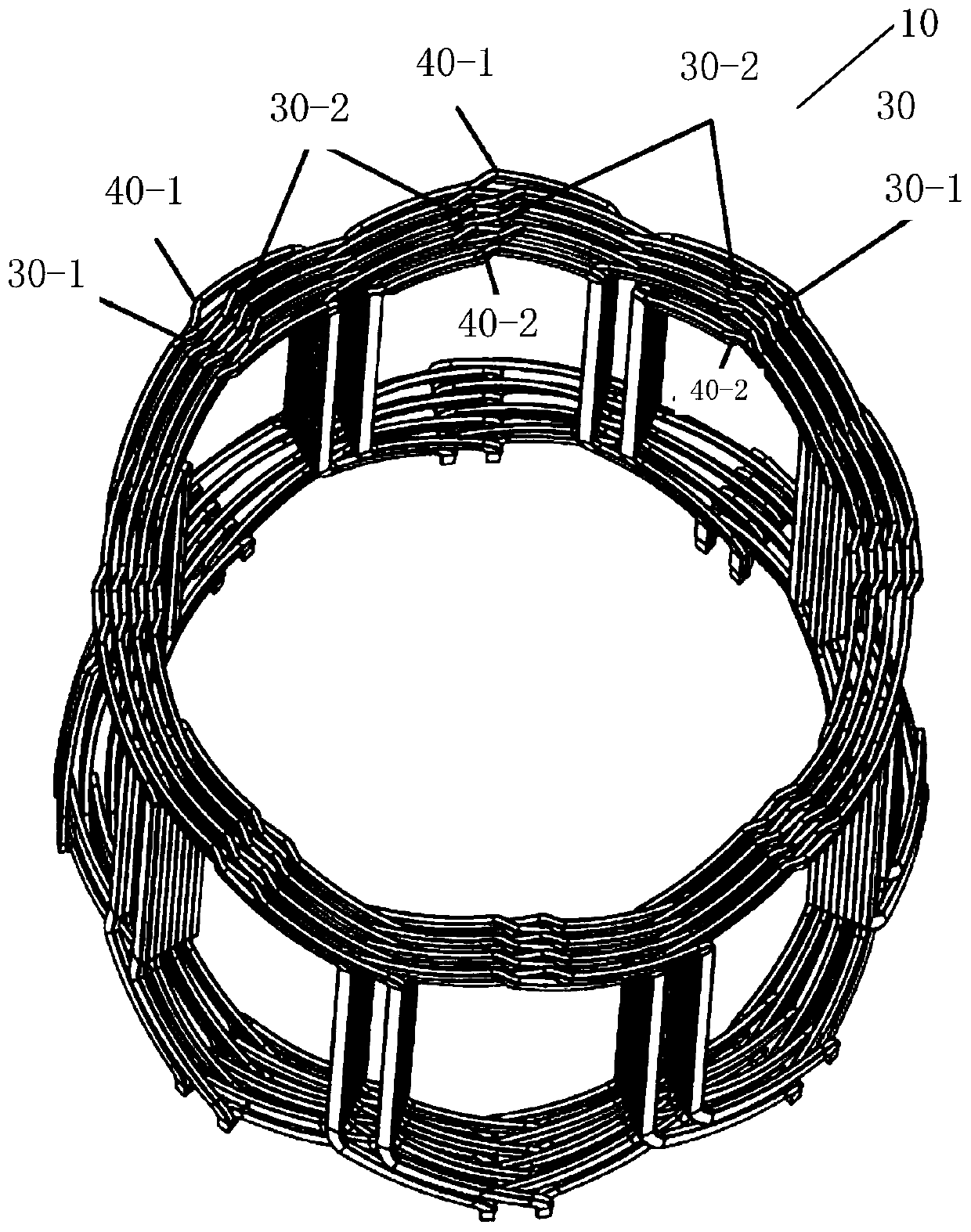

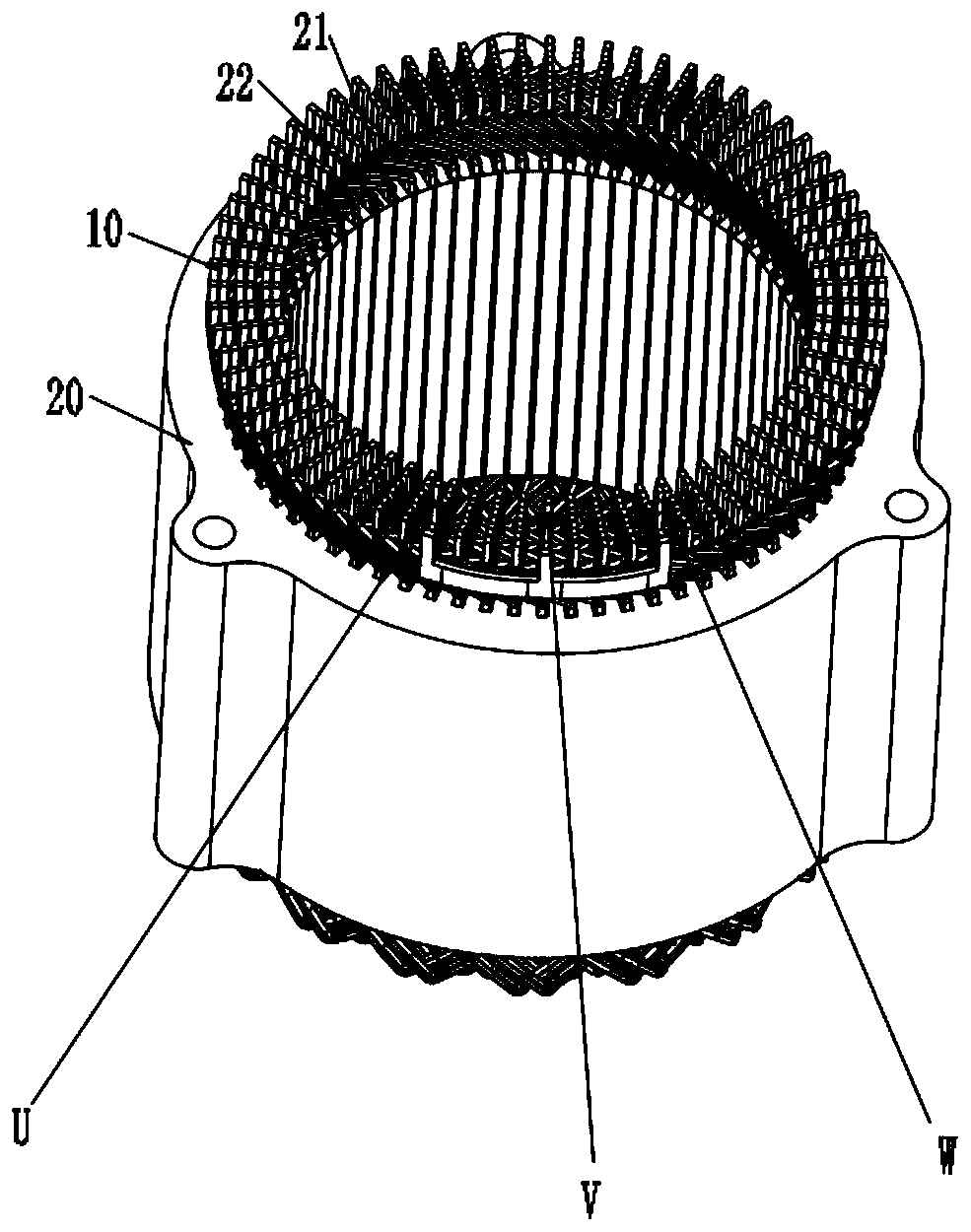

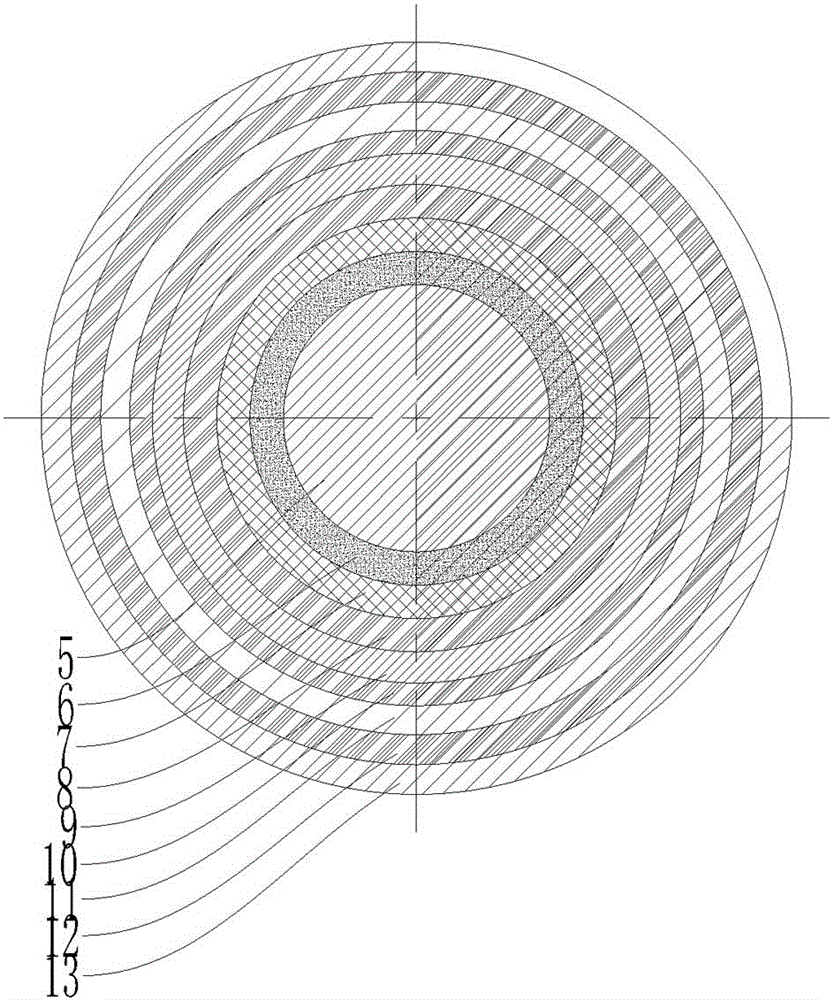

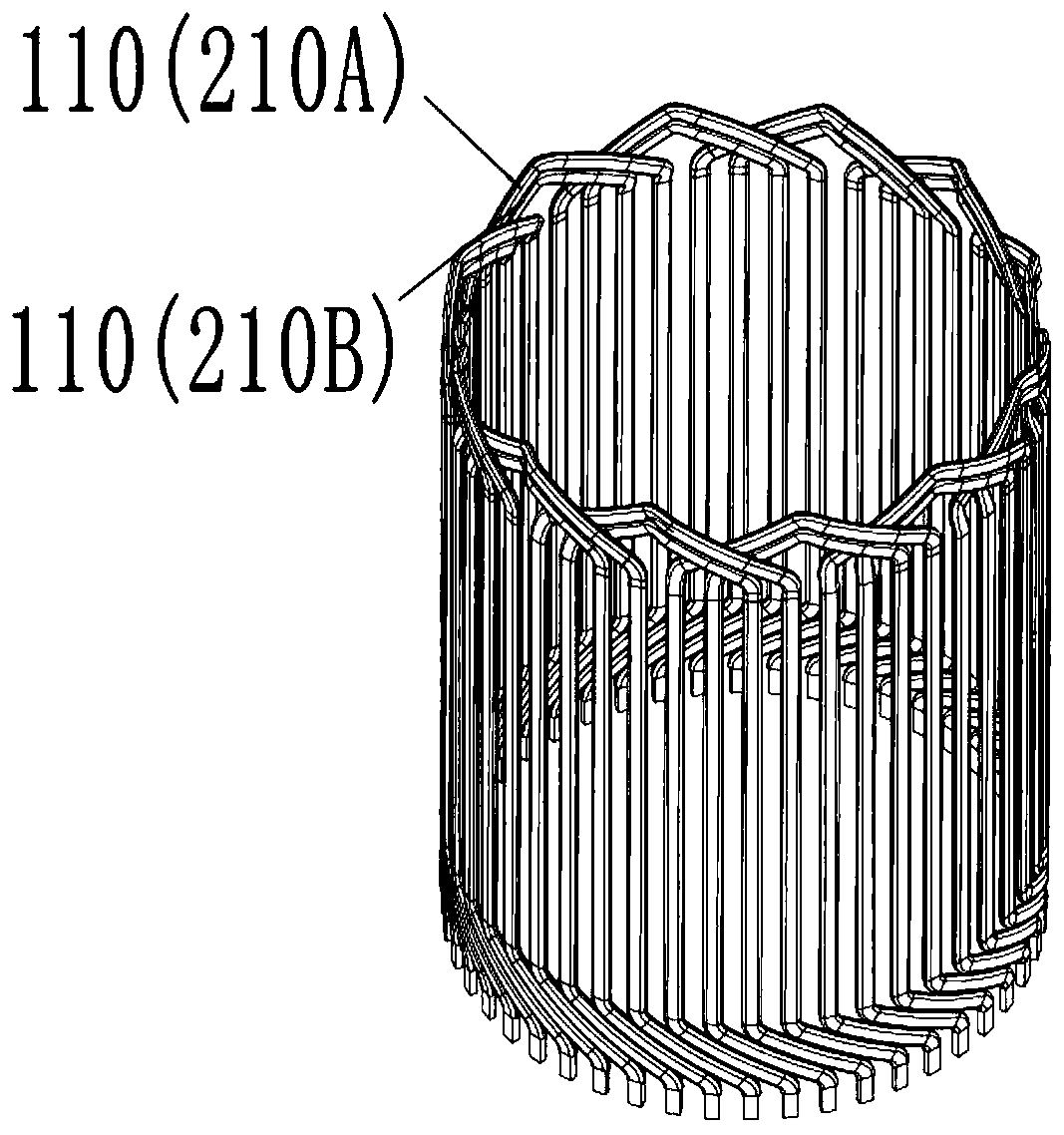

Motor winding and motor stator

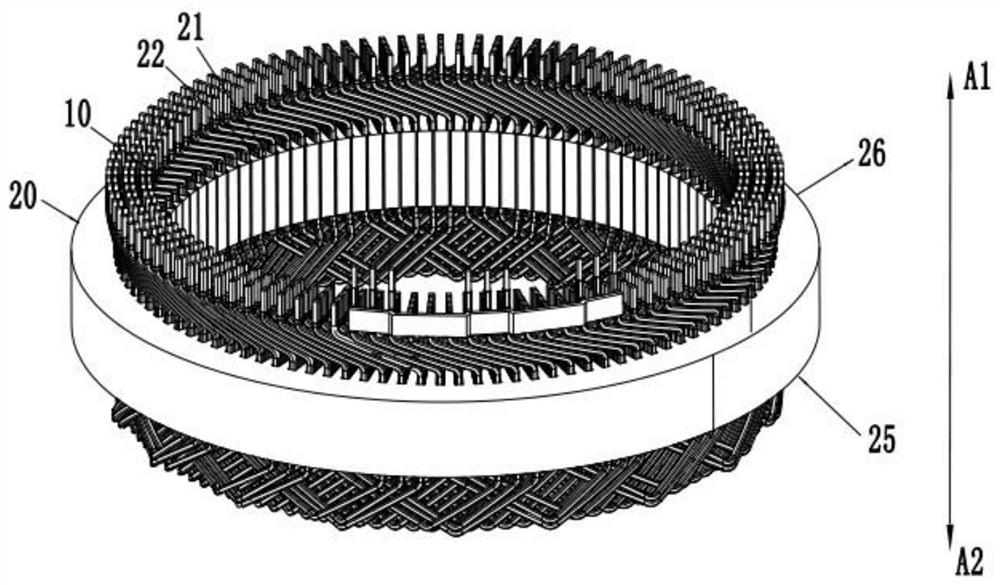

PendingCN111342585ALow costEliminate circulating currentMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineBusbar

The invention provides a motor winding and a motor stator. According to the motor winding, N first sectional type coil units and M second sectional type coil units are sequentially arranged in the circumferential direction, the first in-groove part and the second in-groove part of each first sectional type coil unit are distributed in two layers in the radial direction, and the first sectional type coil units are arranged on any layer of the motor winding in the radial direction; the third in-groove part and the fourth in-groove part of each second sectional type coil unit are distributed on the same layer in the radial direction, and the second sectional type coil units are arranged on the outermost layer and the innermost layer of the motor winding in the radial direction. According to the winding structure, a completely symmetrical structure is adopted in a magnetic circuit; the problem of circulating current generated by an asymmetric structure is eliminated, busbars among phases are canceled, direct connection among the phases is realized, branches and neutral points of windings of each phase are arranged on any layer of any groove, the complexity of a manufacturing process isreduced, the production cost is reduced, the material cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

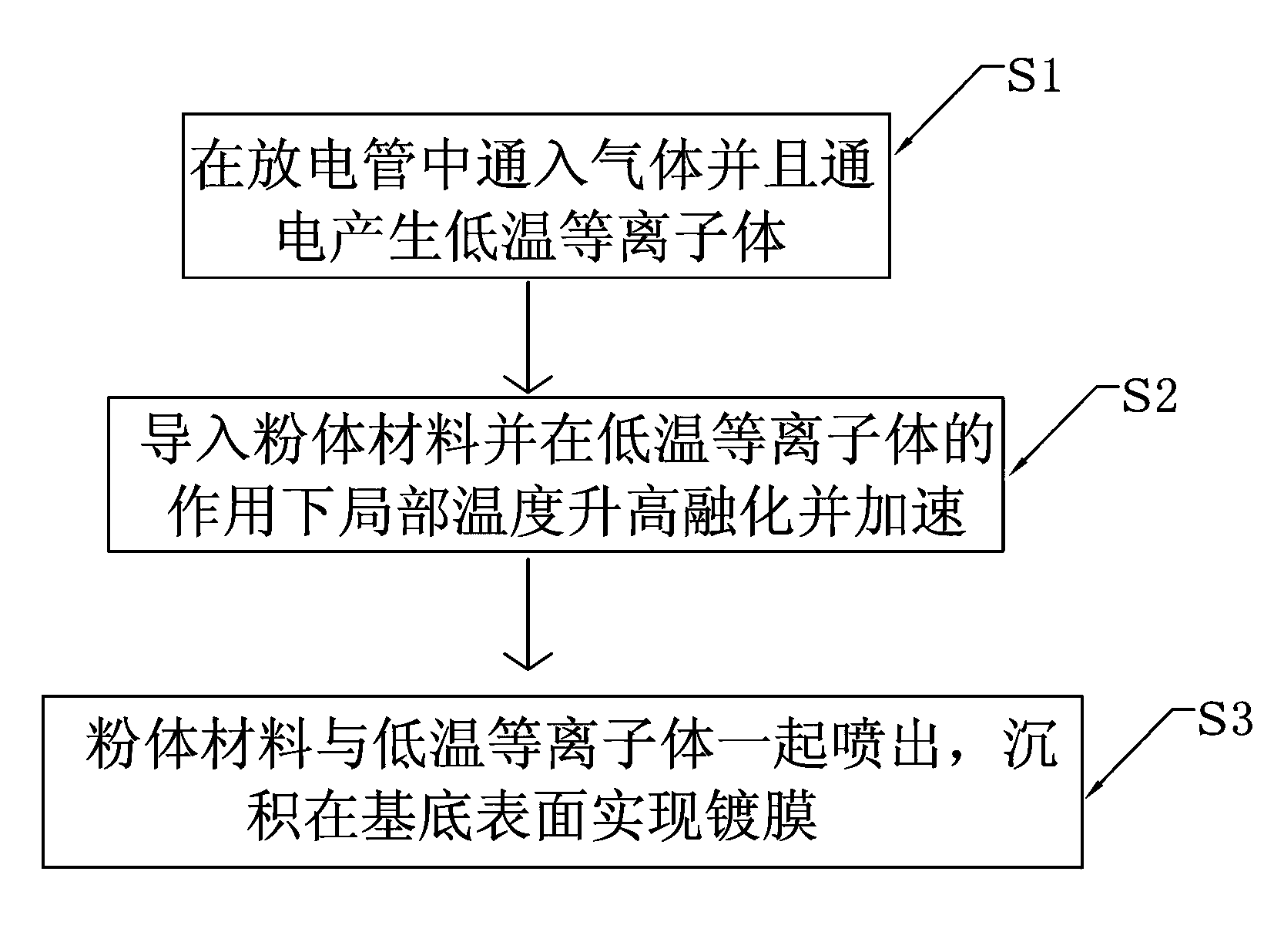

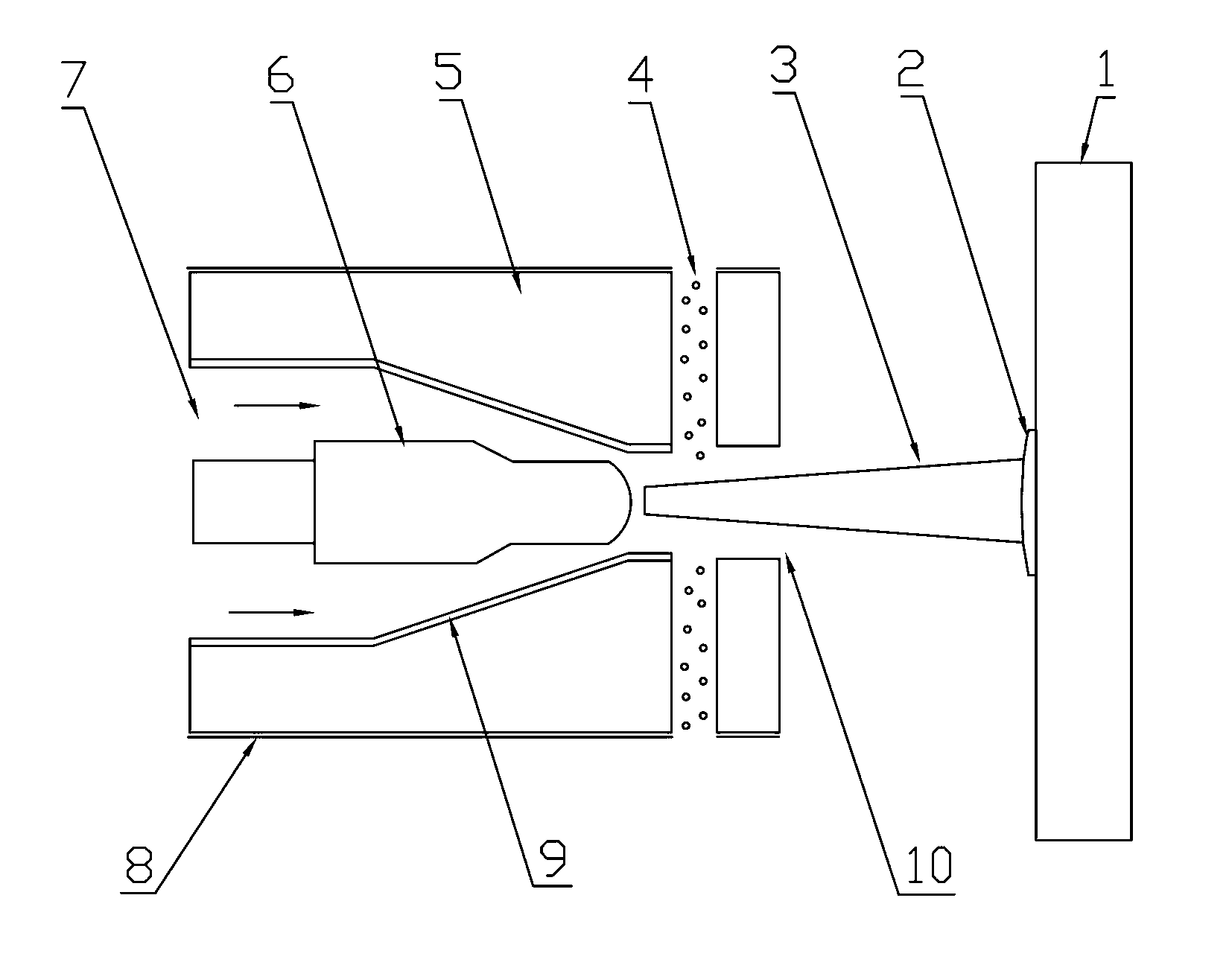

Airglow-discharge low-temperature plasma coating technique

ActiveCN103060740AReduce the complexity of the preparation processExpand the scope of useMolten spray coatingPhysicsElectronics

The invention provides an airglow-discharge low-temperature plasma coating technique, belonging to the field of plasma coating. The technique can effectively solve the problems of the overhigh coating temperature can damage the substrate and the preparation technique is complex in the field of coating. The technique comprises the following steps: a. low-temperature plasma breakdown by electrifying a discharge tube: gas introduced from a gas source reaches breakdown voltage under the action of a power source with an excitation source, and discharge is initiated to excite and generate low-temperature plasma; b. introduction of a powder material: the fed powder material is locally heated to be molten under the action of the low-temperature plasma and is accelerated; and c. injection and coating of low-temperature plasma: the powder material and the low-temperature plasma are injected together and deposited on the substrate surface to implement coating. The invention can be widely used for preparing metal materials, semiconductor materials, compound materials, polymers and other materials in the fields of printing electronics, 3D printing and the like.

Owner:INFINITE MATERIALS TECH

Motor stator winding, motor stator and motor

PendingCN111564919AReduce typesSimple arrangementMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator winding, which comprises at least one coil group I arranged on two radially adjacent layers of a stator core; at least one coil group II arranged on two adjacentlayers of the stator core in the radial direction; a coil group III arranged on the first layer of the radial inner side or the first layer of the radial outer side of the stator core; and a coil group IV arranged on the first layer, opposite to the radial direction, of the coil group III in the stator core. The lap winding rotation direction of the coil group I is opposite to that of the coil group II. According to the invention, conductors in fewer types are used arrangement mode is simple, a bus strip and a bus bar can be canceled, so that the twisting direction and the twisting groove pitch of the welding end part extending towards the inside of the same layer in the stator core groove are consistent, the lead end and the neutral point between the windings of each phase are arranged atany layer of any groove in the same radial direction, the complexity of the manufacturing process is reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

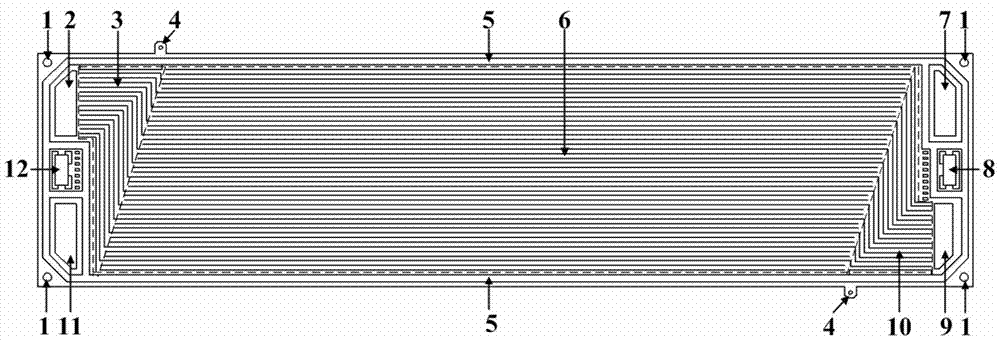

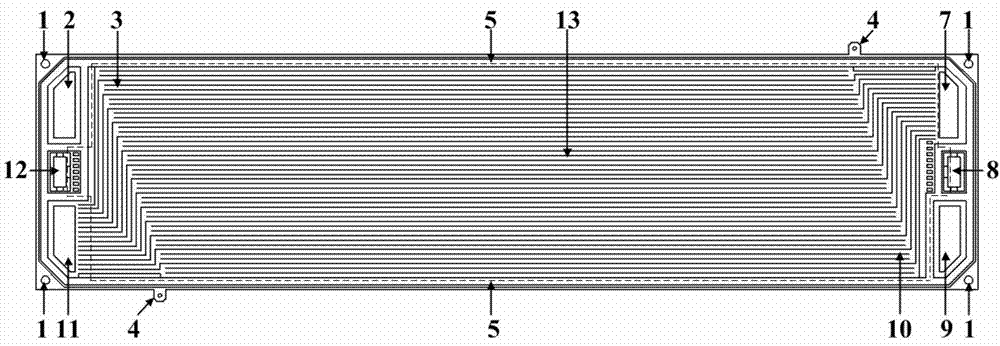

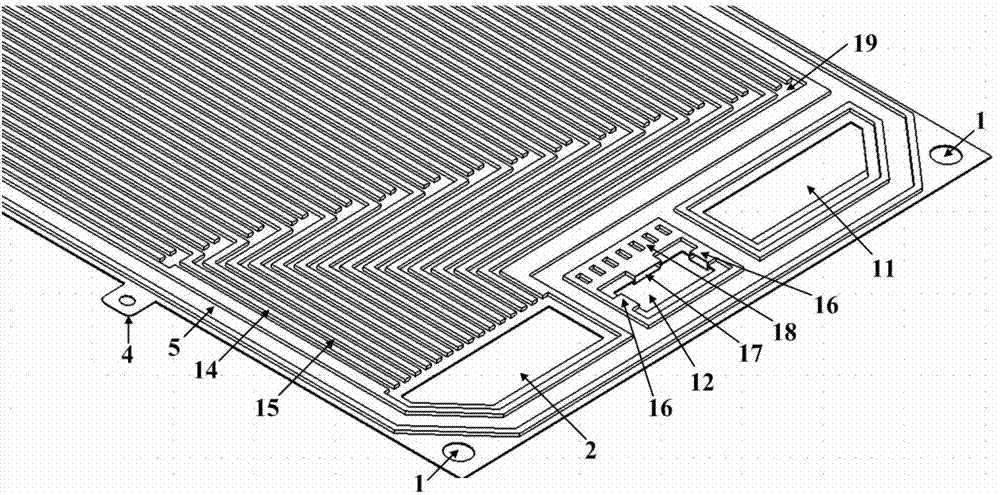

Metal bipolar plate of miniature fuel battery

The invention discloses a metal bipolar plate of a miniature fuel battery. The metal bipolar plate comprises an anode single-pole plate and a cathode single-pole plate having a same structure, the single-pole plate comprises an inlet end and an outlet end respectively positioned at two sides, and a flow path area positioned at a central section, the inlet end comprises a fuel inlet, a cooling medium inlet and an oxidizing agent inlet, the outlet end comprises a fuel outlet, a cooling medium outlet and an oxidizing agent outlet, a groove at a right side of the single-pole plate and a ridge forma right side channel of the single-pole plate, the right side channel of the anode single-pole plate is a fuel flow channel, the right side channel of the cathode single-pole plate is an oxidizing agent channel, the anode single-pole plate and the cathode single-pole plate are applied to form a cooling channel, and the oxidizing agent channel and the fuel flow channel are the snakelike flow channels. Three snakelike flow channels are arranged on the anode single-pole plate and the cathode single-pole plate, the gas conveying pressure of the bipolar plate is large, the drainage is good, the fuel concentration of the bipolar plate is uniform and consistent, the fuel utilization rate is increased, and the reaction efficiency of the fuel battery is high.

Owner:苏州中氢能源科技有限公司

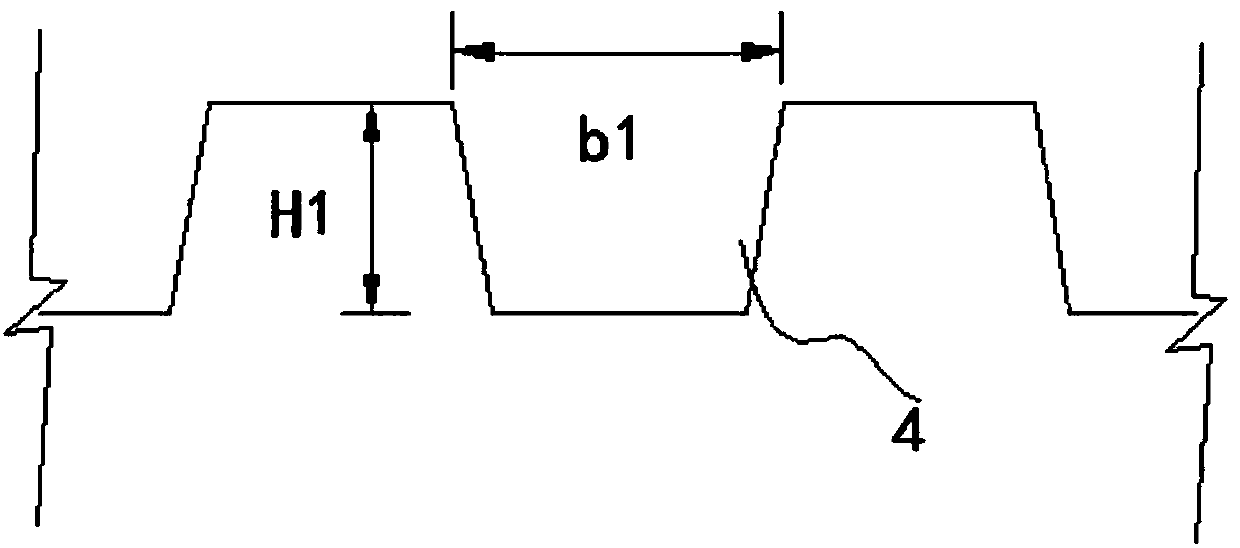

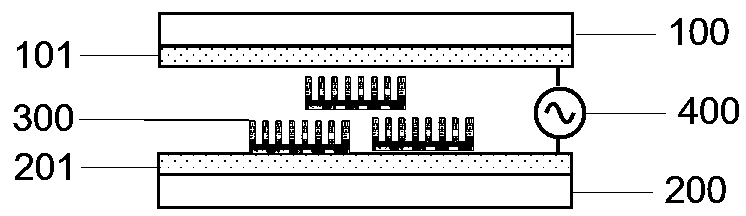

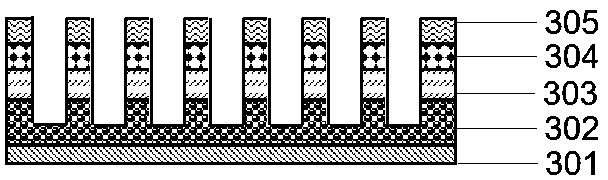

Non-direct electrical contact orientation ordered nLED light-emitting display device

ActiveCN110690246AAvoid complex bondingReduce the complexity of the manufacturing processSolid-state devicesNanotechnologyPhysicsEngineering

The invention relates to a non-direct electrical contact orientation ordered nLED light-emitting display device. The device comprises in order from top to bottom: an upper driving electrode substrate,an upper driving electrode, a nano LED crystal grain sheet, a lower driving electrode and a lower driving electrode substrate. The device further comprises an alternating-current driving control module, the two ends of the alternating-current driving control module are respectively connected with the upper driving electrode and the lower driving electrode, the nano LED crystal grain sheet is formed by orderly arranging a plurality of nano LED crystal grains, so that when the nano LED crystal grain sheet is placed between the electrode substrates, and the light-emitting layer of each nano LEDcrystal grain is parallel to the electrode substrates and is perpendicular to the direction of an electric field; and at least one of the upper driving electrode and the lower driving electrode is isolated from the nano LED crystal grains through an insulating dielectric layer, and the nano LED crystal grains are lightened through electromagnetic coupling under an alternating driving signal. According to the invention, an indirect electrical contact method is adopted to achieve ordered nLED light-emitting display, a huge transfer process of micron-scale and nano-scale LEDs can be omitted, andthe process cost is effectively reduced.

Owner:FUZHOU UNIVERSITY

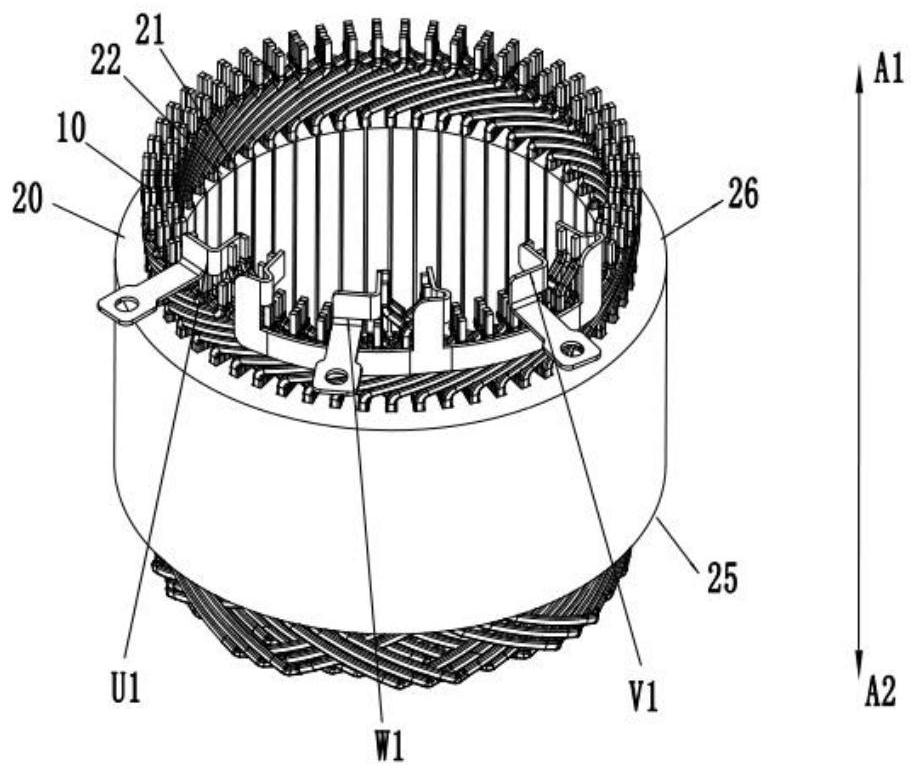

Motor stator and motor

InactiveCN111555505ALow costEliminate circulating currentMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineBusbar

The present invention discloses a motor stator and a motor. The motor stator comprises a stator iron core, wherein the stator iron core has a plurality of slots formed on a radial inner surface of thestator iron core and spaced apart by a predetermined slot pitch in a circumferential direction of the stator iron core; and stator windings, which are arranged on the stator iron core. The stator windings are three phases of stator windings, and the three phases of stator windings are sequentially connected in parallel in the circumferential direction of the stator iron core. Each phase of statorwinding comprises a first coil assembly, at least one second coil assembly and a third coil assembly which are sequentially arranged in a sleeving mode in the radial direction of the stator core. A completely-symmetrical structure is adopted on a magnetic circuit through a winding structure, so that the problem of circulating current generated by an asymmetric structure is eliminated; and each interphase busbar is canceled, so that direct connection in each phase is realized, branches and neutral points of each phase of winding are arranged on any layer of any groove, the complexity of a manufacturing process is reduced, the production cost is reduced, the material cost is reduced, and the processing efficiency is improved.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

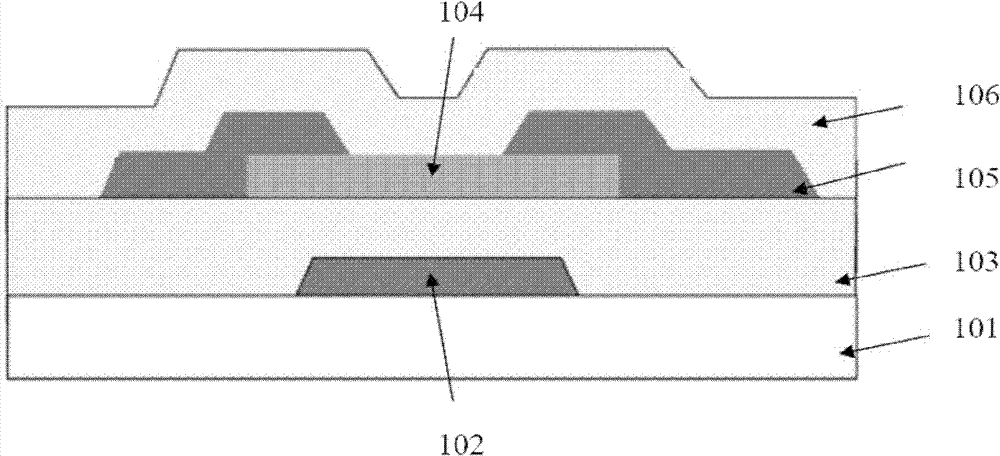

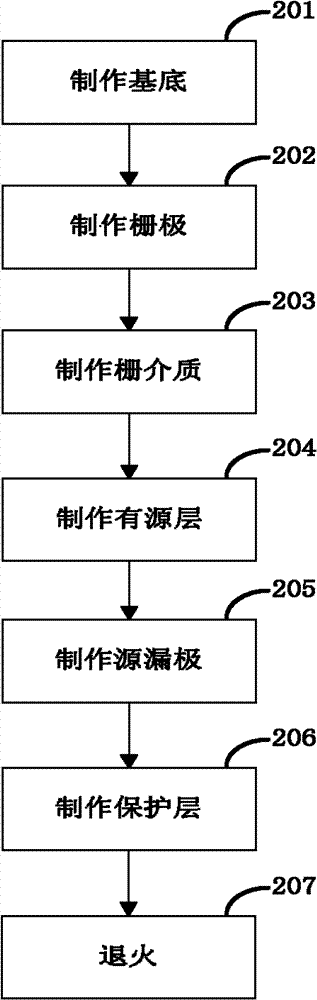

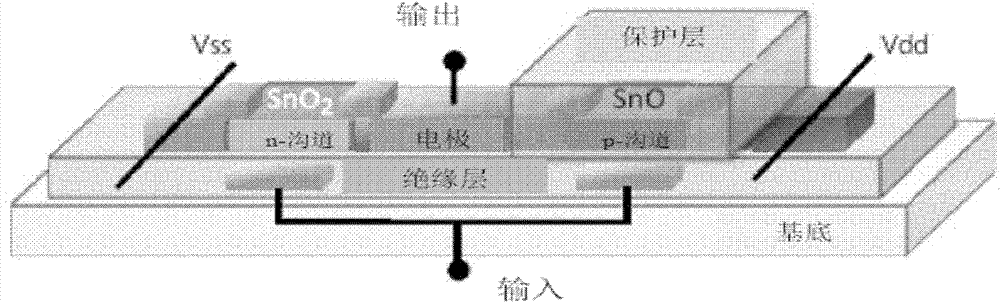

Bipolar thin film transistor and preparation method thereof

ActiveCN102263134BReduce the complexity of the manufacturing processImprove performanceTransistorSemiconductor/solid-state device manufacturingCMOSActive matrix

The invention provides a bipolar thin film transistor (TFT). An active layer of the transistor is a SnOx-based thin film. By the bipolar TFT and a preparation method thereof which are provided by the embodiment of the invention, as preparation processes and electric performance of channel materials of a p-TFT and an n-TFT are close to each other, the complexity of the preparation processes of a complementary metal oxide semiconductor (CMOS) circuit (using a SnO or Al-doped SnO2(ATO)p-TFT and a SnO2n-TFT) and an active-matrix organic light emitting diode (AM-OLED) display pixel circuit (in which the SnO2n-TFT is used as a switch TFT and the SnO or ATOp-TFT is used as a driving TFT) can be reduced greatly and the circuit performance can be enhanced; therefore, the bipolar TFT has a great application prospect.

Owner:BOE TECH GRP CO LTD

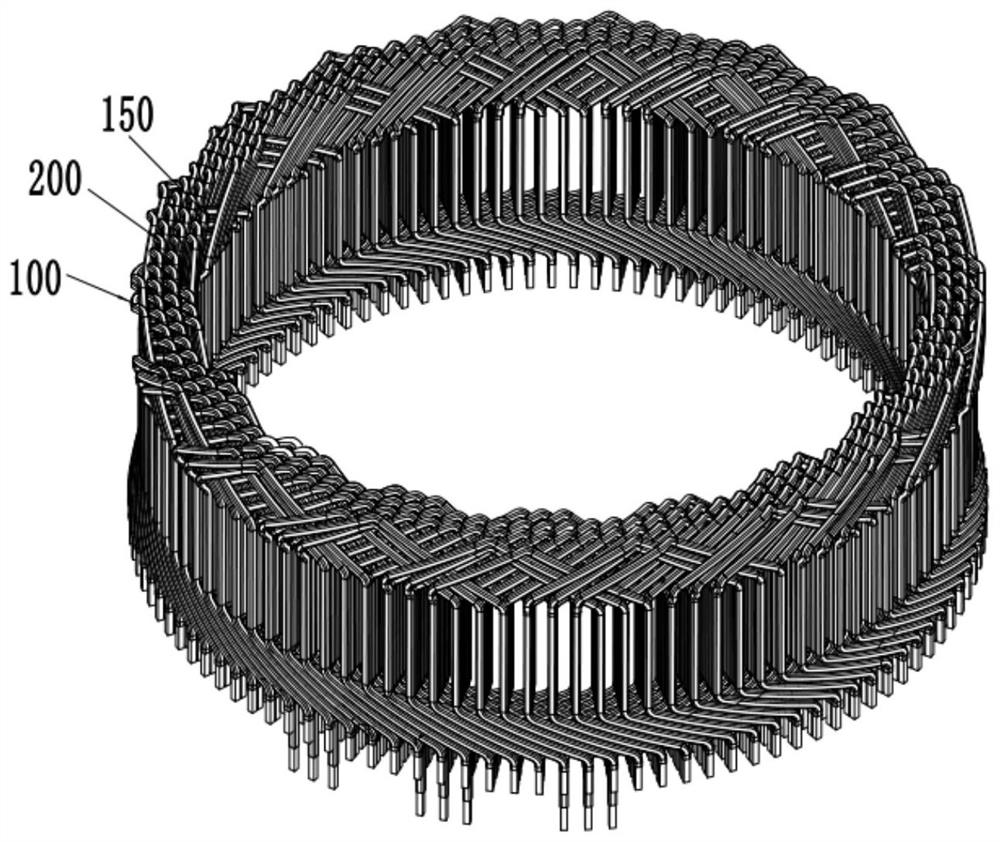

Motor stator winding, stator using same and motor

ActiveCN112583165AReduce in quantityThe same bending methodWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator winding, a stator using the same and a motor, and belongs to the field of motors, the motor stator winding comprises a first coil assembly, a fourth coil assemblyand at least two second coil assemblies which are coaxially arranged, and the first coil assembly and the fourth coil assembly are arranged on the same layer of the radial inner side first layer andthe radial outer side first layer of a stator core; the first coil assembly and the fourth coil assembly have long and short distances, and in the same stator winding, the structures of the pluralityof second coil assemblies are the same or different; the pitch between the two welding ends of the two conductors welded with each other of the two second coil groups arranged adjacently is a long pitch; and the pitch between the second coil and the first coil group or between the second coil group and the fourth coil group and between the two welding ends of the two welded conductors is the wholepitch. The wiring mode is simple, the process is simplified, the complexity of the manufacturing process can be reduced, and the machining efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

Subcutaneous tissue-intervening needle-like glucose sensor and preparation method thereof

ActiveCN105266826BSolve the conduction problemSignal acquisition is stableDiagnostic recording/measuringSensorsSubcutaneous tissueBiomedical engineering

The invention is a sensor, in particular to a subcutaneous tissue-intervening needle-shaped glucose sensor and a preparation method thereof. It includes a base, and the bottom of the base is provided with a working electrode, a counter electrode and a reference electrode, and the working electrode, the counter electrode and the reference electrode form a split needle-shaped three-electrode system. The subcutaneous tissue-intervening needle-like glucose sensor and the preparation method thereof have a compact structure, improved operation performance, and improved service life.

Owner:杭州瀚科医疗科技有限公司

Motor stator and motor

InactiveCN111478479ALow costEliminate circulating currentMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineBusbar

The present invention relates to the field of motors, and discloses a motor stator and a motor. The motor stator comprises: a stator core having a plurality of slots, wherein the slots are formed on aradially inner surface of the stator core and spaced apart by a predetermined slot pitch in a circumferential direction of the stator core; and a stator winding including a plurality of phase windings mounted on the stator core so as to be different from each other in electrical phase, wherein at least two branch windings in each phase winding are sequentially connected in parallel along the circumferential direction of the stator core, and the stator winding comprises an inner side coil assembly, a middle coil assembly and an outer side coil assembly which are sequentially sleeved along theradial direction of the stator core. According to the invention, a winding structure is adopted, and a completely symmetrical structure is adopted on a magnetic circuit, so that the problem of circulating current generated by an asymmetric structure is eliminated; and the busbars among the phases are cancelled, so that direct connection among the phases is realized, the complexity of a manufacturing process is reduced, the production cost is reduced, the material cost is reduced, and the processing efficiency is improved.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

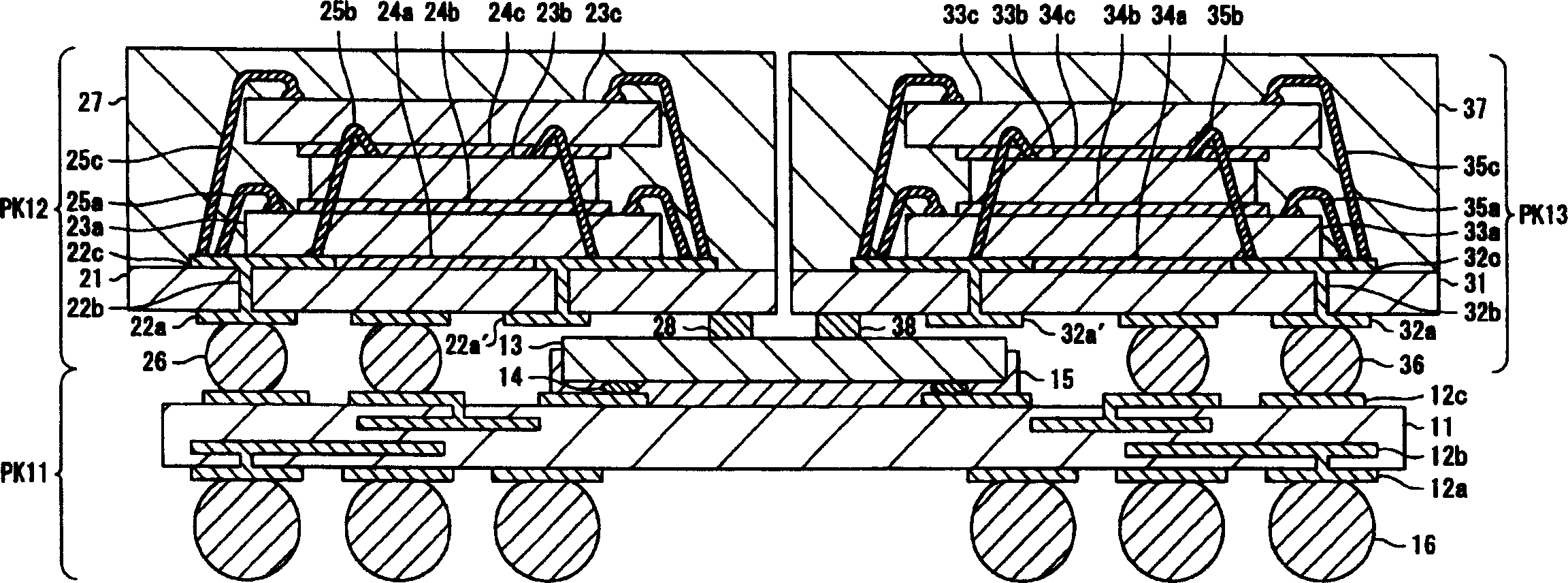

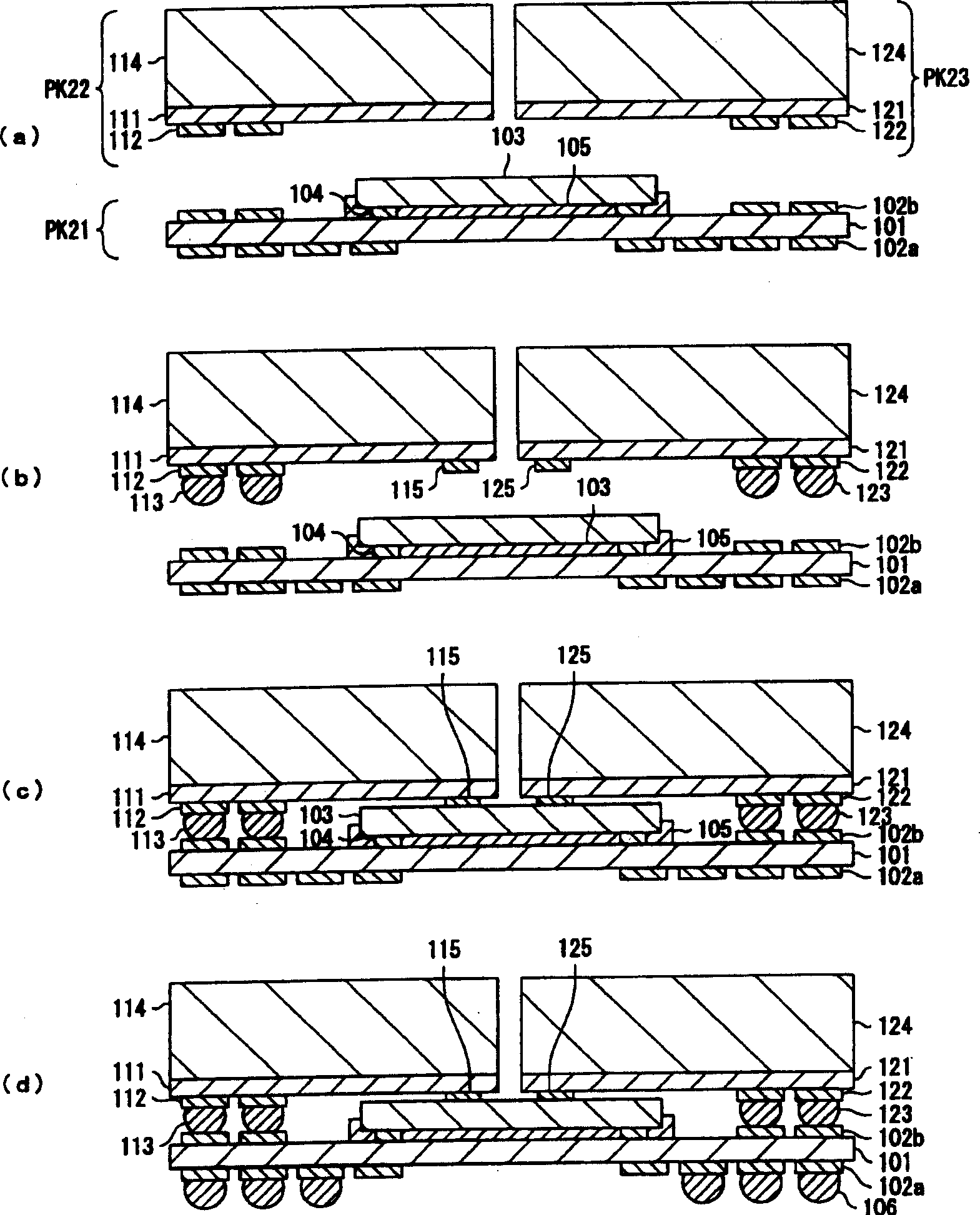

Semiconductor device, electronic apparatus and their manufacturing methods, electronic equipment

InactiveCN1531088AStable configurationReduce the complexity of the manufacturing processSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A technique is provided to three-dimensionally mount different types of packages with stability. According to the technique, projections are contacted to a semiconductor chip and bumps are bonded to lands disposed on a first carrier substrate so that an end of each other carrier substrate is held right above the semiconductor chip and the other carrier substrates are independently mounted above the first carrier substrate.

Owner:SEIKO EPSON CORP

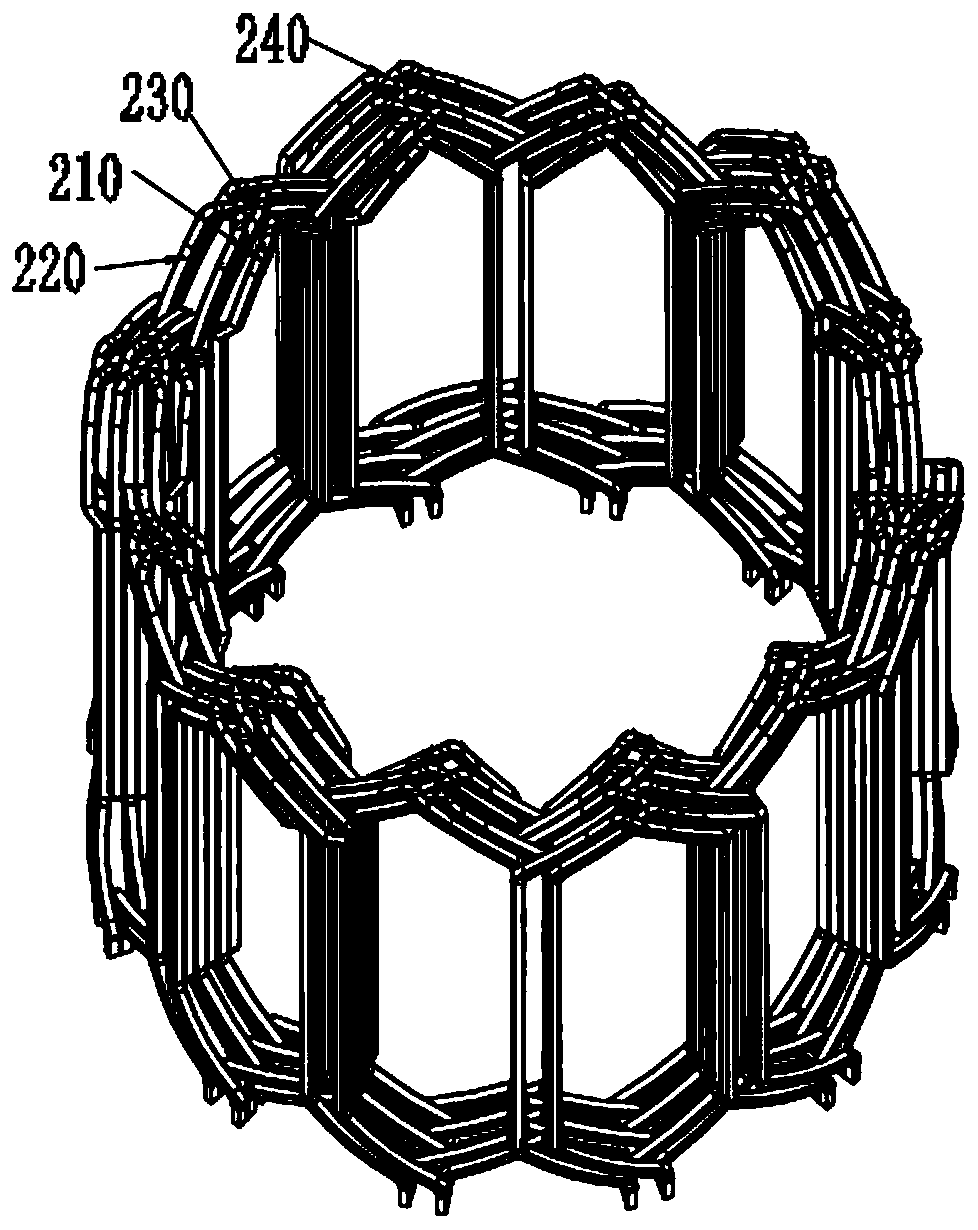

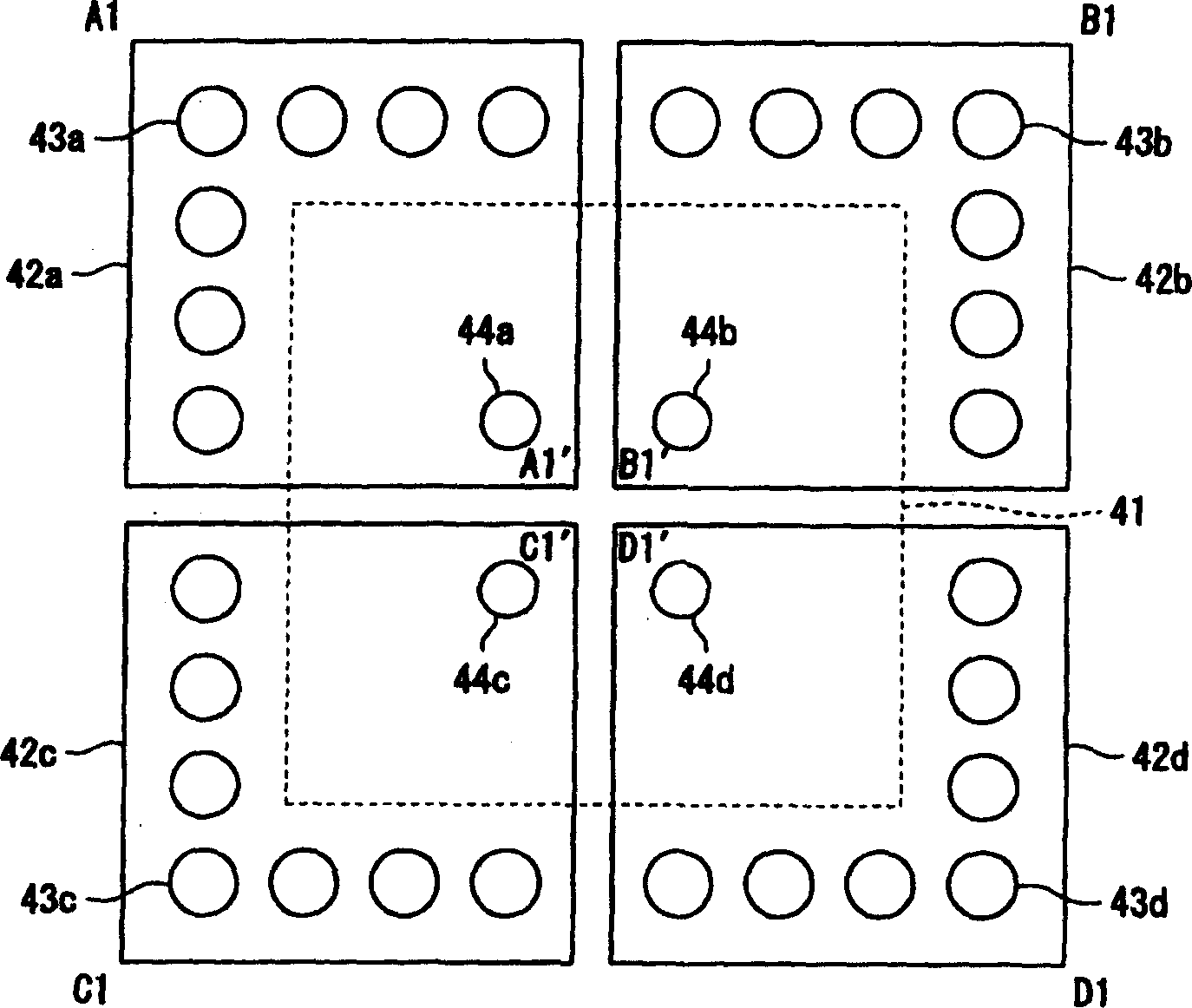

Color [mu]LED huge transfer method

PendingCN111769054AAccurately realize simultaneous mass transferReduce the complexity of the manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLED displayPhysical chemistry

The invention relates to a color [mu]LED mass transfer method. the method comprises: modifying different antibody molecules on the upper surfaces of the mu LED chips with different light emitting colors; modifying corresponding antigen molecules on a transfer transition substrate or a driving back plate, simultaneously transferring different colors of [mu]LED chips to the transfer transition substrate or the driving back plate in batches by utilizing the specificity of antigen-antibody reaction, and finally, transferring the color [mu]LED chip array on the loading plate to the corresponding driving back plate in batches to be welded and packaged. According to the method, simultaneous mass transfer of the [mu]LED chips with different light emitting colors can be accurately achieved, the transfer process is simplified, the transfer efficiency is improved, and meanwhile the production cost of the [mu]LED display screen is reduced.

Owner:FUZHOU UNIV +1

Motor stator and motor

InactiveCN112332565AReduce typesSimple arrangementMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorMechanical engineering

The invention provides a motor stator and a motor, wherein the motor stator comprises a stator winding which comprises a plurality of phase windings installed on a stator core, and enables each grooveto be divided into M layers through the number of grooves accommodated in the radial direction of the stator core; the transformer is characterized in that each phase winding comprises a first conductor group, a plurality of second conductor groups, a plurality of third conductor groups and a fourth conductor group which are connected in series. According to the technical scheme of the motor stator in the embodiment of the invention, a bus bar connected in series among all phases of windings in related technologies is canceled, and the first conductor group, the second conductor group, the third conductor group and the fourth conductor group of each phase of winding can be directly connected, so that each phase of winding and a neutral point can be arranged in any slot and any layer of the winding; complexity of a manufacturing process is reduced, production cost is reduced, material cost is reduced, and machining efficiency is improved.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Motor stator and motor

InactiveCN112531933AEven heat dissipationIncrease powerMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The present invention provides a motor stator and a motor, the motor stator comprising: a stator core having Y core slots formed on a radially inner surface of the stator core and spaced apart by a predetermined slot pitch in a circumferential direction of the stator core; and a stator winding which comprises a plurality of phase windings mounted on the stator core, each groove is divided into M layers by the number of the phase windings in the grooves which can be accommodated in the radial direction of the stator core, and M is an even number greater than or equal to 4. The number of slots per pole and per phase of the stator winding is 2 or 3, each phase winding is provided with a plurality of conductor groups, the plurality of conductor groups comprise X first conductor groups, a plurality of second conductor groups, a plurality of third conductor groups and X fourth conductor groups, and X is an integer greater than or equal to 2 and less than Y / 4; and bus bars and bus bars are omitted, heat dissipation is uniform, power and torque are improved, the wiring mode is simplified, the complexity of the manufacturing process is reduced, the production cost is reduced, and the machining efficiency is improved.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Motor stator and motor

InactiveCN112531932AEven heat dissipationIncrease powerMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator and a motor, the motor stator comprises a stator winding, the number of slots per pole and per phase of the stator winding is 3, each phase winding is K parallelbranch windings, the K parallel branch windings comprise a plurality of first conductor groups, a plurality of second conductor groups, a plurality of third conductor groups and a plurality of fourthconductor groups, and K is an integer greater than or equal to 2; and the first conductor groups are located on the Mth radial layer of the stator core, the fourth conductor groups are located on thefirst radial layer of the stator core, and the first conductor groups located on the Mth radial layer of the stator core and the fourth conductor groups located on the first radial layer of the statorcore are adjacently arranged in the circumferential direction of the stator core. According to the technical scheme of the motor stator in the embodiment of the invention, bus bars and bus bars whichare connected in parallel among windings of each phase in related technologies are canceled, heat dissipation is uniform, power and torque are improved, a wiring mode is simplified, the complexity ofa manufacturing process is further reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Motor stator and motor

PendingCN112821601AReduce typesSimple arrangementMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator and a motor. Each phase winding is formed by connecting a plurality of conductor groups in series along the circumferential direction of a stator core. The plurality of conductor groups comprise a plurality of first conductor groups, a plurality of second conductor groups and a plurality of third conductor groups, and any conductor group comprises K conductors; the plurality of first conductor groups are sequentially arranged on the radial Mth layer of the stator iron core along the circumferential direction of the stator iron core; the plurality of third conductor groups are sequentially arranged on the first layer in the radial direction of the stator core along the circumferential direction of the stator core, and the plurality of second conductor groups are sequentially arranged in the (M / 2) th layer and the (M / 2 + 1) th layer which are adjacent in the radial direction of the stator core along the circumferential direction of the stator core; the adopted conductors are few in types and simple in arrangement mode, and bus bars and busbars can be omitted, so that the twisting direction and the twisting slot pitch of the welding end parts extending towards the interiors of the slots in the same layer in the slots of the stator iron core are consistent, and the lead ends and the neutral points among the windings of all phases are arranged in any layer of any slot in the same radial direction. The manufacturing process complexity is reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

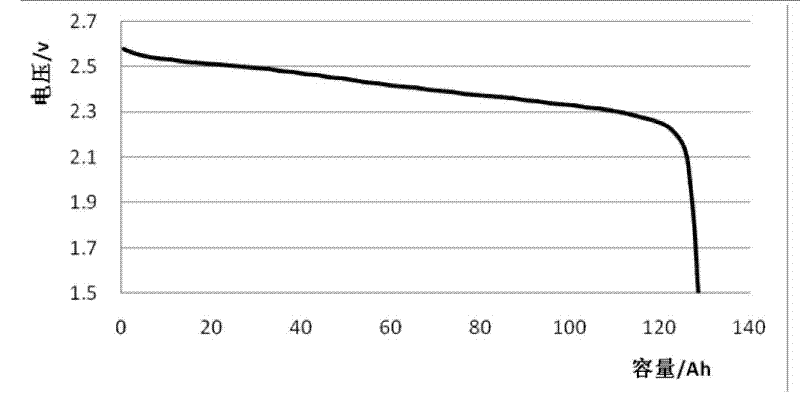

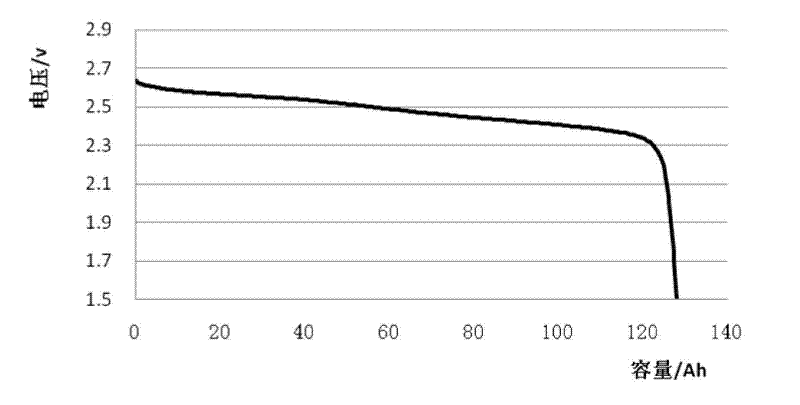

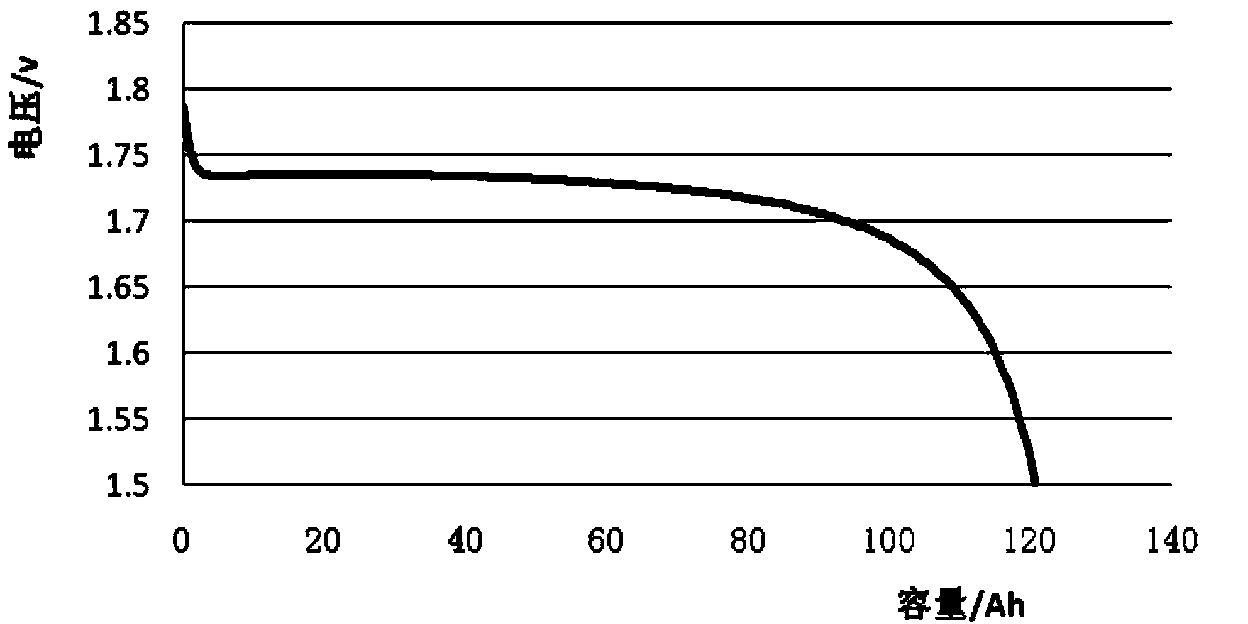

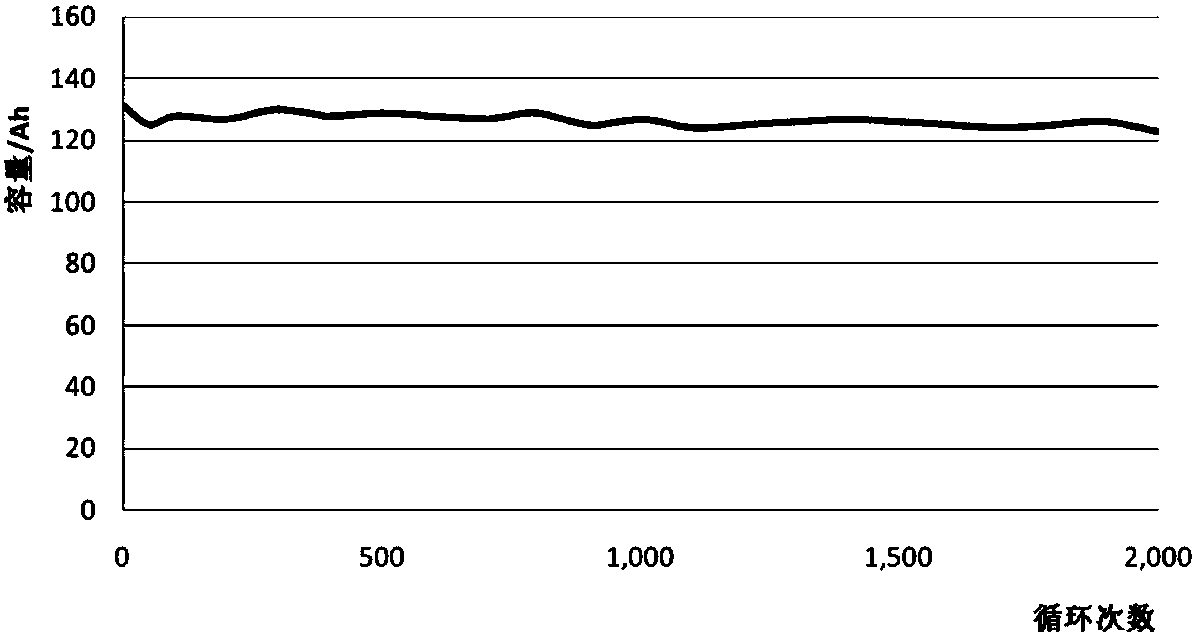

Lithium-ion power battery and preparation method of lithium-ion power battery

InactiveCN102299372ALow costLarge capacityCell electrodesFinal product manufacturePower batteryElectrical battery

The invention discloses a lithium ion power battery and a preparation method thereof. According to the invention, the cathode pole piece of the lithium ion power battery comprises, on a mass percentage basis, 83 to 94% of lithium titanate, 2 to 10% of an adhesive and 3 to 10% of a conductive agent; the cathode material of the lithium ion power battery comprises, on a mass percentage basis, 85 to 96% of lithium manganate, 1 to 10% of an adhesive and 3 to 11% of a conductive agent. The lithium ion power battery provided in the invention has the advantages of low cost, great capacity, a long cycle life and good safety performance, and is applicable to a plurality of fields like hybrid electric vehicles and military articles with high performance requirements; the preparation method provided in the invention is simple; since no n-methylpyrrolidone (NMP) is used in the process of preparing electrodes and water is used as a solvent, no pollution is produced, dangerous accidents like blast or burning do not happen, zero discharge of pollution is realized, and complexity of a preparing process for lithium ion power batteries is lowered down as well.

Owner:ZHUHAI LIYUAN NEW ENERGY TECH

Motor stator and motor

PendingCN112821597AEven heat dissipationIncrease powerMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator and a motor. The motor stator comprises a stator winding, the stator winding comprises a plurality of first conductor groups and a plurality of second conductor groups, the plurality of first conductor groups are sequentially arranged on the Mth layer in the radial direction of a stator core along the circumferential direction of the stator core, and the plurality of first conductor groups are sequentially arranged on the first layer in the radial direction of the stator core along the circumferential direction of the stator core; the plurality of second conductor groups are sequentially arranged on the (N + 1) th layer and the (N + 2) th layer in the radial direction of the stator core along the circumferential direction of the stator core, and N is an odd number; and each first conductor group comprises at least one first large conductor and at least one first small conductor, and each second conductor group comprises a second large conductor, a second conductor and a second small conductor. According to the technical scheme of the motor stator provided by the embodiment of the invention, bus bars and bus bars connected in parallel among all phase windings in the related technology are canceled, heat dissipation is uniform, power and torque are improved, a wiring mode is simplified, the complexity of a manufacturing process is further reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

Motor stator and motor

PendingCN112467898AReduce typesSimple arrangementMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The present invention provides a motor stator and a motor. The motor stator comprises a stator core anda stator winding; the stator core has a plurality of core grooves which are formed on a radiallyinner surface of the stator core and spaced apart by a predetermined groove pitch in a circumferential direction of the stator core; the stator winding includes a plurality of phase windings mounted on the stator core and forming an even number of layers in a radial direction of the stator core; each phase winding comprises a first conductor group, a plurality of second conductor groups, a plurality of third conductor groups and a fourth conductor group which are connected in series; the number of adopted conductors is small, the arrangement mode is simple, bus bars and cylinder manifolds canbe omitted, the twisting direction and twisting groove pitch of the welding end, extending towards the interior of the same layer of groove, in the stator core grooves are made to be consistent, and it is achieved that the lead ends and the neutral points of all phases of windings are arranged on any layer of any groove in the same radial direction. Complexity of a manufacturing process is reduced, production cost is reduced, and machining efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

Motor stator and motor

PendingCN112821594AEven heat dissipationIncrease powerMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator and a motor, the motor stator comprises a stator winding, and the stator winding comprises a plurality of first conductor groups and a plurality of third conductor groups. The plurality of first conductor groups are sequentially arranged on the M-th layer in the radial direction of a stator core along the circumferential direction of the stator core, and the plurality of third conductor groups are sequentially arranged on the first layer in the radial direction of the stator core along the circumferential direction of the stator core. Each first conductor group comprises a first large conductor, a first conductor and a first small conductor, and each third conductor group comprises three identical third conductors, or each third conductor group comprises a third large conductor, a third conductor and a third small conductor. According to the technical scheme of the motor stator provided by the embodiment of the invention, bus bars and busbars connected in parallel among all phase windings in the related technology are canceled, heat dissipation is uniform, power and torque are improved, a wiring mode is simplified, the complexity of a manufacturing process is further reduced, the production cost is reduced, and the processing efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

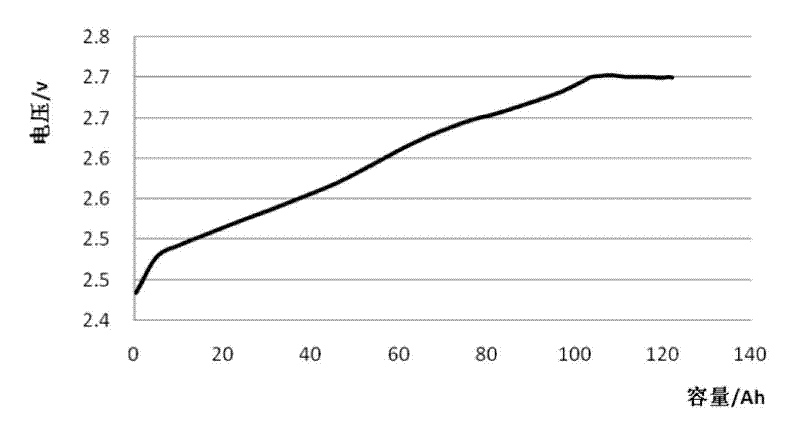

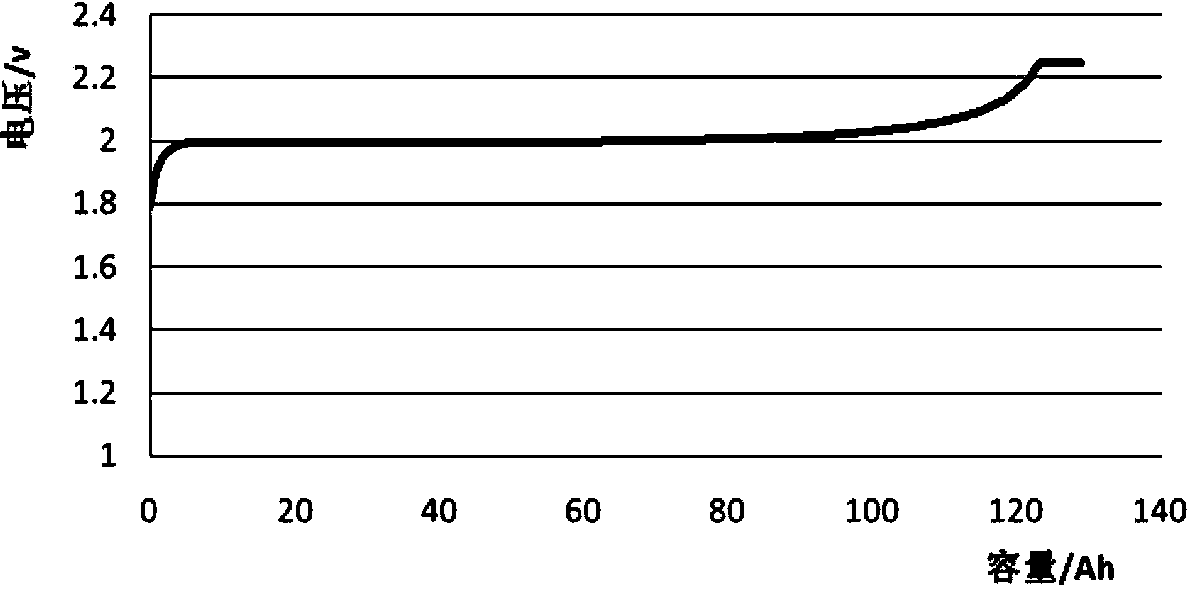

Lithium ion power cell and preparation method thereof

InactiveCN102299370BLow costLarge capacityCell electrodesFinal product manufacturePower batteryLithium iron phosphate

The invention discloses a lithium ion power cell and a preparation method thereof. A cathode piece of the lithium ion power cell comprises: by mass, 84 to 95% of lithium titanate, 2 to 10% of at least one adhesive and 3 to 10% of at least one conductive agent. An anode piece of the lithium ion power cell comprises: by mass, 83 to 95% of lithium iron phosphate, 1 to 10% of at least one adhesive and 3 to 11% of at least one conductive agent. In preparation of the cathode piece or the anode piece of the lithium ion power cell, pollutants of N-methyl-2-pyrrolidone (NMP) and polyvinylidene fluoride (PVDF) are not utilized, and thus preparation processes have the advantages of low energy consumption, environmentally friendly characteristics and low cost. The lithium ion power cell prepared by the preparation method has the advantages of high safety and long service life.

Owner:ZHUHAI LIYUAN NEW ENERGY TECH

Motor stator and motor

PendingCN112821598AReduce typesSimple arrangementMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a motor stator and a motor. The motor stator comprises stator windings, each phase winding comprises two first conductor groups, a plurality of second conductor groups and a plurality of third conductor groups which are connected in series; and each first conductor group comprises a first large conductor, a first conductor and a first small conductor, and the first conductor groups are located on the first radial layer and the Mth radial layer of a stator core. According to the technical scheme of the motor stator in the embodiment of the invention, busbars connected in series among all phases of windings in the related technology are omitted, and the first conductor groups, the second conductor groups, the third conductor groups and fourth conductor groups of each phase of winding can be directly connected, so that each phase of winding and a neutral point can be arranged in any slot and any layer of the winding, the manufacturing process complexity is reduced, the production cost is reduced, the material cost is reduced, and the machining efficiency is improved.

Owner:BORGWARNER POWERDRIVE SYST (TIANJIN) CO CHINA

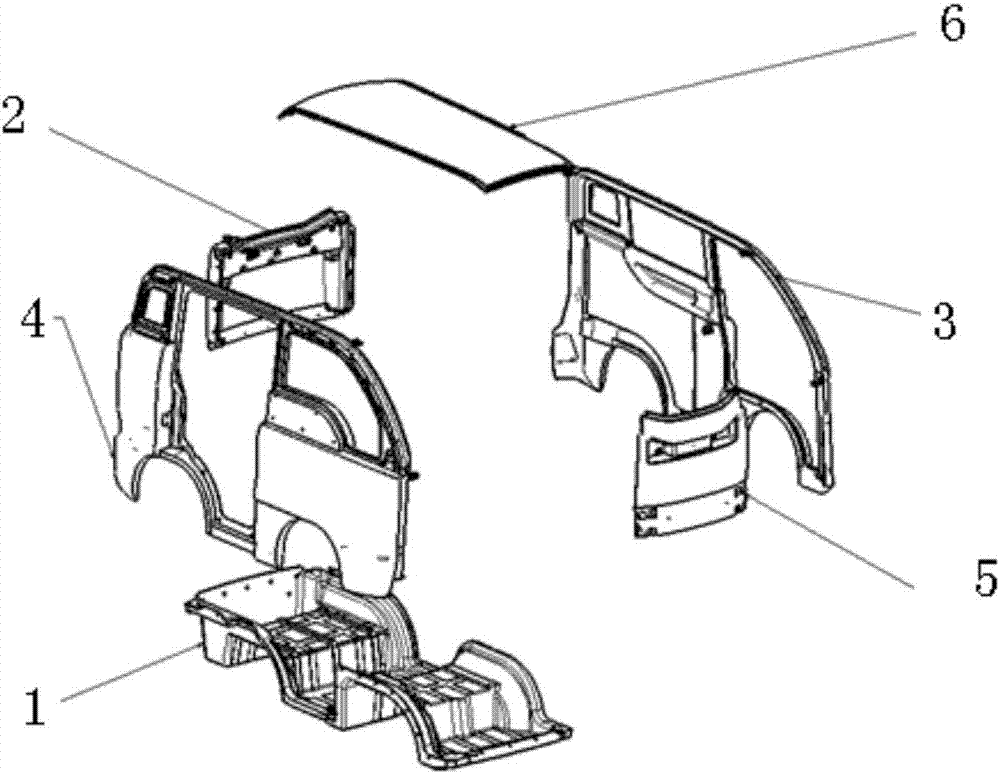

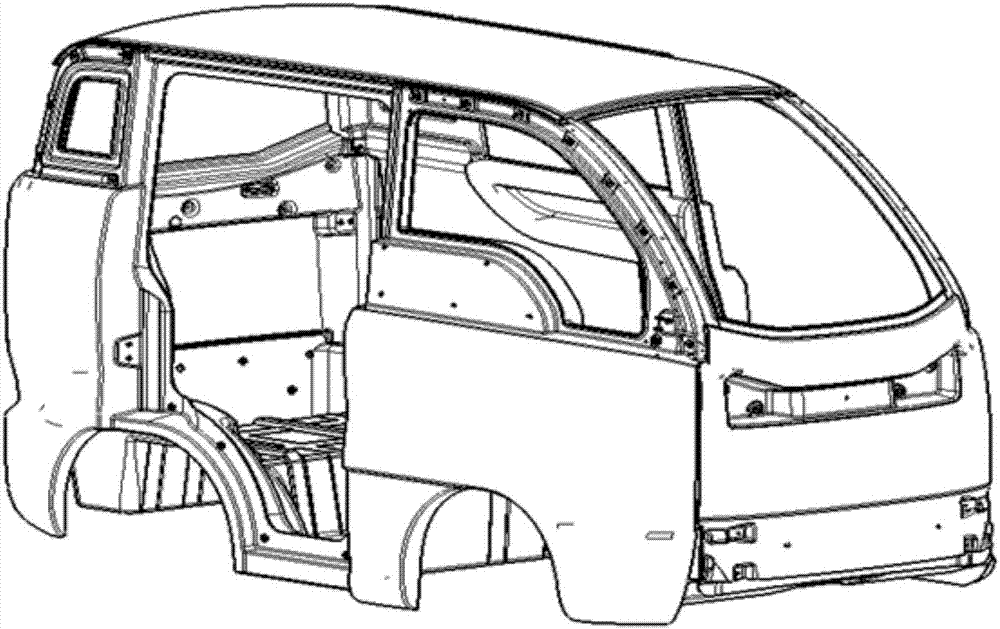

Method for manufacturing an automobile body system

ActiveCN105730524BReduce the complexity of the manufacturing processShorten production timeSuperstructure subunitsSuperstructure connectionsDual actionEngineering

The invention provides an automobile body system and a manufacturing method thereof. The automobile body system is mainly composed of six major components including a floor (1), a rear wall (2), a left side wall (3), a right side wall (4), a front wall (5) and a top cover (6). The injection molding technology is adopted in each component, splicing welding is not needed, and accuracy is more easily controlled. In addition, all the components are connected and fixed through the double effect of bolts and glue, and the automobile body system has the beneficial effects of being high in connecting and fixing strength and easy to assemble and operate, so that the complexity of the manufacturing process of an automobile body is reduced, and the manufacturing time of the automobile body is shortened.

Owner:北京开云汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Color [mu]LED huge transfer method Color [mu]LED huge transfer method](https://images-eureka.patsnap.com/patent_img/57329753-0ef3-443e-a262-7cc5a83aa361/200612153425.png)

![Color [mu]LED huge transfer method Color [mu]LED huge transfer method](https://images-eureka.patsnap.com/patent_img/57329753-0ef3-443e-a262-7cc5a83aa361/200612153427.png)

![Color [mu]LED huge transfer method Color [mu]LED huge transfer method](https://images-eureka.patsnap.com/patent_img/57329753-0ef3-443e-a262-7cc5a83aa361/200612153430.png)